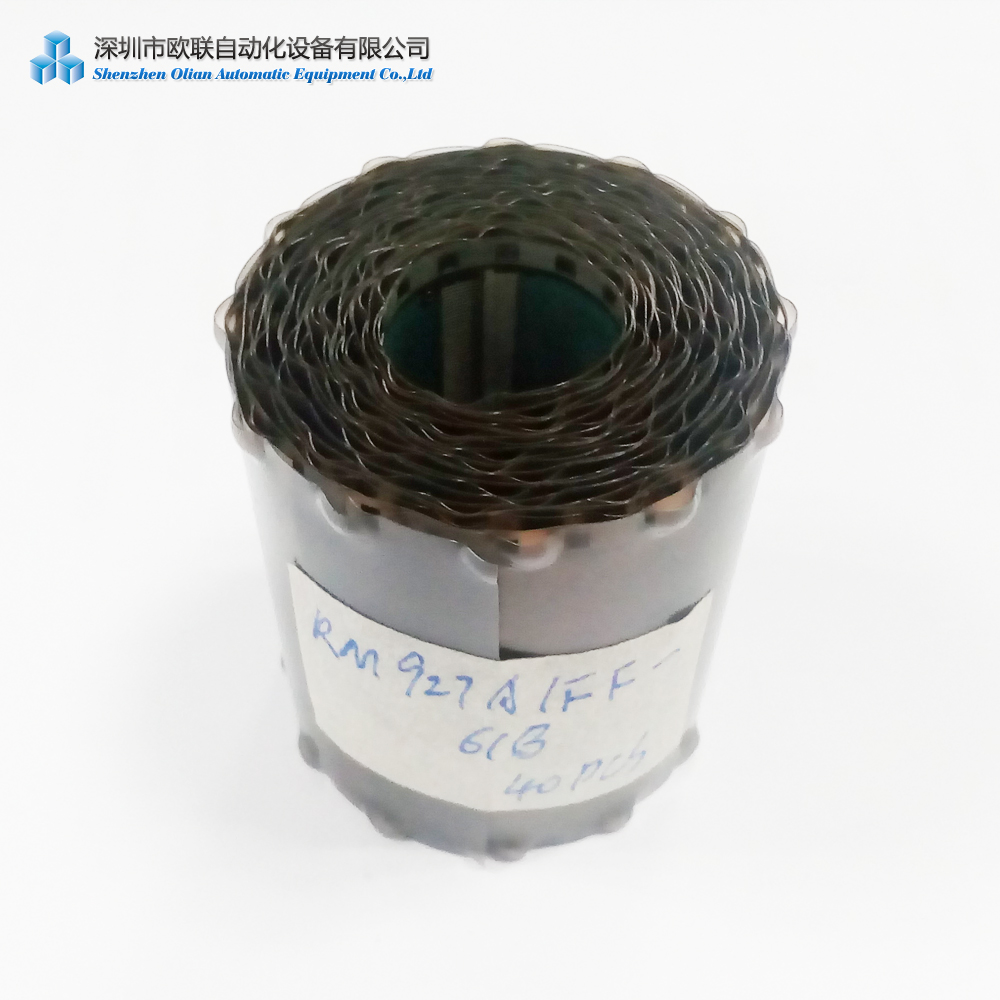

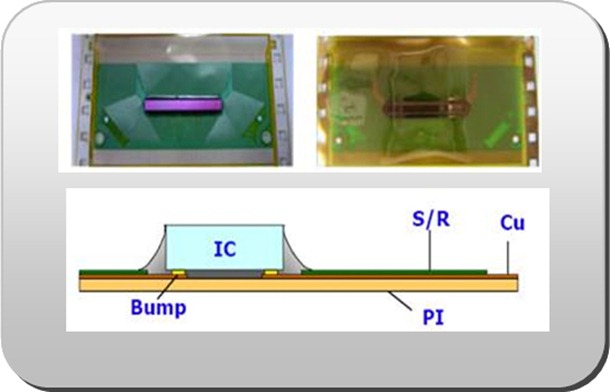

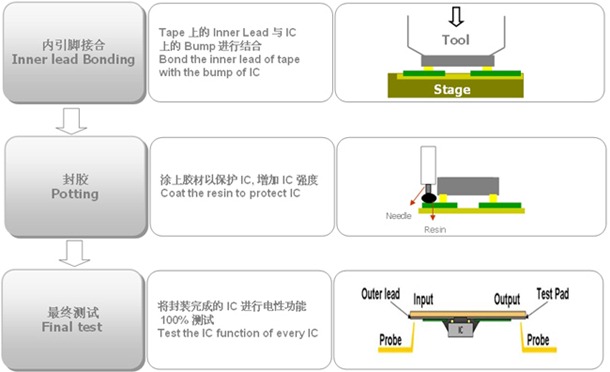

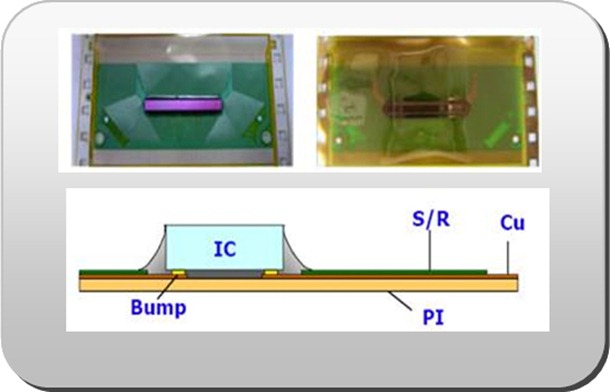

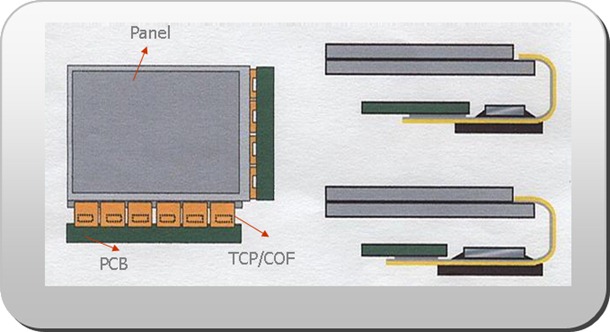

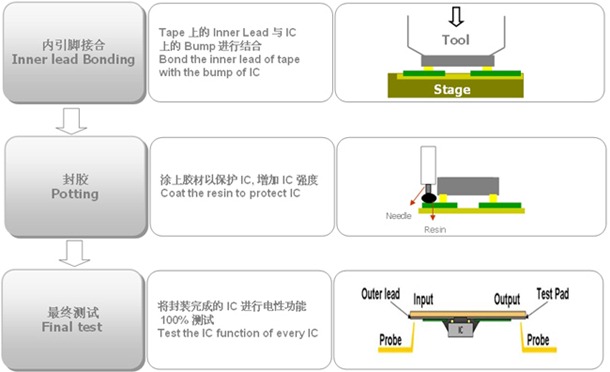

COF IC (chip on film) is an IC packaging technology that uses a flexible printed circuit film as a carrier for a packaged chip. The gold bumps on the chip are bonded to the Inner Lead of the flexible substrate circuit by thermal compression bonding technique.

We offer all kinds of COF IC, chip on Film,chip on flex,TAB IC, TV Repair COF,LCD T-con COF IC, LCD TV COF IC, Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,COF,PANDA COF, SONY COF,LCD COFS,COF bonding machine repairing for you .

COF( CHIP ON FILM) 是一种 IC 封装技术,是运用软性基板电路(flexible printed circuit film) 作为封装芯片的载体,透过热压合将芯片上的金凸块(Gold Bump) 与软性基板电路上的内引脚(Inner Lead) 进行接合(Bonding) 的技术。

COF is an IC packaging technology that uses a flexible printed circuit film as a carrier for a packaged chip. The gold bumps on the chip are bonded to the Inner Lead of the flexible substrate circuit by thermal compression bonding technique.

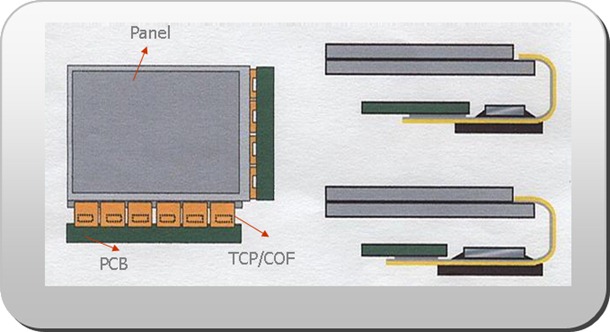

After the COF production is completed, the LCD panel module factory will cut the reel tape COF IC into single piece by the COF Punching Machine. There are outer leads of Input and Output on the flexible substrate circuit of the COF, the Input external pins will be bonded to the LCD glass substrate, and the Onput pins will be connected to the control signal printed circuit board ( PCB) .

COF package has High Density / High Pin Count, Fine Pitch, Gang Bond, High Throughput and High Reliability characteristics. In addition, it is lightweight, short, flexible and Reel to Reel production, which is not possible with other traditional packaging methods. For COF products, multi-chip or passive components can also be designed on the substrate circuit.

Some COF ic can not find,and may be stop produce,so need to find some replace COF to use.Some replace COF ic for reference only.Replace COFDownload

NT39562H-C12Q9A

8656-MCY61

RM76731FD-60y

NT39992H-C12E2A

8157-RCY60

RM76C30FA-F02

8656-FCY0B

NT61227H-C1217B

RM92A31FA-908

NT39525H-C14F1A

S6C2BD1-54U

DB7500-FD07SB

DB7501-FD02S

S6C2T94A01-58U

NT39823H-C6501A

8033-HCU67B

36-D064129

MT3196C-VE

EK77211CF129A

S6C1125-65

8033-HEX39

LH165V08-S332

S6C1125-62

RM92370FC-80K

S6C2BD1-54U

SPLC-1698A

DB7500-FD07SB

DB7501-FT03S

DB7501-FD03S

DB7501-FD03S

DB7501-FD07SB

MN838994LF-1

RM92122FA-058

RM92165FM-OE9

NT65060H-C0205A

MT3196B

NT61207H-C6802A

ICN9305-05

NT39931H-CO2F7A

S6C2BD1-55U

MT3173VF

8697-A

RM91C30FA-F01

RM91C30FB-F04

DB7500-FD04S

NT39992H-C12E2A

D160418NL-057-C1 108

LS08S6HT3A-C3LS

RM76320FB-61A

NT39931H-CO2F74

MT3173VF

DB7893-FT11M

S62B91-63

DB7500-FDO75B

S6C2BD1-58U

RM76153FS-0A1

MT3714VM

DB7501-FT03S

DB7501-FD03S

RM9113BFG-OG1

VH1L5032786-2L

S6CG239-52 H COF

NT39985H-C02M4A

S6C277J-54

RM9216EFA-OG6

DB78913-FT11M

S6C2BD1-55U

DB7500-FD07S

S62LD1-58U

DB7500-FD758

S6C2B91-63

DB7893-FT11M

RM76155FS-0A1

MT371UVM

D78913-63

RM92A131FD-90E

8160-C558

ICN9506-01

RM92A31FA-908

NT39658H-C1294A

NT 61227h C1217A

RM76731FD-60Y

NT65001H-C02P3A

DB7500-FD07SB

EK77211CFI29A

SSD3258UR1

DB7897B-FT08M

NT39935H-C5216B

8154-ECBM3

RM9216DFJ-OFP

RM92122FA-058

56C1104

NT39759H-C12E3C

RM92122FA-058

NT61610H-C07928

LS0856HEASHZ-C3LX

MT3753VD

DB7878-FS02U

ILI5381M2AB2

ILI305K5CD2

S6C2T96-60U

NT39573H-C6007A

S6C2T92J-55U

DB6894-FS06M

S6C277U-53U

RM76113FD-OCX

NT61702H-C6801A

NT39833H-C6511B

NT61720H-C12J3C

8157-RCBRG

MT3166VB

NT39980H-C5266A

NT39992H-C1279A/C

NT61804H-C6520A

RM927A1FF-61B

8159-KCBR8

HX8157-NCA03

ILI3102K6CB1-S

LS0610BH1-C2LX

LS0610BH1-C1LX

MT3220A-VA

NT39892H-C12H5A/B/C

RM92A31FA-908

SSD3273UR4

5253-ACBPQ

MT3725VB-10260UTE

Nt39548H-C5801A

NT61702H-C6801A……

| RM76731FD-60Y |

| RM92120FA-038 |

| 8159-CCBQG |

| 8157-RC563 |

| S6C2BD1-56U |

| NT61300H-C5283A |

| NT39565H-C5253A |

| S6C2T94C01-39 |

| NT61302H-C5290A |

| NT39529H-C14F2A |

| NT39985H-C02M9A-OBO |

| NT39759H-C1216A |

| MT3213C-VA/VB |

| 8157-RC579 |

| NT39530H-C5208A |

| NT39820H-C5249A/B |

| RM9217OFD-ODC |

| NT39525H-C14F1A |

| NT61720H-C12J3C |

| S6C2T96-60U |

| NT39548H-C5801A |

| D160994NL-054 |

| S6C2BD1-54U |

| NT39823H-C6501A |

| S6C2T96-57U |

| SSD3268UR1 |

| NT39759H-C12E3C |

| NT39935H-C5207A |

| NT61852H-C52F1A |

| NT61852H-C52D4A |

| RM91130FE-OAO |

| RM92155FE-OFG |

| NT39565H-C5253A |

| NT617014-06015A |

| RM9216DFJ-OFP |

| SSD3239UR4 |

| S6C2141-51C |

| S6C2B71-56 |

| S6C2T96-59U |

| S6C277J-51 |

| LH163Y02 |

| NT39658H-C12A2B |

| LS08S6HEASH2-C3LX |

| NT61909H-C6806A |

| 8033-GCYOTE |

| S6CT92J-59U |

| S6C2732-53 |

| S6C2B91-51 |

| S6C2A71-51 |

| S6C2B93-54/DB7897B-FT08M |

| RM92311FB-803 |

| RM76180FC-086 |

| NT39562H-C12G9A |

| 8154-ECBML |

| NT39810H-C5215A |

| RM92170FC-OBT |

| DB7890A-FS03S |

| DB7899A-FS03U |

| DB7920A-FS04 |

| DB7890B-FS05S |

| S6C2T9J-82U |

| RM76312FB-80E |

| SW9848-C1LSA |

| 8157-RC559 |

| CXD3817F-2 |

| CXD3818F-2 |

| CXD3828F-1 |

| LH169K01 |

| RM92155FB-ODA |

| RM92161FD-OAS |

| RM92163FA-OB8 |

| RM9216AFD-ODN |

| RM9216DFB-OEG |

| RM9216DFD-OEV |

| S6C2B95-54U |

| SW98100-C2LS |

| RM9216AFC-ODM |

| NT61807H-C52A/A |

| DB7894E-FL17X |

| NT65905H-C027BA |

| NT39693H-C14G8A |

| ICN9305-04 |

| MT3180-VA |

| NT39918H-C02M2A |

| NT39504H-C02E8C |

| 8154-ECBM3 |

| LH165V05 |

| NT39992H-C12D4A |

| 8031-NCY07 |

| NT39529H-C14F4A |

| NT39538H-C1298A |

| RM927A3FD-622 |

| 8157-RCBRA |

| LS08S6HEH1-C9LX |

| MT3228A-VH |

| LS08S2SSD1-C1LX |

| S6C2A72-52 |

| MT3232A-VC |

| 8157-RCBSE |

| EK77212CF142A |

| NT65001BH-C0208D |

| S6C2A72-52U |

| D160038NL-053 |

| ILI5381M2AB2/ 1 |

| NT61702H-C6804A |

| RM76112FD-032 |

| S6C27A9-63 |

| NT39941H-C5206A |

| 5276-ACBR6 |

| 8154-ECBM3 |

| NT39935H-C5254A |

| NT61212H-C6517A |

| RM 9113BFG-OG1/ OLJ/F |

| S6C277J-56 |

| S6C2B71-52 |

| NT3928H-C52B3A |

| S6C2LD1-58U |

| NT61305H-C52A3A |

| NT61300H-C52C4A |

| NT39528H-C3921A |

| 8697-BC562 |

| RM76321FA-80Q |

| NT39395H-C14D8A |

| RM92365FL-ODE |

| NT39686H-C5118A |

| 8656-JC506 |

| 8656-MCY40 |

| NT60901H-C52H6A |

| 8157-CCBPP |

| S6C274J-52U |

| NT39935H-C5216B |

| 8154-ECBMN |

| 8658-BCBHI |

| NT39671H-C0762B |

| 8697-AC516 |

| D160994NL-054 |

| RM92160FF-OAE |

| NT39992H-C12A3A/8157-CCY13 |

| D160256NL-052 |

| 8157-RC559 |

| S6C2T93X02-60U |

| RM92370FB-801/ C6501 |

| 8157-KC556 |

| 8020-GCBI4 |

| LH160804 |

| 8697-BCE10 |

| NT39538H-C1295A |

| 8157-HCBPS |

| 8159-ACBPU |

| VM21109 |

| NT61702H-C6022A |

| LS0896BM1-C9LX |

| ICN9305-03 |

| RM91341FA-903 |

| MT3201-VA01 |

| RM91135FR-OEC |

| LS08S2M4-C1LS |

| 8157-CCBPV |

| 8021-ACBD6 |

| S6CG331-53 |

| NT39980H-C5256A |

| LS0306M1-C5LX |

| 8656-MC607/ RM76A30FA-906 |

| NT39941H-C0217B/RM92150FB-09 |

| SSD3272U2R4 |

| S6C277C-53U |

| ILI5271M2AA1 |

| S6C2T98-30U |

| MT3196C-VF |

| ILI3105K6CB1-D |

| D160998NL-053-C1 |

| NT39992H-C1279C |

| MT3197b-VC |

| NT39892H-C12H5C/ -61B |

| RM92150FB-095 |

| NT39759H-C12F3A |

| 8033-MEY96 |

| NT39986H-C5257A |

| RM92370FC-80K |

| MT3179BVE |

| 8020-GCB14 |

| 8157-CCBPV |

| RM76153FJ-OA1 |

| NT39988H-C023LA |

| NT39658H-C12A2C |

| NT61720H-C6802A |

| DB6896-FL14X |

| D160994NL-055 |

| RM927A3FA-61D |

| 8157-RCY60 |

| MT3749-VA |

| 8033-ICYB2 |

| D160994NL-054 |

| nt62566bh-c3933a |

| EK775125032A |

| S6C2741-81 |

| NT61909H-C6806A |

| RM91C31FB-F09 |

| RM76190FB-0AZ |

| S6CT9LJ-51U |

| NT39538H-C12E4A |

| S6C2LD3-52 |

| DB7899-FLO1U |

| S6CG220-52B |

| S6C2B95-51U |

| NT39656H-C0773A |

| NT39860H-C6526A |

| DB7501-FD02S |

| LH16DD06 |

| RM91C30FA-F01 |

| SS8409D-C2FV |

| NT65065H-C02U2A |

| NT39992H-C1279C |

| RM91135FU-OEK |

| LS08S6HEASH2-C1LX |

| MT3213C-VA/VB |

| RM92155FE-OFG |

| DB7899-FL01U |

| RM76370FA-80A |

| RM92365FL-ODE |

| NT39986H-C5248A |

| NT61228H-C5607A |

| S6C2T91-52U |

| DB7899-FL02U/ LS0896BM1-C9LX |

| RM92150FE-OA9 |

| 8031-NCY07 |

| NT39573H-C6007A |

| S6CG331-58 |

| SSD3273U2R4/U3R4 |

| NT61702H-C6801A |

| NT61909H-C6808A |

| NT61212H-C6517A |

| DB7932-FL05M |

| 8033 MCYAS |

| SW98100-C5LS |

| 8157-SCA21 |

| SS6307H-C2LV |

| NT30211H-C12Q2B |

| NT39567H-C5251A |

| SW9848-C1LSA |

| RM9217OFD-ODC |

| RM92165FM-OE9 |

| RM7611WFD0-006C |

| RM76312FB-80E |

| NT39892H-C1219B |

| RM92A31FA-908 |

| 8157-RC606 |

| SW9848-C3LS |

| DB7897-FT04M |

| NT65001BH-C025AA |

| NT39548H-C5801A |

| S6C274J-56U |

| DB7875A-FT02S |

| CXD3829F-1 |

| 8033-DCB02 |

| RM92165FC-OCC/NT39985H-C02L6A |

| 8697-BCE10 |

| RM9216DFF-OFA |

| MT3181VB |

| RM927A1FD-612 |

| 8157-RCYAK |

| NT39525H-C14F1A |

| NT39985H-C02M9A |

| RM76C70FA-F03 |

| ICN9506-01 |

| NT39395H-C14D8A |

| 8157-RCY67D |

| NT65001BH-C02S2B |

| S6C274J-51U |

| RM76350FA-902 |

| RM76153FL-OC1 |

| NT65800H-C022BA |

| NT65001BH-C02Q2A |

| NT65001BH-C02Q2B |

| NT61228H-C5607A |

| NT61227H-C1217A/B |

| NT39935H-C5254A |

| ILI5381M2AB2/ 1 |

| D160038NL-053 |

| 8656-FCY50 |

| 8157-RC563 |

| 8033-ICY78 |

| MT3749-VA |

| 8656-FCYOB |

| 8656-GCYOU |

| ILI3723K6CA1 |

| S6C2732-51B |

| 8031-hccbd |

| MT3202VA / MT3179AVF |

| NT39981H-C02J5C/ RM92160FE-OAD |

| S6C2774-82B |

| D160253NL-051 |

| RM92313FB-80M |

| S6C2B91-63/ s6c2b91-61 |

| S6C2B91-64 |

| S6C27A9-51 CC505 |

| NT39529H-C14E4A |

| RM92161FF-OCO/ C02M9A |

| SS6302b-C1LX |

| NT3966H-C14D1A |

| S6C2T96-57U |

| MT3807-VB |

| NT39530H-C5208A |

| NT39828H-C5275A |

| Rm92370fd-81a |

| RM92165FL-ODE |

| RM9216DFK-OFR |

| S6C2B91-61 |

| NT39828H-C5291A |

| NT39986H-C5255A |

| NT39941DH-CO2Q9A |

| 8157-CCYOHD/ CCYOHE |

| 8157-RCY88/ 8157-RCYAK |

| MT3725VJ |

| NT39329H-C0264A |

| NT39604H-COF0634 |

| NT39985H-C02P1A/ RM92161FB-OAN |

| SS6307H-C6FV |

| D160975NL-051 |

| NT39567H-C5251B |

| RM97160FC-OJO |

| 8651-CCCB7 |

| 8658-CCBJC |

| NT39986H-C5265A/ -C5265B |

| SS6491A-C4SB |

| 5276-ACBR6 |

| DB689BA-FL07X |

| ILI3105K5CD2 |

| NT39541H-C02L3A |

| NT39692H-C5003B |

| SW98001C-C3LS |

| SSD3252UR4 |

| NT39596H-C6001A |

| NT39665H-C14D1A |

| NT39892H-C12P1B/C12P2B |

| NT39860H-C6519A |

| NT39935H-C5227B |

| RM92170FB-OBD |

| NT39981H-C02J5C / RM92160FG-OA |

| NT39981H-C02J1A |

| 8159-ACBO3 |

| MT3179BVE |

| NT39986H-C5257A |

| RM7611WFD0-006C |

| RM76153FL-OC1 |

| RM76311FC-805 |

| RM92155FF-OFN |

| RM92160FE-OAD |

| SS8902CA-C3LVR |

| MT3202-VD/ DB7893-FT10M |

| DB689E-FL04X |

| NT39567H-C5286A |

| NT39810H-C5225A/ C5233A |

| RM92165FM-OE9 |

| Rm91c30Fb-F04 |

| RM92165FK-OCU |

| RM92165FH-OCL |

| S6C2T9C-55 |

| db6894-fs03m |

| MT3166BVD |

| DB7501-FD04S |

| Db7897b-fl10m |

| LS08S6HT3A-C3LS |

| S6C274K-51U |

| NT39892H-C12E2A |

| LS086HEASH3-C4LX |

| 5253-BCBS1 |

| LS08S2HEASHI-C5LX |

| LS08S6HEH1-C6LX |

| NT61720H-C12G8B/ icy78 |

| 8157-RCYC9 |

| D160261NL-051 |

| RM92165FC-OCC/-C02P1A |

| S6C2T9AX01-53 |

| NT39941DH-C02Q9A |

| S6ct925a01-57 |

| MT3725VB |

| MT3202A-VG |

| NT39565H-C5263A |

| ILI3105K6CB1-D |

| NT61203H-C5604A |

| 8157-RCBRG |

| D160987NL-052 |

| NT65830BH-C023HA |

| DB7677-FL01S |

| RM92122FA-058/ -051 |

| S6C2B93-54/ DB7897B-FT08M |

| NT39538H-C1272A |

| RM76320FB-61A |

| NT39563H-C6502A/ -80A |

| 8159-KCBR8 |

| 8157-CCYOHC/ CCYOHE |

| RM92H32FA-L07 |

| 8033-HCY73 |

| 8157-CCBQA |

| 8157-KC550 |

| 8656-FCY54 |

| D160994NL-051/ D160994NL-054 |

| LS0610BH1-C1LX |

| NT61850H-C52B8A |

| NT65820H-C022PA |

| RM91C30FC-F05 |

| RM9216EFE-OGN |

| S6C27A9-59U |

| S6C2T94A01-60U |

| ssD3250UR4 |

| S6CT92J-51U |

| LS08S2SHESH1-C6LX |

| NT39986H-C52A6A |

| D160256NL-053 |

| S6C22732-61 |

| Sw9846D-Blsd/ B1LSB |

| SW98100-C3LS |

| LS0896BD-C5SX |

| 8157-RC571 |

| RM92165FJ-OCT/ RM92165FG-OCJ |

| LH16DH03 |

| LS08S6HEH1-C3LX |

| NT39538H-C12B9C |

| NT39540H-C5224A |

| S6c277u-51u |

| S6C2774-54U/8154-ECBML |

| RM92163FD-OBY |

| S6C2778-51 |

| NT39986h-c5267a |

| S6C1172-64 |

| ls0609h3-c9lx |

| s6c1172-66 |

| MT3222-VB |

| LS08S2SHEDD1-C4LX/ SS8480-C5LV |

| LS0896CH1-C3LX |

| ili3105k7cc1 |

| 8157-CCYOHE |

| 8033-MCY96 |

| RM91160FD-OE4 |

| S6CT92LX01-61UN |

| Sw9846D-Blsd |

| RM76H70FB-L02 |

| VHIL S0313B1-5L |

| SS8303A-C2SS |

| cxd3841f-2 |

| S6CG22B-52U |

| LH165V08 |

| 8169-ECYBH |

| Nt39980h-c5271b |

| NT39522H-C02H7A |

| VHIL S0327B3-6L |

| D160958NL-052 103/C0255 |

| ICNL9305-AF-11 |

| NT39981H-C02J1C/ OAD |

| ILI3107K7CC1 |

| 5223-FCBQU |

| 8698-CC560 |

| S6C277K-51U |

| ILI3963M7CA1/C52J4A |

| RM76152FJ-OA8 |

| SW98007-C3LR |

| db7500-fd05sb |

| RM92160FG-OAF |

| Lh163y06 |

| s6c2b71-52u |

| RM927C0FB-62H |

| sw98105-c2l |

| s6c1169-51 |

| LS0610BH1-C2LX |

| SS8482-C1LV |

| s6ct92k-53u |

| DB7893-FT05M/MT3202A-VG |

| NT65800H-C026BA |

| SS8482-C3LV |

| NT61960H-C6538A/ C6519A |

All kinds of COF ic,

Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,PANDA COF, SONY COF,LCD COFS ,Welcome you send your list to my Email:2307972393@qq.com, or Wechat:+8618025364779,We will reply you ASAP.

Related products:

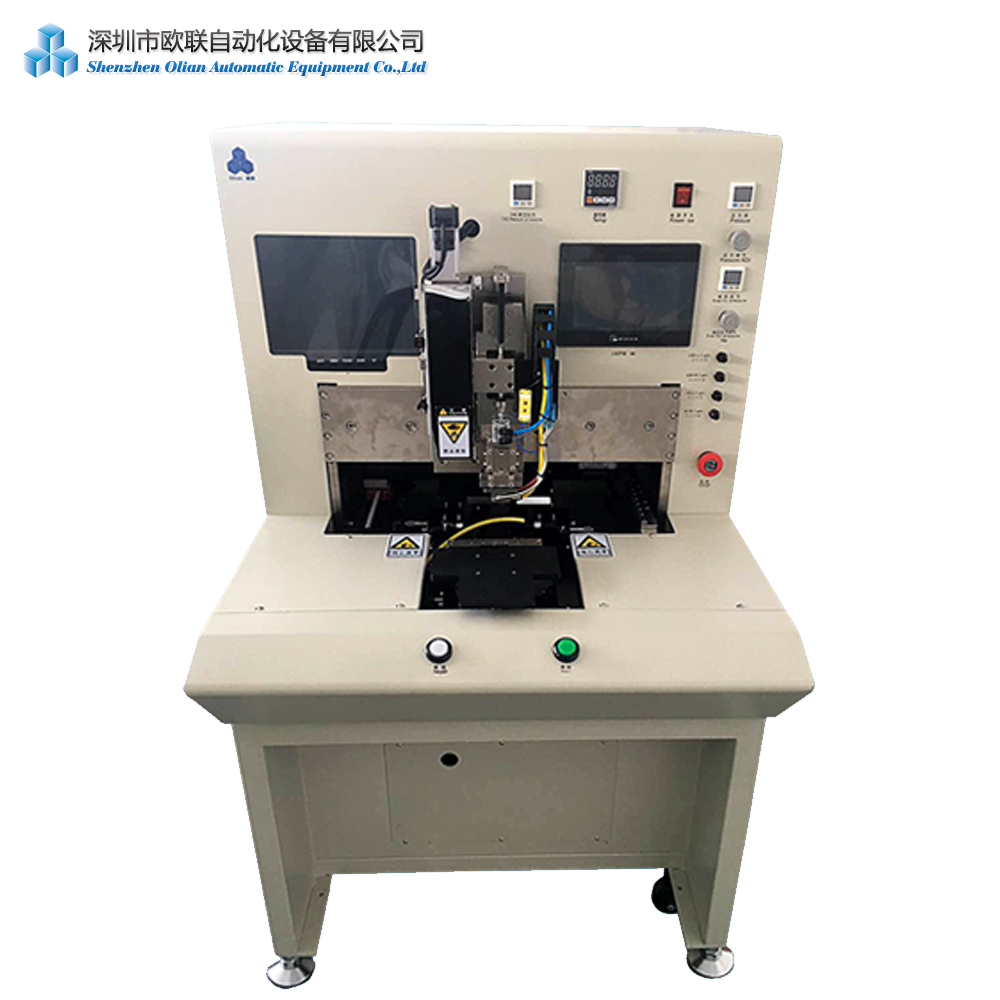

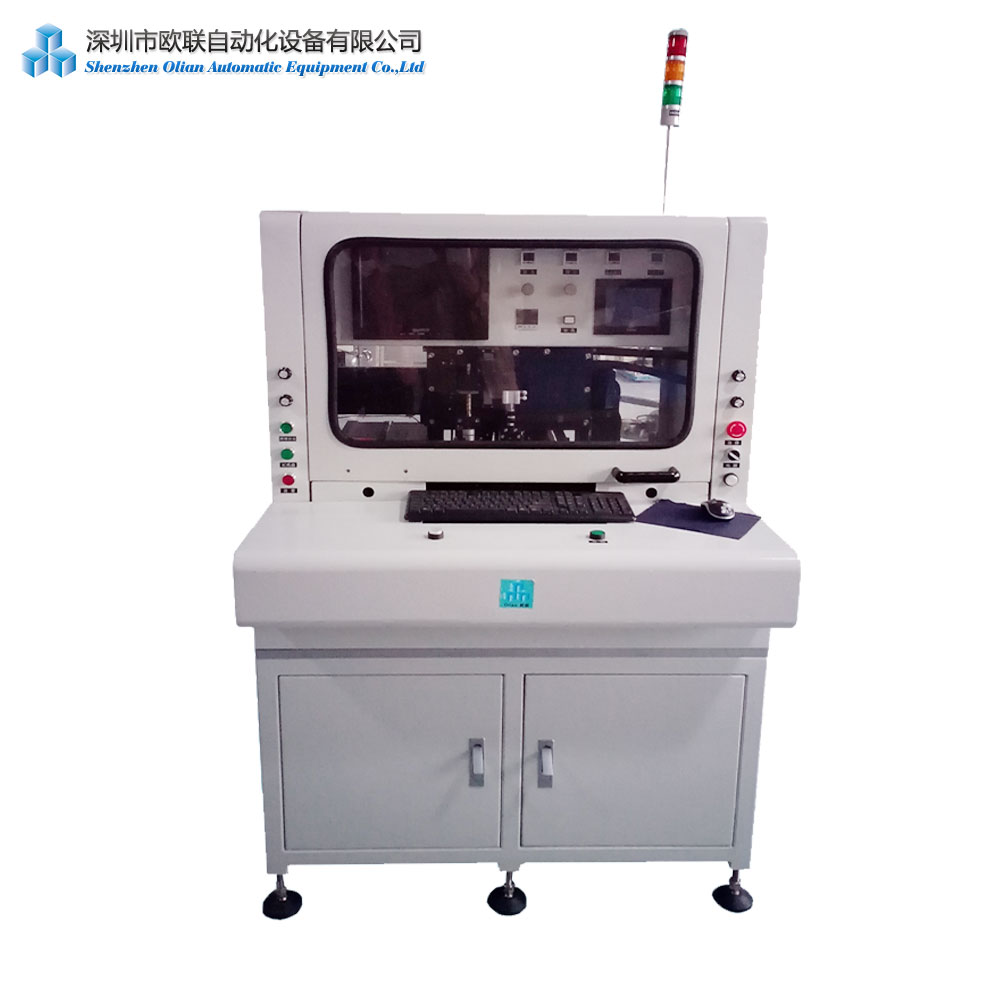

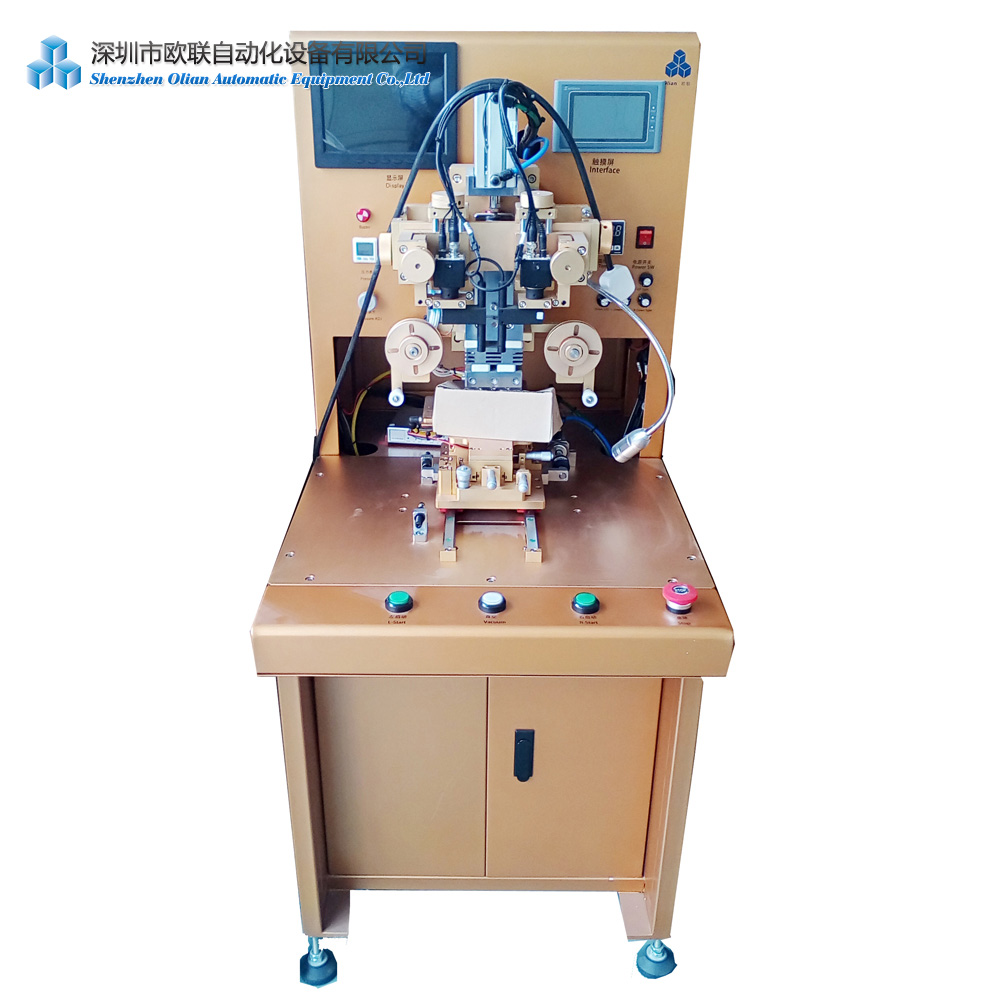

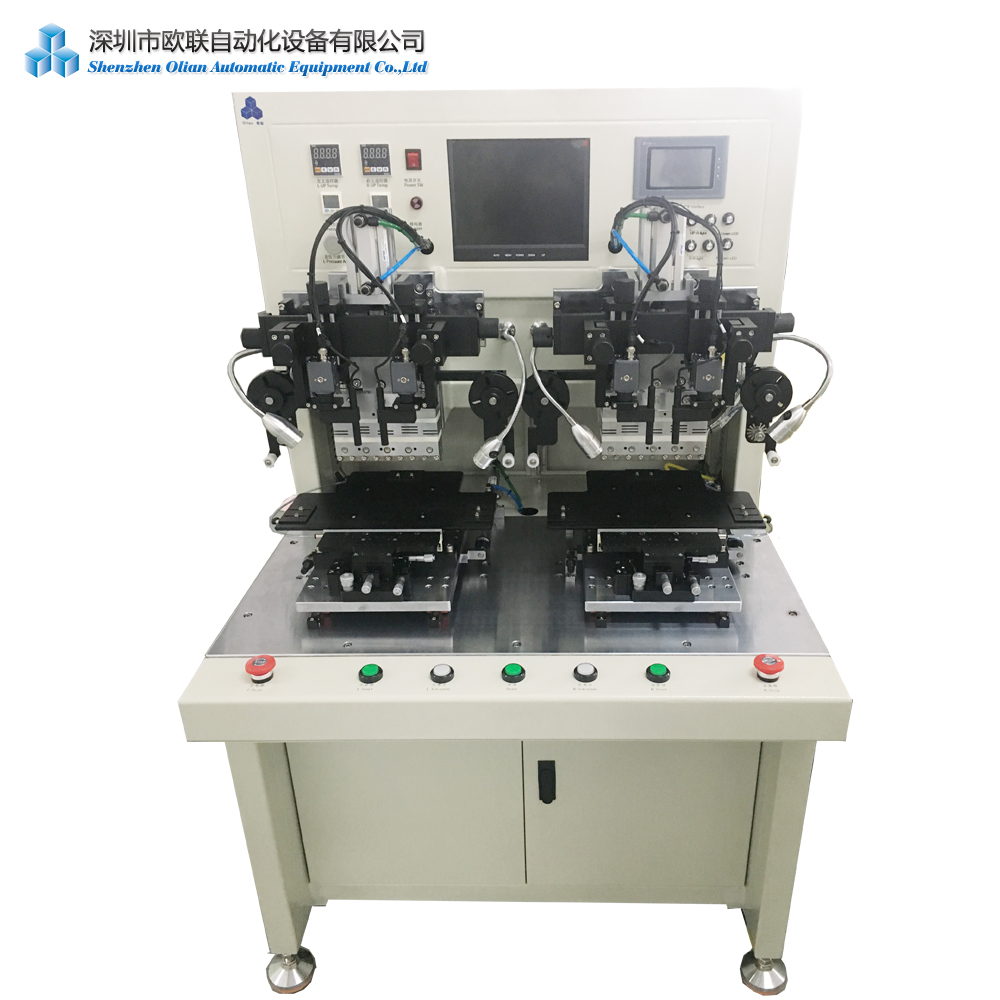

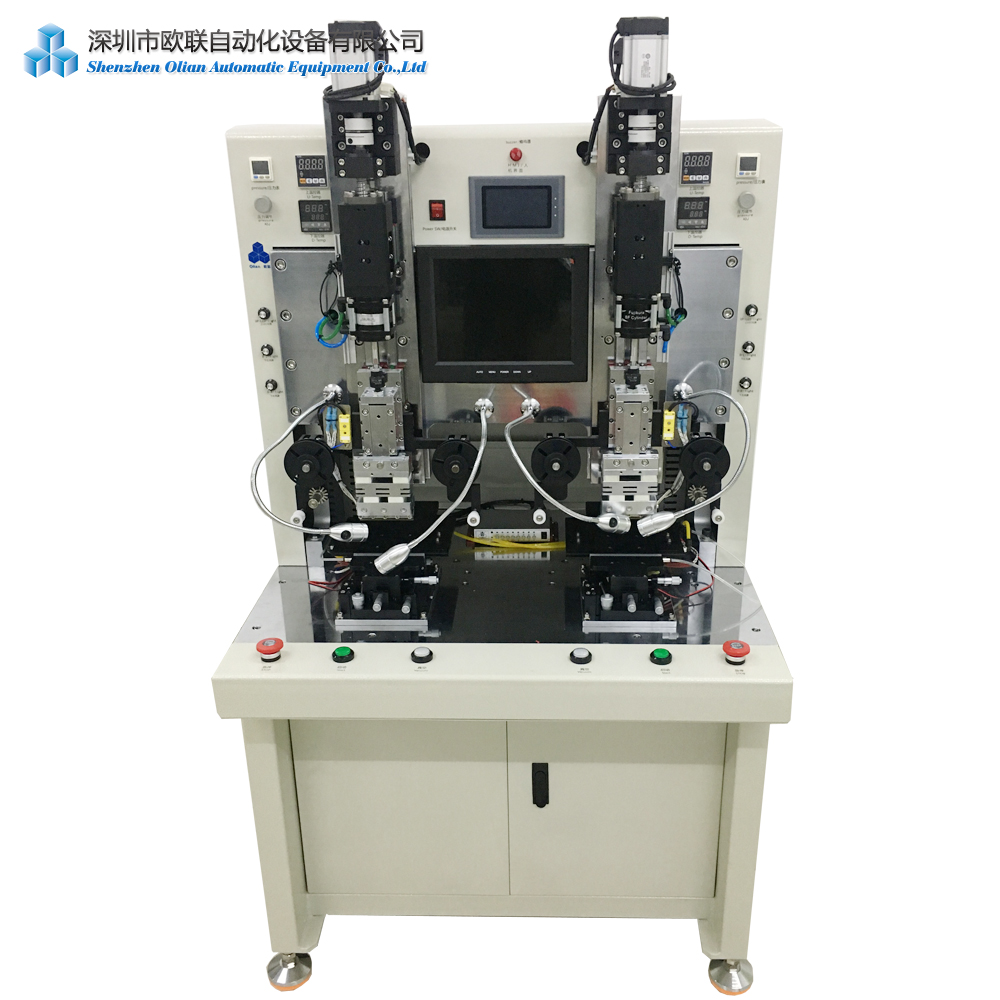

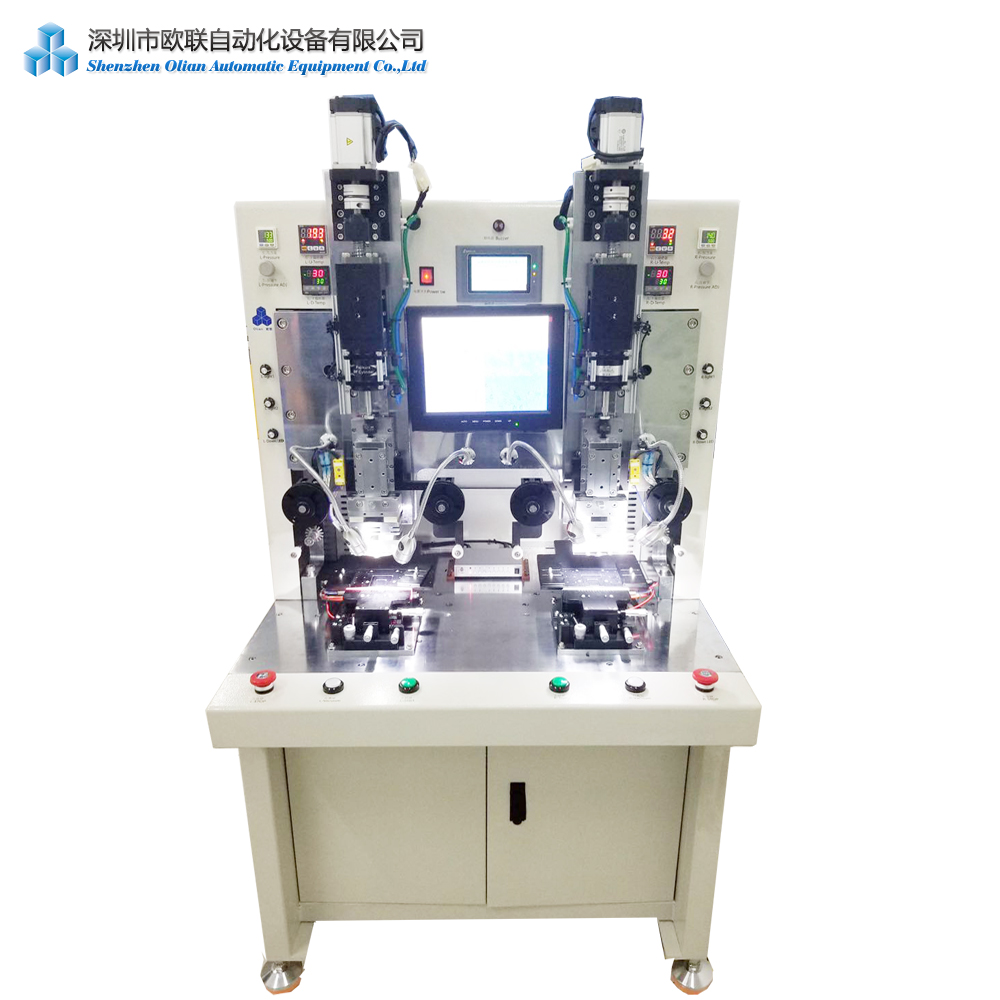

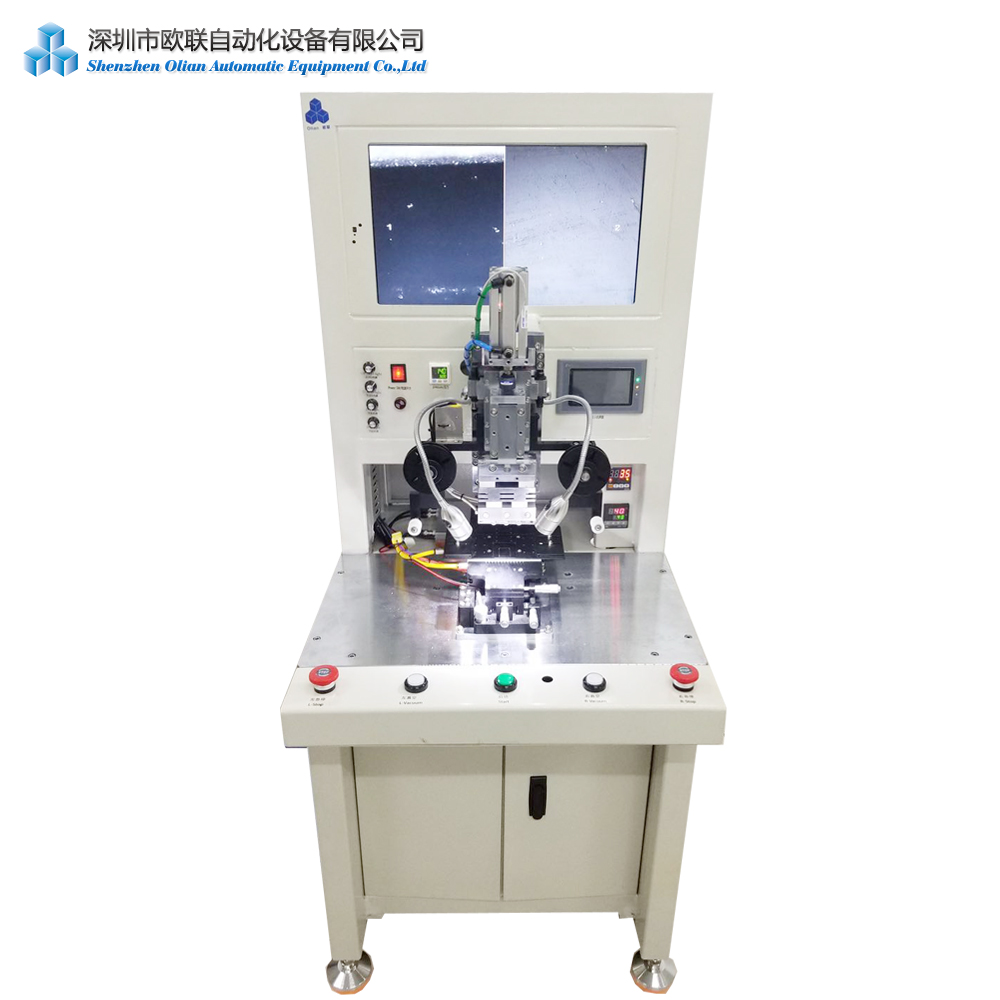

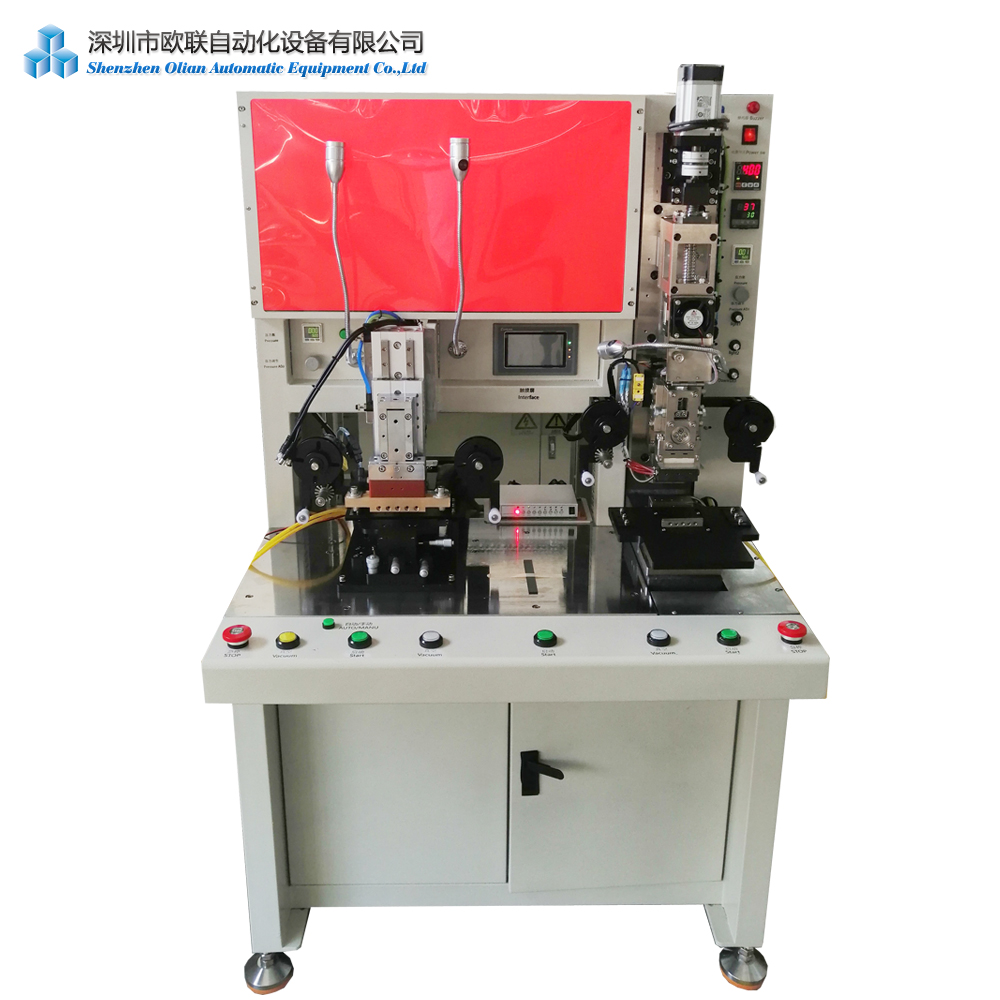

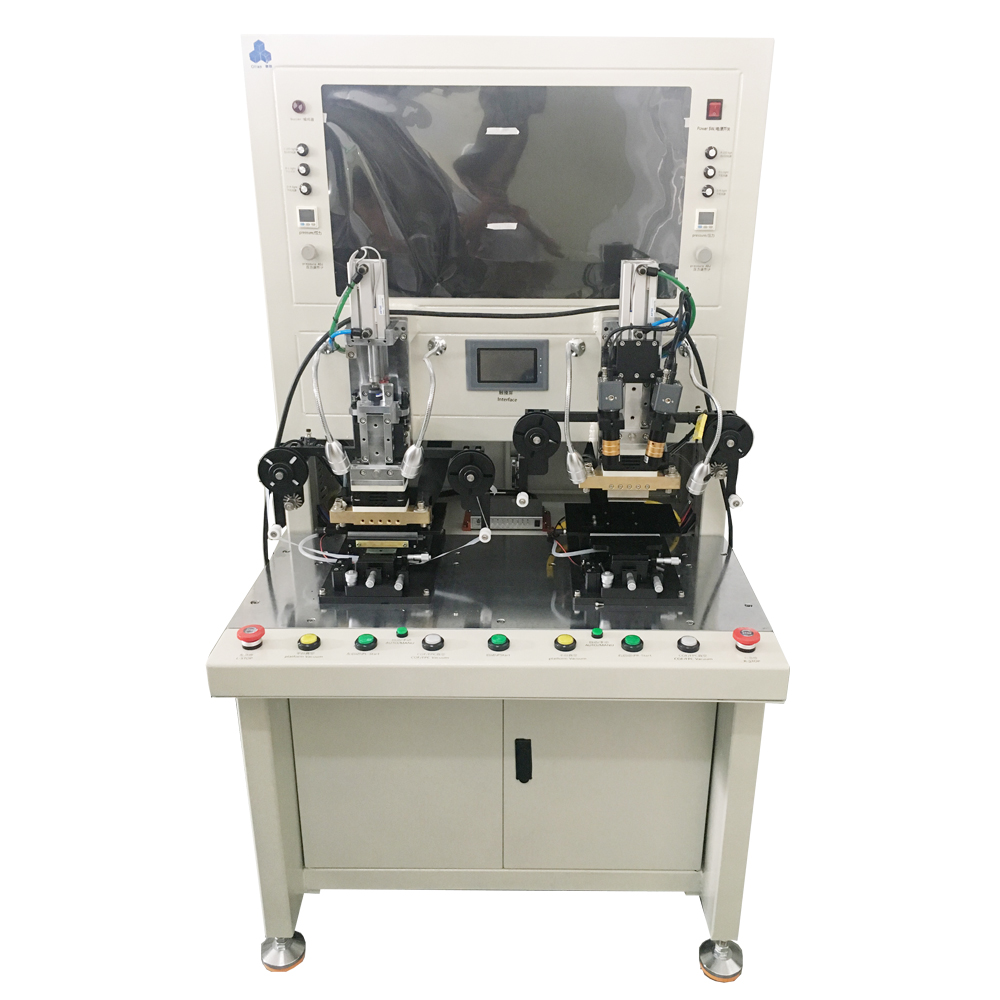

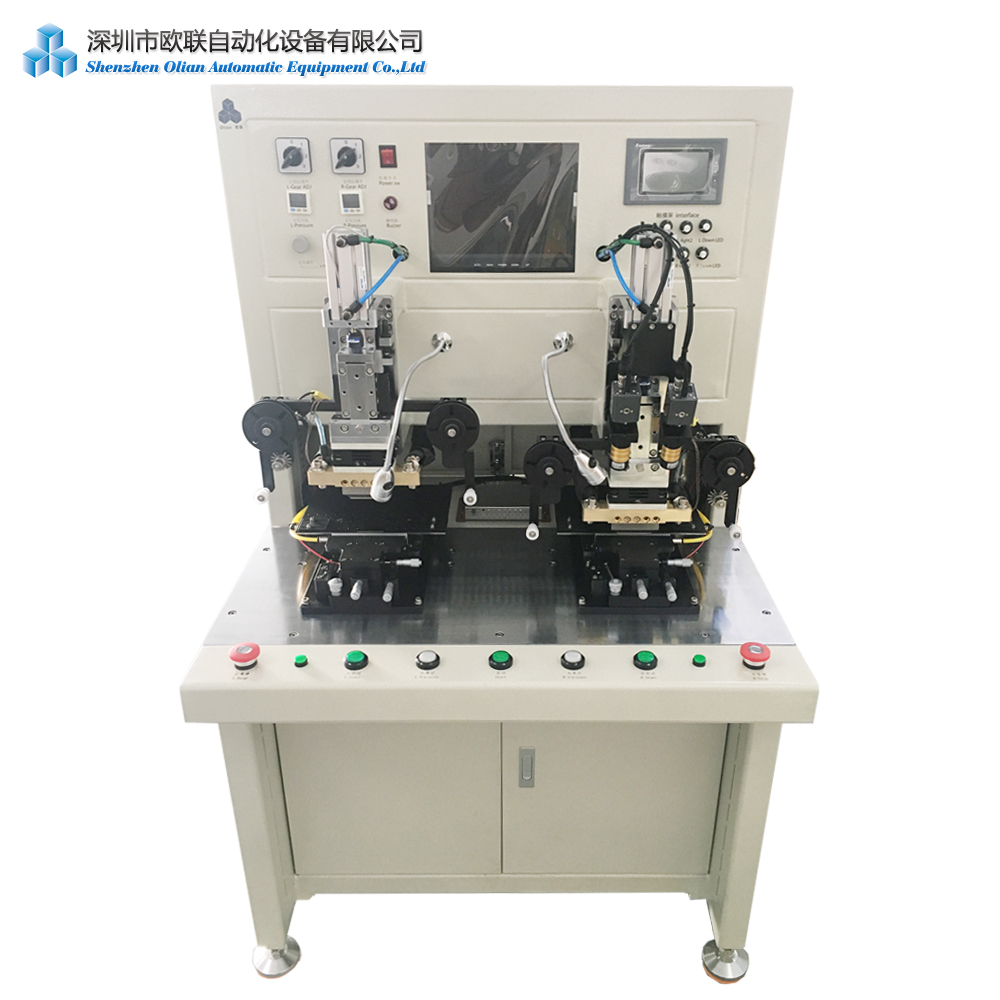

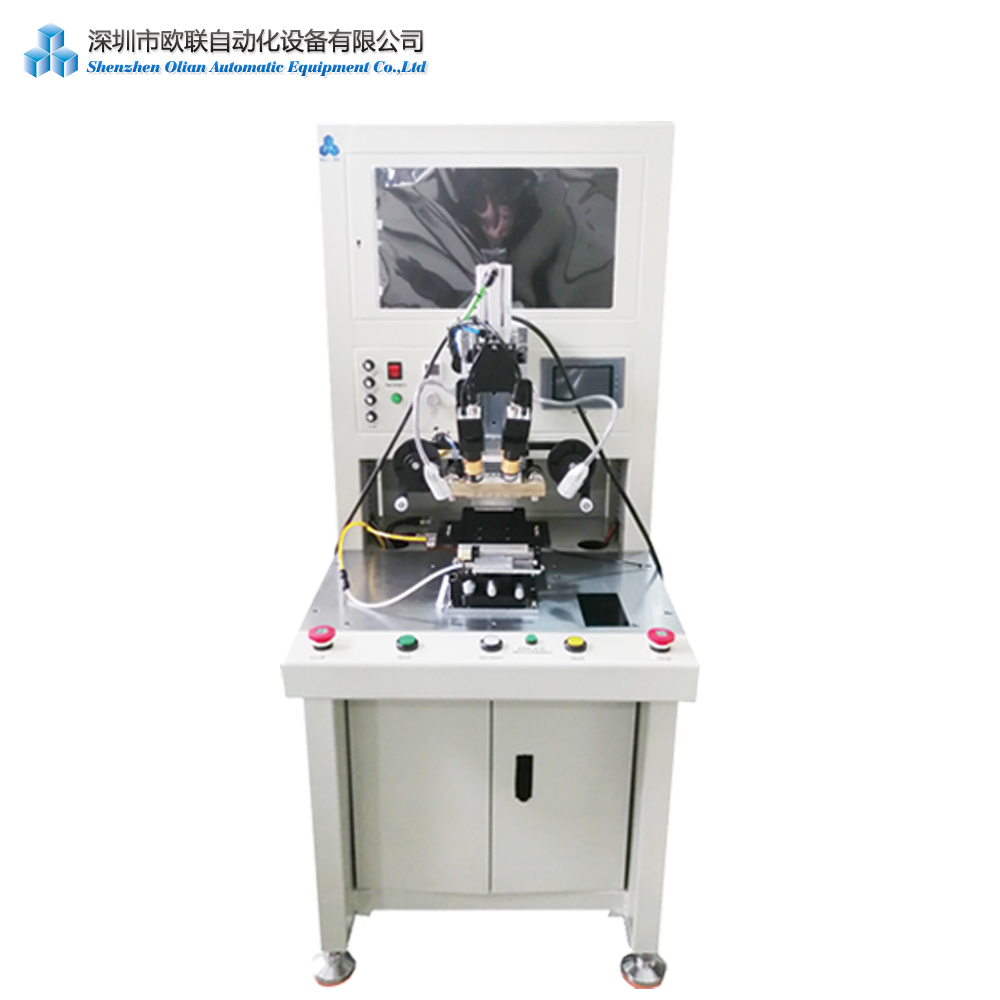

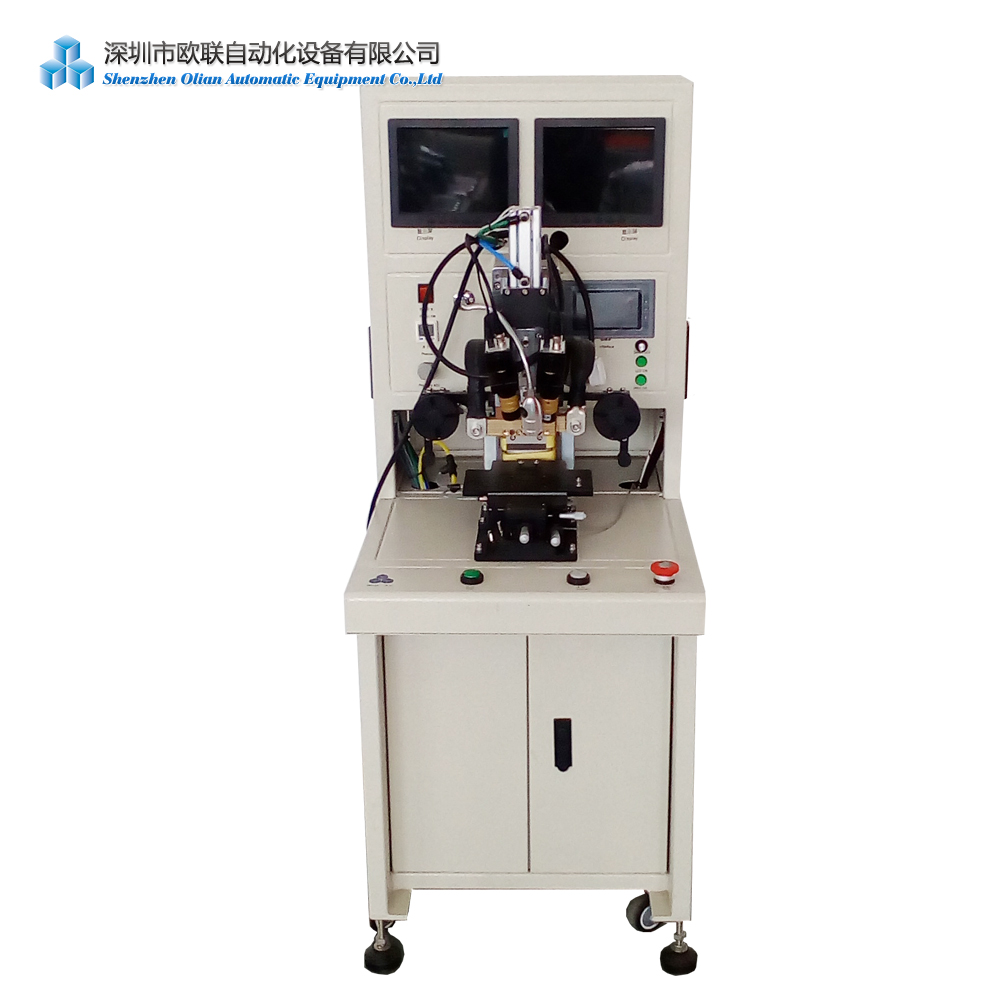

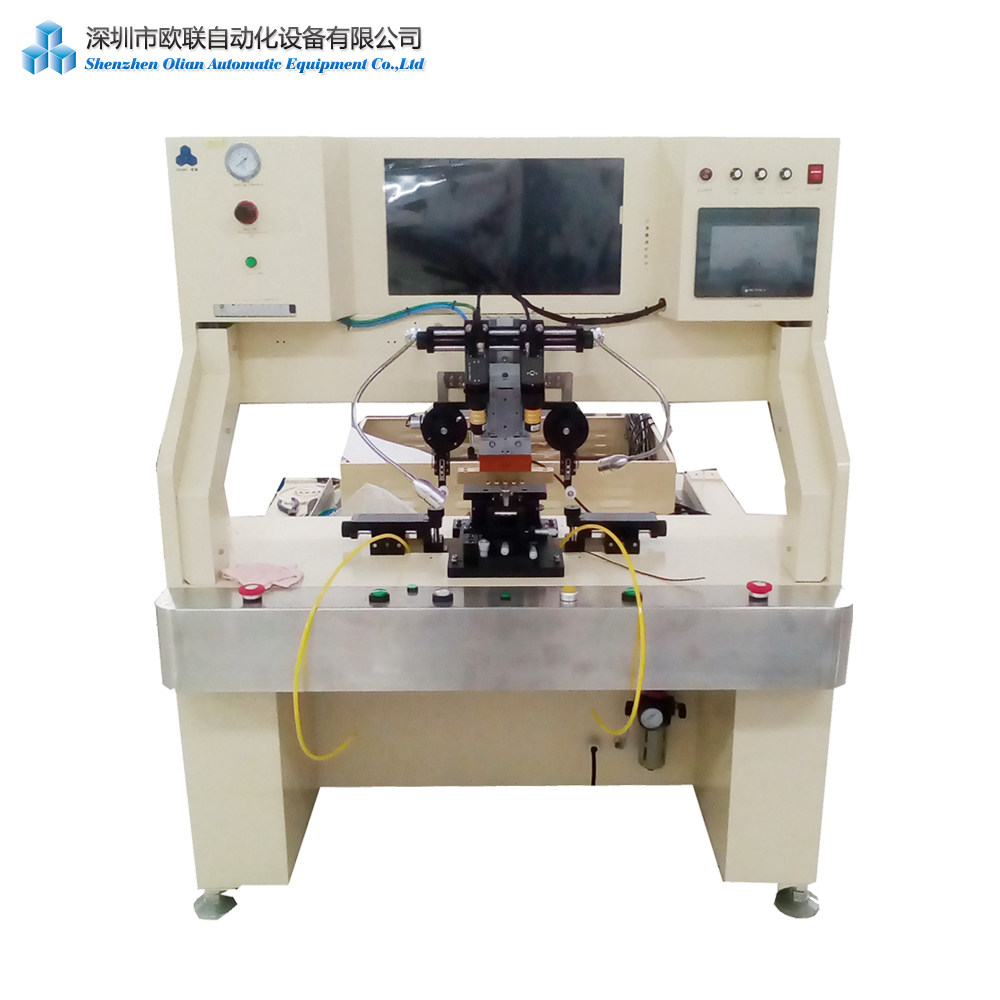

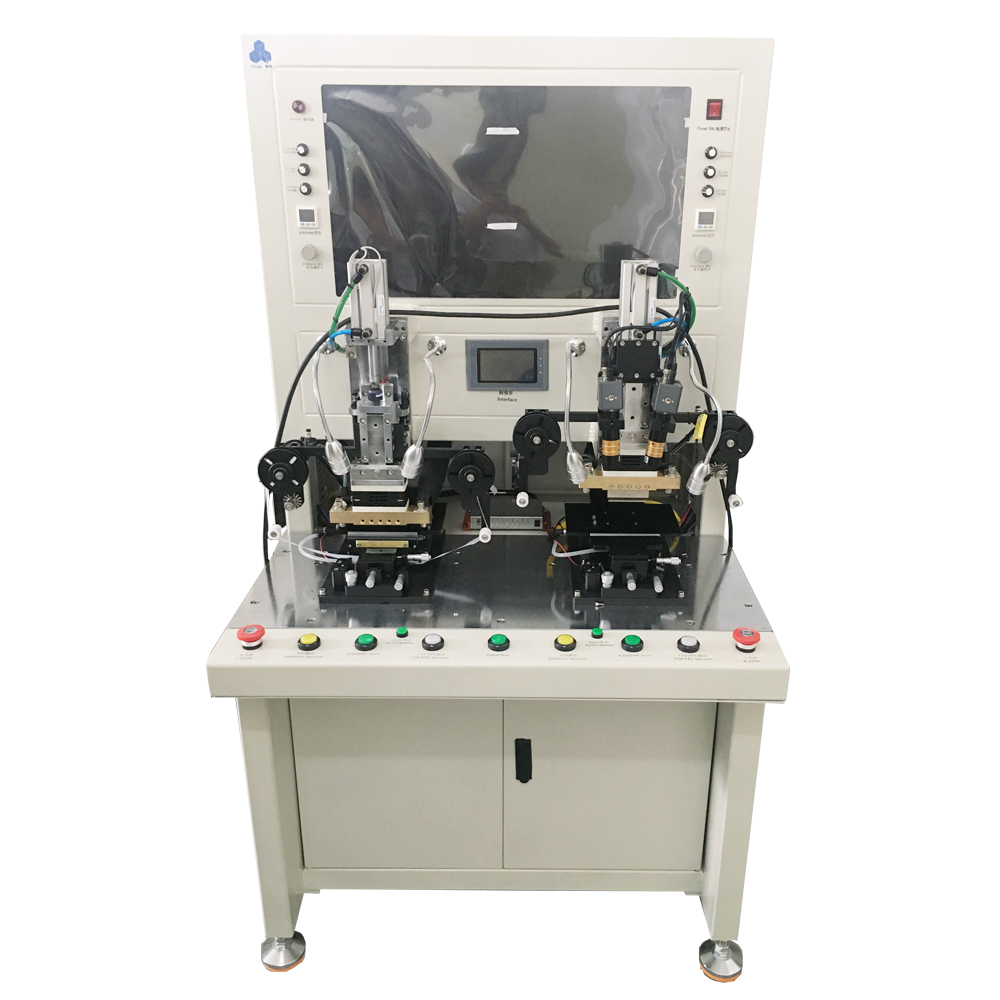

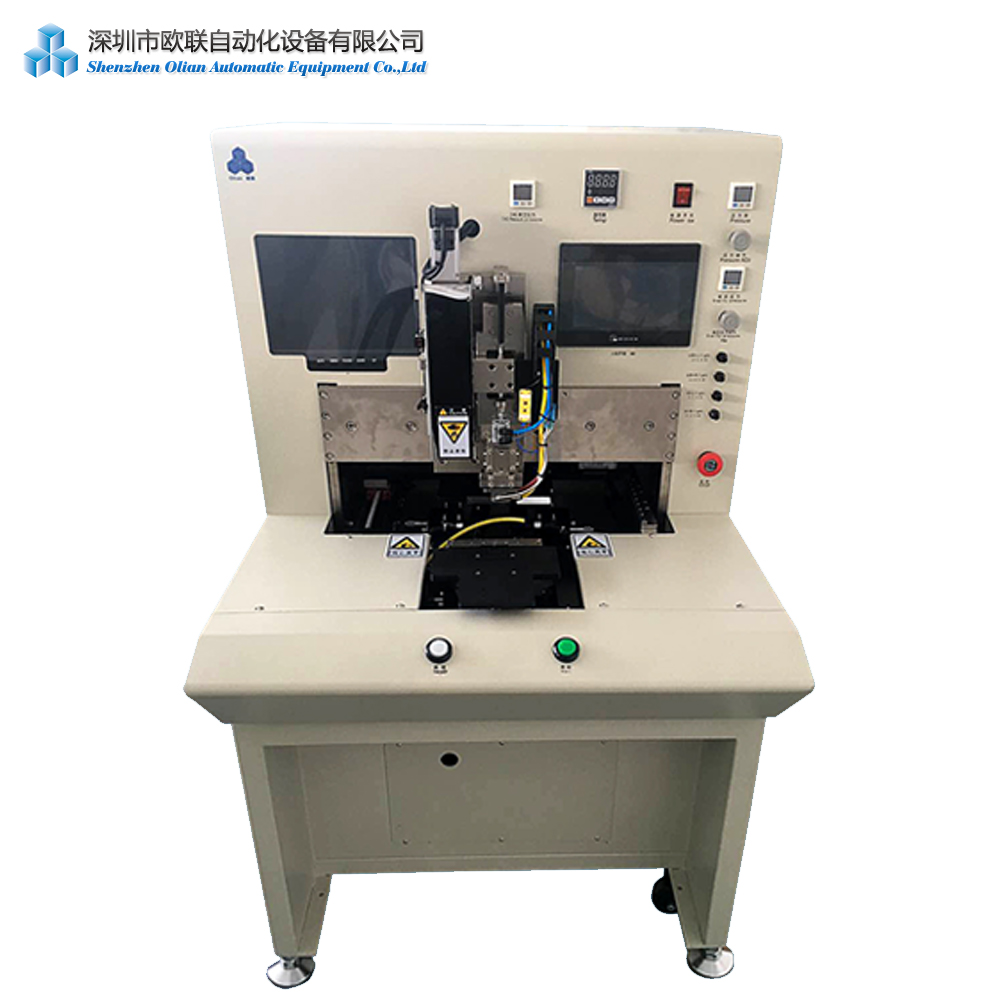

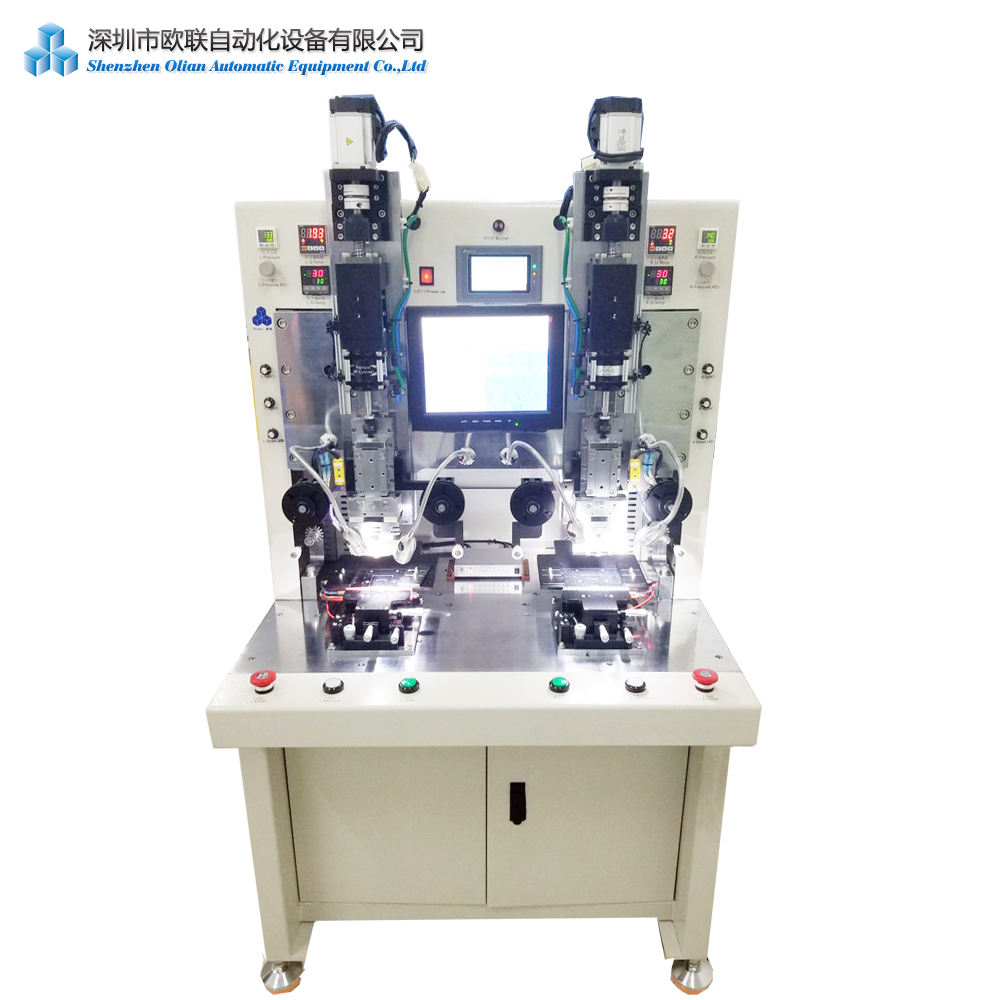

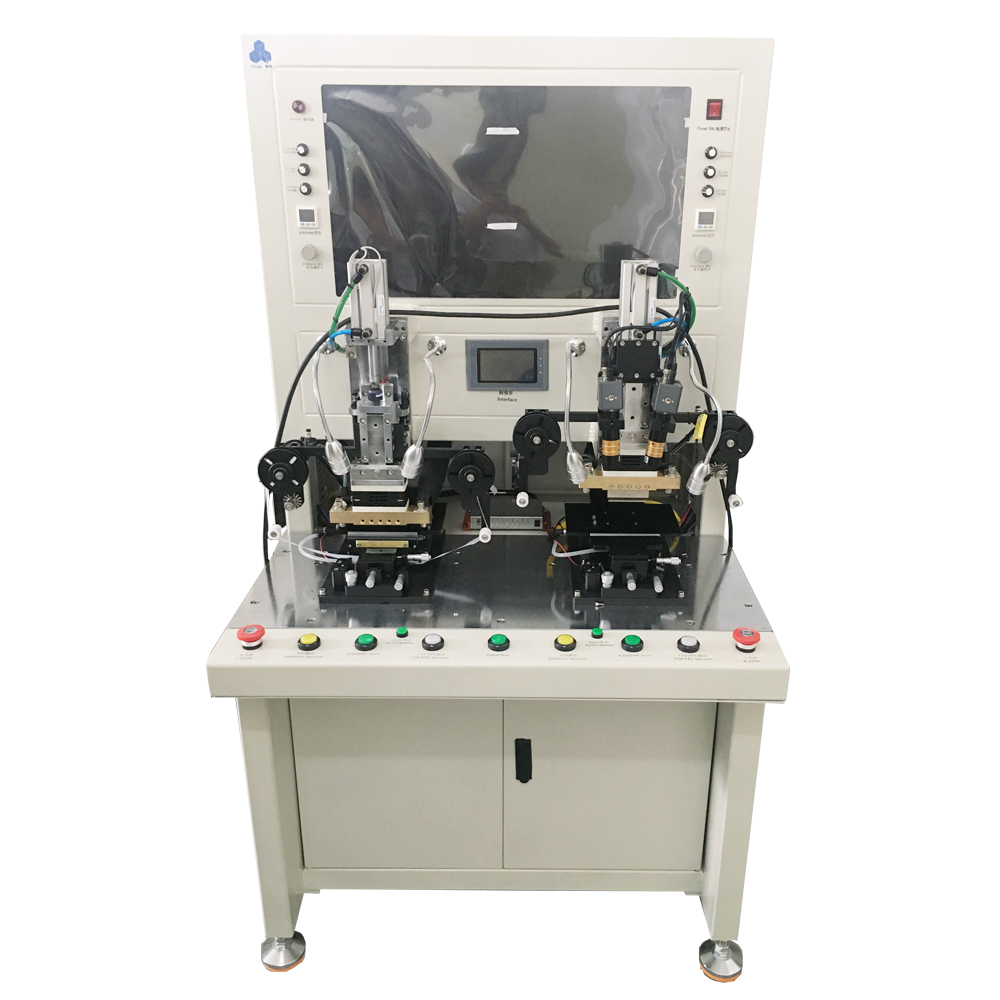

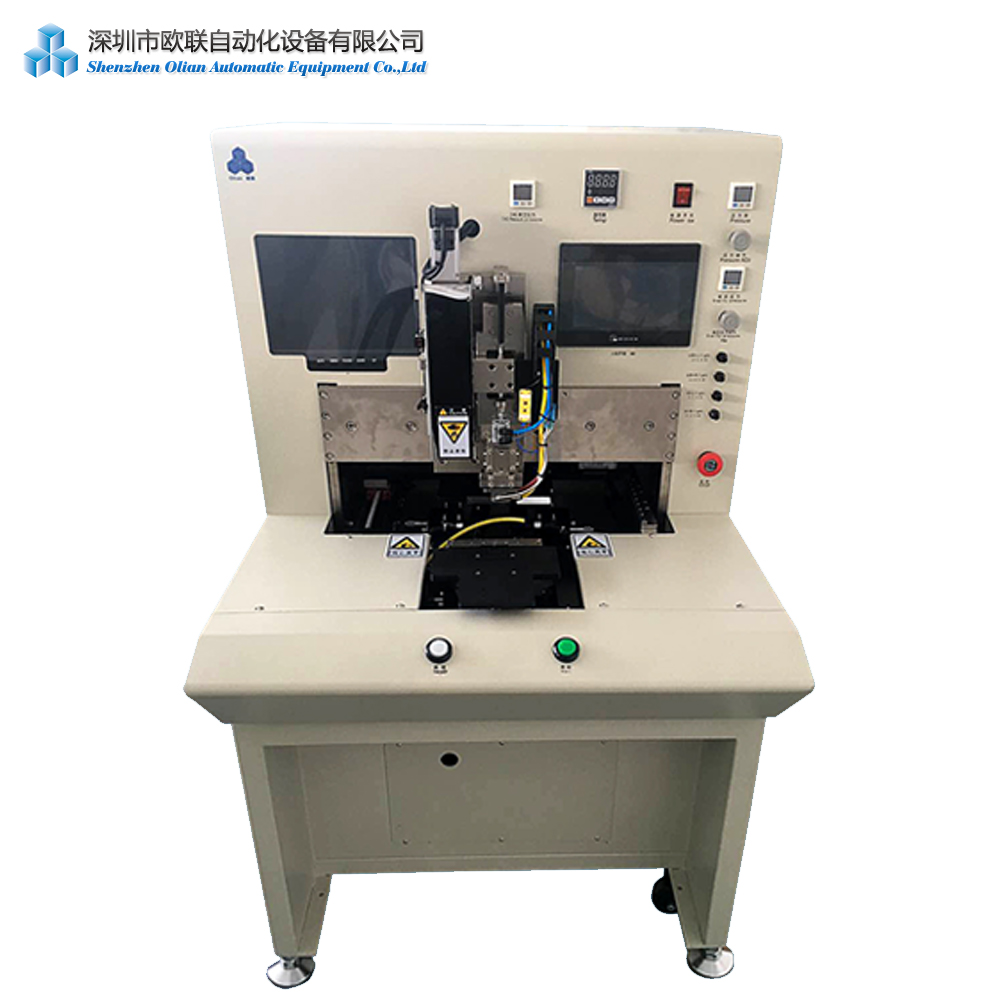

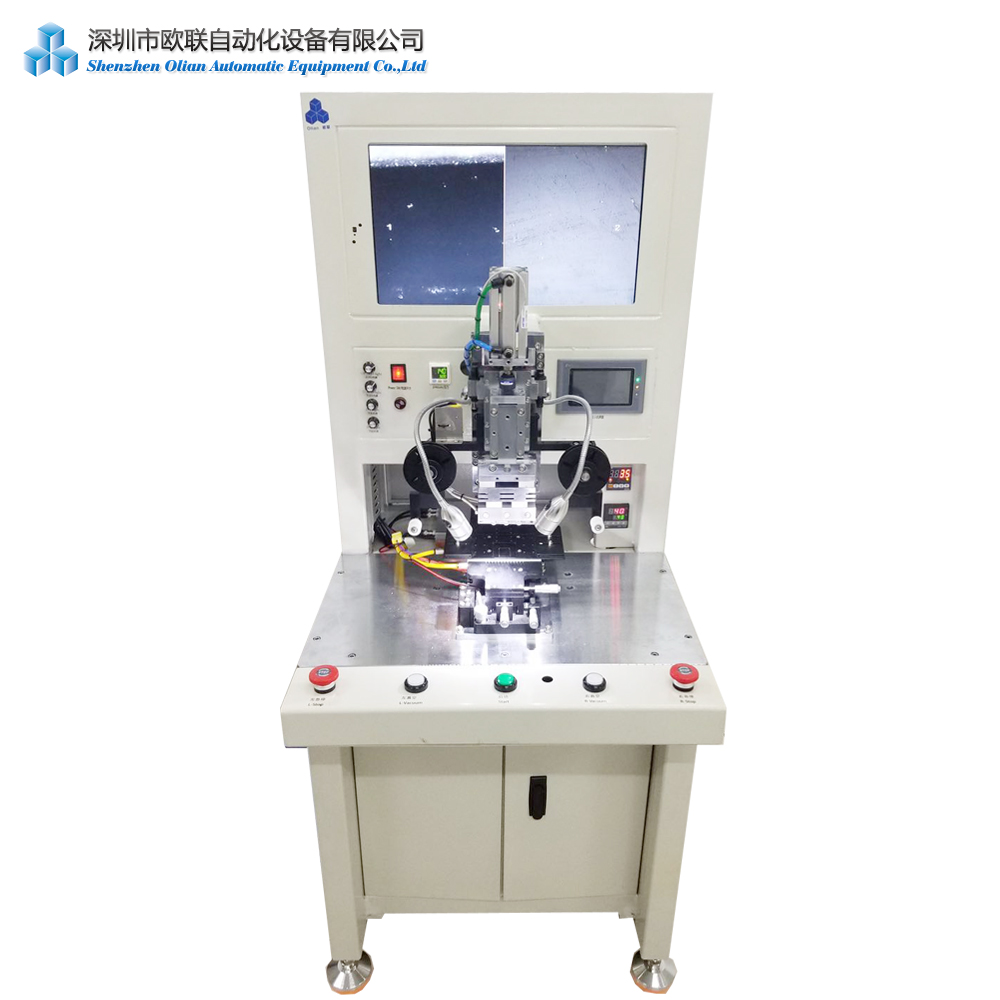

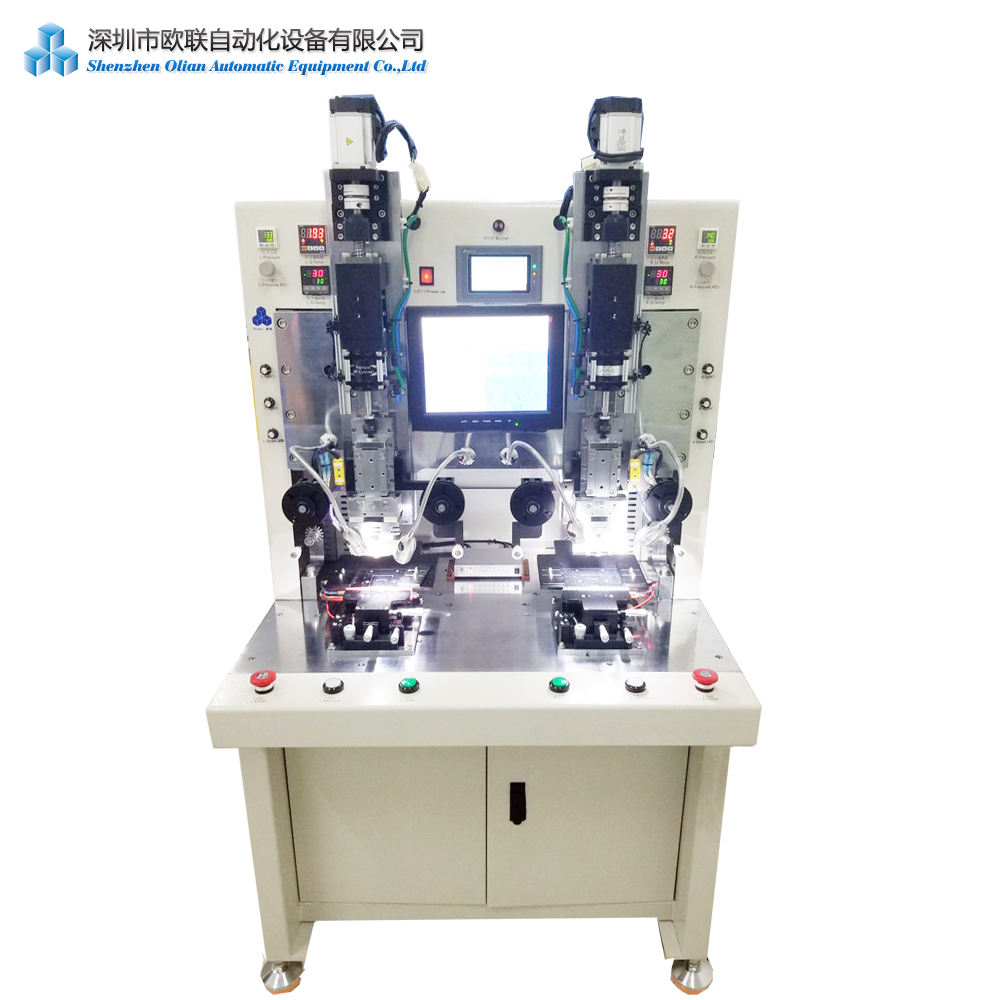

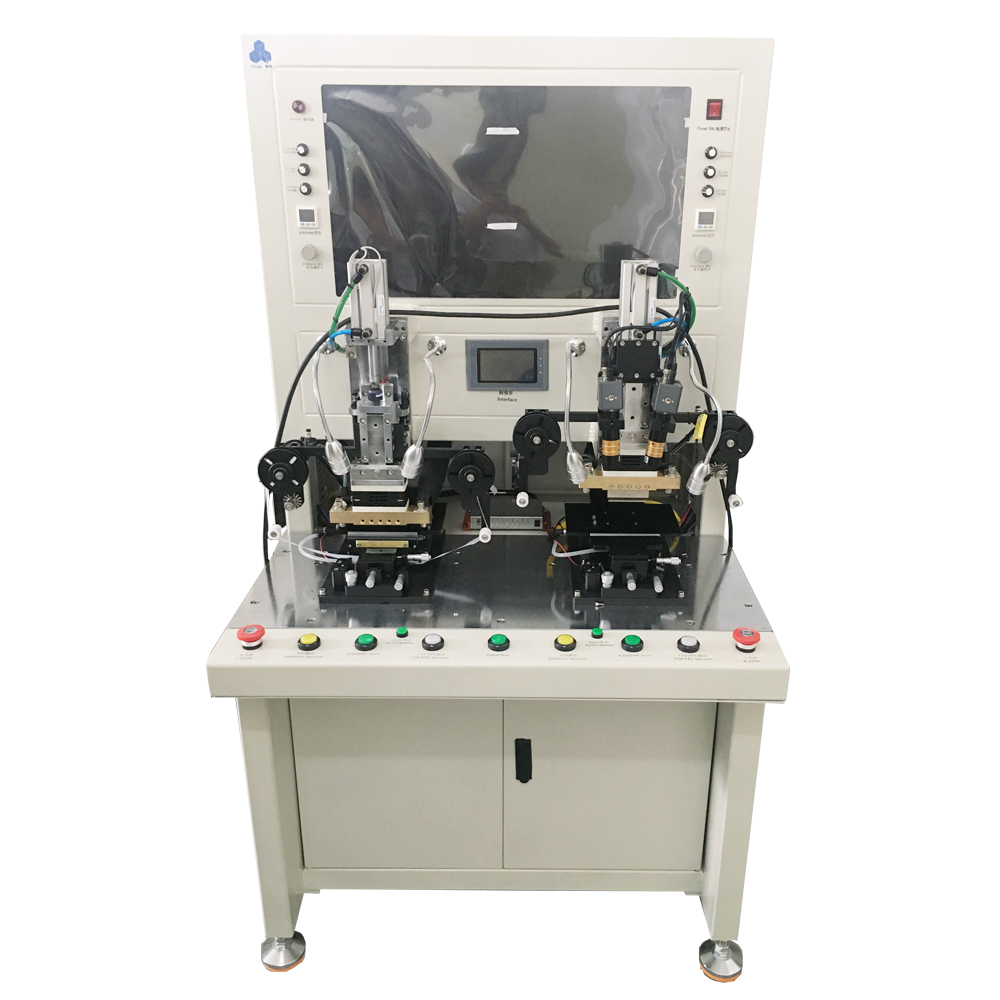

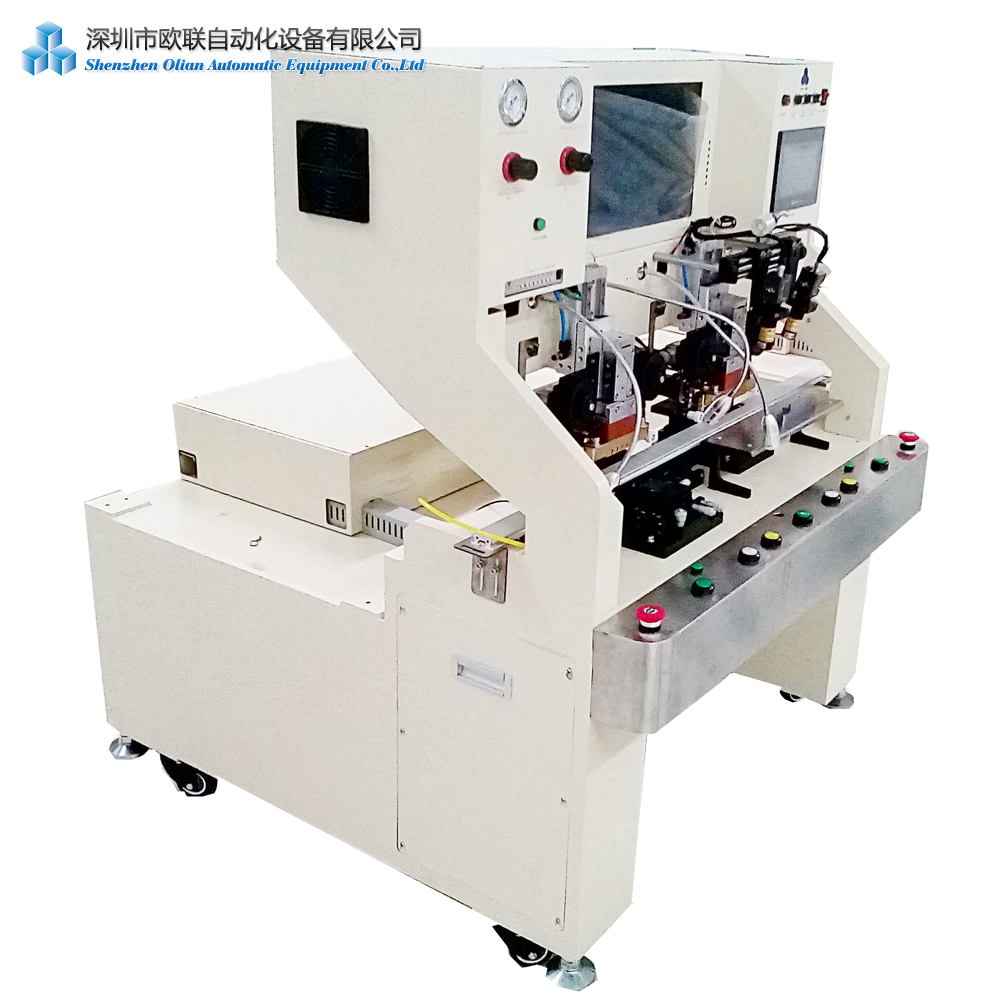

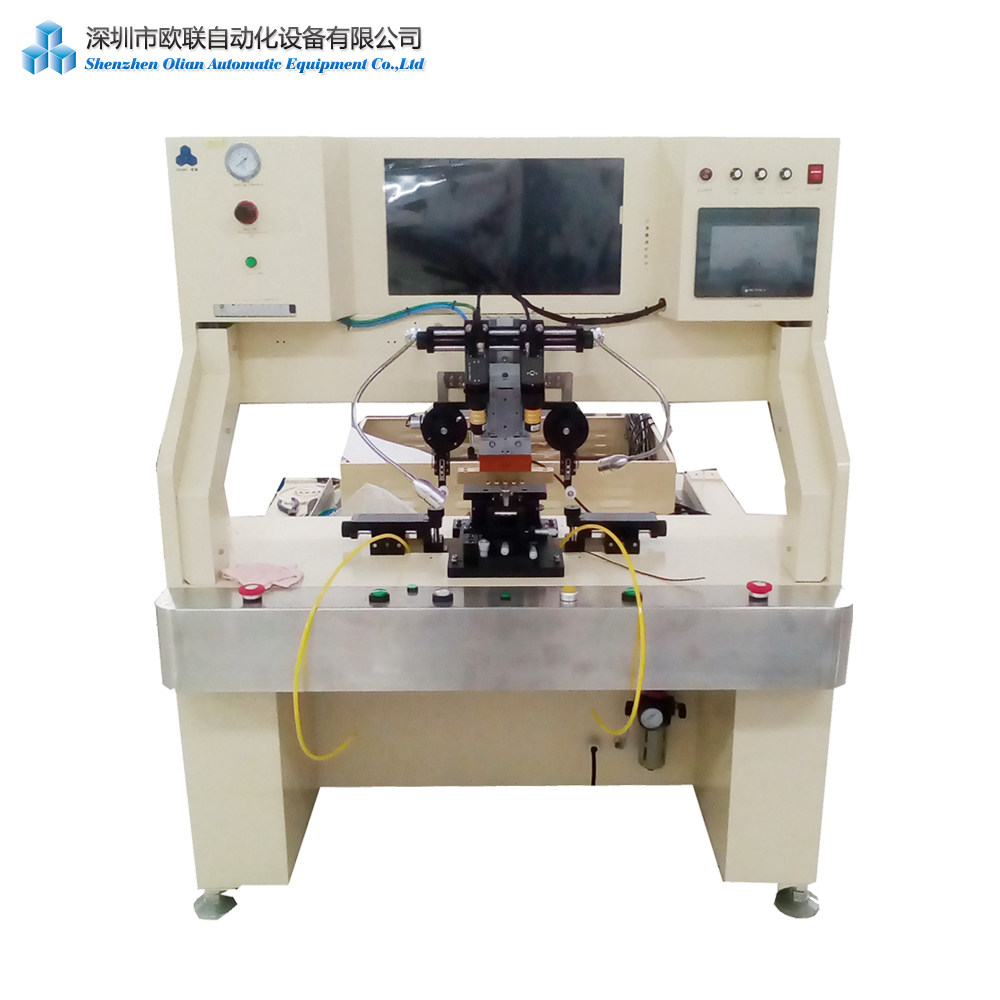

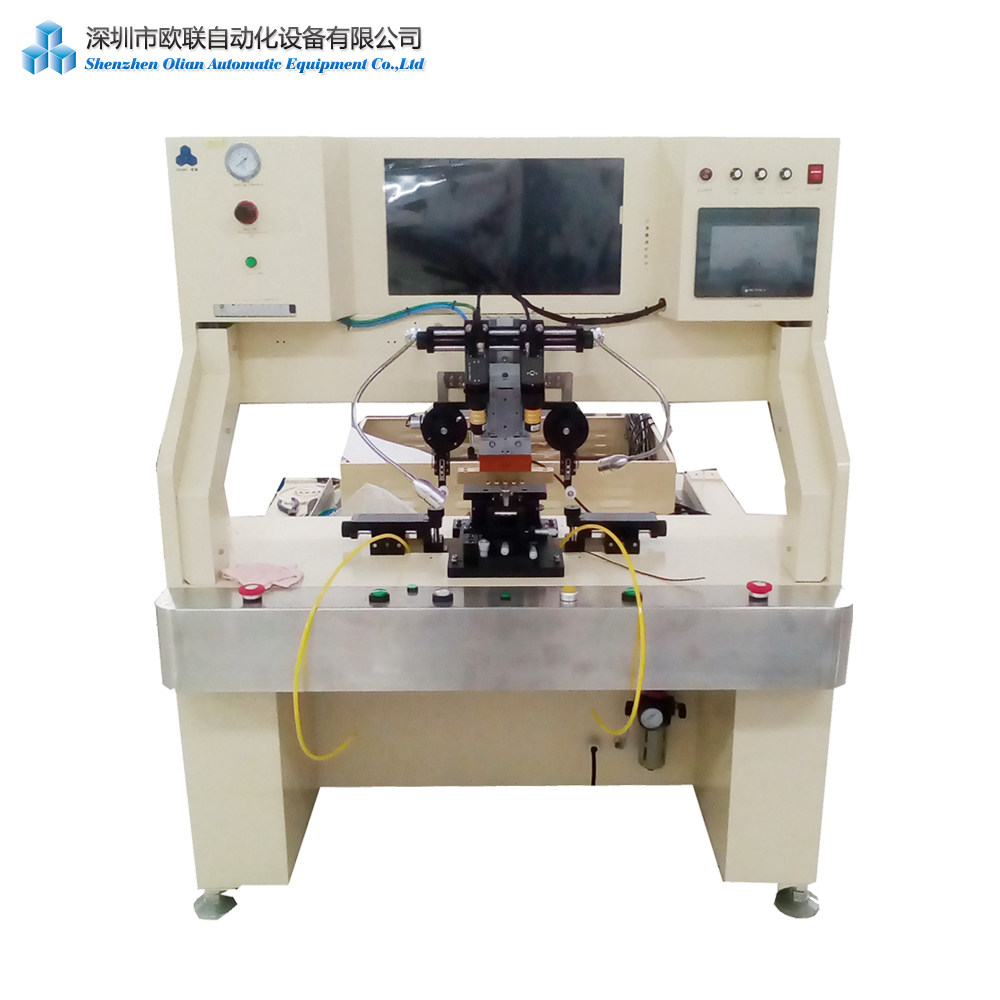

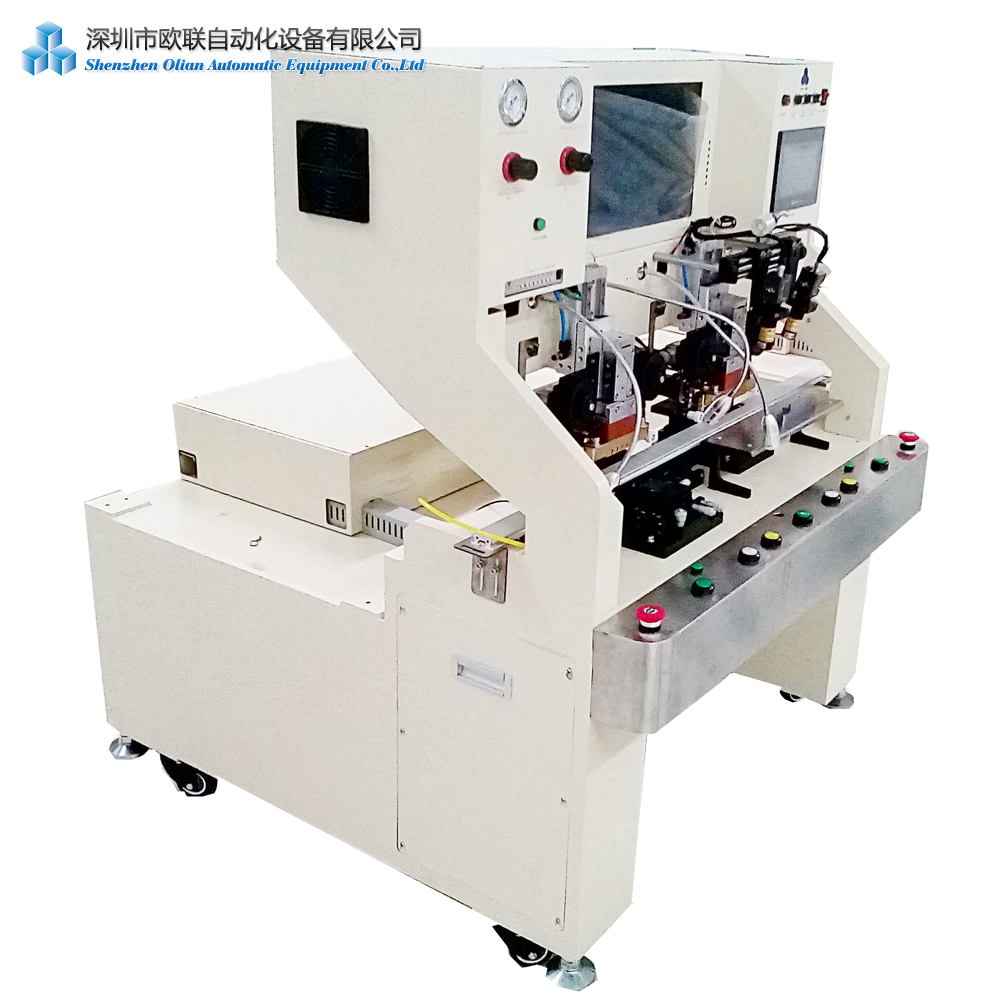

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

This COF bonding machine is mainly designed for TV/Laptop/cellphone repairing, it is for LCD/LED/OLED Panel repairing with COF changing functions,so it is also named COF change machine, COF repair machine, TV bonding machine, TV Repair machine,Laptop repair machine,LCD panel repair machine,LCD bonding machine,LCD repair machine,LCD fix machine, and so on..

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

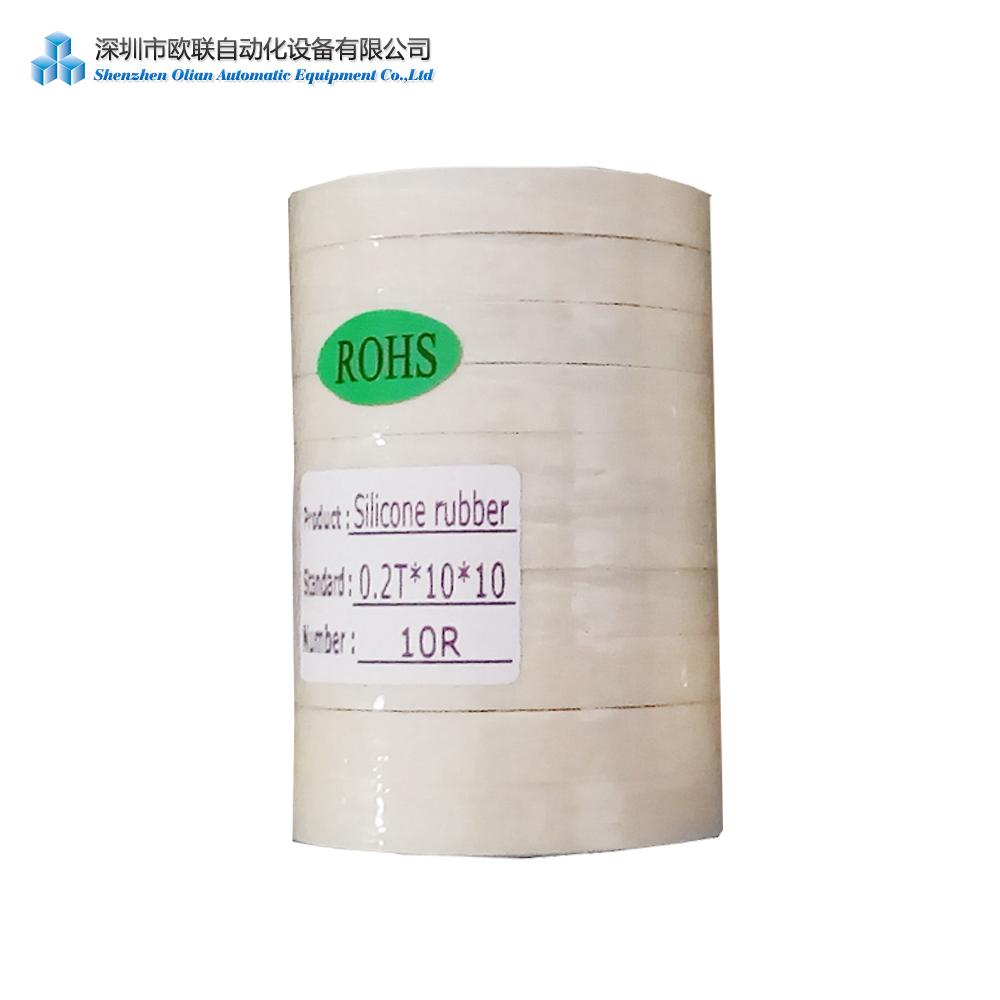

We also offer all the COF Bonding machine accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

COF ic China supplier,please contact us for more..

Wechat/whatsapp:+86 18025364779

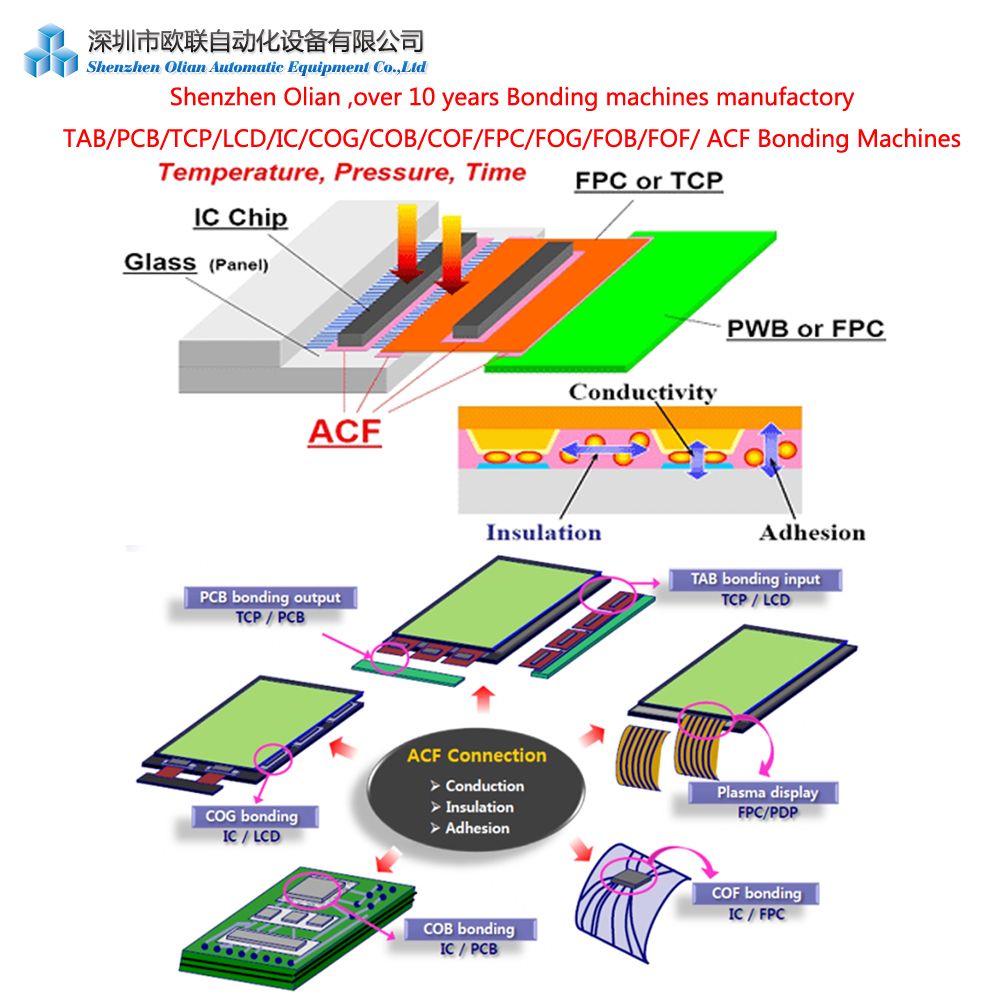

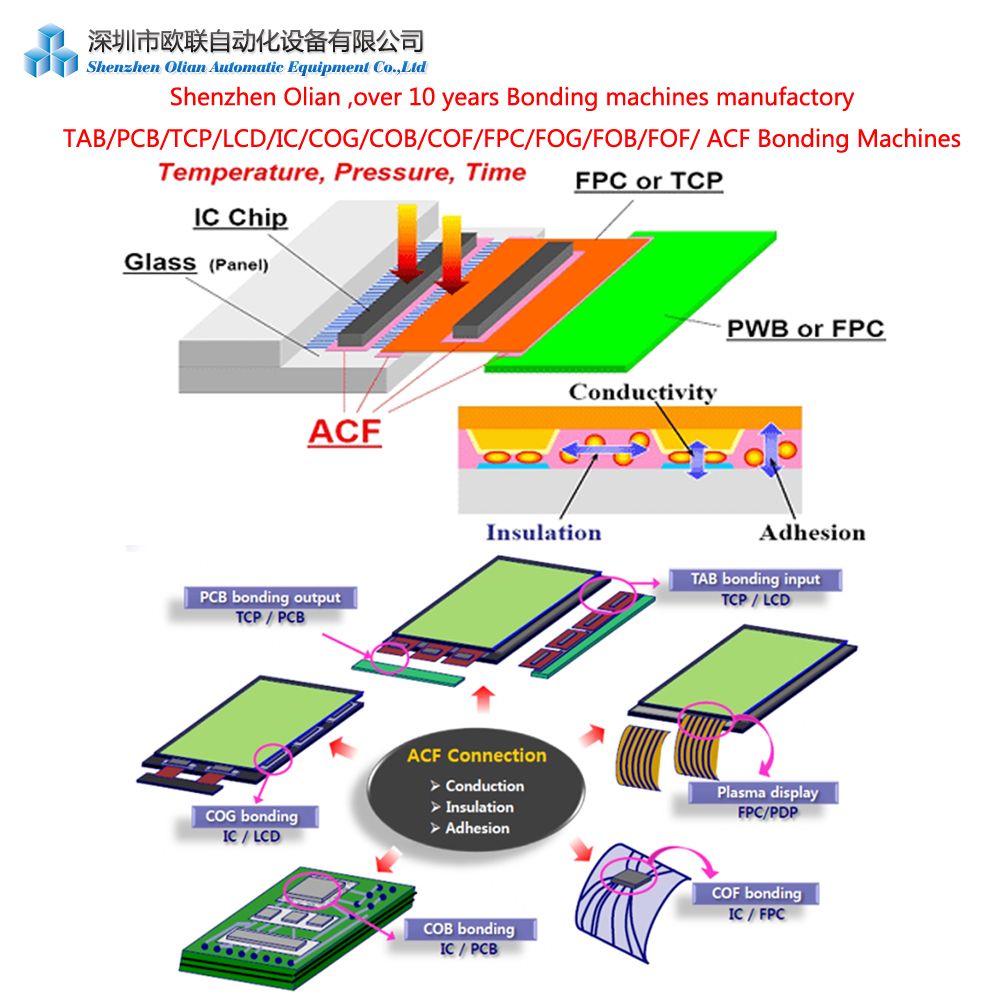

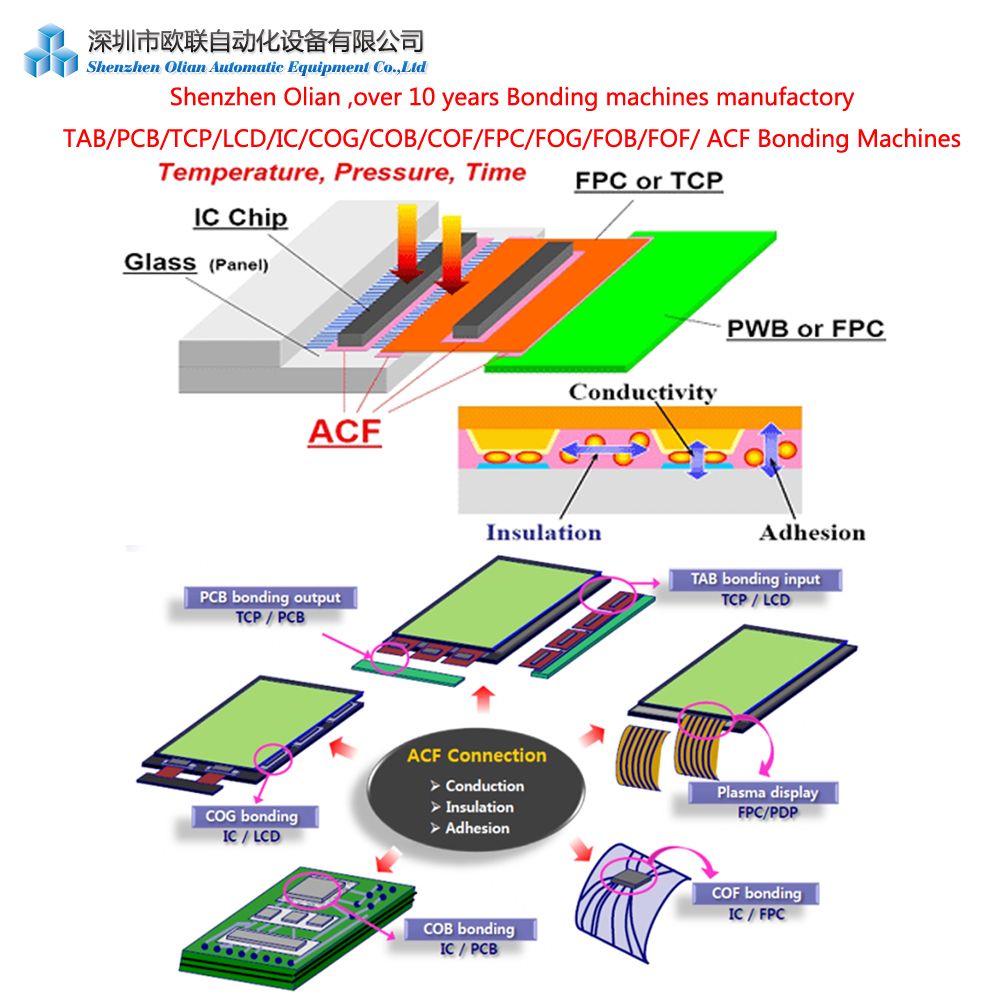

Bonding machine ,it may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time. also some use the Solder paste as the medium.

It has pulse heat and constant temperature machines.

The machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the pressing process.

The Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

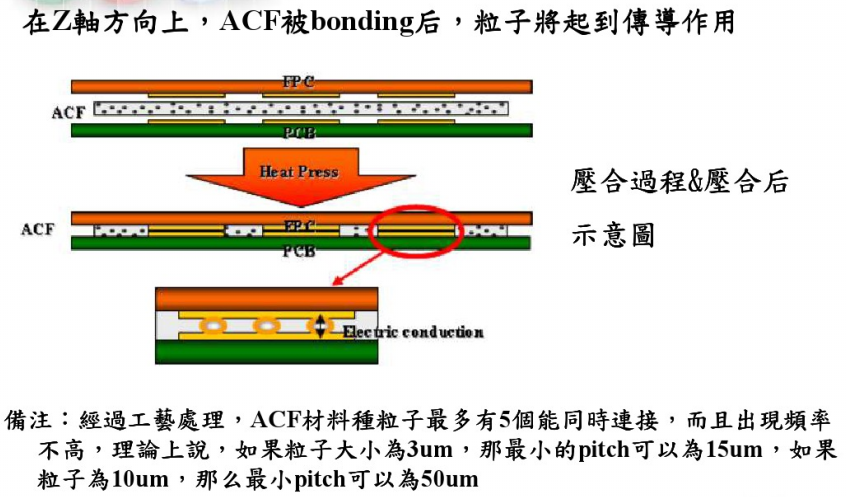

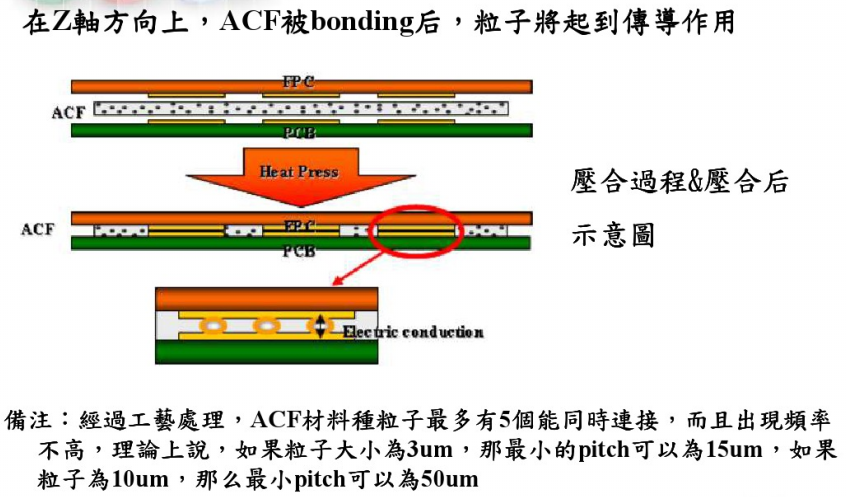

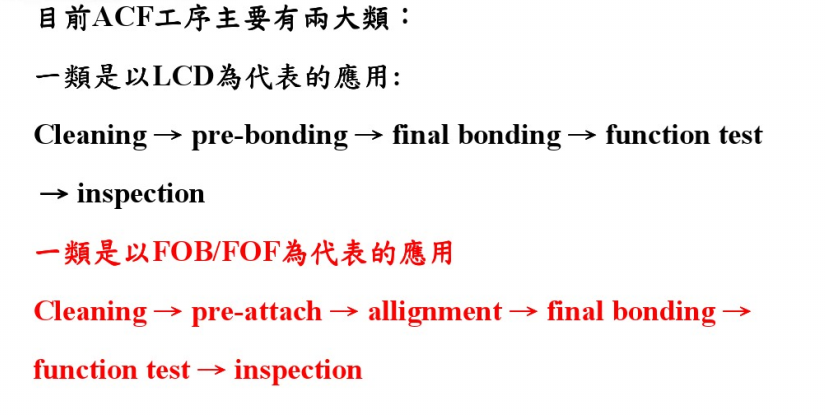

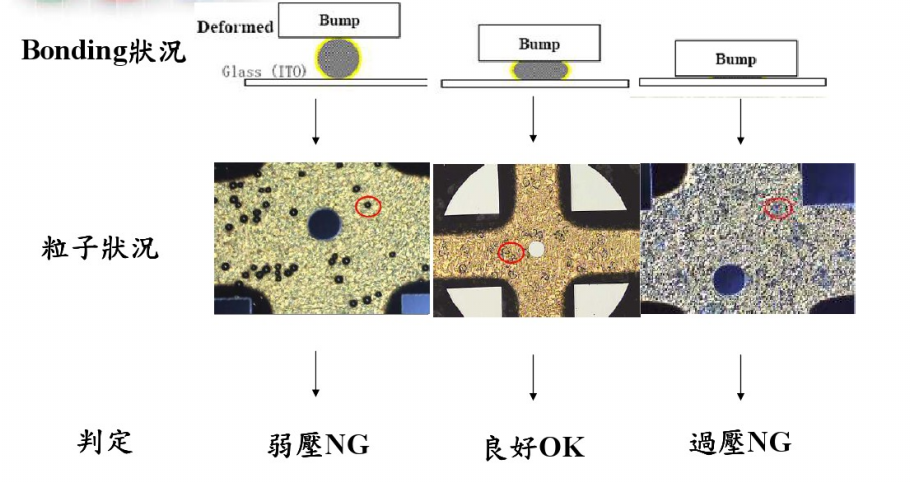

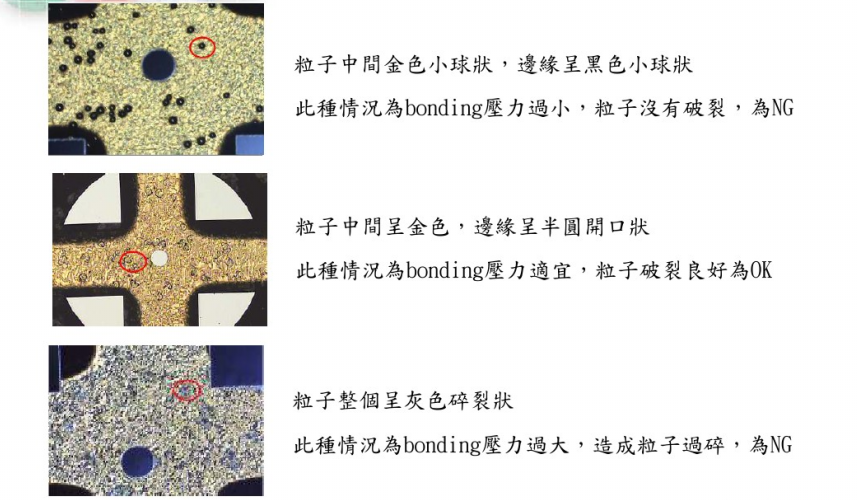

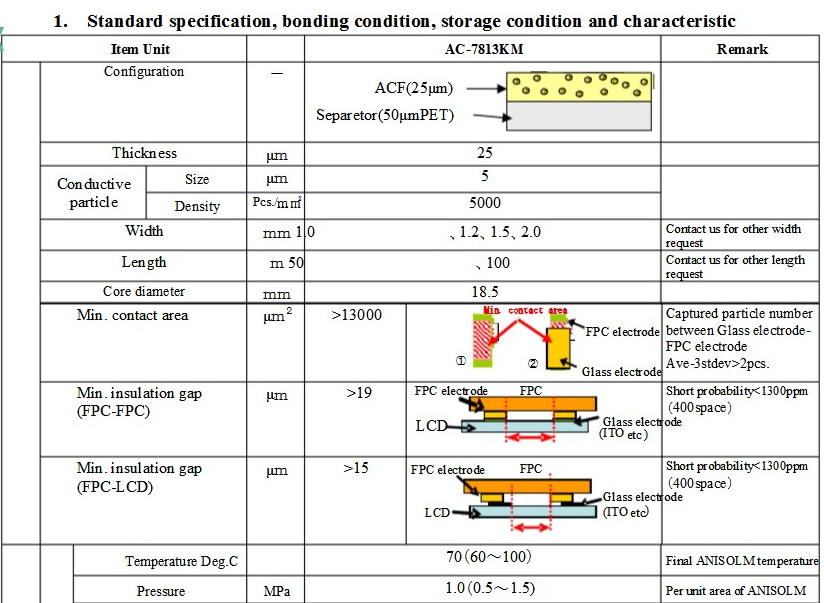

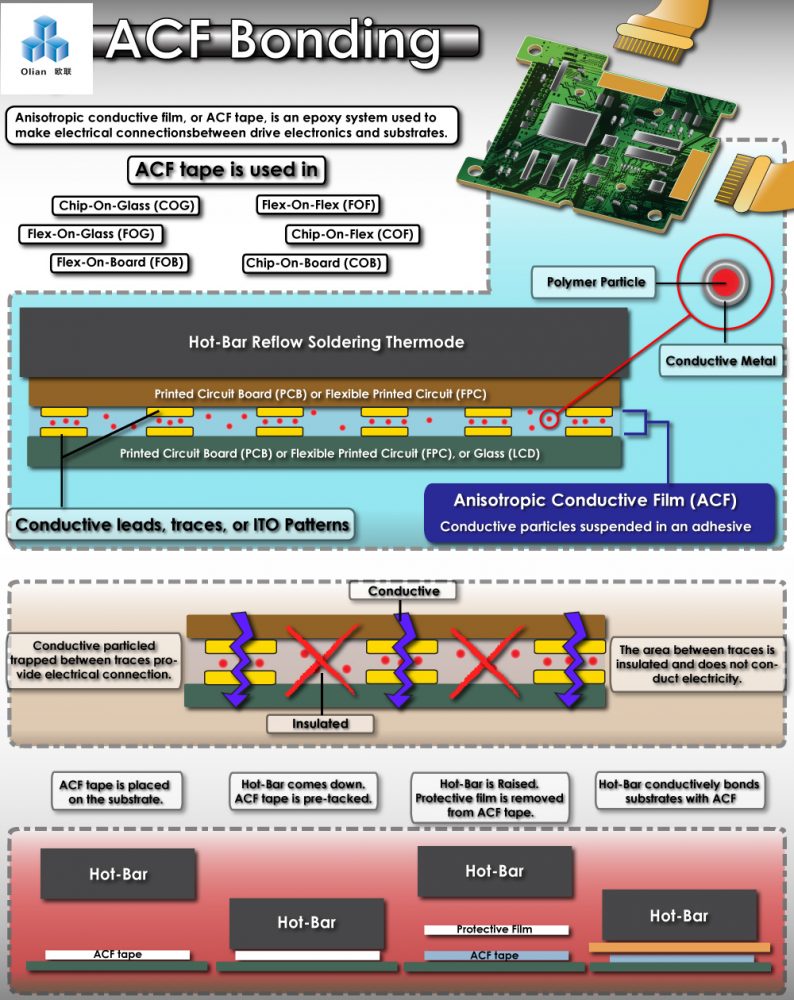

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

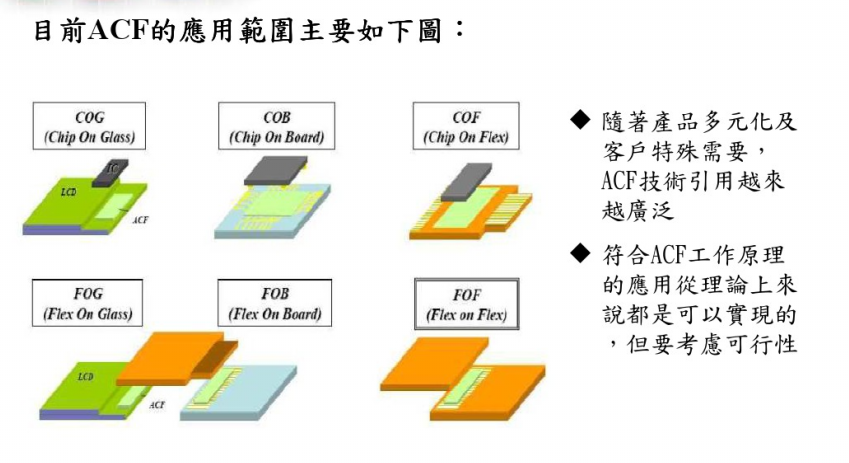

ACF has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Because of many advantages and features ,the machine is becoming more and more popular and useful.

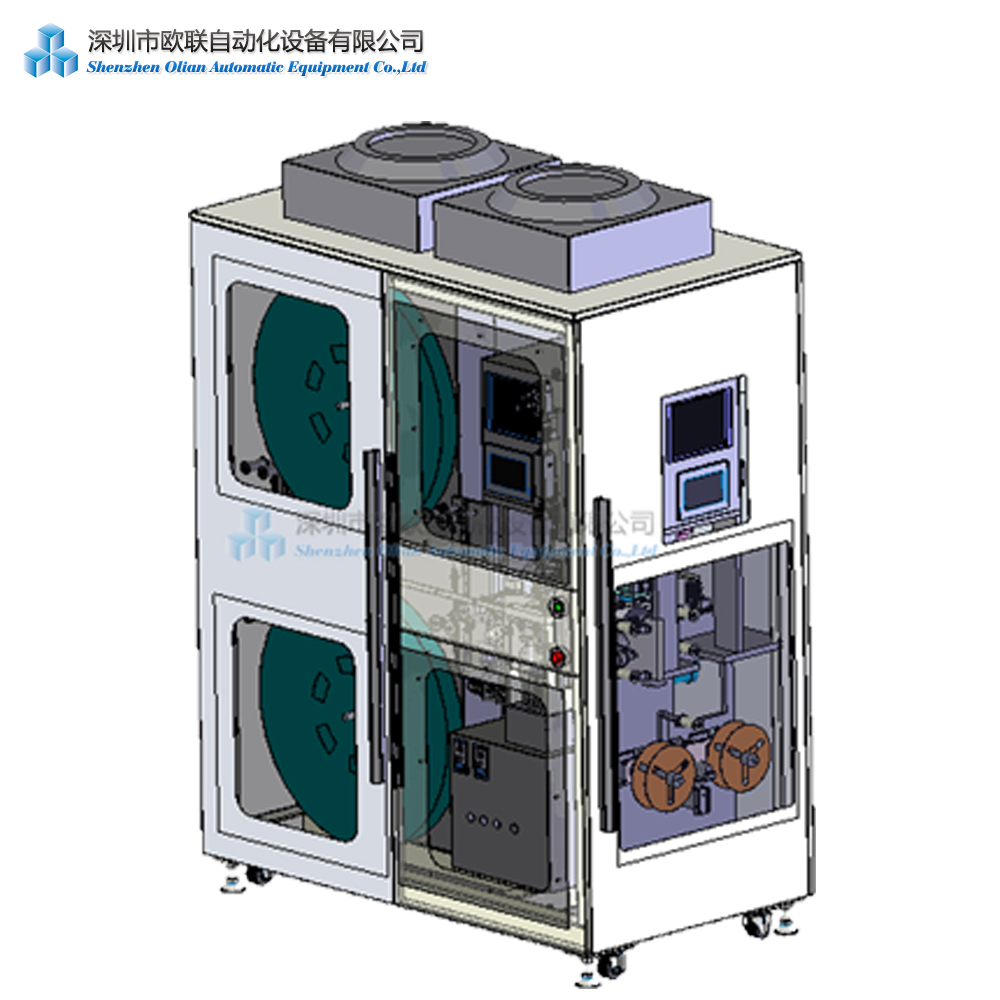

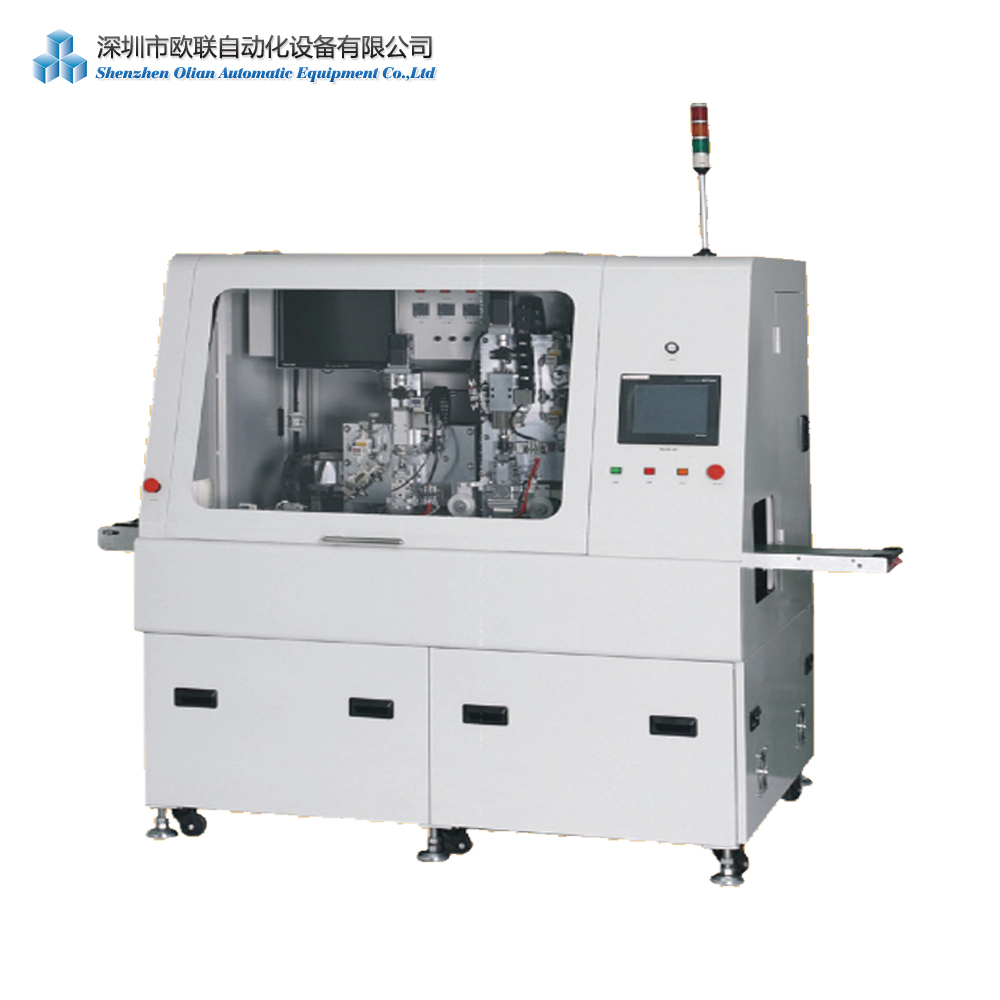

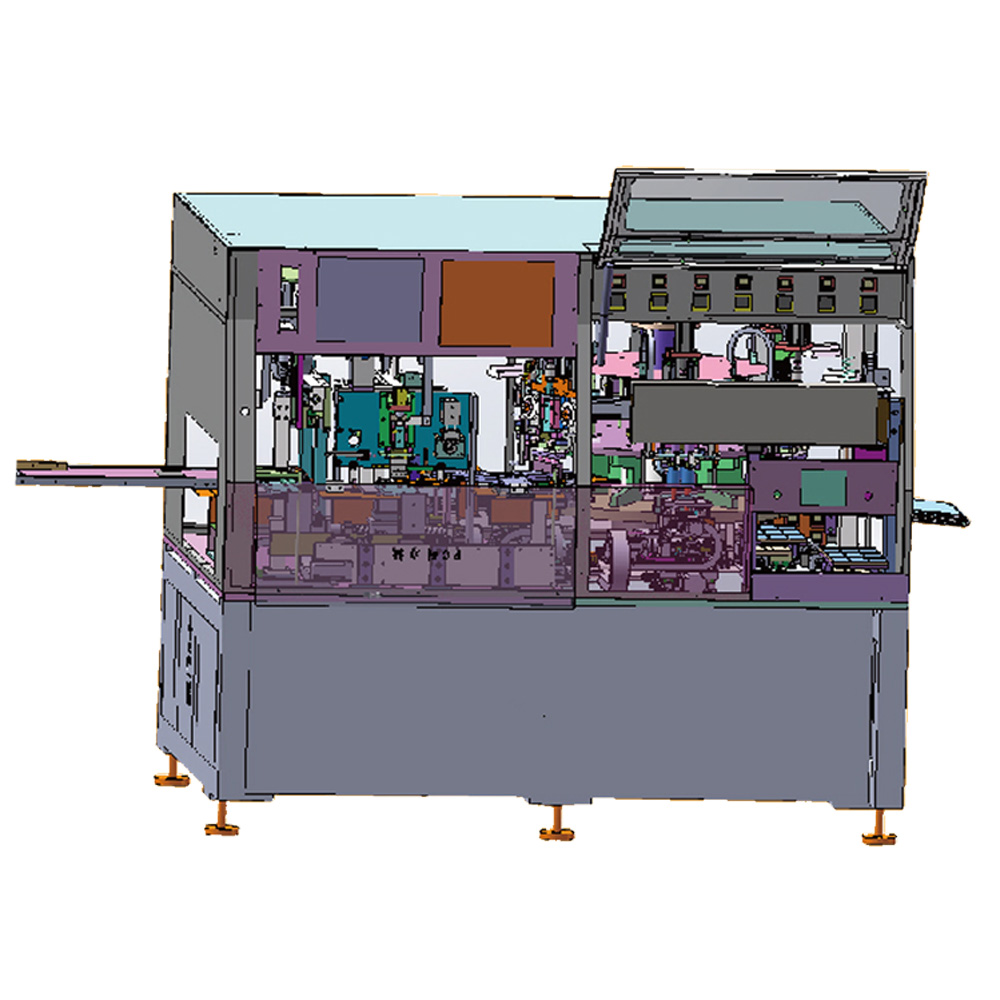

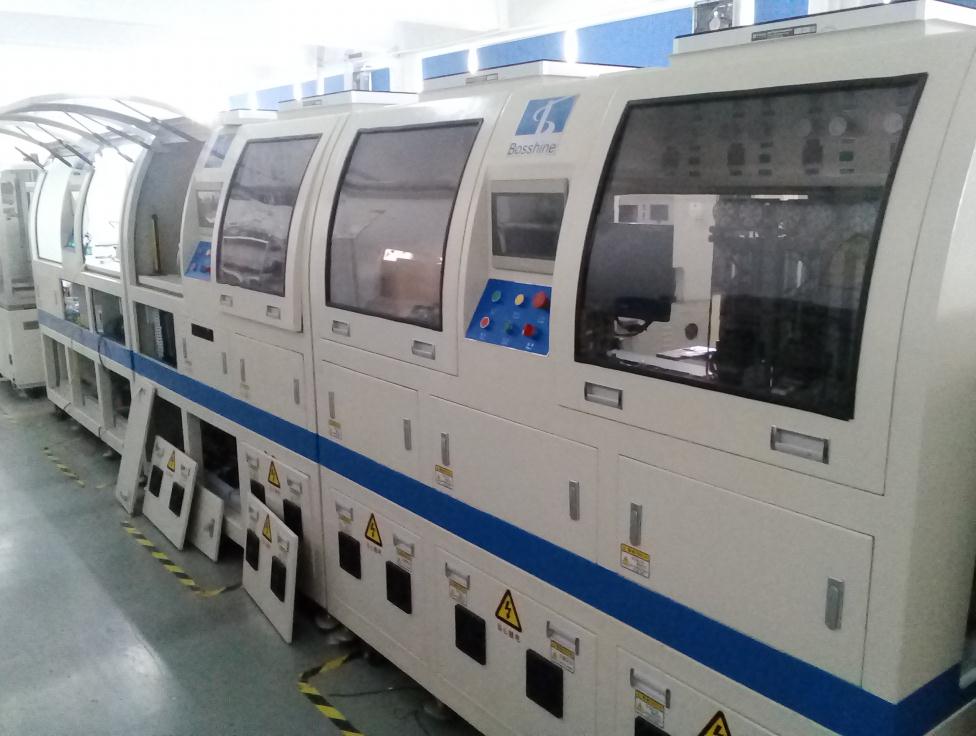

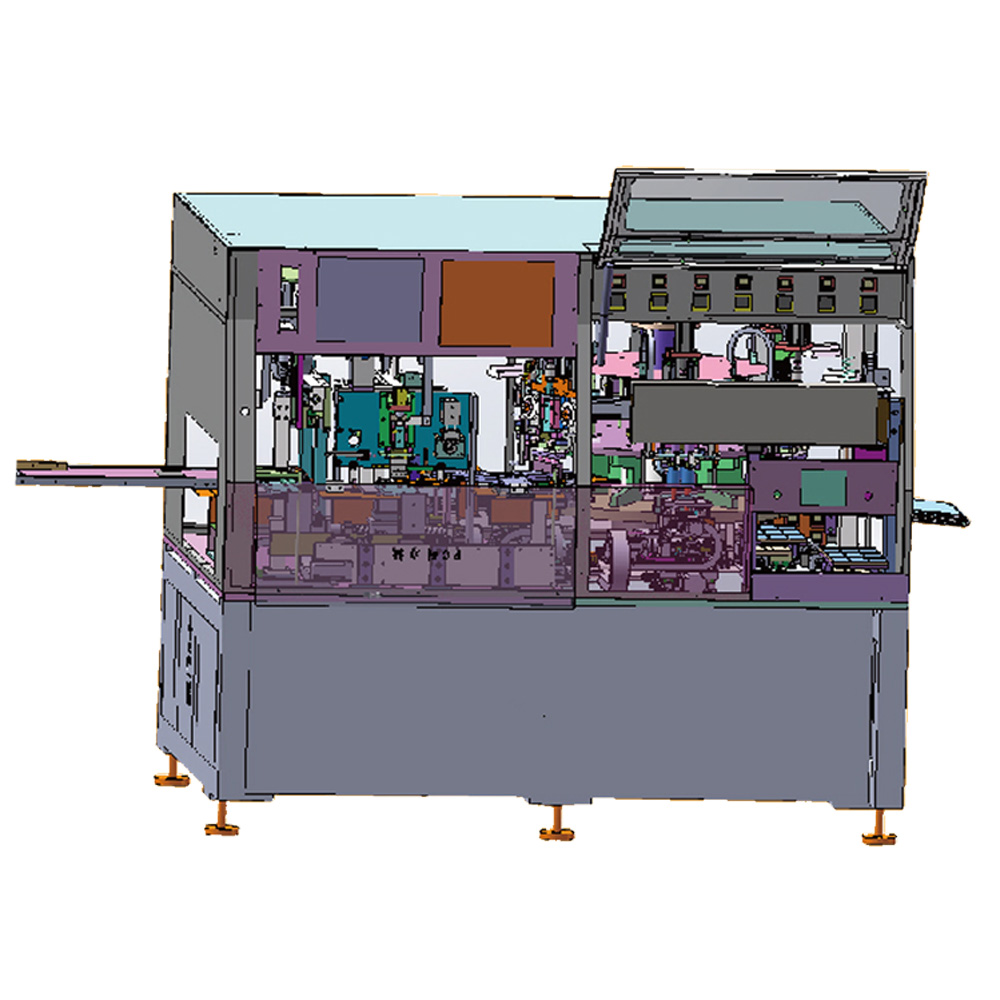

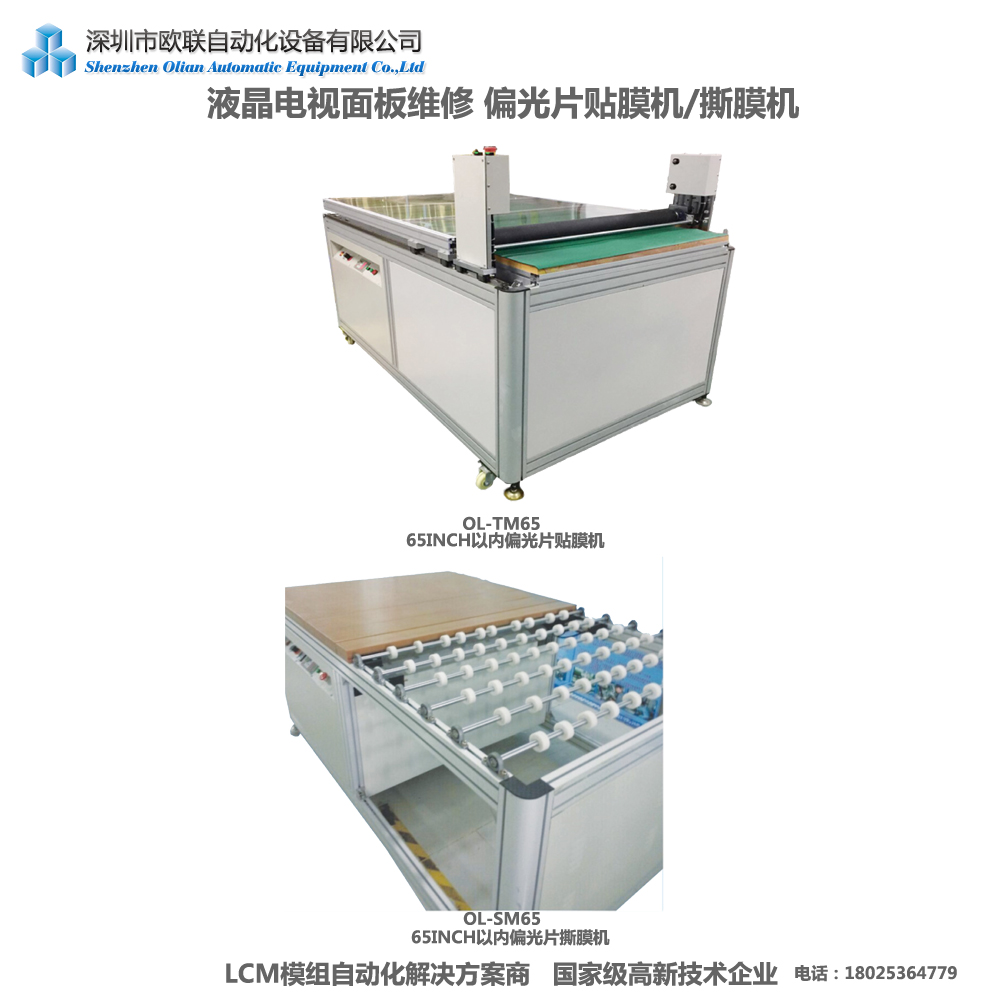

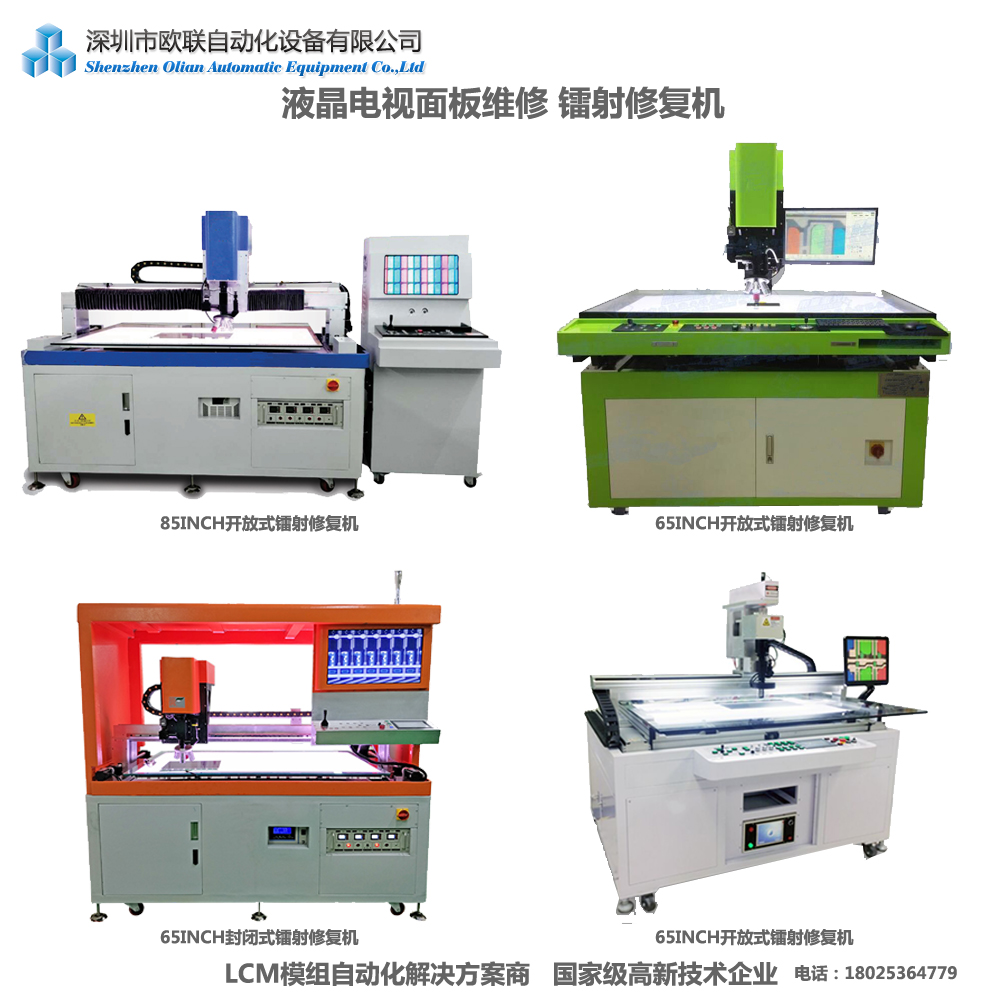

Shenzhen Olian, specializing in the production of pulse hot press, constant temperature hot press, FPC/FOG/FOB/FOF bonding machine, ACF attaching machines, IC/CHIP/COG/COF pre-bonding equipments, COG/COF main-bonding equipments, COF cutting machines, LCD TV repair equipment OLB/TAB/PCB/TCP, microscope, plasma cleaning machines, COF punching machines, LCD screen production and maintenance supplies machines parts and other accessoreis one-stop services.

深圳欧联,专业生产脉冲热压机,恒温热压机,FPC/FOG/FOB/FOF邦定机热压机,ACF贴附机,IC/CHIP/COG/COF预压机,COG/COF本压机,COF裁切机,液晶电视维修设备OLB/TAB/PCB/TCP,显微镜,等离子清洗机,COF冲切机,液晶屏生产维修耗材机器零配件等一站式服务。

The bonding machine is a method of heating two parts of the pre-good flux tin-plated (ACF conductive paste) enough to melt and flow the solder (ACF conductive paste), after curing, in parts and solder (ACF conductive paste) ) form a permanent electrical and mechanical connection device. Should be different products, the heating rate can be selected. The hot head ensures an average temperature, fast temperature rise and long service life. The indenter is specially designed with a horizontal adjustment to ensure that the components are pressure averaged. The temperature is numerically controlled and clear and precise. A digital pressure gauge is available to preset the pressure range.

The hot press machine is also known as the bonding machine . According to different media of hot pressing, it can be divided into soldering, ACF (asymmetrical conductive tape), ACP (anisotropic conductive glue), and TBF (hot melt adhesive film). Suitable for FPC (flexible circuit board), HSC (zebra paper), TAB and LCD and PCB connection. Since the Pitch of PCB or FPC in consumer electronics tends to be small, the conventional soldering process has been difficult to meet the requirements of extremely fine hot pressing. The ACF process has been gradually applied by mobile phone designers.

1.Pulse hot press uses pulse heating technology, temperature control is accurate, temperature sampling frequency is 0.1s. Constant temperature heating method, the temperature is constant after the temperature is raised to the preset temperature. 2. Diversified working modes such as single working platform, rotating working platform, and left and right mobile platforms. 3, multi-stage heating control. 4. Real-time temperature curve display. 5, silicone with indexing mechanism. 6, CCD vision system, providing accurate alignment. 7, large-capacity programs are pre-stored. 8, touch operation interface, program password protection.

Constant temperature , pulse hot press , double station machines, desktop machines, vertical bonding machines, etc.

1.Mobile phone manufacturers, 2 TV manufacturers, 3. Touch screen manufacturers, 4. Computers, 5.LCD/LED/OLED display manufacturers, 5. Printers, 6. Membrane switches, etc.

热压机是一种将两个预先上好助焊剂镀锡(ACF导电胶)的零件加热到足以使焊锡(ACF导电胶)熔化、流动的温度,固化后,在零件与焊锡(ACF导电胶)之间形成一个永久的电气机械连接设备。应不同产品,升温速度可供挑选。热压头确保温度平均,升温快速及使用寿命特长。压头特别采用水平可调设计,以确保组件受压平均。 温度数控化,清楚精密。备有数字式压力计,可预设压力范围。

热压机又称为邦定机 。根据热压的媒介不同,可以分为锡焊,ACF(异向导电胶带),ACP(异向导电胶水),TBF(热熔胶膜)。适用于FPC(柔性线路板),HSC(斑马纸),TAB与LCD及PCB的连接。 由于消费类电子产品中PCB或FPC的Pitch趋于细小化,传统锡焊工艺已经难以满足极细热压的要求。ACF制程已逐步被手机设计商所应用。

1、使用脉冲加热技术,温度控制精确,温度采样频率为0.1s。恒温加热方式,开机升温到预设温度后,温度恒定。2、单工作平台,旋转工作平台,左右移动式平台等多样化的工作模式。3、多段升温控制。4、实时温度曲线显示。5、硅胶带索引机构。6、CCD视觉系统,提供精确对位。7、大容量程序预存。8、触控操作界面,程序密码保护。

恒温热压机、脉冲热压机、双工位热压机、双压头脉冲热压机、台式热压机,立式热压机等

1.手机厂商,2电视机厂商,3.触摸屏厂商,4.电脑,5.LCD/LED/OLED等显示屏生产维修厂商 , 5.打印机 , 6.薄膜开关等

恒温热压机是热压机的一种,能够以恒温的状态一直工作,是用于液晶面板组装工艺中最为广泛的一种设备。

其主要功能是对液晶面板上ITO与ACF、FPC之间进行一种机械电子连接。随着这几年国内LCD行业的迅速发展,与其相关的设备产业也同样发展迅速,目前恒温热压机主要生产厂家聚集在深圳宝安。 恒温热压机属于电子制造设备的分支半导体设备,因此设备的精密度要求较高,一般都配备了视觉系统,设备设计一般禁止产生油污等污染空气的成分,所以一般配件使用气缸,精密线性滑轨等,而提供气源的空气机则选用无油空气机。一则有利于设备的寿命,二则对不会对工作的环境产生很大的油污粒子。

恒温热压机一般由热压组件、微调夹具、视觉系统等部分组成。

恒温热压机按安装方式可分为立式恒温热压机、台式恒温热压机。按热压头部件可分为单头恒温热压机,双头恒温热压机,三头恒温热压机,多头恒温热压机。按其使用功能可分为简易恒温热压机和多功能恒温热压机。按视觉对位可分为上对位恒温热压机,下对位恒温热压机,上下对位恒温热压机。按平台是否可移动,可分为固定式平台热压机,前后平台移动式热压机,旋转平台热压机,等等

恒温热压机的正常使用必须满足如下条件,机器所处位置的电源电压波动小,环境温度低于30摄氏度,相对湿度小于80%。机器的位置应远离振源、应避免阳光直接照射和热辐射的影响,避免潮湿和气流的影响。如机床器近有振源,则机床四周应设置防振沟。否则将直接影响机器的加工精度及稳定性,将使电子元件接触不良,发生故障,影响机器的可靠性。以附近无振源的万级无尘室为最佳。

Pulse Heat Bonding Machine, it use the pulse transformer to give a large current and low voltage to give high heat to the press head to bonding the COF/FPC on to the glass/PCB/FPC..

脉冲热压机利用变压器产生一个低电压的大电流,通过焊接头令其迅速发热。脉冲电流就是指电流的ON及OFF频率比例,此脉冲比例越大,电流输出越大,焊接头升温越快。脉冲热压机将工件置于夹具(如有需要,可启动真空将其固定)。将夹具送至焊接头下,按双开始键,焊接头下压着工件(开始加热),温度按输入参数迅速上升及准确恒温,可设多个温度(此时焊锡回流),吹气冷却(焊锡凝固),焊接头上升(完成)。目前手机电视等液晶屏的邦定大部分都是使用ACF胶带。

脉冲热压机通过在热压头上加载一定的脉冲电压,热压头发热,将与此相连接的物体升温,当温度升到焊锡熔点后(即升到事先设定的温度后),将与此相连的物体间锡(ACF导电粒子)熔融并将其连接在一起. 一般的脉冲热压机使用温度闭环的控制。

脉冲热压机主要应用在不能使用正常SMT+回流炉进行焊接的器件进行焊接操作,而使用烙铁进行焊接时容易出现焊接外观不一致、不平整,容易出现虚焊以及容易焊坏产品。而脉冲热压机则不同于恒温烙铁,脉冲热压机在通电瞬间即可达到所要温度,而一旦焊头两端不加电压,瞬间即可达到室温;而且焊头平整,所以焊接出来的外观平整一致,极少出现虚焊不良。脉冲加热焊接机可以通过温度反馈功能防止因散热产生的温度下降,和常时定温加热方式相比效率更高。预压工程中脉冲电流加热方法可以更有效的控制管理温度。加压后的热硬化方法可以防止ACF的偏移或导电粒子的未连接.

1、脉冲加热技术,快速升温、降温

2、具备温度校正/温度及时补偿功能,内置热压头温度过温保护功能

3、4个高清摄像头可独立上下、左右、前后三轴精确微调、对焦、对位

4、配备彩色触摸操作屏和高分辨率液晶显示屏,清晰观看对位情况再热压

5、PLC可编程控制器,可设置、储存多种工作程序

6、可更换不同尺寸的钛合金压头,热压各种不同品牌手机的排线/COF.

7、独有的双缸结构可消除压头自重,压力精准平衡,稳定

8、可根据不同产品以及ACF胶带要求,配置不同的升温速度、热压时间,压力等

9、工作台运用千分尺调节X,Y,Z, θ轴微调定位

10、适用各种手机触膜和显示排线,COF屏热压邦定, 11、排线,平台可根据产品设计专用的定位模具,并配备真空吸附,保证良率

脉冲热压机应用于手机厂商,电视机厂商,触摸屏厂商 ,电脑 ,平板,打印机等等厂家,

脉冲热压机应用在以下产品生产工艺中:COF与柔性屏的热压,COF与PCB的热压,COF与FPC的热压,排线热压、软排线FFC与软性线路板FPC或硬性线路板PCB的焊接、TCP与线路板PCB或软性线路板FPC之间的焊接、软性线路板FPC与线路板PCB之间的焊接热压等。

深圳市欧联自动化设备有限公司,专注 FPD 平板显示、3C 领域自动化装备自动化设备的研发、制造、销售及服务于一体的国家级高新技术生产企业。先后获得国家级高新技术企业及多项研发专利及著作权。目前公司拥有近五十人专业研发、生产管理、品质管理、售后服务专业团队,公司设有精密 CNC 机加中心(精密 CNC、车床、铣床、磨床、二次元等生产设备),具备从产品设计到生产加工的整体制造能力。自成立以来,以精湛的技术、优质的品质、高效的售后服务于客户,现已成为业内知名的 LCM 整线自动化设备解决方案商。

Shenzhen Olian Automation Equipment Co., Ltd. is a national high-tech manufacturing enterprise focusing on RPD flat panel display, 3C field automation equipment automation equipment research and development, manufacturing, sales and service. Olian has won state-level high-tech enterprises and a number of research and development patents and copyrights. At present, Olian has nearly 50 professional R & D, production management, quality management, after-sales service professional team, Olian has a precision CNC machine plus center (precision CNC, lathe, milling machine, grinding machine, two yuan and other production equipment), with product design To the overall manufacturing capacity of production and processing. Since its establishment, Olian has become a well-known LCM complete line automation equipment solution provider in the industry with its exquisite technology, high quality and efficient after-sales service.

ACF 贴附系列、Plasma 端子清洗系列、单颗及多边多颗 COG/COF 邦定系列、单段及单边多段 FOG/FOF 邦定(恒温/脉冲)系列、OGS/On Cell/In Cell 热压系列、OLB 邦定系列,COF 冲裁各类非标设备以及智能化工厂整体解决方案等。

Existing products mainly include: ACF attach series, Plasma terminal cleaning series, single and multilateral COG/COF bonding series, single-stage and single-sided multi-stage FOG/FOF bonding (constant/pulse) series, OGS/On Cell/In Cell hot press bonding series, OLB bonding series, COF punching and all kinds of non-standard equipment and intelligent factory overall solutions.

公司拥有国内最早研发 FPD 平板显示领域设备的资深技术团队。为让技术一直创新并突破,我们与浙江大学深圳研究院建立了长期专项合作,研发并取得了多项关键技术的突破性成果。目前公司产品主要应用在全面屏、OLED、LCM、BLU 等多个领域。现与创维集团、帝晶光电、重庆中光电、深圳国显、天山微电子、立德通讯、中光电科技、亚世光电、中山国信通、拓佳、科森光电、闻太、德景、福瑞达、光弘等国内外两百多家知名企业建立起了长期友好的合作关系。产品覆盖广东、广西、江苏、浙江、江西、辽宁、湖南、湖北、福建、重庆等全国 20 多个省市。

SHENZHEN OLIAN has the earliest domestic technical team to develop equipment in the field of FPD flat panel display. In order to make technology always innovate and break through, we have established long-term special cooperation with Zhejiang University Shenzhen Research Institute, and have developed and achieved breakthrough results in a number of key technologies. At present, the company’s products are mainly used in multiple fields such as full screen, OLED, LCM, and BLU. Now with Skyworth Group, Dijing Optoelectronics, Chongqing Zhongguang, Shenzhen Guoxian, Tianshan Microelectronics, Lide Communications, China Optoelectronics Technology, Yashi Optoelectronics, Zhongshan Guoxintong, Tuojia, Kesen Optoelectronics, Wentai, Dejing, More than 200 well-known companies at home and abroad such as Freda and Guanghong have established long-term friendly cooperative relations. Products cover more than 20 provinces and cities in Guangdong, Guangxi, Jiangsu, Zhejiang, Jiangxi, Liaoning, Hunan, Hubei, Fujian, Chongqing and other countries.

我们的宗旨是“品质至上、技术创新”。我们推崇“诚信经营、实事求是、互利合作、共同发展”的经营方针我们不断追求完善、力求做得更好。立志成为该行业具有代表性的公司!

深圳市欧联自动化设备有限公司的诚信、实力和产品质量获得业界的认可。欢迎各界朋友莅临参观、指导和业务洽谈。也欢迎各类有志人士加盟代理设备。

公司质量做到如下承诺:

1.我司保证所供设备为全新、合格的原装材料制成,并符合国家有关机械的国内、行业标准2.我司保证所开发设备能满足客户的使用需求3.我司对售出设备实行终生服务,并提供免费1年的设备维护及使用的相关技术指导服务4.我司负责一年内不少于6次关于设备使用情况的电话回访

关键词:热压机,脉冲热压机(邦定机),恒温热压机(邦定机),排线热压机,COF热压机,COF邦定机,FPC热压机,, FPC邦定机,FPC 脉冲热压机,手机排线热压机,银行U盾热压机, 斑马纸热压机,脉冲焊接机,ACF热压机,FOG热压机,FOB 热压机,FOF热压机,压排机,软排线热压机,绿排邦定机,液晶屏绑定机,COG热压机,

ACF attaching machine, ACF贴附机,ACF粘贴机,ACF贴胶机,玻璃端ACF贴附,IC端ACF贴附,PCB端ACF贴附,多段ACF贴胶机,多工位ACF邦定机,PCB ACF邦定机,大尺寸ACF贴胶机,600长ACF邦定机

COG预压机,半自动高速COG,COG邦定机,预压机,ic绑定机,IC邦定机,IC预压机,COF预压机,高速COG,COG邦定机,预压机,IC绑定机,IC邦定机,IC预压机, COF预压机 .

COG本压机,伺服本压机,OLED本压机,OLED热压机,COG本压机,IC本压机,OLED本压良率高机器,COF本压机,三头本压机,高速COG,COG本压机,本压机,COF本压机

恒温热压机 ,恒温压排机,FPC邦定机,FOG热压机,FPC热压机,FOG本压机,压排机,三星压排机,苹果压排机,手机屏压屏机,手机屏维修邦定机,,OGS邦定机,毛毛虫热压机 , 上下加热FOG热压机,三工位本压机,三头FPC邦定,国产苹果热压机 , 单工位脉冲机,上下对位热压机,压排机,FOG热压机,FOG邦定,手机维修机 , 单工位下对位FOG,苹果三星压排机,热压机

Pulse Pressing Machine,

脉冲热压机,脉冲压排机,FPC邦定机,FOG热压机,FPC热压机,FOG本压机,压排机,三星压排机,苹果压排机,手机屏压屏机,手机屏维修邦定机,OLED邦定机,OLED本压机,ON-CELL热压机,斑马纸热压机,高清晰邦定机,FPC邦定,ONCELL,OLED产品, 转盘脉冲机,脉冲机,脉冲热压机,高精度热压机 , 万能热压机,万能排线邦定机,单工位压排机 , 上下对位脉冲机,脉冲邦定机,脉冲热压机

LCD TV repair equipment, large size OLB bonding equipment, LCD screen repair machine, COF bonding machine,

液晶电视维修机,液晶电视返修设备,大尺寸OLB设备,液晶屏返修机,COF邦定机, COF本压,PCB半自动预本压机 ,脉冲热压机Pulse Heat Bonding Machine

深圳欧联,专业热压机,脉冲热压机,恒温热压机,ACF贴附机,COG/COF预压本压机,全自动,半自动生产设备,欢迎来厂参观打样。

Shenzhen Olian, professional in Bonding machine over 10 years. Welcome you visit us any time. Thank you .

ACF bonder, also named ACF machine, ACF equipment, ACF heat bonder, ACF tape bonding machine, ACF film bonder, ACF heat press machine, ACF device, ACF tool, ACF bonding machine.It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The ACF bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The ACF bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

According to the different bonding materials, the ACF bonder can be divided into different Bonders.

COG/COF bonder, also name IC bonder, Chips bonder, COG(Chip on glass) bonder, COF(chip on film) bonder, it is bonding the Chip IC on the glass, using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG/COF bonder has COG/COF Pre-Bonder and COG/COF Final-Bonder(COG/COF Main bonder). They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations COG/COF bonder.

FOG bonder, also name FOB bonder, FPC bonder, Flex cable bonder .FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonder, COF on PCB board bonder, COF on film bonder. It have Pulse Heating Bonder and Constant Temperature Bonder.

ACF attaching bonder which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The ACF attaching bonder,

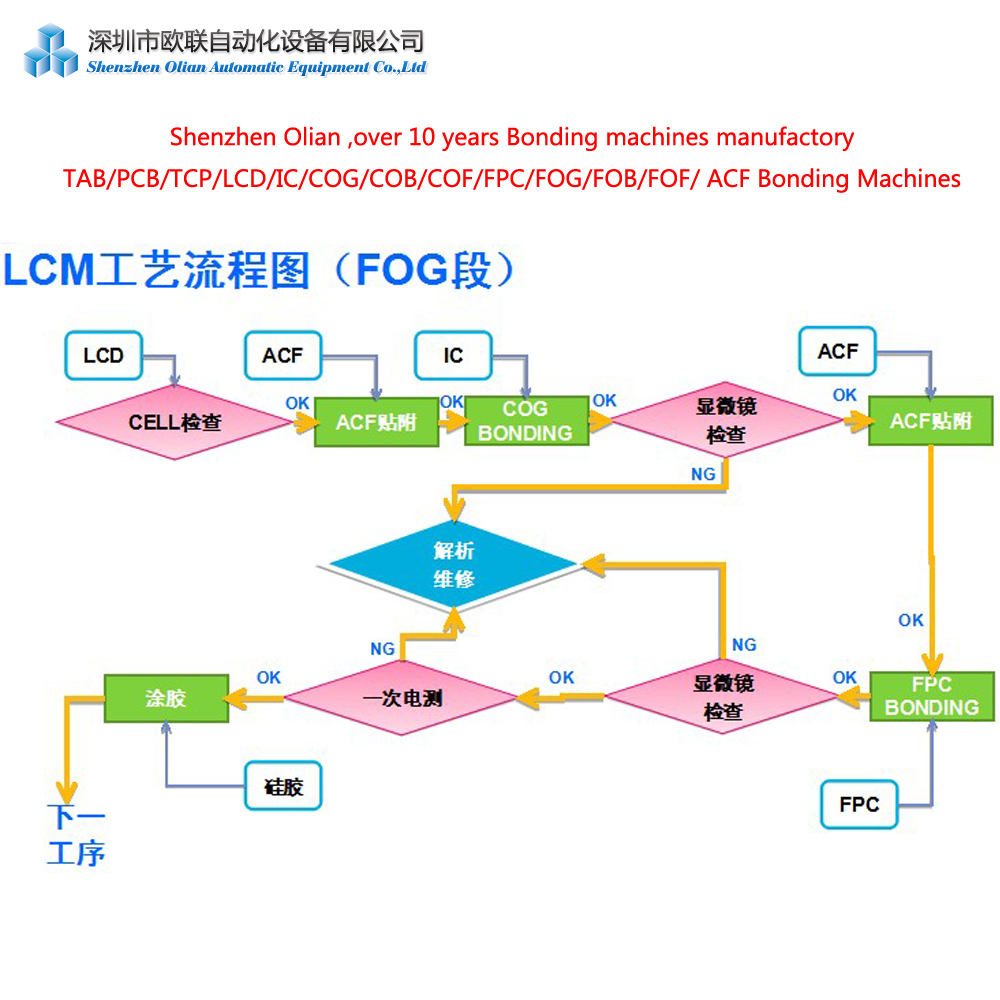

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG pre-bonder, COG final-bonder , FOG(FOB) bonder, as below:

Full automatic COG bonder, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce line include all the process of the COG and FOG bonding.

We design and make the standard ACF Bonders and customized acf bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonder, also name TAB bonder, ACF bonder, OLB Bonder , Chip on Film bonder. COF(Chip on Film, Chip on Flex).COF bonder is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonder also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonder for TV Repairing is Pulse heating bonding machine with Titanium alloy press bonding head.

Our COF bonder and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Please contact us feel free to purchase the COF bonding machine accessories.

Buy machine, send all the accessories free.

| 1 | COF bonding machine |

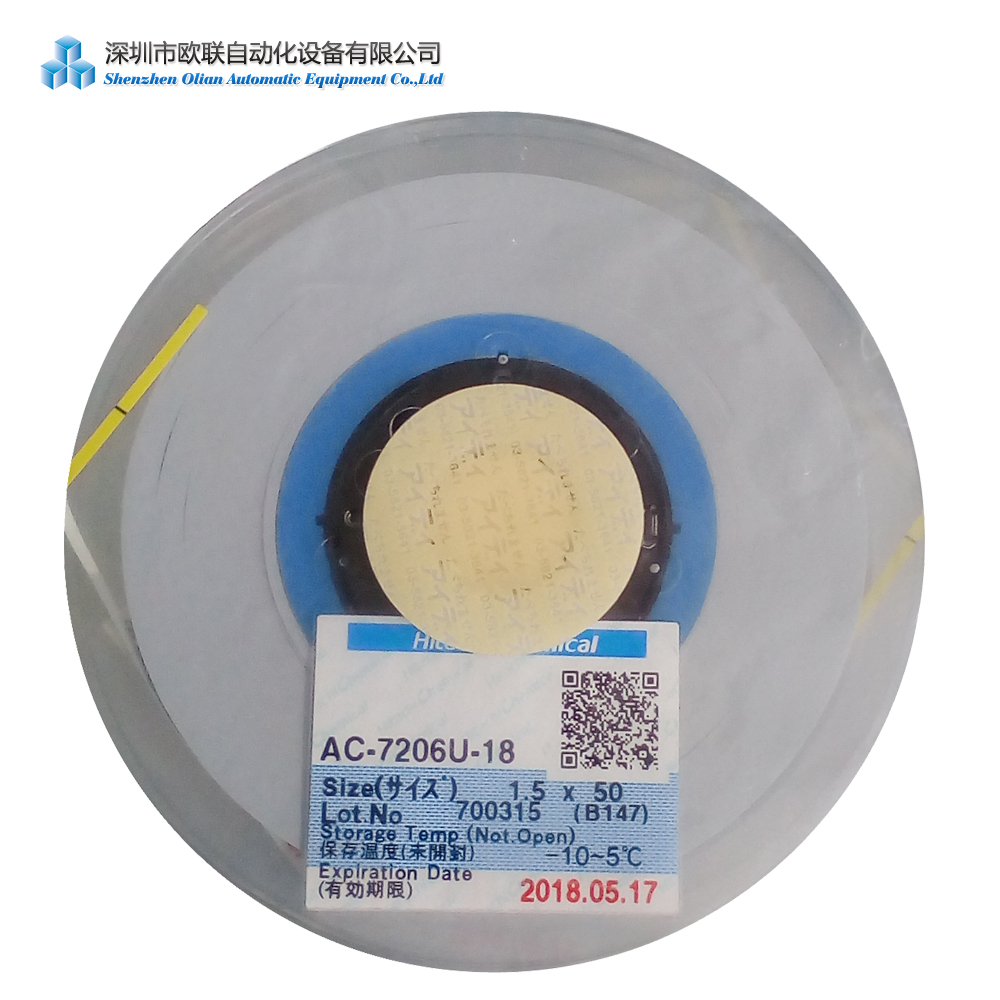

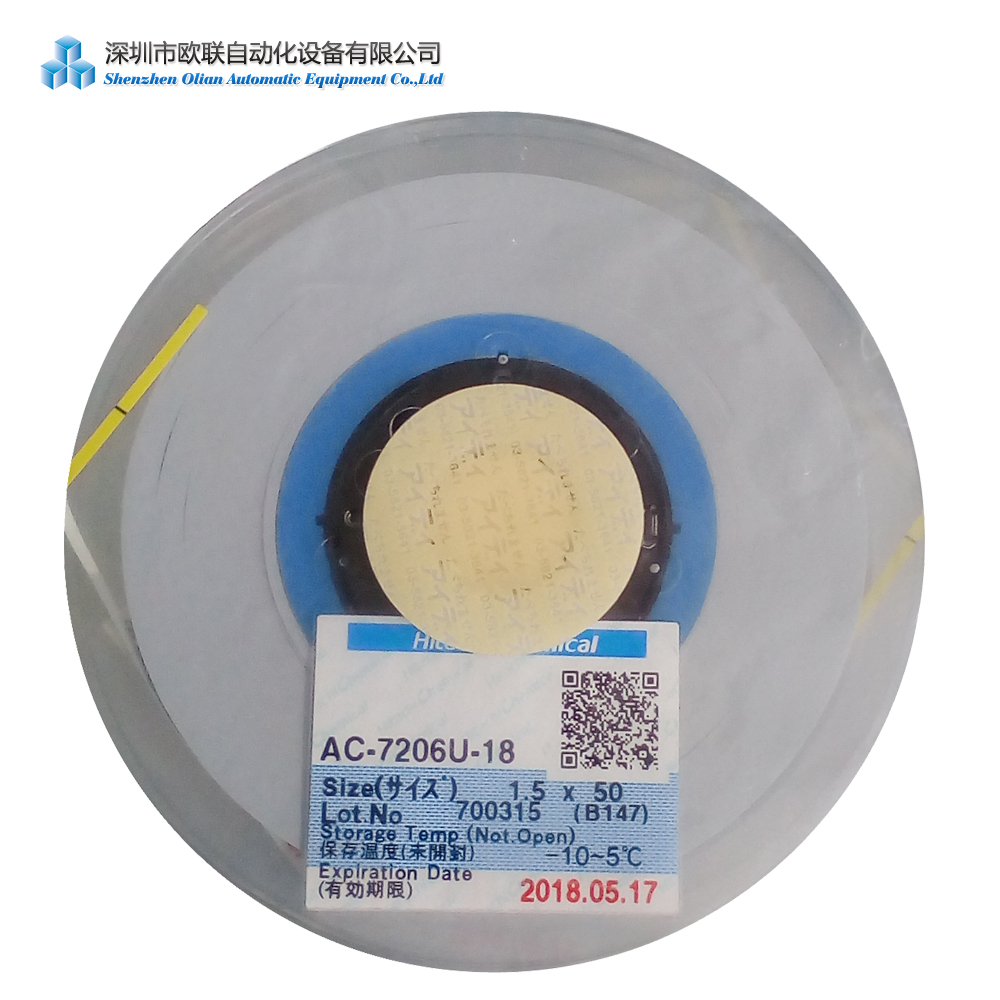

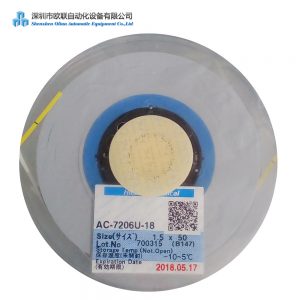

| 2 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 |

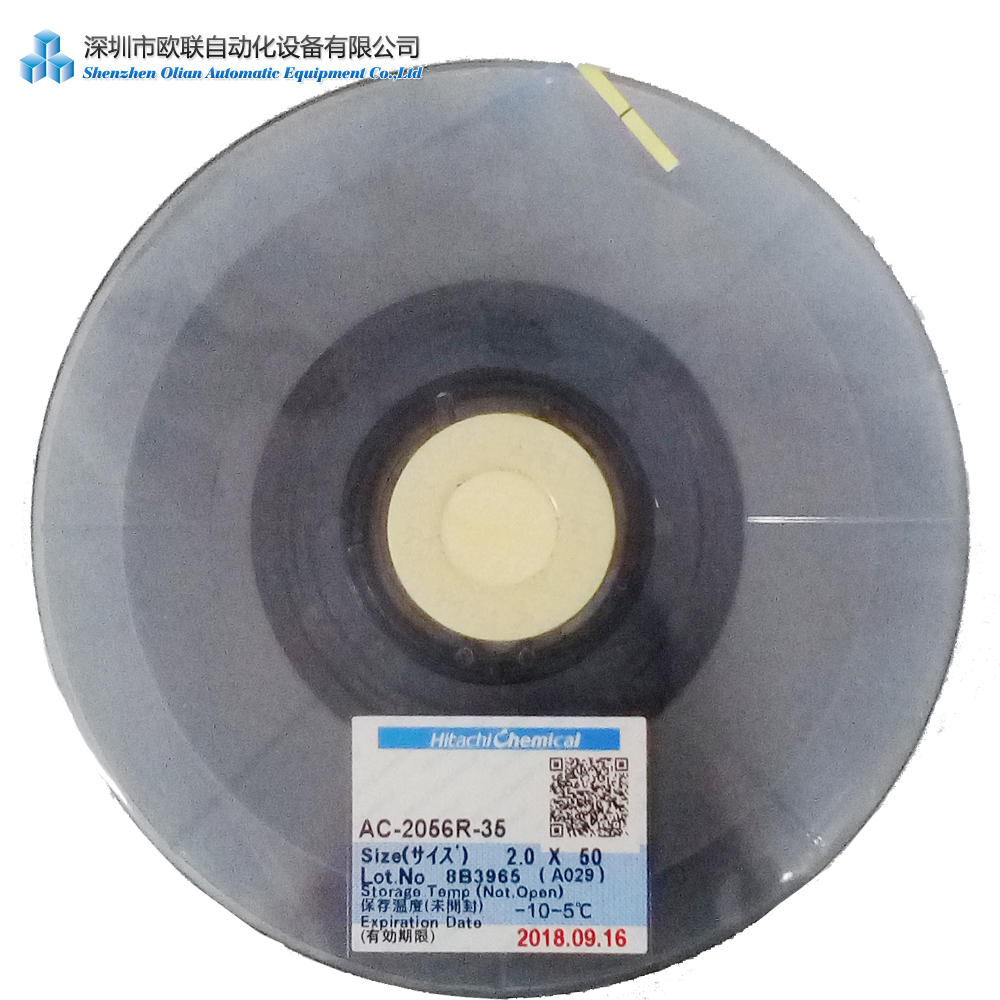

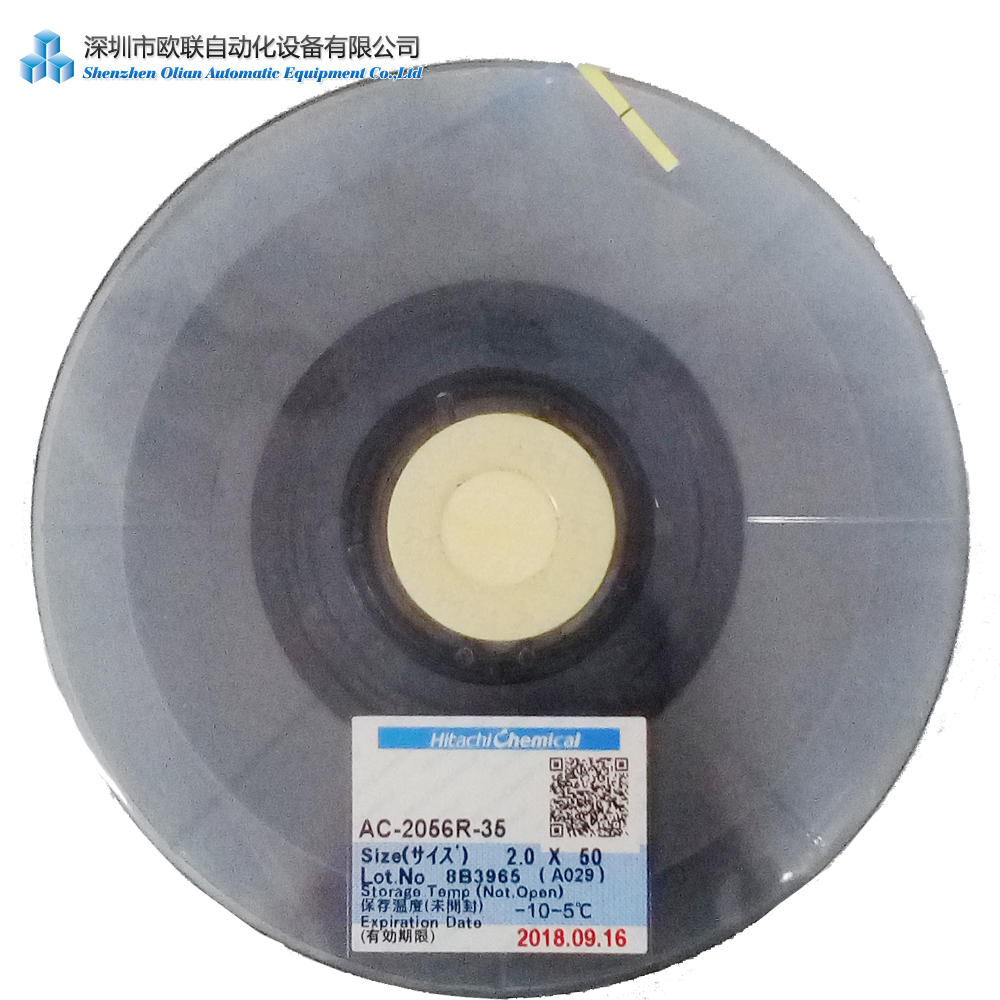

| 3 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 |

| 4 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 |

| 5 | Acetone Liquid BT-H1-500ML 丙酮 |

| 6 | Hitachi Blue Glue 100ML 蓝色胶水 |

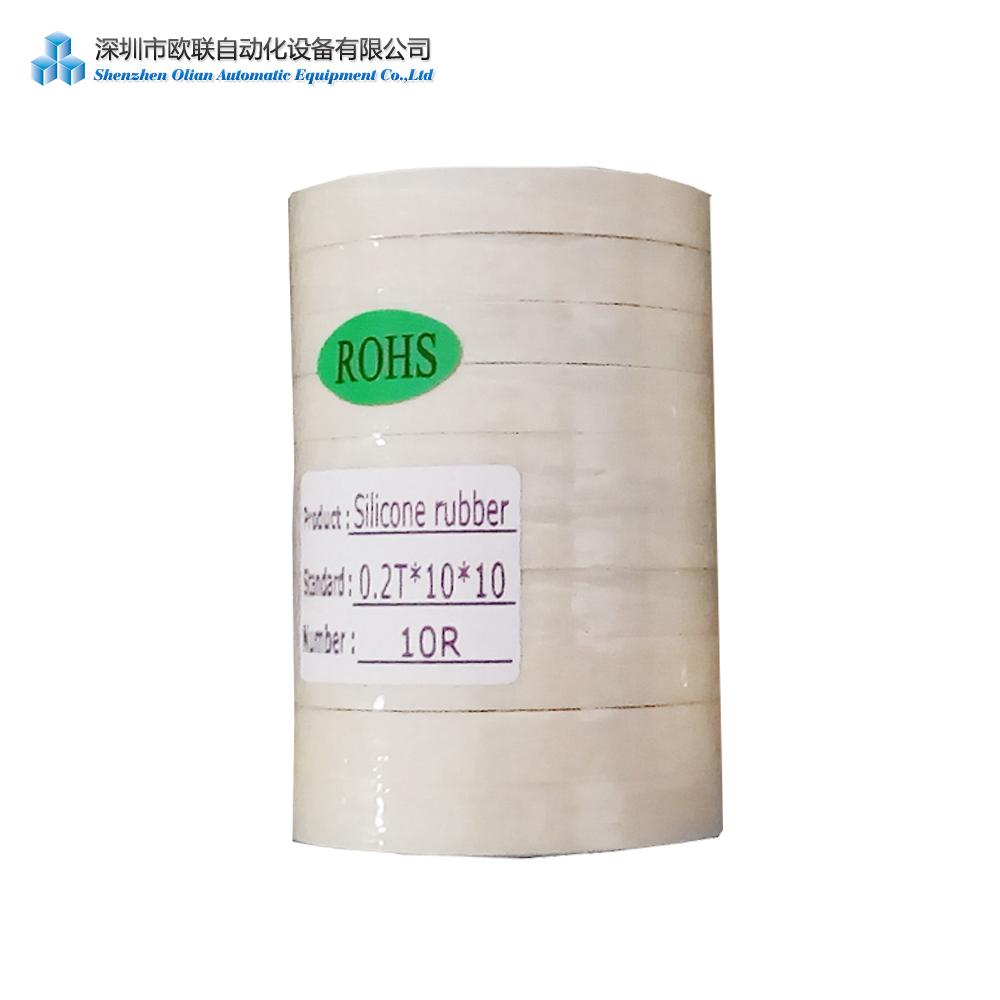

| 7 | Fuji Silicone 50M 硅胶皮 |

| 8 | Teflon 50M 铁氟龙 |

| 9 | Alcohol 酒精 |

| 10 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 |

| 11 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 |

| 12 | Optical Microscope 显微镜 |

| 13 | TAB Cutter COF切刀 |

| 14 | Correction table 校正表 |

| 15 | LVDS LVDS接头 |

| 16 | LCD Test Board LCD测试板 |

| 17 | Allen Key 六角扳手 |

| 18 | Air Compressor OTS550 空压机 |

| 19 | Static Wipe Cloth 静电擦拭布 |

| 20 | Cotton swabs 棉签 |

| 21 | Handheld Magnifier 手持放大镜 |

| 22 | Precision Tweezers 精密镊子 |

| 23 | Nano Sponge 纳米海绵 |

| 24 | quatz bar spare one 备用石英条 |

| 25 | Alcohol bottles 空酒精瓶 |

COF bonding machine accessories

Welcome to buy the COF bonder for TV Repairing and all the COF bonding machine accessories.

COF bonders for full screen /edge screen/OLED screen mobilephone

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our COF bonder for cellphones.

All the ACF bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

ACF bonding process ,is the process of Chip ic/COF ic/FPC bonded to the LCD(Glass)/PCB/Film/FPC/ ,use the ACF tape as the medium connecting materials,use the hot bar/bonding head as the source of the heat and pressure,use the tooling as the holder,and the silicone rubber or teflon as the Cushioning material, all the ACF bonding process finished by the ACF bonding equipments.

ACF tape has little conductive particles in the conductive lines of the tape.

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

This process is what produces the connection between the ACF tape and the components. Advanced Integrated Technologies is equipped to assist you with your ACF bonding process.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the important medium of the ACF bonding process.

ACF Tape is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

| Model(Hitachi) | Process type | For Glass |

| AC-823CY W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-832L W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-832L W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.5mm L100m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-7813KM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| MF-331-25 W2.0mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.5mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.2mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.0mm L50m | FOG Low Temp | For Touch Screen |

| AC-4255KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7206U-18 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.2mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-9851YM-35 W1.5mm L50m | FOG Low Temp | Common Glass |

| AC-9851YM-35 W2.0mm L50m | FOG Low Temp | Common Glass |

| AC-896C W1.5mm L100m | COG Low Temp | Thin Glass |

| Model(Sony) | Process type | For Glass |

| CP6920F3 W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.2mm L50m | COG Low Temp | Common Glass |

| CP34531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP34531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP35231 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP35231 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36931 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36931 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP33731 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP33731 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP31831 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP31831 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP1220 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP1220 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP13941 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP6920F W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.2mm L50m | COG Low Temp | Common Glass |

| CP920 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W2.0mm L100m | FOG Low Temp | For Touch Screen |

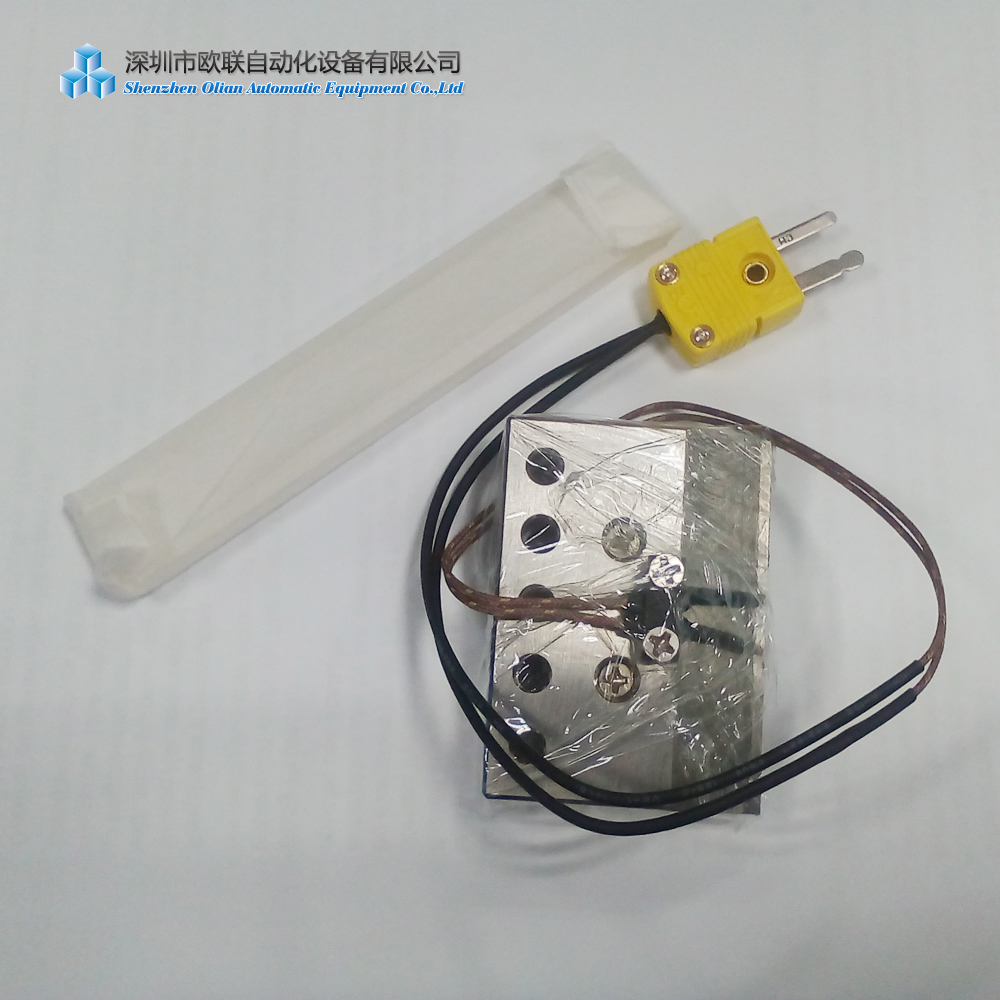

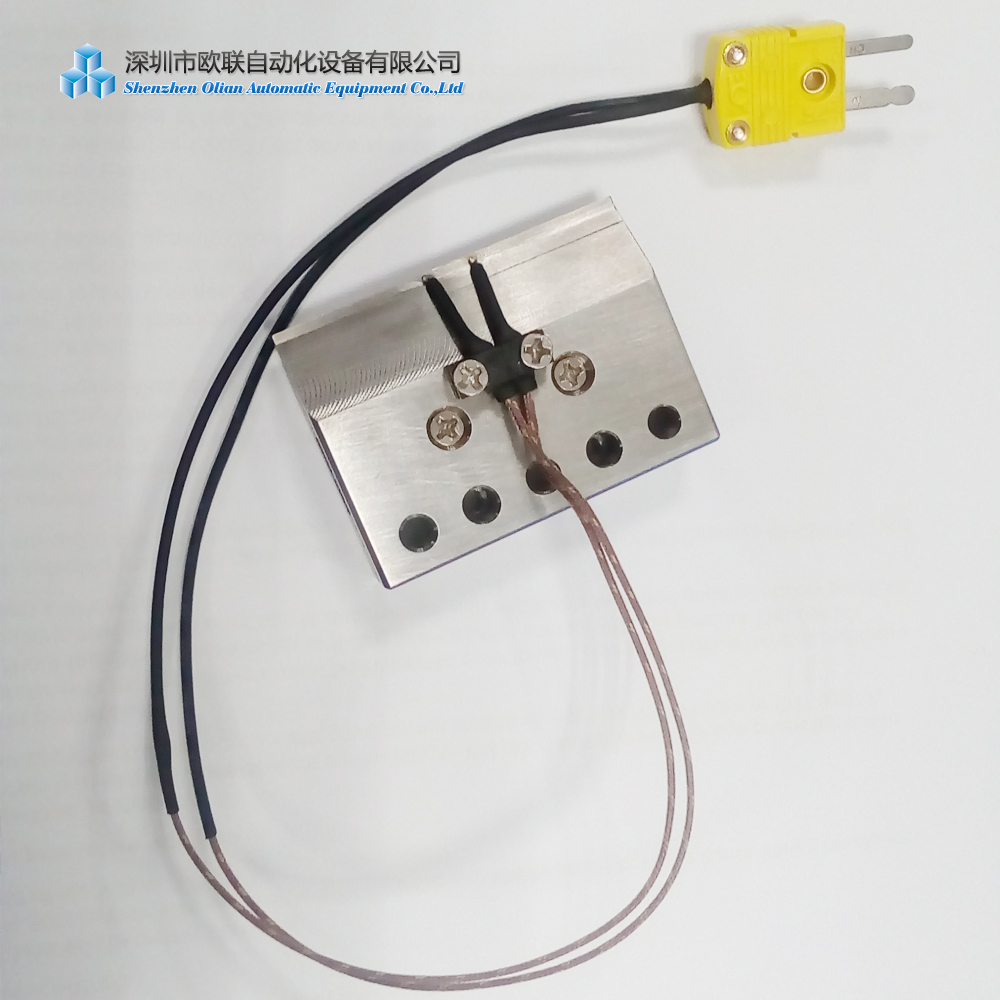

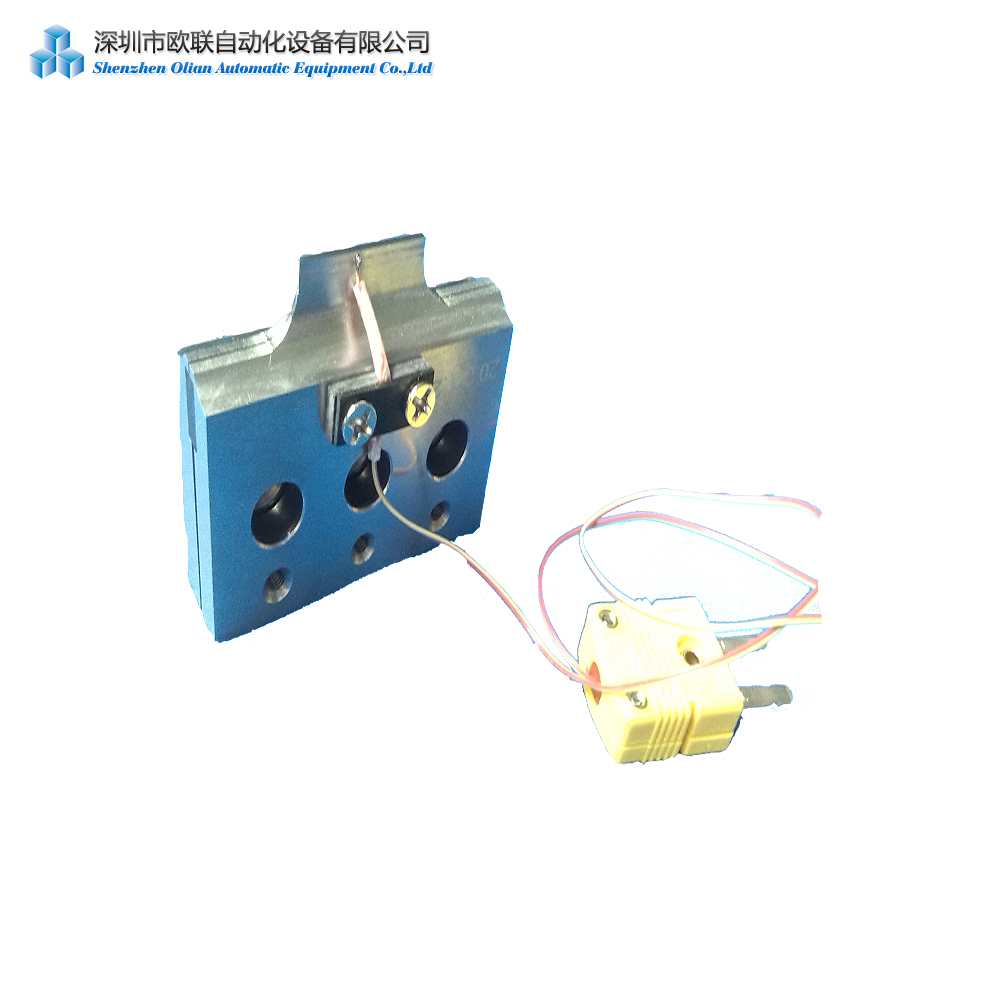

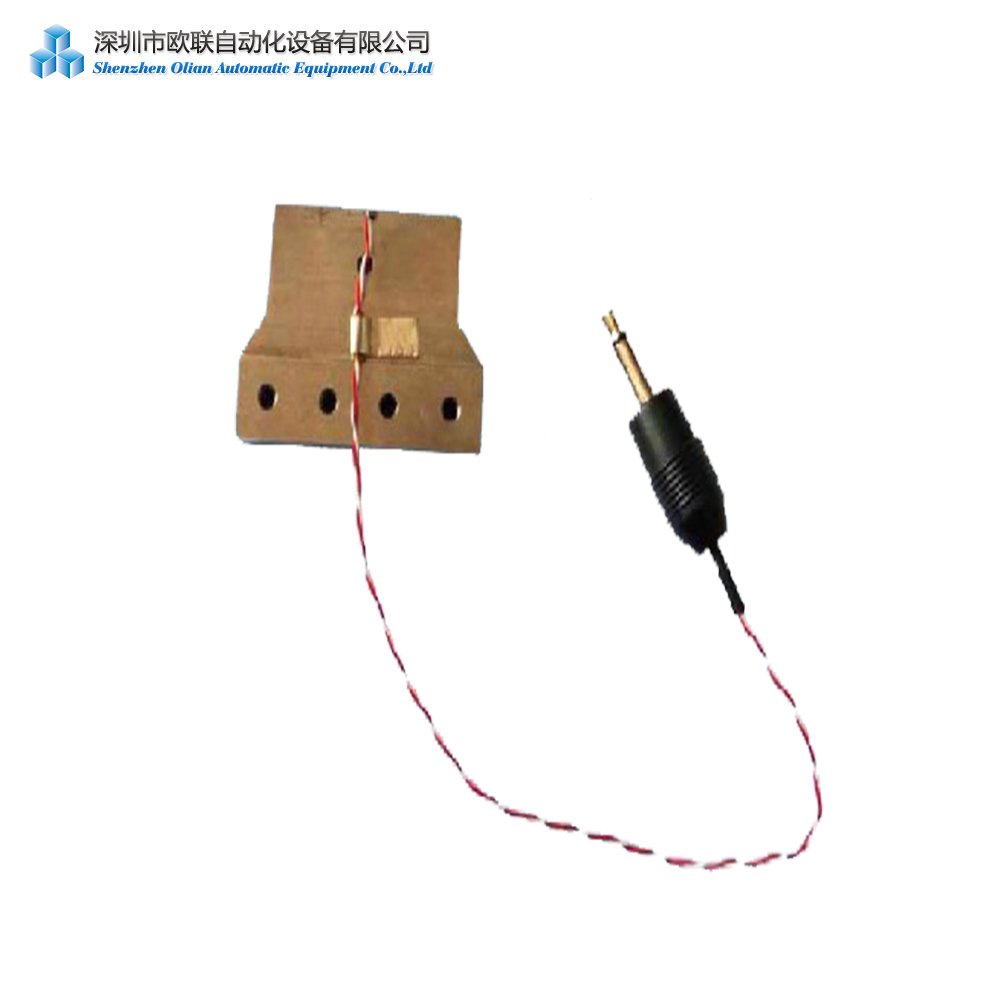

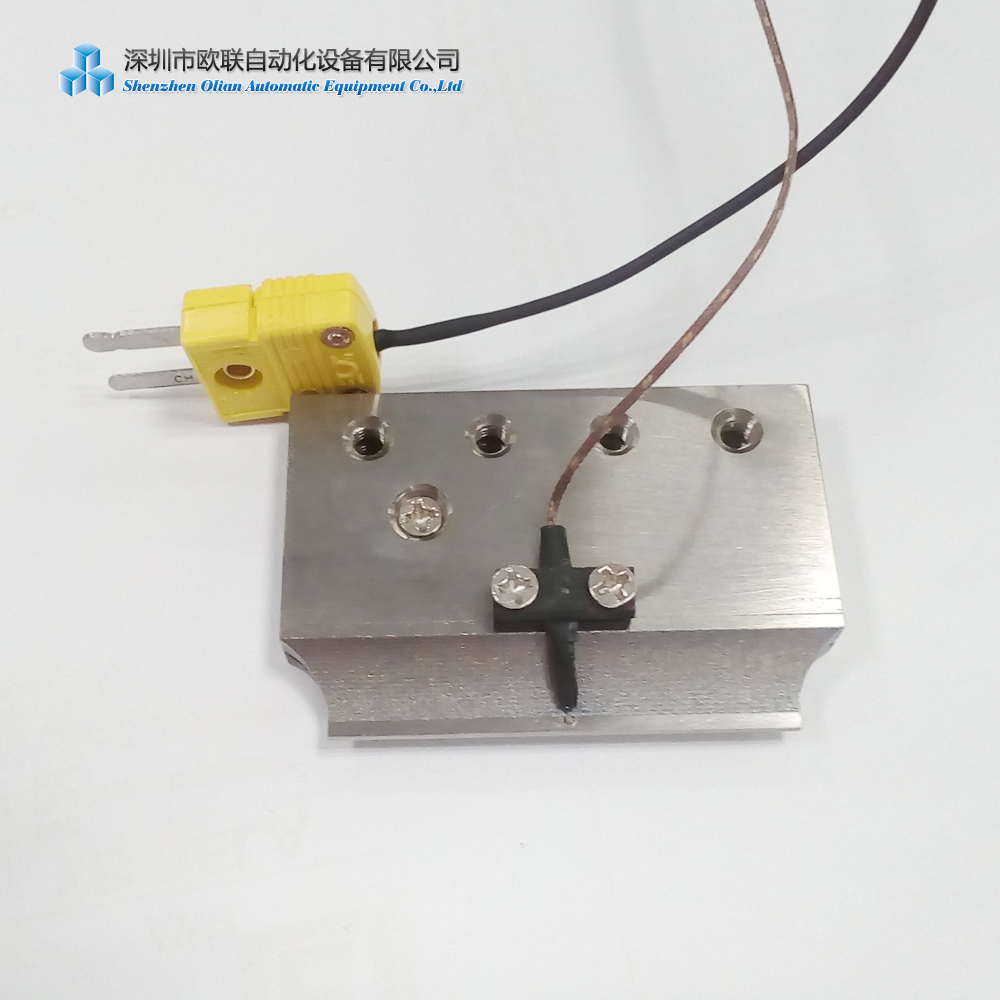

The source for heat and pressure in ACF bonding process is most often a hot bar/thermode/bonding head/bonding cutter.

Hot bar bonding systems are designed to heat the hot bar to a specific temperature using low voltage electricity, which temperature is fed back to the controller via a thermocouple.

Tooling is designed to hold the components and position the ACF tape to line up correctly with the conductive pads on the PCB or other component.

The hot bar is then brought into contact with the ACF film over the top of the bonding pad, heated to the bonding temperature, and held for a specified time.

Tell us which products you want to bonding ,then we can suggest you the right ACF bonding equipments for you ..

ACF bonding equipment has been used in glass display applications for many years. It has recently become widely used in COF, COB,COG,FOG,FOB,FOF areas.

Industries that use this technology most are the mobile phone manufacturing, automotive industry, and LCD production, mobile computers, TV manufacturing, open cell panels factories, touch panel ,AD shower, Watch, Pad… factories. and many Labs who researching in the LCD/LED/OLED/MICRO LED/MINI LED displays industries.

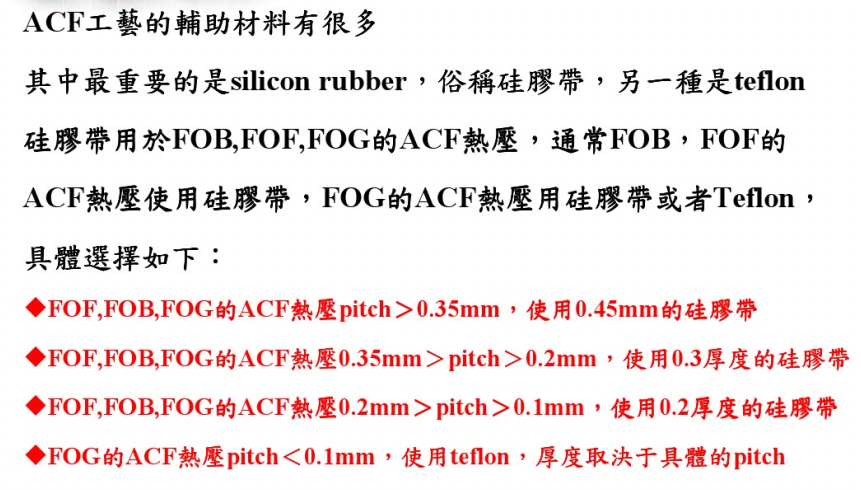

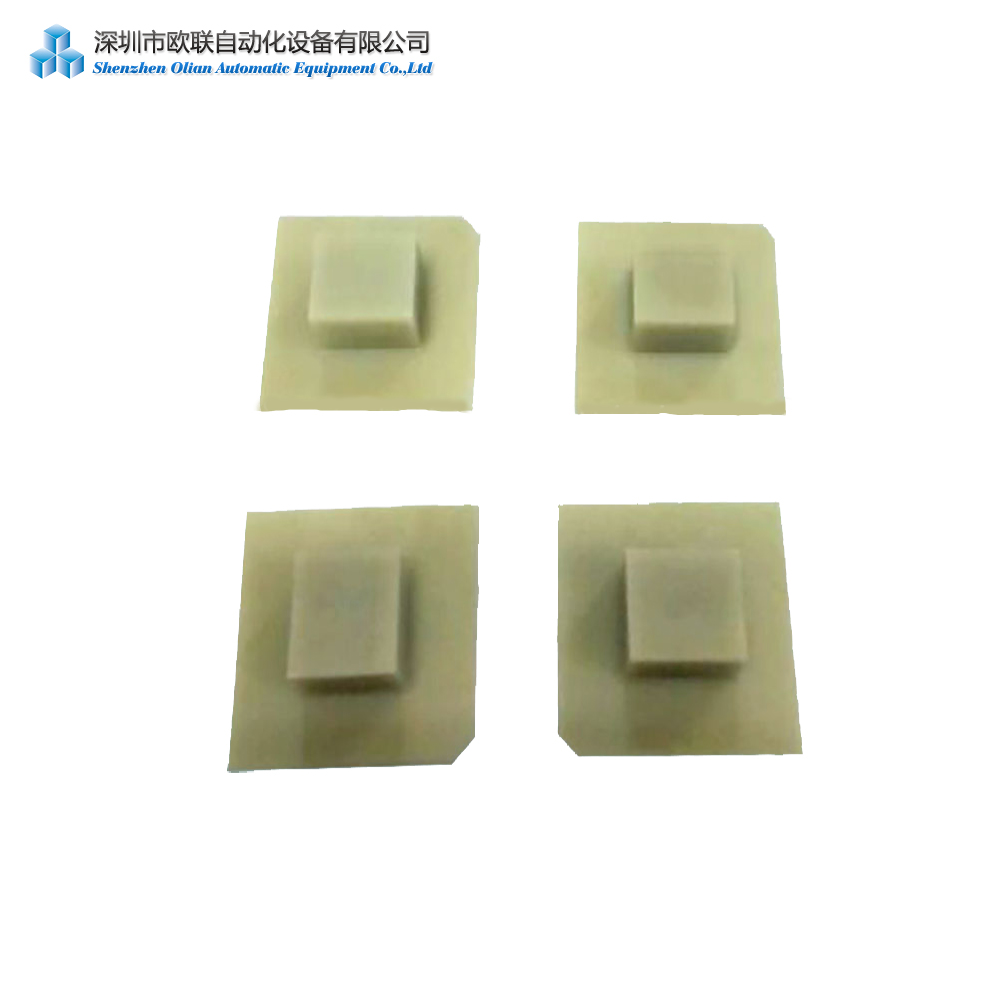

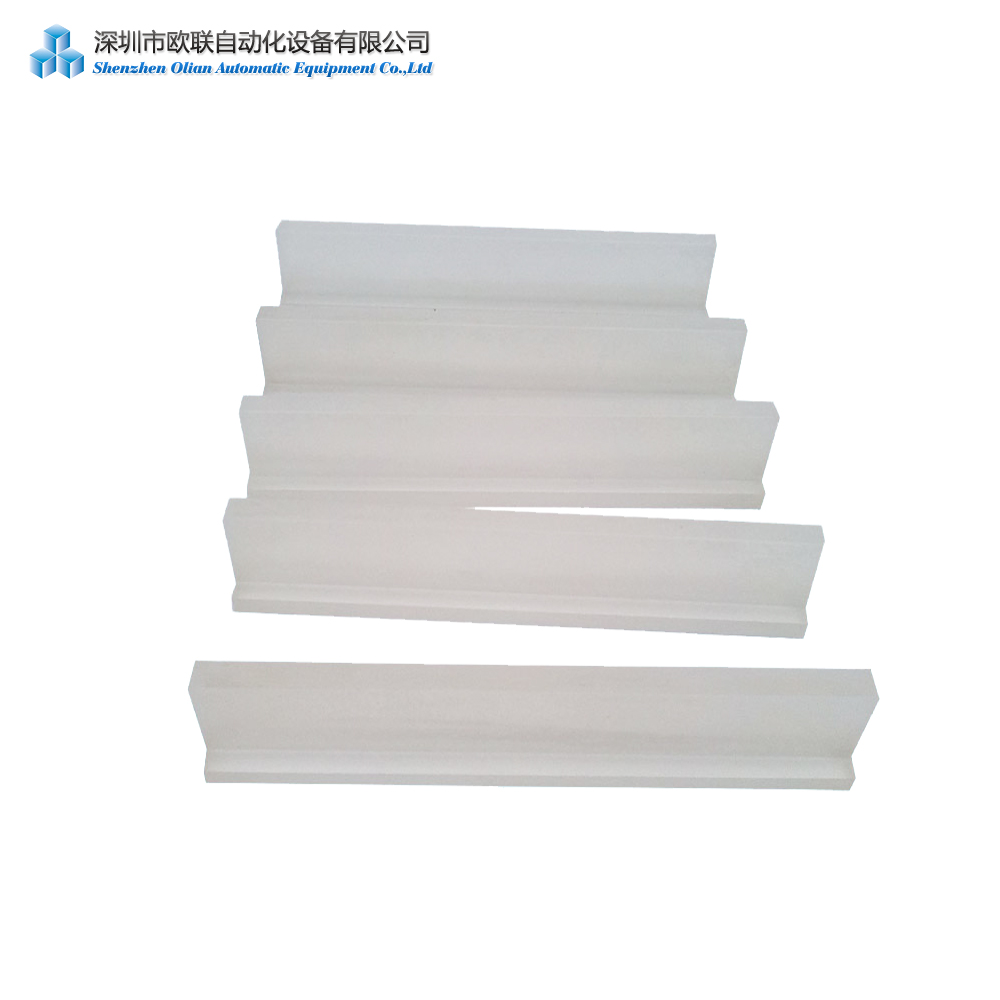

Similar to Silicone rubber, Teflon tape is often used to provide evenly distributed pressure and temperature on the ACF bonding process.

Features of Teflon Tape :

1. Superior chemical resistance – hardly affected by acids and alkalis.

2. Excellent electrical properties, including little dielectric loss, high insulation resistance and breakdown voltage.

3. Extremely high volume resistivity and remain stable over a wide range of temperature.

4. Continuous use in a wide range of temperature from -100degC to +260degC

5. Lowest friction cofficient among all solid materials and excellent self-lubricating ability.

6. Non-adhesiveness and mold releasing property

7. Excellent weather and moisture resistance

8. Superior flame resistance

Shenzhen olian is a professional ACF bonding equipment design&making factory, We know all the ACF bonding process, we also offer all the bonding machine accessories and parts. Welcome you visit us .

Wechat/whatsapp:+86 18025364779, QQ:2307972393, https://bonding-machine.com

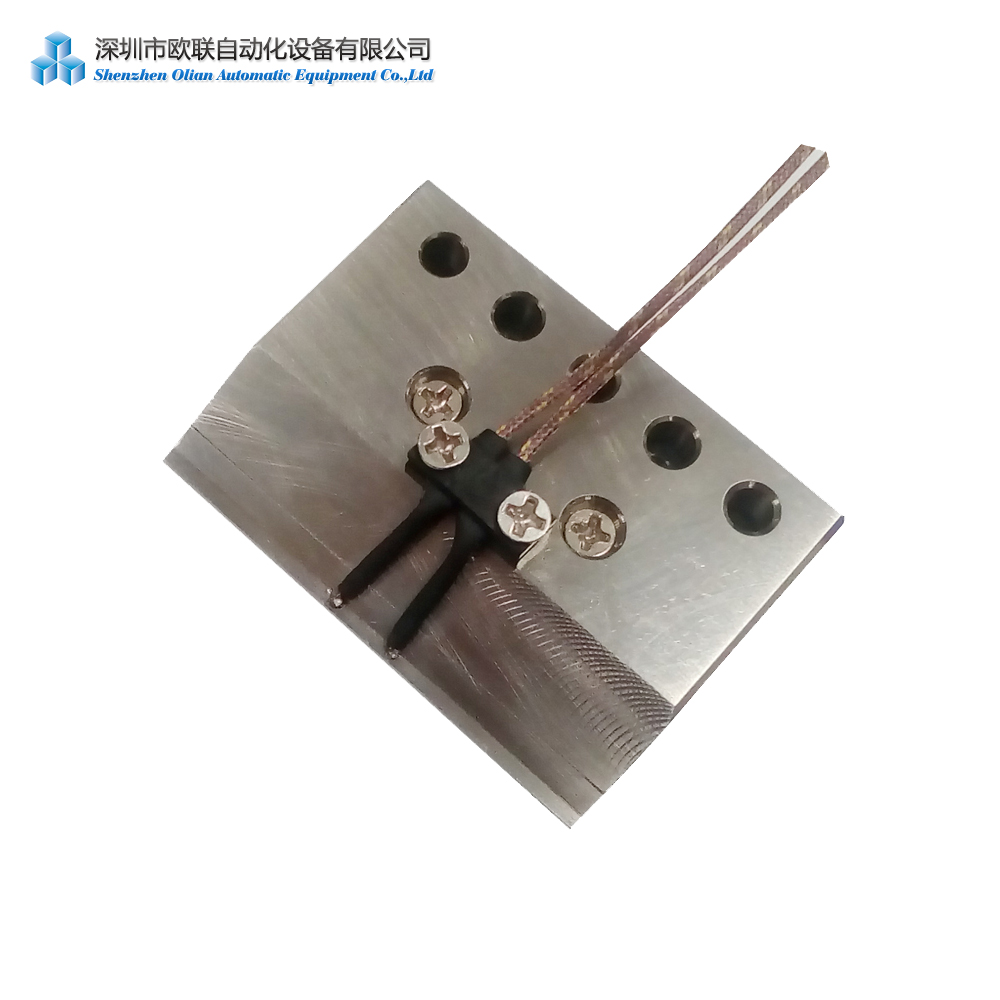

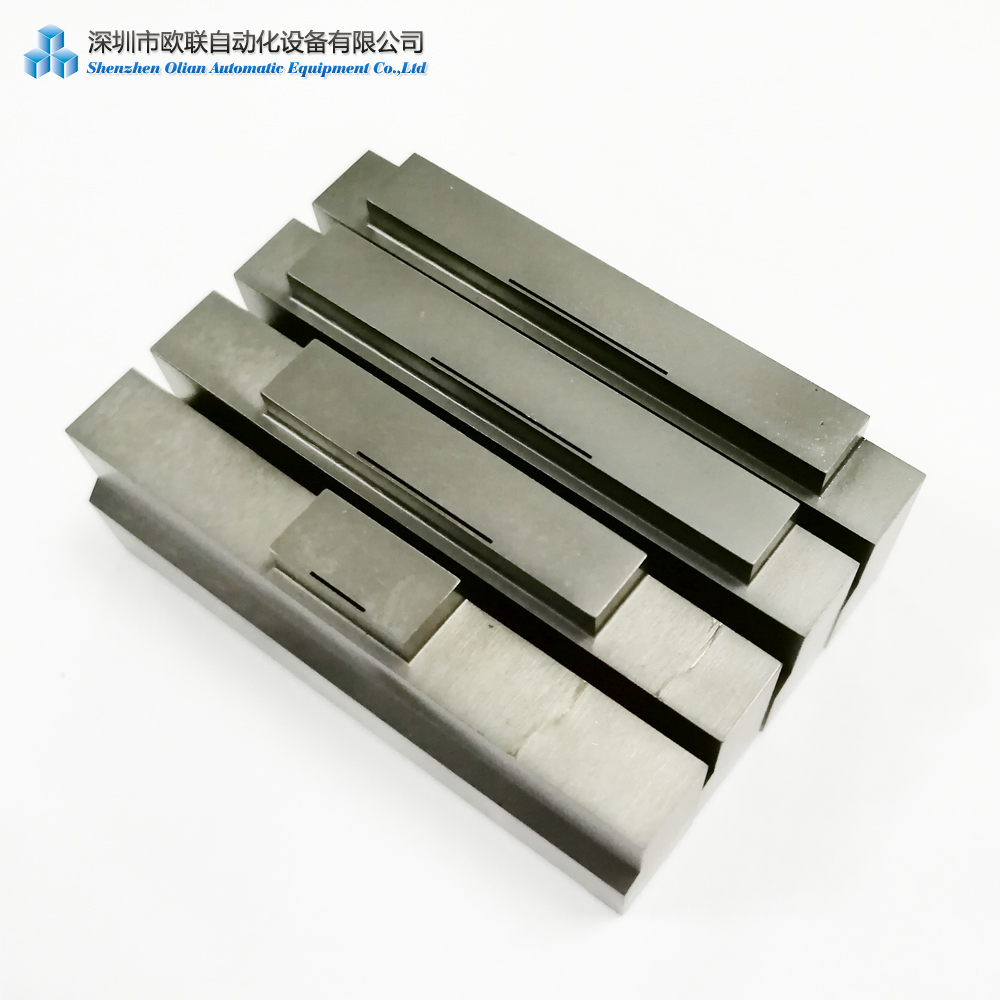

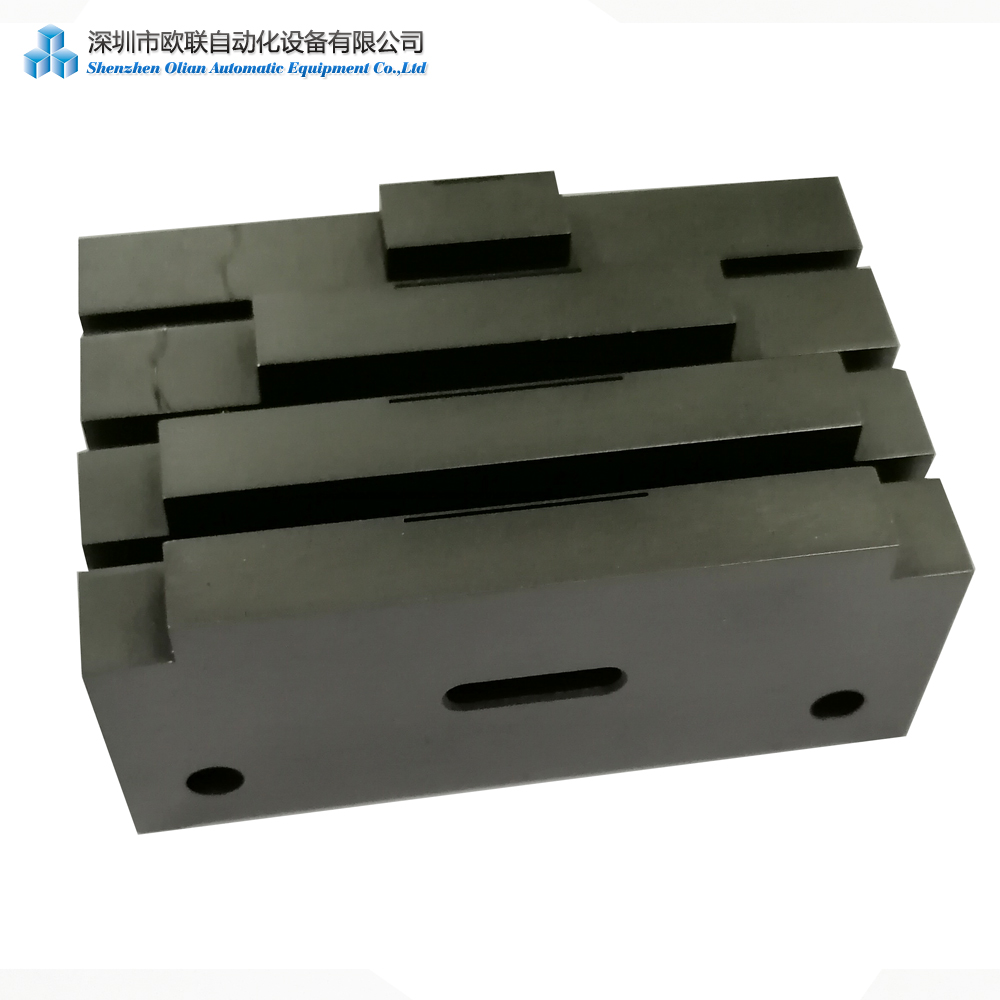

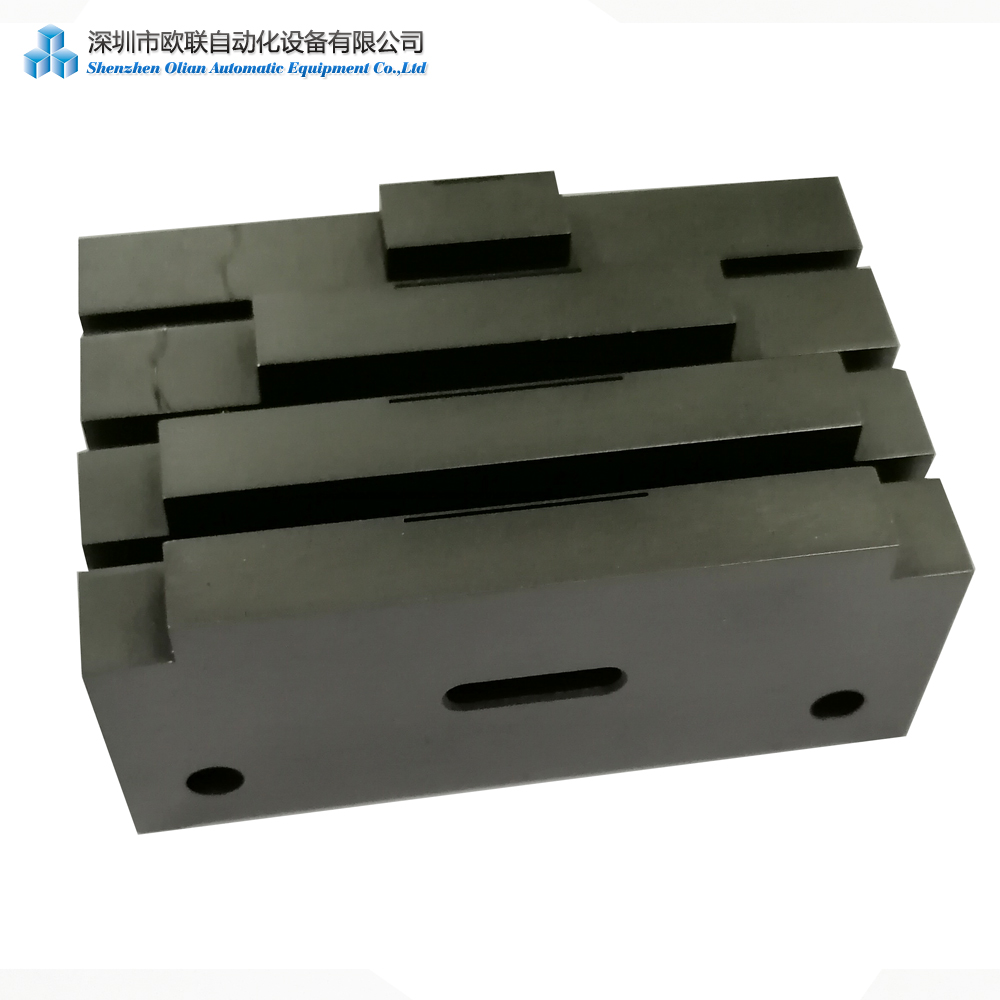

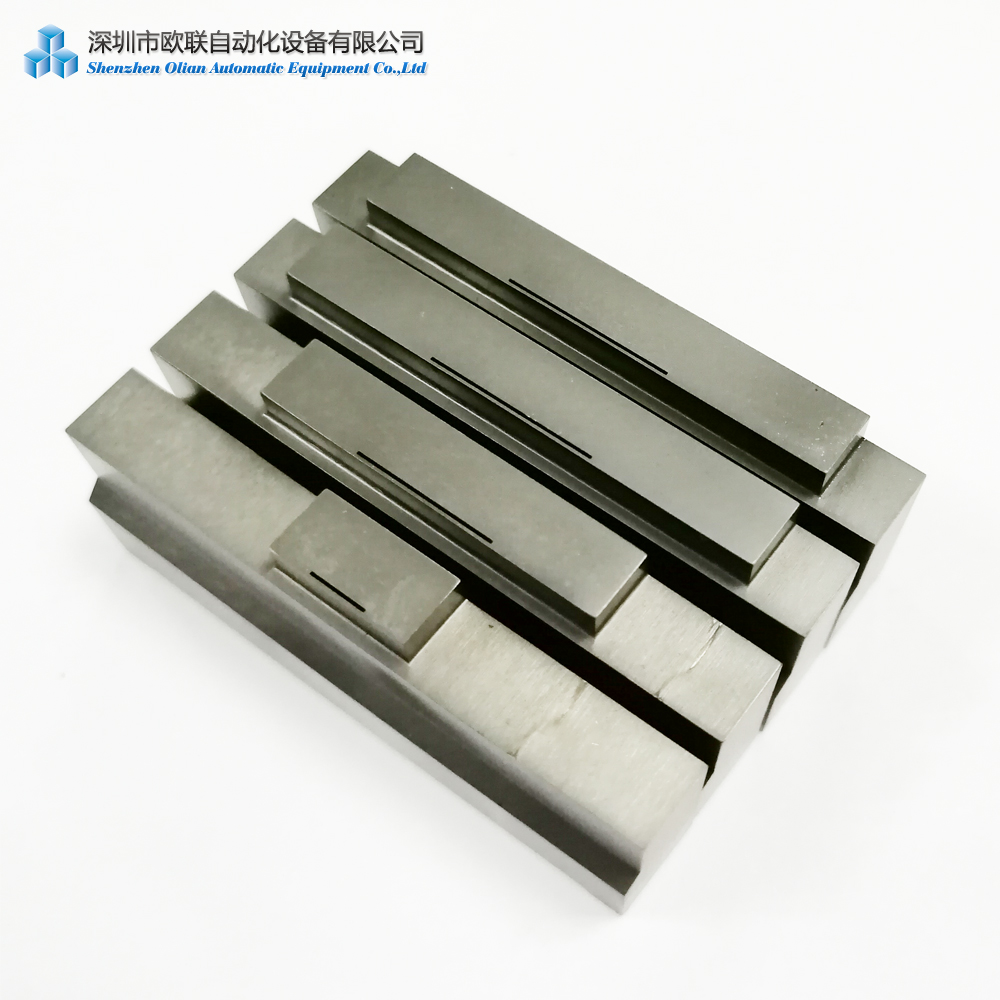

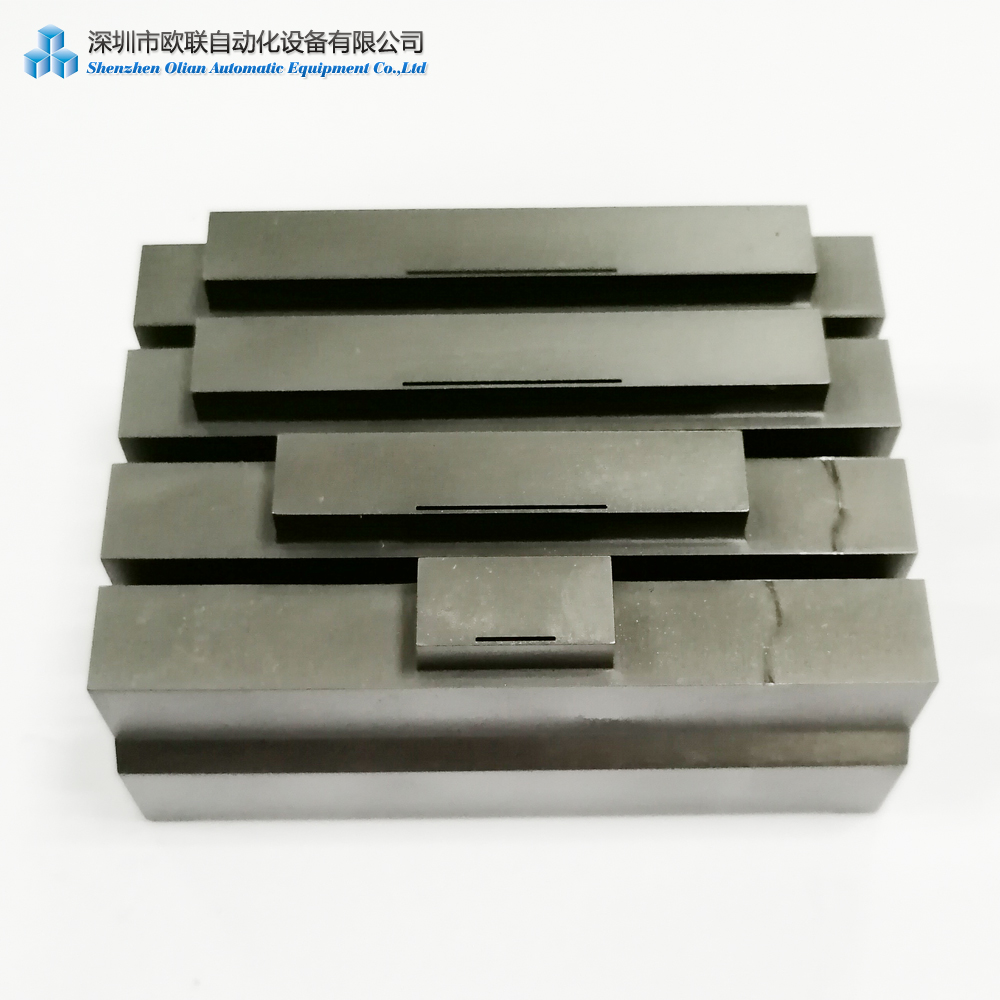

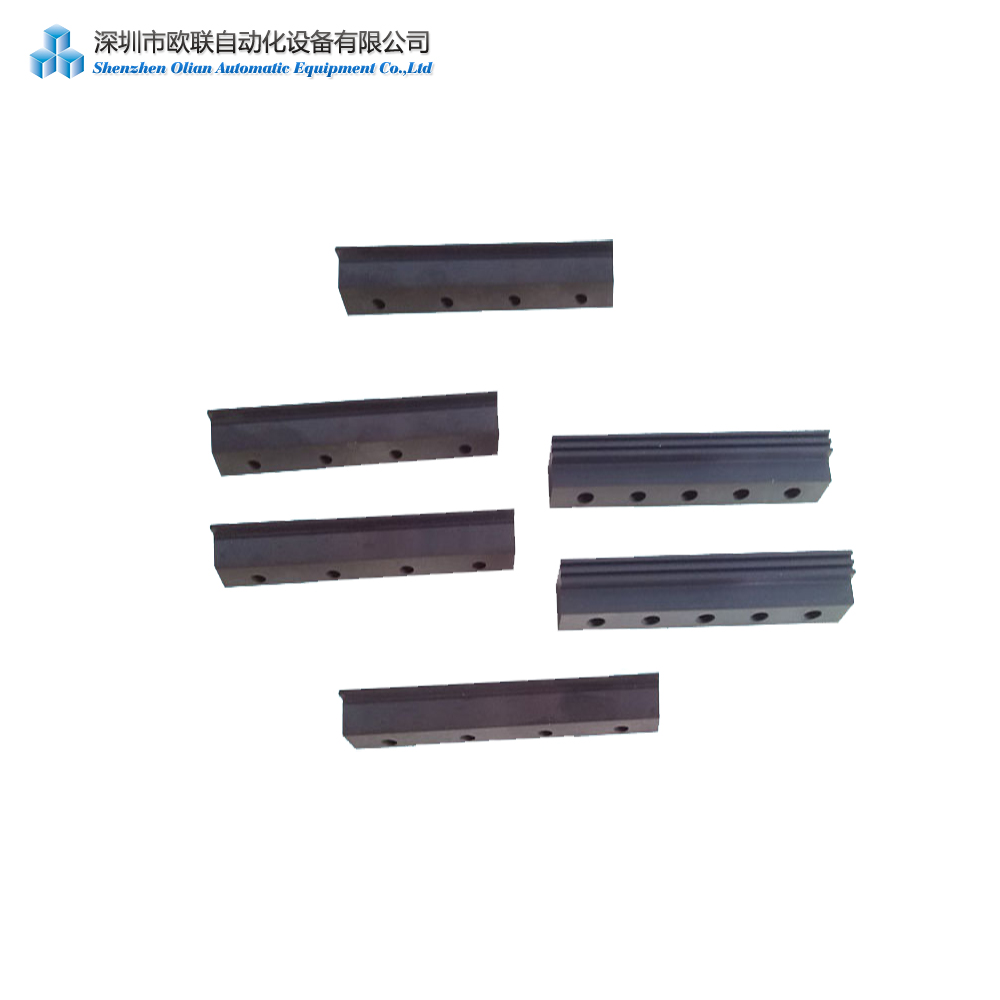

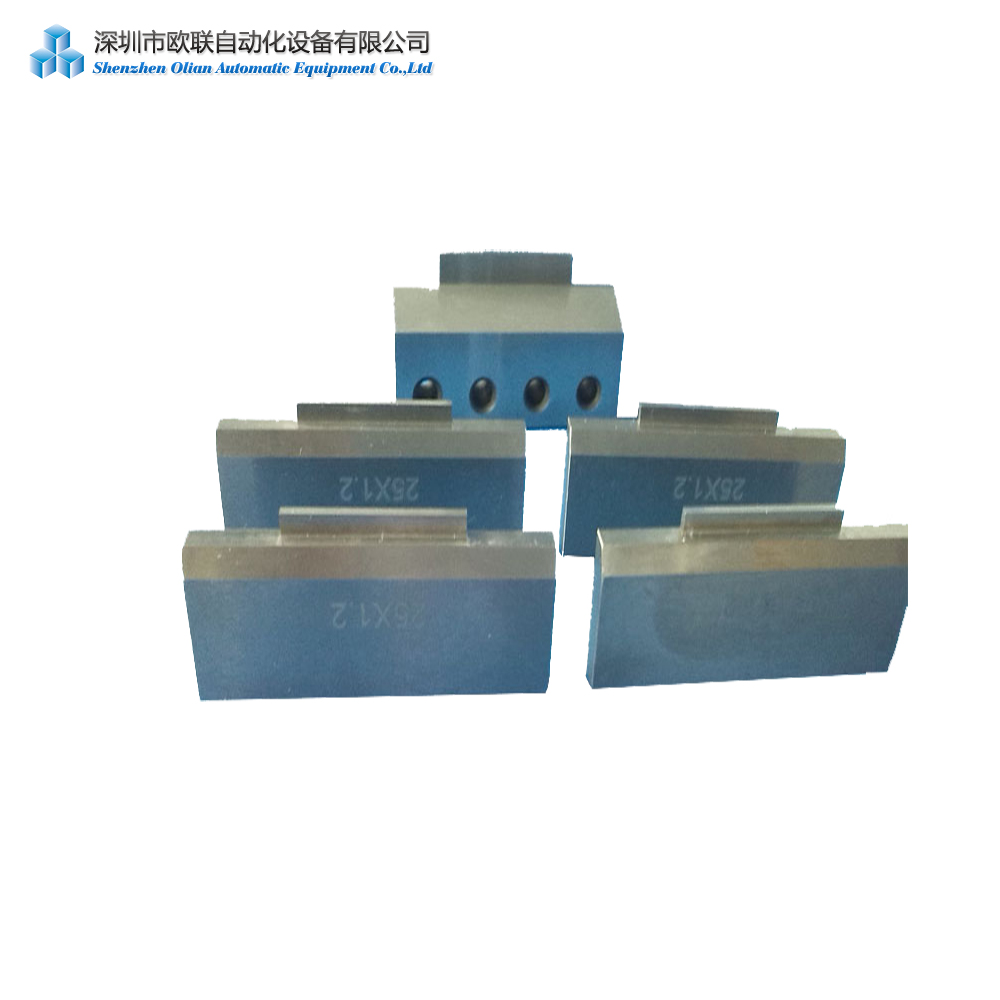

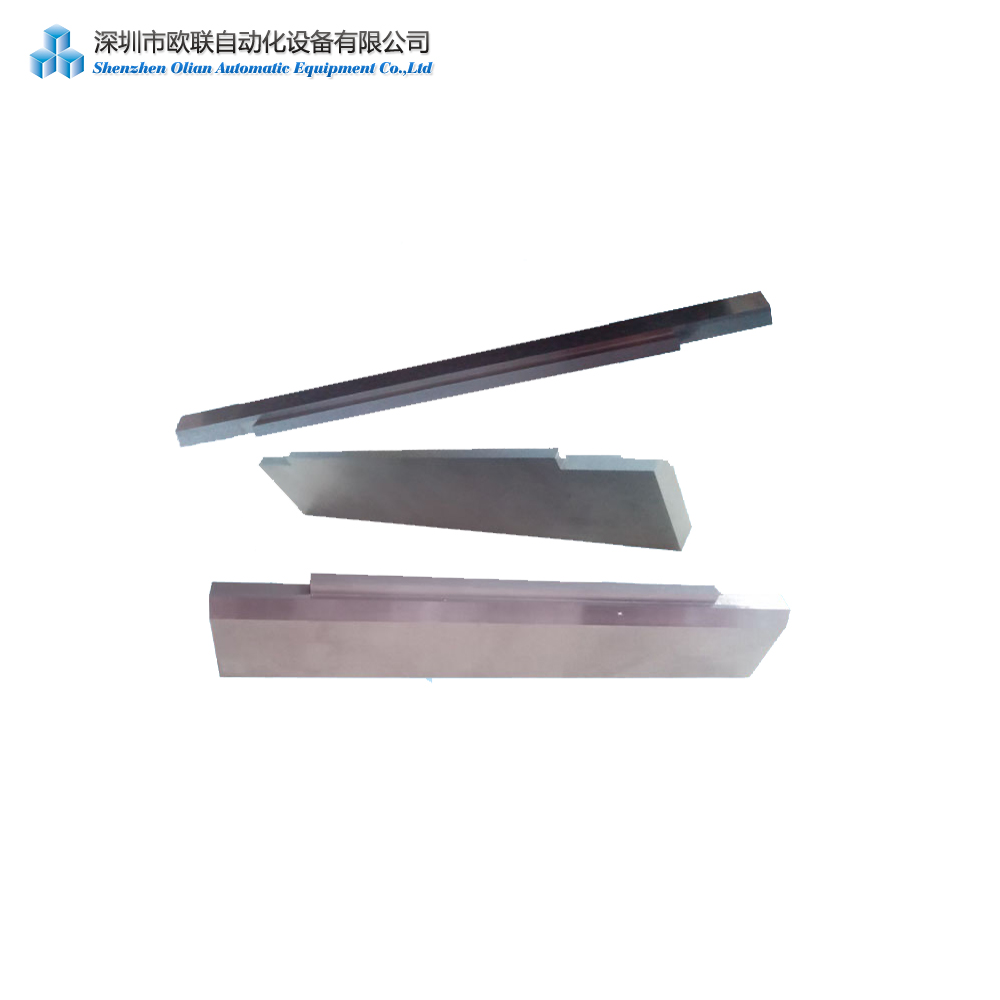

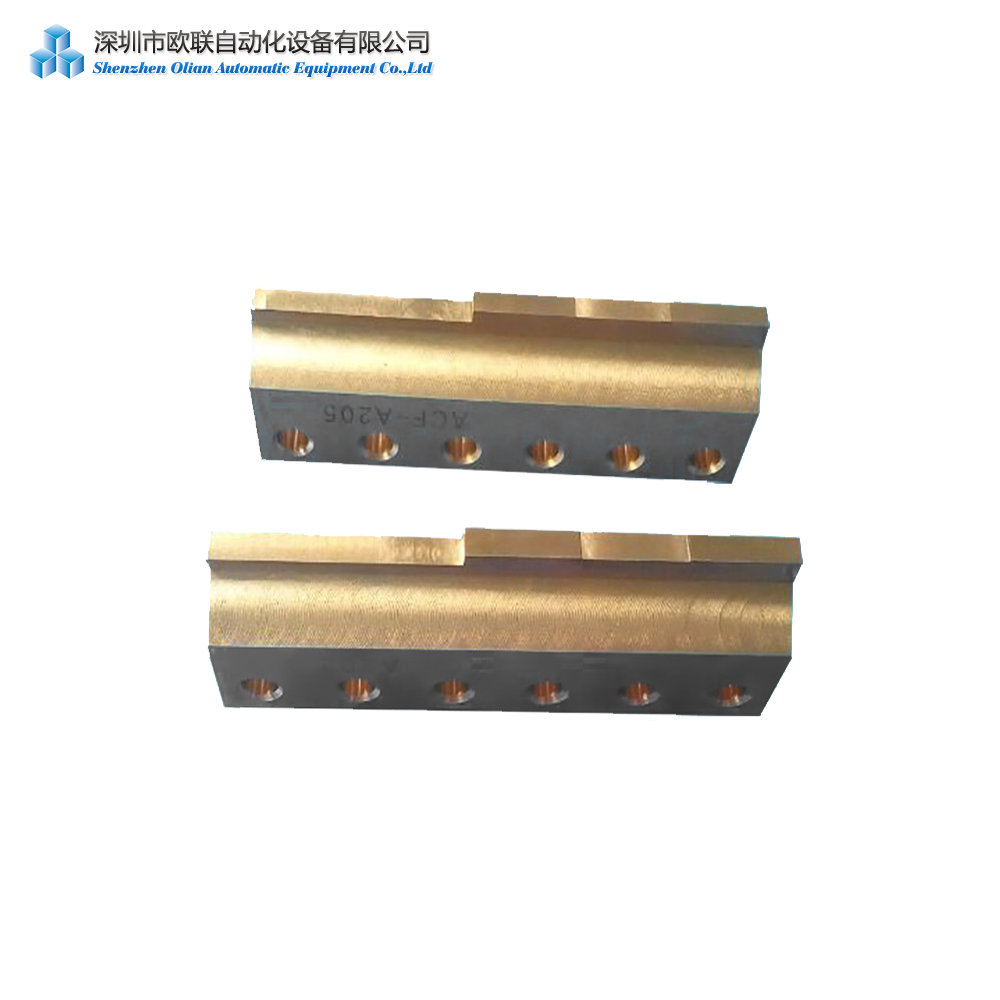

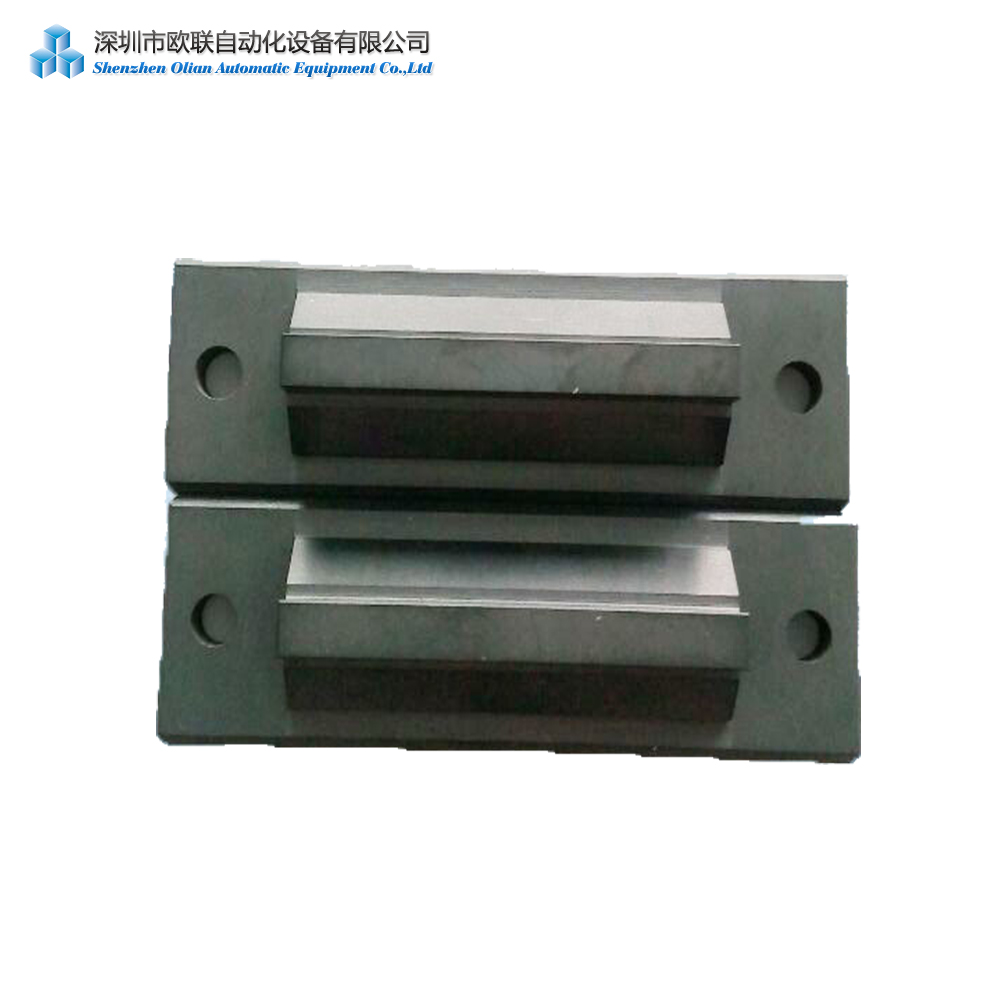

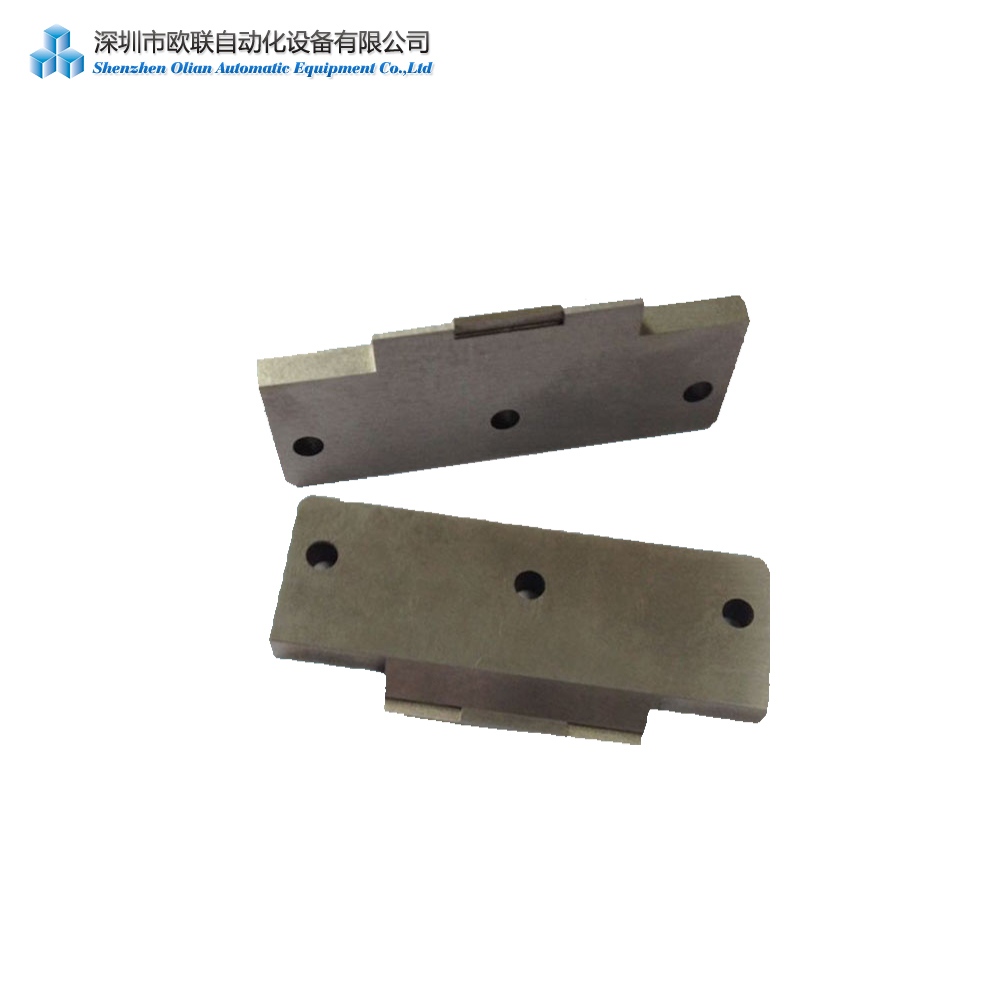

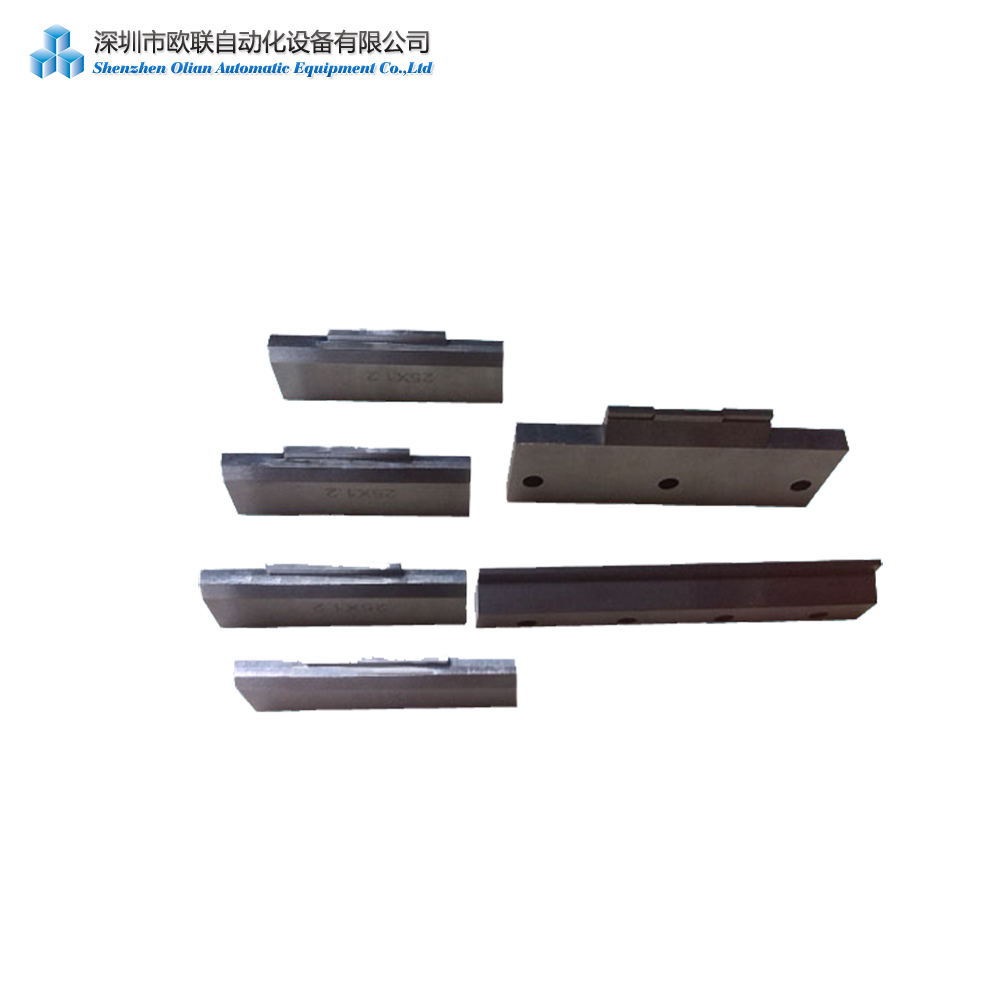

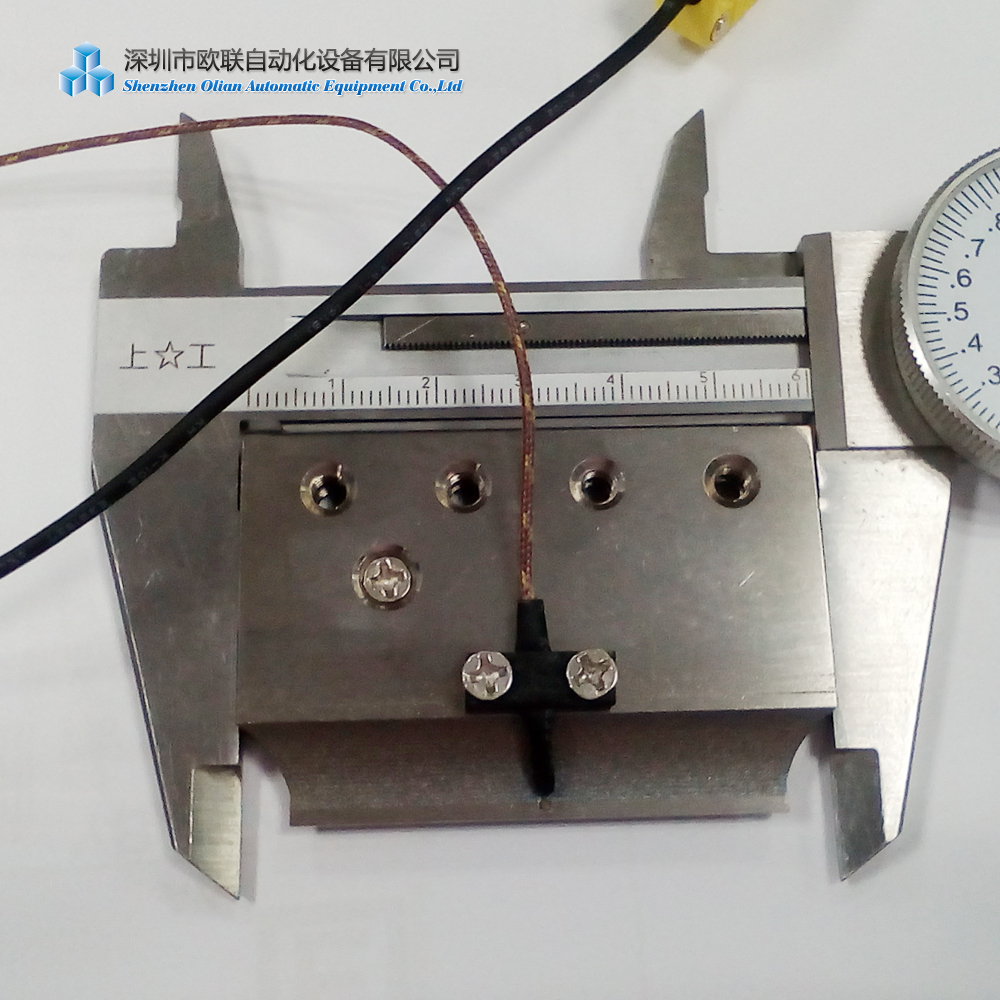

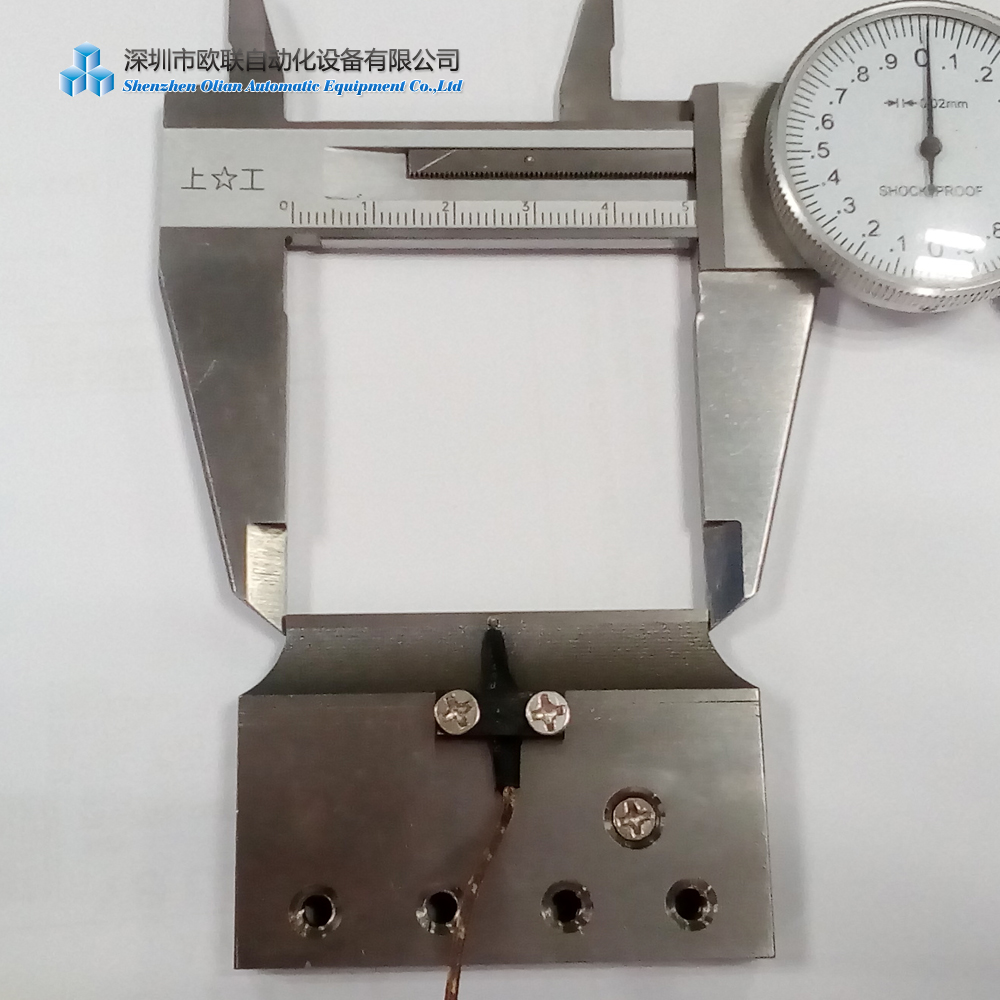

ACF bonding head also name:ACF/TAB/COF/COG/FOG/FPC/FOF Bonding machine press head /bonding tip/welding heads/ Hot Bar / soldering heads / heater tip / heater tools/ thermode for hot bar / ACF Bonding machine cutter head/bonding cutter/heat cutter……

It have pulse heating and constant temperature bonding head.

Normal materials:

-SUS440C steel(440C不锈钢)

-Tungsten steel(钨钢,钨钢(硬质合金)具有硬度高、耐磨、强度和韧性较好、耐热、耐腐蚀等一系列优良性能,特别是它的高硬度和耐磨性,即使在500℃的温度下也基本保持不变,在1000℃时仍有很高的硬度 )

-Titanium alloy (normal used in pulse heating bonding machine), (钛合金,脉冲压头一般用钛合金制作)

-Ceramic (陶瓷,一般用在COG压头)

-Brass (黄铜)

-and others.

It will be different sizes for different products, such as TV Panel/cell phone/Touch panel/camera/watch/ Heat Seal Paper/, every products have the different shapes and sizes, so we need to make the customized bonding head according to your products.

ACF Bonding head has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

-Heat cure

-Fast bonding time

-High adhesion to plastic PET,COF & FPC, substrate

-Excellent thermal stability

-Good contact resistance for reliability

-Good corrosion resistance

-Excellent chemical resistance

-Good for wide bonding temperature range

-Replaces solder for lead-free solution

Shenzhen Olian Automatci Equipment make all the ACF bonding machine heads/hot bar/welding tips……

Olian,is a high-tech enterprise established in 2008, specialized in R&D, manufacturing and sales of LCD/LED/OLED module automatic bonding machine (COG/FOG/ FOB/ACF/COF/OLB/TAB/FOF bonding machine)and all the parts,accessories(ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.)

Welcome you visit us.

Tel:+86-755-23209022 Fax:+86-755-23209033

QQ:2307972393

Mobilephone/WeChat:+86 18025364779

WhatsApp/Line: +86 18025364779

E-mail:olian@szolian.com

Address: Floor 5,Building D, Sogood Science Park, Aviation Road, Sanwei Village, Xixiang Town, Bao’an District, Shenzhen, China

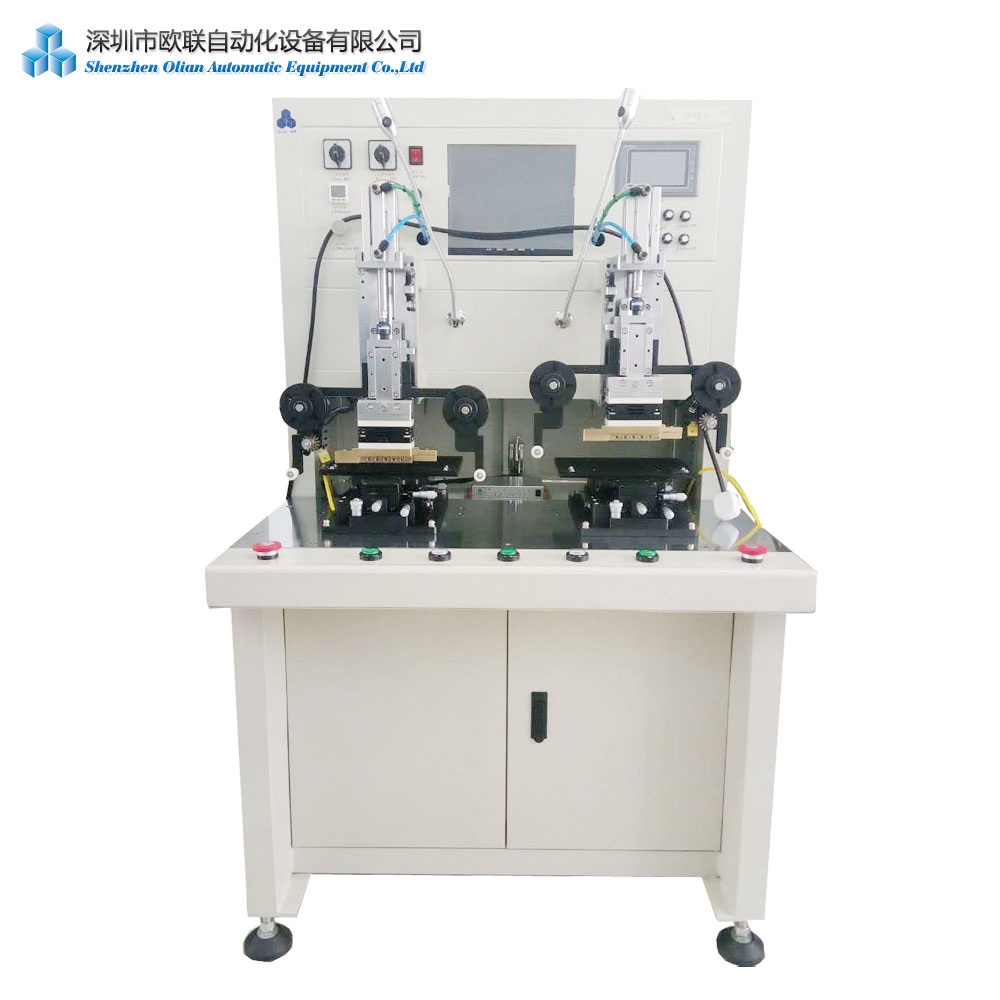

TAB bonding machine ,upto 100inch panel doubel press head single screen COF bonding machine/ACF bonding machine/TAB bonding machine

Welcome to be our sales and service agents /dealers in your country.

TAB bonding machine, also name COF bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

Our TAB bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Wechat/Whatsapp:+8618025364779

Machine Operating Video in Youtube:

OL-TVCBM-1285-DH-SH-SS- SPEC.pdf

TAB bonding machine is a widely used machine all over the world. This bonding machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED, and television. This bonding machine may consist of has two Digital Microscope, and also has a Digital Pressure Gauge. The ACF bonding machine consists of vacuum generator which may help to hold the panel during the bonding process. It may also provide the quick as well as easy solutions for various mobile problems. COF (TAB Bonding Machine ) is fast as well as it is very easy to access this bonding machine. This bonding machine is able to provide high accuracy repair apparatus for repair different size of the LED or LCD screen as well as LCD Panel. COF bonding machine also consists a process of repairing the technical equipment in an easy way.

We provide the various sizes and types of this machine, as well as all the services, are available if any defect may occur in the machine. Anisotropic conductive film (ACF) bonding machine commonly use in connectivity with electrical and mechanical connections from electronics driver to glass substrate of the LCD/LED/TV. During the ACF bonding process, heat and pressure are applied via a thermode (or hot bar) on to the ACF film or other component that is sandwiching the ACF film.

TAB bonding machinehelps to repair LED,LCD,TV, of lining issues on panel . Ultimate solutions of bonding of COF (COF Bonding Machine)with fast and easy to operate bonding machine. it is a kind of high precision repair equipment for repair various size LED/LCD screen/LCD Panel.

Single Head Manual platform ACF/TAB/COF Bonding machinefor TV repair,Television repair,Panel repair,screen repair.

1) Machine Model Number: OL-1285-DH/SH-SS (Single Head &Double head)

2) Device Description :Screen Repair machine / LCD Bonding machine

3) Device Uses :FPC、 COF、TAB、 LCD Panel and PCB combination bonding

4) Applicable LCD panel specifications :12″-100″(65″,85″100″ options)

5) Applicable LCD panel thickness :0.3MM-1.1MM[Single glass]

6) Bonding IC number :Multiple / Panel Can be set

7) Bind direction :X or Y Unidirection

8) Bonding IC size :Replaceable blade according to IC specifications (The original machine is equipped45X1.5X10)

9) Device processing time :TFT,3.8S/chip

10) Production Beats :TAB,100 pcs/H

11) TAB Bonding machine Accuracy :Within ± 1.5μm (support 4K screen)

12) Highest positioning accuracy setting :±0.5μm (Currently domestic the highest index)

13) Equipment requirements the work environment :Clean, No dust, Clean room

14) Supply Pressure :0.5~0.7Mpa (Dry air source)

15) Power Supply :AC 220V±10%,50HZ,3500W

16) Cylinder Device :Japan SMC original thin cylinder MXS20-75/MXS20-100

17) Heating Type :Pulse (rapid heating / cooling and auxiliary cooling function)

18) PID Temperature Control System :Brand: YUDIAN (516 model)

Adjustable heating curve Precision PID self-tuning type

The peak temperature : within +/- 3 degrees Celsius

Room temperature time to 180 degrees the response time within 2-3 seconds

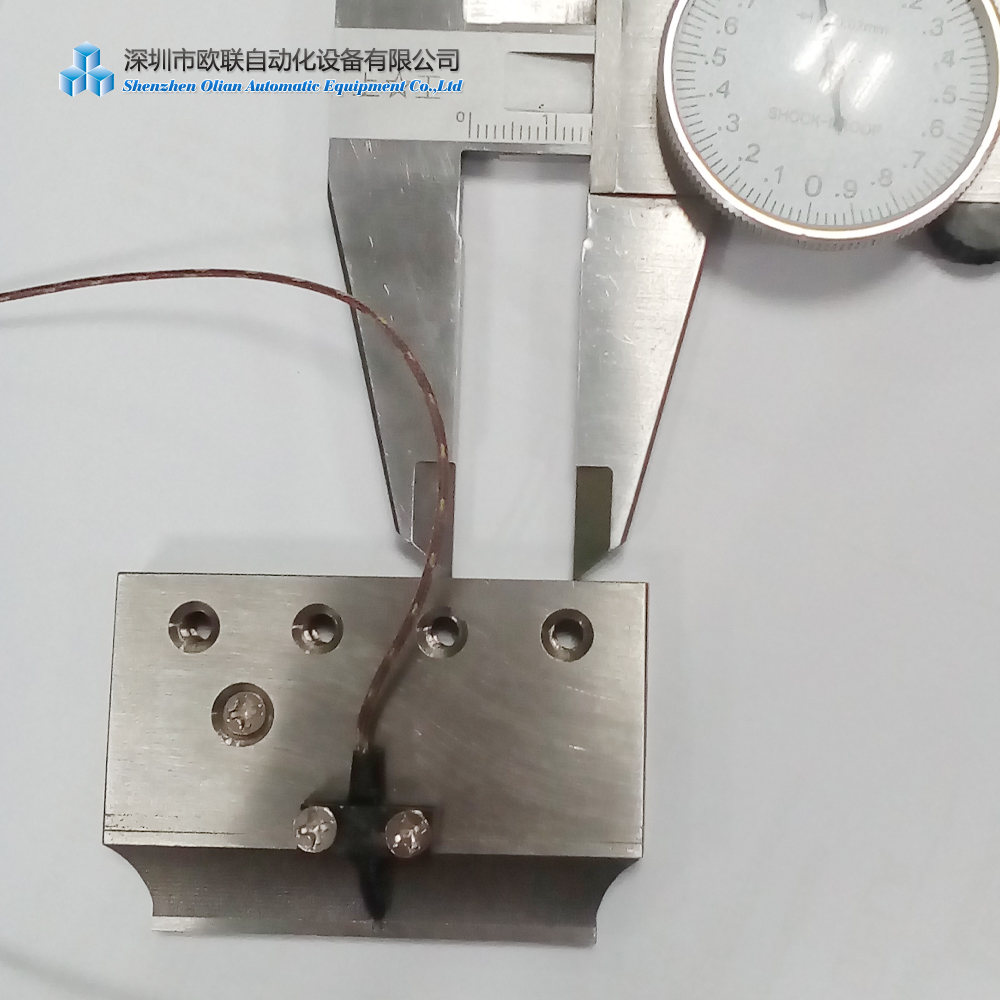

19) TAB bonding machine Hot pressing head :

Materials: Japan Titanium

origin: United States

Plane precision (hot press side) :0.001mm

Plane thickness 0.5 (Reserved 3 times grinding)

20) Thermocouple Type :K type Original US OMEGA wire

21) Industrial control units / Programmer :Import Panasonic PLC FX-C40T

22) Image unit :

Panasonic image processing system

COF counterpoint: down counterpoint

PCB counterpoint : UP counterpoint

Number of lenses : 4

Microscopy: 30-120 Continuous zoom

COF Display: 19-inch HD 1PCS

PCB counterpoint the display : same (Can be installed )

Upper light source : have

Down light source : have

23)COF trimming unit :

Origin: Taiwan

Rail Type: U-rail (2056 high)

Accuracy : 0.01

Adjustable direction :X/Y/R

R Itinerary : Coarse 360 degrees, fine tuning +/- 5 degrees

24)COF Fixture : COF mechanical clamping type, Z tilt radius micrometer trimming

25) Lens spinner unit :

Control mode: X / Y / Z micrometer control

Focus Adjustment: Manually adjust the focus

26) Position detection : None

27) Silicone / Teflon :Manual switching position

28) LCD stage (platform) :Manual sliding or fixed optional ,automatic stage can be customized

29) Alarm device :Pressure abnormal/ temperature anomalies / thermocouple abnormal / action abnormal

30) Hot press head counterpoint :Cylinder stop can be set at any position in the vertical direction

31) COF bonding machine Control mode :Touch screen + button operation Using Taiwan’s Wei Lun touch screen dual-core

32) Parameter setting :According to the need to set up Store multiple sets of hot pressing parameters

33) Rated voltage :180-220 (customizable 110V)

34) Peak power :400-2200W (Supports 68X1.5X10 lengthened tool bit

35) Maximum power :2200W

36) Actual power :500W

37) Body size :1200X1200x1380mm(L*W*H)

38) ACF bonding machine Machine weight :500KG

TAB bonding machine OL-TVCBM1285-DH/SH-SS , is our company in the R&D process , according to maintenance staff tailored high-end products , machine not only in the accuracy of the temperature and the mechanical accuracy do the precision design , the procedures also increases the glass and circuit board parameters direct selected function , working pressure automatically switch , greatly facilitate the technical staff selected the parameters , increased the tool bit preheating function , to ensure that the machine at any temperature difference can ensure heating rate and temperature accuracy , double head design , glass and circuit board independent bonding reached factory-class level , high bonding excellent rate、low repair rate , this COF bonding machine is the maintenance and after-sales staff preferred the classic model.

TAB bonding machine OL-1285-DH/SH-SS platform Up to 100inch, the COF/TAB/ACF Bonding machine for TV repair,Television repair,Panel repair,screen repair. Welcome you visit us,our website:www.szoulian.com, It is your best choose for your TV COF repairing.

液晶电视维修辅助设备耗材 ,ACF胶带 AC-7206,AC-2056,G450去除液,日立蓝胶,酒精,丙酮,酒精瓶,棉布,纳米海绵,棉签,COF裁切刀,空压机,显微镜,热风枪,石英条,硅胶皮,铁氟龙,精密镊子,六角扳手,烙铁头,放大镜,校正仪,LVDS链接线, 驱动测试板等,免费随机附送整套,免费来厂学习,免费打出口木箱,欢迎来厂试机购买。

| 1 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 | |

| 2 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 | |

| 3 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 | |

| 4 | Acetone Liquid BT-H1-500ML 丙酮 | |

| 5 | Hitachi Blue Glue 100ML 蓝色胶水 | |

| 6 | Fuji Silicone 50M 硅胶皮 | |

| 7 | Teflon 50M 铁氟龙 | |

| 8 | Alcohol 酒精 | |

| 9 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 | |

| 10 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 | |

| 11 | Optical Microscope 显微镜 | |

| 12 | TAB Cutter COF切刀 | |

| 13 | Correction table 校正表 | |

| 14 | LVDS LVDS接头 | |

| 15 | LCD Test Board LCD测试板 | |

| 16 | Allen Key 六角扳手 | |

| 17 | Air Compressor OTS550 空压机 | |

| 18 | Static Wipe Cloth 静电擦拭布 | |

| 19 | Cotton swabs 棉签 | |

| 20 | Handheld Magnifier 手持放大镜 | |

| 21 | Precision Tweezers 精密镊子 | |

| 22 | Nano Sponge 纳米海绵 | |

| 23 | quatz bar spare one 备用石英条 | |

| 24 | Alcohol bottles 空酒精瓶 |

TAB/COF/ACF Bonding machine,12-65/85/100inch Single/Double Stations bonding head TV Repair machine,ACF/TAB/COF bonding machine for TV/laptop repair,Television repair,Panel repair,screen repair.

ACF Tape/ACF Film is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

| Model(Hitachi) | Process type | For Glass |

| AC-823CY W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-832L W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-832L W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.5mm L100m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-7813KM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| MF-331-25 W2.0mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.5mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.2mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.0mm L50m | FOG Low Temp | For Touch Screen |

| AC-4255KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7206U-18 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.2mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-9851YM-35 W1.5mm L50m | FOG Low Temp | Common Glass |

| AC-9851YM-35 W2.0mm L50m | FOG Low Temp | Common Glass |

| AC-896C W1.5mm L100m | COG Low Temp | Thin Glass |

| Model(Sony) | Process type | For Glass |

| CP6920F3 W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.2mm L50m | COG Low Temp | Common Glass |

| CP34531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP34531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP35231 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP35231 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36931 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36931 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP33731 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP33731 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP31831 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP31831 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP1220 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP1220 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP13941 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP6920F W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.2mm L50m | COG Low Temp | Common Glass |

| CP920 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| TF-4200EB-45/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-451/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-452/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-75/1000ML | Blue | LCM Insulation protective adhesive |

| Model(ACF Remover) | ||

| Remover/G-430/1L | Clean FPC Side | common |

| Remover/G-450/1L Thick | Clean IC Side | common |

| Remover/G-450/1L Diluted | Clean FPC Side | common |

| Remover/G-550/1L Thick | Clean IC Side | common |

| Remover/G-550/1L Diluted | Clean IC Side | common |

| Remover/G-650/1L Thick | Clean IC Side | common |

| Remover/G-650/1L Diluted | Clean IC Side | common |

Please contact us if you need any other ACF tapes and ACF removers.

ACF has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Because of ACF bonding advantages and features ,the ACF bonding machine is becoming more and more popular and useful.

The Bonding Machine use the ACF tape as the medium ,so it named ACF bonding machine.

ACF Bonding Machine, is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

The ACF Bonding Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The ACF Bonding Machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to the different bonding materials, the ACF bonding machine can be divided into different bonding machines.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

Semi Automatic LCM making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonding machine, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce machine include all the process of the COG and FOG bonding machines.

If you need the ACF bonding machines and the ACF tapes and all the accessories,please contact us Olian .Wechat/whatsapp:+86 18025364779,QQ:2307972393, E-mail:2307972393@qq.com

We offer all kinds of COF IC, chip on Film,chip on flex,TAB IC, TV Repair COF,LCD T-con COF IC, LCD TV COF IC, Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,COF,PANDA COF, SONY COF,LCD COFS,COF bonding machine repairing for you .

COF is an IC packaging technology that uses a flexible printed circuit film as a carrier for a packaged chip. The gold bumps on the chip are bonded to the Inner Lead of the flexible substrate circuit by thermal compression bonding technique.

After the COF production is completed, the LCD panel module factory will cut the reel tape COF IC into single piece by the COF Punching Machine. There are outer leads of Input and Output on the flexible substrate circuit of the COF, the Input external pins will be bonded to the LCD glass substrate, and the Onput pins will be connected to the control signal printed circuit board ( PCB) .

COF package has High Density / High Pin Count, Fine Pitch, Gang Bond, High Throughput and High Reliability characteristics. In addition, it is lightweight, short, flexible and Reel to Reel production, which is not possible with other traditional packaging methods. For COF products, multi-chip or passive components can also be designed on the substrate circuit.

Some COF ic can not find,and may be stop produce,so need to find some replace COF to use. Some replace COF ic for reference only.

NT39562H-C12Q9A

8656-MCY61

RM76731FD-60y

NT39992H-C12E2A

8157-RCY60

RM76C30FA-F02

8656-FCY0B

NT61227H-C1217B

RM92A31FA-908

NT39525H-C14F1A

S6C2BD1-54U

DB7500-FD07SB

DB7501-FD02S

S6C2T94A01-58U

NT39823H-C6501A

8033-HCU67B

36-D064129

MT3196C-VE

EK77211CF129A

S6C1125-65

8033-HEX39

LH165V08-S332

S6C1125-62

RM92370FC-80K

S6C2BD1-54U

SPLC-1698A

DB7500-FD07SB

DB7501-FT03S

DB7501-FD03S

DB7501-FD03S

DB7501-FD07SB

MN838994LF-1

RM92122FA-058

RM92165FM-OE9

NT65060H-C0205A

MT3196B

NT61207H-C6802A

ICN9305-05

NT39931H-CO2F7A

S6C2BD1-55U

MT3173VF

8697-A

RM91C30FA-F01

RM91C30FB-F04

DB7500-FD04S

NT39992H-C12E2A

D160418NL-057-C1 108

LS08S6HT3A-C3LS

RM76320FB-61A

NT39931H-CO2F74

MT3173VF

DB7893-FT11M

S62B91-63

DB7500-FDO75B

S6C2BD1-58U

RM76153FS-0A1

MT3714VM

DB7501-FT03S

DB7501-FD03S

RM9113BFG-OG1

VH1L5032786-2L

S6CG239-52 H COF

NT39985H-C02M4A

S6C277J-54

RM9216EFA-OG6

DB78913-FT11M

S6C2BD1-55U

DB7500-FD07S

S62LD1-58U

DB7500-FD758

S6C2B91-63

DB7893-FT11M

RM76155FS-0A1

MT371UVM

D78913-63

RM92A131FD-90E

8160-C558

ICN9506-01

RM92A31FA-908

NT39658H-C1294A

NT 61227h C1217A

RM76731FD-60Y

NT65001H-C02P3A

DB7500-FD07SB

EK77211CFI29A

SSD3258UR1

DB7897B-FT08M

NT39935H-C5216B

8154-ECBM3

RM9216DFJ-OFP

RM92122FA-058

56C1104

NT39759H-C12E3C

RM92122FA-058

NT61610H-C07928

LS0856HEASHZ-C3LX

MT3753VD

DB7878-FS02U

ILI5381M2AB2

ILI305K5CD2

S6C2T96-60U

NT39573H-C6007A

S6C2T92J-55U

DB6894-FS06M

S6C277U-53U

RM76113FD-OCX

NT61702H-C6801A

NT39833H-C6511B

NT61720H-C12J3C

8157-RCBRG

MT3166VB

NT39980H-C5266A

NT39992H-C1279A/C

NT61804H-C6520A

RM927A1FF-61B

8159-KCBR8

HX8157-NCA03

ILI3102K6CB1-S

LS0610BH1-C2LX

LS0610BH1-C1LX

MT3220A-VA

NT39892H-C12H5A/B/C

RM92A31FA-908

SSD3273UR4

5253-ACBPQ

MT3725VB-10260UTE

Nt39548H-C5801A

NT61702H-C6801A……

All kinds of COF ic,

Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,PANDA COF, SONY COF,LCD COFS ,Welcome you send your list to my Email:2307972393@qq.com, or Wechat:+8618025364779,We will reply you ASAP.

Related products:

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

This COF bonding machine is mainly designed for TV/Laptop/cellphone repairing, it is for LCD/LED/OLED Panel repairing with COF changing functions,so it is also named COF change machine, COF repair machine, TV bonding machine, TV Repair machine,Laptop repair machine,LCD panel repair machine,LCD bonding machine,LCD repair machine,LCD fix machine, and so on..

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the COF Bonding machine accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.