Bonding Machines, is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

The Bonding Machines is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

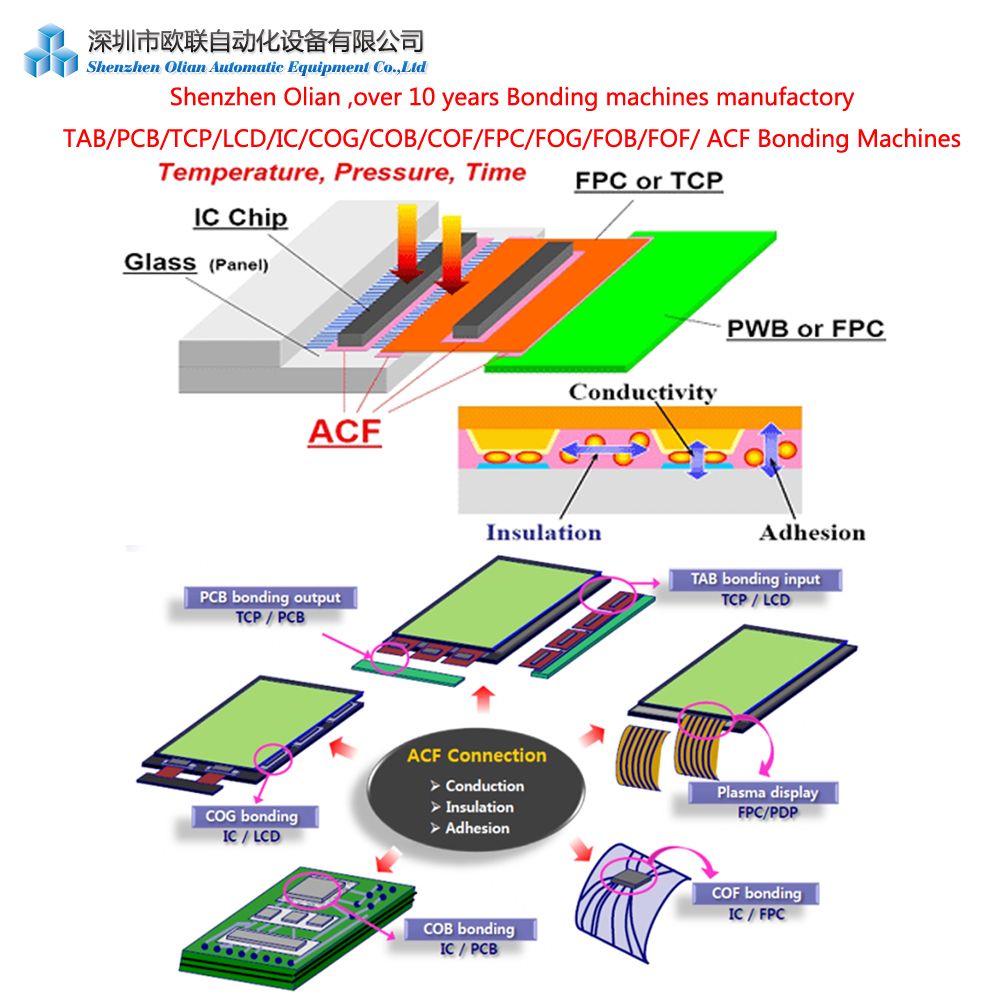

The Bonding Machines may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time. also some bonding machine use the Solder paste as the medium.

The machine use the ACF tape as the medium ,so it also named ACF bonding machines.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the important medium of the bonding process.

ACF Tape is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF TAPE

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

ACF has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Because of ACF bonding machine’s advantages and features ,the machine is becoming more and more popular and useful.

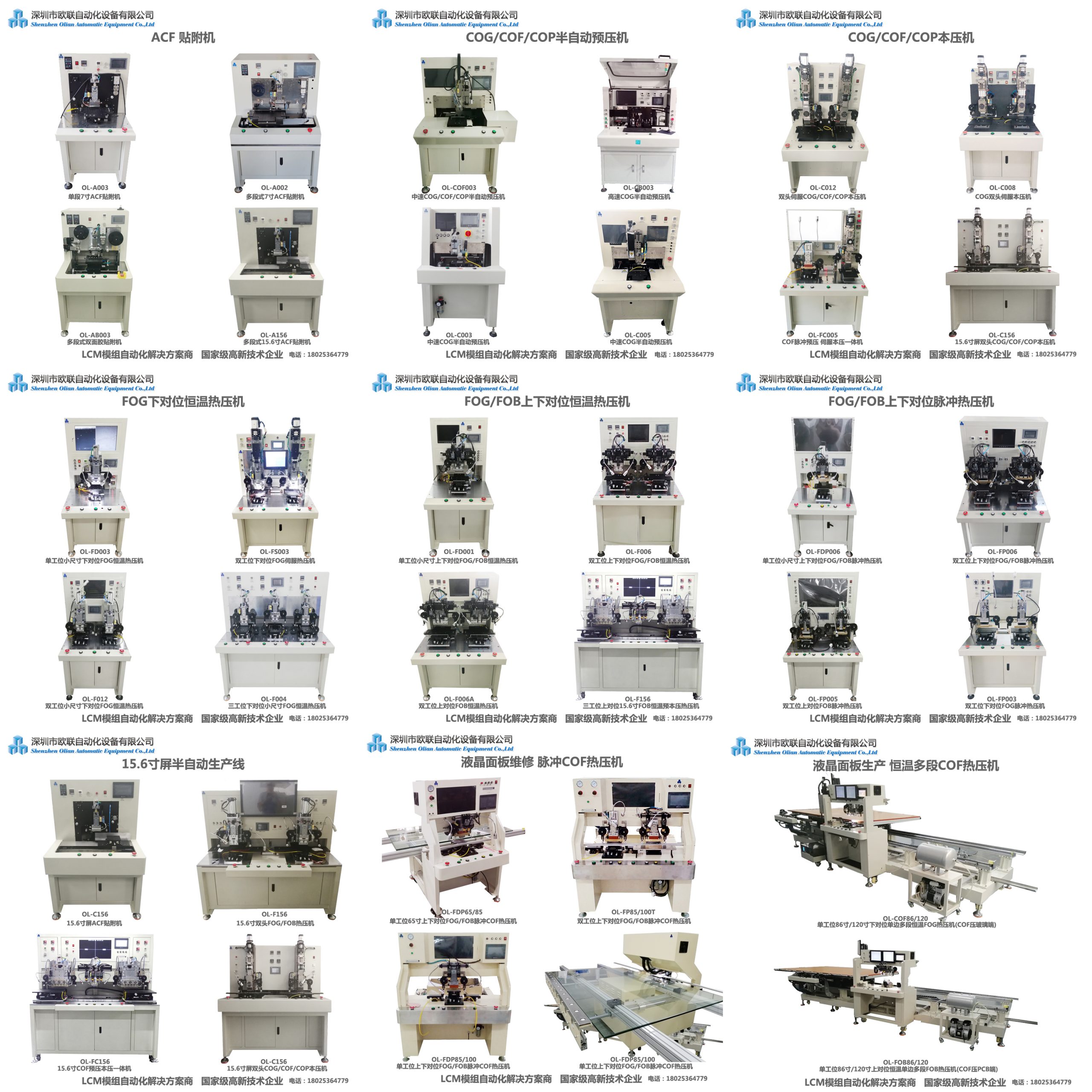

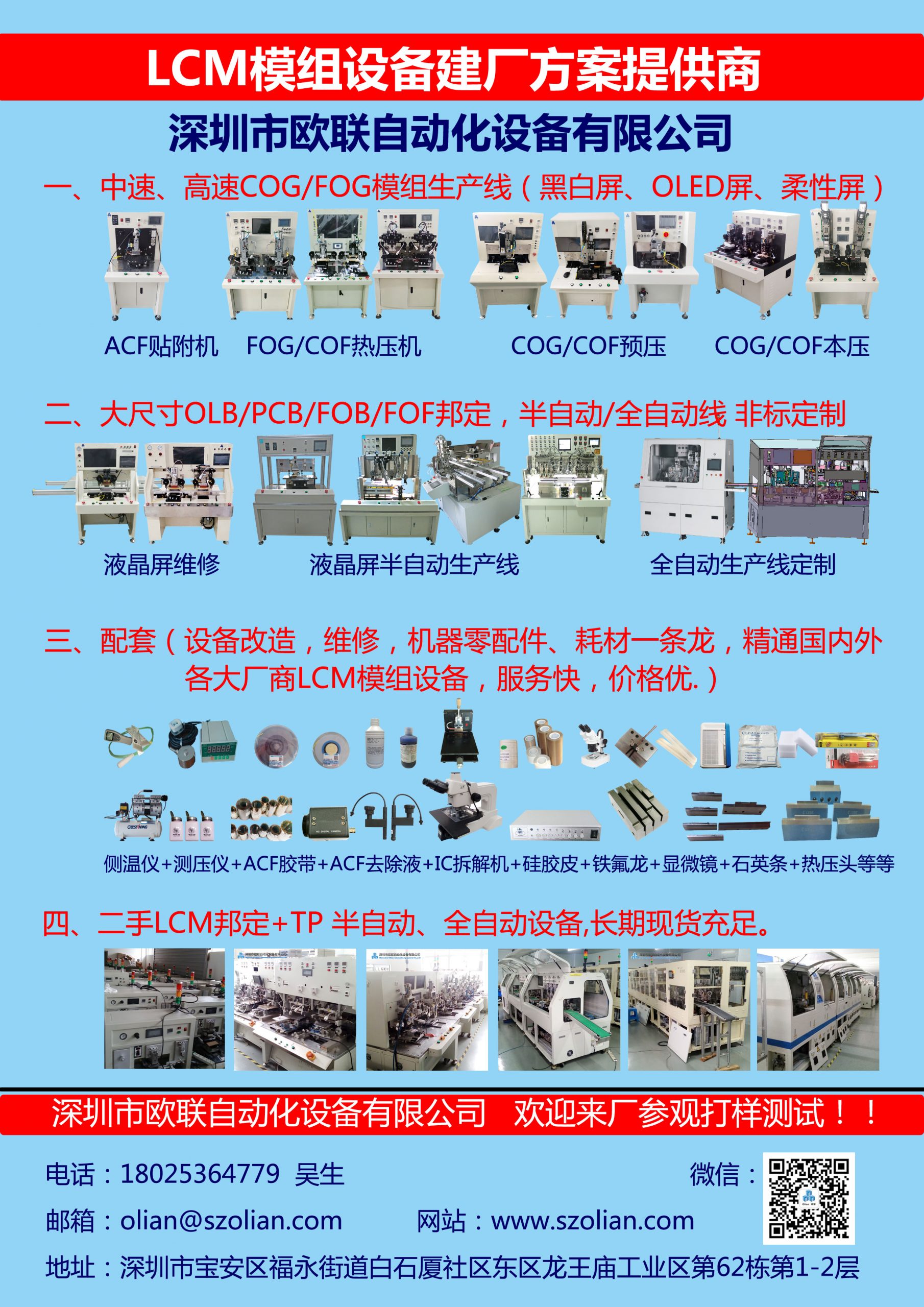

Semi Automatic LCM Making machines include:COG pre-bonding , COG main-bonding , FOG(FOB) bonding , ACF attaching machine as below:

According to the different bonding materials, the bonding machine can be divided into different bonding machine.

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

ACF Attaching machine

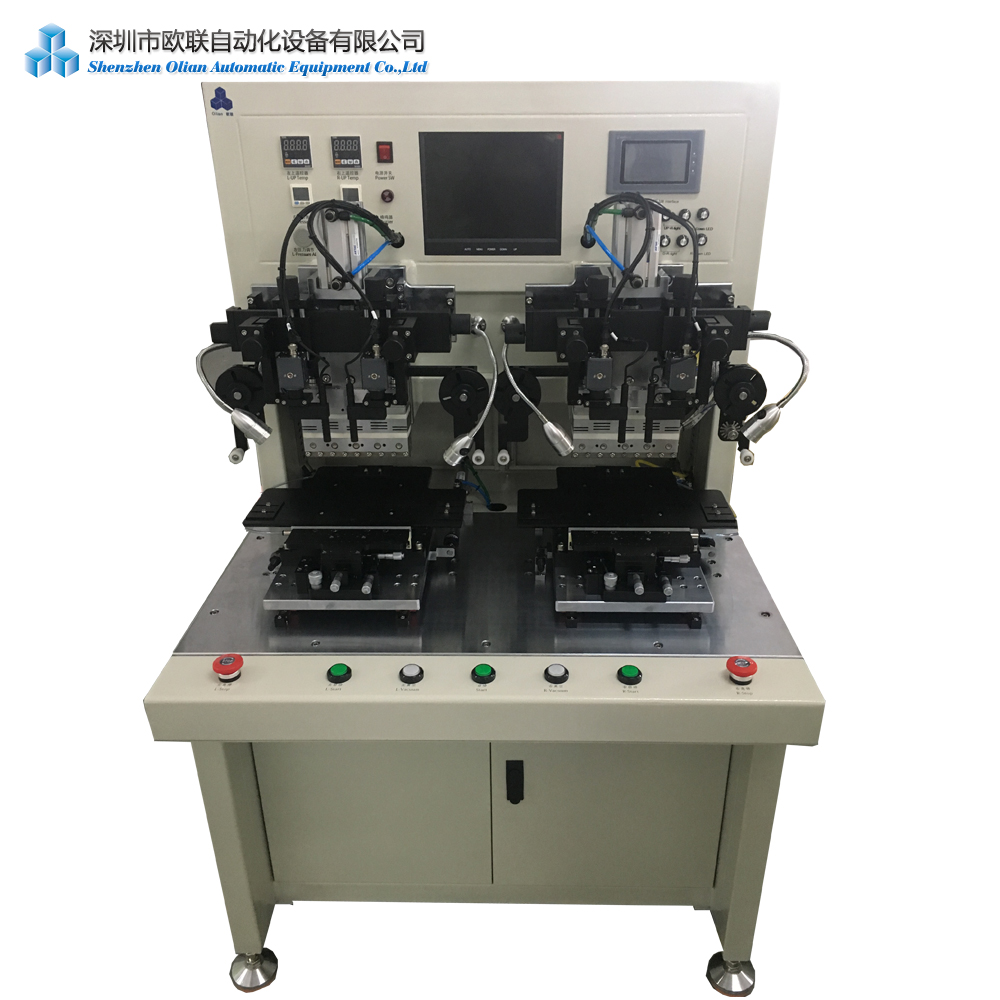

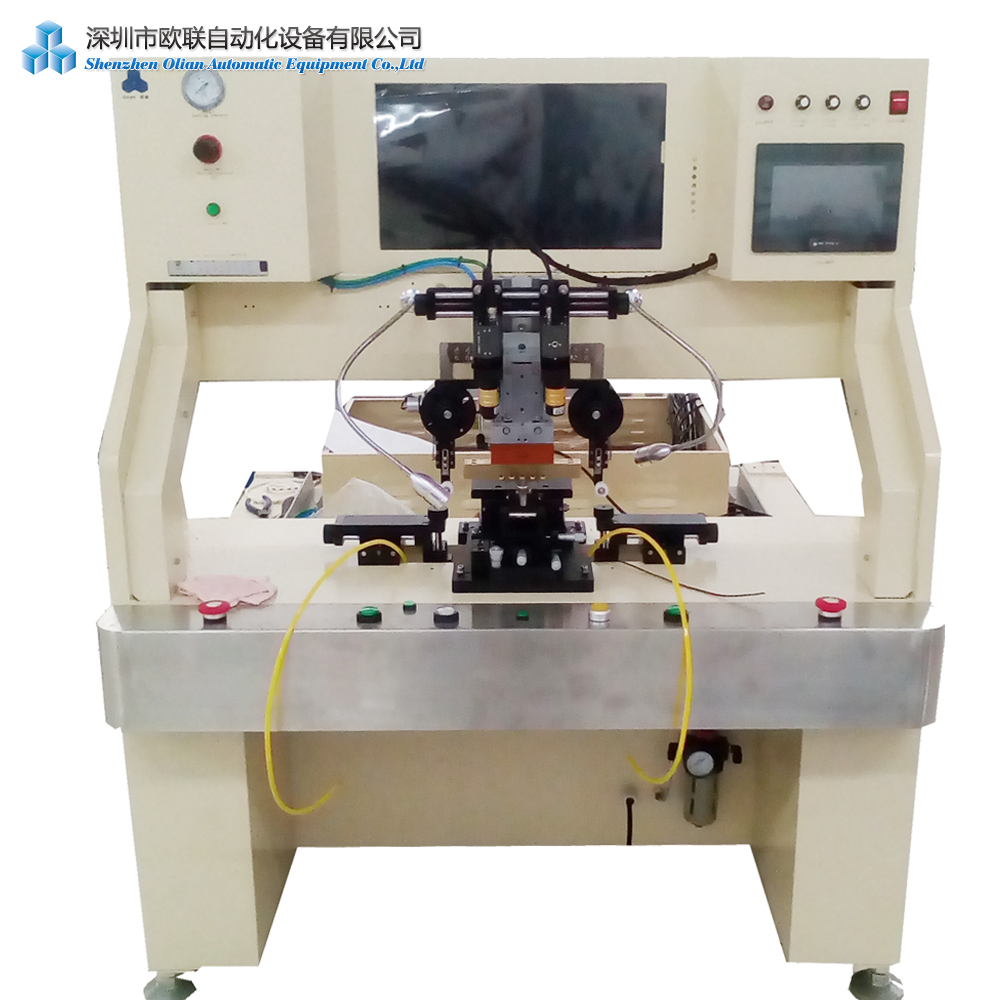

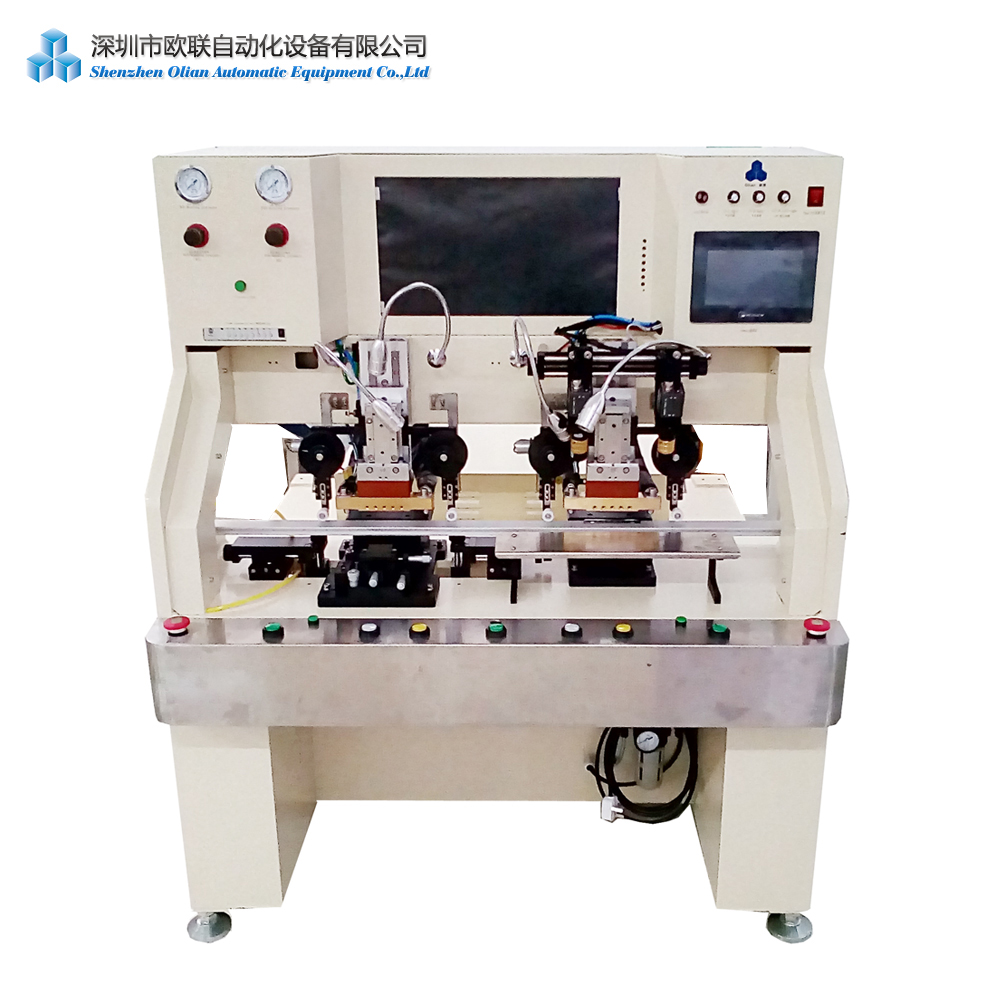

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

COF pre-bonding machine

COG MAIN-BONDING-MACHINE

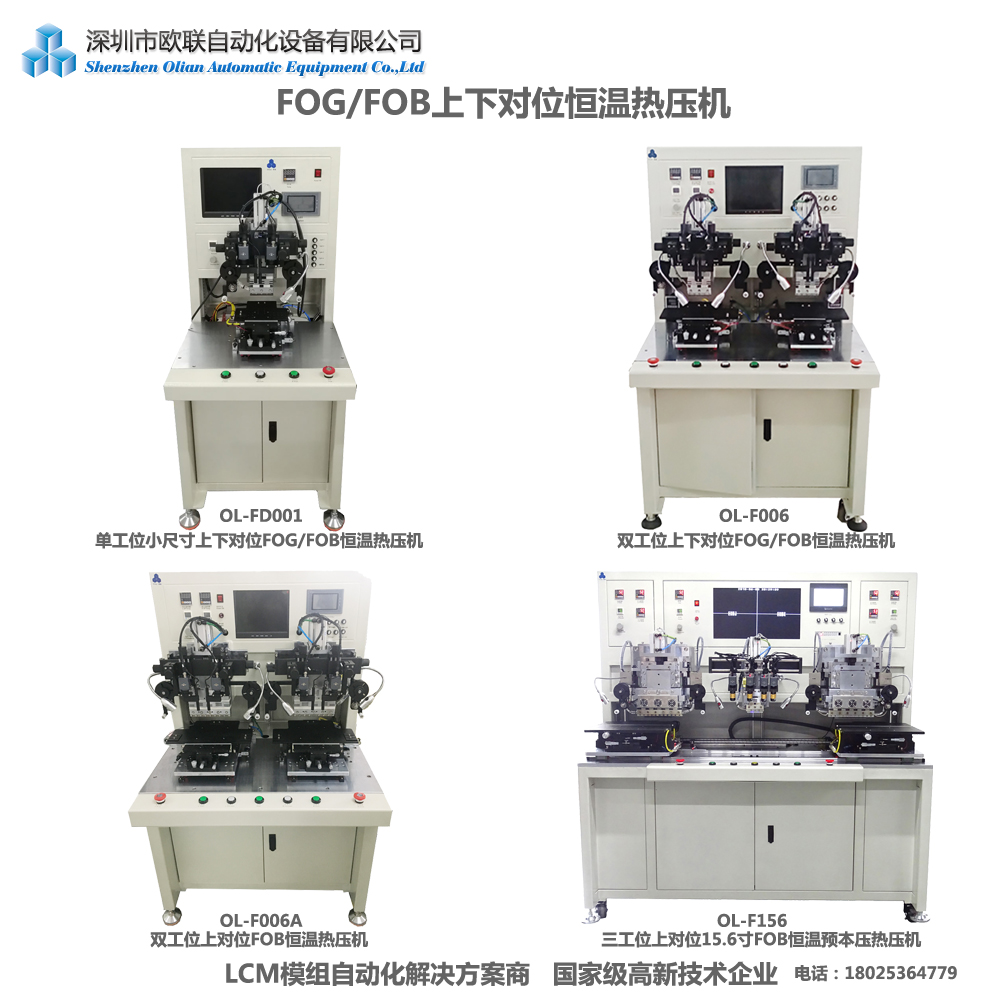

FOG bonding machine, also name FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

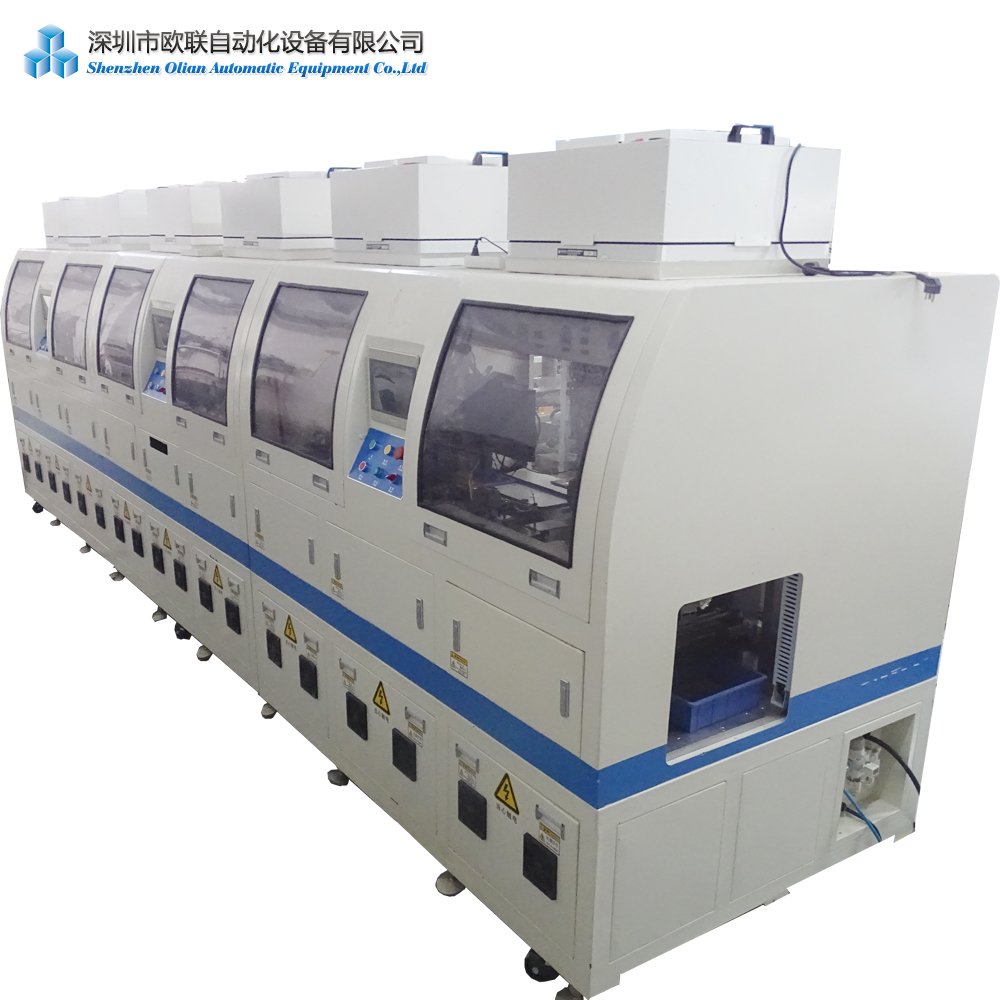

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonding machine, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

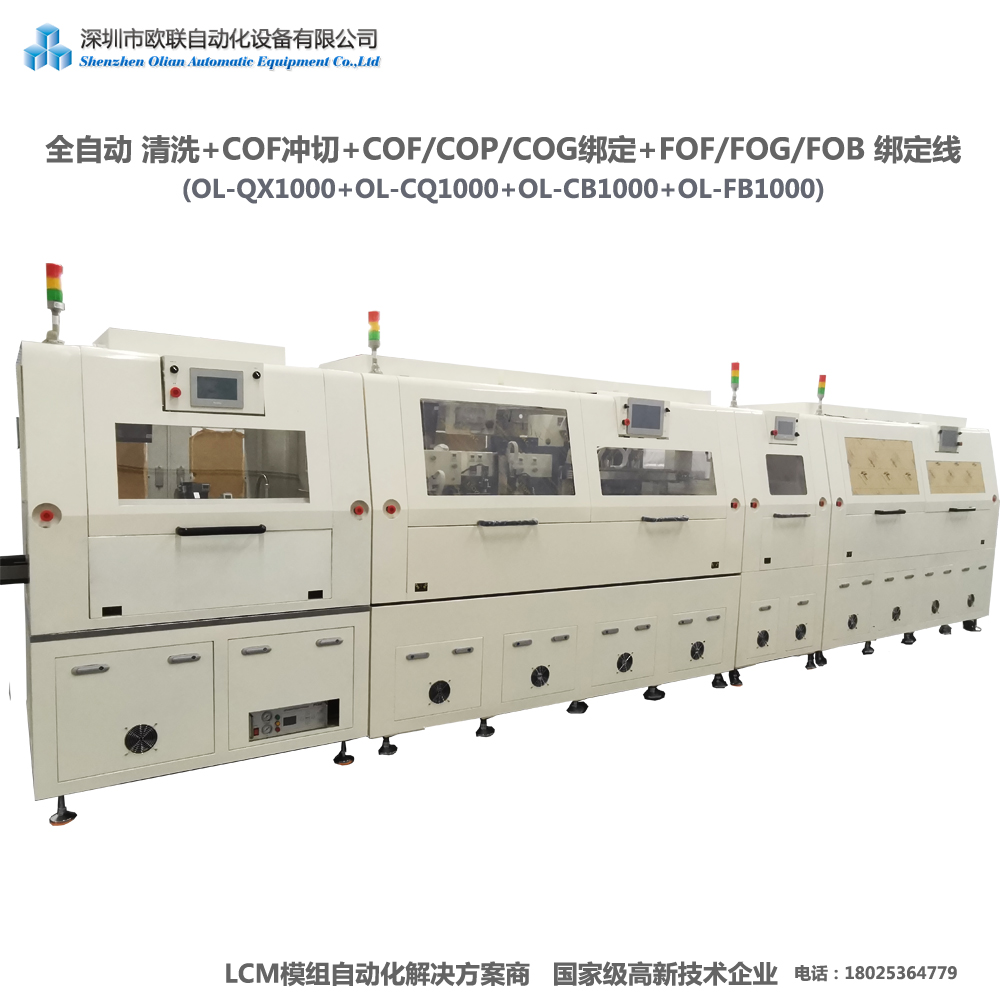

LCM full automatic produce machine include all the process of the COG and FOG bonding machines, include the glass cleaning, IC loading, ACF attaching for COG, IC pre-bonding, IC final-bonding, ACF attaching for FOG, FPC bonding,and output to testing..

Shenzhen Olian design and make the standard bonding machines and customized bonding machines for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

bonding machine

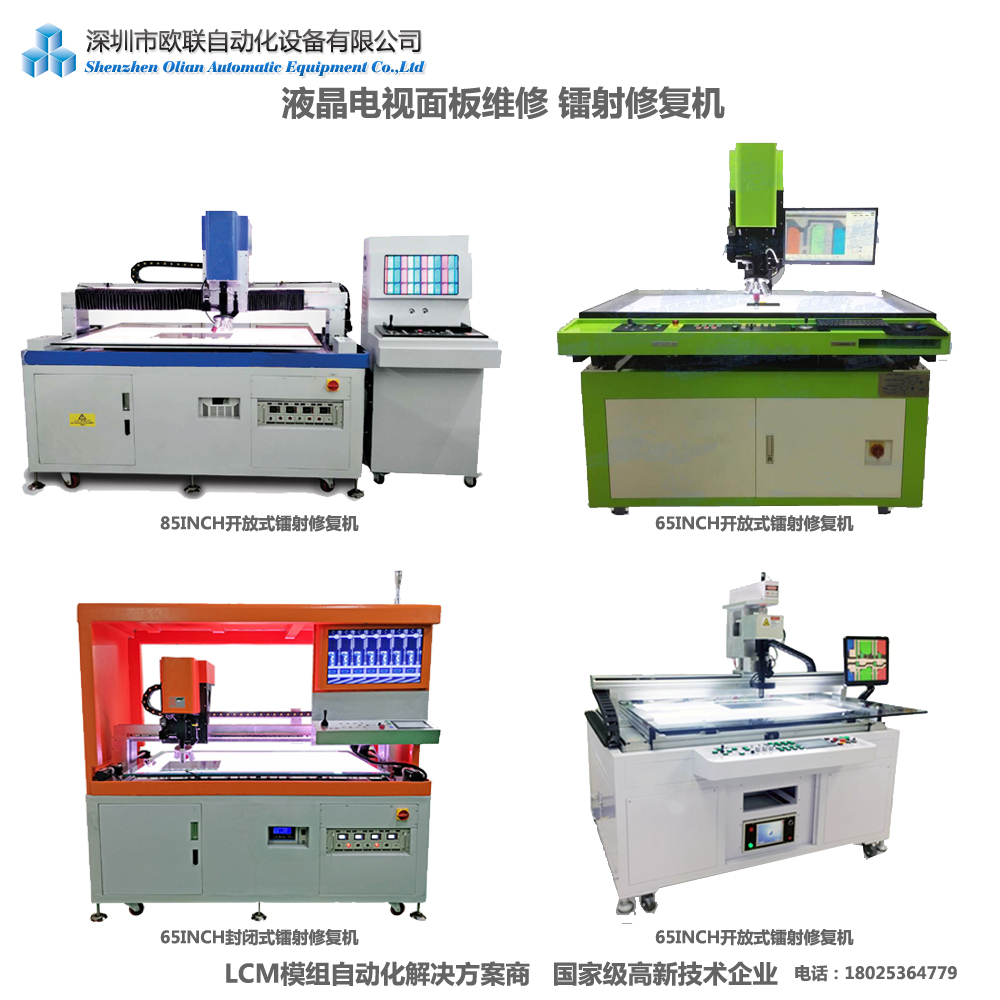

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

This COF bonding machine is mainly designed for TV/Laptop/cellphone repairing, it is for LCD/LED/OLED Panel repairing with COF changing functions,so it is also named COF change machine, COF repair machine, TV bonding machine, TV Repair machine,Laptop repair machine,LCD panel repair machine,LCD bonding machine,LCD repair machine,LCD fix machine, and so on..

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the COF Bonding machine accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

OLED namely Organic Light-Emitting Diodes (OLED), also known as Organic laser Display (Organic Electroluminescent Display, OELD).It has illuminated, simple structure, ultra-thin, fast response, wide Angle, low power consumption, and can realize the flexible display features, known as the “dream” monitor, OLED display technology and the traditional LCD display in a different way, no need backlight, with very thin organic materials coating and glass substrates, when a current through the organic material will glow.

OLED including passive-matrix organic light-emitting diode (PMOLED) and active-matrix organic light-emitting diode (AMOLED), is a technology that organic materials emit light under the action of electronic field. Succeeding CRT and LCD, OLED is a new-generation flat panel display technology and extolled as “dream like display technology”.

The NTSC color gamut of OLED can break through 100%, much higher than that of LCD.

The response time of OLED is normally in microseconds, only 1/1000 of that of LCD, which is in milliseconds.

The contrast ratio of OLED is at least 100000:1, which is much higher than that of LCD, which is at the level of 1000:1

OLED is suitable for flexible display due to its ultra-thin, large visual angle and good mechanical properties.

Shenzhen Olian Automatic Equipment Co.,LTD have the OLED bonding machine for AMOLED screens cell phone as HUAWEI,XIAOMI,VIVO,OPPO,APPLE,SUMSANG…bands edge screen models phone. if you need the machine for the OLED screen repairing, please contact us .

Wechet/Whatsapp:+86 18025364779

你需要登陆后才能评论。