COF screen / Flexible screen / Edge/Curved screen / OLED screen professional bonding machine factory – Shenzhen Olian

Now developed products: Huawei Mate10,Mate 20, 8X, Iphone X,8X, Samsung S8 S9 series etc.

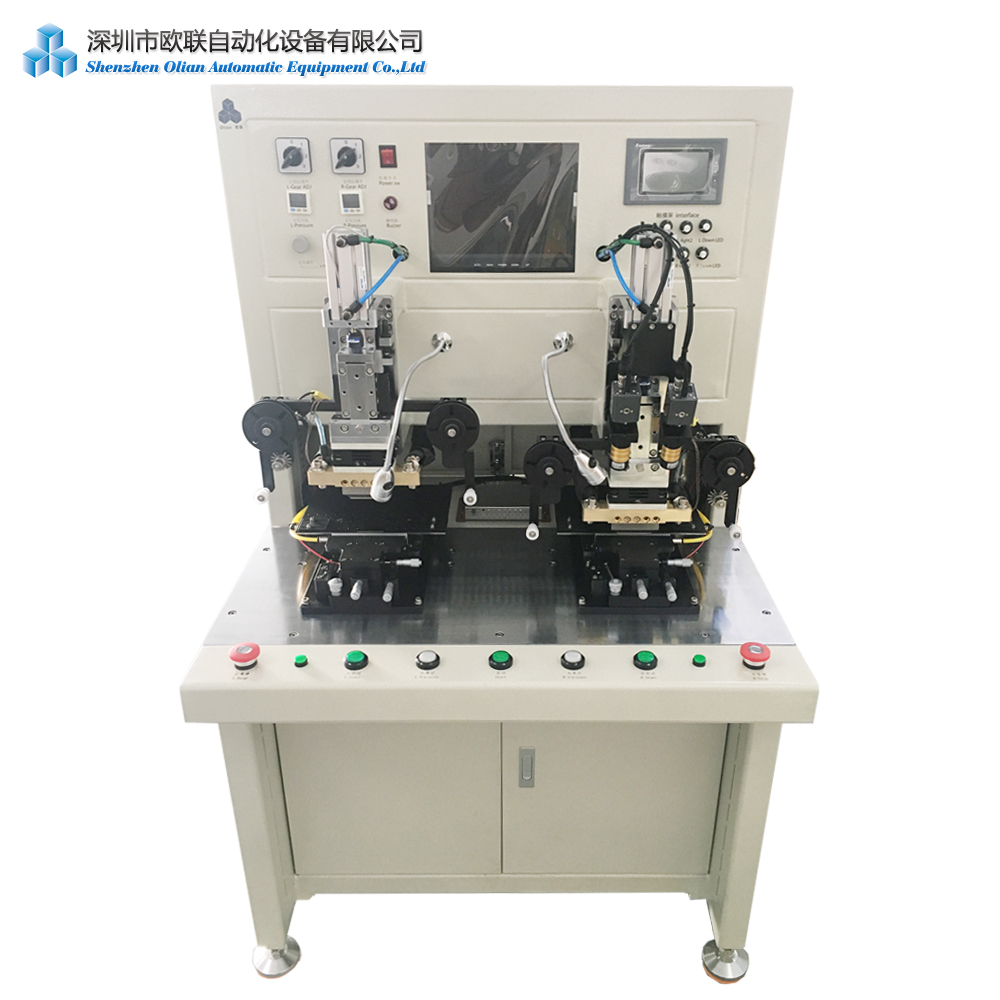

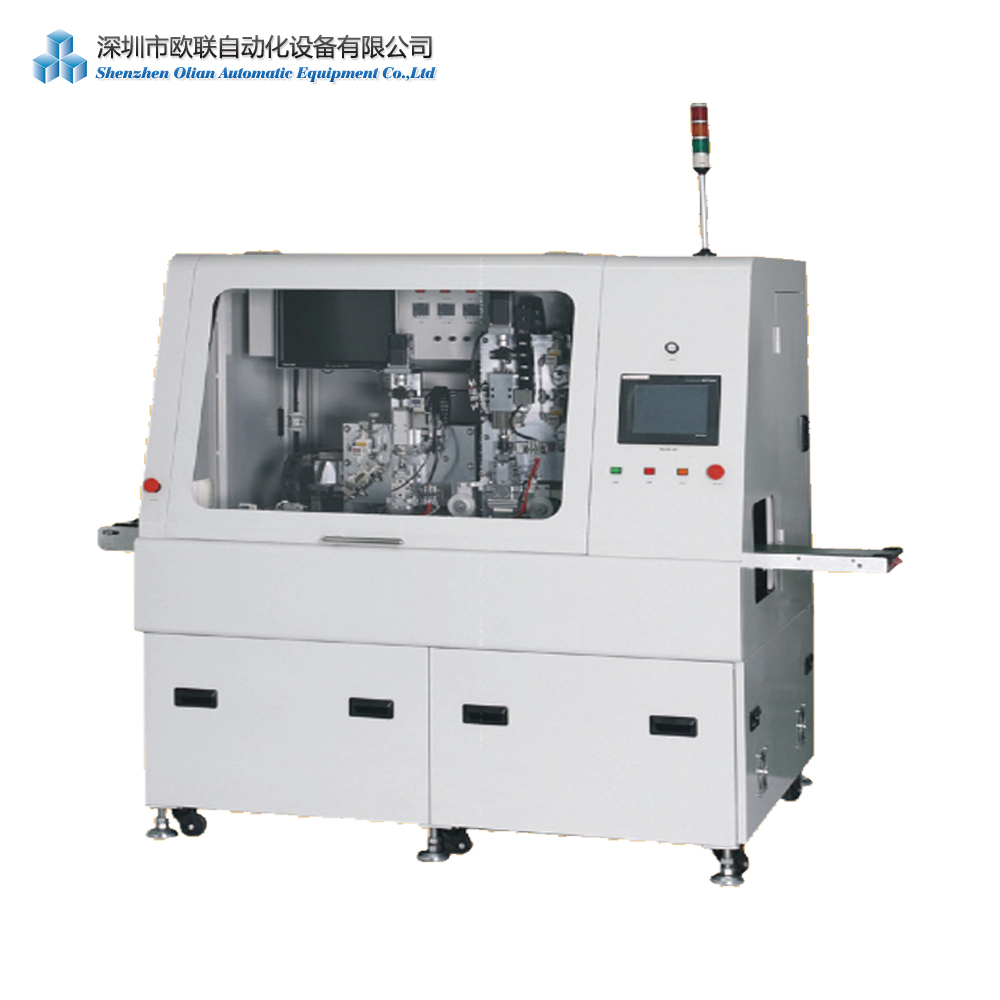

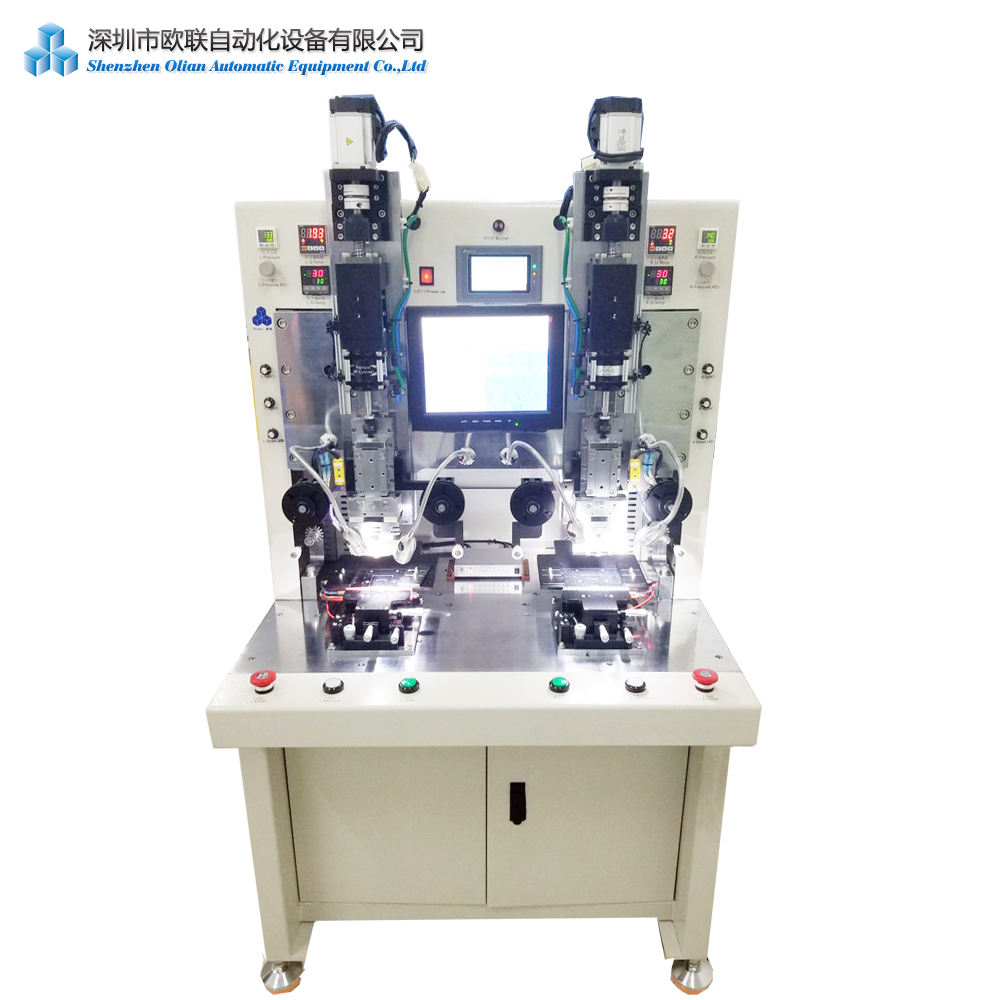

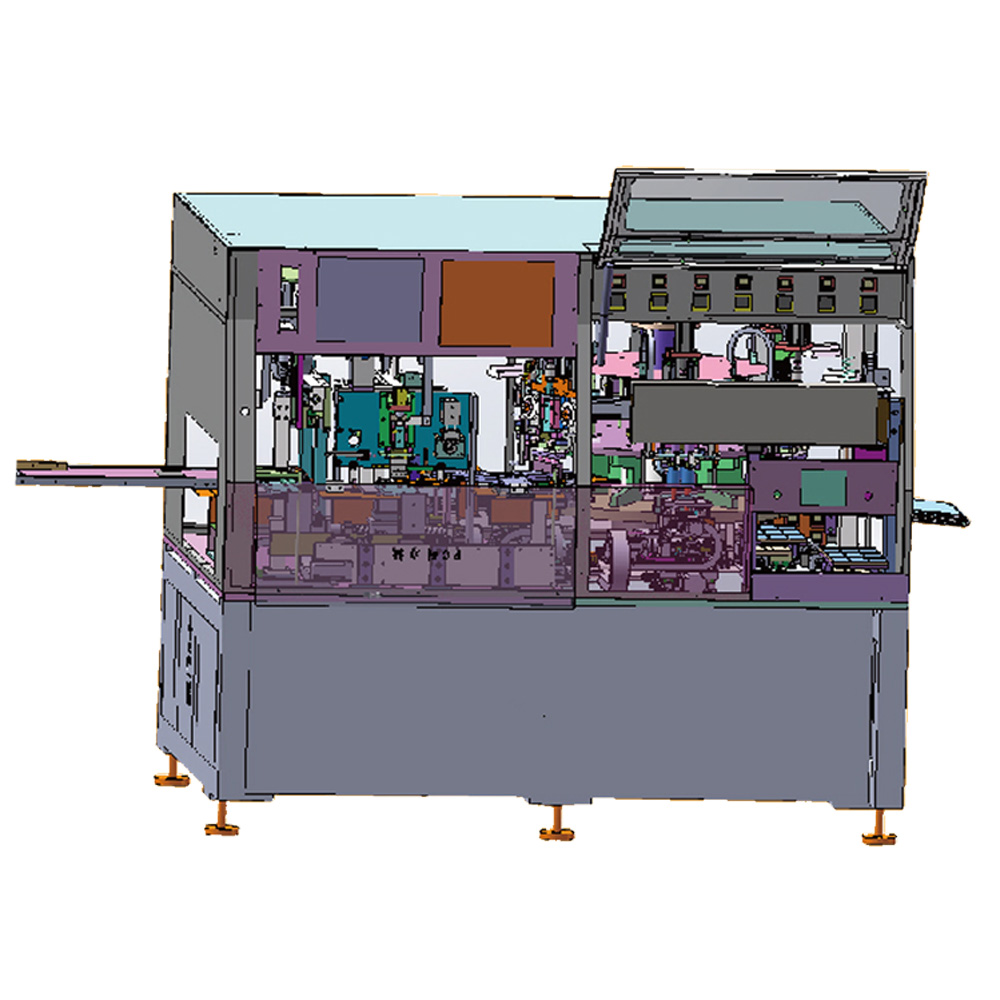

ACF Attaching machine+COF pre-bonding machine+COF finan-bonding machine

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

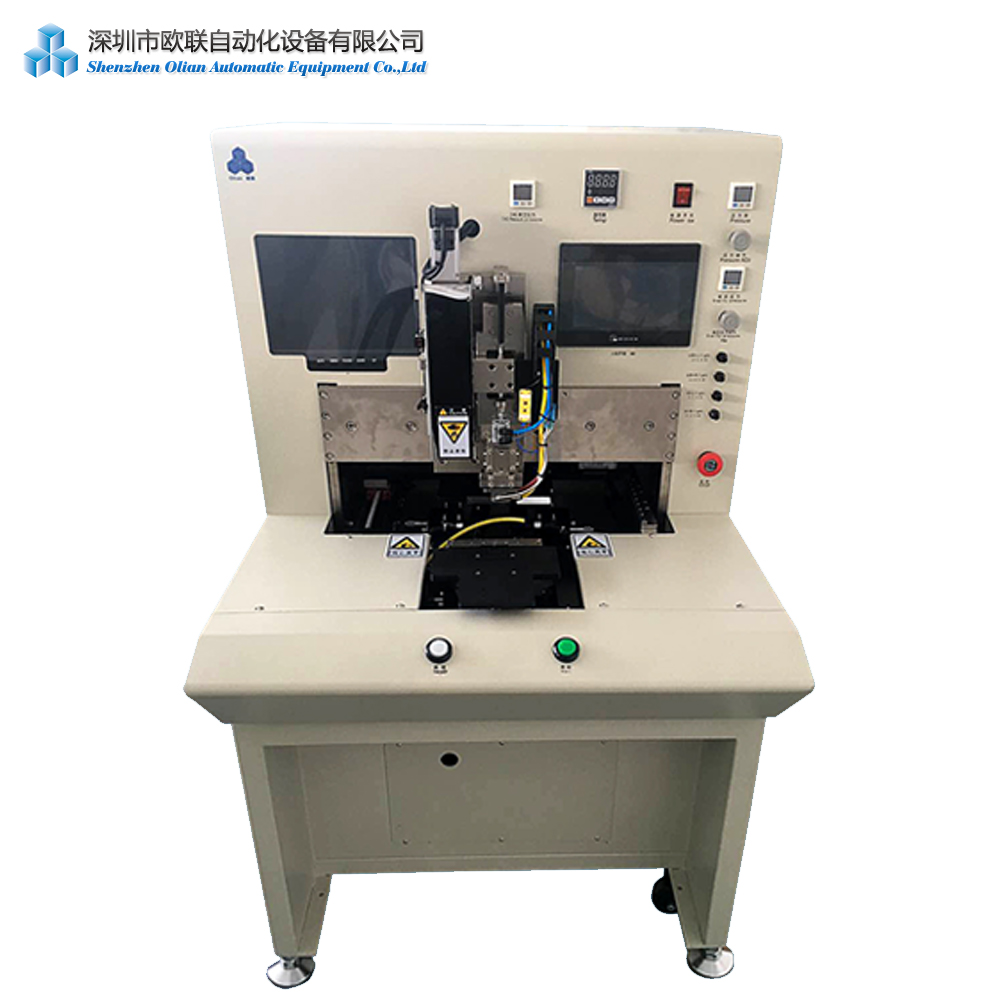

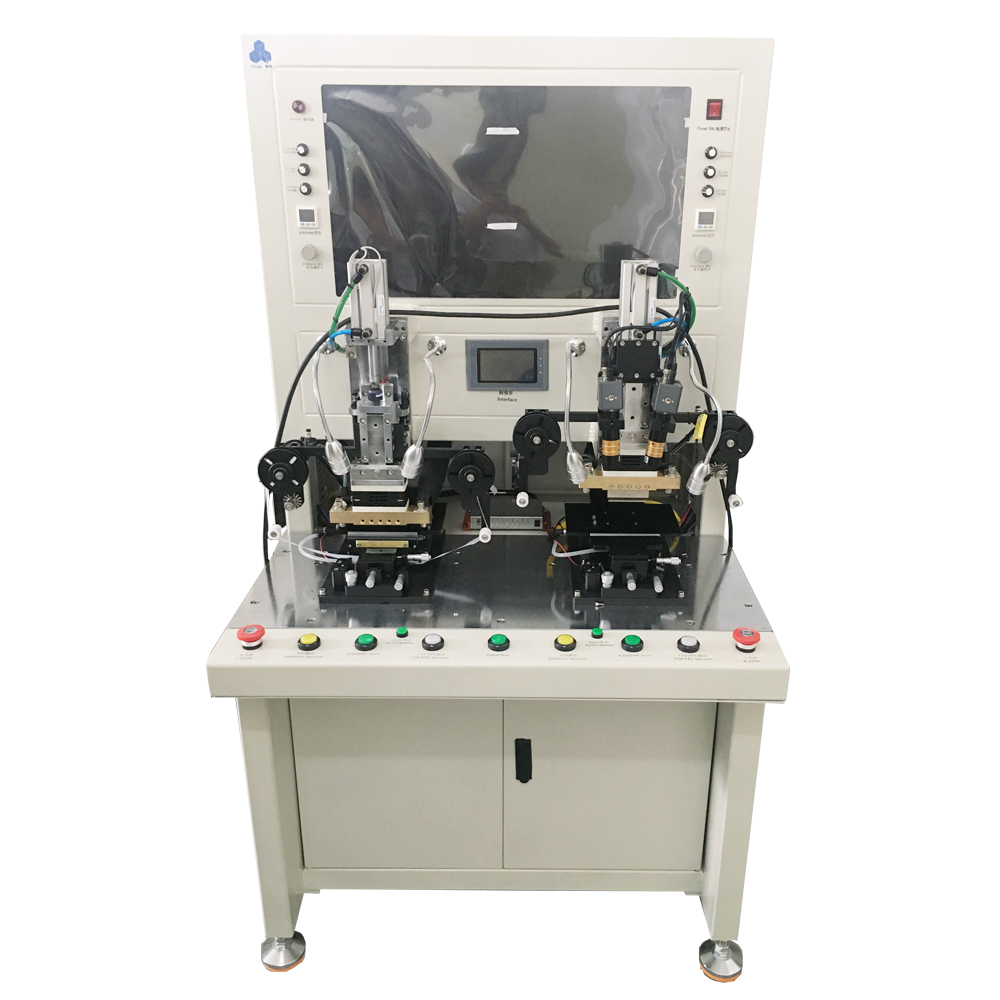

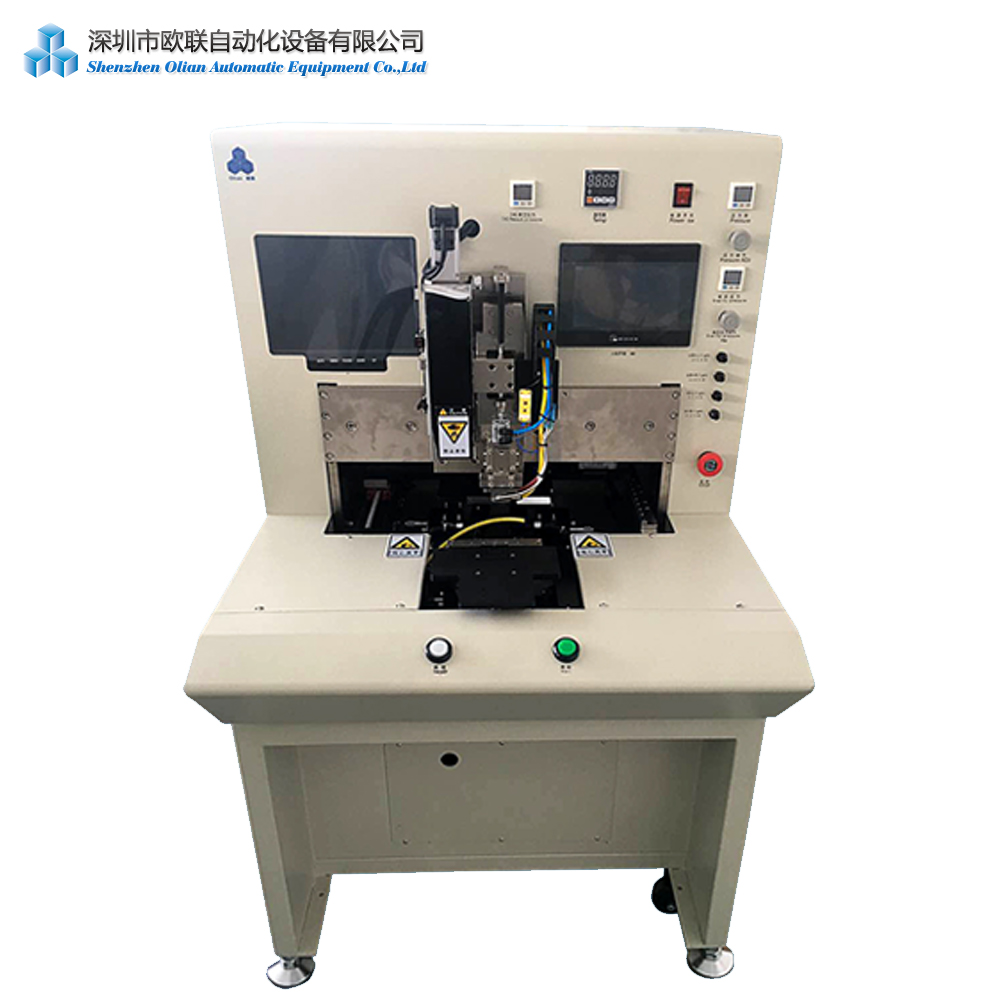

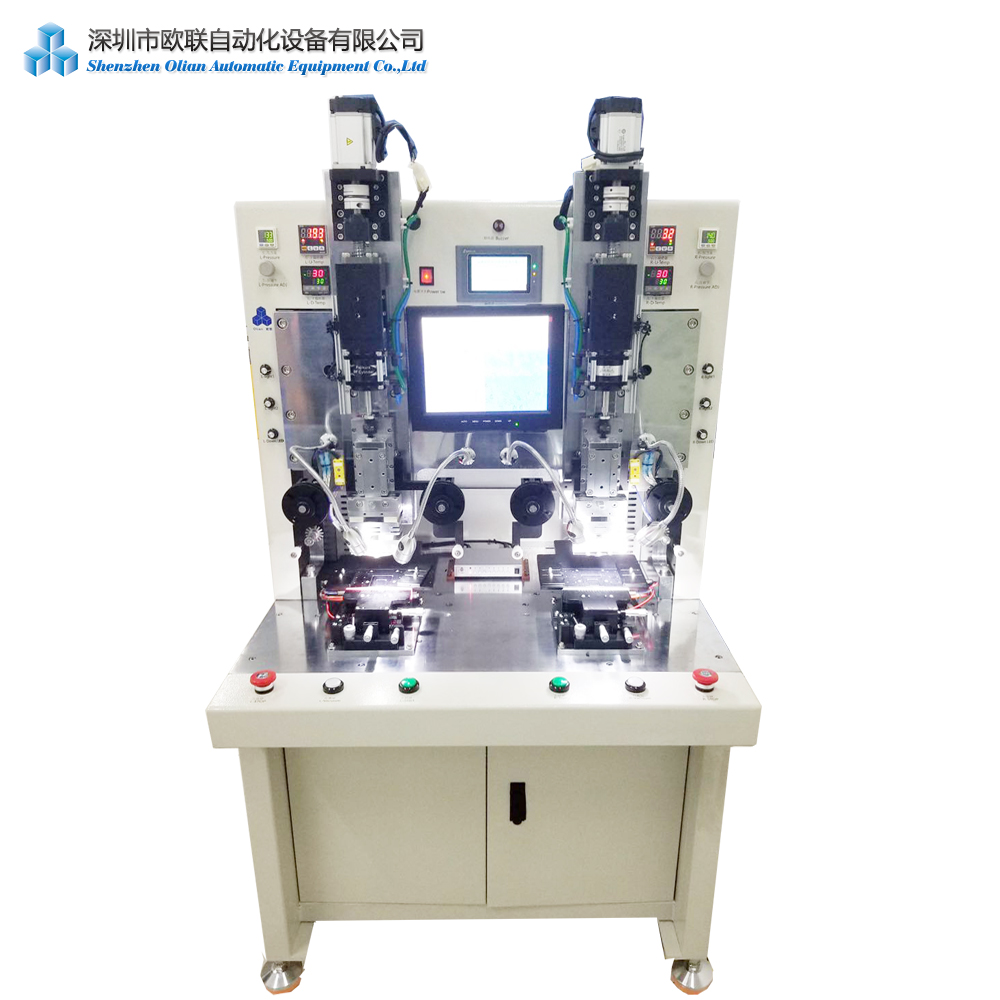

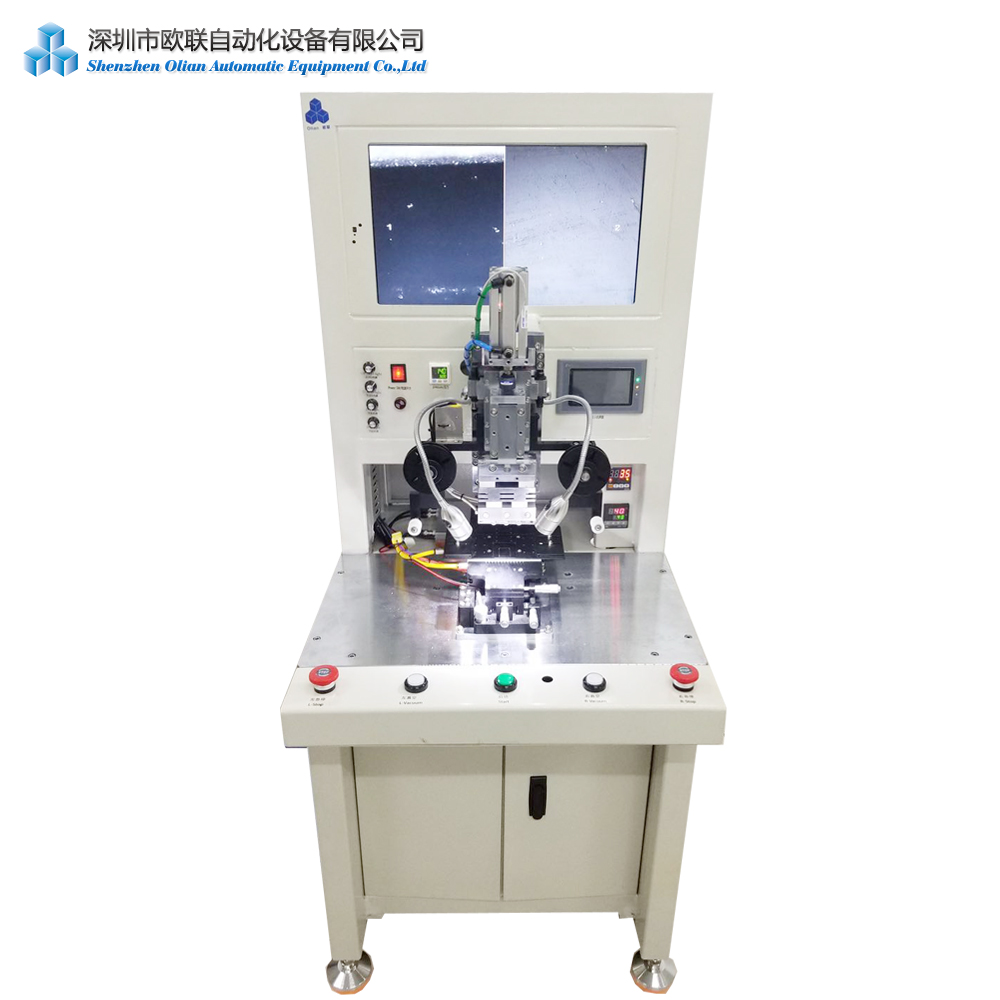

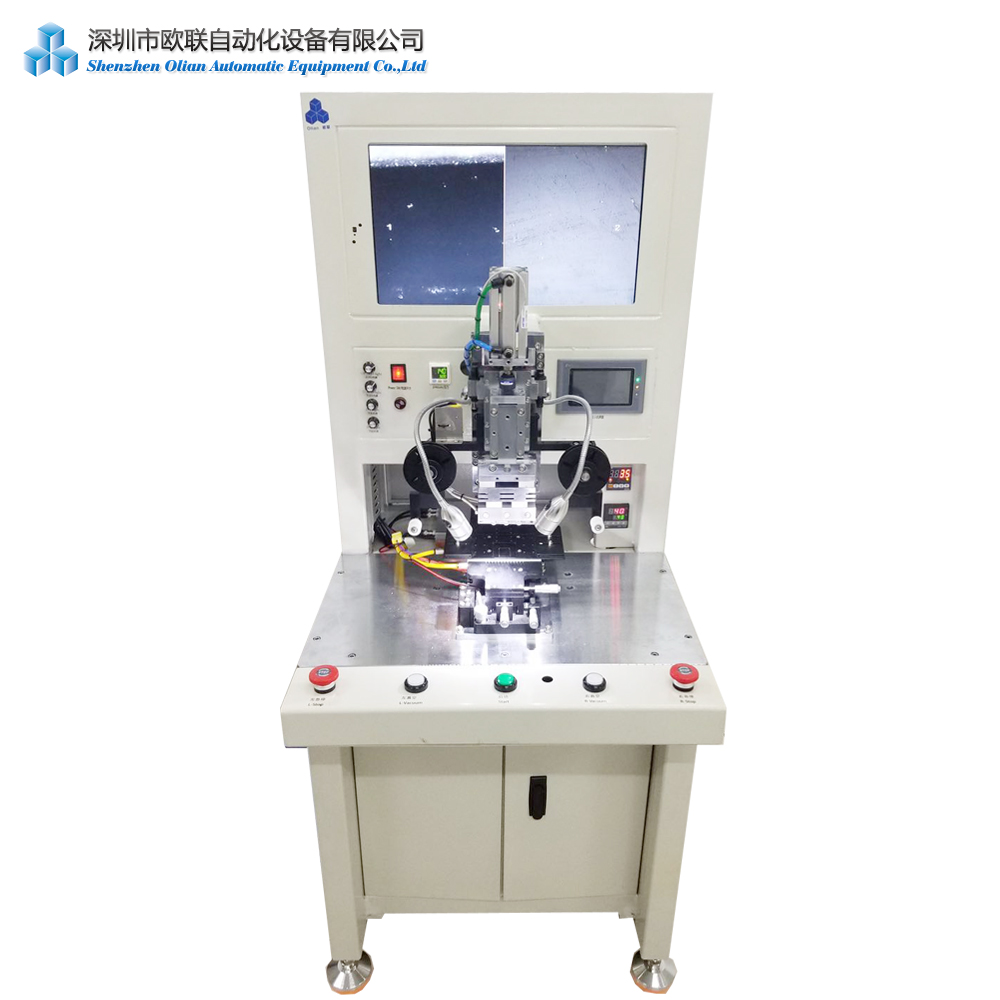

we use the FOG pulse heating bonding machine as the COF Pre-bonding machine. FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. we have single station COF pre-bonding machine and double stations COF pre-bonding machine.

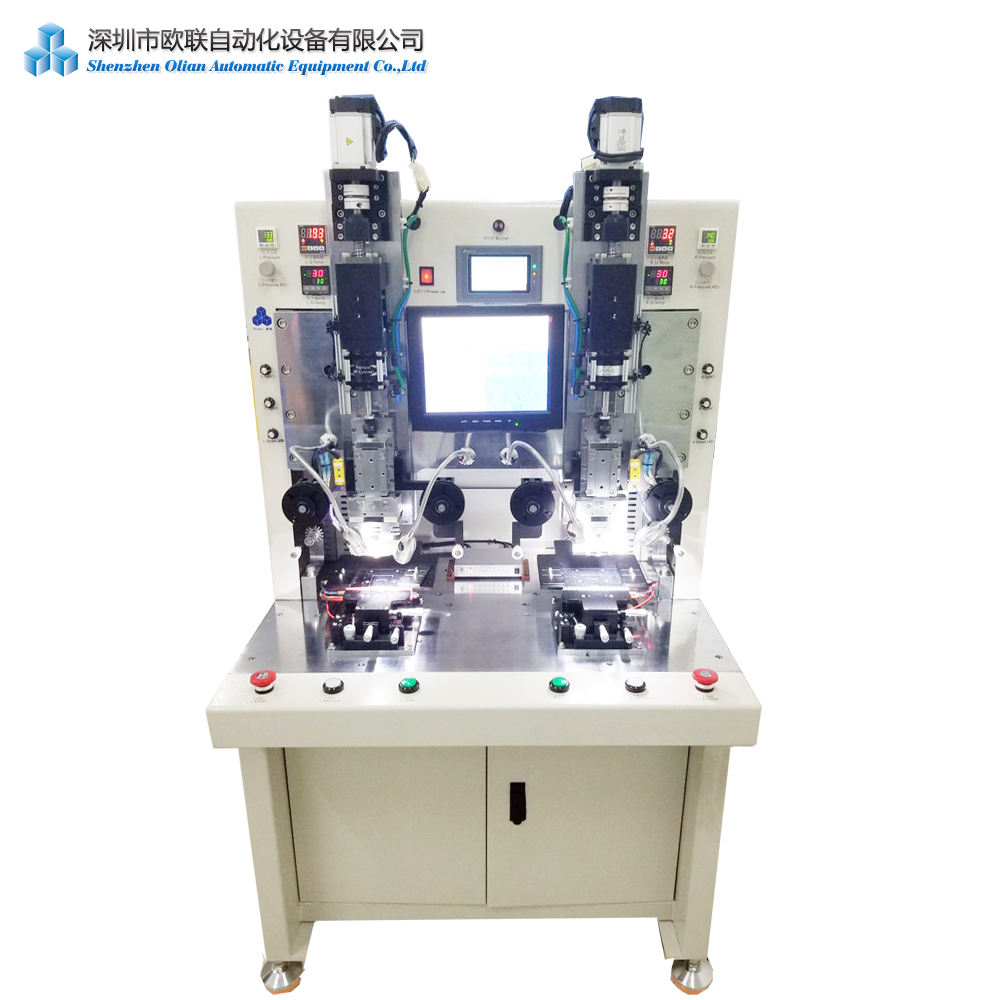

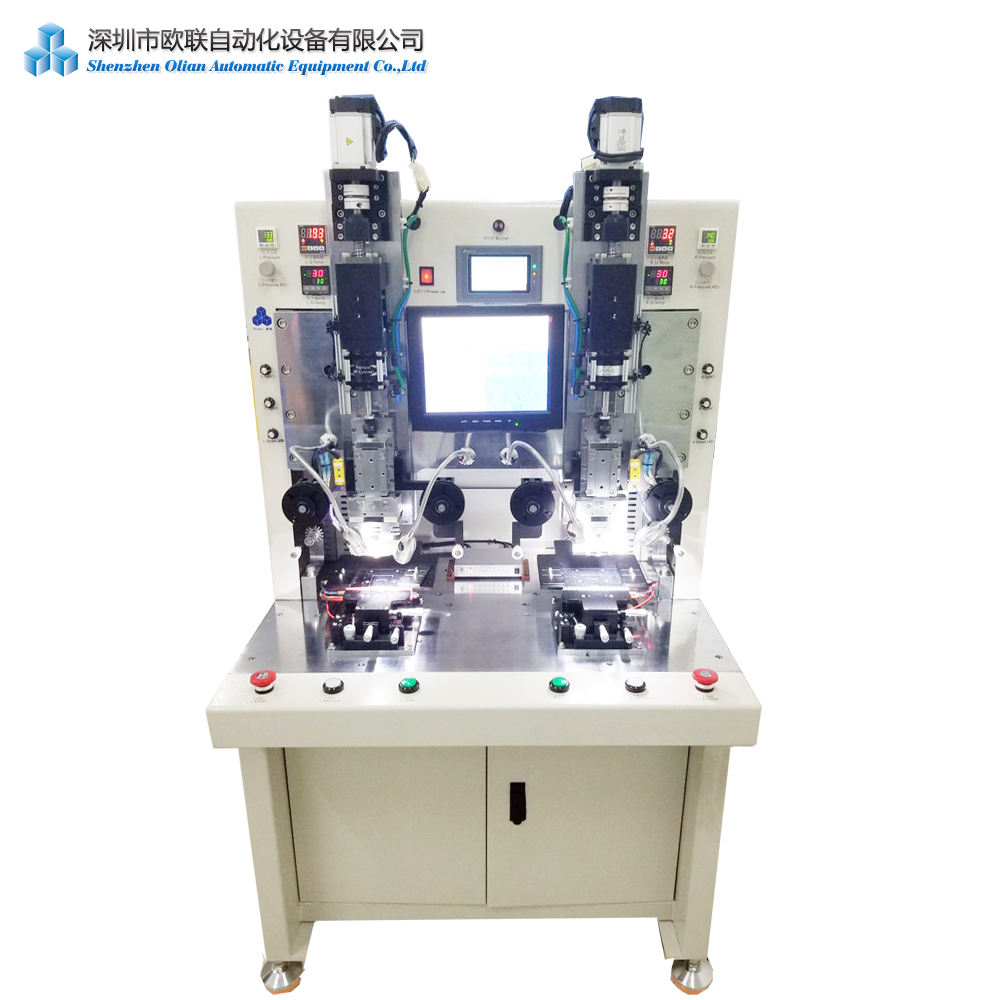

COF/COG final-bonding machine, COF/IC Final-Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC/COF will be bonded onto the glass. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.The COF bonding ,use this servo main-bonding machine.

ACF attaching machine+COF pre-bonding machine+COF final-bonding machine+FOG bonding machine

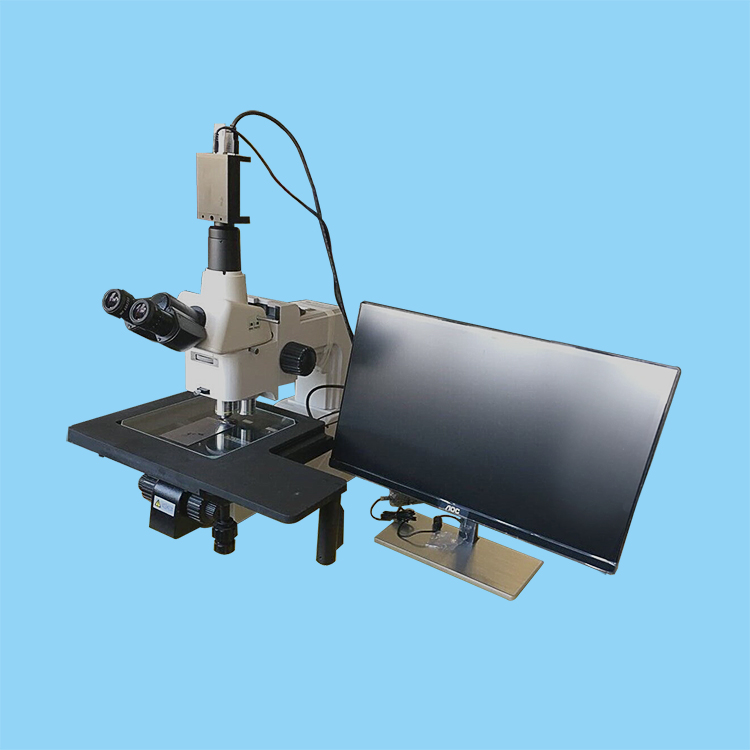

Differential interference microscope+COF punching machine+Plasma cleaner machine+other

COF screen / Flexible screen / Edge/Curved screen / OLED screen professional bonding machine factory – shenzhen olian.

Shenzhen Olian Automation Equipment Co., Ltd. is a national high-tech production enterprise focusing on the R&D, manufacturing, sales and service of FPD flat panel display and 3C automation equipment automation equipment. Has won state-level high-tech enterprises and a number of research and development patents and copyrights.

At present, the company has nearly 50 professional R & D, production management, quality management, after-sales service professional team, the company has a precision CNC machine plus center (precision CNC, lathe, milling machine, grinding machine, two yuan and other production equipment), with product design To the overall manufacturing capacity of production and processing. Since its establishment, it has become a well-known LCM complete line automation equipment solution provider in the industry with its exquisite technology, high quality and efficient after-sales service.

Existing products mainly include: ACF attach series, Plasma terminal cleaning series, single and multilateral COG/COF bonding series, single-stage and single-sided multi-stage FOG/FOF bonding (constant/pulse) series, OGS/On Cell/In Cell hot press series, OLB bonding series, COF blanking all kinds of non-standard equipment and intelligent factory overall solutions.

Our company has the earliest domestic technical team to develop equipment in the field of FPD flat panel display. In order to make technology always innovate and break through, we have established long-term special cooperation with Zhejiang University Shenzhen Research Institute, and have developed and achieved breakthrough results in a number of key technologies. At present, the company’s products are mainly used in multiple fields such as full screen, OLED, LCM, and BLU.

Now with Skyworth Group, Dijing Optoelectronics, Chongqing Zhongguang, Shenzhen Guoxian, Tianshan Microelectronics, Lide Communications, China Optoelectronics Technology, Yashi Optoelectronics, Zhongshan Guoxintong, Tuojia Optoelectronics, Kesen Optoelectronics, Wentai, Dejing More than 200 well-known companies at home and abroad, such as Freda and Guanghong, have established long-term friendly cooperative relations.

Products cover more than 20 provinces and cities in Guangdong, Guangxi, Jiangsu, Zhejiang, Jiangxi, Liaoning, Hunan, Hubei, Fujian, Chongqing and other countries.

Our aim is “quality first, technological innovation”. We advocate the management policy of “integrity management, seeking truth from facts, mutual benefit and common development”. We are constantly pursuing perfection and striving to do better. Determined to become a representative company in the industry!

LCD bonding machine, widely used in the Phone/TV/Watch/Touch panel products produce and repairing area.

LCD Liquid crystal display (LCD) is LCD panel that is widely used in mobile phones, LCD, LCM and other production processes. Is composed of two glass sheets laminated together, the middle is LCD, the lower plate is TFT circuit, the board is RGB and subsidiary structure, Glass is called a glass substrate when the lcd production, which not been cut is called Glass, a process finished cutting called CELL.

LCD GLASS can be divided into TN, VA, IPS, CPA and many other types. Can largely determine the brightness of the LCD display, contrast, color, viewing angle and speed the development of LCD panel soon , the part of LCD panel with liquid crystal displays are very closely linked, its production and market environment, the pros and cons variety of factors related tothe quality of the liquid crystal display , price and market trends, as an LCD display for about 80 percent of its costs are concentrated in the panel.

LCD panel used in digital watches and clocks, and many display type of portable computer.LCD display to use two pieces of polarized materials, is a liquid crystal solution between them.Current by rearranging will make the liquid crystal, so that the light can’t through them.As a result, each crystal is like a shutter, both can allows light to pass through and can block the light.

Liquid crystal display (LCD) technology information Towards the target OF thin, short, small development, display with a long history in computer peripheral products, of course, is no exception.Under easy to carry and transport for the former title, the traditional way of display, such as the CRT image tube display and LED display boards, etc., are subject to the volume is too large or giant factors such as power consumption, unable to reach the user’s actual demand.And the development of liquid crystal display technology is to the current trend of the information goods, whether it is right Angle display, low power consumption, small volume, or zero radiation, etc, can let users enjoy the best visual environment.

Application in the resistive screen, touch screen, capacitance composite and LCD screen, Lens and Lens laminating, LCD, LCM, OCA laminating, soft on soft joint, ITO film, PMMA, PC, PET, glass, electronic paper, projection screen assembly, display assembly, Lens assembly, G + F +F resistive touch screens, F + F, capacitive touch screen, panel, ICON, and other related electronic.

According to the different bonding materials, the bonding machine can be divided into different bonding machines.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, also name FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

Semi Automatic LCM Making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

LCD bonding machine

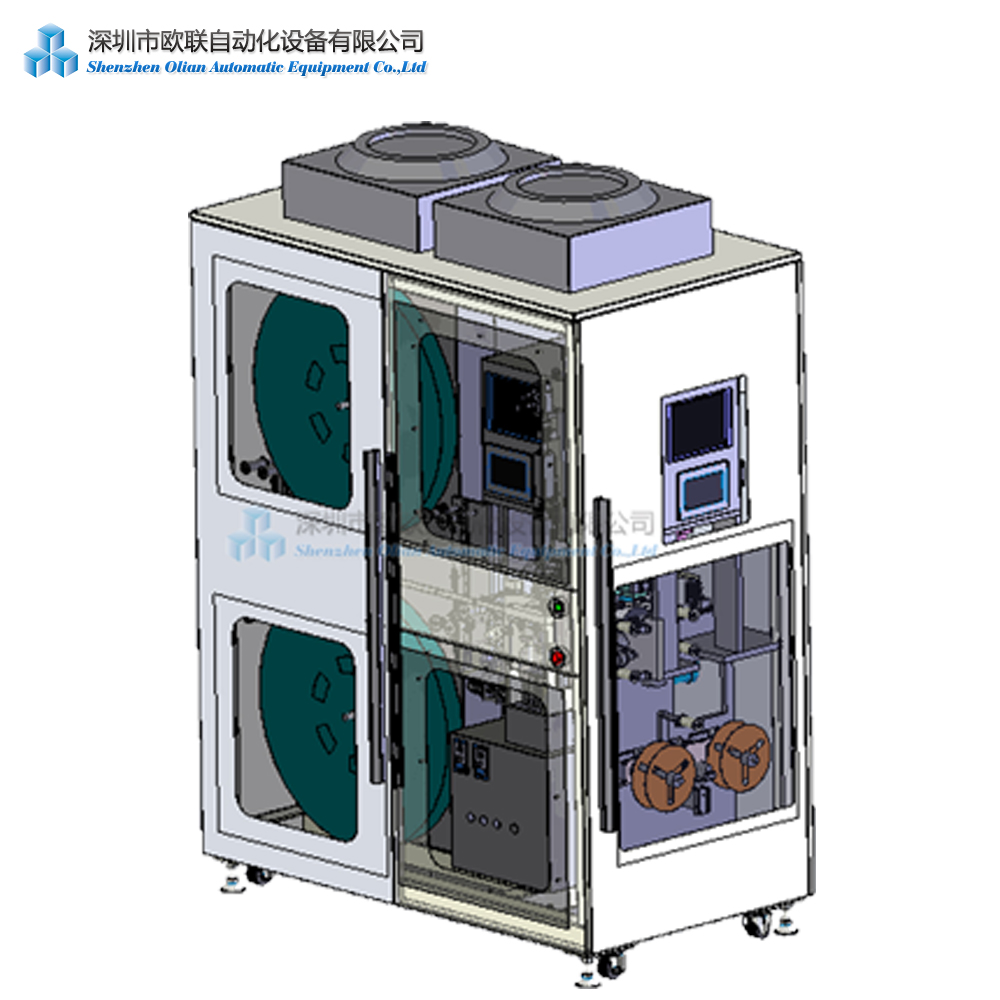

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonding machine, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce machine include all the process of the COG and FOG bonding machines.

We design and make the standard bonding machines and customized bonding machines for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Please contact us feel free to purchase the COF bonding machine accessories.

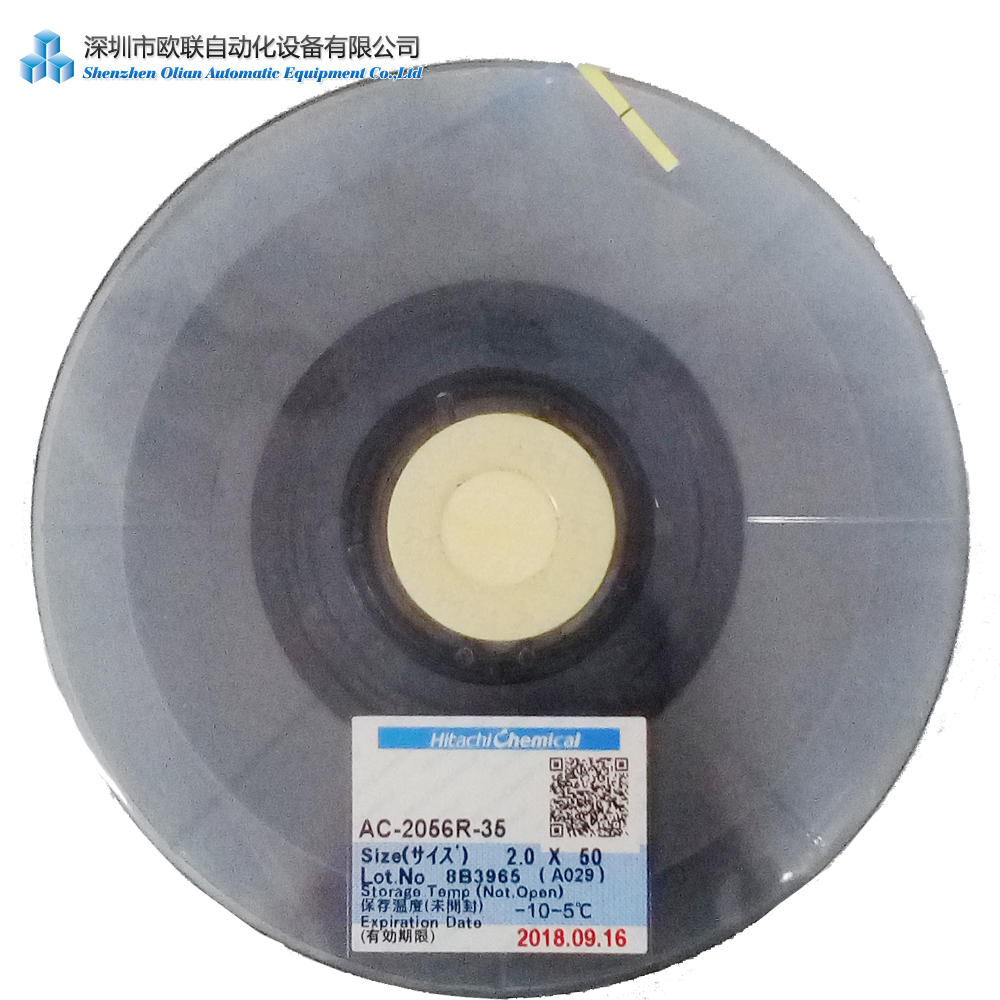

ACF Tape is normally made up of two main components, namely Adhesive & conductive particles.

Adhesives

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

ACF Conductive Particles

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF TAPE

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

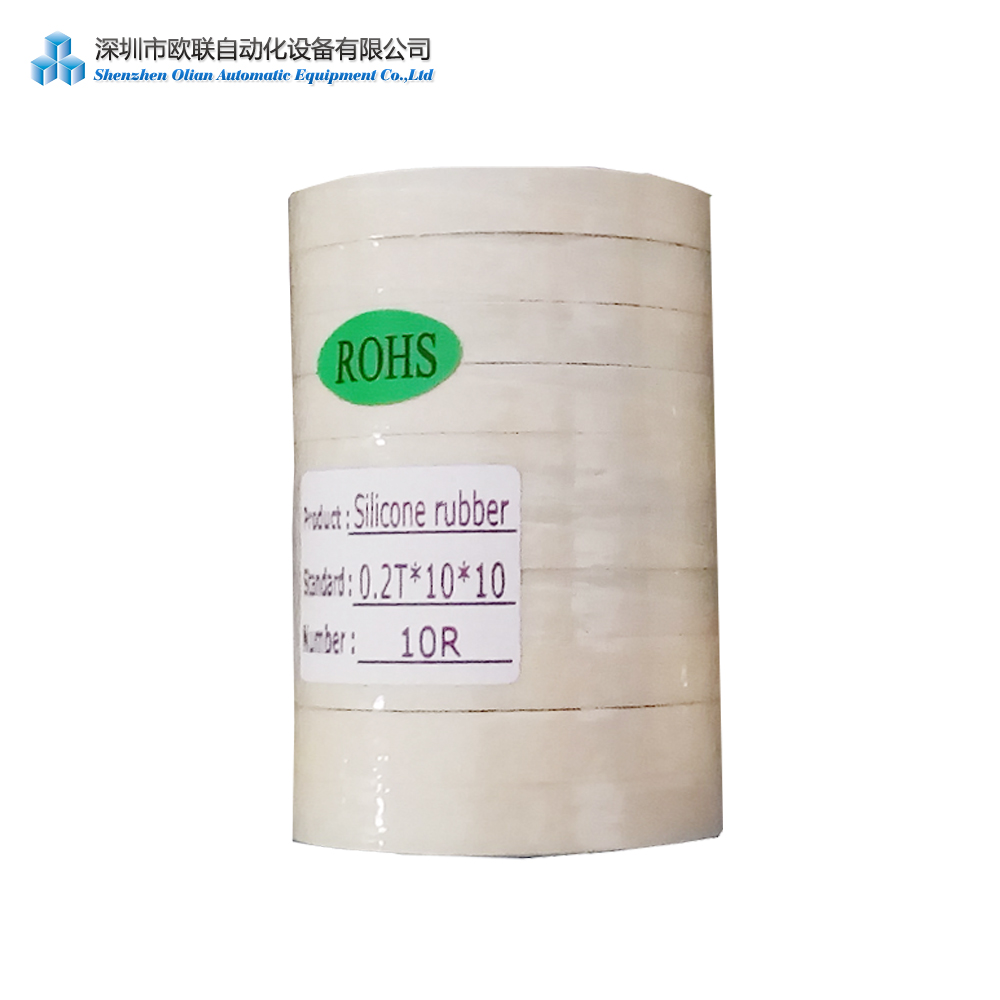

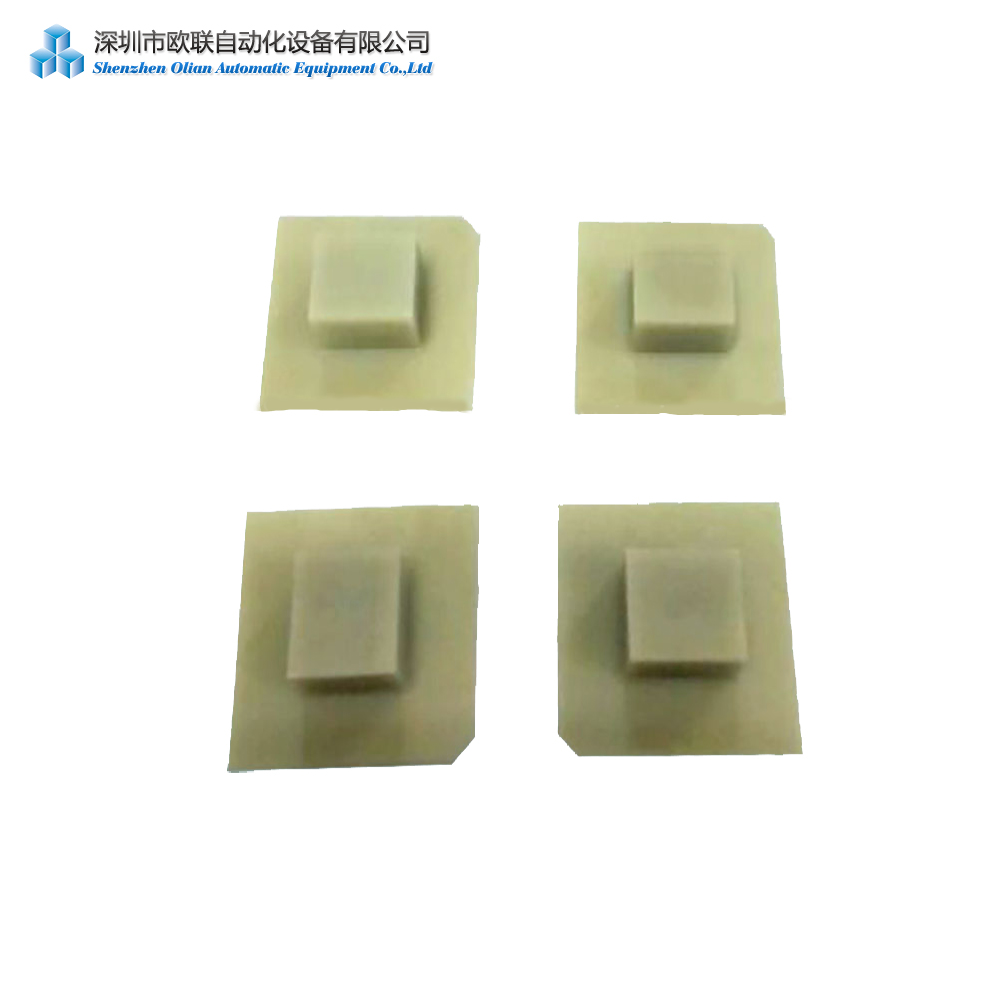

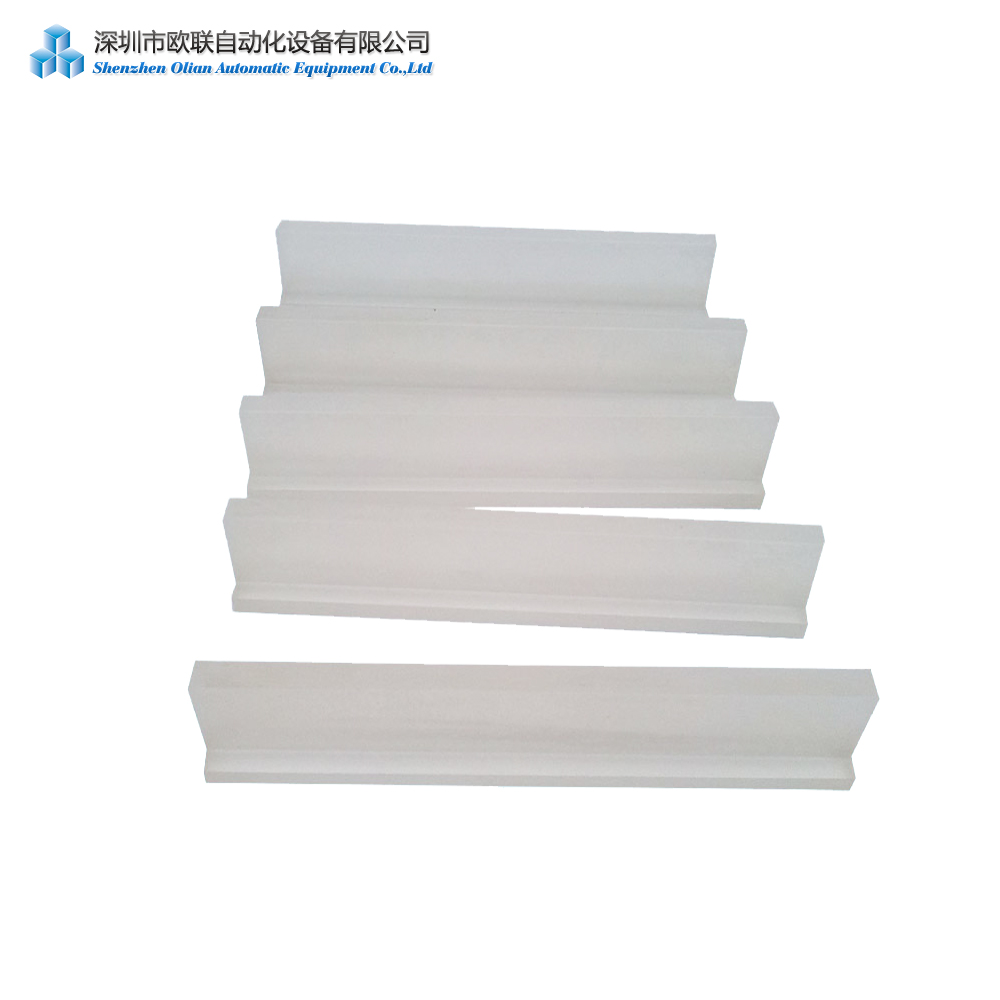

Similar to Silicone rubber, Teflon tape is often used to provide evenly distributed pressure and temperature on the ACF bonding process.

Features of Teflon Tape :

ACF REMOVER G450/G550/G650/G750

ACF Remover is a solvent designed to removed hardened ACF during rework of LCD module assembly. have many model number as: G430,G450,G550,G650,G750

ACF Remover Removing Process :

Buy machine, send all the accessories free.

| 1 | COF bonding machine |

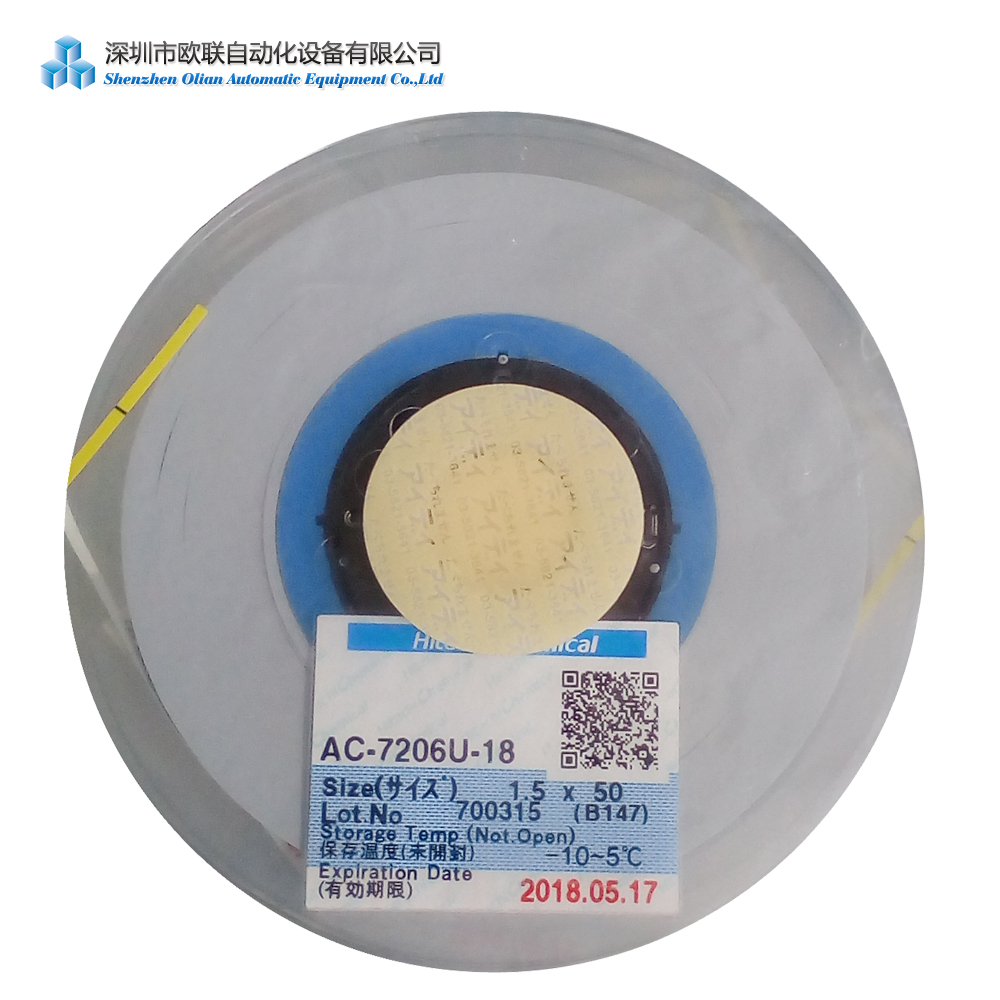

| 2 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 |

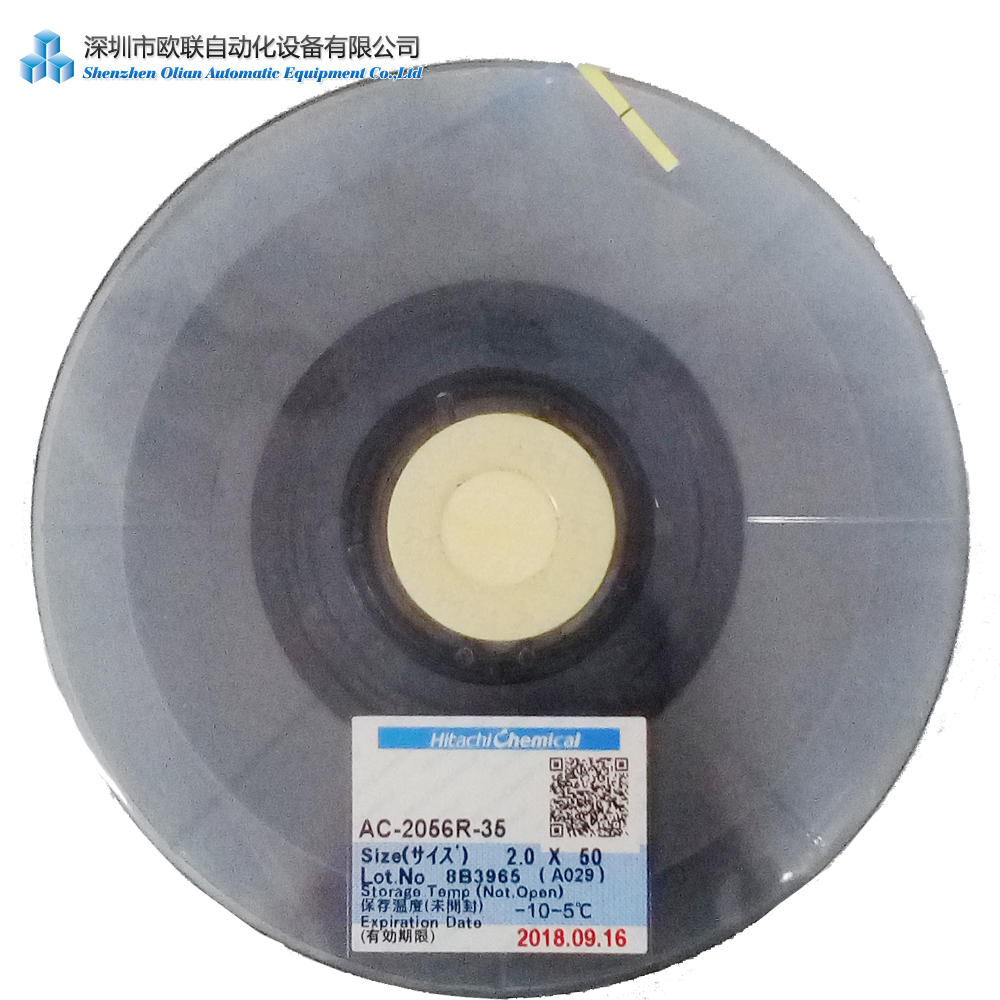

| 3 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 |

| 4 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 |

| 5 | Acetone Liquid BT-H1-500ML 丙酮 |

| 6 | Hitachi Blue Glue 100ML 蓝色胶水 |

| 7 | Fuji Silicone 50M 硅胶皮 |

| 8 | Teflon 50M 铁氟龙 |

| 9 | Alcohol 酒精 |

| 10 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 |

| 11 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 |

| 12 | Optical Microscope 显微镜 |

| 13 | TAB Cutter COF切刀 |

| 14 | Correction table 校正表 |

| 15 | LVDS LVDS接头 |

| 16 | LCD Test Board LCD测试板 |

| 17 | Allen Key 六角扳手 |

| 18 | Air Compressor OTS550 空压机 |

| 19 | Static Wipe Cloth 静电擦拭布 |

| 20 | Cotton swabs 棉签 |

| 21 | Handheld Magnifier 手持放大镜 |

| 22 | Precision Tweezers 精密镊子 |

| 23 | Nano Sponge 纳米海绵 |

| 24 | quatz bar spare one 备用石英条 |

| 25 | Alcohol bottles 空酒精瓶 |

COF bonding machine accessories

Welcome to buy the COF bonding machine and all the COF bonding machine accessories.

OLED panel bonding machine, is for AMOLED panel produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the OLED panel and flexible FPCs.

An organic light-emitting diode (OLED) is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and PDAs. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row (and line) in the display is controlled sequentially, one by one,whereas AMOLED control uses a thin-film transistor backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

The different manufacturing process of OLEDs has several advantages over flat panel displays made with LCD technology.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

Shenzhen Olian Automatic Equipment have the OLED bonding machine for AMOLED screens.

if you need the machine for the OLED screen repairing, please contact us .

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our OLED bonding machine.

LCD-bonding-machine

All the LCD bonding machines ,welcome you visit us-Shenzhen Olian(Professional in design&making all kinds of bonding machines)

OLED panel bonding machine, is for AMOLED panel produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the OLED panel and flexible FPCs.

An organic light-emitting diode (OLED) is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and PDAs. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row (and line) in the display is controlled sequentially, one by one,whereas AMOLED control uses a thin-film transistor backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

The different manufacturing process of OLEDs has several advantages over flat panel displays made with LCD technology.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

Shenzhen Olian Automatic Equipment have the OLED bonding machine for AMOLED screens.

if you need the machine for the OLED screen repairing, please contact us .

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our OLED bonding machine.

OLED-panel-bonding-machine

All the bonding machines ,welcome you visit us-Shenzhen Olian(Professional in design&making all kinds of bonding machines)

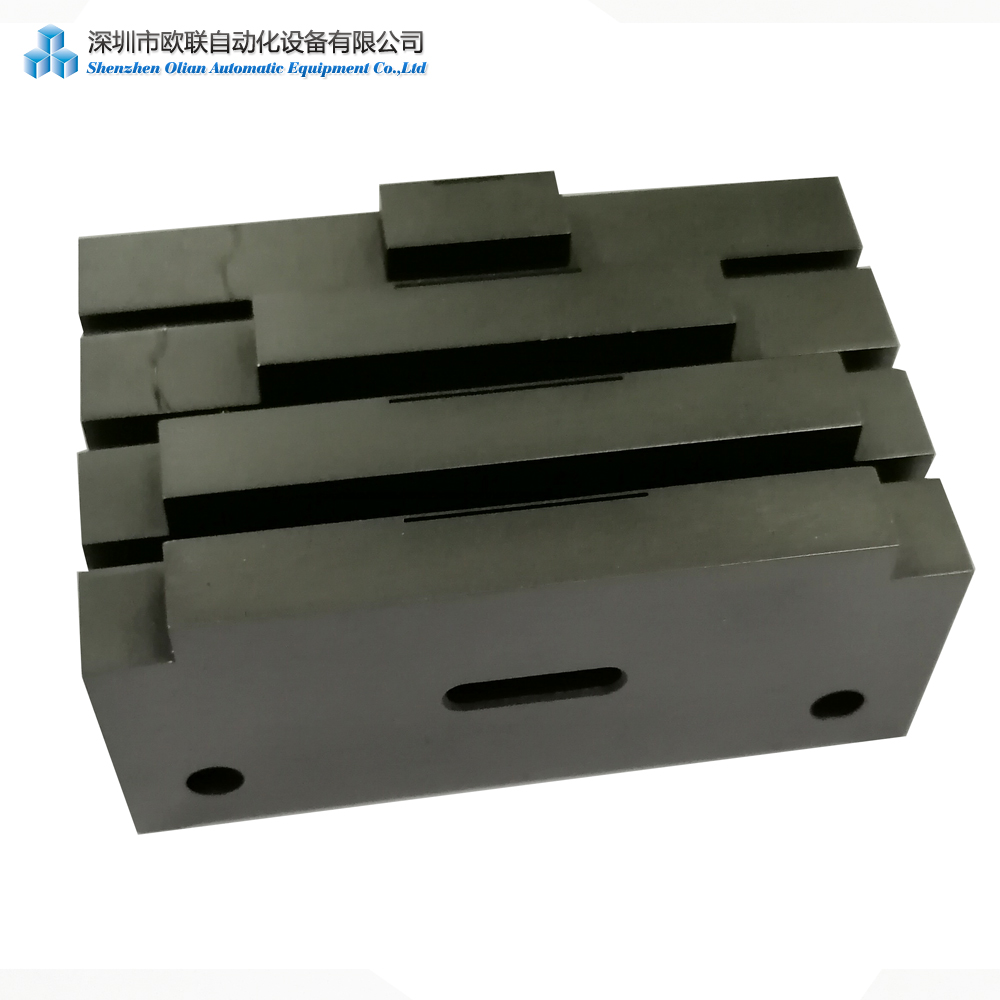

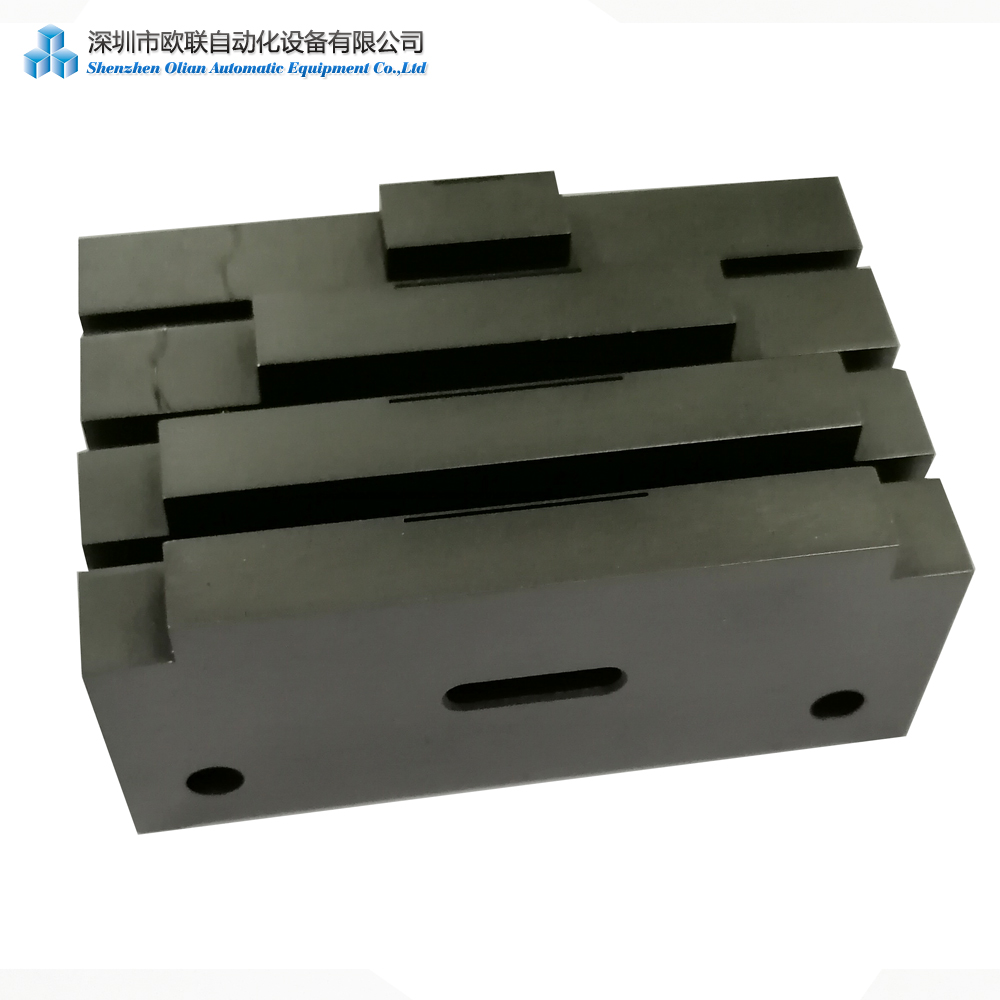

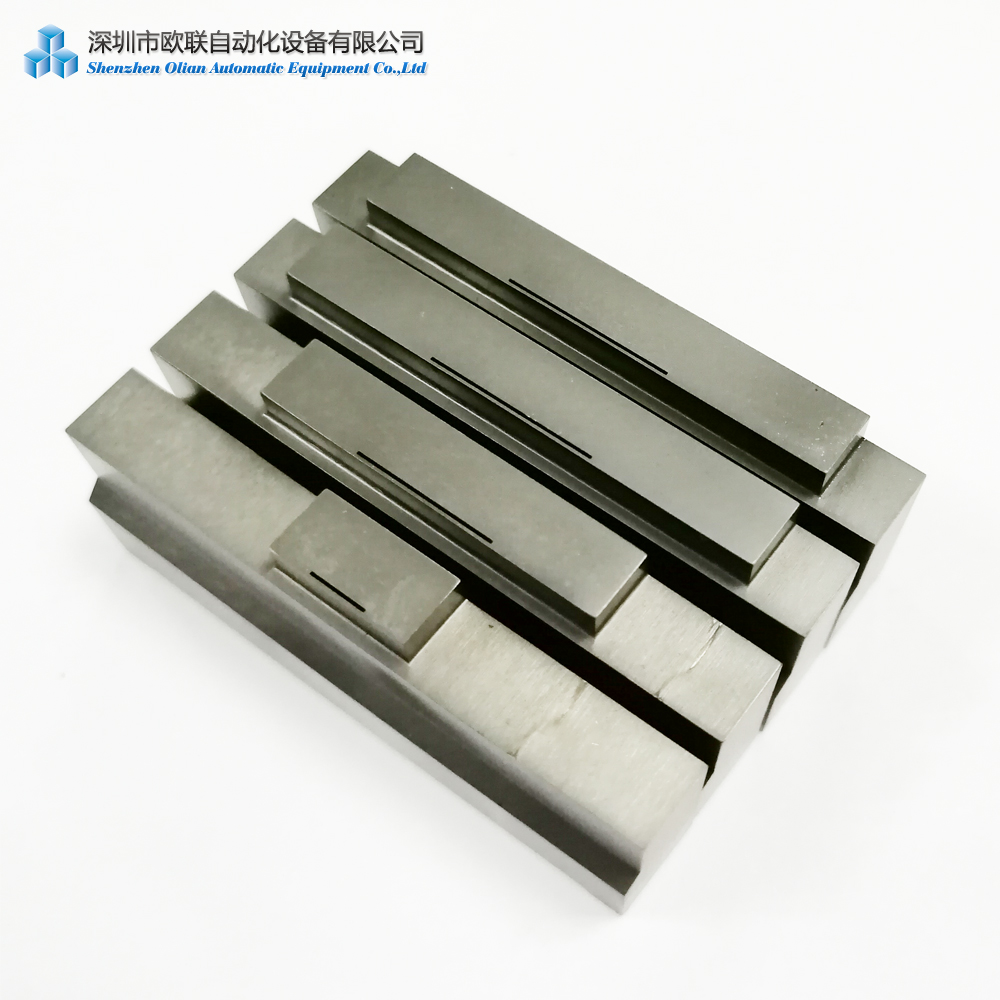

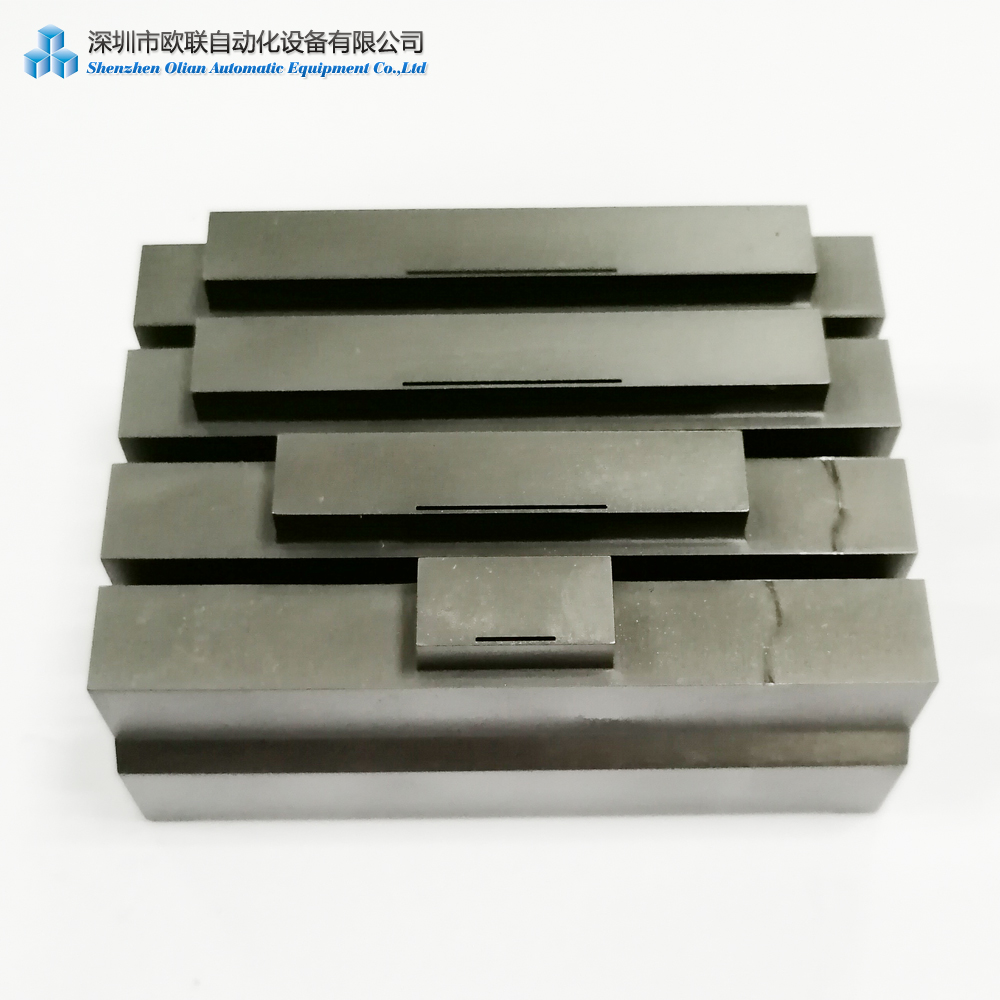

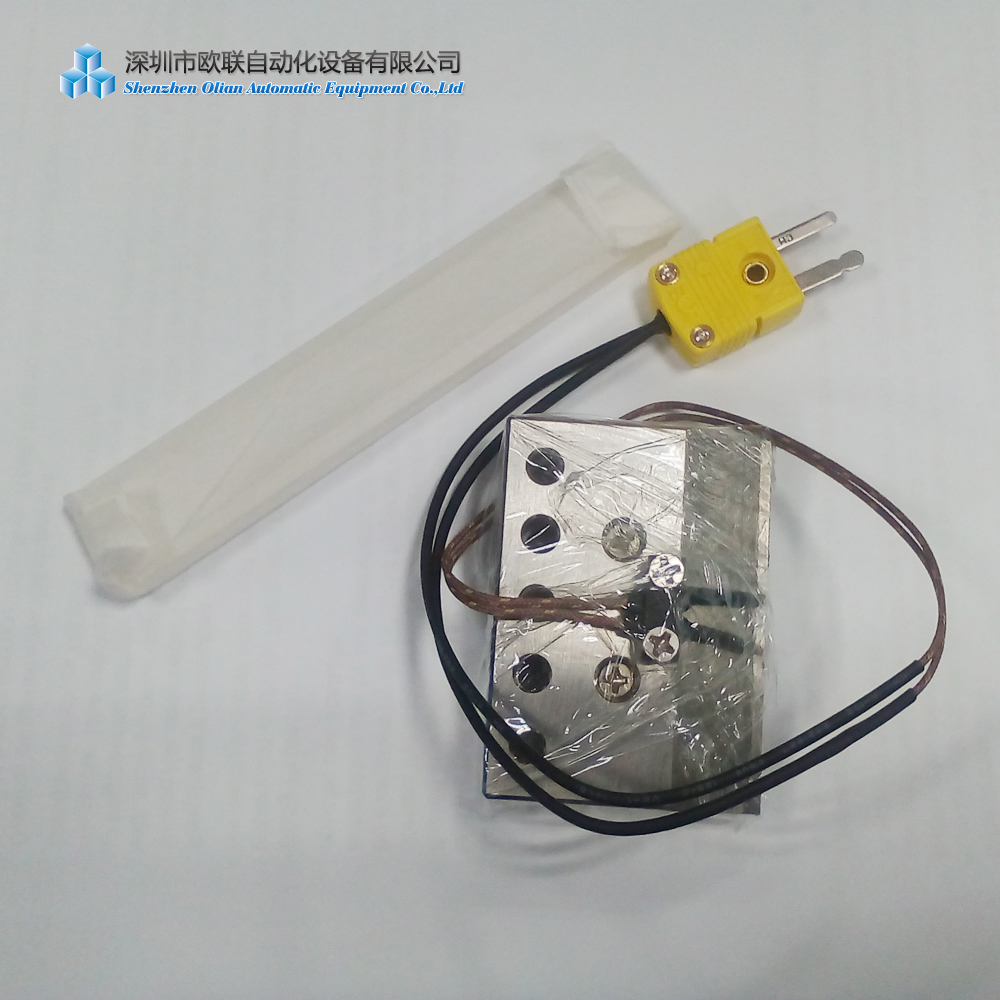

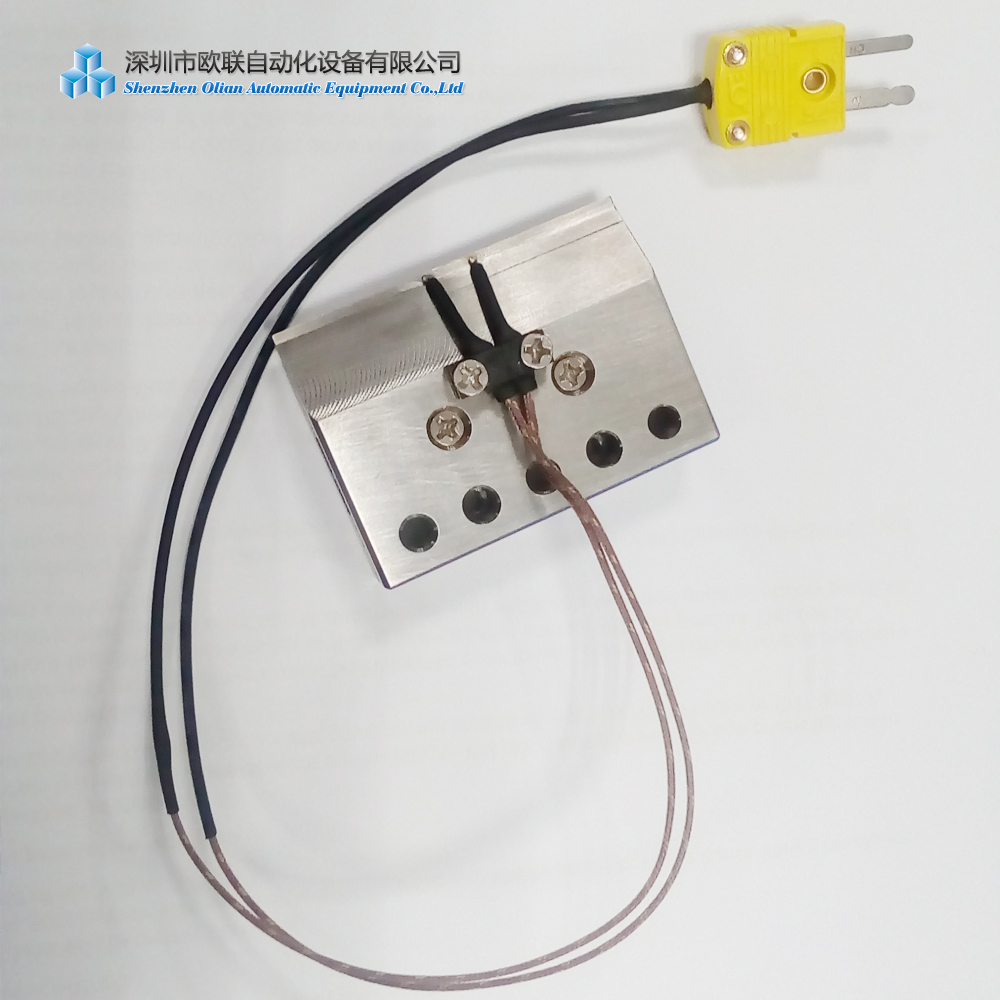

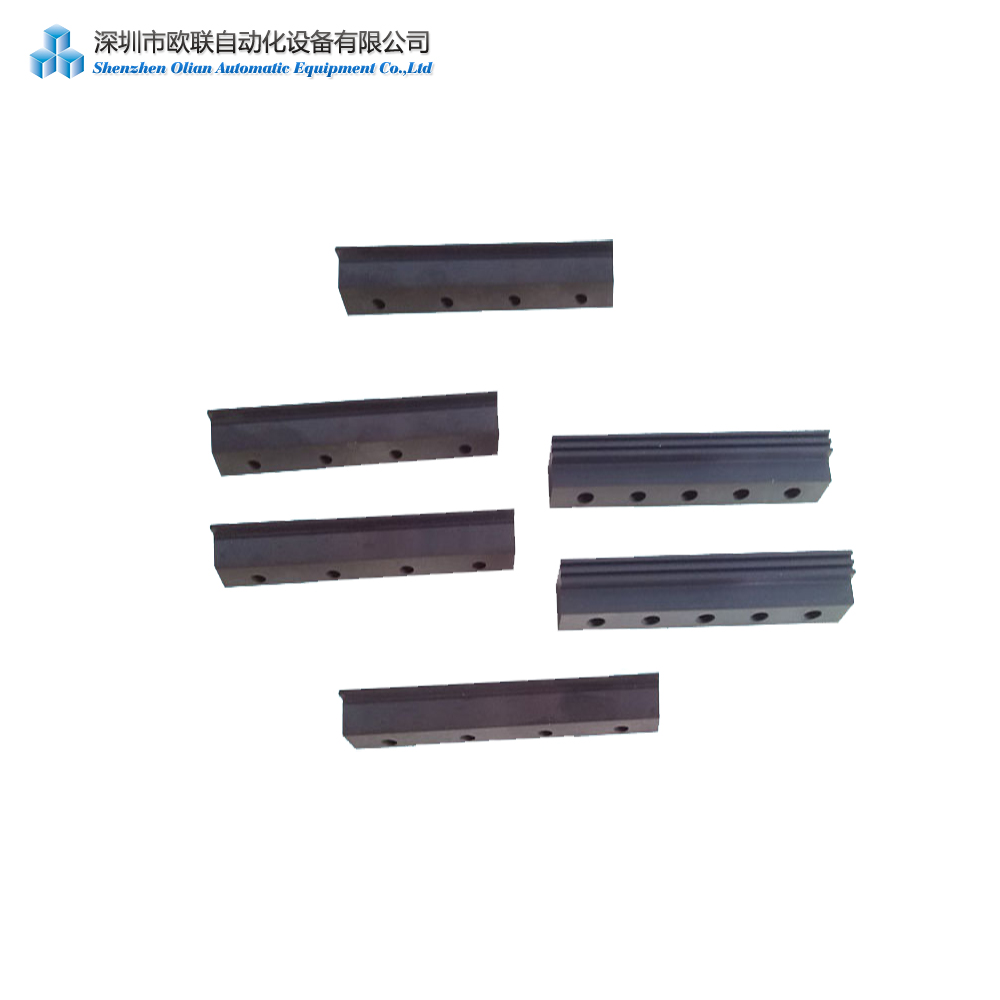

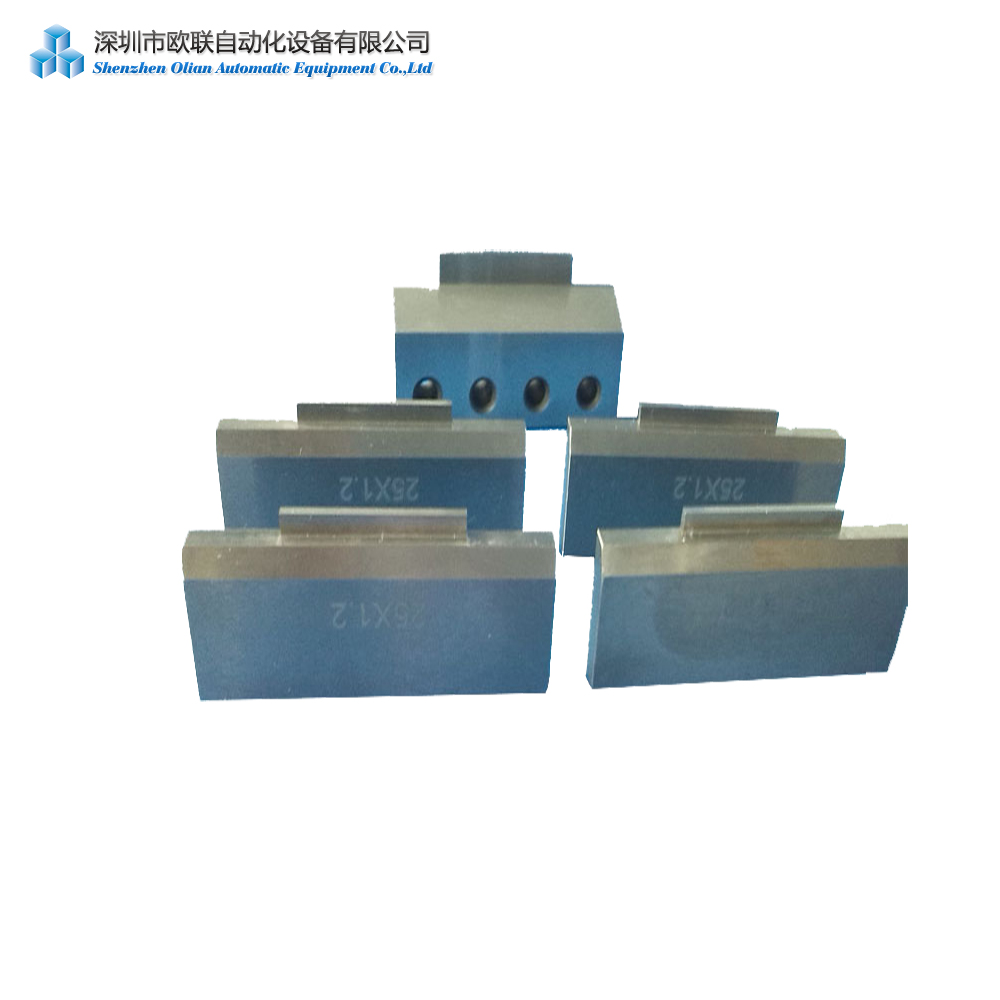

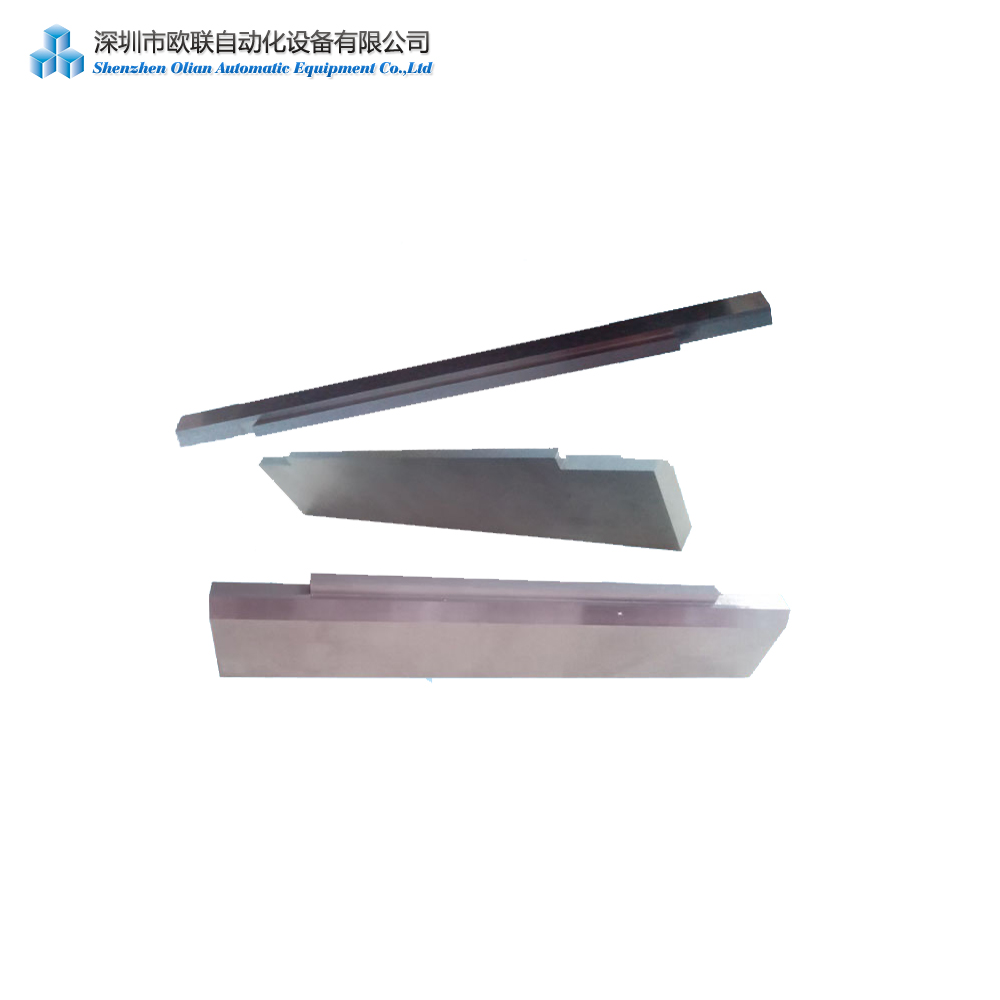

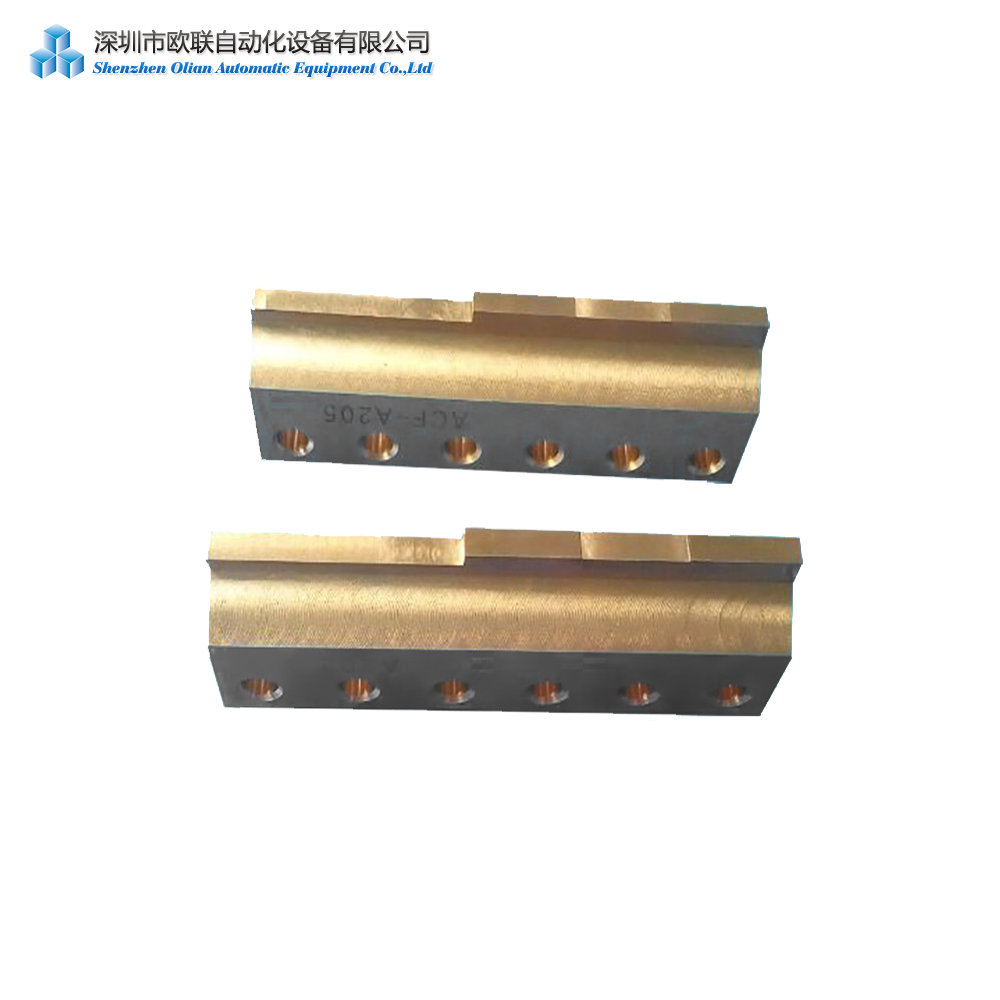

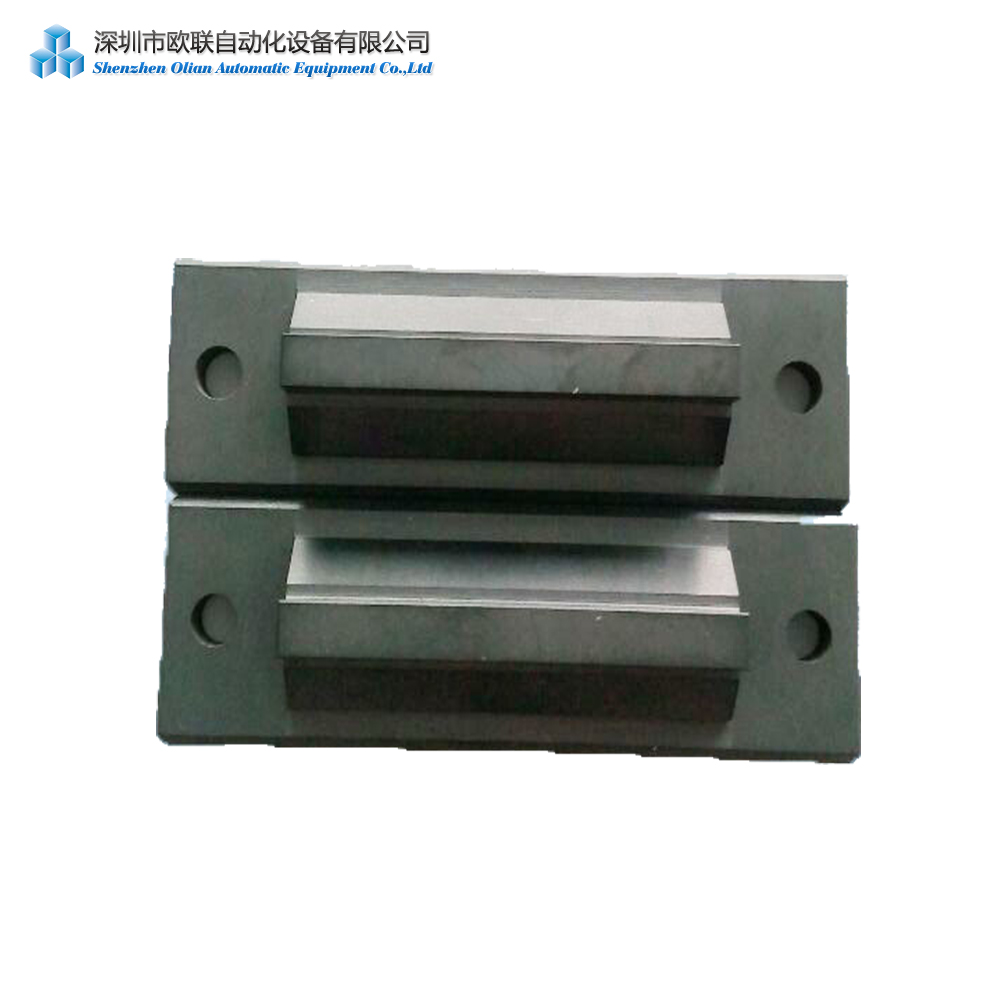

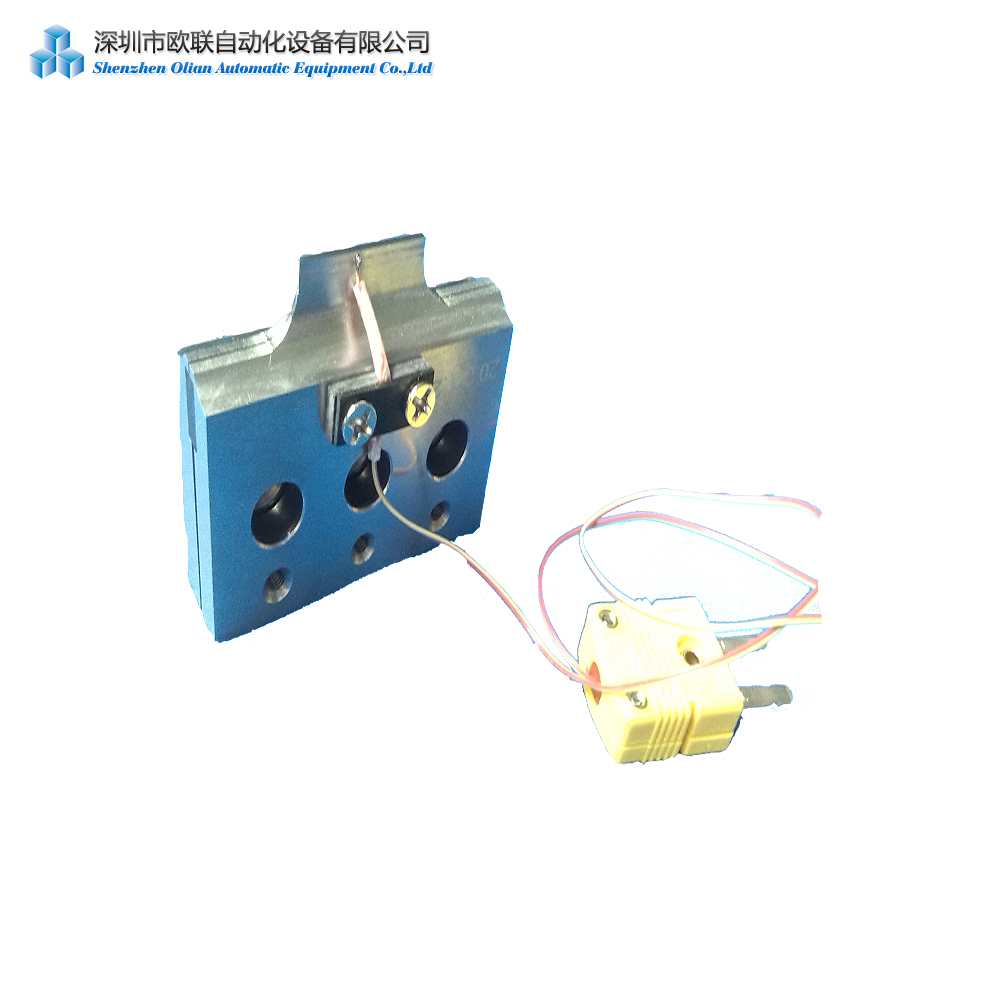

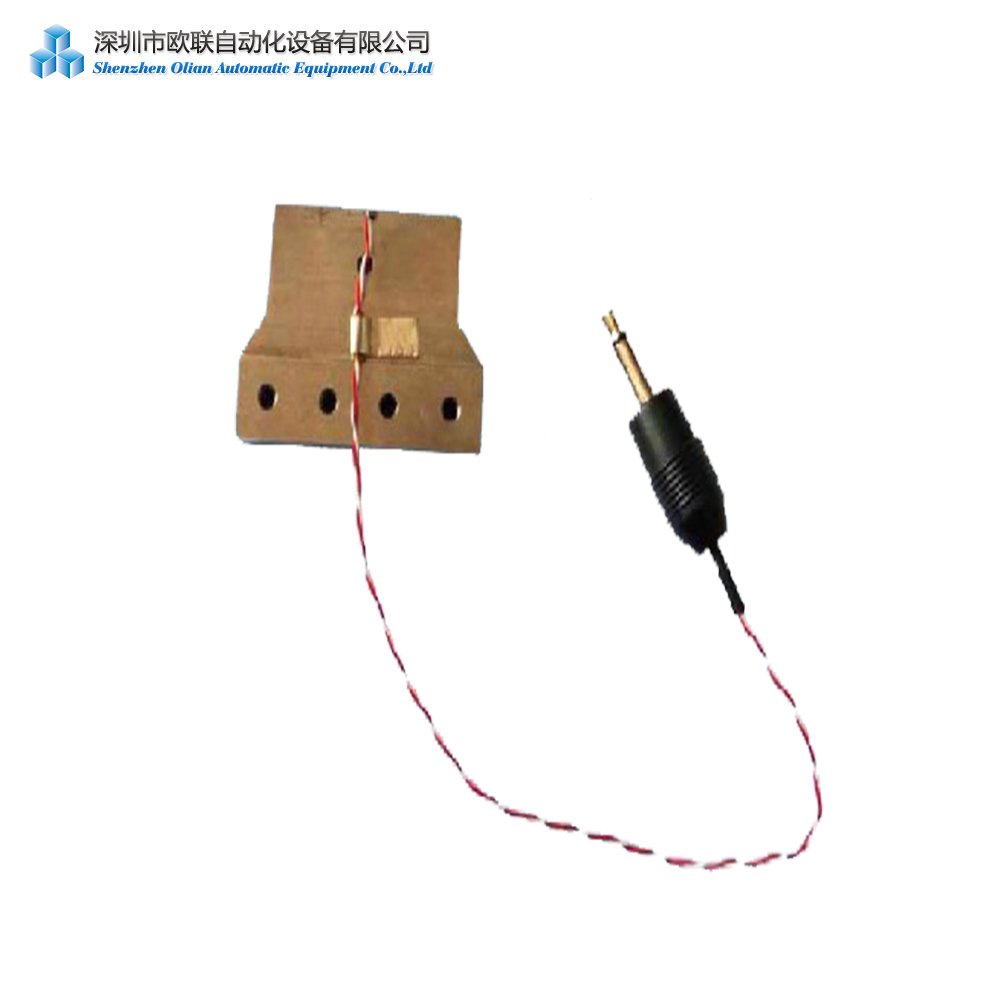

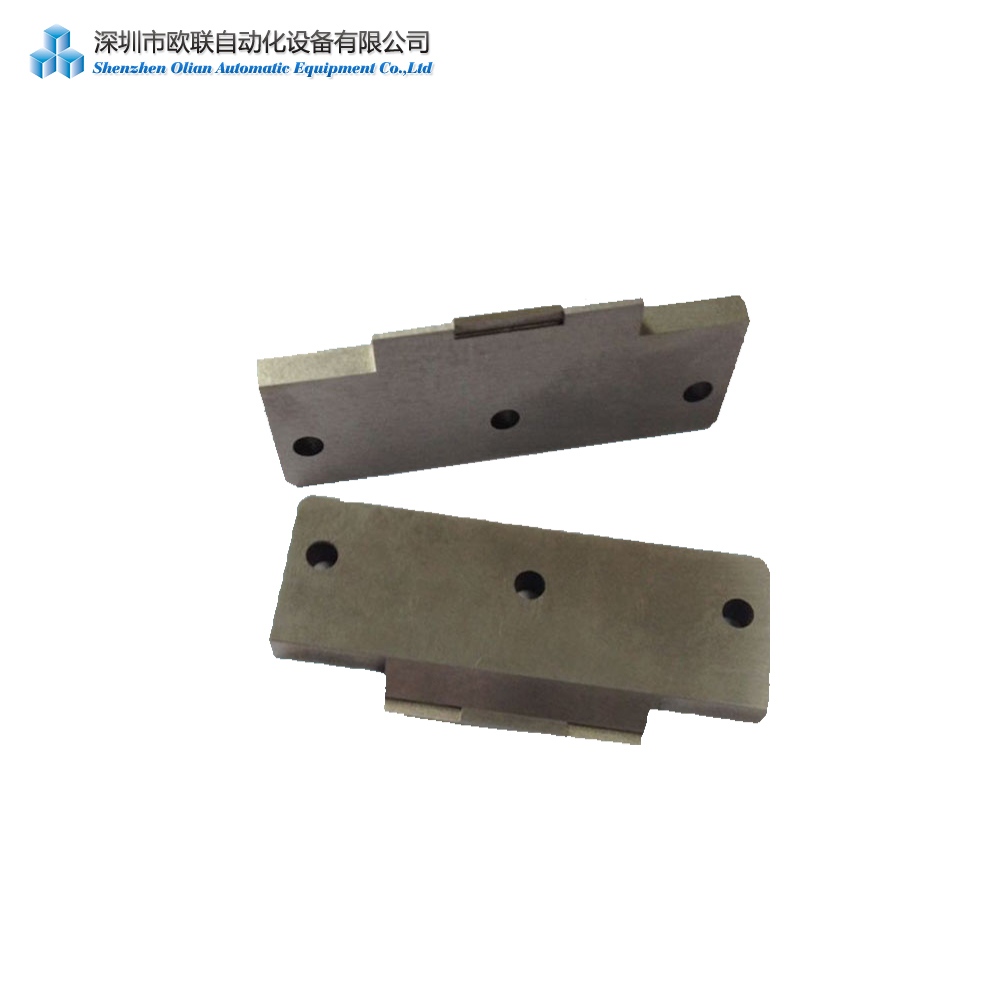

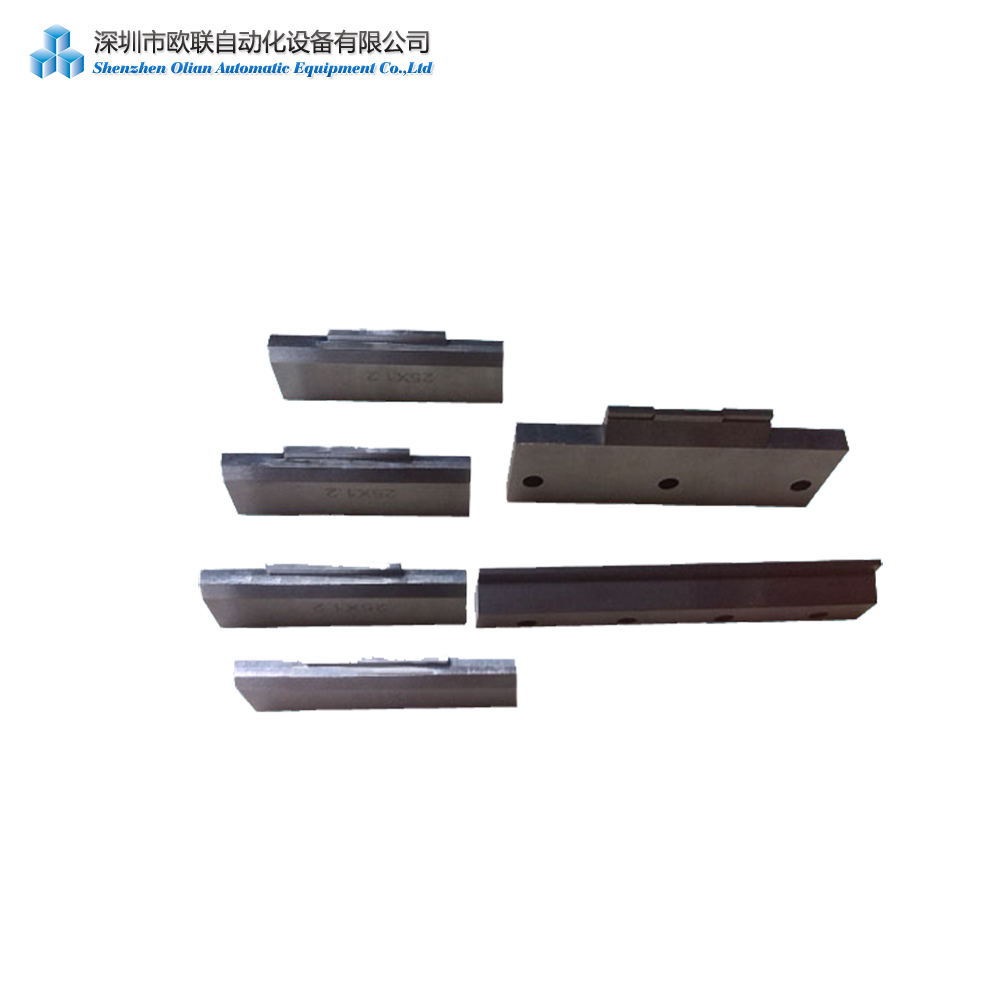

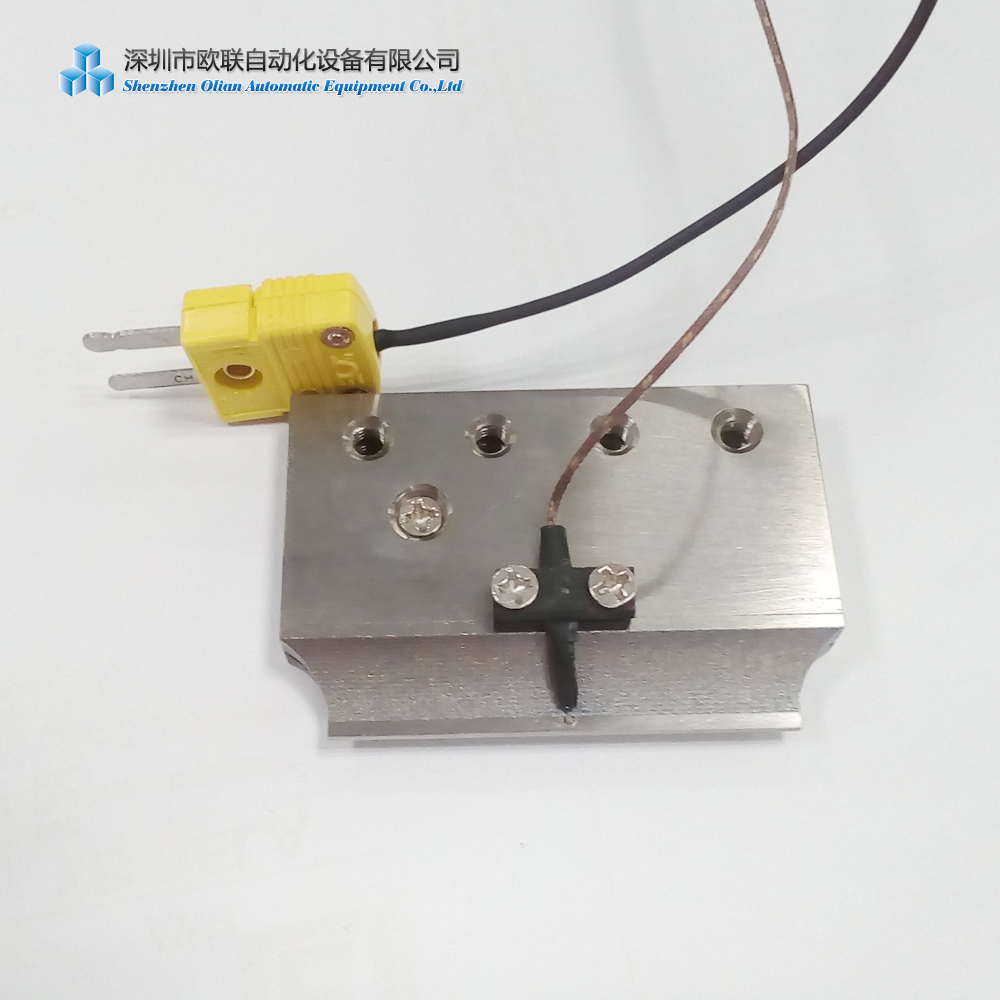

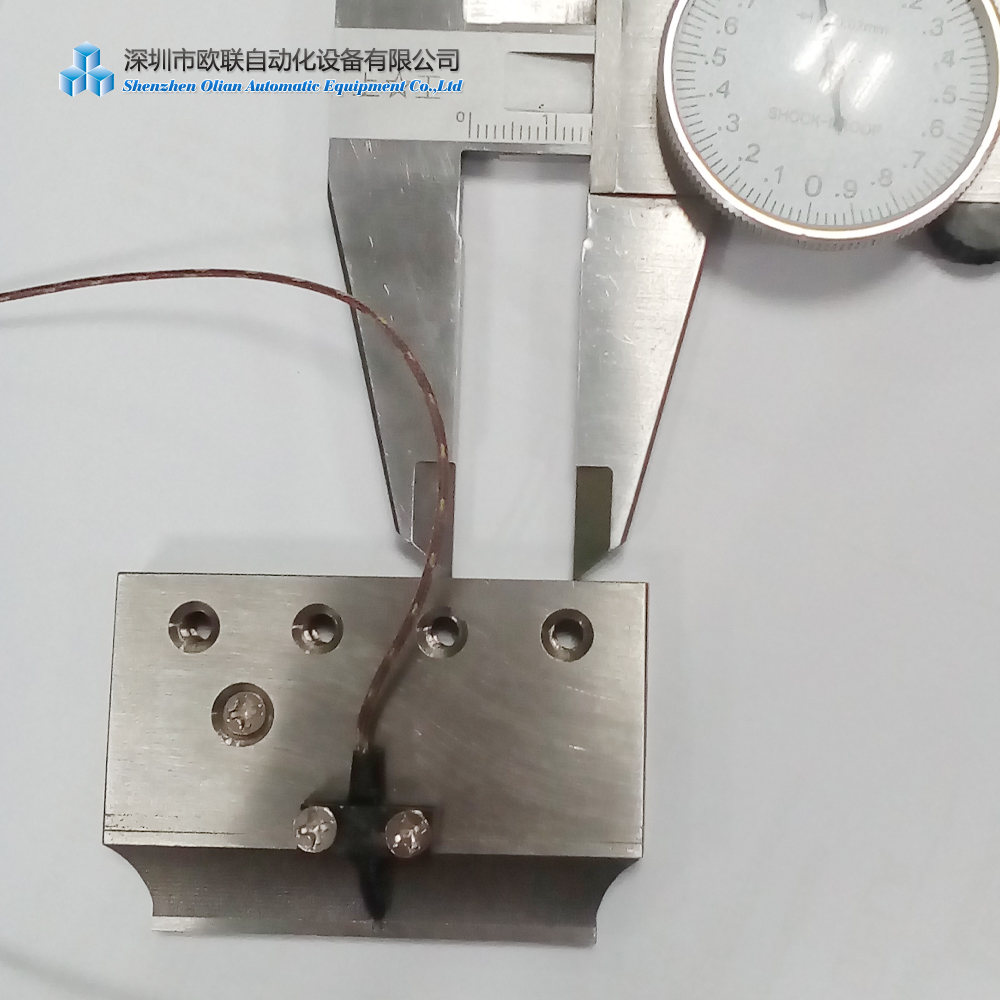

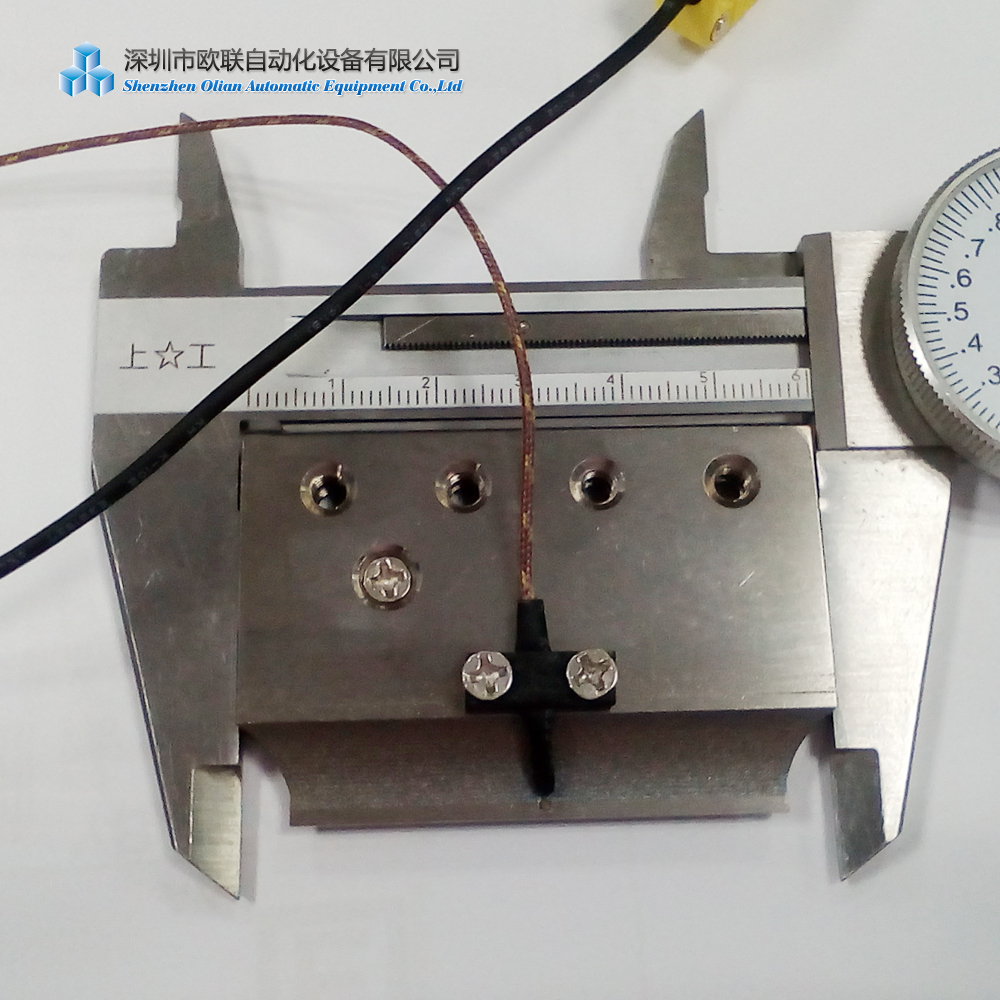

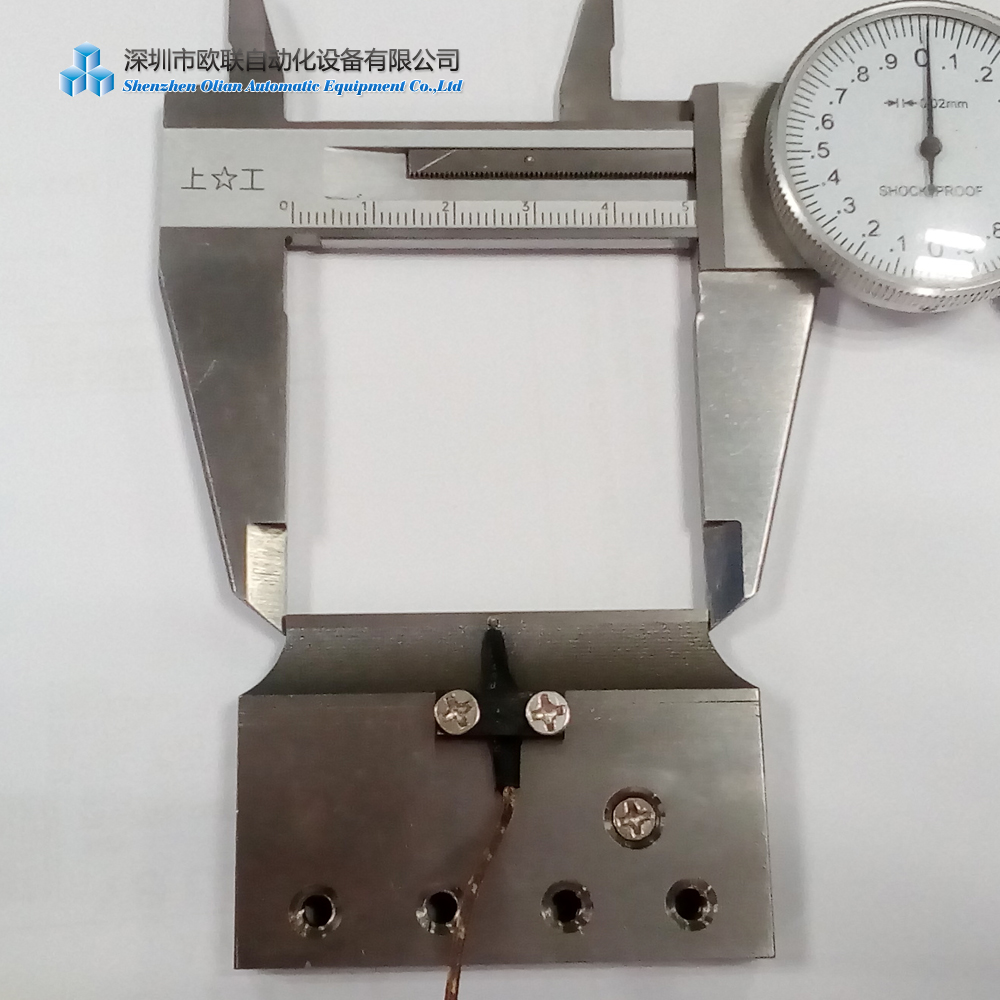

ACF bonding head also name:ACF/TAB/COF/COG/FOG/FPC/FOF Bonding machine press head /bonding tip/welding heads/ Hot Bar / soldering heads / heater tip / heater tools/ thermode for hot bar / ACF Bonding machine cutter head/bonding cutter/heat cutter……

It have pulse heating and constant temperature bonding head.

Normal materials:

-SUS440C steel(440C不锈钢)

-Tungsten steel(钨钢,钨钢(硬质合金)具有硬度高、耐磨、强度和韧性较好、耐热、耐腐蚀等一系列优良性能,特别是它的高硬度和耐磨性,即使在500℃的温度下也基本保持不变,在1000℃时仍有很高的硬度 )

-Titanium alloy (normal used in pulse heating bonding machine), (钛合金,脉冲压头一般用钛合金制作)

-Ceramic (陶瓷,一般用在COG压头)

-Brass (黄铜)

-and others.

It will be different sizes for different products, such as TV Panel/cell phone/Touch panel/camera/watch/ Heat Seal Paper/, every products have the different shapes and sizes, so we need to make the customized bonding head according to your products.

ACF Bonding head has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

-Heat cure

-Fast bonding time

-High adhesion to plastic PET,COF & FPC, substrate

-Excellent thermal stability

-Good contact resistance for reliability

-Good corrosion resistance

-Excellent chemical resistance

-Good for wide bonding temperature range

-Replaces solder for lead-free solution

Shenzhen Olian Automatci Equipment make all the ACF bonding machine heads/hot bar/welding tips……

Olian,is a high-tech enterprise established in 2008, specialized in R&D, manufacturing and sales of LCD/LED/OLED module automatic bonding machine (COG/FOG/ FOB/ACF/COF/OLB/TAB/FOF bonding machine)and all the parts,accessories(ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.)

Welcome you visit us.

Tel:+86-755-23209022 Fax:+86-755-23209033

QQ:2307972393

Mobilephone/WeChat:+86 18025364779

WhatsApp/Line: +86 18025364779

E-mail:olian@szolian.com

Address: Floor 5,Building D, Sogood Science Park, Aviation Road, Sanwei Village, Xixiang Town, Bao’an District, Shenzhen, China

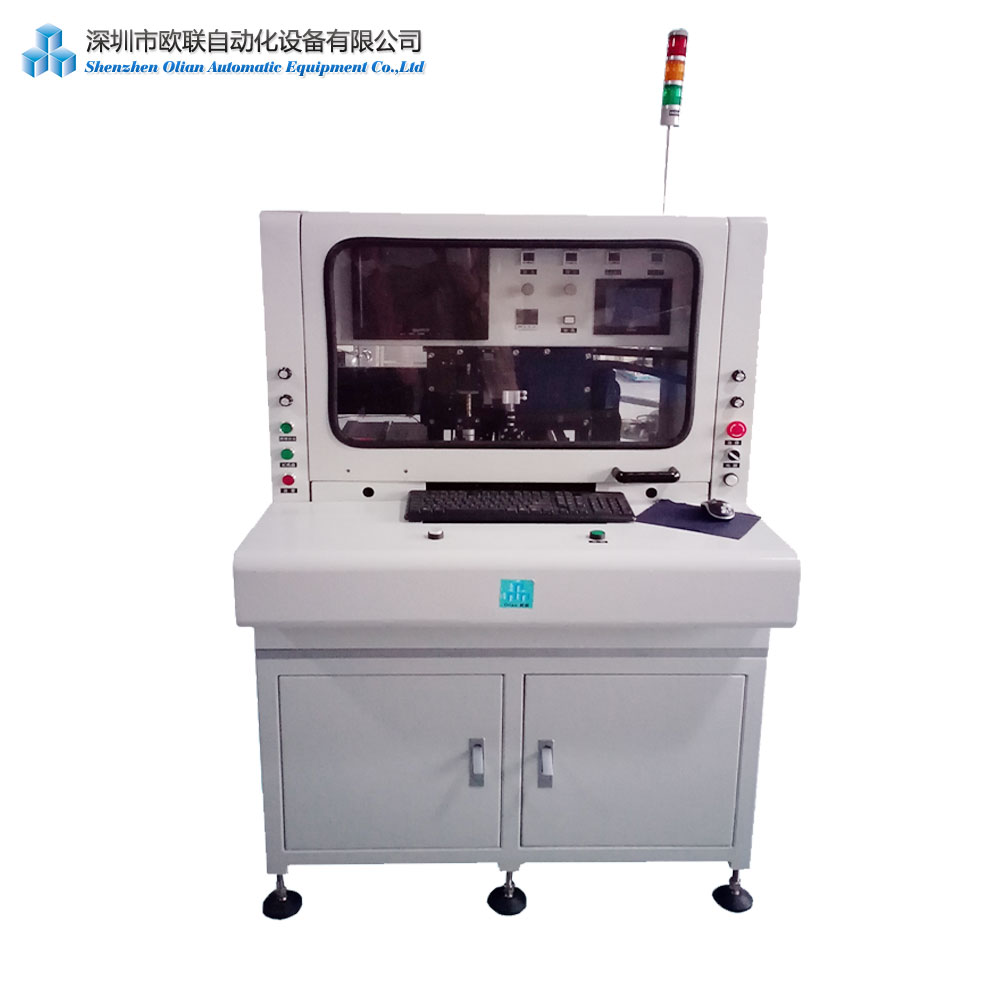

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COF(chip on film),COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. it has Pre-Bonding and Main-Bonding machines . They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations.

*Suitable for multi variety small batch production

*Constant temperature heating system

*Panasonic PLC Control system

*FAST Visual processing system

*Imported Japanese CCD Automatic Contraposition Configuration

*Manual / automatic switching

*Imported electrical configuration

Model: CP005/CP006

Product Name: Semi-Automatic Mid/High-speed COG Pre-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 650pcs/H–1000pcs/H

Power Supply: 220V±10%,50HZ,1000W/1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 140*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 40*2MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

N.W: About 300KG/350KG

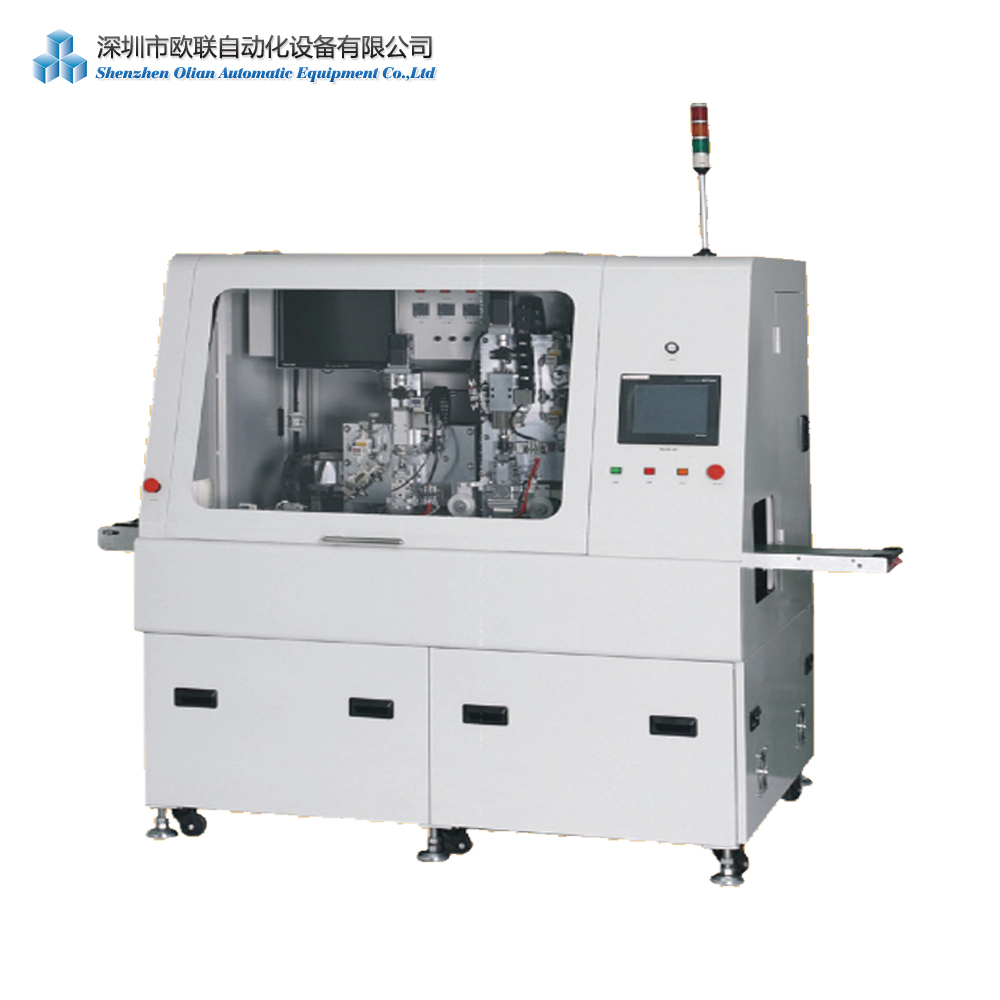

*PID Control Constant Temp Heating System,Automatic temperature compensation to ensure that the temperature of hot pressing is stable.

*Panasonic PLC Control system.

*Use high precision low-friction cylinder control pressure to ensure the accuracy of pressure control.

*High steel structure set, dual ceramic indenter configuration, to ensure the stability of the equipment.

*Imported electrical configuration,

*For OLED high-end products,high quality,high successful rate。

Product Name: 1-12 inch Triple Stations Semi-Automatic High-speed COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1100pcs/H

Power Supply: 220V±10%,50HZ,2000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L1025*W750*H1400 MM

N.W: About 350KG

Product Name: 1-12 inch Double Stations Semi-Automatic Mid-speed Servo COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 600pcs/H

Power Supply: 220V±10%,50HZ,1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L640*W700*H1320MM

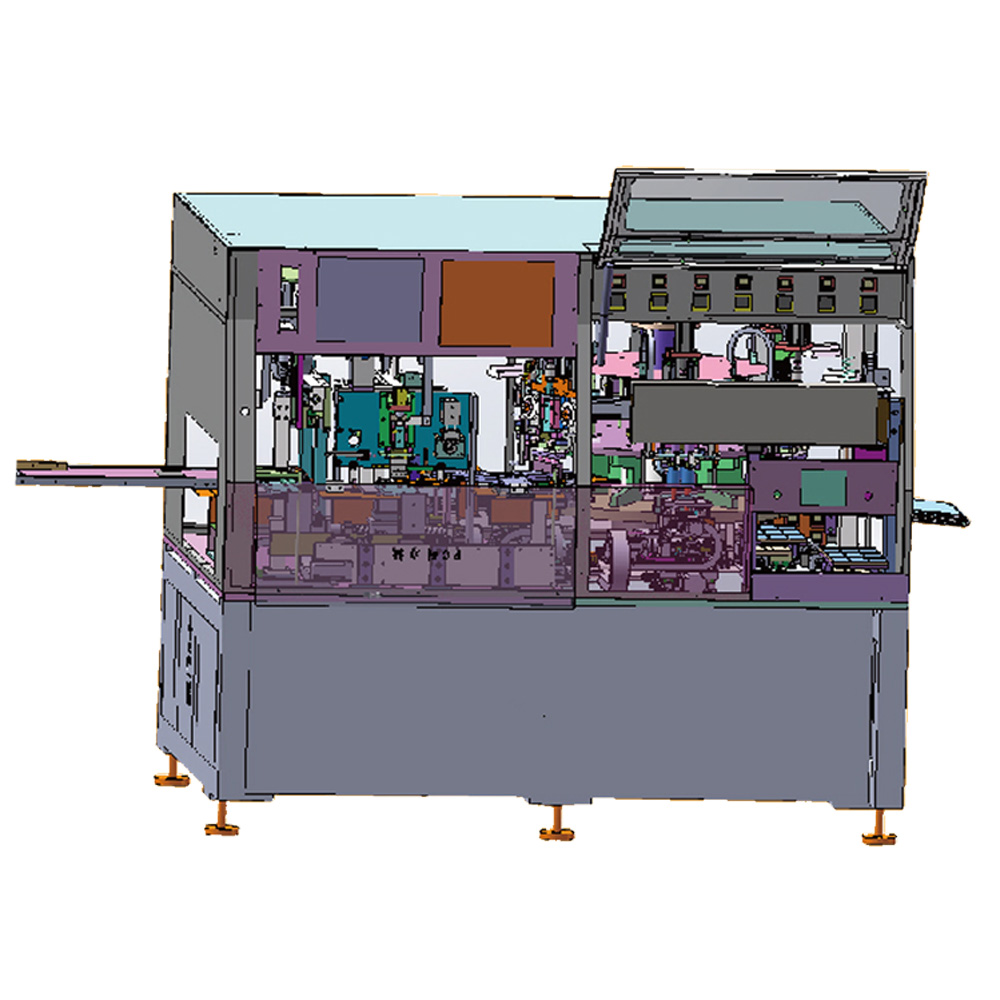

Full automatic machine include all the glass loading/glass cleaning/IC Loading/ACF pre-attaching/COG pre-bonding/COG main-bonding /COG output.

*Constant temperature heating system

*Panasonic PLC Control system

*Human – Machine interface

*Imported electrical configuration

*High Precision contraposition system

*Include the glass loading,glass cleaning,IC loading,ACF pre-attaching,COG pre-bonding,COG main-bonding ,COG output processes,it is COG processes all in one machine.

Product Name: 1~7inch Full Automatic COG bonding line

Suitable For: Suitable for IC Bonding to the LCD, ACF attach, IC preload and pre-bonding, main-bonding,output, completed in one machine.

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1000pcs/H

Power Supply: 220V±10%,50HZ,5000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

Product Size: W1500*D2300*H1700MM

Shenzhen Olian Automatic Equipment design and make the COG bonding machine for LCD/LED/OLED screens of cell phone: HUAWEI,XIAOMI,VIVO,OPPO,Apple,Samsung…brands flat/edge screen models phones. If you are doing the LCD/LED/OLED TV/Cell phone/watch/touch panel produce,repairing and trading business, please contact us.

Wechat/whatsApp:+86 18025364779

ACF Tape/ACF Film is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

| Model(Hitachi) | Process type | For Glass |

| AC-823CY W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-832L W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-832L W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.5mm L100m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-7813KM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| MF-331-25 W2.0mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.5mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.2mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.0mm L50m | FOG Low Temp | For Touch Screen |

| AC-4255KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7206U-18 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.2mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-9851YM-35 W1.5mm L50m | FOG Low Temp | Common Glass |

| AC-9851YM-35 W2.0mm L50m | FOG Low Temp | Common Glass |

| AC-896C W1.5mm L100m | COG Low Temp | Thin Glass |

| Model(Sony) | Process type | For Glass |

| CP6920F3 W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.2mm L50m | COG Low Temp | Common Glass |

| CP34531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP34531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP35231 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP35231 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36931 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36931 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP33731 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP33731 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP31831 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP31831 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP1220 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP1220 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP13941 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP6920F W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.2mm L50m | COG Low Temp | Common Glass |

| CP920 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| TF-4200EB-45/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-451/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-452/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-75/1000ML | Blue | LCM Insulation protective adhesive |

| Model(ACF Remover) | ||

| Remover/G-430/1L | Clean FPC Side | common |

| Remover/G-450/1L Thick | Clean IC Side | common |

| Remover/G-450/1L Diluted | Clean FPC Side | common |

| Remover/G-550/1L Thick | Clean IC Side | common |

| Remover/G-550/1L Diluted | Clean IC Side | common |

| Remover/G-650/1L Thick | Clean IC Side | common |

| Remover/G-650/1L Diluted | Clean IC Side | common |

Please contact us if you need any other ACF tapes and ACF removers.

ACF has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Because of ACF bonding advantages and features ,the ACF bonding machine is becoming more and more popular and useful.

The Bonding Machine use the ACF tape as the medium ,so it named ACF bonding machine.

ACF Bonding Machine, is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

The ACF Bonding Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The ACF Bonding Machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to the different bonding materials, the ACF bonding machine can be divided into different bonding machines.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

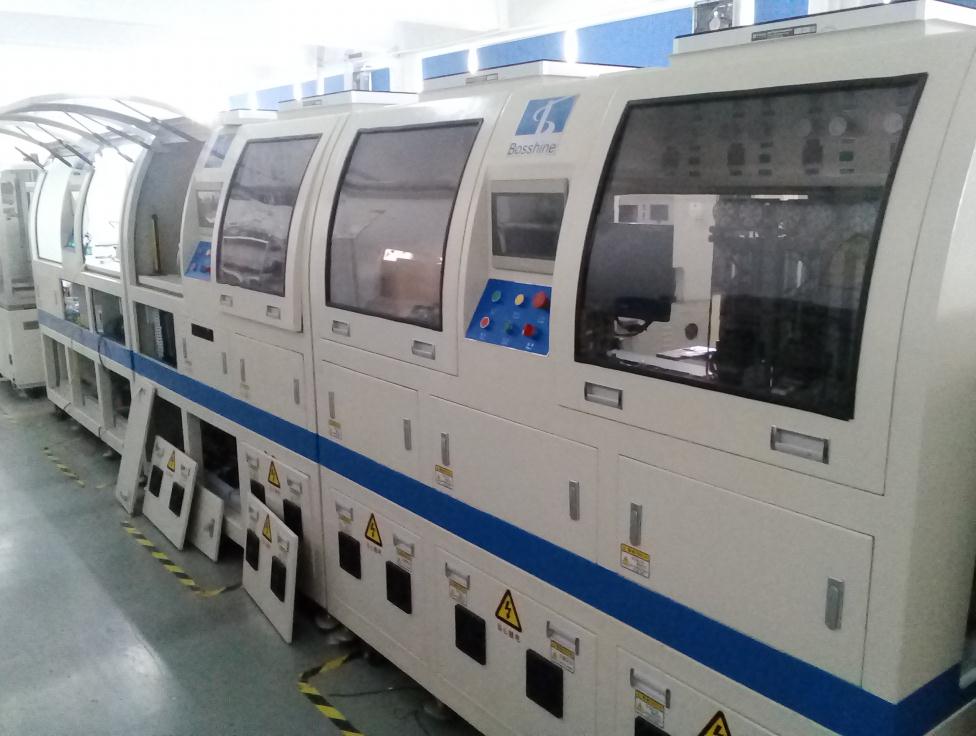

Semi Automatic LCM making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonding machine, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce machine include all the process of the COG and FOG bonding machines.

If you need the ACF bonding machines and the ACF tapes and all the accessories,please contact us Olian .Wechat/whatsapp:+86 18025364779,QQ:2307972393, E-mail:2307972393@qq.com

LCM Making machines ACF+COG+FOG Semi-Automatic Machines Operating Video.

How to do a small phone LCM making factory? How to do the IC pre-bonding? how to do the IC Final-bonding, How to sitck the ACF tape,,

how to do the flex cable bonding? which machines a small cell phone LCM facotory need? the list of the LCM making machines,

LCM Making machines:ACF Machine+COG Pre-bonding machine+COG final-bonding machine+Flex Cable bonding machine