ACF bonding machine

What is an ACF bonding machine?

ACF stands for Anisotropic Conductive Film. ACF bonding machine is a specialized piece of equipment designed to create reliable electrical connections between flexible and rigid electronic components. This article will provide a detailed overview of ACF bonding machines, covering their definition, working principles, applications, advantages, and more.

An ACF bonding machine is a device that utilizes Anisotropic Conductive Film to bond electronic components, such as flexible printed circuits (FPCs), flexible flat cables (FFCs), and integrated circuits (ICs), to substrates like glass or printed circuit boards (PCBs). The machine applies precise heat, pressure, and time parameters to ensure a secure and conductive connection. The primary function of the ACF bonding machine is to enable electrical conductivity in the vertical (Z-axis) direction while maintaining insulation in the horizontal (X and Y-axis) directions, thus preventing short circuits between adjacent circuits.

The working principle of an ACF bonding machine involves several key steps:

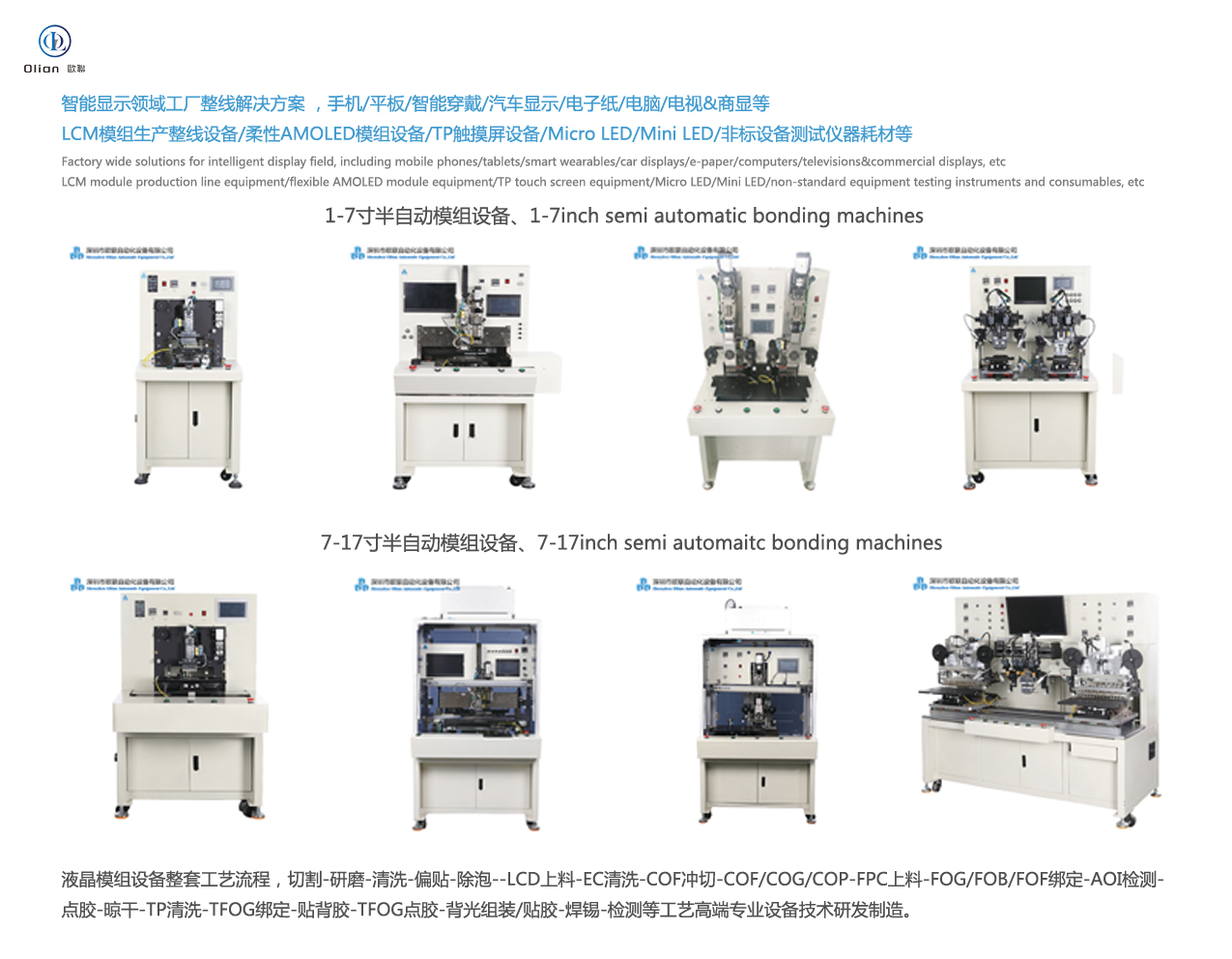

ACF bonding machines are widely used in various industries, including:

The use of ACF bonding machines offers several advantages:

Modern ACF bonding machines come with a range of technical specifications to meet diverse manufacturing needs:

Proper maintenance and safety protocols are essential for the optimal operation of ACF bonding machines:

ACF bonding machines are indispensable in the electronics manufacturing industry, providing a reliable, efficient, and cost-effective solution for creating high-quality electrical connections. Their ability to bond fine-pitch components with precision and flexibility makes them ideal for a wide range of applications, from consumer electronics to medical devices. As technology continues to advance, ACF bonding machines will remain a critical tool in the production of next-generation electronic devices.

ACF bonding uses anisotropic conductive film.

It creates vertical conductivity and horizontal insulation.

The film holds tiny conductive particles in adhesive.

Heat and pressure activate the particles.

Only the Z-axis becomes conductive.

This prevents short circuits between adjacent traces.

ACF bonding is clean and lead-free.

It suits fine-pitch flexible assemblies.

A robust frame ensures thermal stability.

Precision heaters raise temperature quickly.

Programmable pressure cylinders apply even force.

High-resolution cameras align parts accurately.

Vacuum chucks hold substrates flat.

Touch-screen HMI sets recipes easily.

Safety shields protect operators from heat.

Data ports log every bond parameter.

First, the operator loads ACF onto substrate.

Vision cameras detect fiducial marks automatically.

The machine aligns flex to glass.

Bond head descends with controlled pressure.

Pulse heat ramps to target temperature.

Adhesive flows and particles touch pads.

Cooling solidifies the joint within seconds.

The head lifts; the circuit is connected.

Smartphone OLED displays rely on ACF bonding.

Tablet touch sensors use the same process.

Vehicle dashboards need durable flex connections.

Medical wearables demand biocompatible joints.

Industrial cameras require vibration-proof bonds.

AR glasses pack ultra-fine pitch traces.

All benefit from ACF’s reliable conductivity.

ACF needs no flux or cleaning.

It tolerates bending and thermal cycling.

Pitch below 30 µm is achievable.

The bond is shock-resistant and lightweight.

Production throughput is higher and greener.

Overall cost per joint drops significantly.

Temperature range: ambient to 500 °C.

Force accuracy: ±0.1 N across range.

Alignment precision: ±3 µm at 3σ.

Cycle time: under 8 seconds per bond.

Heater cooling: forced air or water.

Camera magnification: 2× to 10× selectable.

Machine footprint: 600 mm × 700 mm.

Power supply: single-phase 220 V.

Evaluate your substrate size first.

Check required temperature and force profiles.

Match camera resolution to pad pitch.

Decide between manual and automatic loading.

Request bond-pull data from suppliers.

Ask for local service and spare parts.

Compare software ease and traceability features.

Finally, balance price with throughput needs.

Clean bond head with lint-free wipe.

Inspect heater for adhesive residue daily.

Verify pressure sensor calibration weekly.

Update vision fiducial library after product change.

Keep filters clean on cooling fans.

Log temperature curves for every shift.

Store ACF rolls sealed and refrigerated.

Train operators on safety procedures regularly.

AI vision will self-correct alignment errors.

IoT modules will predict heater failures.

Laser-assisted heating will shorten cycle times.

recyclable ACF will reduce environmental impact.

Nano-silver particles will lower resistance further.

All trends aim for higher yield and speed.