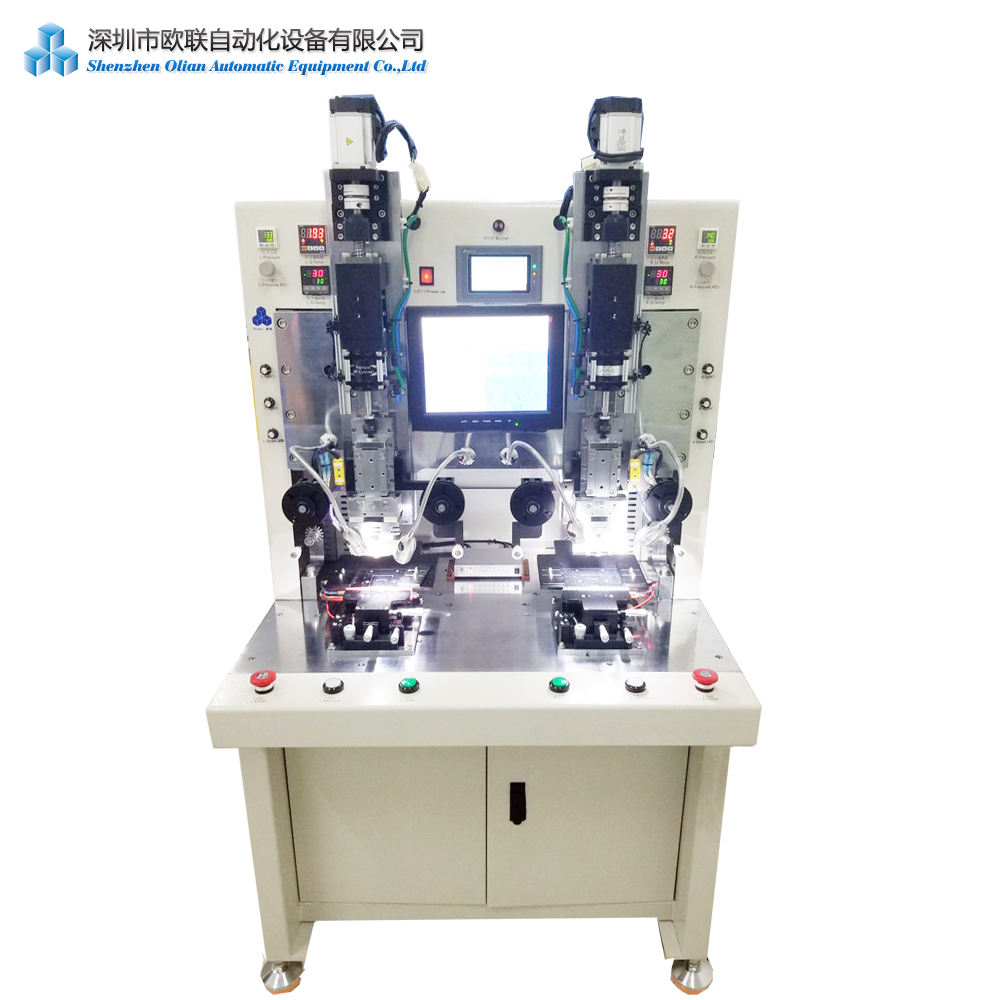

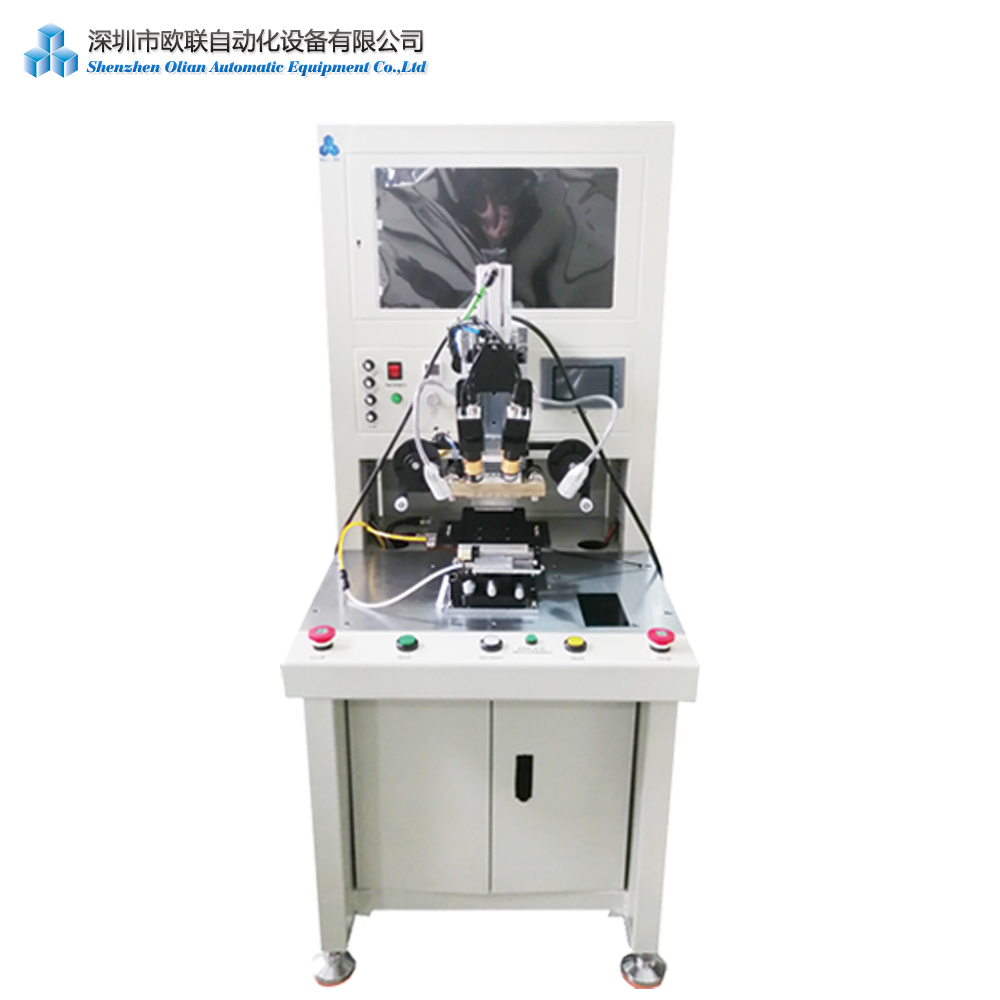

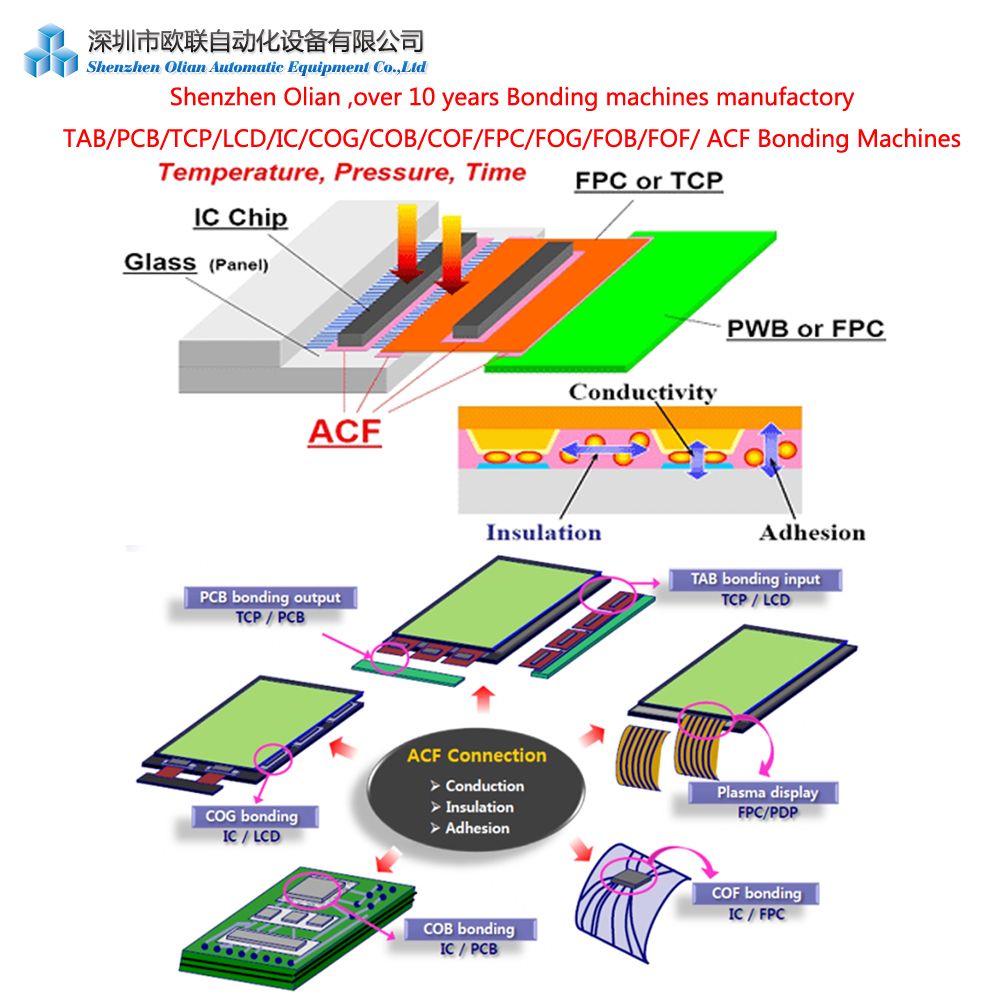

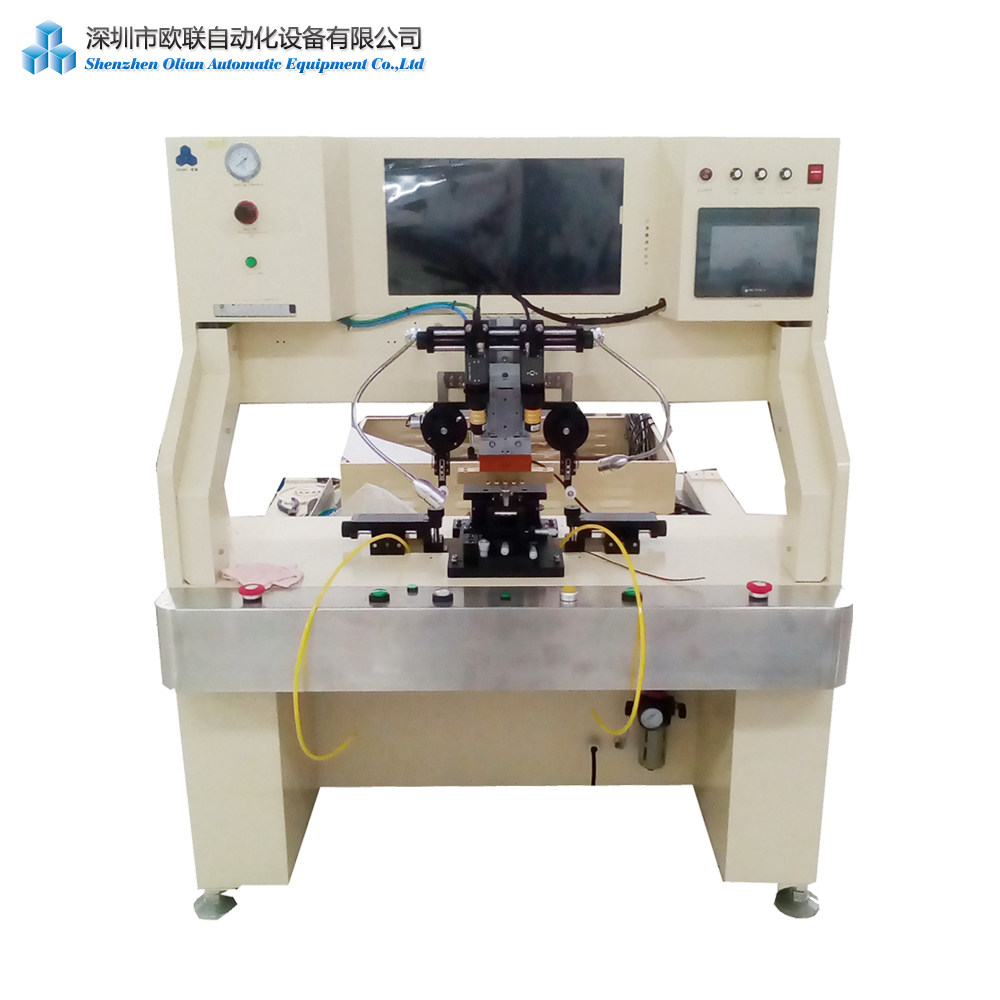

FPC bonder, it may press the FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

It also named FPC Bonding machine,FPC equipment,FPC heat bonder, FPC heat press machine,FPC welding machine,FPC welding tool,FPC soldering machine,FPC thermal compression bonding machine,LCD flex cable repair bonding machine,FOG device,FOG tool,FOG bonding machine, wire bondingmachine,thermal bonding machine,heat bonding machine,ACF bonder.

FPC Bonder is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The FPC bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

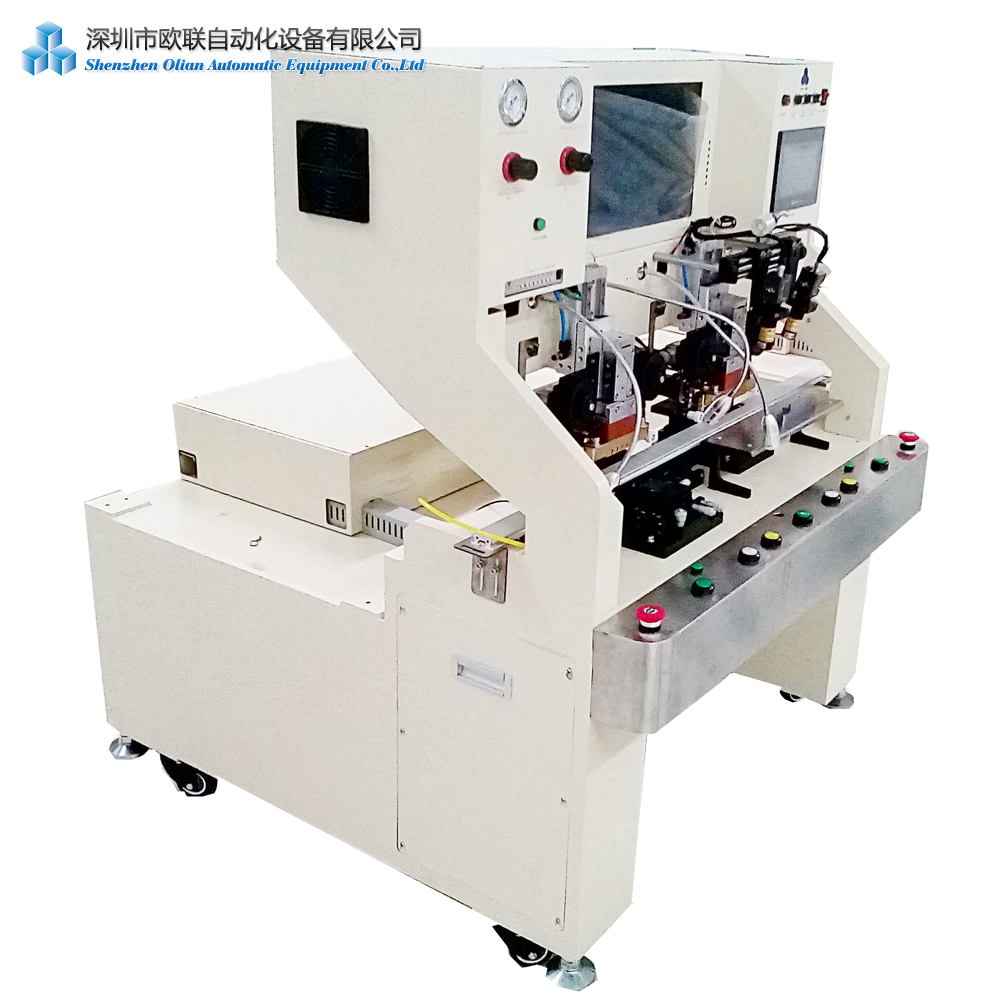

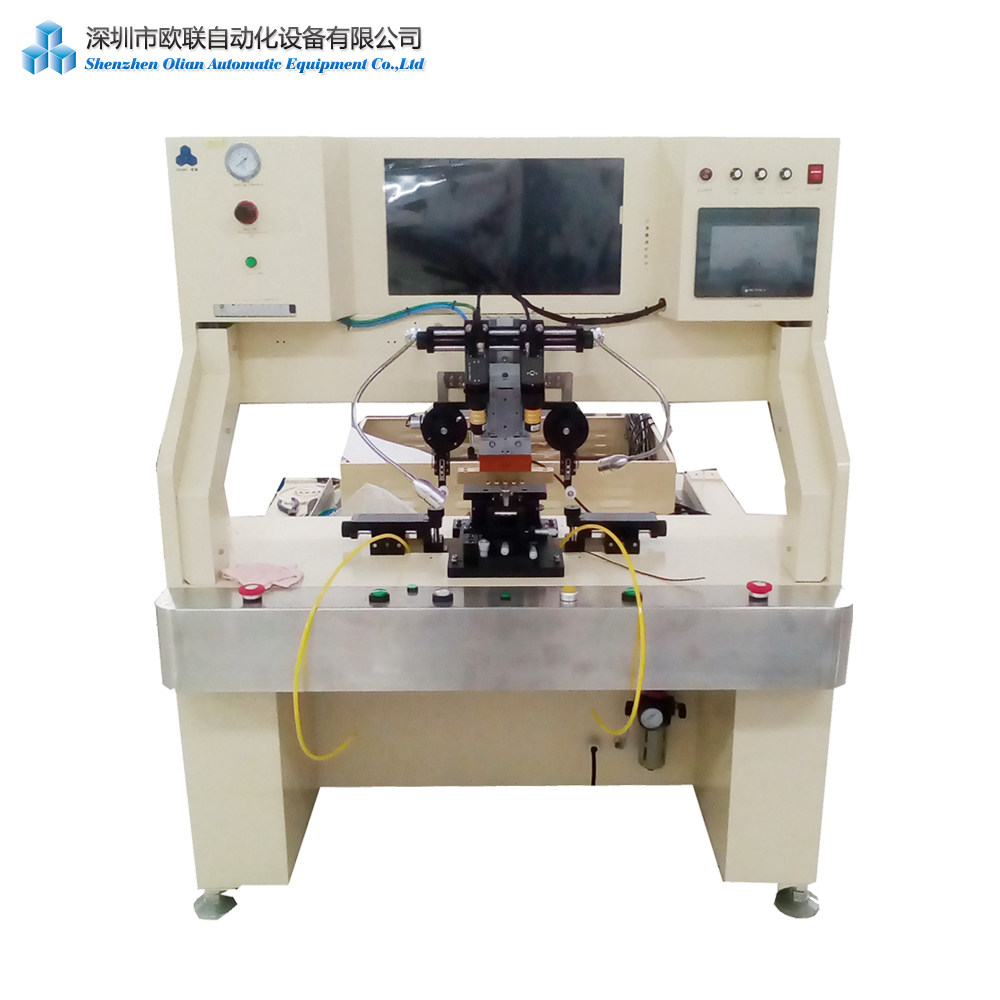

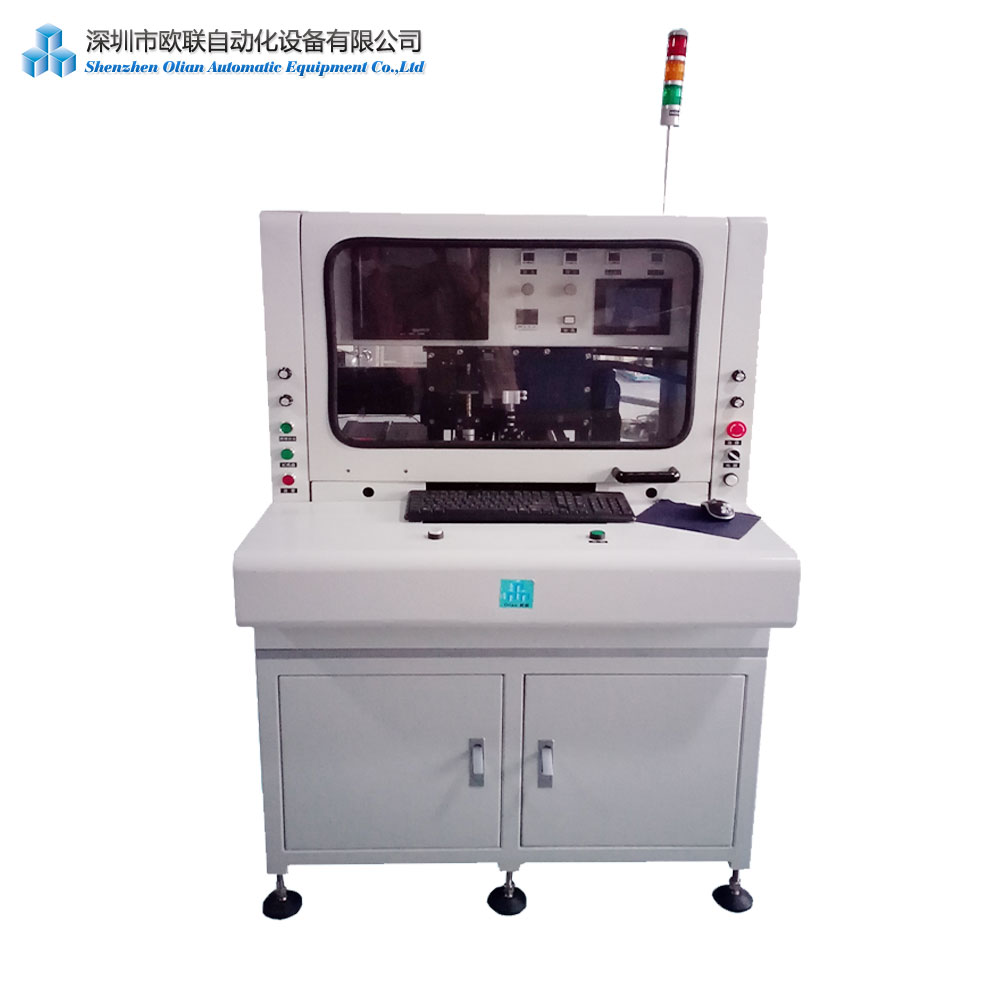

The FPC bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

FPC IS Flexible Printed Circuit,Flexible print circuits (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

In practice there are many different kinds of flexible circuits, including one metal layer, double sided, multilayer and rigid flex circuits. The circuits can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

There are many advantages that come with using flexible circuit technology beyond the initial flex capabilities. Performance advantages, such as, dynamic flexing and increased heat dissipation allow engineers to design these circuits into applications where extreme temperatures and vibrations are common. Other advantages with using flexible circuits include less weight, increased package density, and a more integrated design.Flexible circuits can cost less than traditional assemblies because one flex assembly can replace several, single circuits.

Flex circuits also allow design engineers to utilize space three dimensionally which cuts down on the overall footprint of the circuit and saves space.

Applications of flexible circuits ranges in a variety of fields. Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

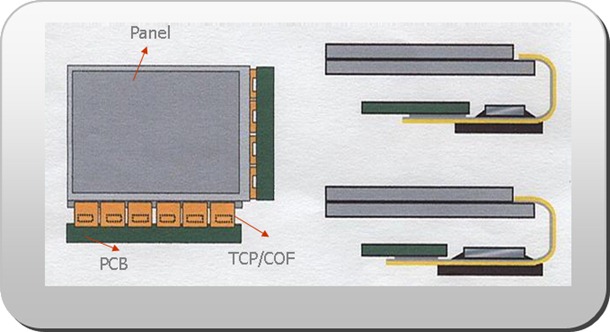

FOG is a kind of use in the flat display industry, such as, LCD screen, electronic paper production process, using ACF conductive adhesive as the media through a certain temperature, pressure, time to FPC bonded on the glass.

FOG is the abbreviation FPC ON the GLASS, that is, FPC bonded ON the GLASS of a kind of process.

Shenzhen Olian design and make all kinds of FPC bonder. Welcome you visit us and OEM&OEM FPC/FOB/FOG/FOF bonding machine with us for your factory and your globe trade business.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models for FPC bonder. ACF tape is the import medium of the bonding process.

FPC bonder, Flexible Printed Circuit bonder,also Flex cable bonding machine , has FOG(FPC on glass ) ,FOB(FPC on PCB Board),FOF(FPC on FPC) , It have Pulse Heating Bonder and Constant Temperature Bonder.

FPC(FOB/FOG/FOF) bonder specifications:

*Constant temperature heating system/Pulse heating system

*Panasonic PLC Control system

*Human – Machine interface

*Automatic temperature alarm

*Press Head Level Adjustable Device

*Down/UP Contraposition HD Colorful CCD and 10.4~24 inch HD LCD

*Manual / automatic switching

*Imported electrical configuration

* apply for all the LCD,LED,ONCELL,OLED panels.

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG Bonder(COG pre-bonder, COG final-bonder ), FPC(FOG) bonder, as below:

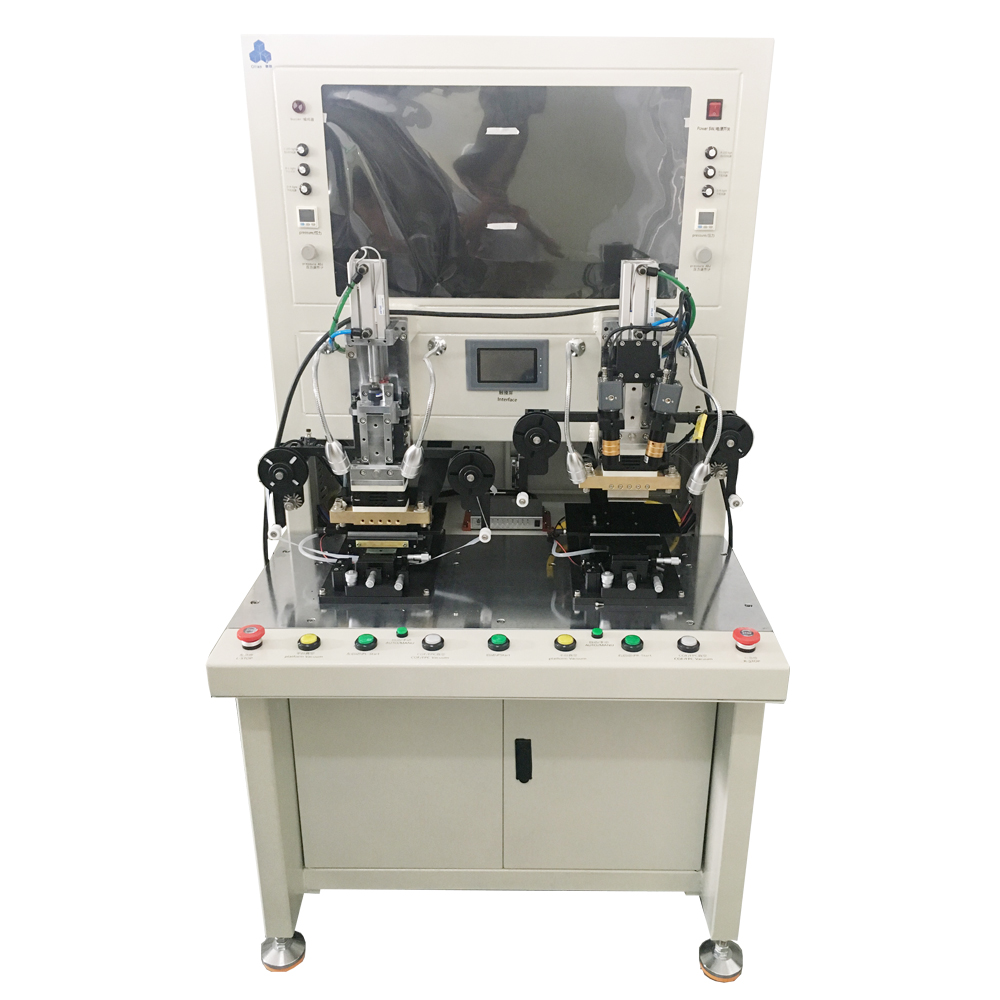

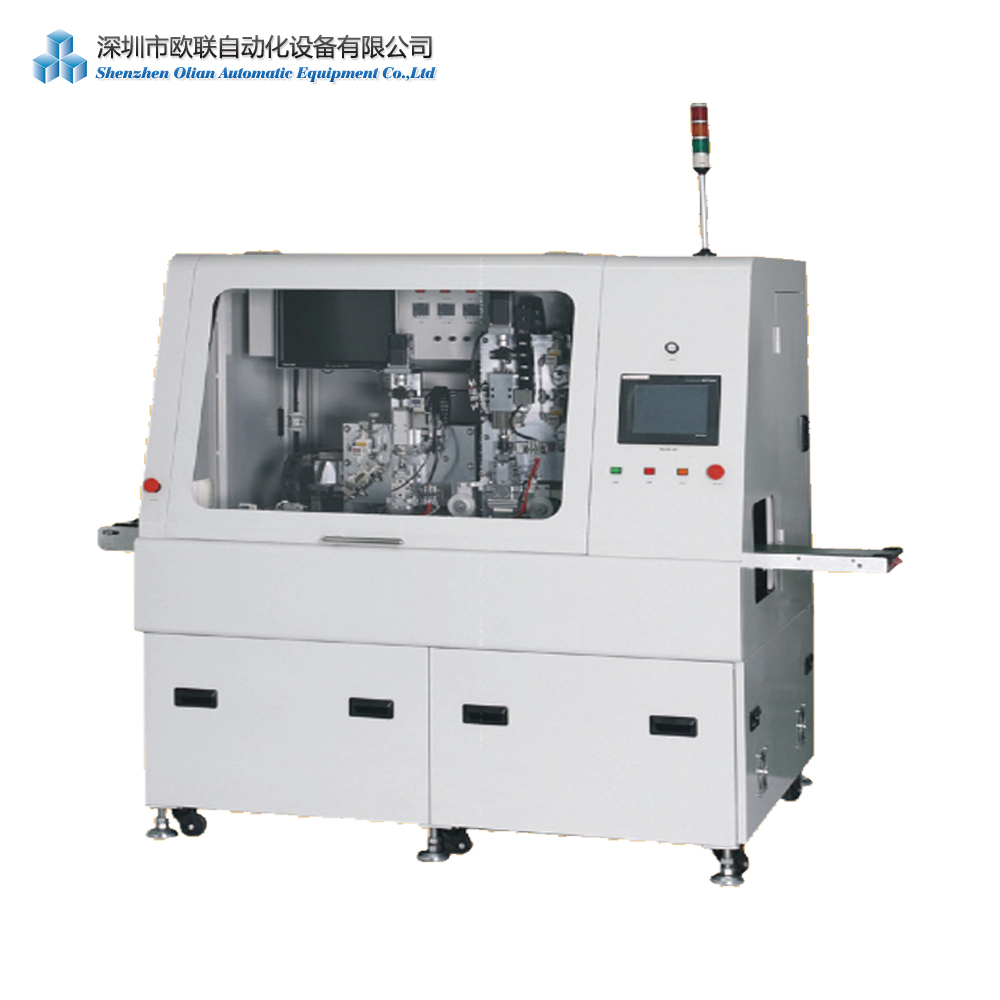

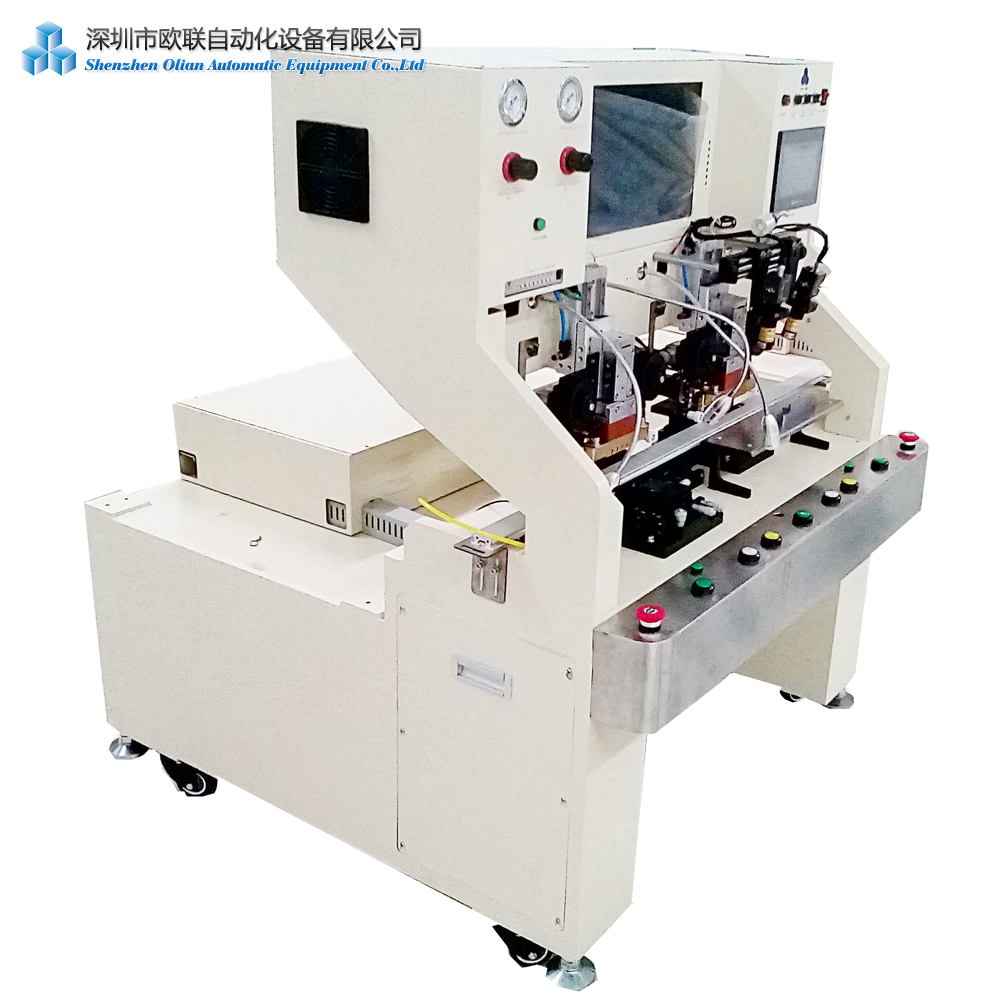

Full automatic FPC(FOG) bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

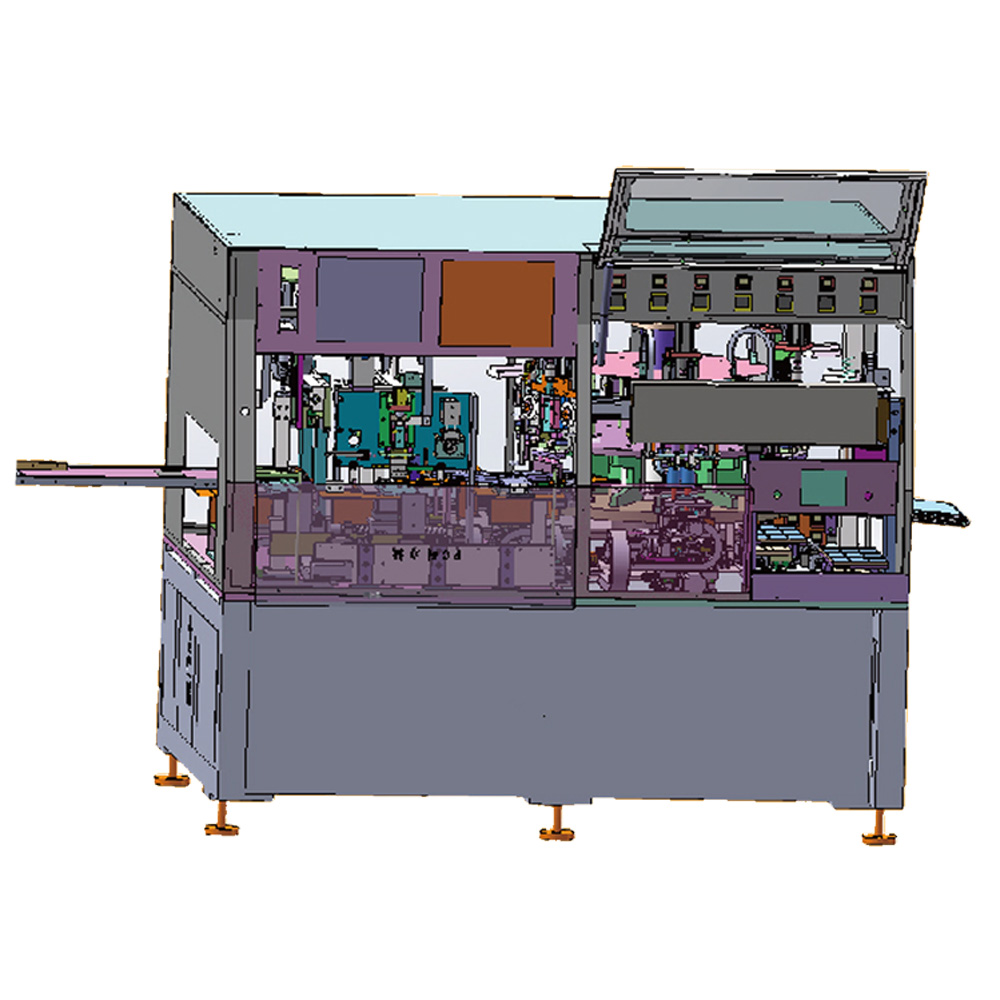

LCM full automatic bonder include all the process of the COG and FOG bonding : the LCD loading,LCD cleaning, IC loading, IC cleaning,ACF attaching on the glass, IC pre-bonding, IC bonding cheking, and IC main-bonding processes. then the ACF attaching for FPC, FPC loading, FPC bonding on the glass and output to testing…

We design and make the standard FPC/FOG/COG/COF/ACF Bonders and customized FPC bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

All the FPC bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

Shenzhen Olian Automatic Equipment Co., Ltd (Olian) is a high-tech manufacturer established in 2008, professional specialized in R&D, manufacturing and sales of LCD/LED/OLED module automatic bonding machines and other equipments

Olian insist on the product concept of ” High quality, High efficiency”, have successfully developed standard and custom products:

Olian Design&Make the best and latest LCD/LED/OLED COG/FOG/FOB/FOF/FPC/OLB/ACF/COF/TAB Bonding Machine for TV/Cell phone/Laptop/Pad/Watch/Touch Screens. All the repairing and produce automatic machines/equipements/tools,and all the parts,accessories.

Large, medium and small size COG machine, Semi-automatic COG machine, Automatic COG machine, ACF attach machine, IC bonding machine, COG pre-bonding machine, COG main-bonding machine, FOB bonding machine, FOG bonding machine, FPC bonding machine, SMT machine, Tear film machine, detection device, PLASMA, LCD clearing machine;

Auxiliary equipment: IC disassembling machine, ACF split machine, Molybdenum wire machine, Heating platform, Manual or pneumatic test stand, etc;

G + F laminating machine, G + G vacuum laminating machine, Touch screen ACF attach machine, Touch screen FOG, Hot press machine, PETOCA laminating machine, F + F, Automatic laminating machine, TP protective film laminating machine

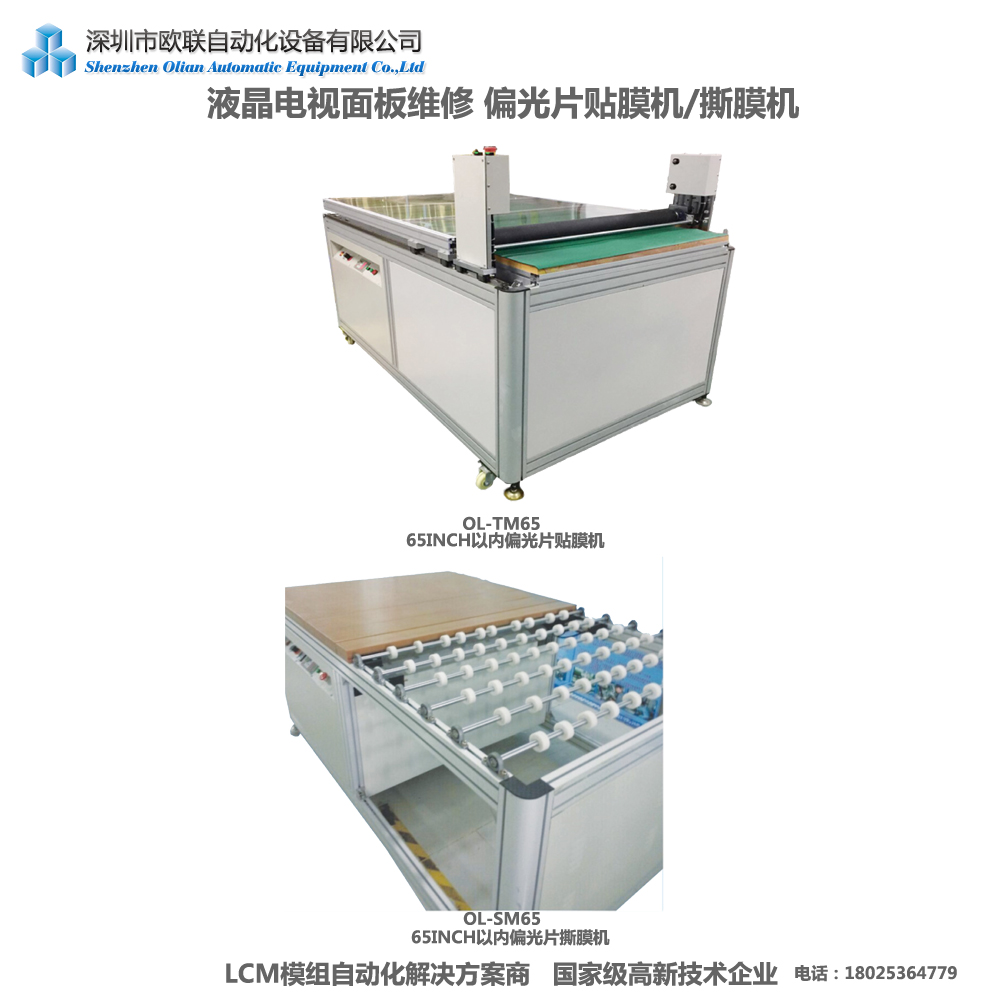

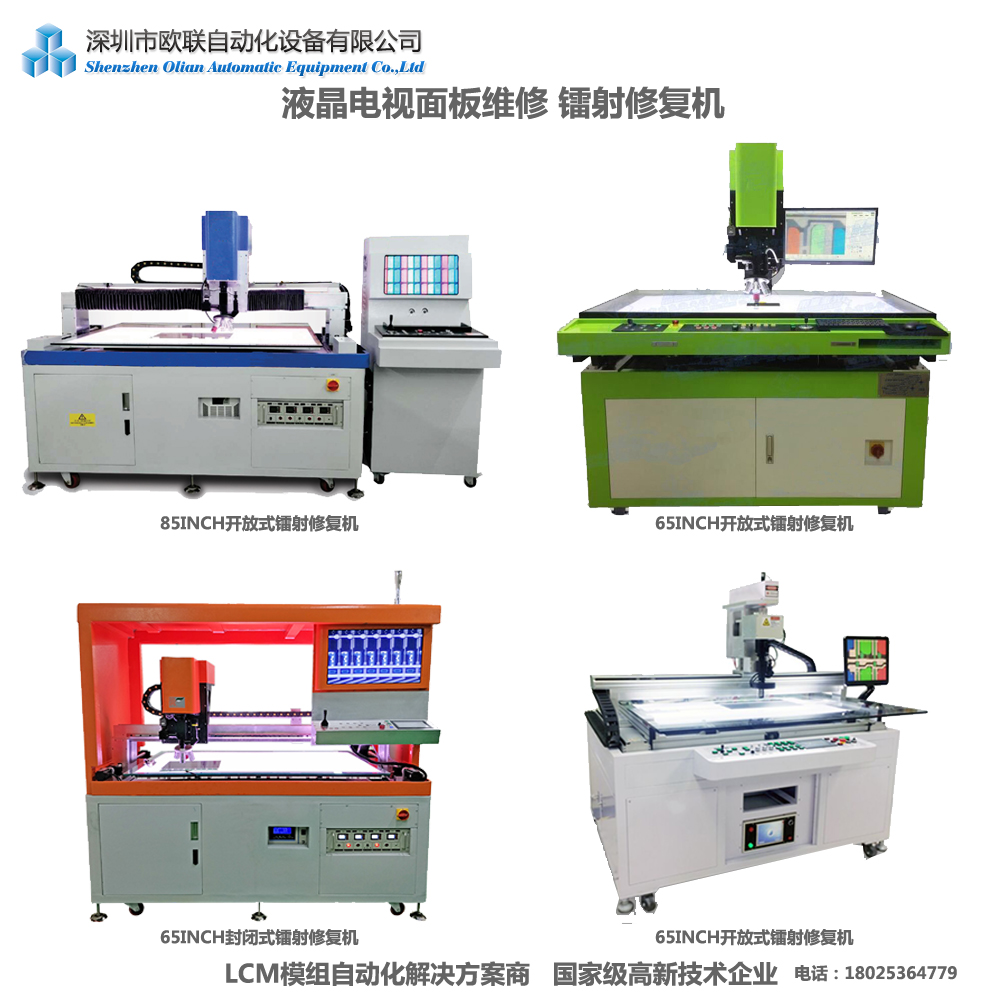

TV repair machines:12-100inch COF bonding machine, LCD laser repair machine, LCD polarizer film repair machine,12-100 inch ACF attaching machine, COF bonding machine, PCB bonding machine, COF Pre-bonding machine, OLB Bonding machine;

LCD separate machine, LCD film machine, LCD laminating machine, LCD bubble remove machine, and other tools.

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning sponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC ,all kinds of bonding press head( SU440C bonding head, Tungsten steel bonding head, Titanium alloy press head) production and maintenance, grinding or design and others,

Olian welcome customers to visit our company for technical exchange and business negotiation. Olian will do the best to provide you with high quality equipment and satisfactory service. Olian determined to become the leading brands of the smart automatic equipment bonding machine industry.

Olian Welcome agents and resellers from around the world,

Welcome OEM&ODM for you.

Some of our bonding machine working videos for your reference.

Bonding Machine, is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

Our bonding machines,

The Bonding Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The Bonding Machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the LCD/LED/OLED Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time. also some bonding machine use the Solder paste as the medium.

Glass cutting machine

Glass grinding and cleaning machine

COG bonding +FOG bonding machine

LCD back light assembling machine

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Shenzhen Olian welcome you visit us for more training if you want to buy any bonding machines.

TAB bonding machine ,upto 100inch panel doubel press head single screen COF bonding machine/ACF bonding machine/TAB bonding machine

Welcome to be our sales and service agents /dealers in your country.

TAB bonding machine, also name COF bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

Our TAB bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Wechat/Whatsapp:+8618025364779

Machine Operating Video in Youtube:

OL-TVCBM-1285-DH-SH-SS- SPEC.pdf

TAB bonding machine is a widely used machine all over the world. This bonding machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED, and television. This bonding machine may consist of has two Digital Microscope, and also has a Digital Pressure Gauge. The ACF bonding machine consists of vacuum generator which may help to hold the panel during the bonding process. It may also provide the quick as well as easy solutions for various mobile problems. COF (TAB Bonding Machine ) is fast as well as it is very easy to access this bonding machine. This bonding machine is able to provide high accuracy repair apparatus for repair different size of the LED or LCD screen as well as LCD Panel. COF bonding machine also consists a process of repairing the technical equipment in an easy way.

We provide the various sizes and types of this machine, as well as all the services, are available if any defect may occur in the machine. Anisotropic conductive film (ACF) bonding machine commonly use in connectivity with electrical and mechanical connections from electronics driver to glass substrate of the LCD/LED/TV. During the ACF bonding process, heat and pressure are applied via a thermode (or hot bar) on to the ACF film or other component that is sandwiching the ACF film.

TAB bonding machinehelps to repair LED,LCD,TV, of lining issues on panel . Ultimate solutions of bonding of COF (COF Bonding Machine)with fast and easy to operate bonding machine. it is a kind of high precision repair equipment for repair various size LED/LCD screen/LCD Panel.

Single Head Manual platform ACF/TAB/COF Bonding machinefor TV repair,Television repair,Panel repair,screen repair.

1) Machine Model Number: OL-1285-DH/SH-SS (Single Head &Double head)

2) Device Description :Screen Repair machine / LCD Bonding machine

3) Device Uses :FPC、 COF、TAB、 LCD Panel and PCB combination bonding

4) Applicable LCD panel specifications :12″-100″(65″,85″100″ options)

5) Applicable LCD panel thickness :0.3MM-1.1MM[Single glass]

6) Bonding IC number :Multiple / Panel Can be set

7) Bind direction :X or Y Unidirection

8) Bonding IC size :Replaceable blade according to IC specifications (The original machine is equipped45X1.5X10)

9) Device processing time :TFT,3.8S/chip

10) Production Beats :TAB,100 pcs/H

11) TAB Bonding machine Accuracy :Within ± 1.5μm (support 4K screen)

12) Highest positioning accuracy setting :±0.5μm (Currently domestic the highest index)

13) Equipment requirements the work environment :Clean, No dust, Clean room

14) Supply Pressure :0.5~0.7Mpa (Dry air source)

15) Power Supply :AC 220V±10%,50HZ,3500W

16) Cylinder Device :Japan SMC original thin cylinder MXS20-75/MXS20-100

17) Heating Type :Pulse (rapid heating / cooling and auxiliary cooling function)

18) PID Temperature Control System :Brand: YUDIAN (516 model)

Adjustable heating curve Precision PID self-tuning type

The peak temperature : within +/- 3 degrees Celsius

Room temperature time to 180 degrees the response time within 2-3 seconds

19) TAB bonding machine Hot pressing head :

Materials: Japan Titanium

origin: United States

Plane precision (hot press side) :0.001mm

Plane thickness 0.5 (Reserved 3 times grinding)

20) Thermocouple Type :K type Original US OMEGA wire

21) Industrial control units / Programmer :Import Panasonic PLC FX-C40T

22) Image unit :

Panasonic image processing system

COF counterpoint: down counterpoint

PCB counterpoint : UP counterpoint

Number of lenses : 4

Microscopy: 30-120 Continuous zoom

COF Display: 19-inch HD 1PCS

PCB counterpoint the display : same (Can be installed )

Upper light source : have

Down light source : have

23)COF trimming unit :

Origin: Taiwan

Rail Type: U-rail (2056 high)

Accuracy : 0.01

Adjustable direction :X/Y/R

R Itinerary : Coarse 360 degrees, fine tuning +/- 5 degrees

24)COF Fixture : COF mechanical clamping type, Z tilt radius micrometer trimming

25) Lens spinner unit :

Control mode: X / Y / Z micrometer control

Focus Adjustment: Manually adjust the focus

26) Position detection : None

27) Silicone / Teflon :Manual switching position

28) LCD stage (platform) :Manual sliding or fixed optional ,automatic stage can be customized

29) Alarm device :Pressure abnormal/ temperature anomalies / thermocouple abnormal / action abnormal

30) Hot press head counterpoint :Cylinder stop can be set at any position in the vertical direction

31) COF bonding machine Control mode :Touch screen + button operation Using Taiwan’s Wei Lun touch screen dual-core

32) Parameter setting :According to the need to set up Store multiple sets of hot pressing parameters

33) Rated voltage :180-220 (customizable 110V)

34) Peak power :400-2200W (Supports 68X1.5X10 lengthened tool bit

35) Maximum power :2200W

36) Actual power :500W

37) Body size :1200X1200x1380mm(L*W*H)

38) ACF bonding machine Machine weight :500KG

TAB bonding machine OL-TVCBM1285-DH/SH-SS , is our company in the R&D process , according to maintenance staff tailored high-end products , machine not only in the accuracy of the temperature and the mechanical accuracy do the precision design , the procedures also increases the glass and circuit board parameters direct selected function , working pressure automatically switch , greatly facilitate the technical staff selected the parameters , increased the tool bit preheating function , to ensure that the machine at any temperature difference can ensure heating rate and temperature accuracy , double head design , glass and circuit board independent bonding reached factory-class level , high bonding excellent rate、low repair rate , this COF bonding machine is the maintenance and after-sales staff preferred the classic model.

TAB bonding machine OL-1285-DH/SH-SS platform Up to 100inch, the COF/TAB/ACF Bonding machine for TV repair,Television repair,Panel repair,screen repair. Welcome you visit us,our website:www.szoulian.com, It is your best choose for your TV COF repairing.

液晶电视维修辅助设备耗材 ,ACF胶带 AC-7206,AC-2056,G450去除液,日立蓝胶,酒精,丙酮,酒精瓶,棉布,纳米海绵,棉签,COF裁切刀,空压机,显微镜,热风枪,石英条,硅胶皮,铁氟龙,精密镊子,六角扳手,烙铁头,放大镜,校正仪,LVDS链接线, 驱动测试板等,免费随机附送整套,免费来厂学习,免费打出口木箱,欢迎来厂试机购买。

| 1 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 | |

| 2 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 | |

| 3 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 | |

| 4 | Acetone Liquid BT-H1-500ML 丙酮 | |

| 5 | Hitachi Blue Glue 100ML 蓝色胶水 | |

| 6 | Fuji Silicone 50M 硅胶皮 | |

| 7 | Teflon 50M 铁氟龙 | |

| 8 | Alcohol 酒精 | |

| 9 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 | |

| 10 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 | |

| 11 | Optical Microscope 显微镜 | |

| 12 | TAB Cutter COF切刀 | |

| 13 | Correction table 校正表 | |

| 14 | LVDS LVDS接头 | |

| 15 | LCD Test Board LCD测试板 | |

| 16 | Allen Key 六角扳手 | |

| 17 | Air Compressor OTS550 空压机 | |

| 18 | Static Wipe Cloth 静电擦拭布 | |

| 19 | Cotton swabs 棉签 | |

| 20 | Handheld Magnifier 手持放大镜 | |

| 21 | Precision Tweezers 精密镊子 | |

| 22 | Nano Sponge 纳米海绵 | |

| 23 | quatz bar spare one 备用石英条 | |

| 24 | Alcohol bottles 空酒精瓶 |

TAB/COF/ACF Bonding machine,12-65/85/100inch Single/Double Stations bonding head TV Repair machine,ACF/TAB/COF bonding machine for TV/laptop repair,Television repair,Panel repair,screen repair.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COF(chip on film),COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. it has Pre-Bonding and Main-Bonding machines . They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations.

*Suitable for multi variety small batch production

*Constant temperature heating system

*Panasonic PLC Control system

*FAST Visual processing system

*Imported Japanese CCD Automatic Contraposition Configuration

*Manual / automatic switching

*Imported electrical configuration

Model: CP005/CP006

Product Name: Semi-Automatic Mid/High-speed COG Pre-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 650pcs/H–1000pcs/H

Power Supply: 220V±10%,50HZ,1000W/1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 140*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 40*2MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

N.W: About 300KG/350KG

*PID Control Constant Temp Heating System,Automatic temperature compensation to ensure that the temperature of hot pressing is stable.

*Panasonic PLC Control system.

*Use high precision low-friction cylinder control pressure to ensure the accuracy of pressure control.

*High steel structure set, dual ceramic indenter configuration, to ensure the stability of the equipment.

*Imported electrical configuration,

*For OLED high-end products,high quality,high successful rate。

Product Name: 1-12 inch Triple Stations Semi-Automatic High-speed COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1100pcs/H

Power Supply: 220V±10%,50HZ,2000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L1025*W750*H1400 MM

N.W: About 350KG

Product Name: 1-12 inch Double Stations Semi-Automatic Mid-speed Servo COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 600pcs/H

Power Supply: 220V±10%,50HZ,1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L640*W700*H1320MM

Full automatic machine include all the glass loading/glass cleaning/IC Loading/ACF pre-attaching/COG pre-bonding/COG main-bonding /COG output.

*Constant temperature heating system

*Panasonic PLC Control system

*Human – Machine interface

*Imported electrical configuration

*High Precision contraposition system

*Include the glass loading,glass cleaning,IC loading,ACF pre-attaching,COG pre-bonding,COG main-bonding ,COG output processes,it is COG processes all in one machine.

Product Name: 1~7inch Full Automatic COG bonding line

Suitable For: Suitable for IC Bonding to the LCD, ACF attach, IC preload and pre-bonding, main-bonding,output, completed in one machine.

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1000pcs/H

Power Supply: 220V±10%,50HZ,5000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

Product Size: W1500*D2300*H1700MM

Shenzhen Olian Automatic Equipment design and make the COG bonding machine for LCD/LED/OLED screens of cell phone: HUAWEI,XIAOMI,VIVO,OPPO,Apple,Samsung…brands flat/edge screen models phones. If you are doing the LCD/LED/OLED TV/Cell phone/watch/touch panel produce,repairing and trading business, please contact us.

Wechat/whatsApp:+86 18025364779

We offer all kinds of COF IC, chip on Film,chip on flex,TAB IC, TV Repair COF,LCD T-con COF IC, LCD TV COF IC, Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,COF,PANDA COF, SONY COF,LCD COFS,COF bonding machine repairing for you .

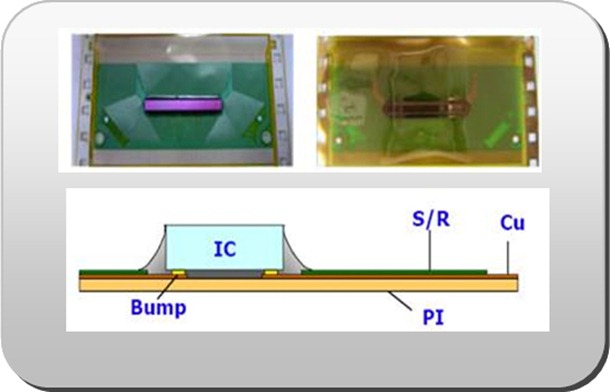

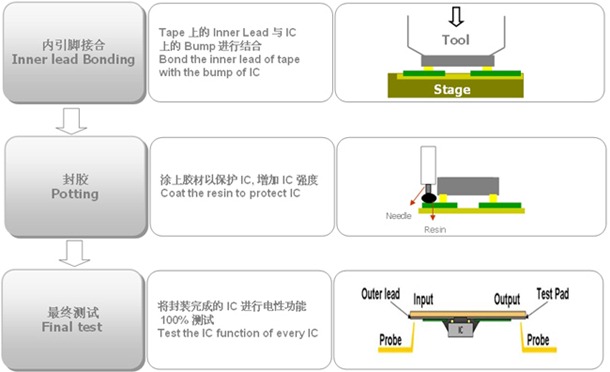

COF is an IC packaging technology that uses a flexible printed circuit film as a carrier for a packaged chip. The gold bumps on the chip are bonded to the Inner Lead of the flexible substrate circuit by thermal compression bonding technique.

After the COF production is completed, the LCD panel module factory will cut the reel tape COF IC into single piece by the COF Punching Machine. There are outer leads of Input and Output on the flexible substrate circuit of the COF, the Input external pins will be bonded to the LCD glass substrate, and the Onput pins will be connected to the control signal printed circuit board ( PCB) .

COF package has High Density / High Pin Count, Fine Pitch, Gang Bond, High Throughput and High Reliability characteristics. In addition, it is lightweight, short, flexible and Reel to Reel production, which is not possible with other traditional packaging methods. For COF products, multi-chip or passive components can also be designed on the substrate circuit.

Some COF ic can not find,and may be stop produce,so need to find some replace COF to use. Some replace COF ic for reference only.

NT39562H-C12Q9A

8656-MCY61

RM76731FD-60y

NT39992H-C12E2A

8157-RCY60

RM76C30FA-F02

8656-FCY0B

NT61227H-C1217B

RM92A31FA-908

NT39525H-C14F1A

S6C2BD1-54U

DB7500-FD07SB

DB7501-FD02S

S6C2T94A01-58U

NT39823H-C6501A

8033-HCU67B

36-D064129

MT3196C-VE

EK77211CF129A

S6C1125-65

8033-HEX39

LH165V08-S332

S6C1125-62

RM92370FC-80K

S6C2BD1-54U

SPLC-1698A

DB7500-FD07SB

DB7501-FT03S

DB7501-FD03S

DB7501-FD03S

DB7501-FD07SB

MN838994LF-1

RM92122FA-058

RM92165FM-OE9

NT65060H-C0205A

MT3196B

NT61207H-C6802A

ICN9305-05

NT39931H-CO2F7A

S6C2BD1-55U

MT3173VF

8697-A

RM91C30FA-F01

RM91C30FB-F04

DB7500-FD04S

NT39992H-C12E2A

D160418NL-057-C1 108

LS08S6HT3A-C3LS

RM76320FB-61A

NT39931H-CO2F74

MT3173VF

DB7893-FT11M

S62B91-63

DB7500-FDO75B

S6C2BD1-58U

RM76153FS-0A1

MT3714VM

DB7501-FT03S

DB7501-FD03S

RM9113BFG-OG1

VH1L5032786-2L

S6CG239-52 H COF

NT39985H-C02M4A

S6C277J-54

RM9216EFA-OG6

DB78913-FT11M

S6C2BD1-55U

DB7500-FD07S

S62LD1-58U

DB7500-FD758

S6C2B91-63

DB7893-FT11M

RM76155FS-0A1

MT371UVM

D78913-63

RM92A131FD-90E

8160-C558

ICN9506-01

RM92A31FA-908

NT39658H-C1294A

NT 61227h C1217A

RM76731FD-60Y

NT65001H-C02P3A

DB7500-FD07SB

EK77211CFI29A

SSD3258UR1

DB7897B-FT08M

NT39935H-C5216B

8154-ECBM3

RM9216DFJ-OFP

RM92122FA-058

56C1104

NT39759H-C12E3C

RM92122FA-058

NT61610H-C07928

LS0856HEASHZ-C3LX

MT3753VD

DB7878-FS02U

ILI5381M2AB2

ILI305K5CD2

S6C2T96-60U

NT39573H-C6007A

S6C2T92J-55U

DB6894-FS06M

S6C277U-53U

RM76113FD-OCX

NT61702H-C6801A

NT39833H-C6511B

NT61720H-C12J3C

8157-RCBRG

MT3166VB

NT39980H-C5266A

NT39992H-C1279A/C

NT61804H-C6520A

RM927A1FF-61B

8159-KCBR8

HX8157-NCA03

ILI3102K6CB1-S

LS0610BH1-C2LX

LS0610BH1-C1LX

MT3220A-VA

NT39892H-C12H5A/B/C

RM92A31FA-908

SSD3273UR4

5253-ACBPQ

MT3725VB-10260UTE

Nt39548H-C5801A

NT61702H-C6801A……

All kinds of COF ic,

Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,PANDA COF, SONY COF,LCD COFS ,Welcome you send your list to my Email:2307972393@qq.com, or Wechat:+8618025364779,We will reply you ASAP.

Related products:

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

This COF bonding machine is mainly designed for TV/Laptop/cellphone repairing, it is for LCD/LED/OLED Panel repairing with COF changing functions,so it is also named COF change machine, COF repair machine, TV bonding machine, TV Repair machine,Laptop repair machine,LCD panel repair machine,LCD bonding machine,LCD repair machine,LCD fix machine, and so on..

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the COF Bonding machine accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

LCM Making machines ACF+COG+FOG Semi-Automatic Machines Operating Video.

How to do a small phone LCM making factory? How to do the IC pre-bonding? how to do the IC Final-bonding, How to sitck the ACF tape,,

how to do the flex cable bonding? which machines a small cell phone LCM facotory need? the list of the LCM making machines,

LCM Making machines:ACF Machine+COG Pre-bonding machine+COG final-bonding machine+Flex Cable bonding machine

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, COF bonder,ACF Bonder,TAB bonder,TCP bonder,PCB bonder, TV panel repairing machine, panel bonding machine.

COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the machine is Pulse heating bonding machine with Titanium alloy press bonding head.

Machine Operating Video in Youtube:

COF bonding machine is the widely used machine all over the world. This bonding machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED, and television. This bonding machine may consist of has two Digital Microscope, and also has a Digital Pressure Gauge. The machine consists of vacuum generator which may help to hold the panel during the bonding process. It may also provide the quick as well as easy solutions for various mobile problems. The machine is fast as well as it is very easy to access this bonding machine. This bonding machine is able to provide high accuracy repair apparatus for repair different size of the LED or LCD screen as well as LCD Panel. the machine also consists a process of repairing the technical equipment in an easy way.

We provide the various sizes and types of this machine, as well as all the services, are available if any defect may occur in the machine. Anisotropic conductive film (ACF) bonding machine commonly use in connectivity with electrical and mechanical connections from electronics driver to glass substrate of the LCD/LED/TV. During the ACF bonding process, heat and pressure are applied via a thermode (or hot bar) on to the ACF film or other component that is sandwiching the ACF film.

The bonding machine helps to repair LED,LCD,TV, of lining issues on panel . Ultimate solutions of bonding of COF with fast and easy to operate bonding machine. it is a kind of high precision repair equipment for repair various size LED/LCD screen/LCD Panel.

SPEC Download:

OL-TVCBM-1285-DH-SH-SS- SPEC.pdf

Single/double Head Manual platform ACF/TAB/COF Bonding machine for TV repair,Television repair,Panel repair,screen repair.

1) Machine Model Number: OL-1285-DH/SH-SS (Single Head &Double head)

2) Device Description :Screen Repair machine / LCD Bonding machine

3) Device Uses :FPC、 COF、TAB、 LCD Panel and PCB combination bonding

4) Applicable LCD panel specifications :12″-100″(65″,85″100″ options)

5) Applicable LCD panel thickness :0.3MM-1.1MM[Single glass]

6) Bonding IC number :Multiple / Panel Can be set

7) Bind direction :X or Y Unidirection

8) Bonding IC size :Replaceable blade according to IC specifications (The original machine is equipped45X1.5X10)

9) Device processing time :TFT,3.8S/chip

10) Production Beats :TAB,100 pcs/H

11) Accuracy :Within ± 1.5μm (support 4K screen)

12) Highest positioning accuracy setting :±0.5μm (Currently domestic the highest index)

13) Equipment requirements the work environment :Clean, No dust, Clean room

14) Supply Pressure :0.5~0.7Mpa (Dry air source)

15) Power Supply :AC 220V±10%,50HZ,3500W

16) Cylinder Device :Japan SMC original thin cylinder MXS20-75/MXS20-100

17) Heating Type :Pulse (rapid heating / cooling and auxiliary cooling function)

18) PID Temperature Control System :Brand: YUDIAN (516 model)

Adjustable heating curve Precision PID self-tuning type

The peak temperature : within +/- 3 degrees Celsius

Room temperature time to 180 degrees the response time within 2-3 seconds

19) Hot pressing head :

Materials: Japan Titanium

origin: United States

Plane precision (hot press side) :0.001mm

Plane thickness 0.5 (Reserved 3 times grinding)

20) Thermocouple Type :K type Original US OMEGA wire

21) Industrial control units / Programmer :Import Panasonic PLC FX-C40T

22) Image unit :

Panasonic image processing system

COF counterpoint: down counterpoint

PCB counterpoint : UP counterpoint

Number of lenses : 4

Microscopy: 30-120 Continuous zoom

COF Display: 19-inch HD 1PCS

PCB counterpoint the display : same (Can be installed )

Upper light source : have

Down light source : have

23)COF trimming unit :

Origin: Taiwan

Rail Type: U-rail (2056 high)

Accuracy : 0.01

Adjustable direction :X/Y/R

R Itinerary : Coarse 360 degrees, fine tuning +/- 5 degrees

24)COF Fixture : COF mechanical clamping type, Z tilt radius micrometer trimming

25) Lens spinner unit :

Control mode: X / Y / Z micrometer control

Focus Adjustment: Manually adjust the focus

26) Position detection : None

27) Silicone / Teflon :Manual switching position

28) LCD stage (platform) :Manual sliding or fixed optional ,automatic stage can be customized

29) Alarm device :Pressure abnormal/ temperature anomalies / thermocouple abnormal / action abnormal

30) Hot press head counterpoint :Cylinder stop can be set at any position in the vertical direction

31) Control mode :Touch screen + button operation Using Taiwan’s Wei Lun touch screen dual-core

32) Parameter setting :According to the need to set up Store multiple sets of hot pressing parameters

33) Rated voltage :180-220 (customizable 110V)

34) Peak power :400-2200W (Supports 68X1.5X10 lengthened tool bit

35) Maximum power :2200W

36) Actual power :500W

37) Body size :1200X1200x1380mm(L*W*H)

38) Machine weight :500KG

OL-TVCBM1285-DH/SH-SS COF bonding machine , is our company in the R&D process , according to maintenance staff tailored high-end products , machine not only in the accuracy of the temperature and the mechanical accuracy do the precision design , the procedures also increases the glass and circuit board parameters direct selected function , working pressure automatically switch , greatly facilitate the technical staff selected the parameters , increased the tool bit preheating function , to ensure that the machine at any temperature difference can ensure heating rate and temperature accuracy , double head design , glass and circuit board independent bonding reached factory-class level , high bonding excellent rate、low repair rate , this machine is the maintenance and after-sales staff preferred the classic model.

OL-1285-DH/SH-SS platform Up to 100inch, the COF/TAB/ACF Bonding machine for TV repair,Television repair,Panel repair,screen repair. Welcome you visit us,our website:www.szoulian.com, It is your best choose for your TV COF repairing.

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Wechat/Whatsapp:+8618025364779

液晶电视维修辅助设备耗材 ,ACF胶带 AC-7206,AC-2056,G450去除液,日立蓝胶,酒精,丙酮,酒精瓶,棉布,纳米海绵,棉签,COF裁切刀,空压机,显微镜,热风枪,石英条,硅胶皮,铁氟龙,精密镊子,六角扳手,烙铁头,放大镜,校正仪,LVDS链接线, 驱动测试板等,免费随机附送整套,免费来厂学习,免费打出口木箱,欢迎来厂试机购买。

| 1 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 | |

| 2 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 | |

| 3 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 | |

| 4 | Acetone Liquid BT-H1-500ML 丙酮 | |

| 5 | Hitachi Blue Glue 100ML 蓝色胶水 | |

| 6 | Fuji Silicone 50M 硅胶皮 | |

| 7 | Teflon 50M 铁氟龙 | |

| 8 | Alcohol 酒精 | |

| 9 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 | |

| 10 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 | |

| 11 | Optical Microscope 显微镜 | |

| 12 | TAB Cutter COF切刀 | |

| 13 | Correction table 校正表 | |

| 14 | LVDS LVDS接头 | |

| 15 | LCD Test Board LCD测试板 | |

| 16 | Allen Key 六角扳手 | |

| 17 | Air Compressor OTS550 空压机 | |

| 18 | Static Wipe Cloth 静电擦拭布 | |

| 19 | Cotton swabs 棉签 | |

| 20 | Handheld Magnifier 手持放大镜 | |

| 21 | Precision Tweezers 精密镊子 | |

| 22 | Nano Sponge 纳米海绵 | |

| 23 | quatz bar spare one 备用石英条 | |

| 24 | Alcohol bottles 空酒精瓶 |

12-85inch 100inch COF Bonding machine for TV Repairing machine,Welcome you visit us !

3M Double-Sided Adhesive Attaching Machine Features:

*3M double-sided adhesive multiple segments attaching at the same time

*over 1000pcs/hour, save 3 workers

*PLC control system, Operateing with HMI,

*Stable performance,Easy commissioning and operation, Durability,