COG bonding machine, also name IC Bonding machine, Chips bonding machine, COF(chip on film),COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. it has Pre-Bonding and Main-Bonding machines . They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations.

*Suitable for multi variety small batch production

*Constant temperature heating system

*Panasonic PLC Control system

*FAST Visual processing system

*Imported Japanese CCD Automatic Contraposition Configuration

*Manual / automatic switching

*Imported electrical configuration

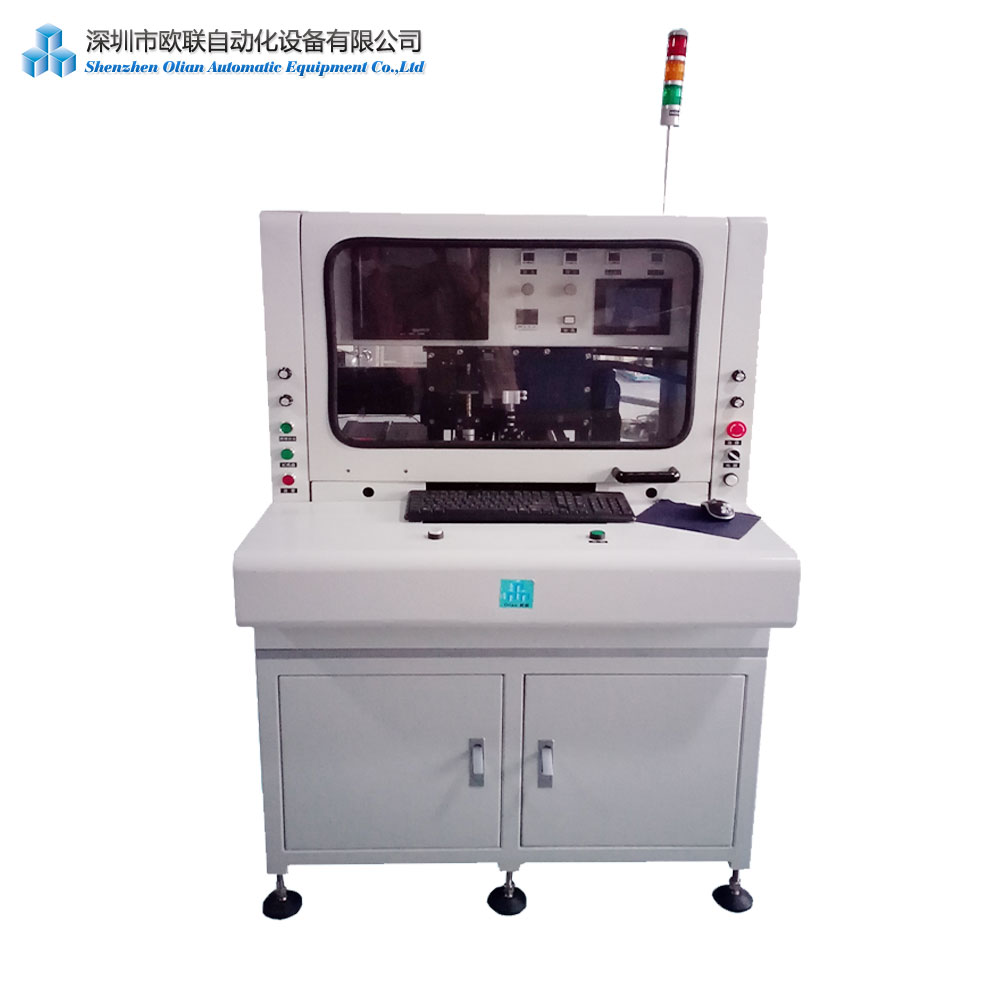

Model: CP005/CP006

Product Name: Semi-Automatic Mid/High-speed COG Pre-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 650pcs/H–1000pcs/H

Power Supply: 220V±10%,50HZ,1000W/1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 140*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 40*2MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

N.W: About 300KG/350KG

*PID Control Constant Temp Heating System,Automatic temperature compensation to ensure that the temperature of hot pressing is stable.

*Panasonic PLC Control system.

*Use high precision low-friction cylinder control pressure to ensure the accuracy of pressure control.

*High steel structure set, dual ceramic indenter configuration, to ensure the stability of the equipment.

*Imported electrical configuration,

*For OLED high-end products,high quality,high successful rate。

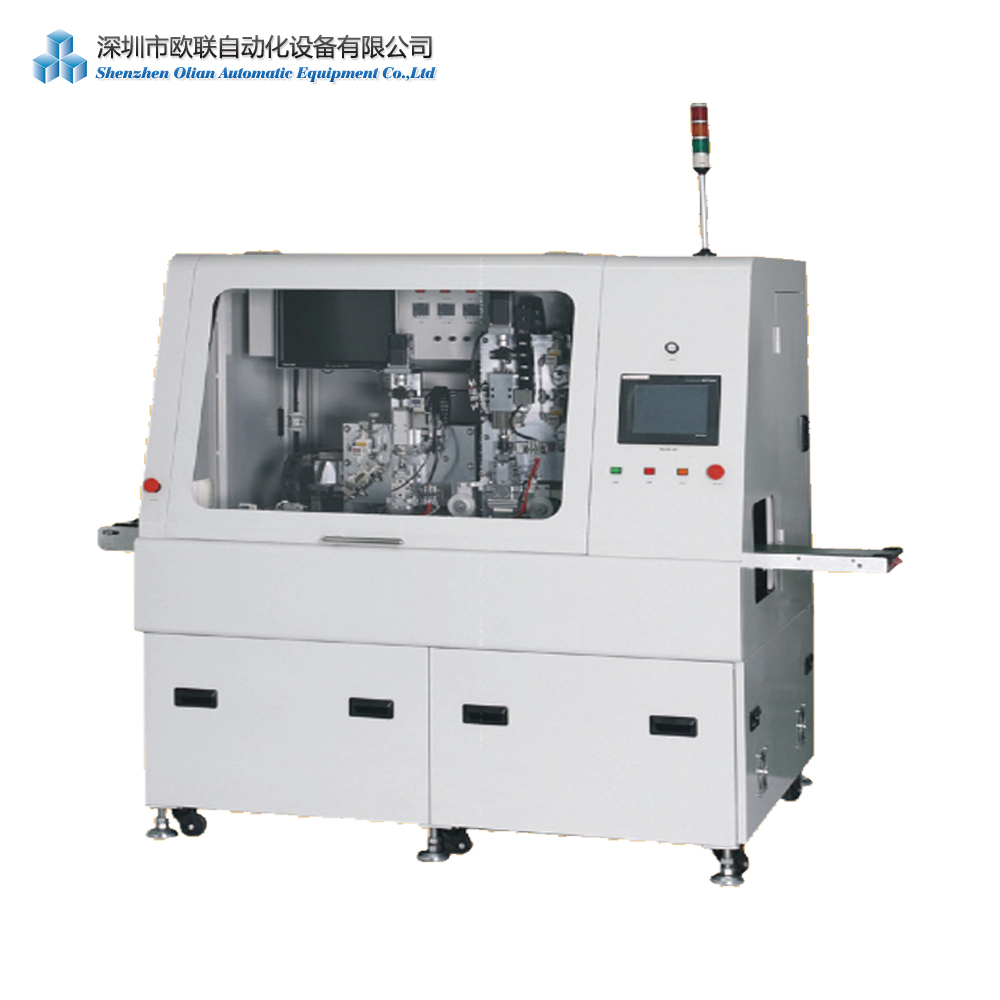

Product Name: 1-12 inch Triple Stations Semi-Automatic High-speed COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1100pcs/H

Power Supply: 220V±10%,50HZ,2000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L1025*W750*H1400 MM

N.W: About 350KG

Product Name: 1-12 inch Double Stations Semi-Automatic Mid-speed Servo COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 600pcs/H

Power Supply: 220V±10%,50HZ,1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L640*W700*H1320MM

Full automatic machine include all the glass loading/glass cleaning/IC Loading/ACF pre-attaching/COG pre-bonding/COG main-bonding /COG output.

*Constant temperature heating system

*Panasonic PLC Control system

*Human – Machine interface

*Imported electrical configuration

*High Precision contraposition system

*Include the glass loading,glass cleaning,IC loading,ACF pre-attaching,COG pre-bonding,COG main-bonding ,COG output processes,it is COG processes all in one machine.

Product Name: 1~7inch Full Automatic COG bonding line

Suitable For: Suitable for IC Bonding to the LCD, ACF attach, IC preload and pre-bonding, main-bonding,output, completed in one machine.

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1000pcs/H

Power Supply: 220V±10%,50HZ,5000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

Product Size: W1500*D2300*H1700MM

Shenzhen Olian Automatic Equipment design and make the COG bonding machine for LCD/LED/OLED screens of cell phone: HUAWEI,XIAOMI,VIVO,OPPO,Apple,Samsung…brands flat/edge screen models phones. If you are doing the LCD/LED/OLED TV/Cell phone/watch/touch panel produce,repairing and trading business, please contact us.

Wechat/whatsApp:+86 18025364779