FPC bonder, it may press the FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

It also named FPC Bonding machine,FPC equipment,FPC heat bonder, FPC heat press machine,FPC welding machine,FPC welding tool,FPC soldering machine,FPC thermal compression bonding machine,LCD flex cable repair bonding machine,FOG device,FOG tool,FOG bonding machine, wire bondingmachine,thermal bonding machine,heat bonding machine,ACF bonder.

FPC Bonder is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The FPC bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

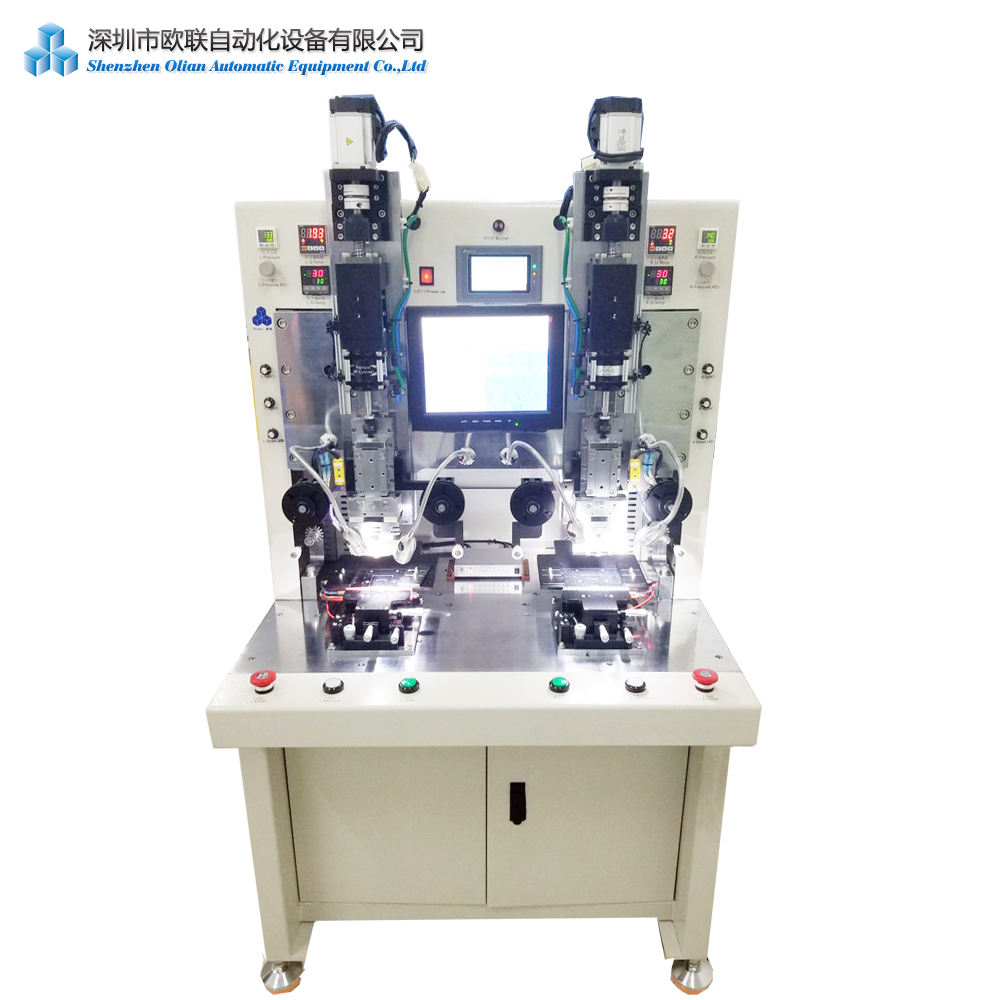

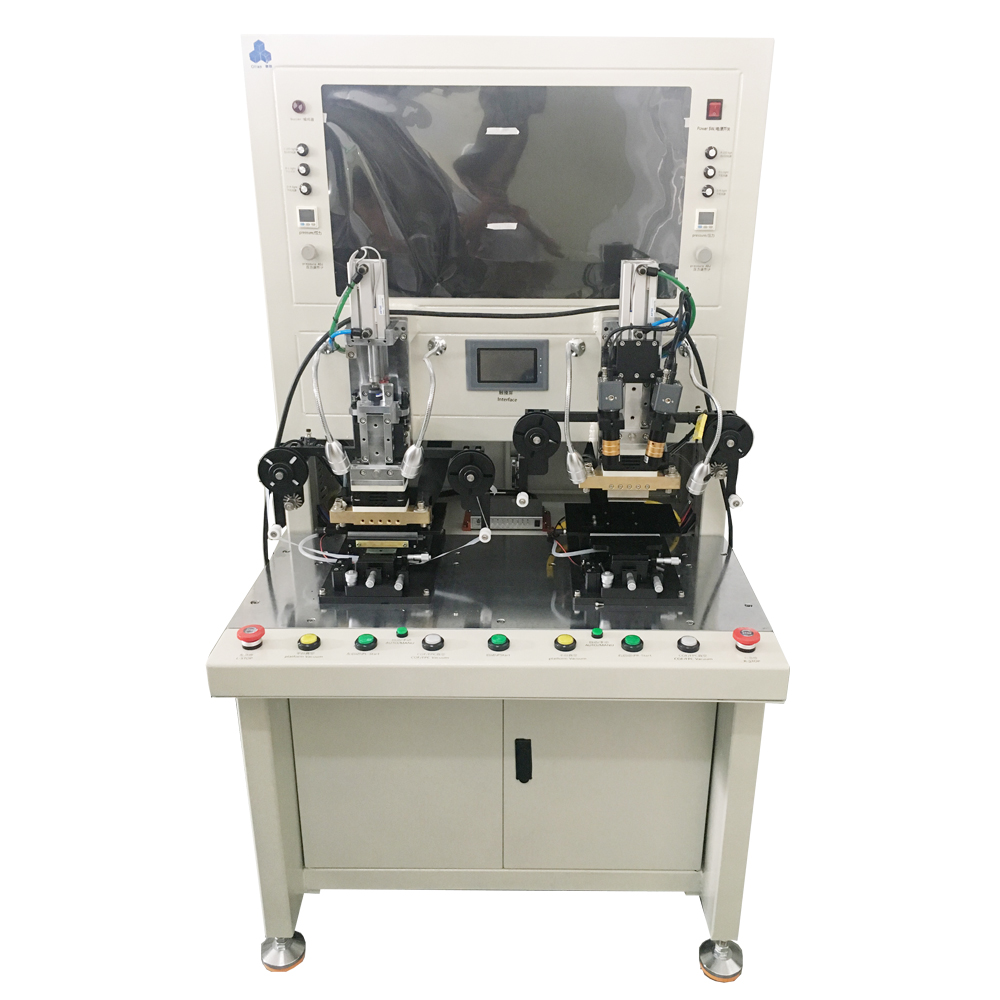

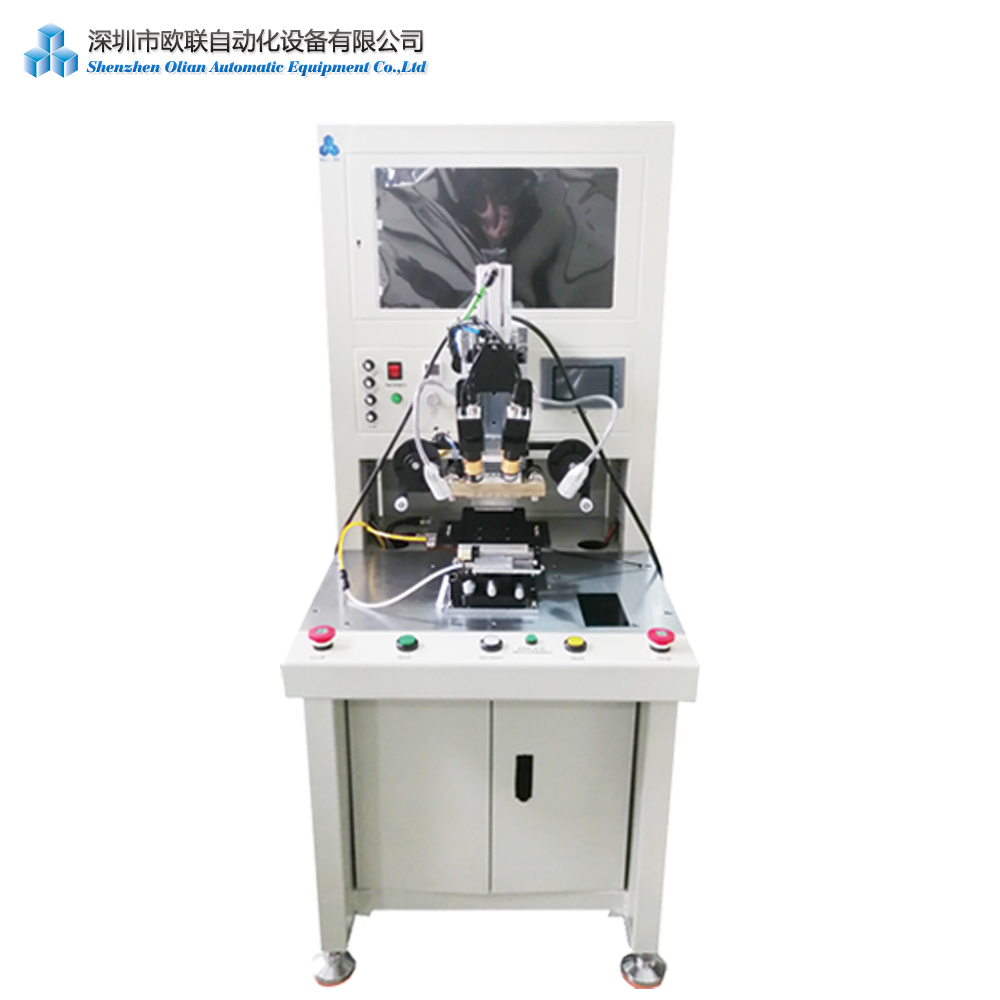

The FPC bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

FPC IS Flexible Printed Circuit,Flexible print circuits (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

In practice there are many different kinds of flexible circuits, including one metal layer, double sided, multilayer and rigid flex circuits. The circuits can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

There are many advantages that come with using flexible circuit technology beyond the initial flex capabilities. Performance advantages, such as, dynamic flexing and increased heat dissipation allow engineers to design these circuits into applications where extreme temperatures and vibrations are common. Other advantages with using flexible circuits include less weight, increased package density, and a more integrated design.Flexible circuits can cost less than traditional assemblies because one flex assembly can replace several, single circuits.

Flex circuits also allow design engineers to utilize space three dimensionally which cuts down on the overall footprint of the circuit and saves space.

Applications of flexible circuits ranges in a variety of fields. Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

FOG is a kind of use in the flat display industry, such as, LCD screen, electronic paper production process, using ACF conductive adhesive as the media through a certain temperature, pressure, time to FPC bonded on the glass.

FOG is the abbreviation FPC ON the GLASS, that is, FPC bonded ON the GLASS of a kind of process.

Shenzhen Olian design and make all kinds of FPC bonder. Welcome you visit us and OEM&OEM FPC/FOB/FOG/FOF bonding machine with us for your factory and your globe trade business.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models for FPC bonder. ACF tape is the import medium of the bonding process.

FPC bonder, Flexible Printed Circuit bonder,also Flex cable bonding machine , has FOG(FPC on glass ) ,FOB(FPC on PCB Board),FOF(FPC on FPC) , It have Pulse Heating Bonder and Constant Temperature Bonder.

FPC(FOB/FOG/FOF) bonder specifications:

*Constant temperature heating system/Pulse heating system

*Panasonic PLC Control system

*Human – Machine interface

*Automatic temperature alarm

*Press Head Level Adjustable Device

*Down/UP Contraposition HD Colorful CCD and 10.4~24 inch HD LCD

*Manual / automatic switching

*Imported electrical configuration

* apply for all the LCD,LED,ONCELL,OLED panels.

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG Bonder(COG pre-bonder, COG final-bonder ), FPC(FOG) bonder, as below:

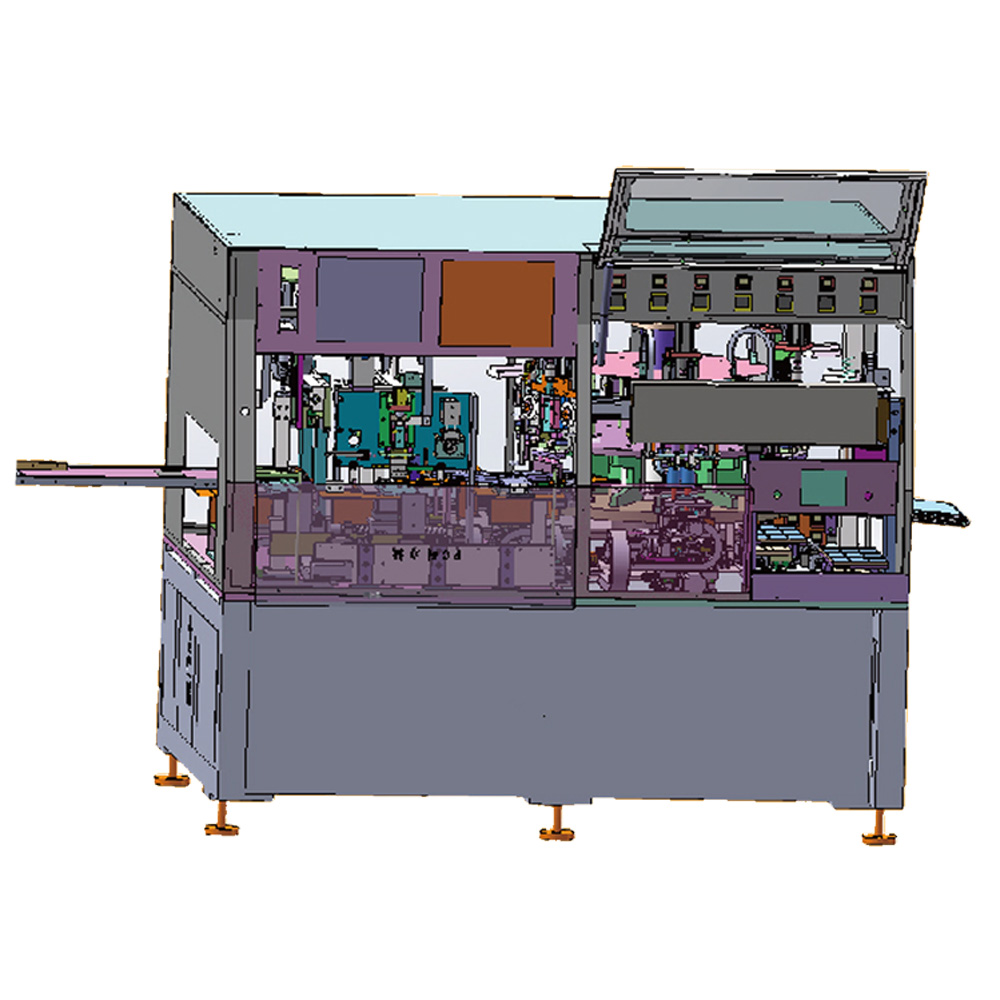

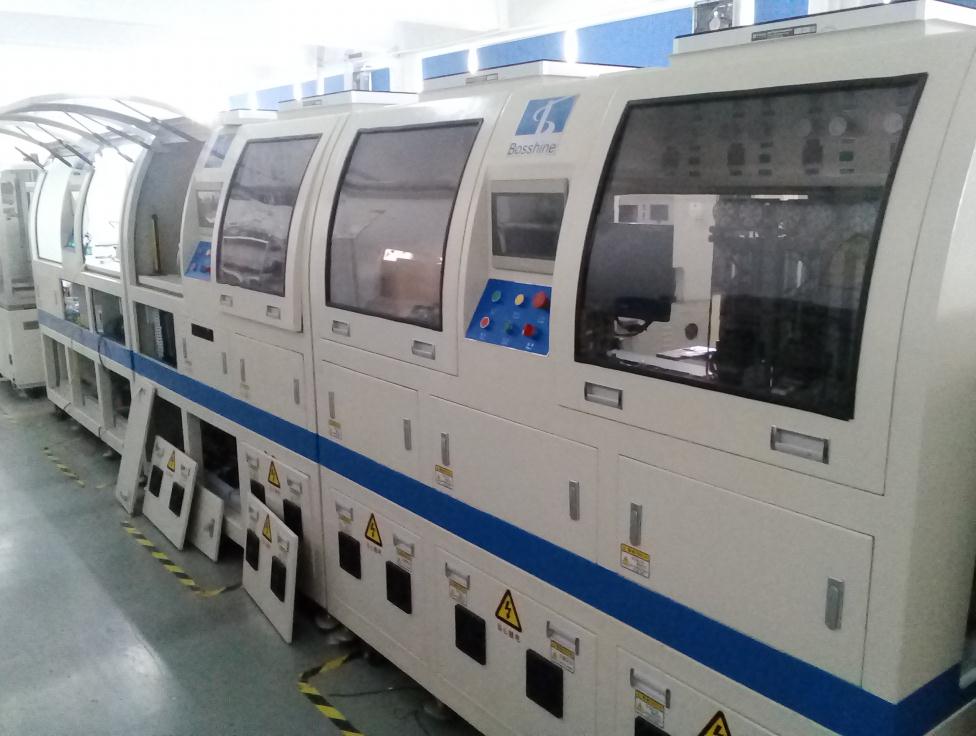

Full automatic FPC(FOG) bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic bonder include all the process of the COG and FOG bonding : the LCD loading,LCD cleaning, IC loading, IC cleaning,ACF attaching on the glass, IC pre-bonding, IC bonding cheking, and IC main-bonding processes. then the ACF attaching for FPC, FPC loading, FPC bonding on the glass and output to testing…

We design and make the standard FPC/FOG/COG/COF/ACF Bonders and customized FPC bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

All the FPC bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)