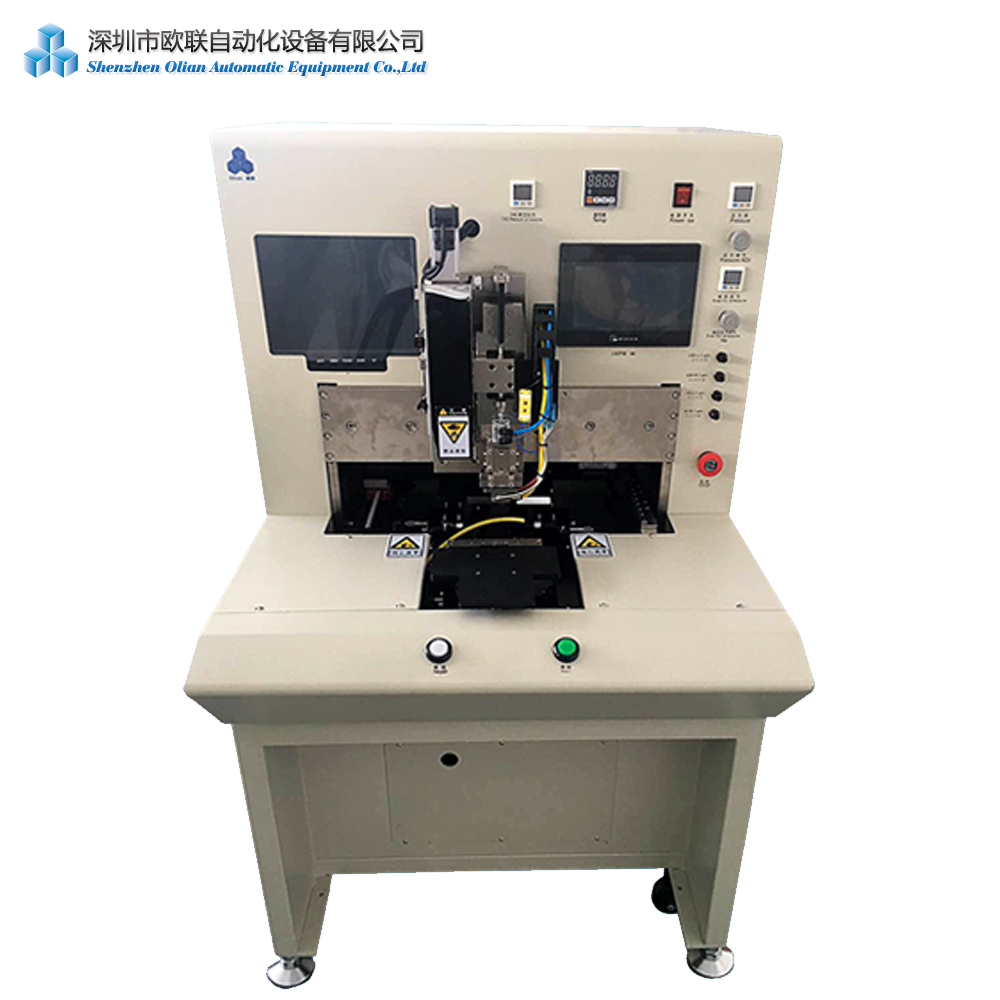

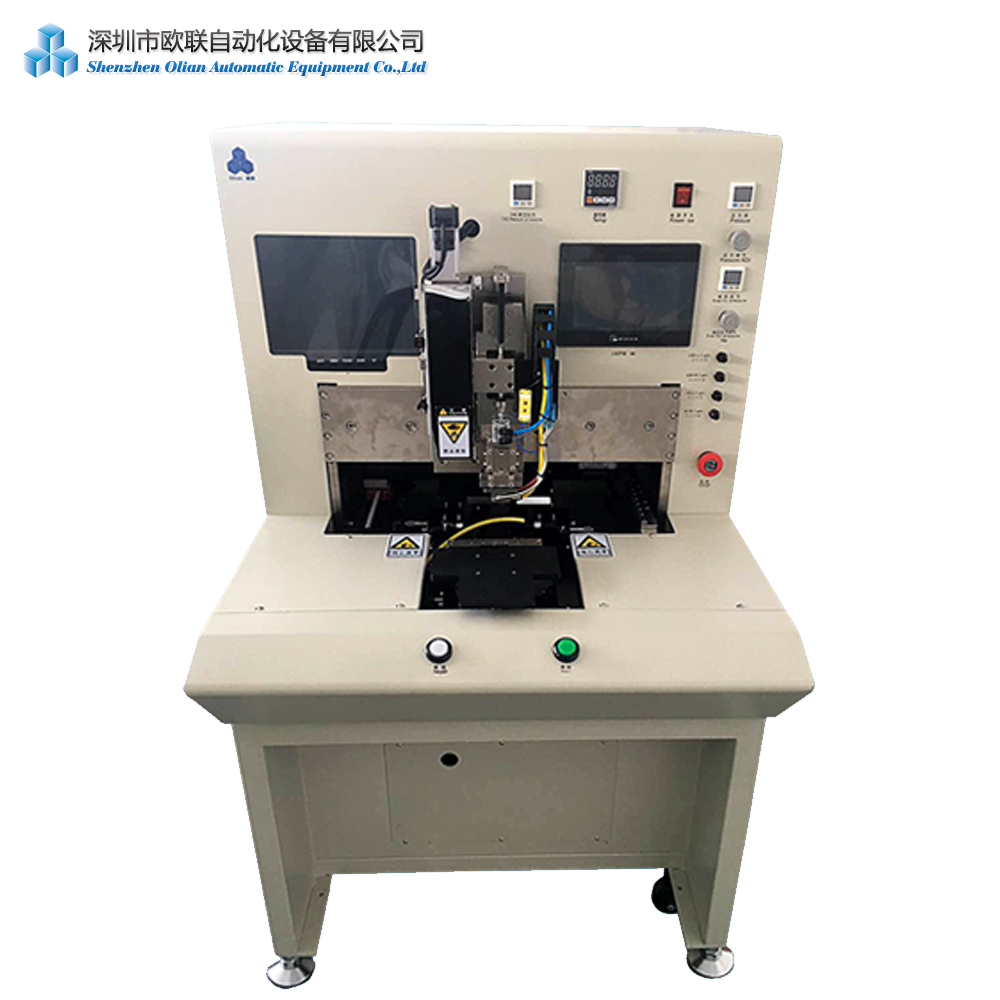

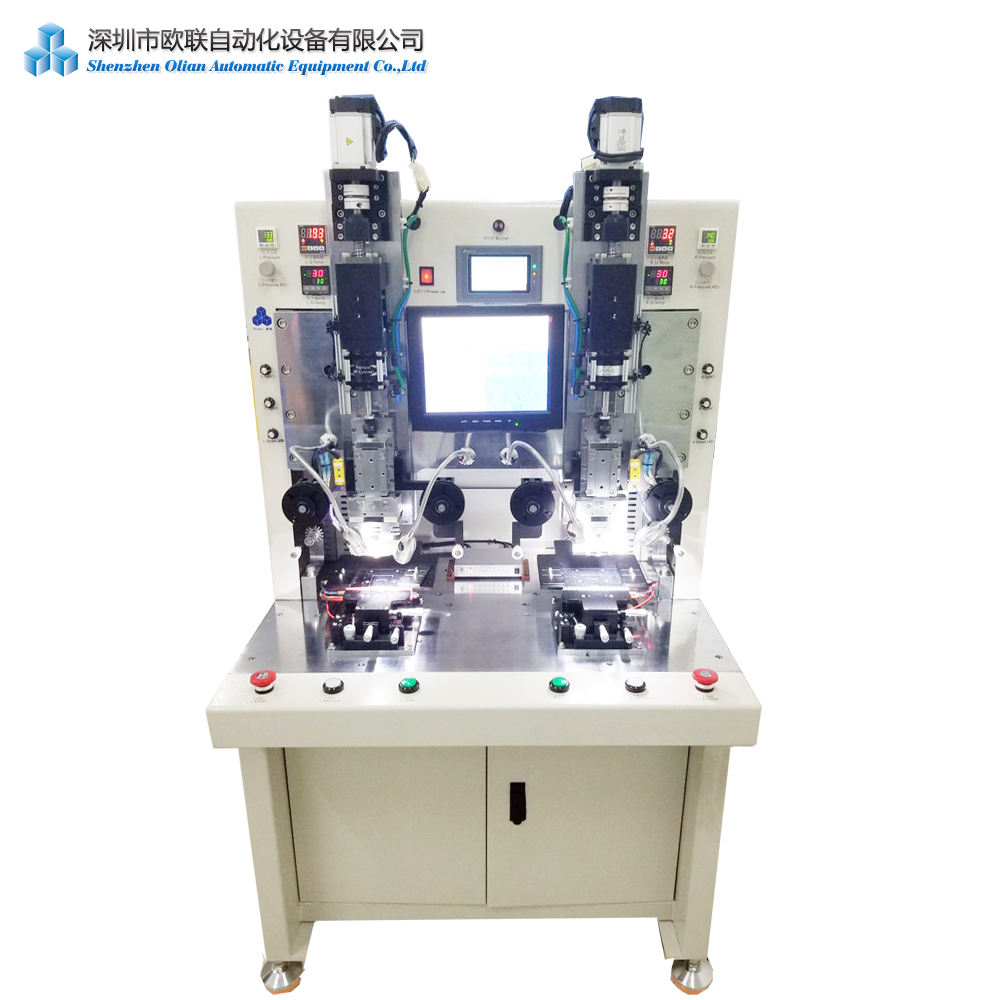

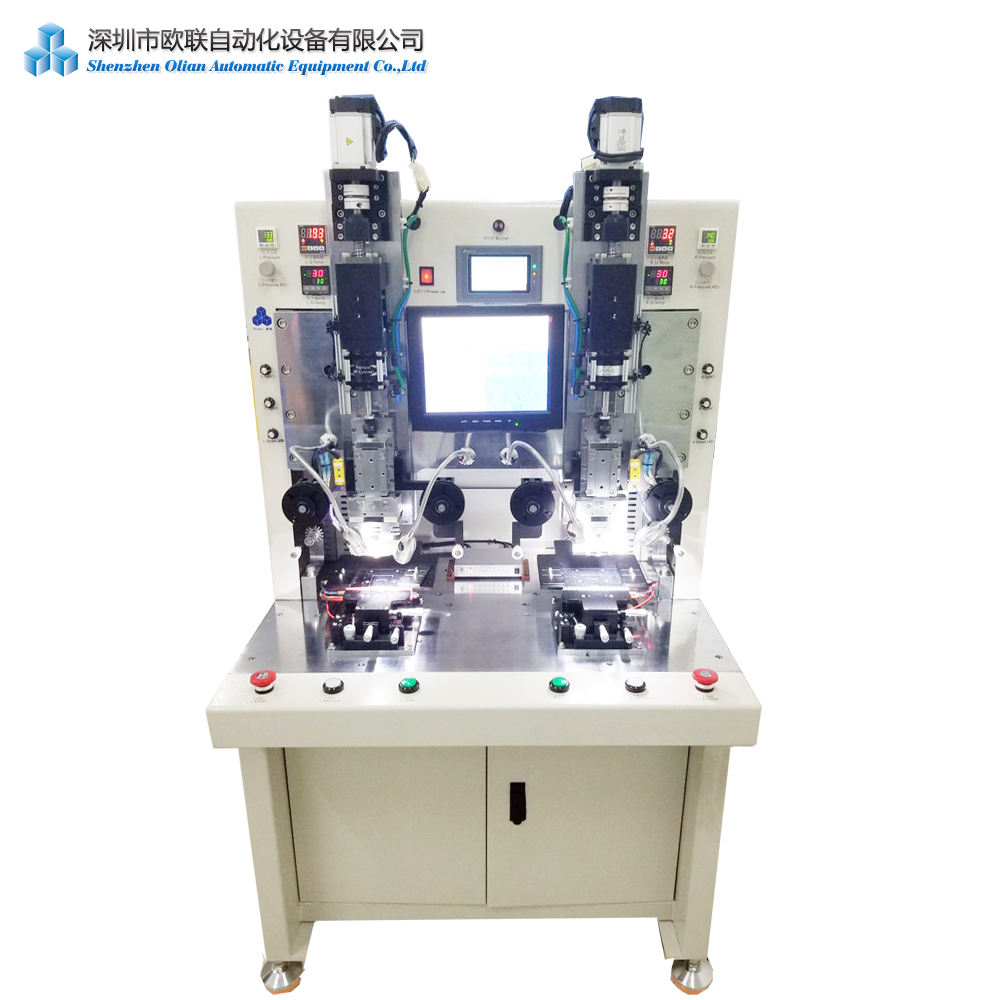

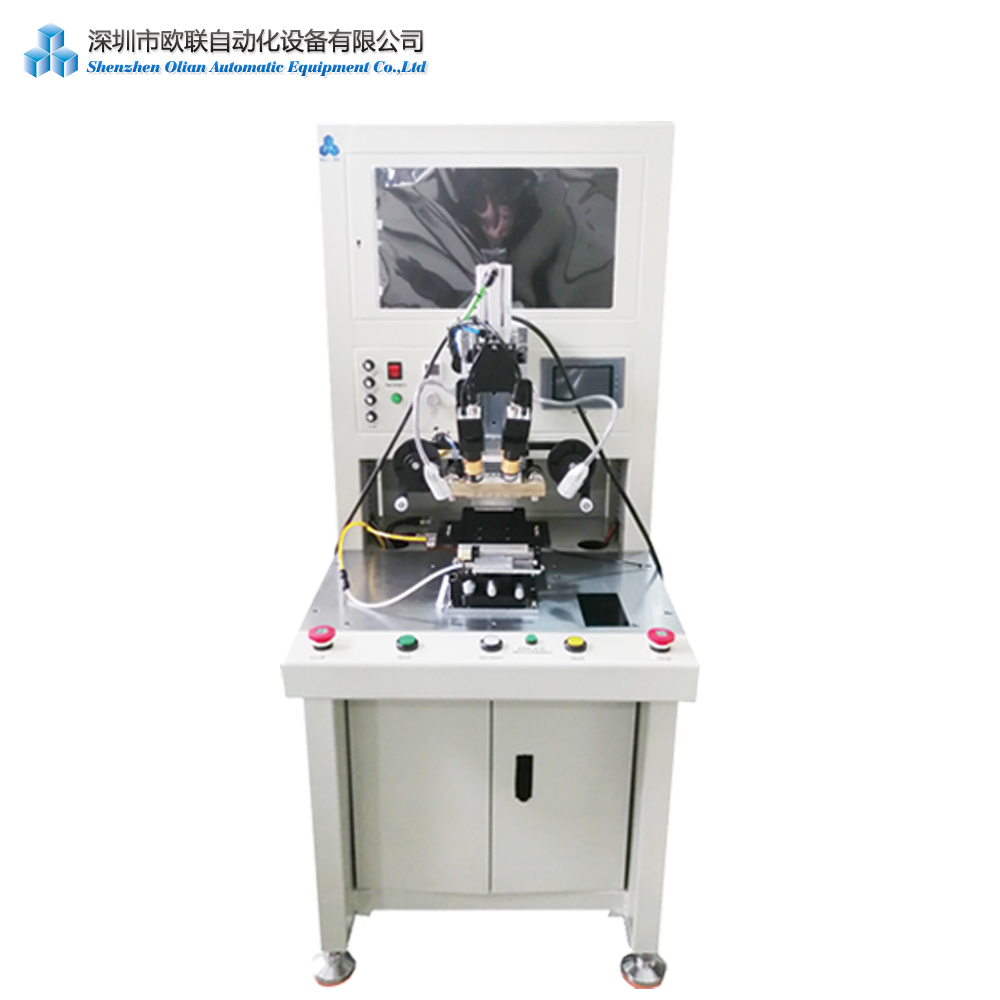

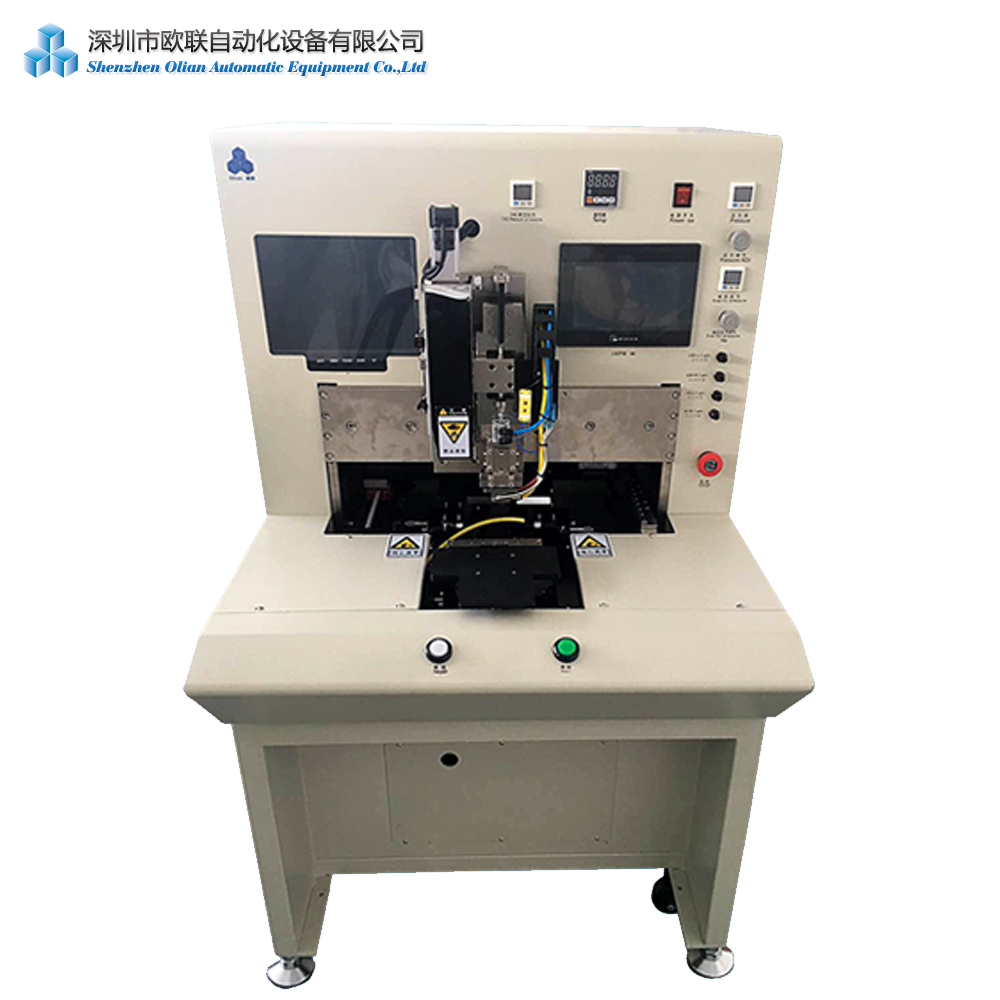

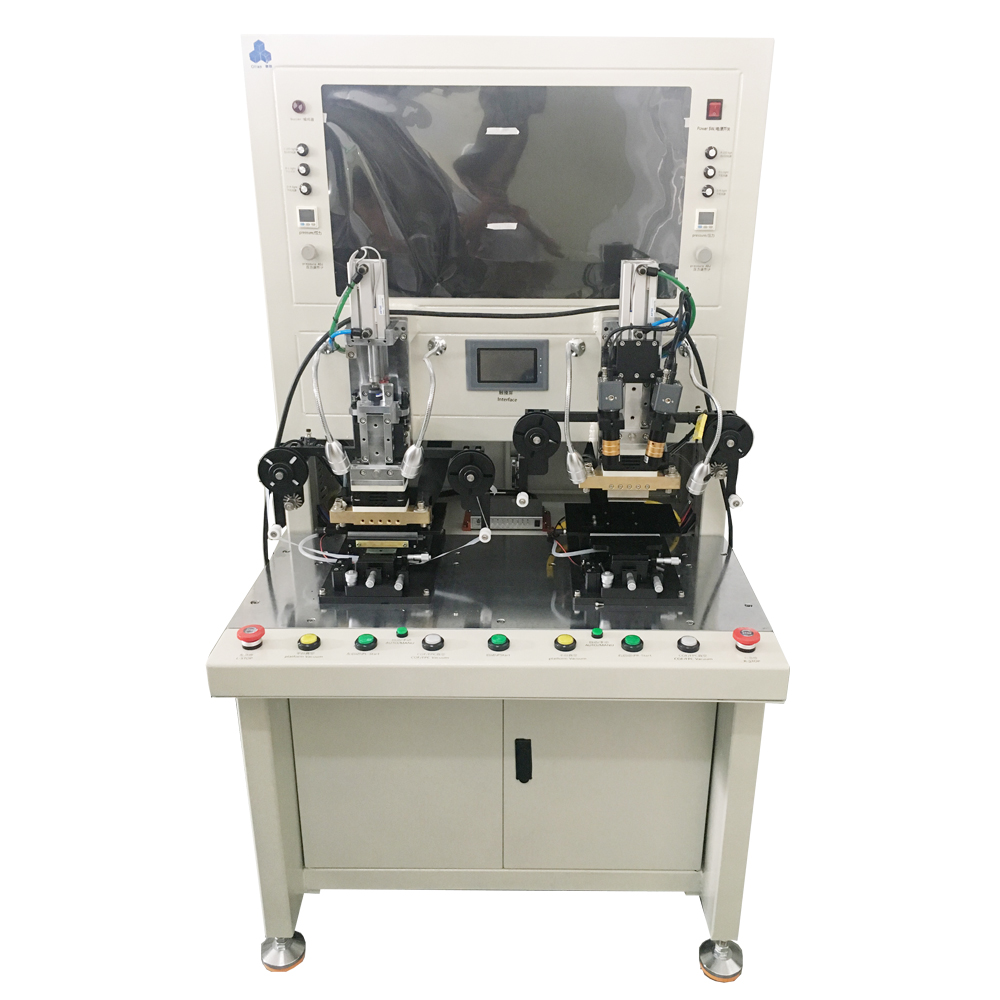

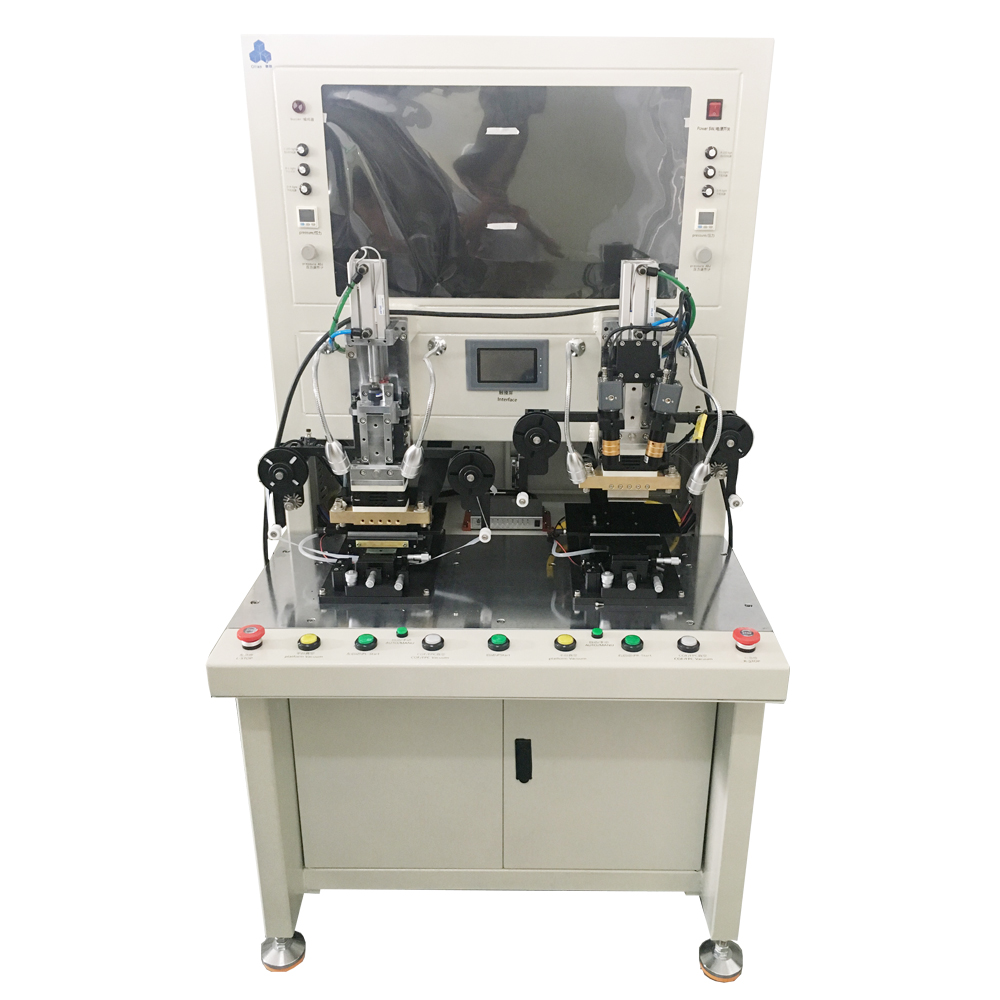

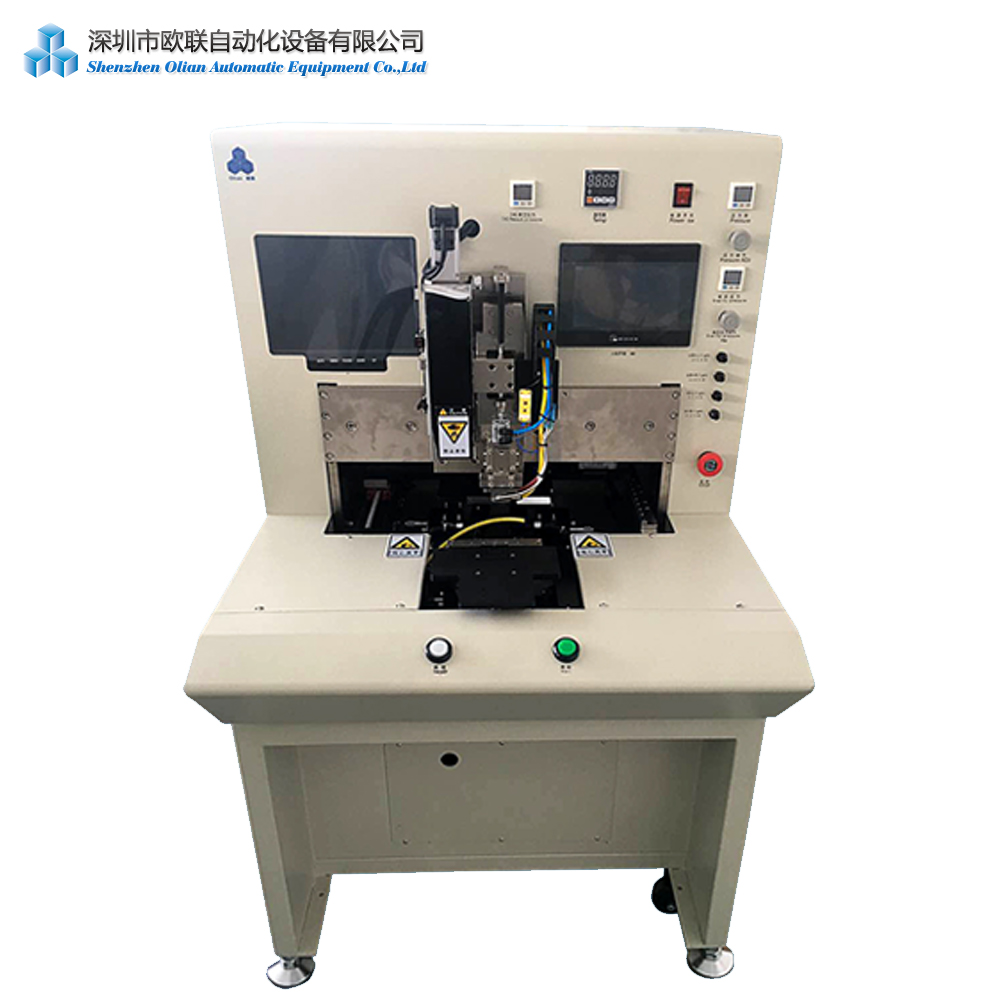

COF bonder, also named COF (Chip on Film) machine,COF ic bonding machine, COF(chip on film) bonder ,COF heat bonder, COF bonding machine, COF heat press machine, COF Pulse heat bonder./COF IC boner,COF Driver IC bonder.

It is widely used in the LCD/OLED, LCM/panel/screen/display , for Mobilephone/Watch/pad/notebook/touch panel/Ad Player/bank card/camera/ and all the flat and edge screens. for produce factories and repairing service shops all over the world.

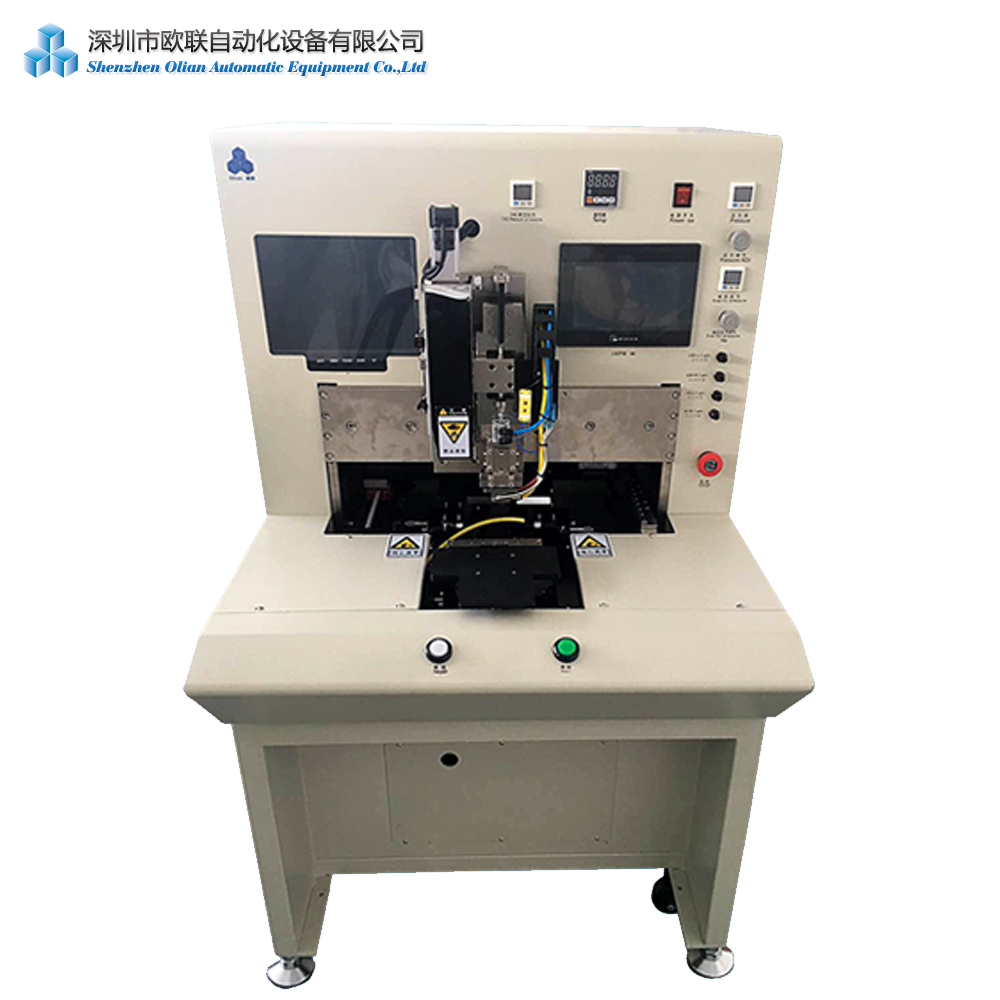

The COF Bonder may consist of HD Digital Microscope and control system, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the COF onto the Glass/PCB/FPC/OLED flexable display, using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

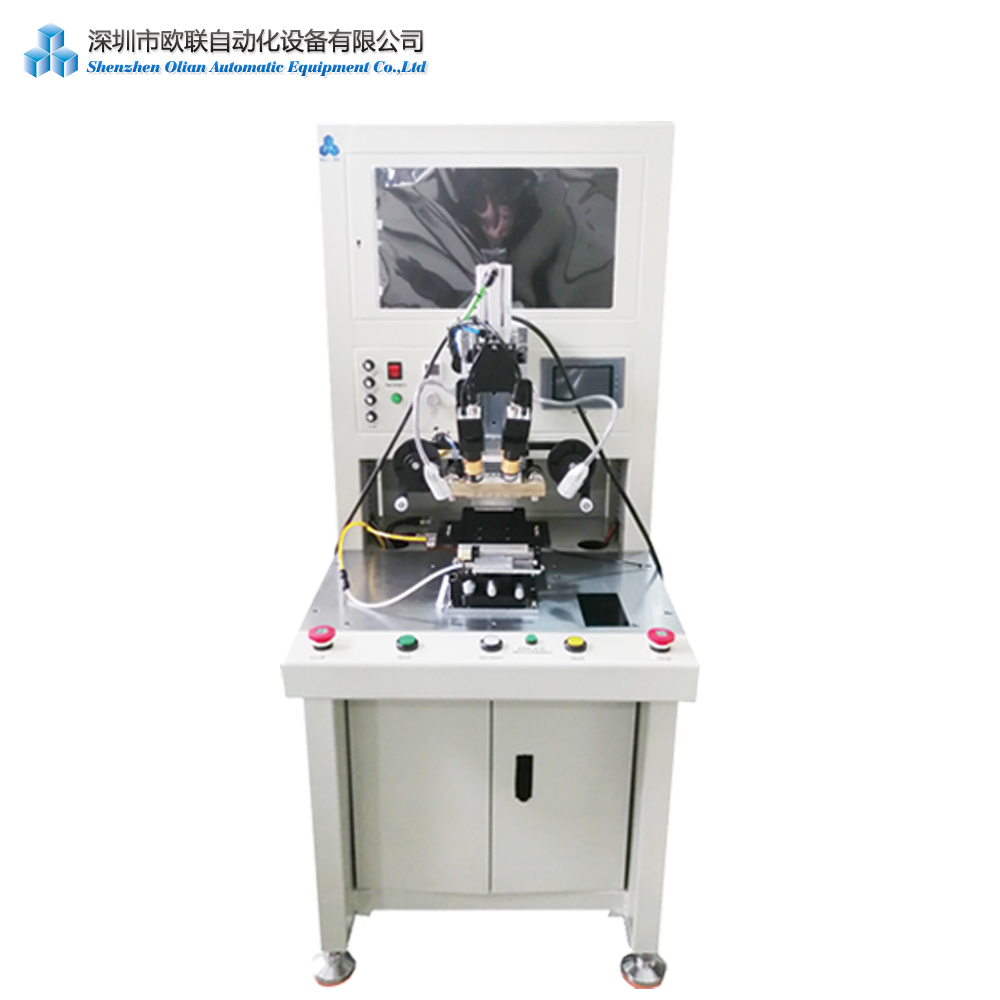

Shenzhen Olian is the professional COF bonder manufactury ,we are the LCM Equipment factory solution provider.

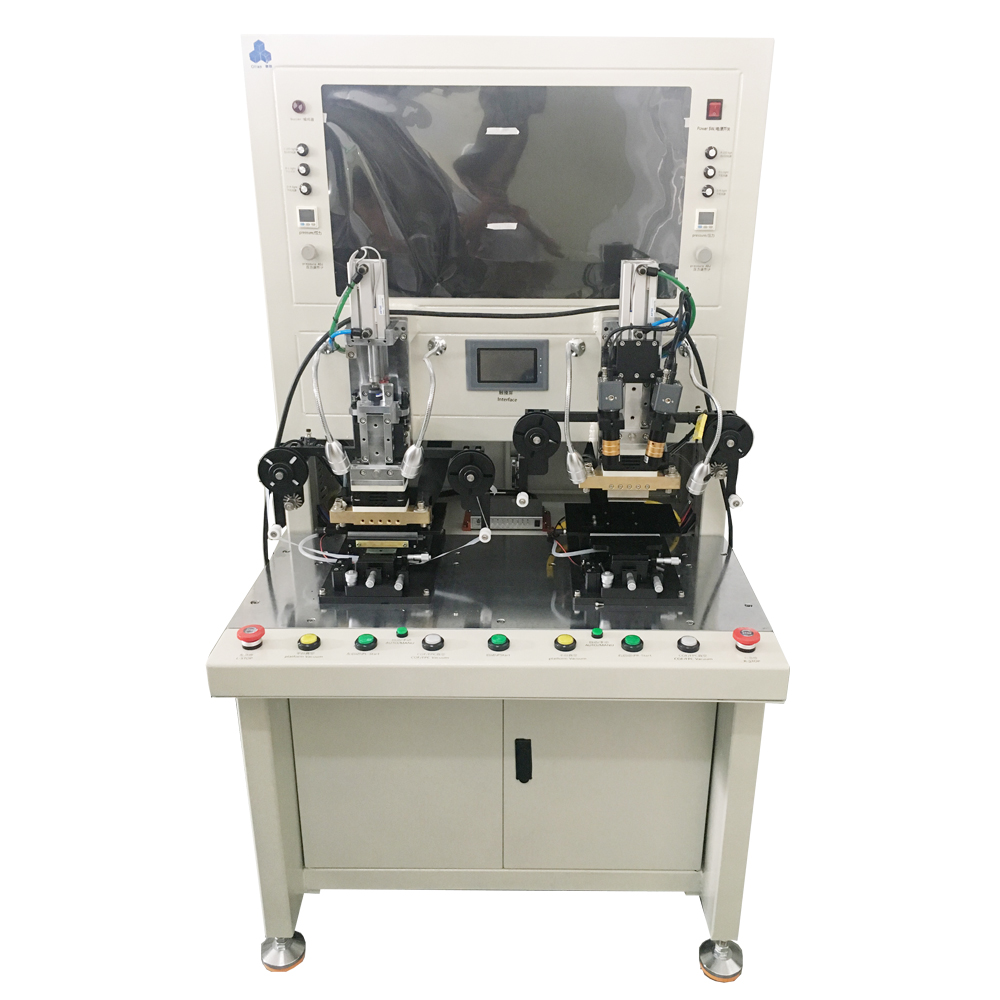

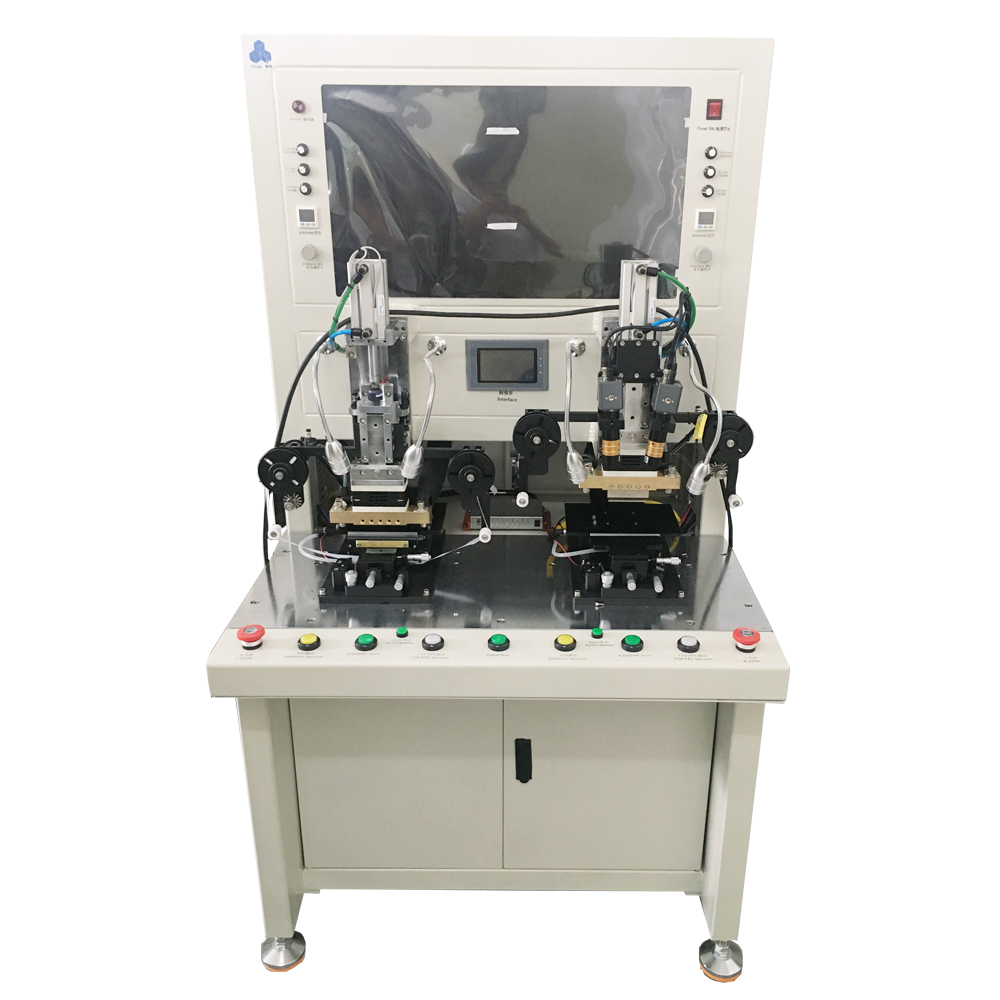

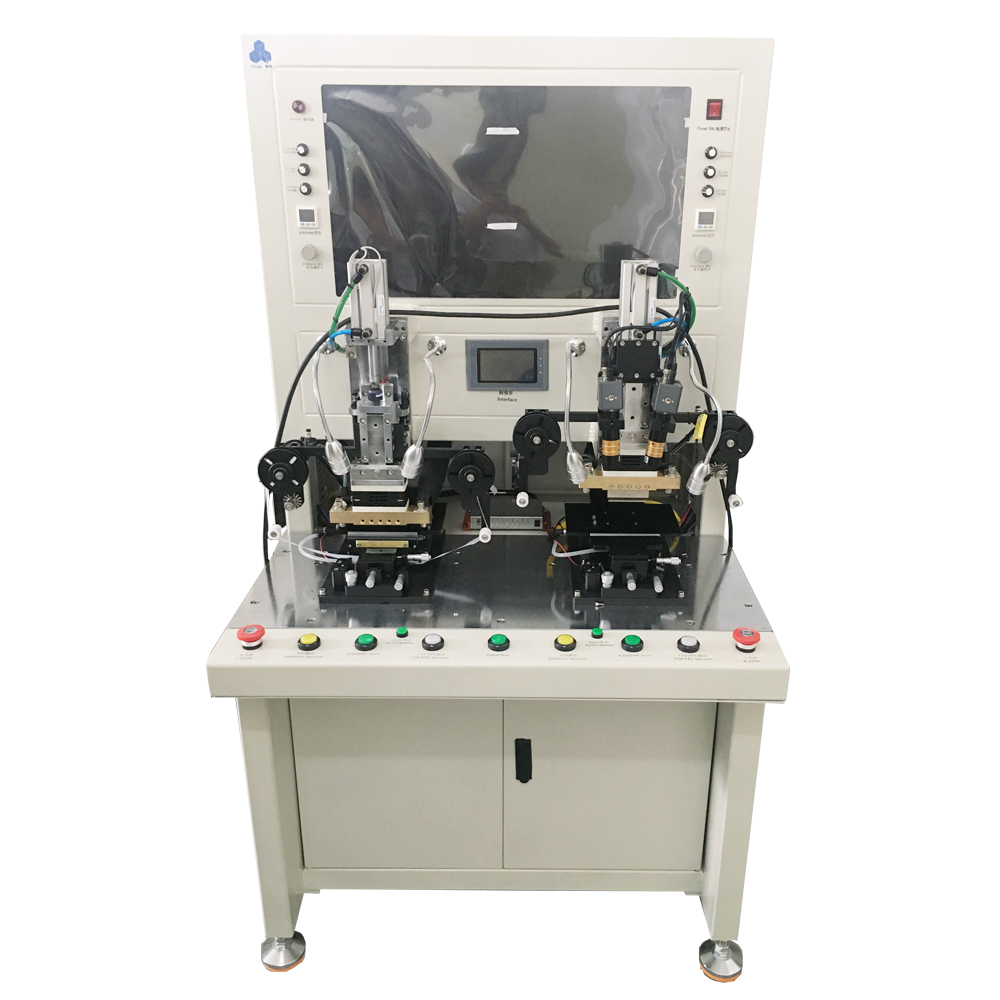

The machine has Pre-Bonder and Main-Bonder . They are all constant temperature machines. it maybe have single station bonder ,double stations , three stations, and maybe four stations bonder.

Features:

*Suitable for multi variety small batch production

*Constant temperature heating system

*Panasonic PLC Control system

*FAST Visual processing system

*Imported Japanese CCD Automatic Contraposition Configuration

*Manual / automatic switching

*Imported electrical configuration

Specification:

Model: OL-C003B/C005/C006

Product Name: Semi-Automatic Mid/High-speed COG/COF Pre-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 650pcs/H–1000pcs/H

Power Supply: 220V±10%,50HZ,1000W/1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 140*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 40*2MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

N.W: About 300KG/350KG

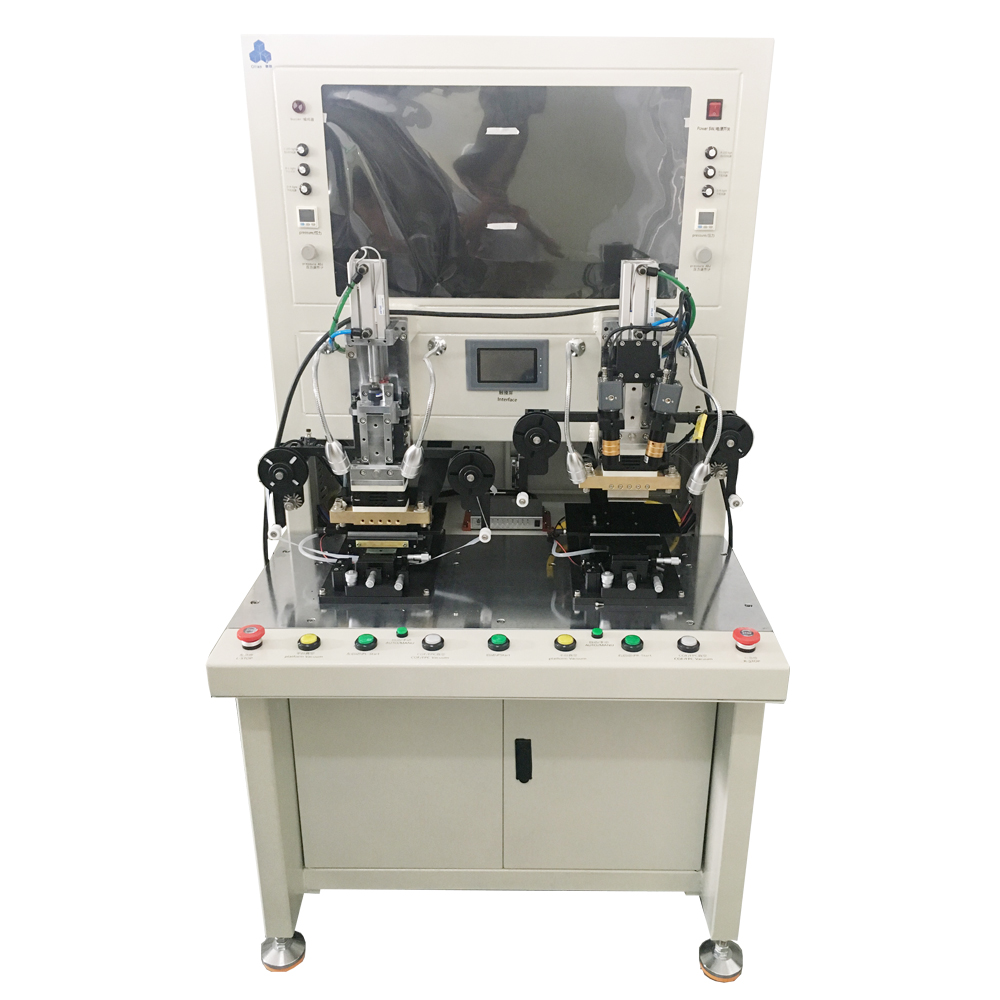

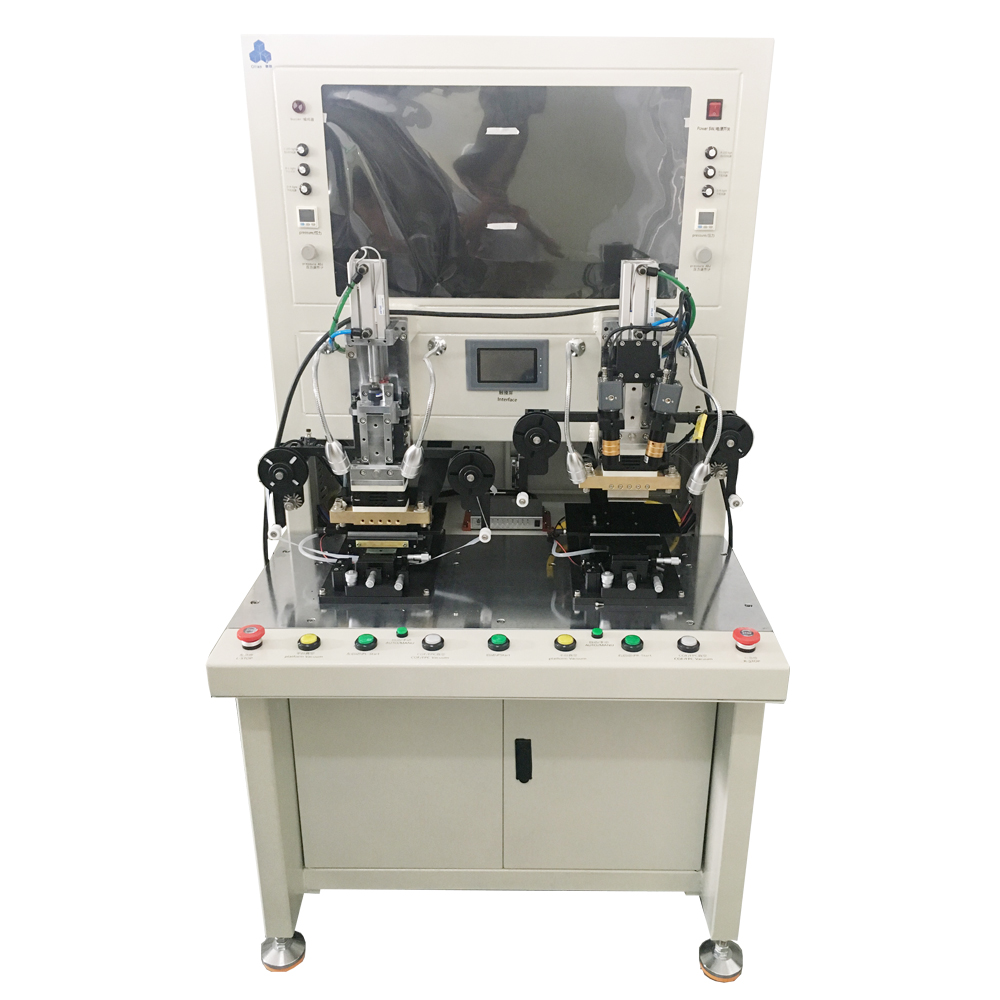

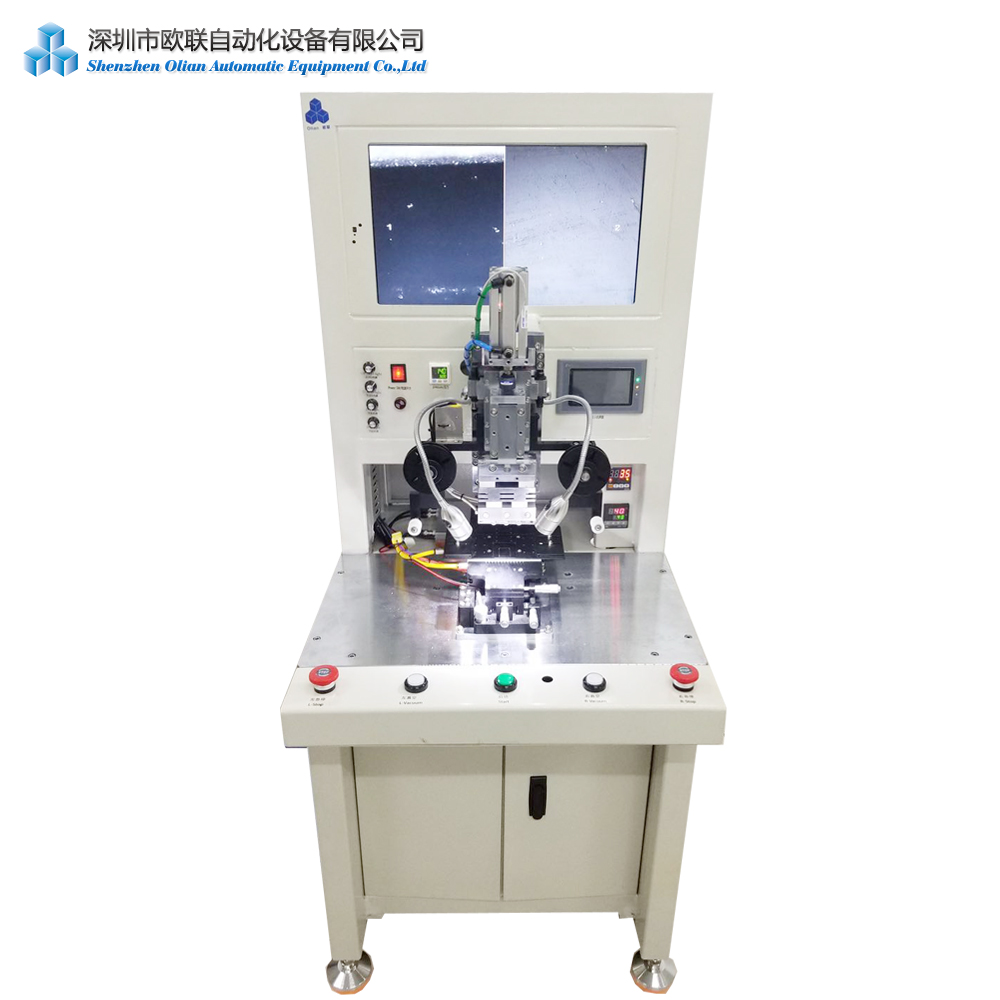

Features:

*PID Control Constant Temp Heating System,Automatic temperature compensation to ensure that the temperature of hot pressing is stable.

*Panasonic PLC Control system.

*Use high precision low-friction cylinder control pressure to ensure the accuracy of pressure control.

*High steel structure set, dual ceramic indenter configuration, to ensure the stability of the equipment.

*Imported electrical configuration,

*For OLED high-end products,high quality,high successful rate。

Specification:

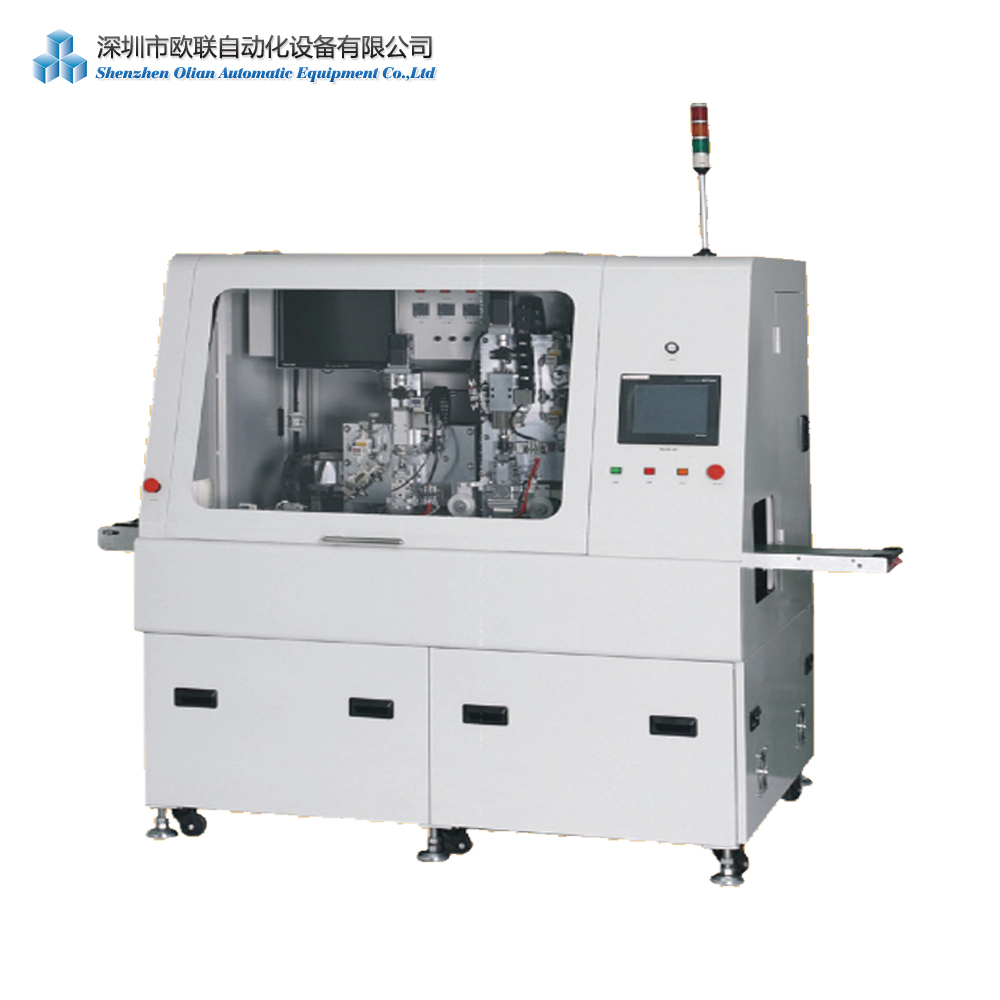

Model: CM006

Product Name: 1-12 inch Triple Stations Semi-Automatic High-speed COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1100pcs/H

Power Supply: 220V±10%,50HZ,2000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L1025*W750*H1400 MM

N.W: About 350KG

Model: OL-C008/OL-C012

Product Name: 1-12 inch Double Stations Semi-Automatic Mid-speed Servo COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 600pcs/H

Power Supply: 220V±10%,50HZ,1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L640*W700*H1320MM

COF bonder, also name TAB bonder, ACF bonder, OLB Bonder , Chip on Film bonder. COF(Chip on Film, Chip on Flex).COF bonder is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonder also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonder for TV Repairing is Pulse heating bonding machine with Titanium alloy press bonding head.

Our COF bonder and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Please contact us feel free to purchase the COF bonder for TV Repairing accessories.

Welcome to buy the COF bonder for TV Repairing and all the COF bonder accessories.

COF bonders for full screen /edge screen/OLED screen mobilephone

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our COF bonder for cellphones.

OLED panel bonding machine, is for AMOLED panel produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the OLED panel and flexible FPCs.

An organic light-emitting diode (OLED) is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and PDAs. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row (and line) in the display is controlled sequentially, one by one,whereas AMOLED control uses a thin-film transistor backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

The different manufacturing process of OLEDs has several advantages over flat panel displays made with LCD technology.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

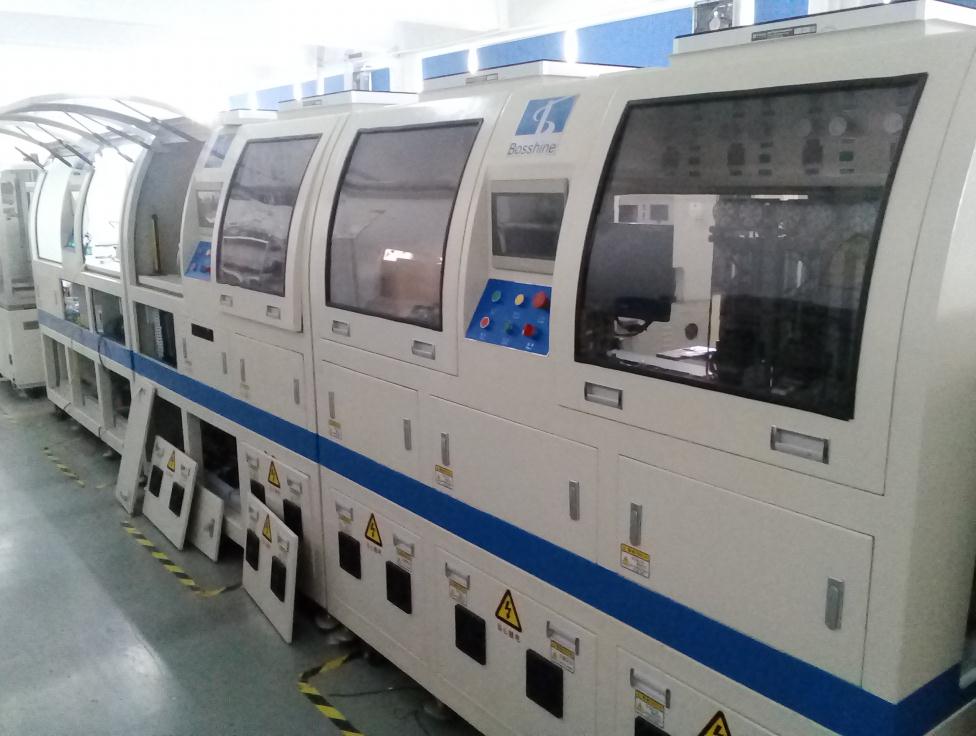

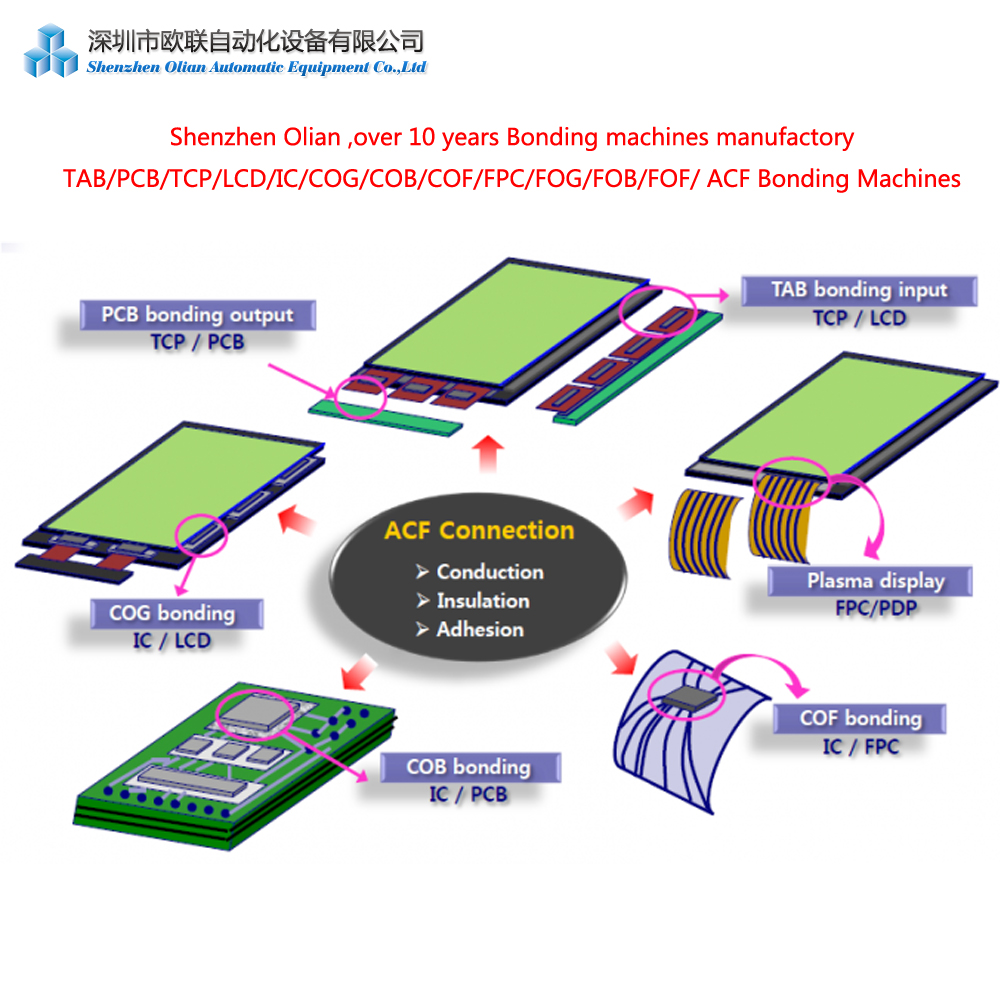

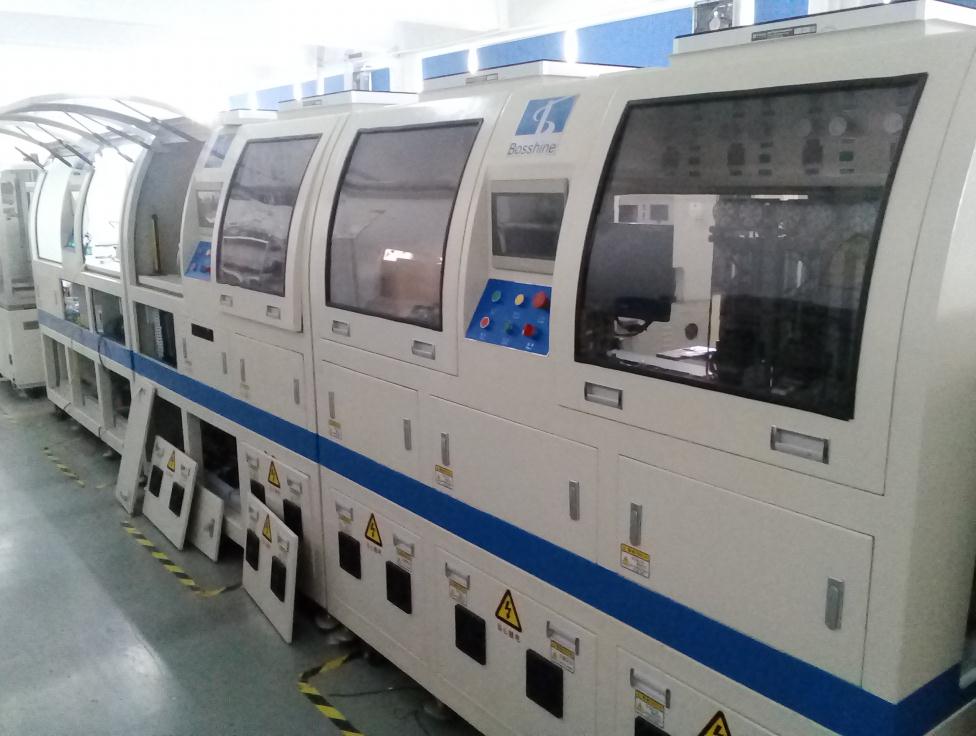

All the bonding machines ,welcome you visit us-Shenzhen Olian(Professional in design&making all kinds of bonding machines)

All the ACF/COG/COF/COB/FOG/FOB/FOF/OLB/TAB/PCB/FPC/TCP/ bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

Shenzhen Olian ACF/COG/COF/COB/FOG/FOB/OLB/FOF/TAB/OGS/PCB/FPC bonder manufactory. Welcome you to be our partner and dealers all over the world.

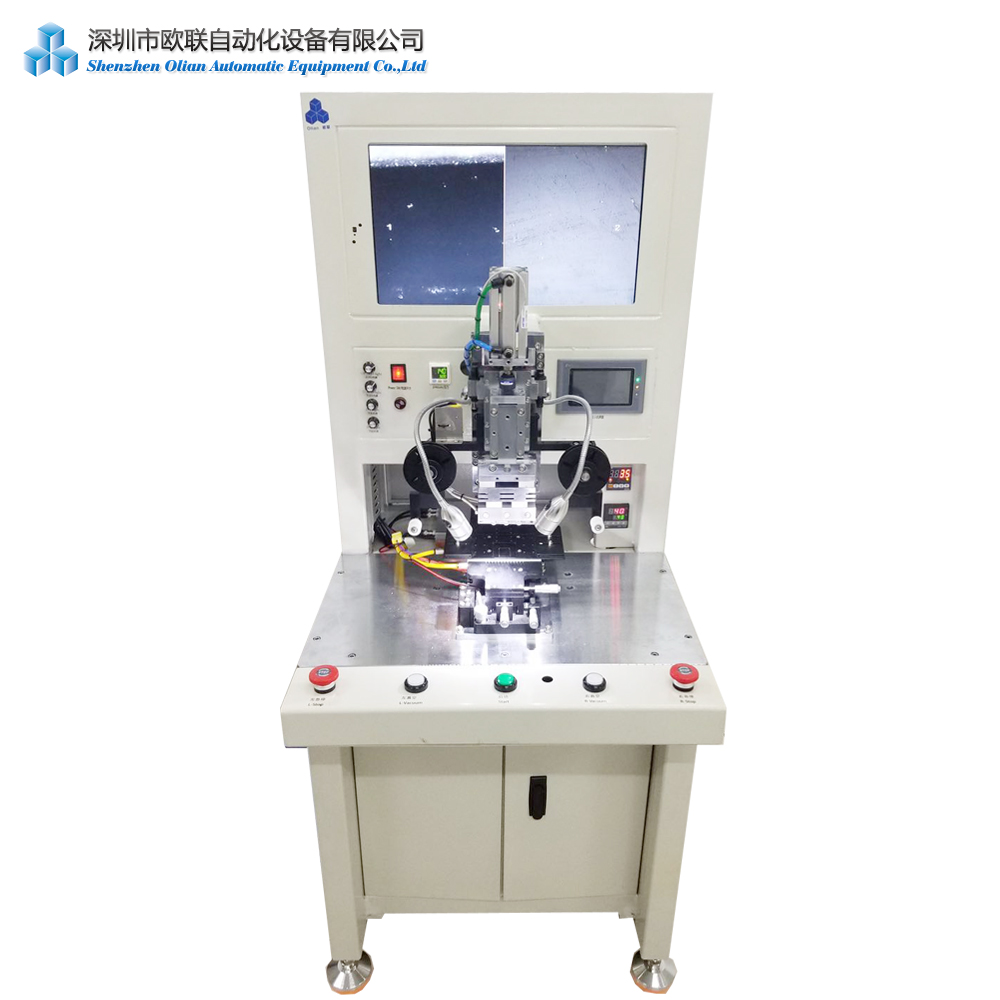

FPC bonder, it may press the FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

It also named FPC Bonding machine,FPC equipment,FPC heat bonder, FPC heat press machine,FPC welding machine,FPC welding tool,FPC soldering machine,FPC thermal compression bonding machine,LCD flex cable repair bonding machine,FOG device,FOG tool,FOG bonding machine, wire bondingmachine,thermal bonding machine,heat bonding machine,ACF bonder.

FPC Bonder is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The FPC bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The FPC bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

FPC IS Flexible Printed Circuit,Flexible print circuits (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

In practice there are many different kinds of flexible circuits, including one metal layer, double sided, multilayer and rigid flex circuits. The circuits can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

There are many advantages that come with using flexible circuit technology beyond the initial flex capabilities. Performance advantages, such as, dynamic flexing and increased heat dissipation allow engineers to design these circuits into applications where extreme temperatures and vibrations are common. Other advantages with using flexible circuits include less weight, increased package density, and a more integrated design.Flexible circuits can cost less than traditional assemblies because one flex assembly can replace several, single circuits.

Flex circuits also allow design engineers to utilize space three dimensionally which cuts down on the overall footprint of the circuit and saves space.

Applications of flexible circuits ranges in a variety of fields. Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

FOG is a kind of use in the flat display industry, such as, LCD screen, electronic paper production process, using ACF conductive adhesive as the media through a certain temperature, pressure, time to FPC bonded on the glass.

FOG is the abbreviation FPC ON the GLASS, that is, FPC bonded ON the GLASS of a kind of process.

Shenzhen Olian design and make all kinds of FPC bonder. Welcome you visit us and OEM&OEM FPC/FOB/FOG/FOF bonding machine with us for your factory and your globe trade business.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models for FPC bonder. ACF tape is the import medium of the bonding process.

FPC bonder, Flexible Printed Circuit bonder,also Flex cable bonding machine , has FOG(FPC on glass ) ,FOB(FPC on PCB Board),FOF(FPC on FPC) , It have Pulse Heating Bonder and Constant Temperature Bonder.

FPC(FOB/FOG/FOF) bonder specifications:

*Constant temperature heating system/Pulse heating system

*Panasonic PLC Control system

*Human – Machine interface

*Automatic temperature alarm

*Press Head Level Adjustable Device

*Down/UP Contraposition HD Colorful CCD and 10.4~24 inch HD LCD

*Manual / automatic switching

*Imported electrical configuration

* apply for all the LCD,LED,ONCELL,OLED panels.

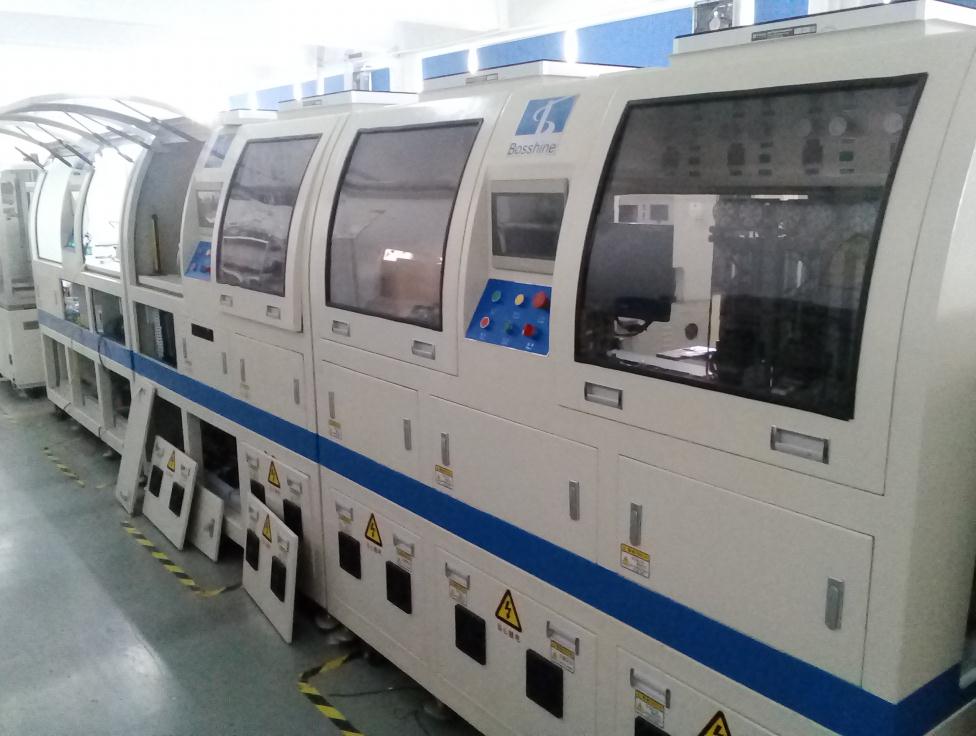

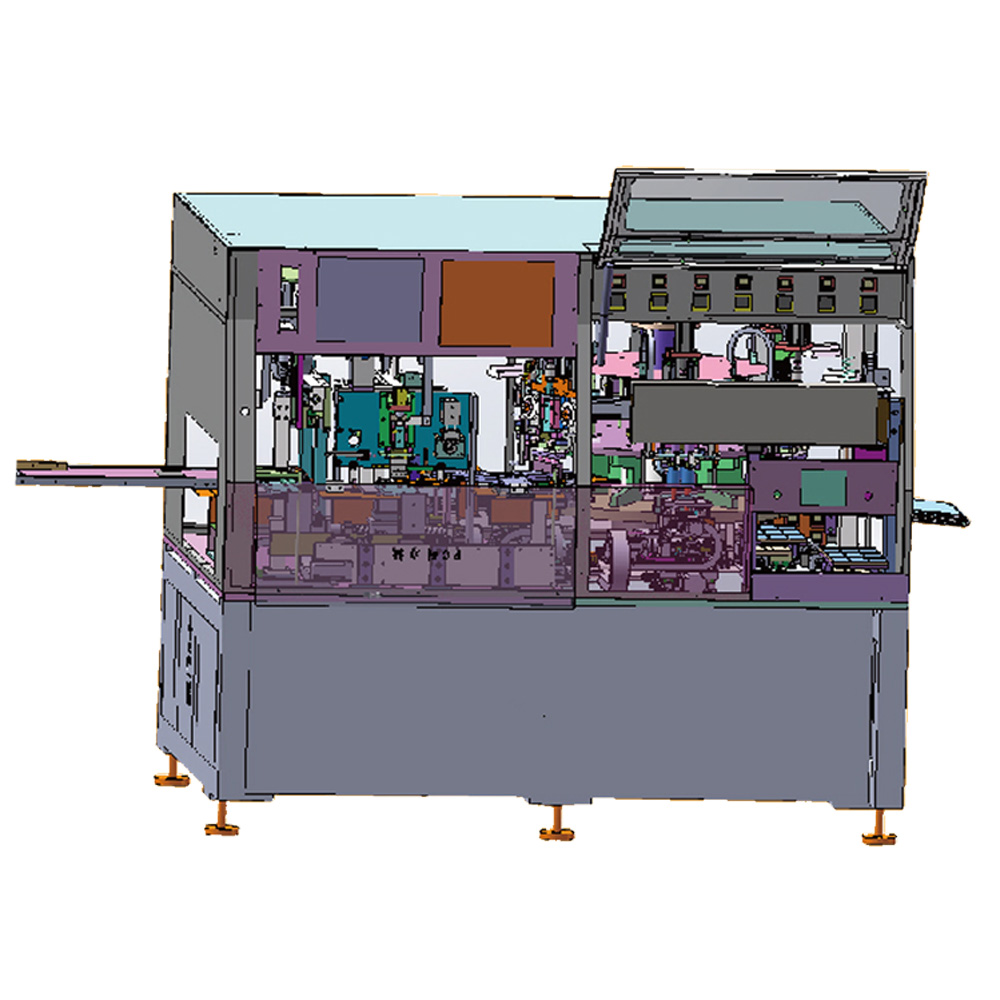

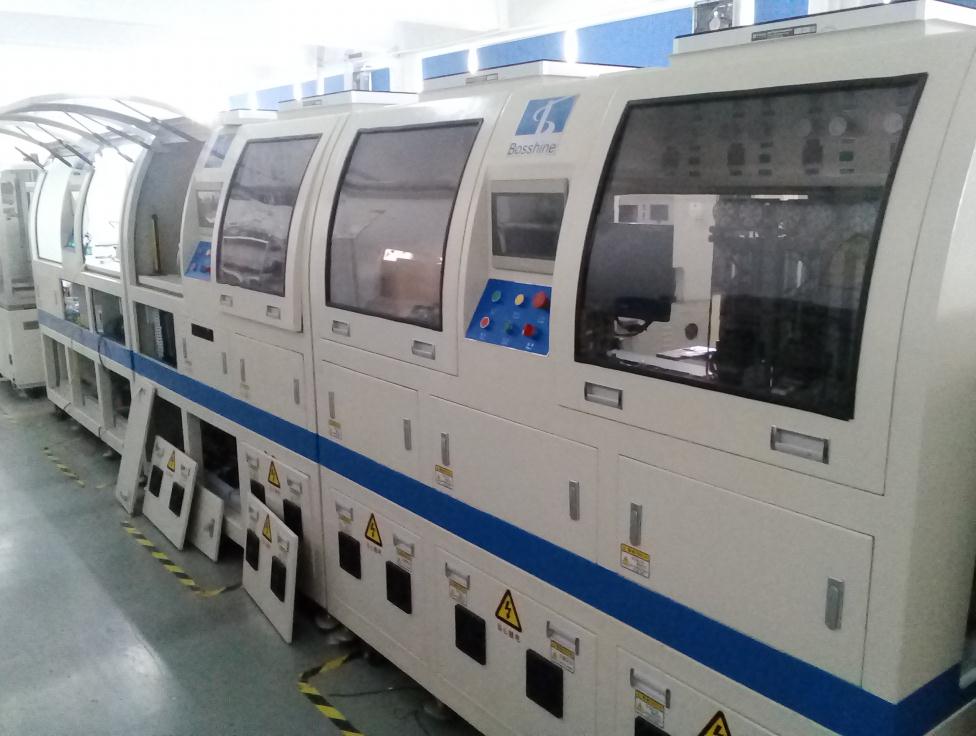

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG Bonder(COG pre-bonder, COG final-bonder ), FPC(FOG) bonder, as below:

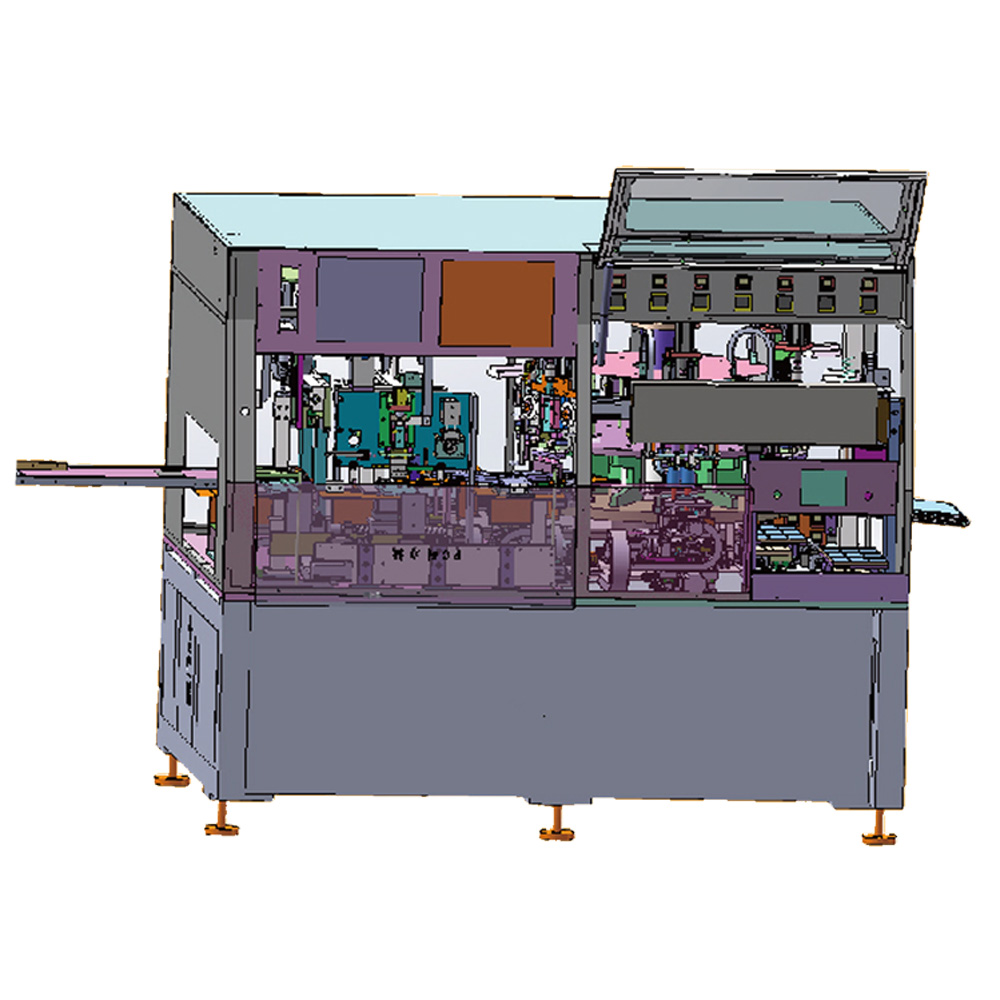

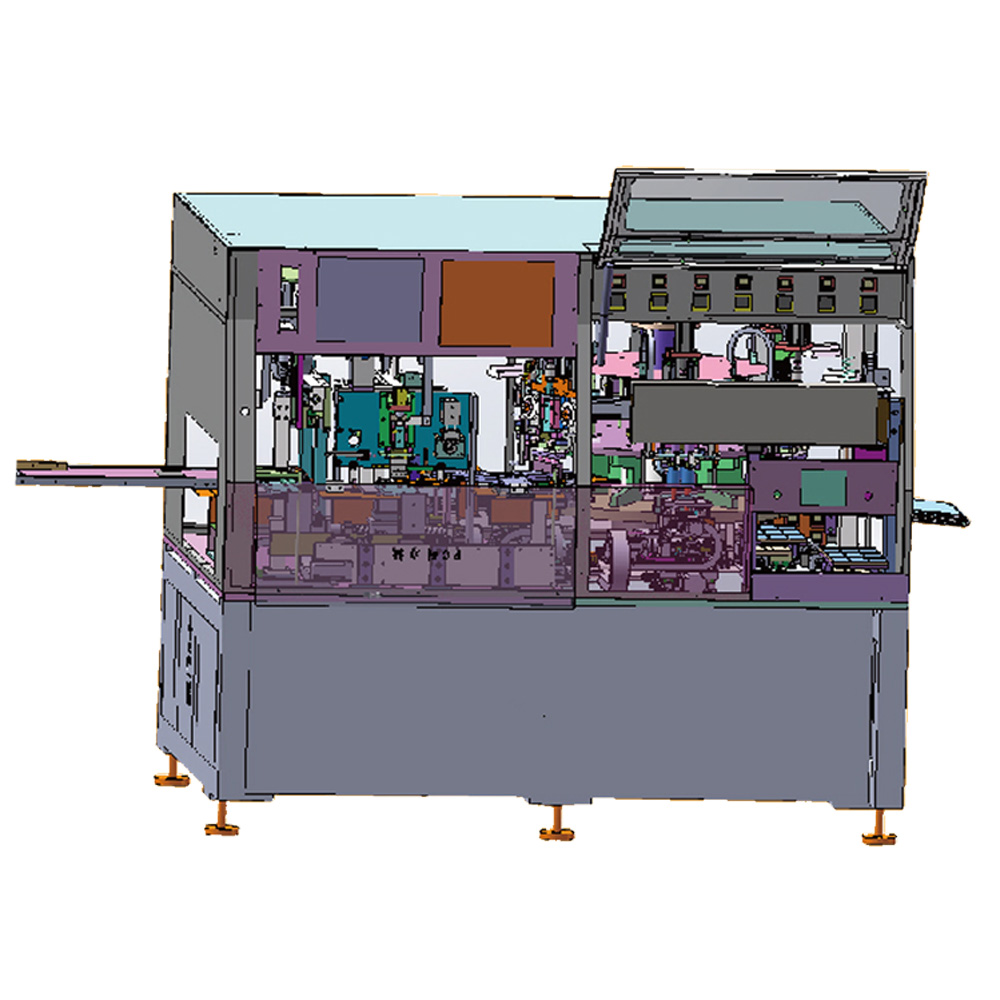

Full automatic FPC(FOG) bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic bonder include all the process of the COG and FOG bonding : the LCD loading,LCD cleaning, IC loading, IC cleaning,ACF attaching on the glass, IC pre-bonding, IC bonding cheking, and IC main-bonding processes. then the ACF attaching for FPC, FPC loading, FPC bonding on the glass and output to testing…

We design and make the standard FPC/FOG/COG/COF/ACF Bonders and customized FPC bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

All the FPC bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

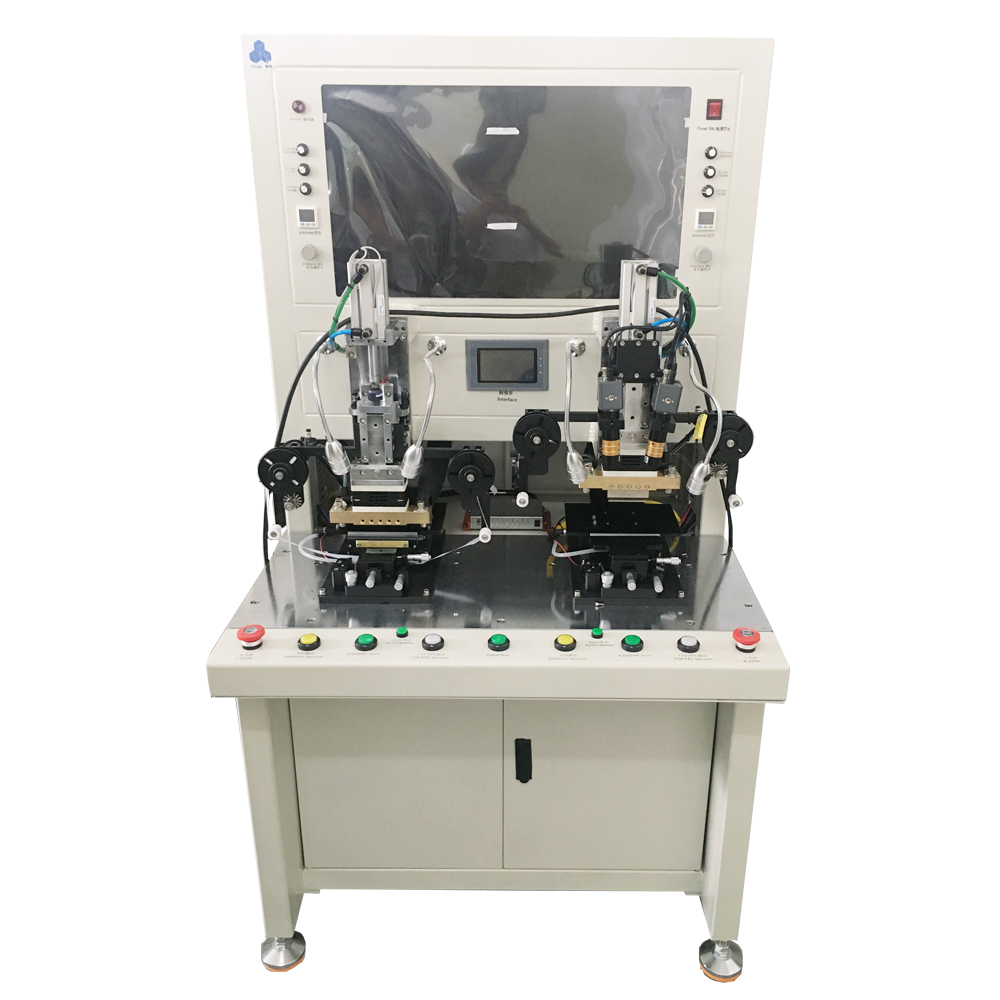

FOG bonder, it may press the FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.it also named FOG machine, FOG equipment, FOG heat bonder, FOG heat press machine, FOG device, FOG tool, FOG bonding machine, ACF bonder. .It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The FOG bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The FOG bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

FOG bonder, also name FOB bonder, FPC bonder, Flex cable bonder .FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonder, COF on PCB board bonder, COF on film bonder. It have Pulse Heating Bonder and Constant Temperature Bonder. Also it will be named wire bondingmachine,thermal bonding machine,heat bonding machine,

FPC/FOB/FOG/FOF bonder specifications:

*Constant temperature heating system/Pulse heating system

*Panasonic PLC Control system

*Human – Machine interface

*Automatic temperature alarm

*Press Head Level Adjustable Device

*Down Contraposition HD Colorful CCD and 10.4 inch HD LCD

*Manual / automatic switching

*Imported electrical configuration * apply for all the LCD,LED,ONCELL,OLED panels.

FPC IS Flexible Printed Circuit,

Flexible print circuits (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

In practice there are many different kinds of flexible circuits, including one metal layer, double sided, multilayer and rigid flex circuits. The circuits can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

There are many advantages that come with using flexible circuit technology beyond the initial flex capabilities. Performance advantages, such as, dynamic flexing and increased heat dissipation allow engineers to design these circuits into applications where extreme temperatures and vibrations are common. Other advantages with using flexible circuits include less weight, increased package density, and a more integrated design.Flexible circuits can cost less than traditional assemblies because one flex assembly can replace several, single circuits.

Flex circuits also allow design engineers to utilize space three dimensionally which cuts down on the overall footprint of the circuit and saves space.

Applications of flexible circuits ranges in a variety of fields. Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

FOG is a kind of use in the flat display industry, such as, LCD screen, electronic paper production process, using ACF conductive adhesive as the media through a certain temperature, pressure, time to FPC bonded on the glass.

FOG is the abbreviation FPC ON the GLASS, that is, FPC bonded ON the GLASS of a kind of process.

Shenzhen Olian design and make all kinds of FPC bonder. Welcome you visit us and OEM&OEM FPC/FOB/FOG/FOF bonding machine with us for your factory and your globe trade business.

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG Bonder(COG pre-bonder, COG final-bonder ), FOG(FOB) bonder, as below:

Full automatic FOG bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic bonder include all the process of the COG and FOG bonding : the LCD loading,LCD cleaning, IC loading, IC cleaning,ACF attaching on the glass, IC pre-bonding, IC bonding cheking, and IC main-bonding processes. then the ACF attaching for FPC, FPC loading, FPC bonding on the glass and output to testing…

We design and make the standard FOG/COG/COF/ACF Bonders and customized FOG bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

All the FOG bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

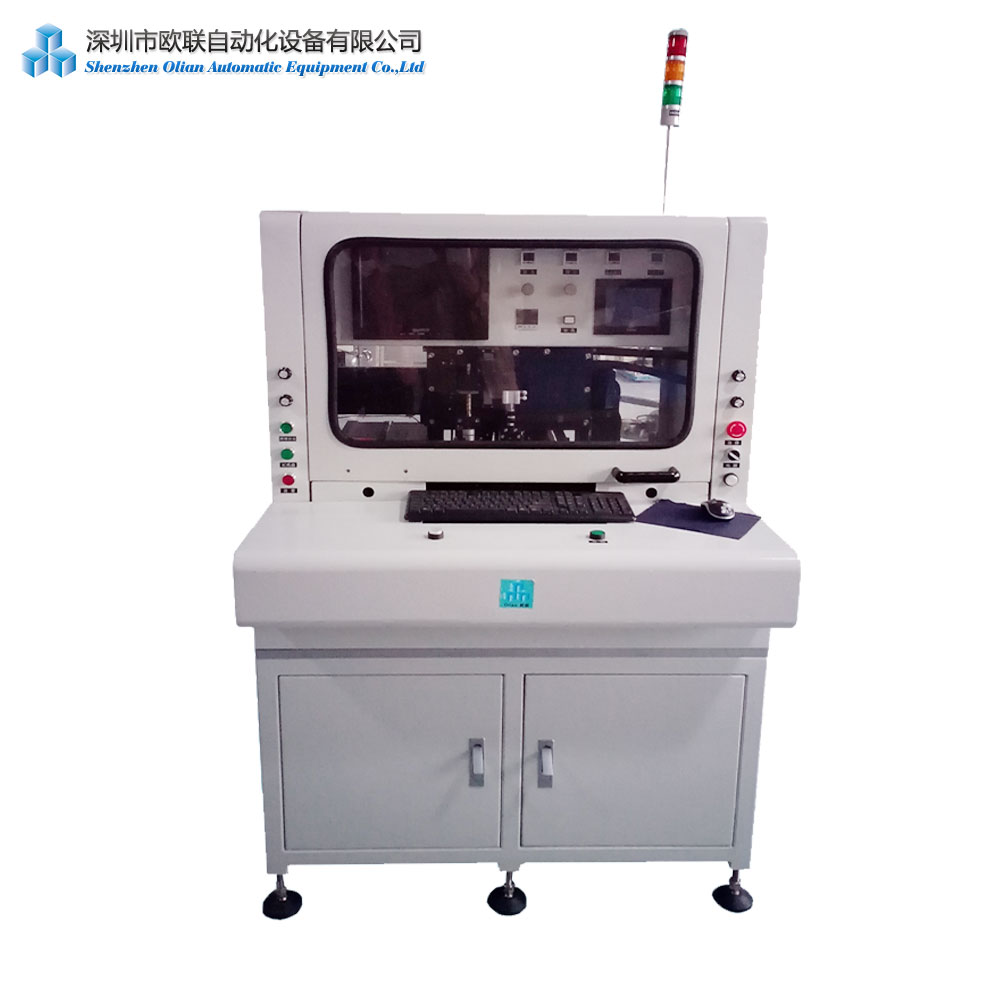

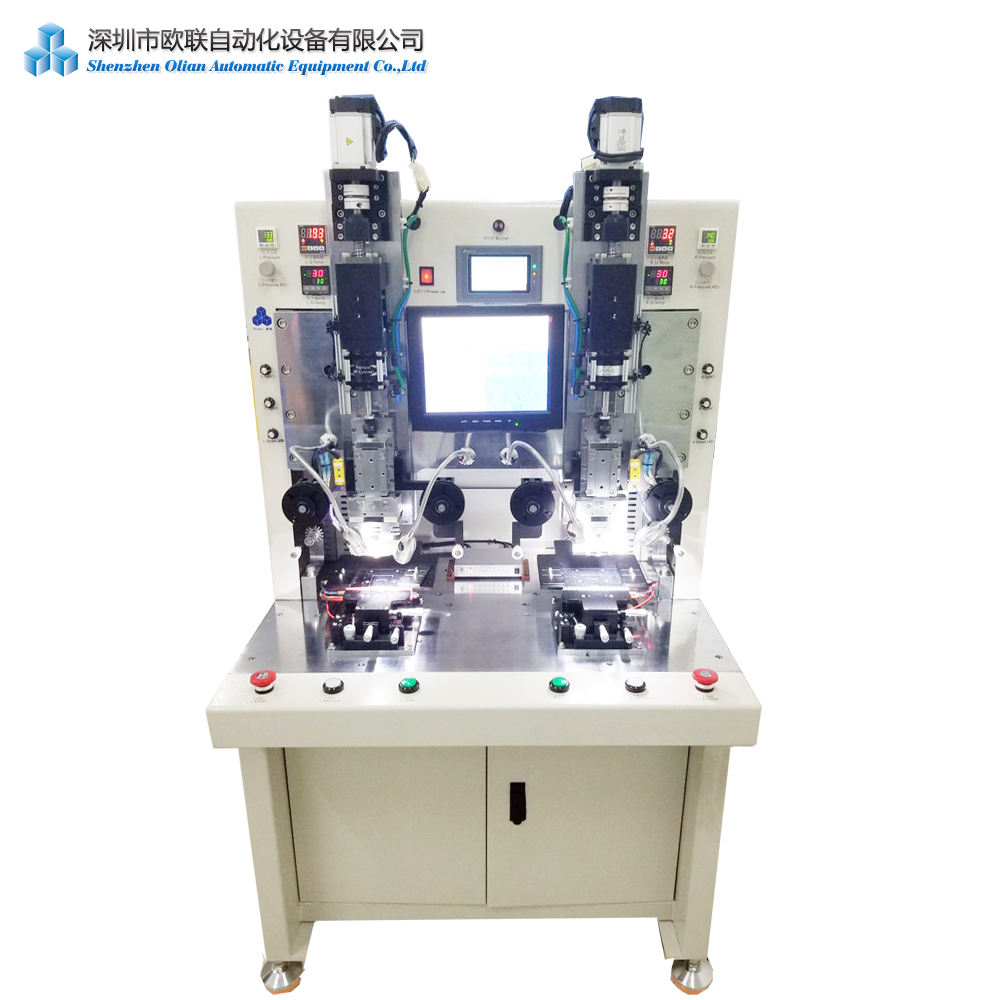

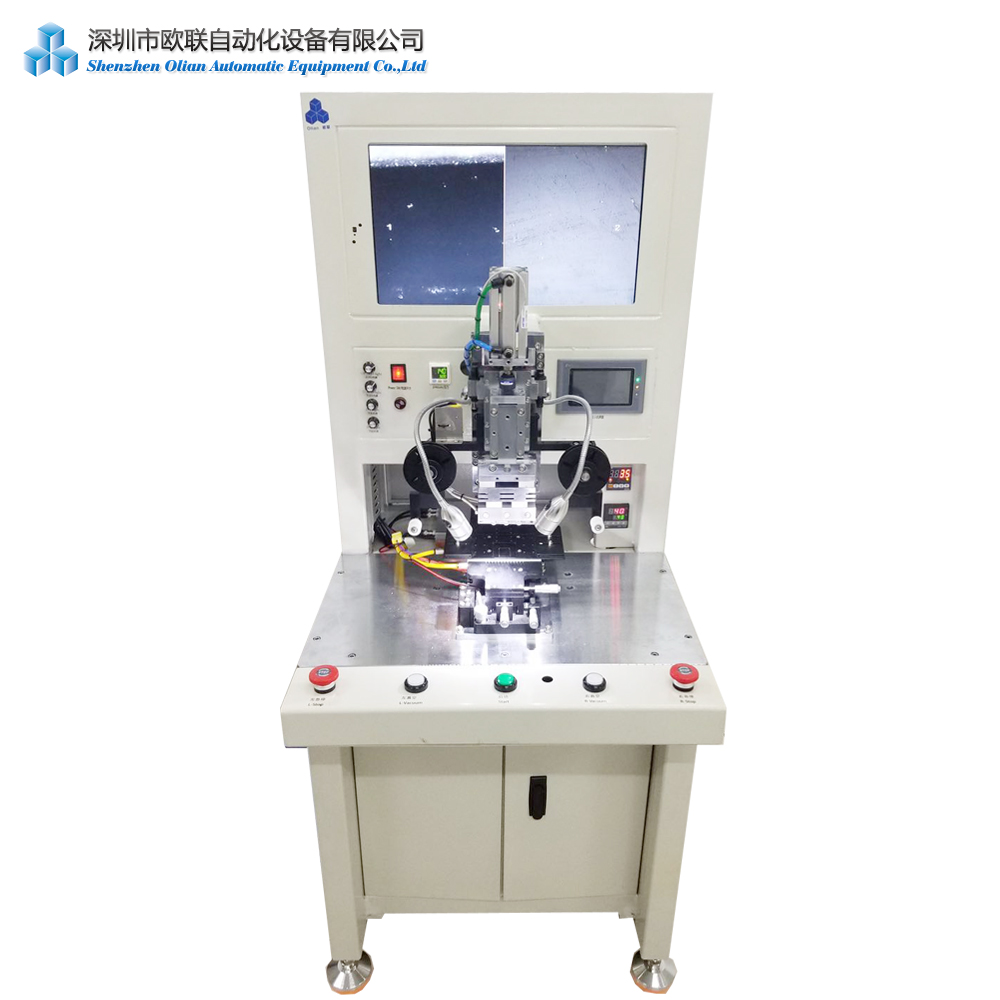

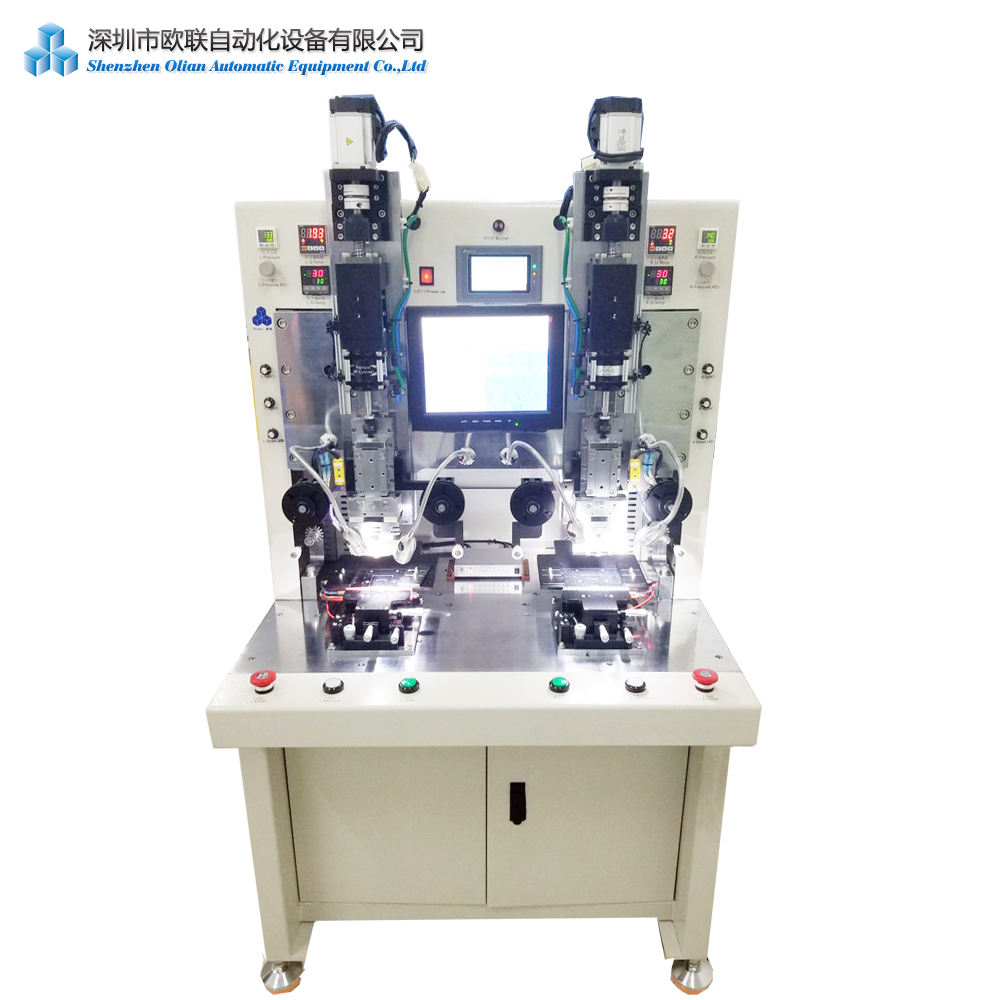

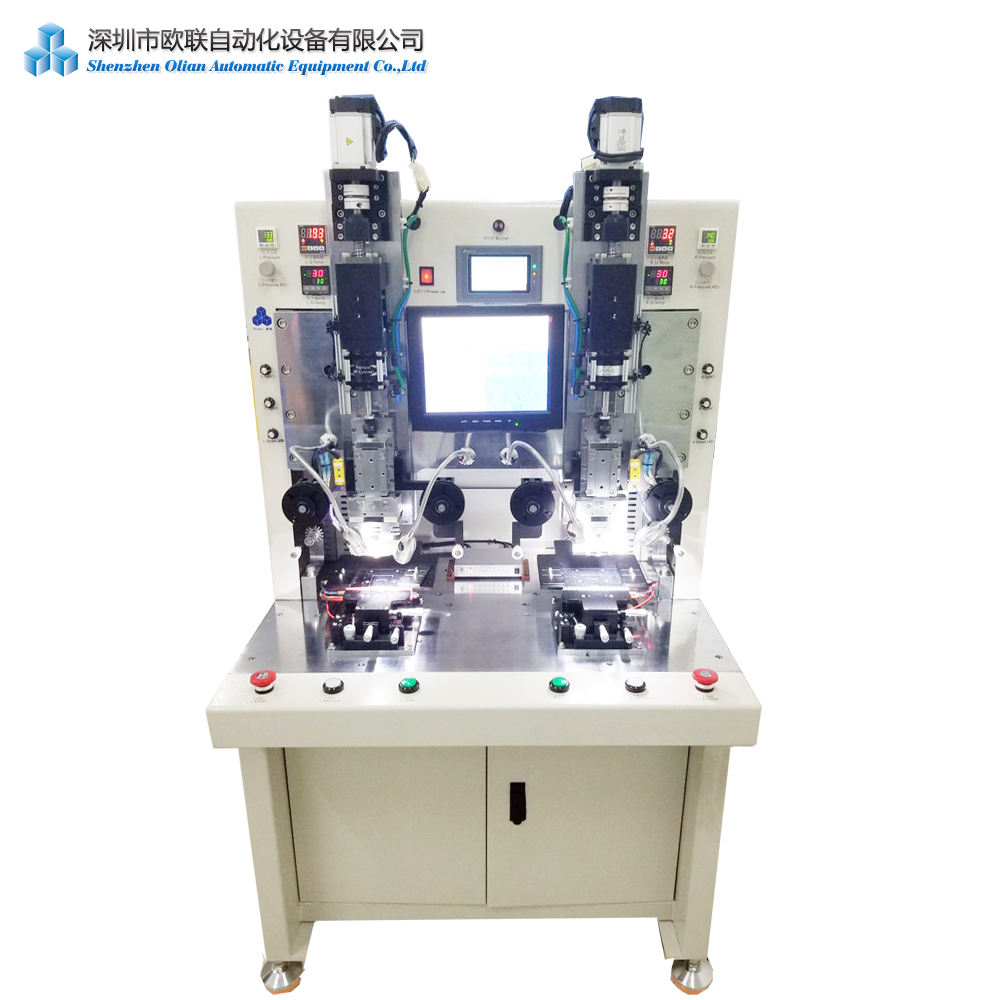

COG bonder, also named COG (Chip on glass) machine,Chip ic bonding machine, COF(chip on film) bonder ,COG heat bonder, COG bonding machine, Chip IC heat press machine, Chip on glass bonding machine.It is widely used in the LCD/LED/OLED, LCM/panel/screen/display , for Mobilephone/Watch/pad/notebook/touch panel/Ad Player/bank card/camera/ and all the flat and edge screens. for produce factories and repairing service shops all over the world.

The COG machine may consist of HD Digital Microscope and control system, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

Shenzhen Olian is the professional COG bonder manufactury ,we are the LCM Equipment factory solution provider.

The machine has Pre-Bonder and Main-Bonder . They are all constant temperature machines. it maybe have single station bonder ,double stations , three stations, and maybe four stations bonder.

Features:

*Suitable for multi variety small batch production

*Constant temperature heating system

*Panasonic PLC Control system

*FAST Visual processing system

*Imported Japanese CCD Automatic Contraposition Configuration

*Manual / automatic switching

*Imported electrical configuration

Specification:

Model: OL-C003B/C005/C006

Product Name: Semi-Automatic Mid/High-speed COG/COF Pre-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 650pcs/H–1000pcs/H

Power Supply: 220V±10%,50HZ,1000W/1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 140*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 40*2MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

N.W: About 300KG/350KG

Features:

*PID Control Constant Temp Heating System,Automatic temperature compensation to ensure that the temperature of hot pressing is stable.

*Panasonic PLC Control system.

*Use high precision low-friction cylinder control pressure to ensure the accuracy of pressure control.

*High steel structure set, dual ceramic indenter configuration, to ensure the stability of the equipment.

*Imported electrical configuration,

*For OLED high-end products,high quality,high successful rate。

Specification:

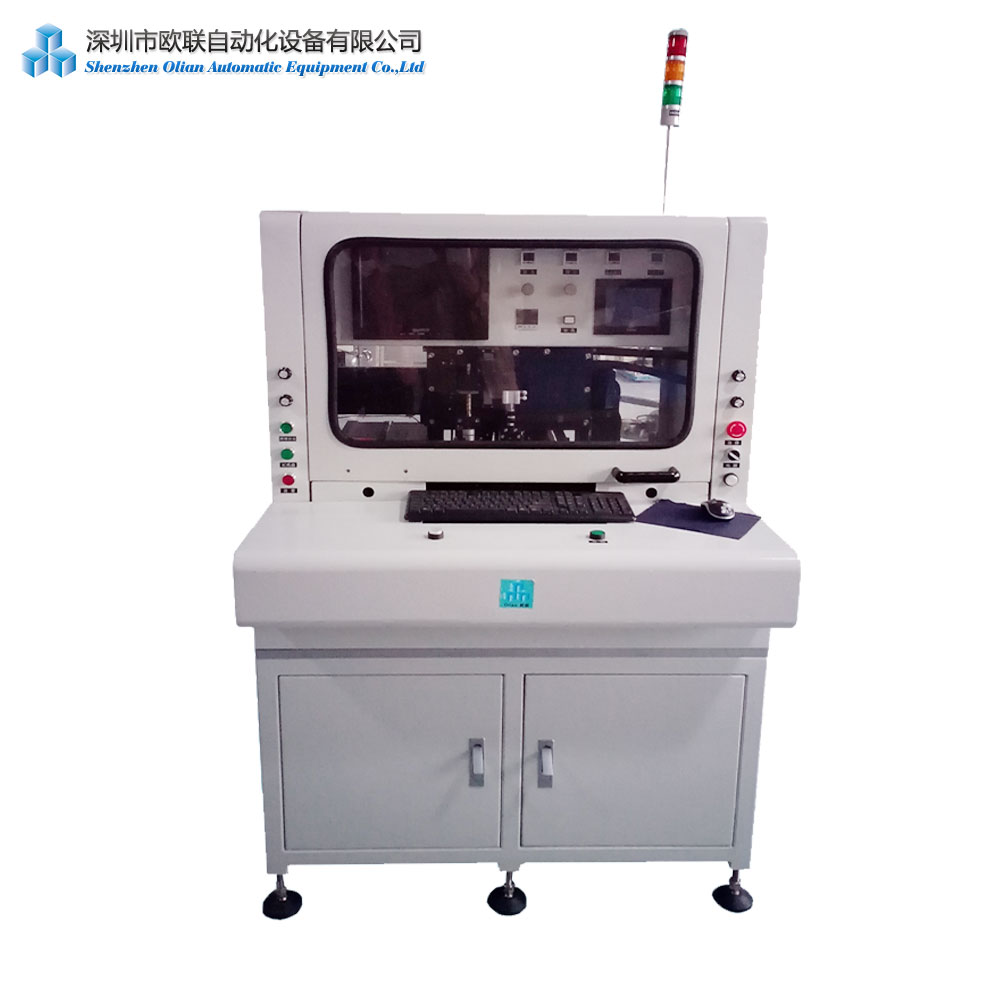

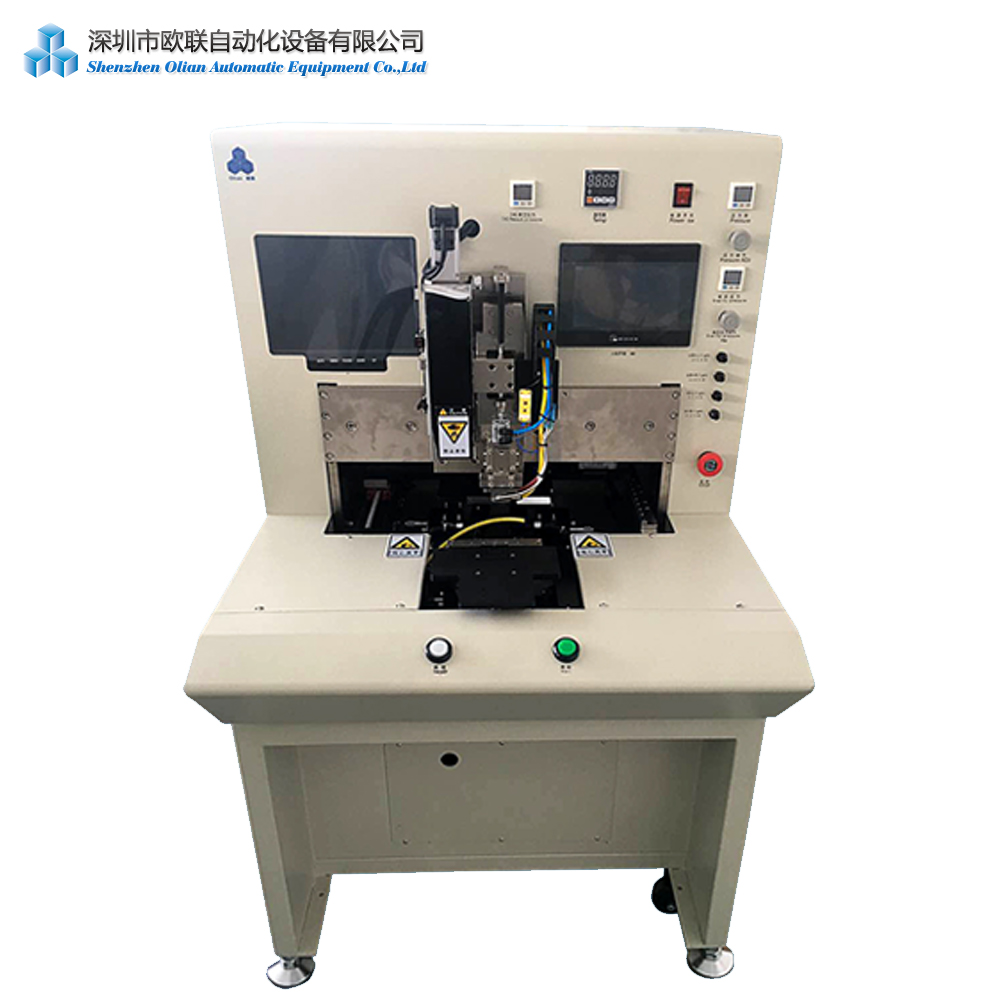

Model: CM006

Product Name: 1-12 inch Triple Stations Semi-Automatic High-speed COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1100pcs/H

Power Supply: 220V±10%,50HZ,2000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L1025*W750*H1400 MM

N.W: About 350KG

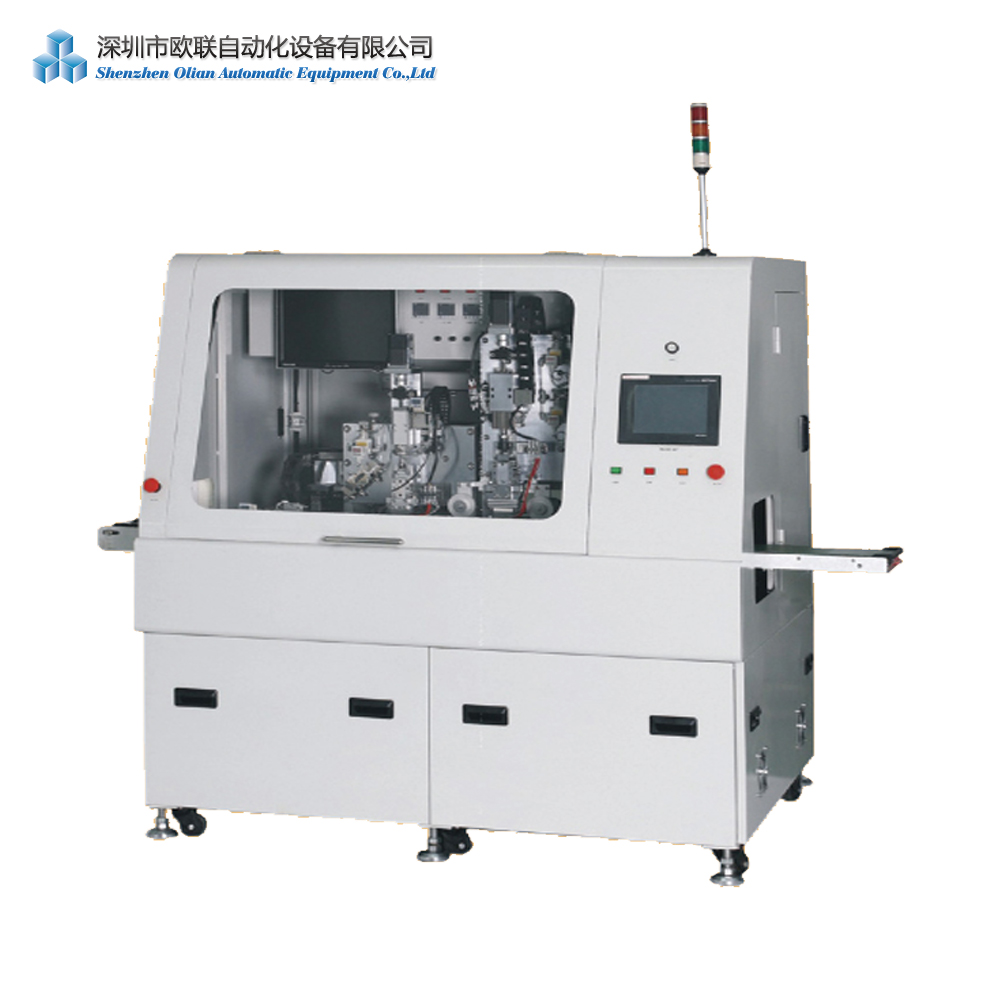

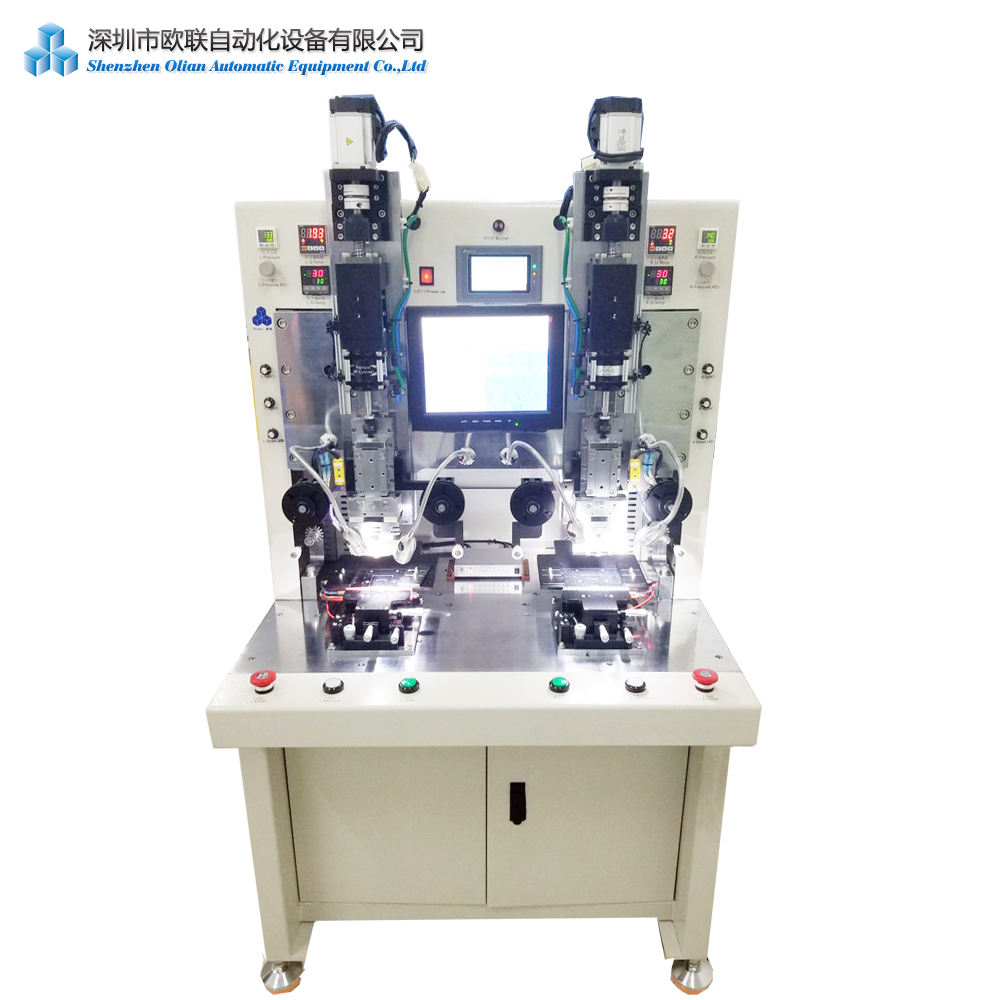

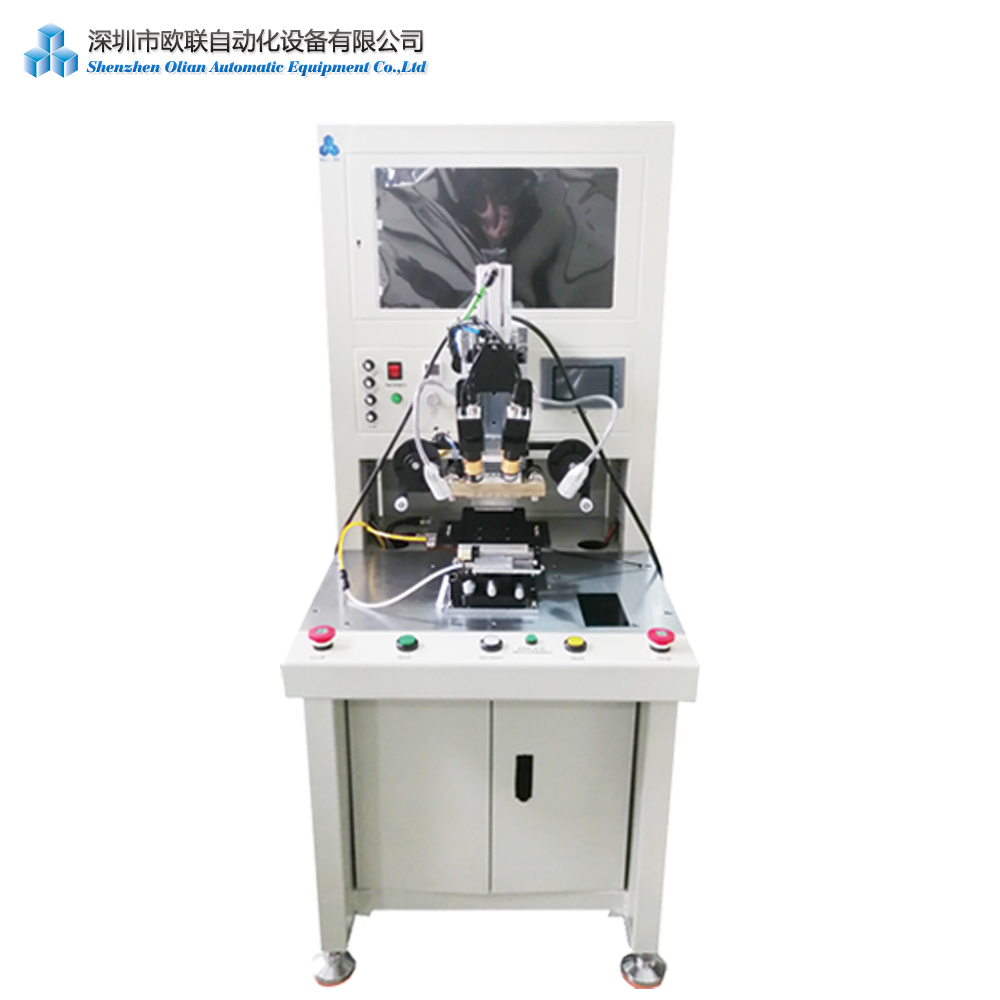

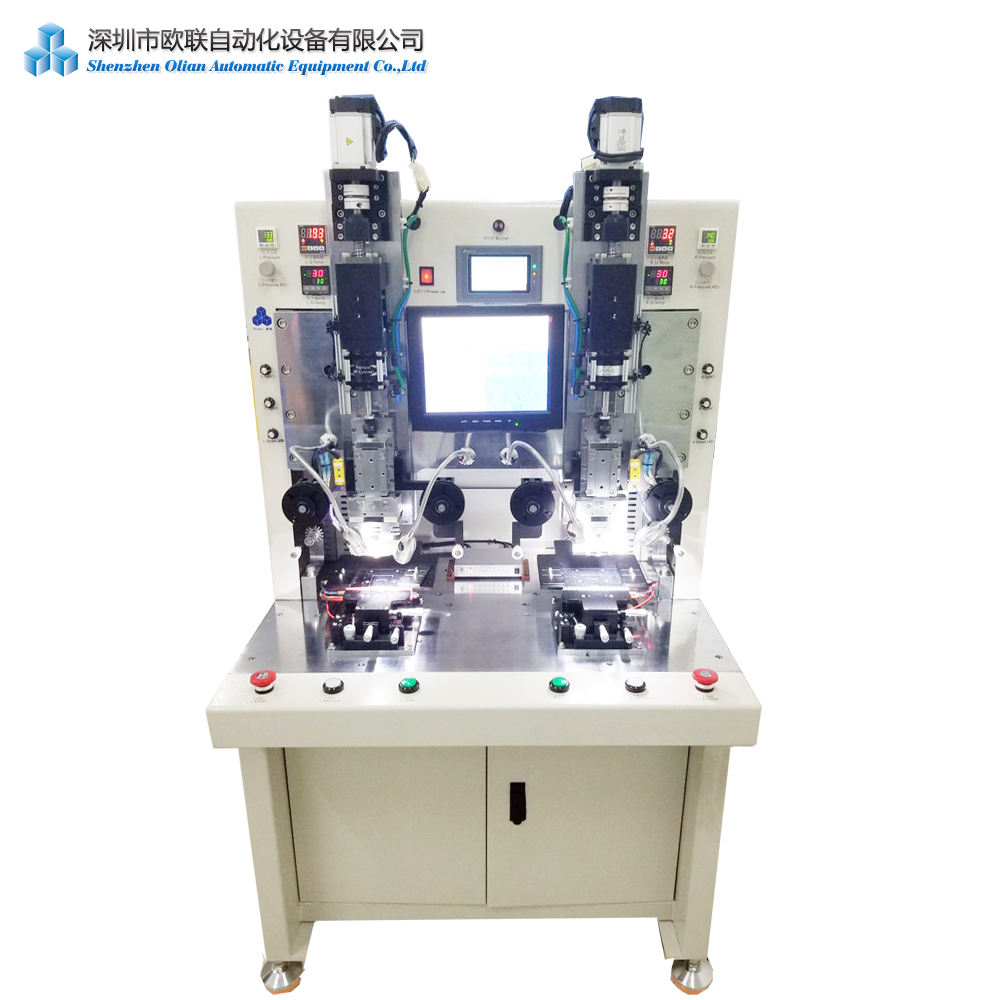

Model: OL-C008/OL-C012

Product Name: 1-12 inch Double Stations Semi-Automatic Mid-speed Servo COG main-bonding machine

Suitable For: Suitable for IC bonded to the LCD which attached ACF

Size Range: 1~12 inch

Attach Precision: ±4.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 600pcs/H

Power Supply: 220V±10%,50HZ,1200W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~400℃

Time Range: 1~99.9

Product Size:L640*W700*H1320MM

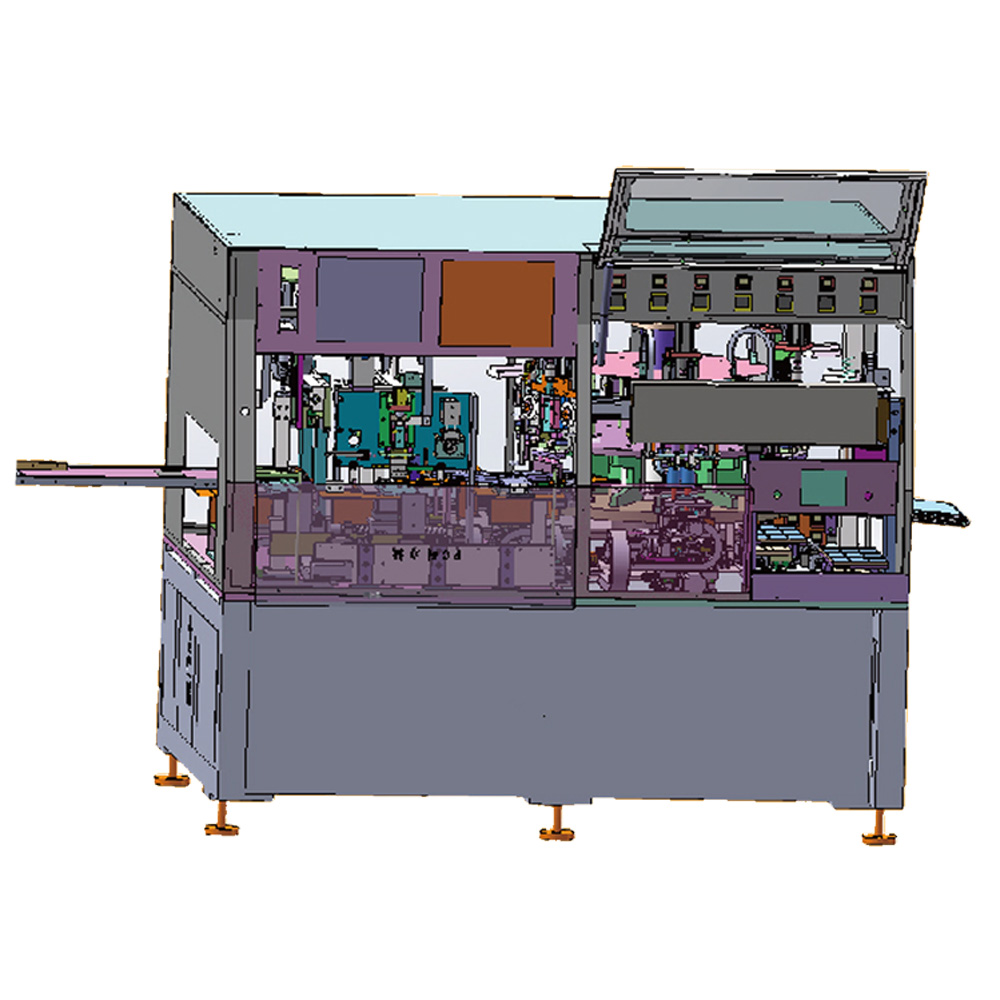

Full automatic COG bonder, include all the glass loading/glass cleaning/IC Loading/ACF pre-attaching/COG pre-bonder/COG main-bonder /COG glass output.

Features:

*Constant temperature heating system

*Panasonic PLC Control system

*Human – Machine interface

*Imported electrical configuration

*High Precision contraposition system

*Include the glass loading,glass cleaning,IC loading,ACF pre-attaching,COG pre-bonding,COG main-bonding ,COG output processes,it is COG processes all in one machine.

Specification:

Model: FAC001

Product Name: 1~7inch Full Automatic COG bonder

Suitable For: Suitable for IC Bonding to the LCD, ACF attach, IC preload and pre-bonding, main-bonding,output, completed in one machine.

Size Range: 1~7 inch

Attach Precision: ±2.5UM

IC Size: L:2~40mm,W:0.8~3mm

Machine Capacity: 1000pcs/H

Power Supply: 220V±10%,50HZ,5000W

Air Supply: 0.5~0.7MPa,dry air

Platform Size: 150*100MM

Platform Precision: ±0.01MM

Pressure Head Size: 45*5MM Customizable

Temp Range: 1~300℃

Time Range: 1~99.9

Product Size: W1500*D2300*H1700MM

Semi Automatic LCM Making produce include: ACF attaching ,COG pre-bonding, COG final-bonding , FOG(FOB) bonding, as below:

Full automatic FOG bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic bonder include all the process of the COG and FOG bonding : the LCD loading,LCD cleaning, IC loading, IC cleaning,ACF attaching on the glass, IC pre-bonding, IC bonding cheking, and IC main-bonding processes. then the ACF attaching for FPC, FPC loading, FPC bonding on the glass and output to testing…

We design and make the standard COG/COF/ACF Bonders and customized ACF bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonder, also name TAB bonder, ACF bonder, OLB Bonder , Chip on Film bonder. COF(Chip on Film, Chip on Flex).COF bonder is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonder also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonder for TV Repairing is Pulse heating bonding machine with Titanium alloy press bonding head.

Our COF bonder and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Please contact us feel free to purchase the COF bonder for TV Repairing accessories.

Welcome to buy the COF bonder for TV Repairing and all the COF bonder accessories.

COF bonders for full screen /edge screen/OLED screen mobilephone

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our COF bonder for cellphones.

All the ACF/COG/COF/COB/FOG/FOB/FOF/OLB/TAB/PCB/FPC/TCP/ bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

Shenzhen Olian ACF/COG/COF/COB/FOG/FOB/OLB/FOF/TAB/OGS/PCB/FPC bonder manufactory. Welcome you to be our partner and dealers all over the world.

FOB bonder, it may press the FPC/COF/TCP onto the PCB Board using ACF conductive adhesive as medium, by a certain temperature, pressure and time. (FPC/COF/TCP-on-PCB Board) ,

It also named PCB Bonder,FOB machine, FOB equipment, FOB heat bonder, FOB heat press machine, FOB device, FOB tool, FOB bonding machine, ACF bonder. It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The FOB bonder (FPC-ON-PCB) is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The FOB bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process.

Shenzhen Olian is a professional FOB bonder design and making manufactury which has over 10 years experience in LCM moduel making machines。

FOB bonder, also FPC bonder, Flex cable bonder .PCB Bonder,FOF(FPC on FPC), COF on PCB board bonder, COF on film bonder. It have Pulse Heating Bonder and Constant Temperature Bonder. Also it will be named wire bondingmachine,thermal bonding machine,heat bonding machine,

FPC/FOB/FOF/COF bonder specifications:

*Constant temperature heating system/Pulse heating system

*Panasonic PLC Control system

*Human – Machine interface

*Automatic temperature alarm

*Press Head Level Adjustable Device

*Down Contraposition HD Colorful CCD and 10.4~24 inch HD LCD

*Manual / automatic switching

*Imported electrical configuration * apply for all the LCD,LED,ONCELL,OLED panels.

PCB means printed circuit board, printed circuit boards, PCB according to its application fields can be divided into single panel, double panel, four layer board above laminated panel and soft panel.In general, the more complex the function of electronic products, foot loop the longer the distance, contact number, the more PCB layer number is more, such as advanced consumer electronics, information and communication products, etc.;And soft board is mainly used in need around the bend products: such as notebook computer, camera, automobile instrument, etc.

PCB is an important electronic components, electronic components to support the body, the provider of the electrical connection in the electronic components.Since it is made of electronic printing, therefore is called “printed circuit board.

Flexible print circuits (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

In practice there are many different kinds of flexible circuits, including one metal layer, double sided, multilayer and rigid flex circuits. The circuits can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

There are many advantages that come with using flexible circuit technology beyond the initial flex capabilities. Performance advantages, such as, dynamic flexing and increased heat dissipation allow engineers to design these circuits into applications where extreme temperatures and vibrations are common. Other advantages with using flexible circuits include less weight, increased package density, and a more integrated design.Flexible circuits can cost less than traditional assemblies because one flex assembly can replace several, single circuits.

Flex circuits also allow design engineers to utilize space three dimensionally which cuts down on the overall footprint of the circuit and saves space.

Applications of flexible circuits ranges in a variety of fields. Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

Shenzhen Olian design and make all kinds of FOB bonder. Welcome you visit us and OEM&OEM FOB/FPC/FOF/COF bonding machine with us for your factory and your globe trade business.

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG Bonder(COG pre-bonder, COG final-bonder ), FOG(FOB) bonder, as below:

In the PCB /TAB/COG/COB/COF/FOG/FOB/ Bonding process, The ACF tape is the middle materials, so all the bonding proces also name ACF bonding,all the PCB /TAB/COG/COB/COF/FOG/FOB/ Bonders,are all ACF bonders。

We design and make the standard FOB/FOG/COG/COF/ACF Bonders and customized FOB bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

All the FPC/FOB/FOG/FOF/IC/COG/COF/ILB/TAB/TCP bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)

ACF bonder, also named ACF machine, ACF equipment, ACF heat bonder, ACF tape bonding machine, ACF film bonder, ACF heat press machine, ACF device, ACF tool, ACF bonding machine.It is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display , for Mobilephone/ TV /Watch/pad/notebook/touch panel/Ad Player/bank card/zebra paper/camera/…produce factories and repairing service shops all over the world.

The ACF bonder is based on the recent innovations as well as planned to peoduce and repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The ACF bonder may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

According to the different bonding materials, the ACF bonder can be divided into different Bonders.

COG/COF bonder, also name IC bonder, Chips bonder, COG(Chip on glass) bonder, COF(chip on film) bonder, it is bonding the Chip IC on the glass, using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG/COF bonder has COG/COF Pre-Bonder and COG/COF Final-Bonder(COG/COF Main bonder). They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations COG/COF bonder.

FOG bonder, also name FOB bonder, FPC bonder, Flex cable bonder .FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonder, COF on PCB board bonder, COF on film bonder. It have Pulse Heating Bonder and Constant Temperature Bonder.

ACF attaching bonder which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The ACF attaching bonder,

Semi Automatic LCM Making produce include: ACF attaching bonder ,COG pre-bonder, COG final-bonder , FOG(FOB) bonder, as below:

Full automatic COG bonder, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonder, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce line include all the process of the COG and FOG bonding.

We design and make the standard ACF Bonders and customized acf bonder for your personalized product requirements, also design and manufacture other automation equipment for your requirements, and welcome OEM&ODM machines.

COF bonder, also name TAB bonder, ACF bonder, OLB Bonder , Chip on Film bonder. COF(Chip on Film, Chip on Flex).COF bonder is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonder also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonder for TV Repairing is Pulse heating bonding machine with Titanium alloy press bonding head.

Our COF bonder and all the accessories list for TV/laptop panel repairing as below:

We also offer all the accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.

Please contact us feel free to purchase the COF bonding machine accessories.

Buy machine, send all the accessories free.

| 1 | COF bonding machine |

| 2 | ACF AC-7206-18 1.5*50M Glass side ACF胶带 |

| 3 | ACF AC-2056R-35 2.0*50M PCB side ACF胶带 |

| 4 | ACF Removing Liquid G-450 1000ML ACF去除液 G450 |

| 5 | Acetone Liquid BT-H1-500ML 丙酮 |

| 6 | Hitachi Blue Glue 100ML 蓝色胶水 |

| 7 | Fuji Silicone 50M 硅胶皮 |

| 8 | Teflon 50M 铁氟龙 |

| 9 | Alcohol 酒精 |

| 10 | Heating Solder Iron 30W +T-Type Soldering Tips T型烙铁+硅胶条 |

| 11 | Removing Wind Station Hot Air Gun 825+Fan 除风站 热风枪 |

| 12 | Optical Microscope 显微镜 |

| 13 | TAB Cutter COF切刀 |

| 14 | Correction table 校正表 |

| 15 | LVDS LVDS接头 |

| 16 | LCD Test Board LCD测试板 |

| 17 | Allen Key 六角扳手 |

| 18 | Air Compressor OTS550 空压机 |

| 19 | Static Wipe Cloth 静电擦拭布 |

| 20 | Cotton swabs 棉签 |

| 21 | Handheld Magnifier 手持放大镜 |

| 22 | Precision Tweezers 精密镊子 |

| 23 | Nano Sponge 纳米海绵 |

| 24 | quatz bar spare one 备用石英条 |

| 25 | Alcohol bottles 空酒精瓶 |

COF bonding machine accessories

Welcome to buy the COF bonder for TV Repairing and all the COF bonding machine accessories.

COF bonders for full screen /edge screen/OLED screen mobilephone

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei Mate10,Mate 20,8X,OPPO/VIVO/MI/Samsung S6 S8 S9/Apple X MAX R etc.) repairing and produce business ,please contact us and test our COF bonder for cellphones.

All the ACF bonders ,welcome you visit us-Shenzhen Olian(LCM Equipments factory solution provider/supplier/manufactury)