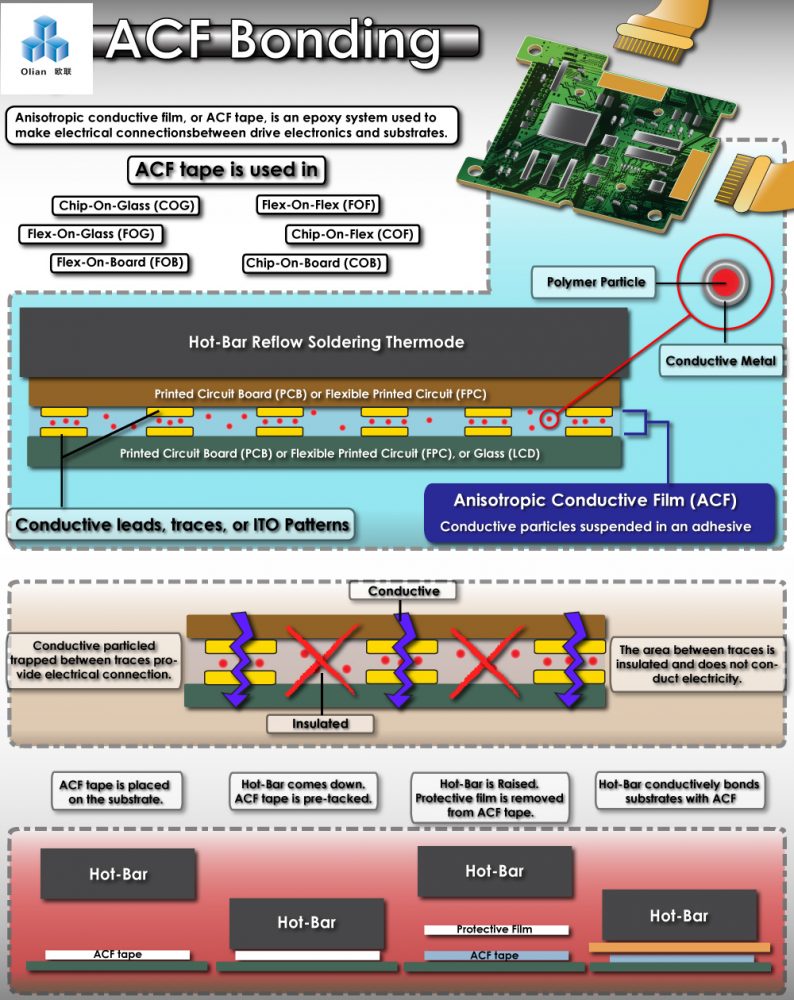

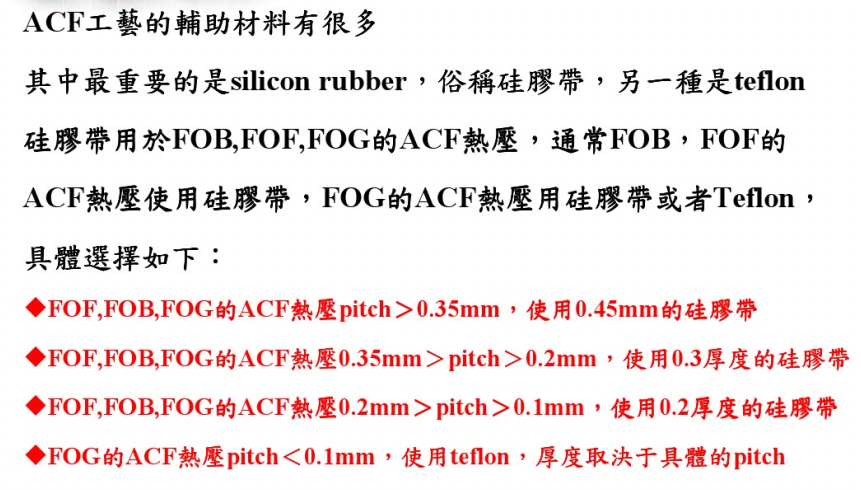

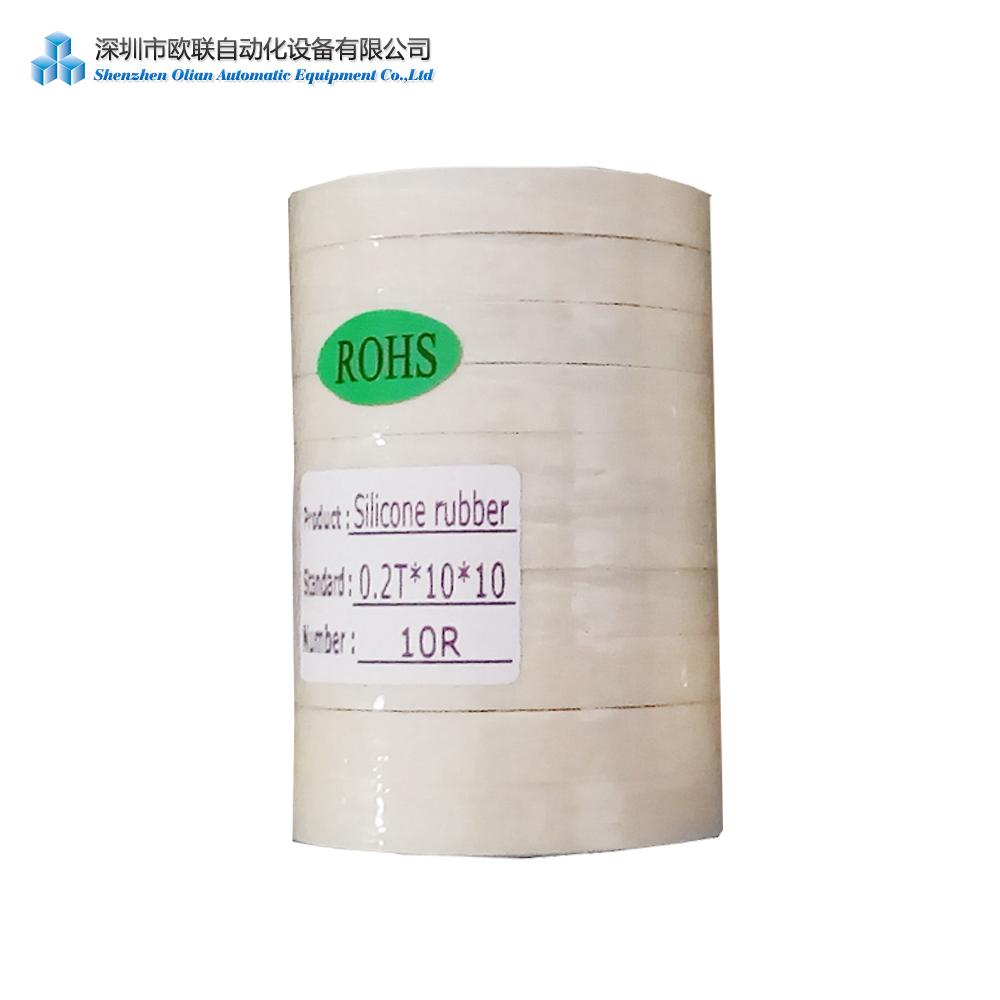

ACF bonding process ,is the process of Chip ic/COF ic/FPC bonded to the LCD(Glass)/PCB/Film/FPC/ ,use the ACF tape as the medium connecting materials,use the hot bar/bonding head as the source of the heat and pressure,use the tooling as the holder,and the silicone rubber or teflon as the Cushioning material, all the ACF bonding process finished by the ACF bonding equipments.

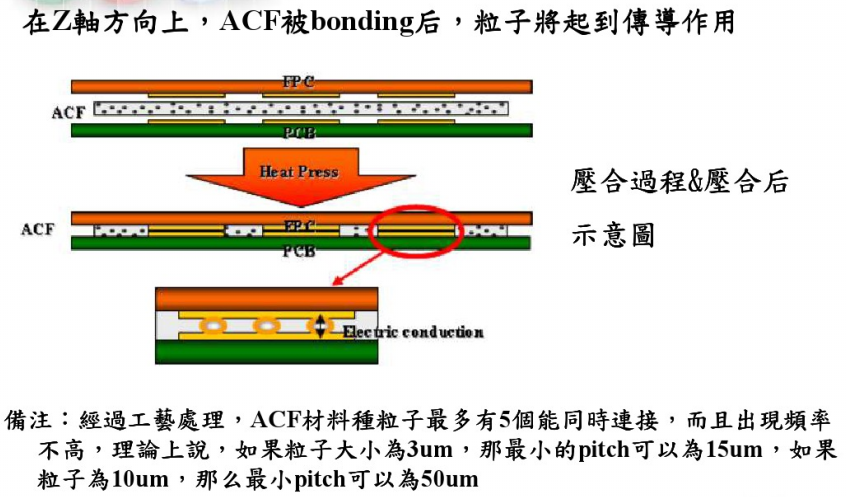

ACF tape has little conductive particles in the conductive lines of the tape.

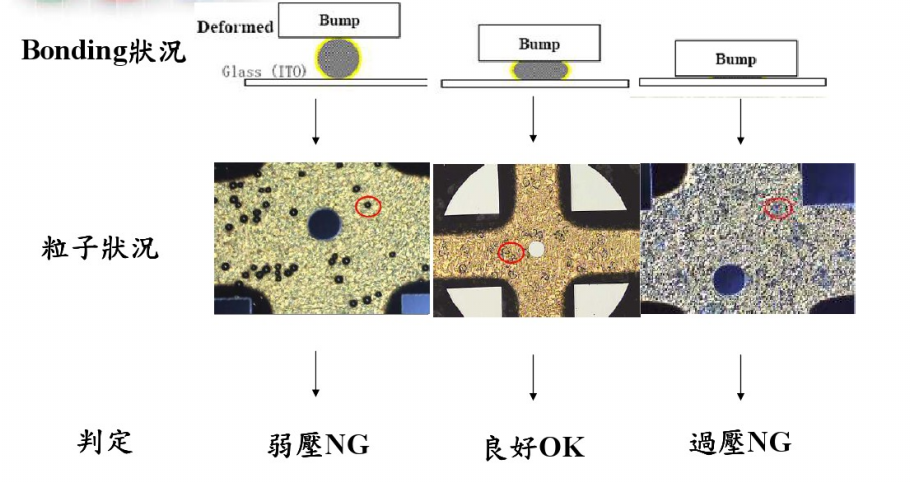

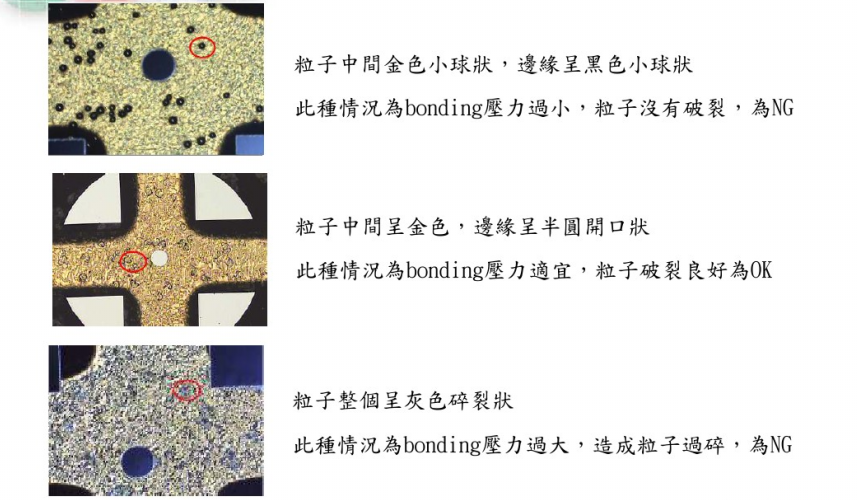

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

This process is what produces the connection between the ACF tape and the components. Advanced Integrated Technologies is equipped to assist you with your ACF bonding process.

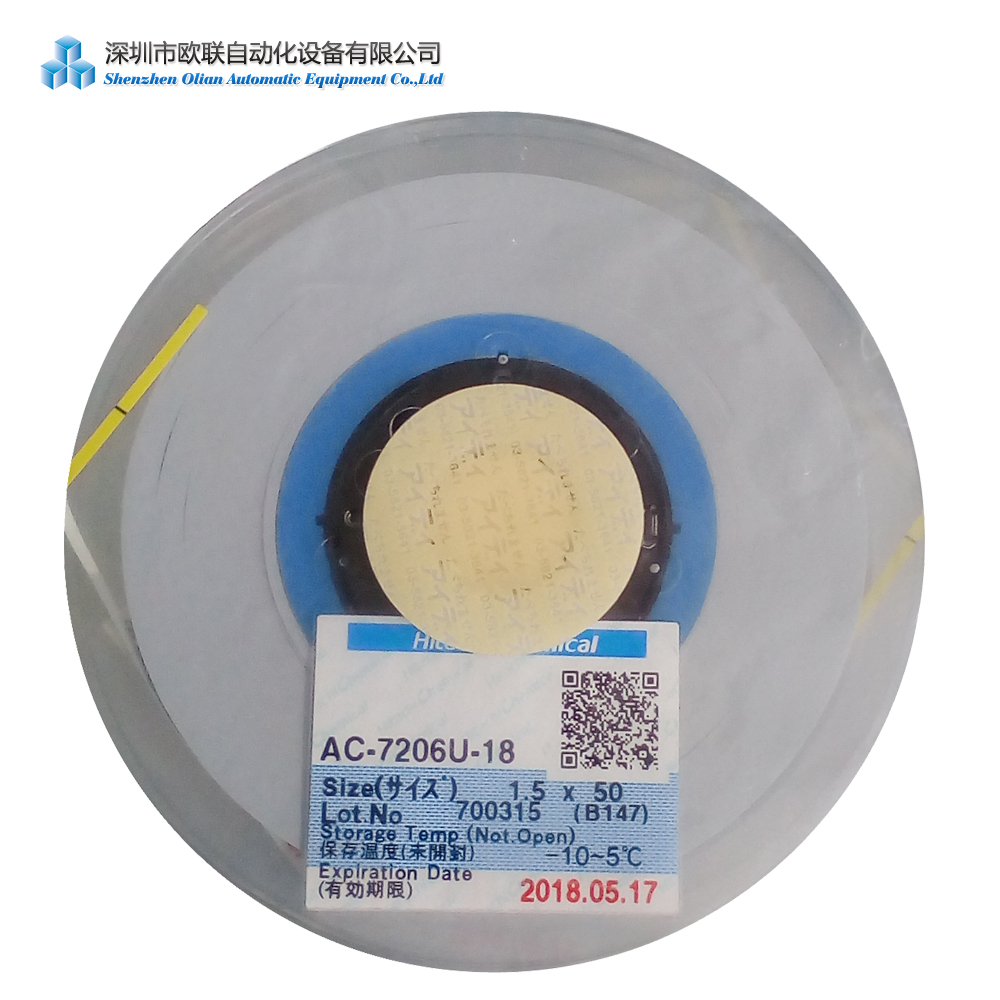

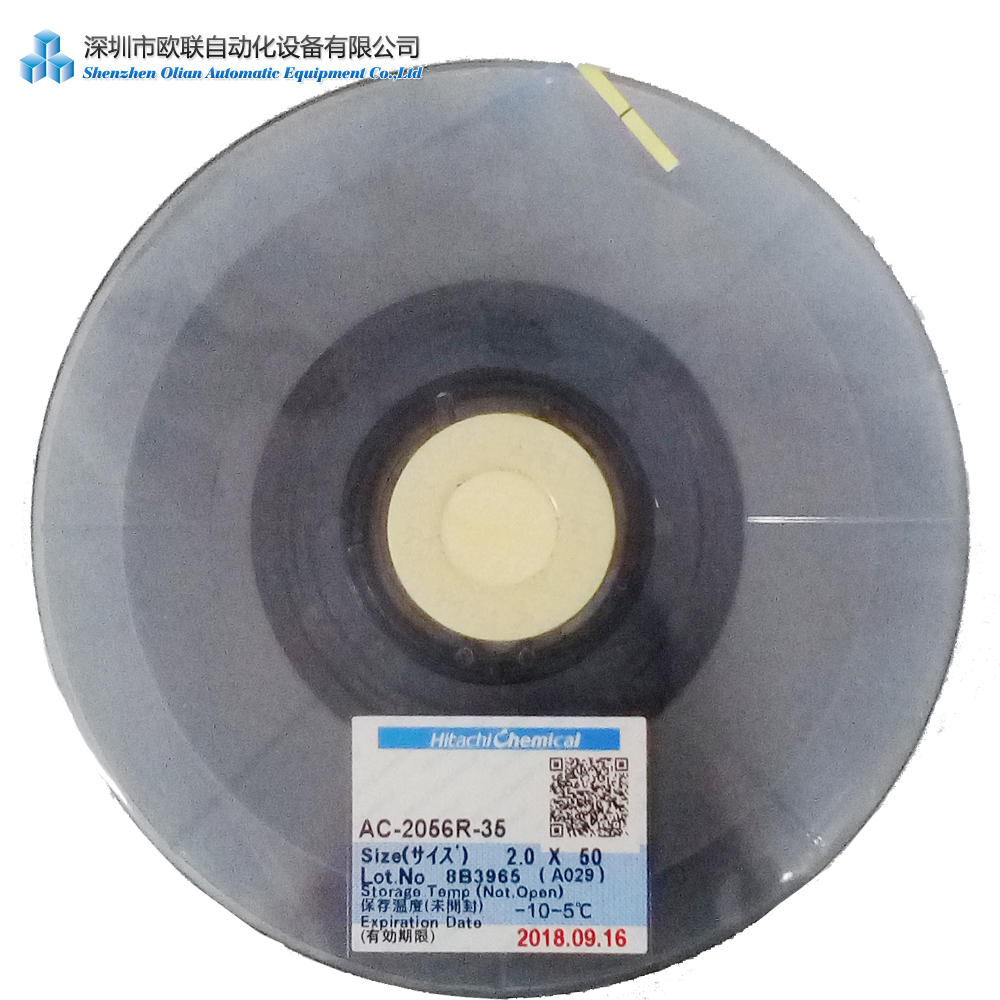

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the important medium of the ACF bonding process.

ACF Tape is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

| Model(Hitachi) | Process type | For Glass |

| AC-823CY W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-832L W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-832L W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.5mm L100m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.3mm L50m | COG Low Temp | Thin Glass |

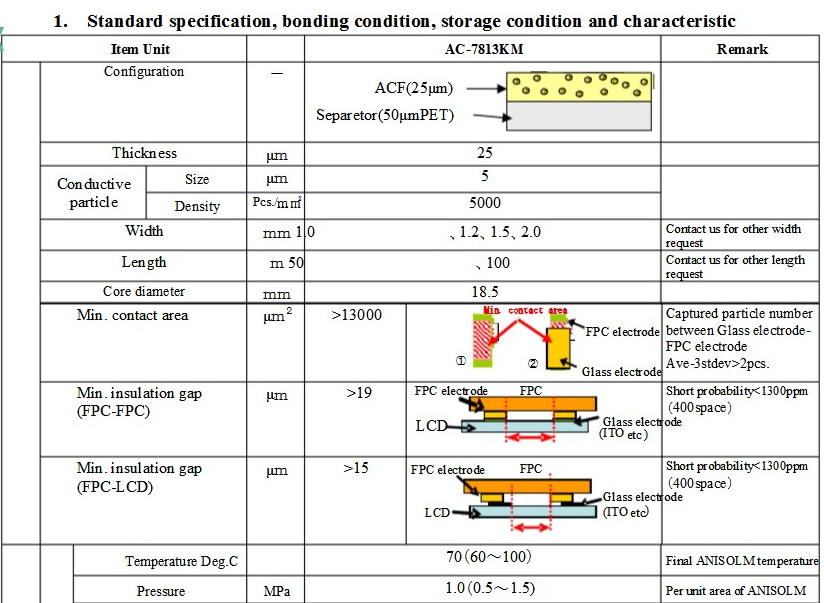

| AC-7813KM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| MF-331-25 W2.0mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.5mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.2mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.0mm L50m | FOG Low Temp | For Touch Screen |

| AC-4255KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W2.0mm L100m | FOG Low Temp | Common Glass |

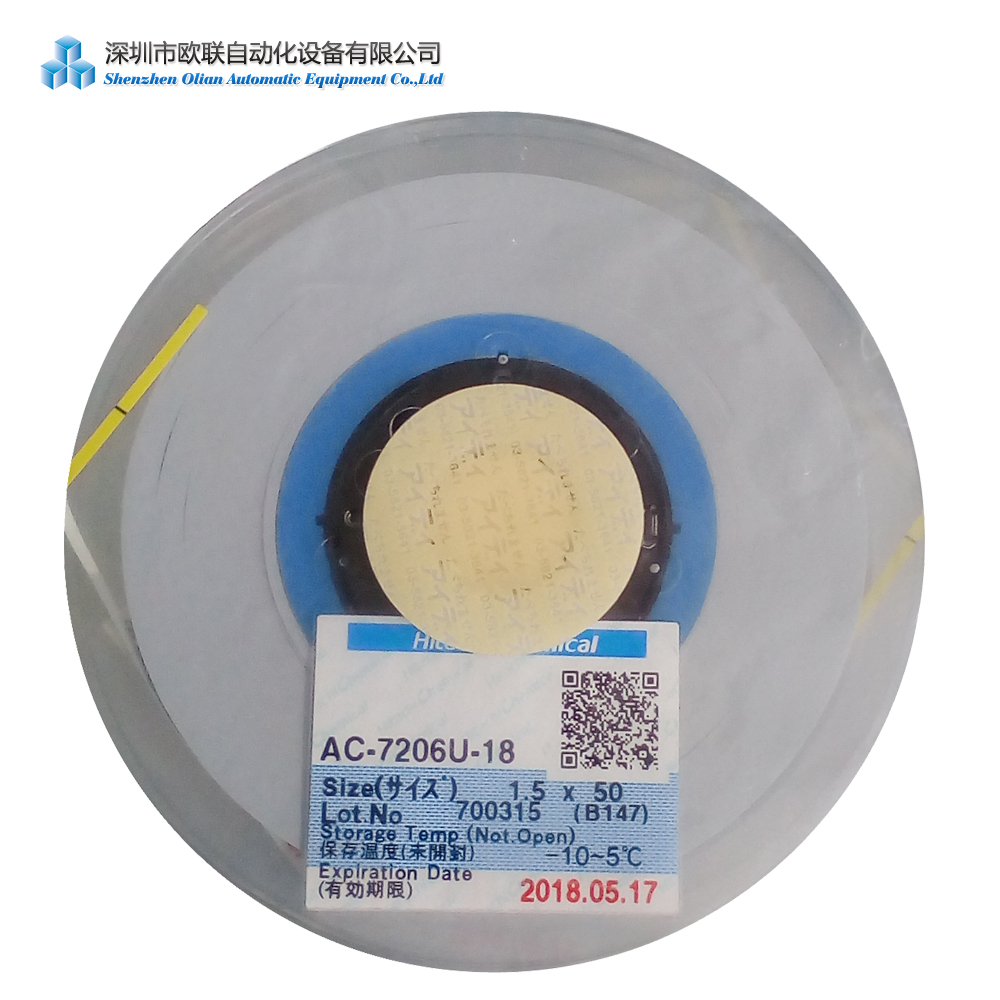

| AC-7206U-18 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.2mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-9851YM-35 W1.5mm L50m | FOG Low Temp | Common Glass |

| AC-9851YM-35 W2.0mm L50m | FOG Low Temp | Common Glass |

| AC-896C W1.5mm L100m | COG Low Temp | Thin Glass |

| Model(Sony) | Process type | For Glass |

| CP6920F3 W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.2mm L50m | COG Low Temp | Common Glass |

| CP34531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP34531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP35231 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP35231 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36931 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36931 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP33731 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP33731 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP31831 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP31831 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP1220 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP1220 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP13941 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP6920F W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.2mm L50m | COG Low Temp | Common Glass |

| CP920 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W2.0mm L100m | FOG Low Temp | For Touch Screen |

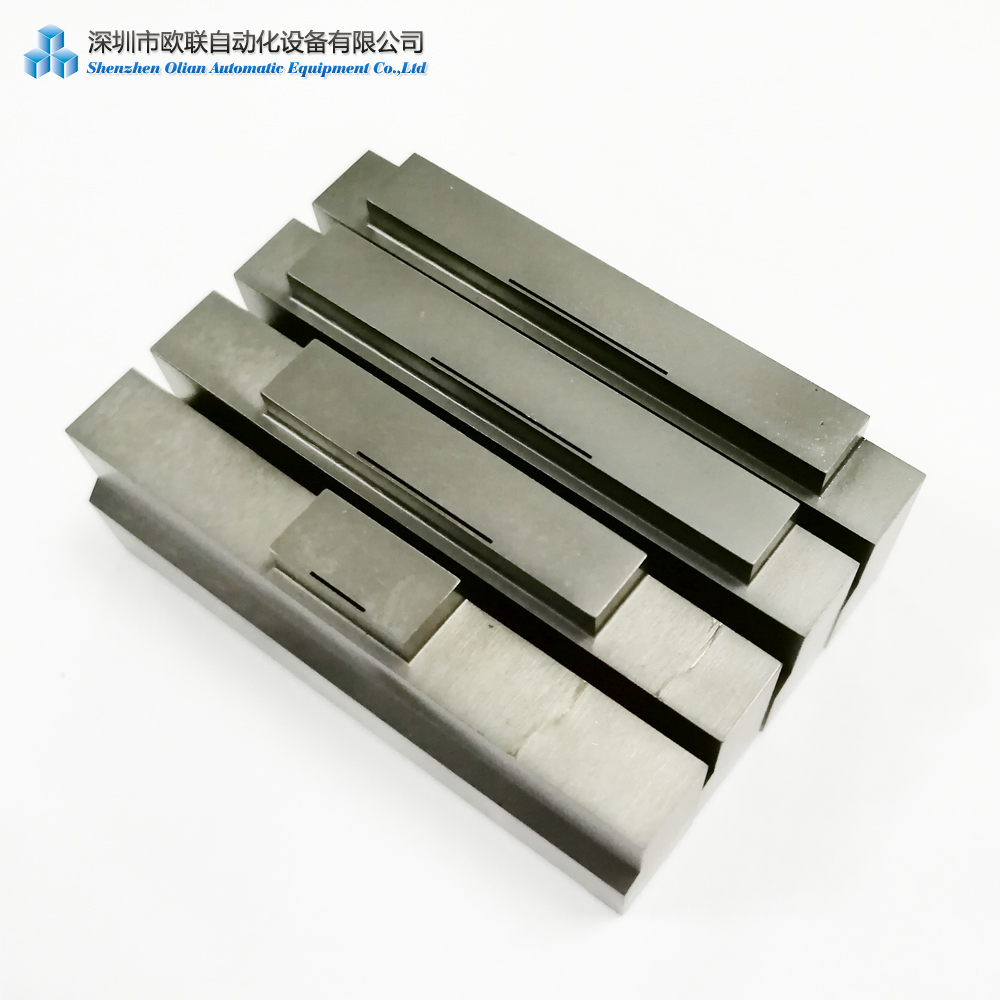

The source for heat and pressure in ACF bonding process is most often a hot bar/thermode/bonding head/bonding cutter.

Hot bar bonding systems are designed to heat the hot bar to a specific temperature using low voltage electricity, which temperature is fed back to the controller via a thermocouple.

Tooling is designed to hold the components and position the ACF tape to line up correctly with the conductive pads on the PCB or other component.

The hot bar is then brought into contact with the ACF film over the top of the bonding pad, heated to the bonding temperature, and held for a specified time.

Tell us which products you want to bonding ,then we can suggest you the right ACF bonding equipments for you ..

ACF bonding equipment has been used in glass display applications for many years. It has recently become widely used in COF, COB,COG,FOG,FOB,FOF areas.

Industries that use this technology most are the mobile phone manufacturing, automotive industry, and LCD production, mobile computers, TV manufacturing, open cell panels factories, touch panel ,AD shower, Watch, Pad… factories. and many Labs who researching in the LCD/LED/OLED/MICRO LED/MINI LED displays industries.

Similar to Silicone rubber, Teflon tape is often used to provide evenly distributed pressure and temperature on the ACF bonding process.

Features of Teflon Tape :

1. Superior chemical resistance – hardly affected by acids and alkalis.

2. Excellent electrical properties, including little dielectric loss, high insulation resistance and breakdown voltage.

3. Extremely high volume resistivity and remain stable over a wide range of temperature.

4. Continuous use in a wide range of temperature from -100degC to +260degC

5. Lowest friction cofficient among all solid materials and excellent self-lubricating ability.

6. Non-adhesiveness and mold releasing property

7. Excellent weather and moisture resistance

8. Superior flame resistance

Shenzhen olian is a professional ACF bonding equipment design&making factory, We know all the ACF bonding process, we also offer all the bonding machine accessories and parts. Welcome you visit us .

Wechat/whatsapp:+86 18025364779, QQ:2307972393, https://bonding-machine.com

AMOLED bonding machine, is for AMOLED display produce and repair machine for TV/Cell phone/Watch/other AMOLED products. bonding the COFs on the flexible FPCs.

An organic light-emitting diode (OLED) is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and PDAs. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row (and line) in the display is controlled sequentially, one by one,whereas AMOLED control uses a thin-film transistor backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight.

The different manufacturing process of OLEDs has several advantages over flat panel displays made with LCD technology.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing, theoretically making them cheaper to produce than LCD or plasma displays. However, fabrication of the OLED substrate is currently more costly than that of a TFT LCD. Roll-to-roll vapor-deposition methods for organic devices do allow mass production of thousands of devices per minute for minimal cost; however, this technique also induces problems: devices with multiple layers can be challenging to make because of registration – lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)can be used, the displays may be produced inexpensively. Furthermore, plastic substrates are shatter-resistant, unlike the glass displays used in LCD devices.

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks. Removing the backlight also makes OLEDs lighter because some substrates are not needed. When looking at top-emitting OLEDs, thickness also plays a role when talking about index match layers (IMLs). Emission intensity is enhanced when the IML thickness is 1.3–2.5 nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1 msfor their fastest color transition, and are capable of refresh frequencies as high as 240 Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,putting conservative estimates at under 10 μs (0.01 ms), which could theoretically accommodate refresh frequencies approaching 100 kHz (100,000 Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

Shenzhen Olian Automatic Equipment have the OLED bonding machine for AMOLED screens.

if you need the machine for the OLED screen repairing, please contact us .

Welcome you visit us if you do the OLED edge screen/curved screen/full screen(Huawei mate10,mate 20,OPPO/VIVO/MI/Samsung S8/Apple X etc.) repairing and produce business ,please contact us and test our OLED bonding machine.

OLED-BONDING-machine

All the bonding machines ,welcome you visit us-Shenzhen Olian(Professional in design&making all kinds of bonding machines)

ACF Tape/ACF Film is normally made up of two main components, namely Adhesive & conductive particles.

The adhesive composition is dependent on the materials being assembled. This means an ACF designed for use in a flex-on-glass (FOG) assembly is usually not suitable for use in a chip-on-glass (COG),chip-on-film(COF), flex-on-board(FOB),flex-on-flex(FOF) or any other configurations. It is specific to the application for which it is designed for.

Conductive particles are used to conduct electricity from one side of the bond to the other. Depending on the application, conductive particles range from 3.5μm to 30μm in size, and can be made from Nickel-gold plated polymer spheres, gold plated nickel particles, or lead-free solder materials. Particles may be individually coated with a outer polymer to insulate them from other uncrushed particles, but which will crack open and allow electrical conduction if the particle is trapped and crushed between two pads during assembly.

ACF (Anisotropic conductive film) or ACF tape is an epoxy adhesive system used by electronics industry to make electrical and mechanical connections from drive electronics to substrates.

ACF are filled with conductive particles which provides electrical interconnection between pads through the film thickness (z-direction).

The conductive particles are distributed far apart thus not electrically conductive in the plane direction (X&Y) of the film.

ACF interconnect offers cost savings by substituting conventional mechanical connectors or soldering interconnect.

ACF interconnect allows low height and fine pitch which enables high density and miniaturizing of assembly.

ACF special conductive particle is made from environmental friendly material (ROHs compliance). It provides good metalic bonding.

According to different LCD/LED/OLED and different screens, there are many ACF tapes models. ACF tape is the import medium of the bonding process.

During ACF bonding, a combination of heat & pressure is applied on to chip (FPC/IC) for an appropriate time.

Conductive particles (each 3~30um) are compressed between IC and substrate (glass / PCB) while insulating materials pushed away.

This allows the compressed Ni-Au layer on the particles to conduct electricity between the IC and the substrates (z-axis).

The insulated particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis.

As the epoxy cures and conductive particles are trapped into permanent compressed form.

The compressed particles, by its elastic nature, are constantly pushing outwards to maintain good electrical conductivity under different environmental conditions.

| Model(Hitachi) | Process type | For Glass |

| AC-823CY W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-823CY W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8412KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-832L W1.2mm L100m | COG Low Temp | Thin Glass |

| AC-832L W1.5mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.0mm L100m | COG Low Temp | Thin Glass |

| AC-832L W2.5mm L100m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.2mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.5mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W1.8mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.0mm L50m | COG Low Temp | Thin Glass |

| AC-8622KZ W2.3mm L50m | COG Low Temp | Thin Glass |

| AC-7813KM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813KM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7246KU-20 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7813YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-7823YM-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| MF-331-25 W2.0mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.5mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.2mm L50m | FOG Low Temp | For Touch Screen |

| MF-331-25 W1.0mm L50m | FOG Low Temp | For Touch Screen |

| AC-4255KU-18 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-4255KU-18 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.0mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.2mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W1.5mm L100m | FOG Low Temp | Common Glass |

| AC-3514-25 W2.0mm L100m | FOG Low Temp | Common Glass |

| AC-7206U-18 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.2mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-7206U-18 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.0mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W1.5mm L50m | FOG Normal Temp | Common Glass |

| AC-2056R-35 W2.0mm L50m | FOG Normal Temp | Common Glass |

| AC-9851YM-35 W1.5mm L50m | FOG Low Temp | Common Glass |

| AC-9851YM-35 W2.0mm L50m | FOG Low Temp | Common Glass |

| AC-896C W1.5mm L100m | COG Low Temp | Thin Glass |

| Model(Sony) | Process type | For Glass |

| CP6920F3 W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F3 W1.2mm L50m | COG Low Temp | Common Glass |

| CP34531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP34531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36531 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36531 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP35231 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP35231 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP36931 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP36931 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP33731 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP33731 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP31831 W1.5mm L100m | COG Low Temp | Thin Glass |

| CP31831 W2.0mm L100m | COG Low Temp | Thin Glass |

| CP1220 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP1220 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP1220 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.0mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.2mm L100m | FOG Low Temp | Common Glass |

| CP13941 W1.5mm L100m | FOG Low Temp | Common Glass |

| CP13941 W2.0mm L100m | FOG Low Temp | Common Glass |

| CP6920F W3.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W3.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W2.0mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.5mm L50m | COG Low Temp | Common Glass |

| CP6920F W1.2mm L50m | COG Low Temp | Common Glass |

| CP920 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP920 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.0mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.2mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W1.5mm L100m | FOG Low Temp | For Touch Screen |

| CP923 W2.0mm L100m | FOG Low Temp | For Touch Screen |

| TF-4200EB-45/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-451/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-452/1000ML | Blue | LCM Insulation protective adhesive |

| TF-4200EB-75/1000ML | Blue | LCM Insulation protective adhesive |

| Model(ACF Remover) | ||

| Remover/G-430/1L | Clean FPC Side | common |

| Remover/G-450/1L Thick | Clean IC Side | common |

| Remover/G-450/1L Diluted | Clean FPC Side | common |

| Remover/G-550/1L Thick | Clean IC Side | common |

| Remover/G-550/1L Diluted | Clean IC Side | common |

| Remover/G-650/1L Thick | Clean IC Side | common |

| Remover/G-650/1L Diluted | Clean IC Side | common |

Please contact us if you need any other ACF tapes and ACF removers.

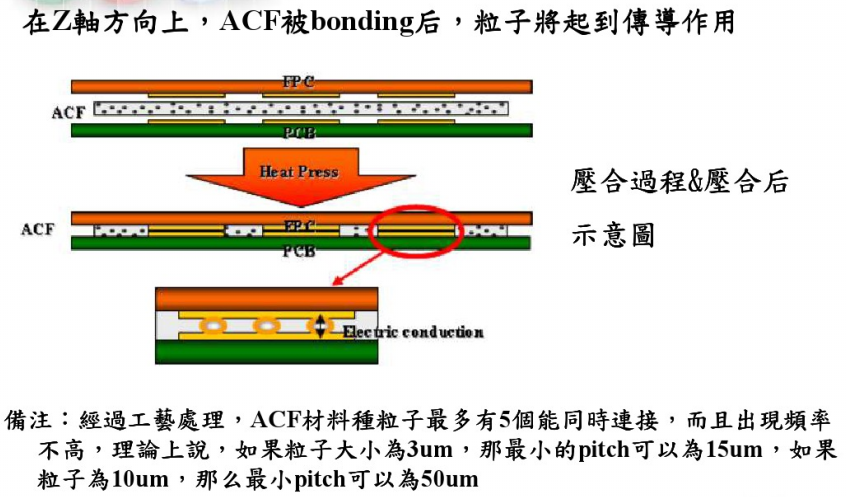

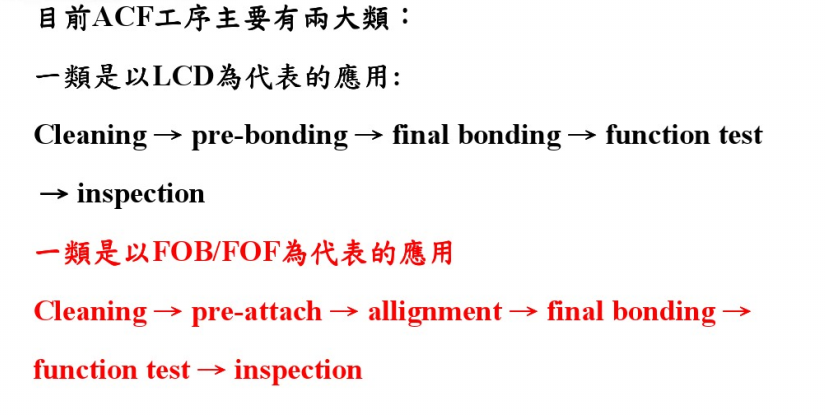

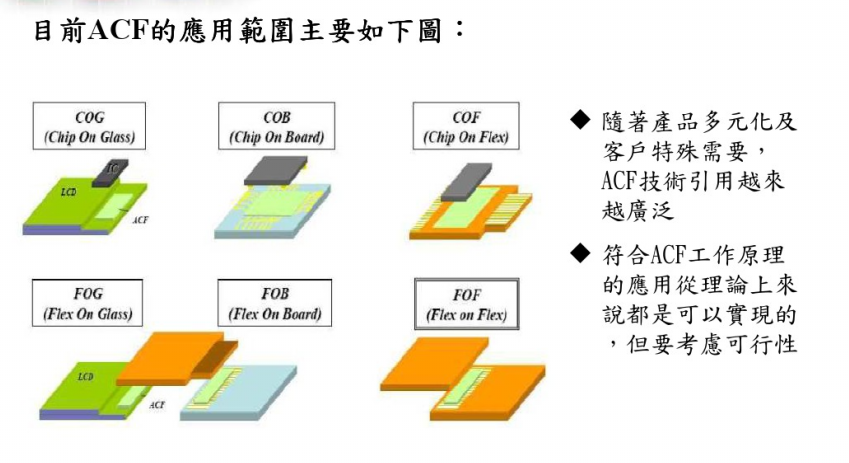

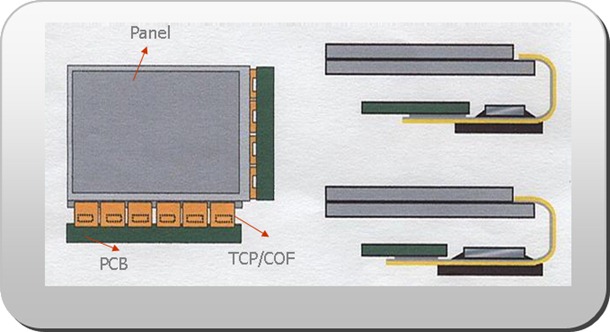

ACF has for many years, been used in glass display applications. Recently, it is also becoming widely used in TAB,COG,FOG,FOB,FOF,COF,COB areas.

– TAB Bonding (TCP-PCB / TCP-LCD)

– COG Bonding (IC-LCD)

– COB Bonding (IC-PCB)

– COF Bonding (COF-LCD/PCB)

– FOG Bonding(FPC-LCD)

– FOB Bonding(FPC-PCB)

– FOF Bonding(FPC-FPC)

– Plasma Display (FPC-PDP)

– Flip Chip Package

– ……

Because of ACF bonding advantages and features ,the ACF bonding machine is becoming more and more popular and useful.

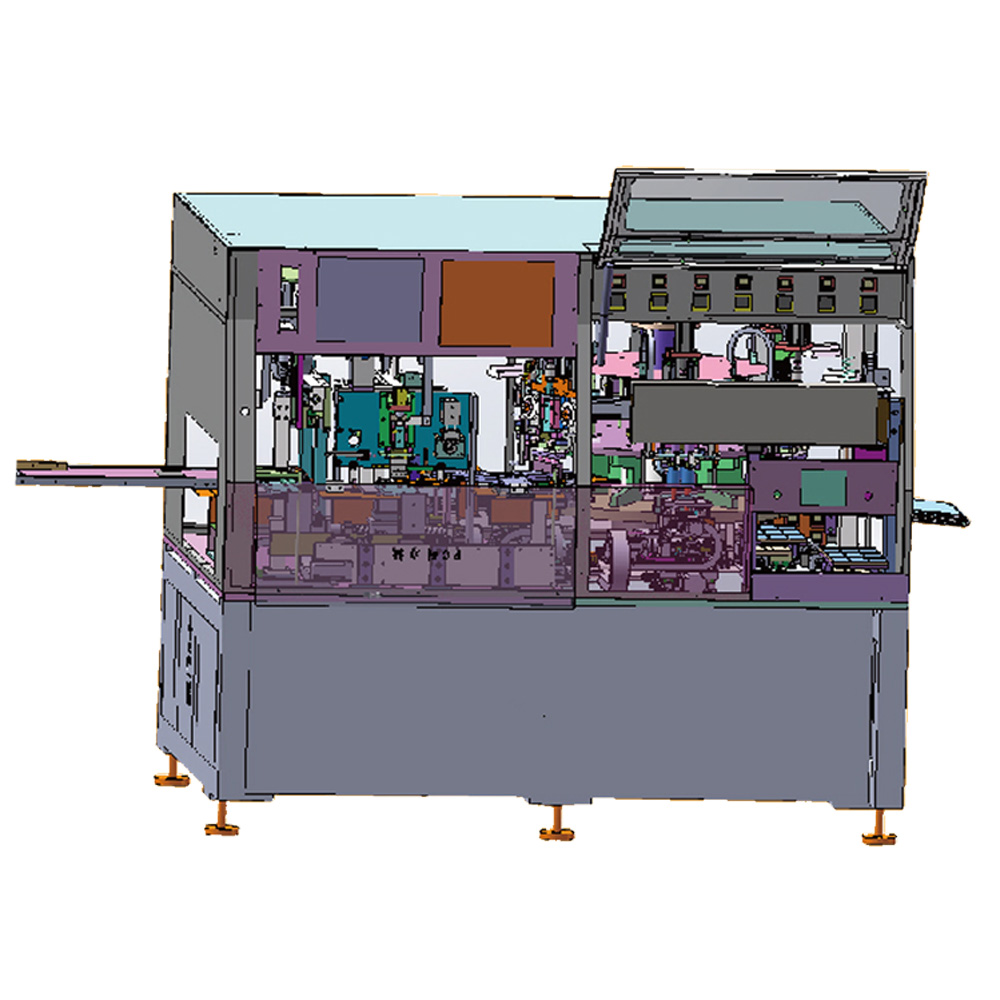

The Bonding Machine use the ACF tape as the medium ,so it named ACF bonding machine.

ACF Bonding Machine, is the widely used machine in the LCD/LED/OLED, LCM/open cell/panel/screen/display produce factories and repairing service shops all over the world.

The ACF Bonding Machine is based on the recent innovations as well as planned to repair the arrangements of LCD, LED,OLED, TV/television, Laptop, Pad, Cell phone, Watch, Touch Panel, Ad Player, and all the flat and edge screens.

The ACF Bonding Machine may consist of HD Digital Microscope, and also has a Digital Pressure Gauge, and vacuum generator which may help to hold the panel during the bonding process. The bonding press head may press the IC/FPC/COF onto the Glass/PCB/FPC using ACF conductive adhesive as medium, by a certain temperature, pressure and time.

According to the different bonding materials, the ACF bonding machine can be divided into different bonding machines.

COG bonding machine, also name IC Bonding machine, Chips bonding machine, COG(Chip on glass) bonding machine, it is bonding the Chip IC on the glass using ACF conductive adhesive as medium, by a certain temperature, pressure, time, driver IC will be bonded onto the glass. COG bonding machine has COG Pre-Bonding Machine and COG Main-Bonding Machine. They are all constant temperature machines. it maybe have single station ,double stations, three stations, and maybe four stations bonding machine.

FOG bonding machine, FOB bonding machine, FPC bonding machine, Flex cable bonding machine.FOG(FPC on glass )or FOB(FPC on PCB Board), FOF(FPC on FPC), also COF on Glass bonding, COF on board bonding, COF on film bonding. It have Pulse Heating Bonding Machines and Constant Temperature Bonding Machines.

ACF attaching machine which is attaching the ACF tape on the Glass/Board/FPC/COF before bonding. it also name ACF machine, ACF attachment machine, ACF Attached machine , ACF bonding machine , ACF pre-paste , ACF equipment , ACF pre-paste machines , ACF pre- affixed equipment, ACF single station machine , ACF multi-station machines and so on. The attaching machine, also can paste the Double-sided tape.

Semi Automatic LCM making machines include:COG pre-bonding machine, COG main-bonding machine , FOG(FOB) bonding machine, ACF attaching machine as below:

Full automatic COG bonding machine, it include the LCD cleaning, IC loading, ACF attaching on the glass, IC pre-bonding, and IC main-bonding processes.

Full automatic FOG bonding machine, It include the ACF attaching on the glass, FPC loading, FPC bonding on the glass and output to testing..

LCM full automatic produce machine include all the process of the COG and FOG bonding machines.

If you need the ACF bonding machines and the ACF tapes and all the accessories,please contact us Olian .Wechat/whatsapp:+86 18025364779,QQ:2307972393, E-mail:2307972393@qq.com

We offer all kinds of COF IC, chip on Film,chip on flex,TAB IC, TV Repair COF,LCD T-con COF IC, LCD TV COF IC, Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,COF,PANDA COF, SONY COF,LCD COFS,COF bonding machine repairing for you .

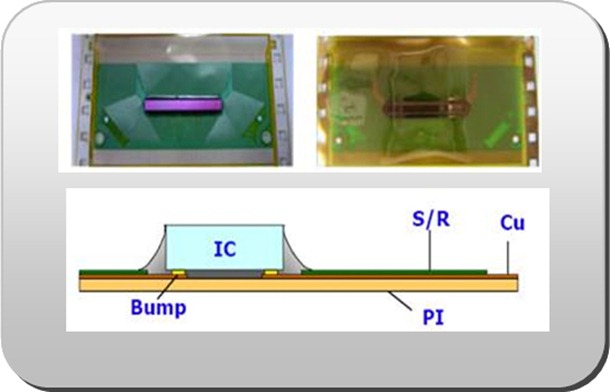

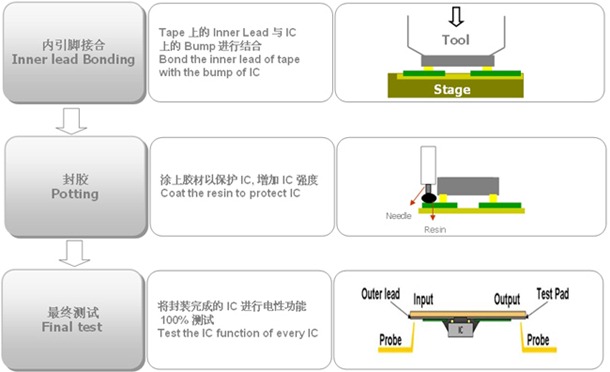

COF is an IC packaging technology that uses a flexible printed circuit film as a carrier for a packaged chip. The gold bumps on the chip are bonded to the Inner Lead of the flexible substrate circuit by thermal compression bonding technique.

After the COF production is completed, the LCD panel module factory will cut the reel tape COF IC into single piece by the COF Punching Machine. There are outer leads of Input and Output on the flexible substrate circuit of the COF, the Input external pins will be bonded to the LCD glass substrate, and the Onput pins will be connected to the control signal printed circuit board ( PCB) .

COF package has High Density / High Pin Count, Fine Pitch, Gang Bond, High Throughput and High Reliability characteristics. In addition, it is lightweight, short, flexible and Reel to Reel production, which is not possible with other traditional packaging methods. For COF products, multi-chip or passive components can also be designed on the substrate circuit.

Some COF ic can not find,and may be stop produce,so need to find some replace COF to use. Some replace COF ic for reference only.

NT39562H-C12Q9A

8656-MCY61

RM76731FD-60y

NT39992H-C12E2A

8157-RCY60

RM76C30FA-F02

8656-FCY0B

NT61227H-C1217B

RM92A31FA-908

NT39525H-C14F1A

S6C2BD1-54U

DB7500-FD07SB

DB7501-FD02S

S6C2T94A01-58U

NT39823H-C6501A

8033-HCU67B

36-D064129

MT3196C-VE

EK77211CF129A

S6C1125-65

8033-HEX39

LH165V08-S332

S6C1125-62

RM92370FC-80K

S6C2BD1-54U

SPLC-1698A

DB7500-FD07SB

DB7501-FT03S

DB7501-FD03S

DB7501-FD03S

DB7501-FD07SB

MN838994LF-1

RM92122FA-058

RM92165FM-OE9

NT65060H-C0205A

MT3196B

NT61207H-C6802A

ICN9305-05

NT39931H-CO2F7A

S6C2BD1-55U

MT3173VF

8697-A

RM91C30FA-F01

RM91C30FB-F04

DB7500-FD04S

NT39992H-C12E2A

D160418NL-057-C1 108

LS08S6HT3A-C3LS

RM76320FB-61A

NT39931H-CO2F74

MT3173VF

DB7893-FT11M

S62B91-63

DB7500-FDO75B

S6C2BD1-58U

RM76153FS-0A1

MT3714VM

DB7501-FT03S

DB7501-FD03S

RM9113BFG-OG1

VH1L5032786-2L

S6CG239-52 H COF

NT39985H-C02M4A

S6C277J-54

RM9216EFA-OG6

DB78913-FT11M

S6C2BD1-55U

DB7500-FD07S

S62LD1-58U

DB7500-FD758

S6C2B91-63

DB7893-FT11M

RM76155FS-0A1

MT371UVM

D78913-63

RM92A131FD-90E

8160-C558

ICN9506-01

RM92A31FA-908

NT39658H-C1294A

NT 61227h C1217A

RM76731FD-60Y

NT65001H-C02P3A

DB7500-FD07SB

EK77211CFI29A

SSD3258UR1

DB7897B-FT08M

NT39935H-C5216B

8154-ECBM3

RM9216DFJ-OFP

RM92122FA-058

56C1104

NT39759H-C12E3C

RM92122FA-058

NT61610H-C07928

LS0856HEASHZ-C3LX

MT3753VD

DB7878-FS02U

ILI5381M2AB2

ILI305K5CD2

S6C2T96-60U

NT39573H-C6007A

S6C2T92J-55U

DB6894-FS06M

S6C277U-53U

RM76113FD-OCX

NT61702H-C6801A

NT39833H-C6511B

NT61720H-C12J3C

8157-RCBRG

MT3166VB

NT39980H-C5266A

NT39992H-C1279A/C

NT61804H-C6520A

RM927A1FF-61B

8159-KCBR8

HX8157-NCA03

ILI3102K6CB1-S

LS0610BH1-C2LX

LS0610BH1-C1LX

MT3220A-VA

NT39892H-C12H5A/B/C

RM92A31FA-908

SSD3273UR4

5253-ACBPQ

MT3725VB-10260UTE

Nt39548H-C5801A

NT61702H-C6801A……

All kinds of COF ic,

Samsung COF,AUO COF, BOE COF,LG COF, SHARP COF,PANISONIC COF,TOSHIBA COF,PANDA COF, SONY COF,LCD COFS ,Welcome you send your list to my Email:2307972393@qq.com, or Wechat:+8618025364779,We will reply you ASAP.

Related products:

COF bonding machine, also name TAB bonding machine, ACF bonding machine, OLB Bonding machine, Chip on Film bonding machine. COF(Chip on Film, Chip on Flex).COF bonding machine is widely used in the TV/laptop/pad panel, it is very popular in the TV/laptop repairing for the LCD/LED/OLED panel bonding. For TV or laptop panel repairing COF bonding machine, has COF on glass bonding and COF on PCB board bonding. The COF Bonding machine also can do COF on flex cable, COF on film bonding, and maybe IC on film bonding. Normal the COF bonding machine is Pulse heating bonding machine with Titanium alloy press bonding head.

This COF bonding machine is mainly designed for TV/Laptop/cellphone repairing, it is for LCD/LED/OLED Panel repairing with COF changing functions,so it is also named COF change machine, COF repair machine, TV bonding machine, TV Repair machine,Laptop repair machine,LCD panel repair machine,LCD bonding machine,LCD repair machine,LCD fix machine, and so on..

Our COF bonding machine and all the accessories list for TV/laptop panel repairing as below:

We also offer all the COF Bonding machine accessories: ACF tapes, ACF Remover, Blue glue, Acetone, Alcohol ,Customized bonding head, Quartz glass, Silicone tape, Teflon tape, Microscope, Air Compressor, COF cutter, Cleaning nanosponge, Cleaning clothes wiper, Ear buds, Pump bottles, T-bit, T-rubber, T-Iron, Magnifier lens, Allen key, Precision tweezers, Soldering Stations, Removing Wind Station Hot Air Gun, LEDS,LVDS cables, LCD Test Board, LCD/LED Tester.RT809H programmer, Open cell, Polarizer, Backlight ,T-Con Board, Main-board, IC, TAB COF IC and others.