The OL-Q006 by Olian Automatic is a manual cleaning machine for LCD panel terminals. It prepares ITO bonding areas by removing contaminants before thermal bonding.

This unit combines lint-free cloth wiping and plasma cleaning to ensure high surface cleanliness. It is designed for panels with pre-applied anisotropic conductive film (ACF).

Suitable for rigid and flexible displays:

Panel size range:

The operator loads and unloads panels manually.

They initiate the cleaning cycle using control buttons.

No automatic alignment or robotic handling is included.

Worktable size: 170 mm (W) × 190 mm (D)

Lint-free roll: inner diameter >25 mm, outer diameter <200 mm

Vacuum system: yellow tubing, flow ≈36 L/min

Compressed air: 0.4–0.7 MPa, transparent Φ8 mm tubing, flow ≈120 L/min

Power supply: single-phase AC 220V, 50/60 Hz, 1500 W

Machine dimensions: 680 mm (W) × 850 mm (D) × 1350 mm (H)

Work height: 800 ± 30 mm

Net weight: ~161 kg

Frame color: beige

Other parts: chrome-plated or anodized

Core components:

Must be used in a cleanroom:

All hazardous zones are labeled with warning signs.

The machine is delivered clean and ready for installation.

This is a pre-bonding cleaning station only.

It does not perform:

Its sole purpose is terminal surface preparation.

Includes one-year warranty (excluding wear parts).

On-site service within 72 hours if remote support fails.

One-day training covers operation and basic maintenance.

Lifetime technical support is provided.

Model: OL-Q006

Function: LCD Terminal Cleaning Only

Methods: Lint-Free Wiping + Plasma Treatment

Operation: Fully Manual

Max Panel Size: 7 inches

SEO Keywords:

LCD terminal cleaner, OL-Q006, Olian Automatic plasma cleaning machine, manual ITO cleaning station, pre-bonding surface prep, lint-free wipe and plasma system, 7-inch display cleaning equipment, ACF-ready terminal cleaner, LCD panel pre-treatment machine, manual LCD cleaning workstation.

OL-FD006 – 7-Inch Single-Station Manual FOG Bonding Machine with Dual-Lens up and down Alignment

The OL-FD006 by Olian Automatic is a single-station manual FOG (Film-on-Glass) bonding machine. It bonds flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches.

This system is designed for high-precision alignment and thermal bonding. It assumes ACF has been pre-applied to the panel or FPC. The machine does not support COF (Chip-on-Flex) bonding.

The unit uses a dual-lens optical system. Operators view panel and FPC marks simultaneously on one screen.

Magnification is 2×. Field of view per lens is 1.9 mm × 1.4 mm.

Lens spacing adjusts from 12 mm to 90 mm to match different mark layouts.

Coaxial LED lighting ensures clear, shadow-free imaging.

Operators manually adjust the panel’s X and Y position using knobs for precise alignment.

The operator places the panel on the lower stage and activates vacuum hold.

They then place the FPC on the upper stage.

After visual alignment via the display, they press both start buttons with two hands.

The bonding head descends automatically. It applies heat, pressure, and holds for a set time.

Temperature reaches up to 300°C with uniformity within ±5°C.

Pressure ranges from 25 N to 400 N. Time is adjustable from 0.1 to 99.0 seconds.

After bonding, the head retracts. The stage returns to load position. The operator removes the product.

The machine includes an automatic buffer tape feed system.

Tape roll inner diameter: ≥33 mm. Outer diameter: ≤80 mm.

Feed pitch: 1–20 mm.

If feeding fails, the system triggers an alarm.

One operator handles all loading and unloading at the same position.

The machine features a PLC controller and color touchscreen.

Standard bonding head size is 60 mm × 1.0 mm, but custom sizes are available.

Machine dimensions: 830 mm (W) × 900 mm (D) × 1340 mm (H). Weight: ~320 kg.

Power: 220V AC, 2000W. Air: 0.5–0.7 MPa, 250 L/min.

Ideal for bonding:

Not suitable for bare ICs or standard COF modules.

Includes one-year warranty (excluding wear parts).

On-site service within 72 hours if phone support fails.

One-day training covers operation, alignment, parameter setup, and maintenance.

Lifetime remote technical support is provided.

Model: OL-FD006

Function: FPC and Touch Flex Bonding Only

Excludes: COF, IC, ACF lamination, EC cleaning

Key Feature: Dual-lens split-screen manual alignment

SEO Keywords:

Manual FOG bonding machine, OL-FD006, Olian Automatic FPC bonder, 7-inch Film-on-Glass press, dual-lens alignment system, FPC to LCD bonding equipment, thermal compression for touch flex, manual X-Y alignment bonder, FPC bonding for rigid displays, split-screen vision FOG machine.

The OL-FPD005 by Olian Automatic is a single-station manual pulse pre-bonding machine. It is designed for COF (Chip-on-Flex) alignment and thermal pre-compression on panels up to 7 inches. The system supports both rigid glass and flexible displays.

This machine requires operators to perform all loading, alignment, and bonding steps manually. It provides precise thermal and pressure control during pre-bonding but does not include vision alignment or automatic motion.

The operator places the panel on the worktable. They press a vacuum button to secure it.

Next, they position the COF on the COF stage and align it roughly with the panel terminals. Vacuum holds the COF in place.

The operator then uses the display screen to fine-tune alignment visually.

After confirming alignment, they press the pre-bond button once—the left press head descends without heating to check contact.

Pressing the same button again lifts the head.

If alignment is acceptable, the operator presses two start buttons simultaneously with both hands. The head then lowers automatically, applies heat, and performs pulse pre-bonding.

When the set time ends, the system blows air to cool the bond area. The head retracts. The cycle is complete.

Finally, the operator removes the bonded panel manually.

All steps are manual except the controlled descent, heating, timing, cooling, and lift during the final bonding phase.

The left press head heats from room temperature to 400°C using pulse heating. Surface temperature uniformity is within ±8°C.

Heating time is adjustable from 0.1 to 99.9 seconds.

Bonding force ranges from 20 N to 300 N.

The standard press head size is 50 mm long × 0.8 mm thick, but custom sizes are available.

Only one operator is needed. All loading and unloading happen at the same position.

The machine includes a display screen for visual alignment reference.

It uses industrial-standard controls: Φ24 vacuum and start buttons, and a Φ22 emergency stop switch.

Core components include a 9.5 mm × 70 mm heating tube, a K-type thermocouple, and a custom hot press head.

Ideal for:

Note: This machine does not apply ACF, does not bond ICs, and has no automated vision system. ACF must be pre-laminated before use.

Olian Automatic offers a one-year warranty on parts and labor (excluding wear items).

On-site service is provided within 72 hours if remote support fails during warranty.

One day of training covers installation, operation, parameter setup, troubleshooting, and consumable replacement.

Lifetime technical support is available.

Model: OL-FPD005

Type: Manual Pulse Pre-Bonding Machine

Function: COF Pre-Bonding Only

Panel Size: Up to 7 inches

Substrates: Glass or Flexible Panels

Operation: Fully manual alignment; semi-automated thermal bonding

SEO Keywords:

Manual COF pre-bonding machine, OL-FPD005, Olian Automatic pulse bonder, 7-inch COF alignment press, hand-operated thermal pre-bonder, COF bonding for flexible display, single-station COF machine, pulse heating bonding system, manual LCD COF pre-compression, hot bar pre-bond equipment.

The OL-COF003 by Olian Automatic is a medium-speed semi-automatic pre-bonding machine. It bonds ICs or COFs onto ACF-pre-applied panels. The system supports both rigid glass and flexible displays up to 7 inches.

This machine is designed for high-precision alignment and thermal pre-compression. Operators load and unload panels manually. All other steps—IC/COF pickup, vision alignment, and pre-bonding—are automated.

The OL-COF003 handles two main workflows: IC pre-bonding and COF pre-bonding.

For IC bonding, the operator loads IC trays (2-inch, 3-inch, or 4-inch). The machine uses a servo motor, lead screw, and linear guide to move the IC stage. A vacuum nozzle picks up the IC. A dedicated jig corrects IC position from both sides. The head then moves down for CCD imaging of IC marks. After vision alignment with the panel mark, the machine performs pre-bonding automatically.

For COF bonding, the operator places COF on a PEEK adsorption platform. The COF stage is driven by a cylinder for left-right motion. Vacuum holds the COF in place. A quartz back-pressure unit ensures flatness during pickup. The bonding head adsorbs the COF, retracts the stage, and moves down for CCD imaging. The system then aligns the COF with the panel and completes pre-bonding.

Panel loading is manual. The operator places the panel on the stage and presses a vacuum button. The stage then moves automatically to the alignment position. After bonding, it returns to the loading position for easy removal.

Temperature control ranges from room temperature to 150°C. Surface uniformity stays within ±5°C.

Bonding time is adjustable from 0.1 to 99.0 seconds.

Pressure is precisely controlled between 20 N and 120 N.

The machine uses industrial-grade components for reliability. It includes safety interlocks and user-friendly controls.

The unit measures 650 mm wide, 660 mm deep, and 1340 mm tall. It weighs about 230 kg.

It runs on single-phase 220V AC at 1500W.

Compressed air must be 0.5–0.7 MPa with a flow rate of 450 L/min, using 8 mm tubing.

Ideal for small-batch production, pilot lines, and R&D.

Supports:

Note: ACF must be pre-applied before use. This machine does not apply ACF.

Olian Automatic provides one year of warranty (excluding wear parts).

On-site service is available within 72 hours if phone support fails.

One day of training covers setup, operation, troubleshooting, and part replacement.

Lifetime technical support is included.

Model: OL-COF003

Type: Semi-Automatic Pre-Bonding Machine

Max Panel Size: 7 inches

Processes: IC Pre-Bonding, COF Pre-Bonding

Substrates: Rigid Glass, Flexible Displays

Operation: Manual panel load/unload; automatic alignment and bonding

Semi-automatic pre-bonding machine, OL-COF003, Olian Automatic COF bonder, 7-inch IC pre-bonder, medium-speed COG FOG pre-bond machine, vision alignment bonding system, thermal pre-compression for display, COF pickup and bond equipment, IC correction and bonding workstation, ACF pre-bond machine for rigid and flexible panels.

OL-A003D 7-Inch Single-Edge Single-Stage ACF Laminating Machine – Compact, Manual Thermal Bonding System for Precision Display Assembly.

The OL-A003D by Olian Automation is a compact, semi-automatic ACF (Anisotropic Conductive Film) laminating machine designed for high-precision bonding of ACF onto LCD panels, flexible printed circuits (FPCs), or rigid PCBs. Optimized for small-format displays up to 7 inches, this manual ACF bonding machine features a 150 mm heated press head and supports both rigid glass substrates and flexible display modules, making it ideal for R&D labs, pilot lines, repair centers, and low-volume production environments.

Unlike complex automated systems, the OL-A003D simplifies the ACF bonding process: operators manually load and unload the panel, while the machine automatically executes the thermal compression cycle, ACF feeding, peeling, and cutting—ensuring consistent, repeatable results with minimal training.

The OL-A003D is widely used in:

Built with robust mechanical design and standard industrial components, the OL-A003D ensures long-term stability. Olian Automation provides:

For engineers seeking a cost-effective 7-inch ACF laminating machine, a compact manual ACF bonder, or a single-stage thermal bonding system for rigid and flexible displays, the OL-A003D delivers exceptional value. Its blend of simplicity, safety, and precision makes it a trusted choice across global electronics manufacturing and development sectors.

Model: OL-A003D

Type: Manual Single-Edge ACF Laminating Machine

Max Panel Size: 7 inches

Press Head Length: 150 mm (standard)

Operation Mode: Manual loading/unloading, automatic bonding cycle

Target Users: Display assemblers, electronics OEMs, R&D labs, repair technicians

SEO Keywords Integrated:

ACF laminating machine, manual ACF bonding machine, 7-inch ACF bonder, single-edge ACF applicator, Olian OL-A003D, thermal compression ACF machine, LCD ACF bonding equipment, FPC to glass laminator, small display ACF贴附机, benchtop ACF bonding system, single-stage ACF laminator, anisotropic conductive film bonder, rigid and flexible display bonding, COG pre-bonding machine, compact ACF applicator.

OL-A003 Semi-Automatic 12-Inch ACF Laminating Machine – Precision Thermal Bonding for LCD, FPC, and Display Module Assembly。

The OL-A003 semi-automatic ACF laminating machine by Olian Automation is a compact, high-accuracy bonding system engineered for reliable application of anisotropic conductive film (ACF) onto LCD panels, flexible printed circuits (FPCs), and printed circuit boards (PCBs). Designed for R&D labs, pilot production lines, and small-to-medium batch manufacturing, this manual ACF bonding machine supports panel sizes from 1 inch up to 12 inches, making it ideal for applications in consumer electronics, automotive displays, medical devices, and industrial HMIs.

Unlike fully automated systems that require complex integration, the OL-A003 desktop ACF bonder strikes the perfect balance between operator control and process automation. Users manually load and unload the panel, while the machine automatically handles ACF feeding, thermal compression bonding, carrier film peeling, and precision cutting—ensuring consistent results with minimal training.

The OL-A003 is built with reliability in mind. It features:

This semi-auto ACF laminator is widely used in:

For engineers and procurement teams searching for a cost-effective 12-inch ACF bonding machine, a benchtop ACF laminating system, or a manual ACF bonder with high positional accuracy, the OL-A003 delivers exceptional value. It eliminates the complexity and cost of full automation while maintaining the precision required for modern micro-electronics assembly.

Backed by Olian Automatic—a certified national high-tech enterprise specializing in LCM automation solutions—the OL-A003 combines proven engineering, robust component selection, and user-centric design into one dependable platform.

Model: OL-A003

Type: Semi-Automatic ACF Laminating Machine

Panel Size Range: 1″ to 12″

Bonding Accuracy: ±0.2 mm (X/Y)

Operation Mode: Manual loading/unloading, automatic bonding cycle

Target Industries: Display manufacturing, electronics assembly, R&D, repair

SEO Keywords Integrated:

ACF laminating machine, ACF bonding machine, manual ACF bonder, semi-automatic ACF laminator, 12-inch ACF bonding equipment, LCD ACF bonding machine, FPC to LCD laminator, anisotropic conductive film bonder, desktop ACF bonding system, benchtop ACF laminator, COG pre-bonding machine, FOG bonding equipment, Olian OL-A003, thermal compression ACF machine, small panel ACF applicator, high-precision ACF bonder, ESD-safe ACF laminator.

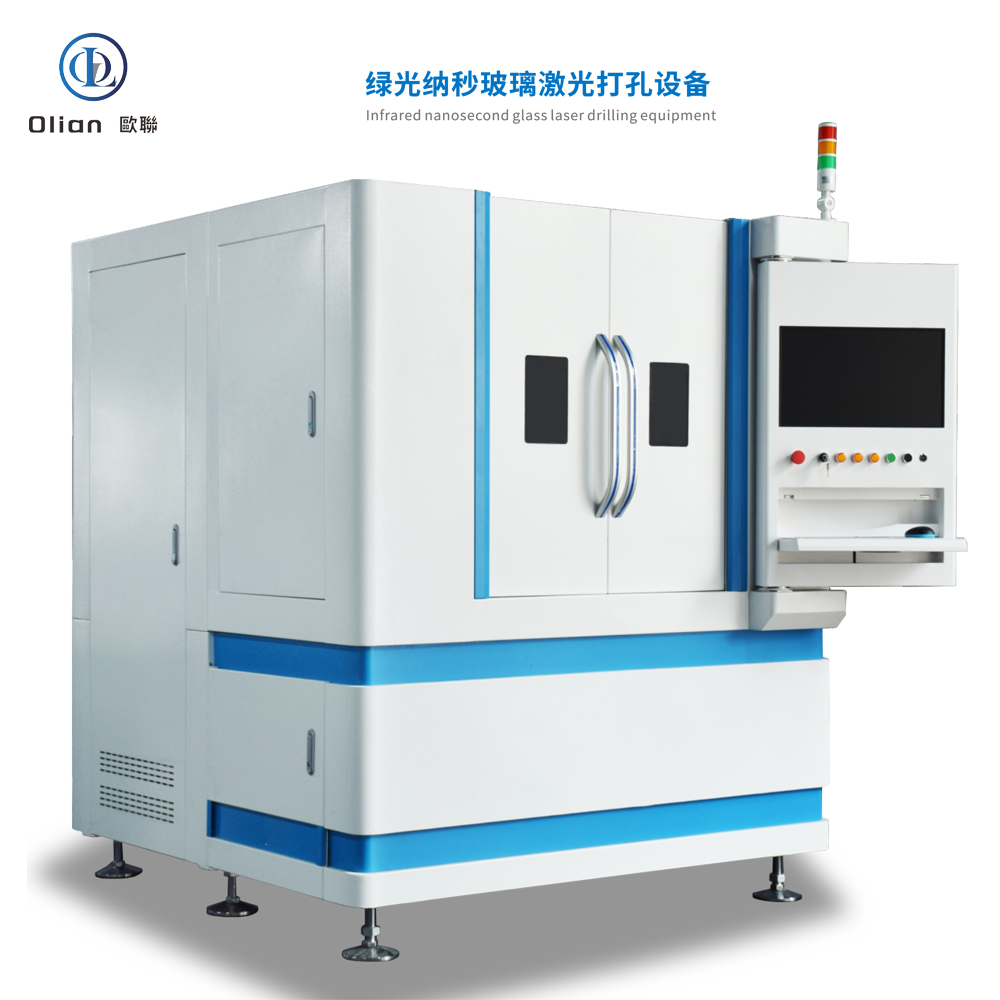

Green-Light Nanosecond Glass Laser Drilling Machine,

Processing Advantages

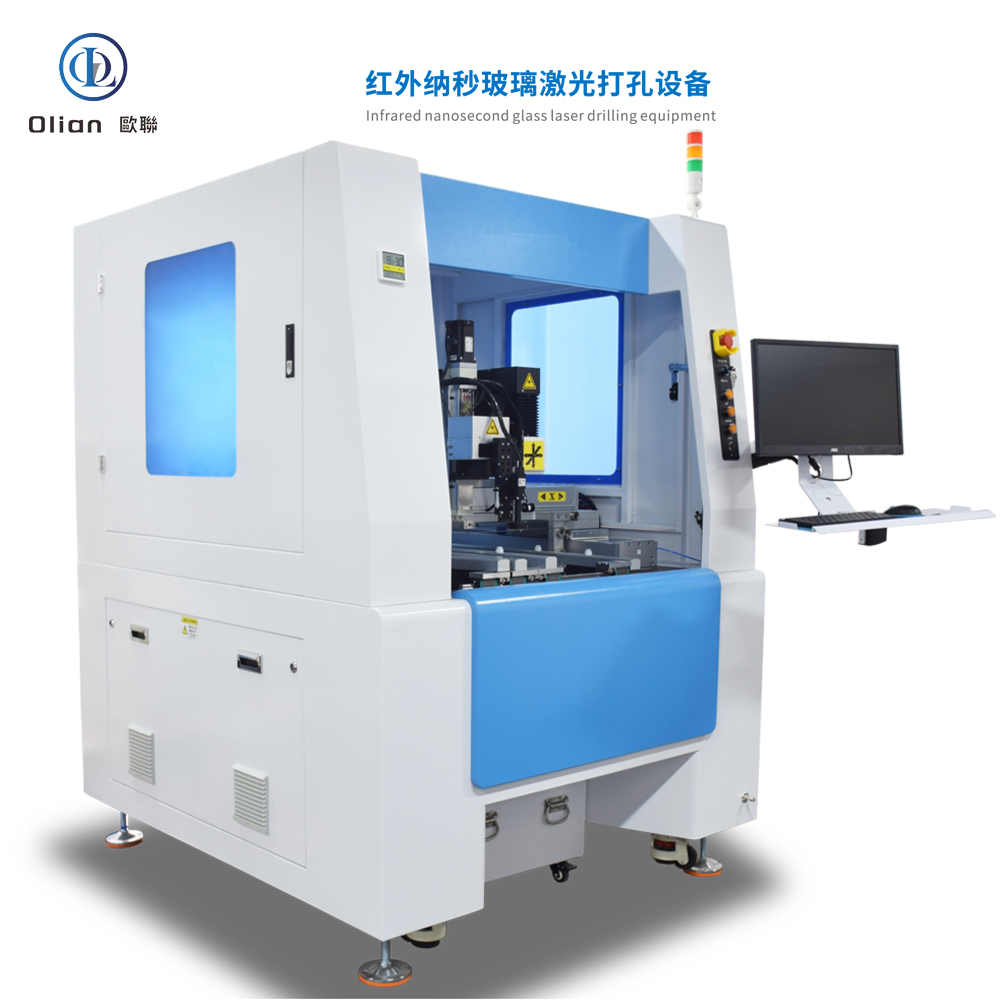

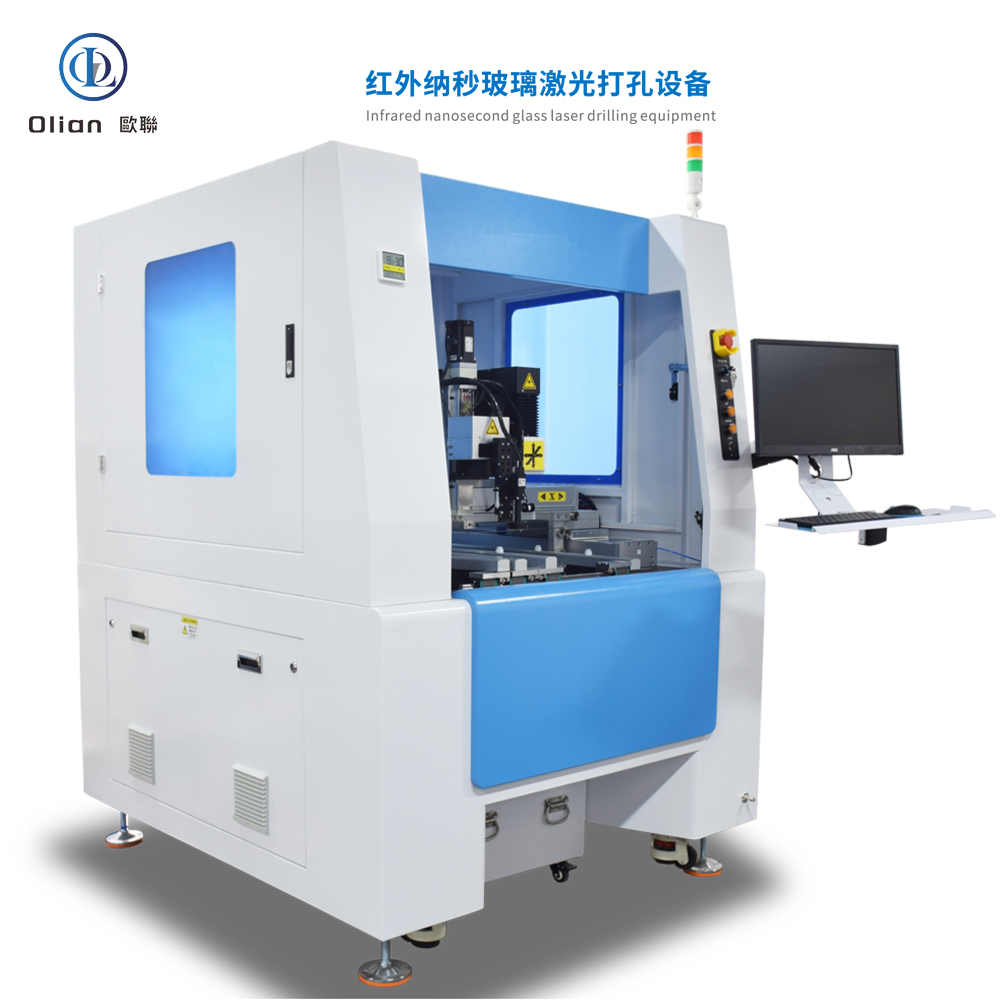

Infrared Nanosecond Glass Laser Drilling Machine

Process Application

Main Parameters

Processing Advantages

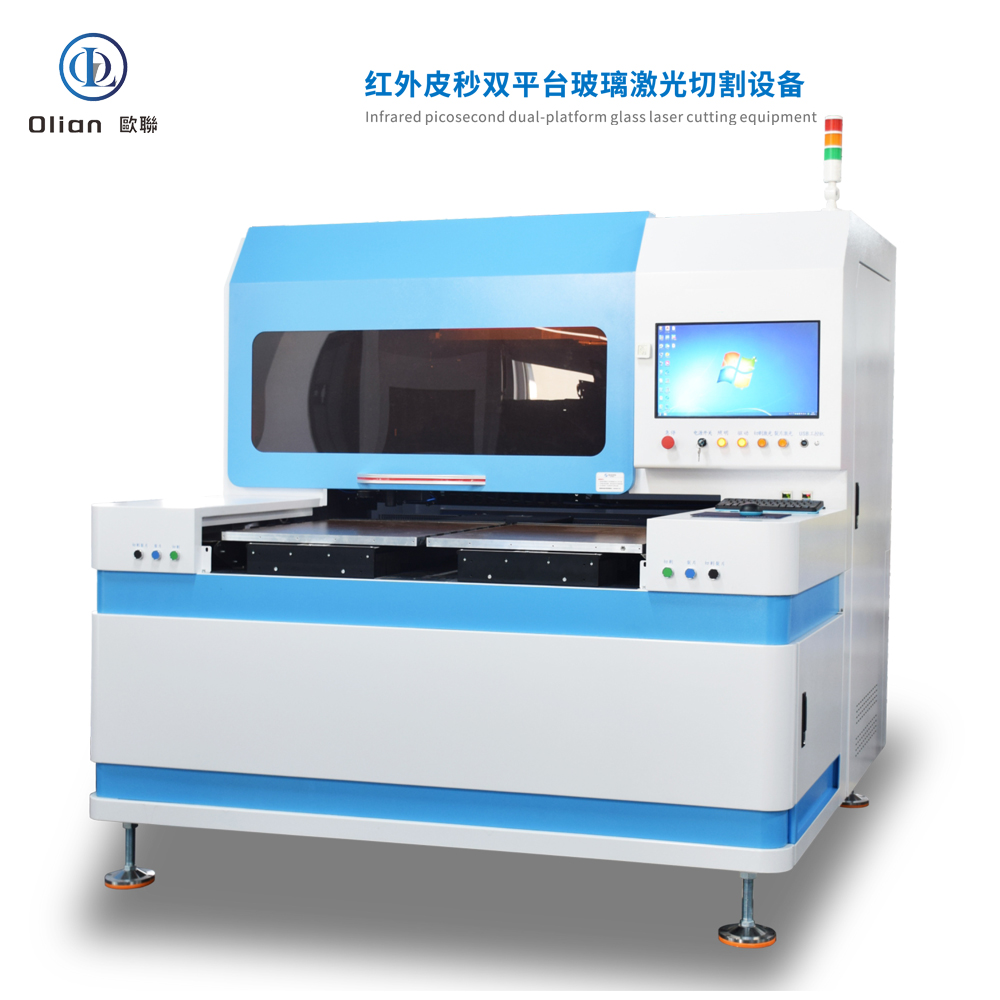

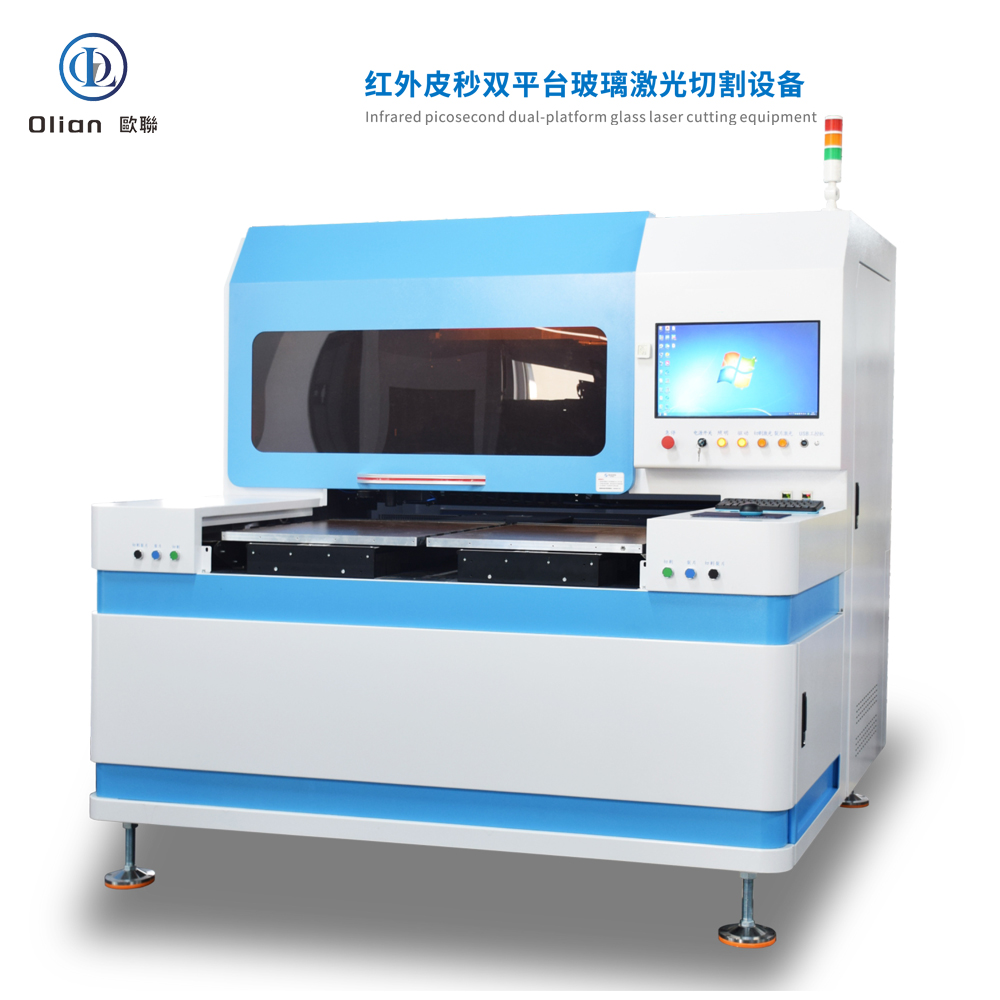

Infrared Picosecond Dual-Platform Glass Laser Cutting Machine

Cuts all hard-brittle sheet materials: ordinary glass, optical glass, quartz, sapphire, reinforced glass, optical filters, mirrors, etc. The same system also produces internal cut-outs and holes to specified dimensions.

Laser type: Infrared picosecond

Model: OL-IPC70120-D/OL-IPC90140-D

Standard platform sizes: 700 mm × 1 200 mm and 900 mm × 1 400 mm (custom sizes on request)

Thickness range: 0.03 – 8 mm

Maximum cutting speed: 1 000 mm/s

Edge chipping: ≤ 10 µm