15.6 inch bonding machines,include the ACF attaching machine, COG/COG bonding machine, FOG/FOB bonding machines,

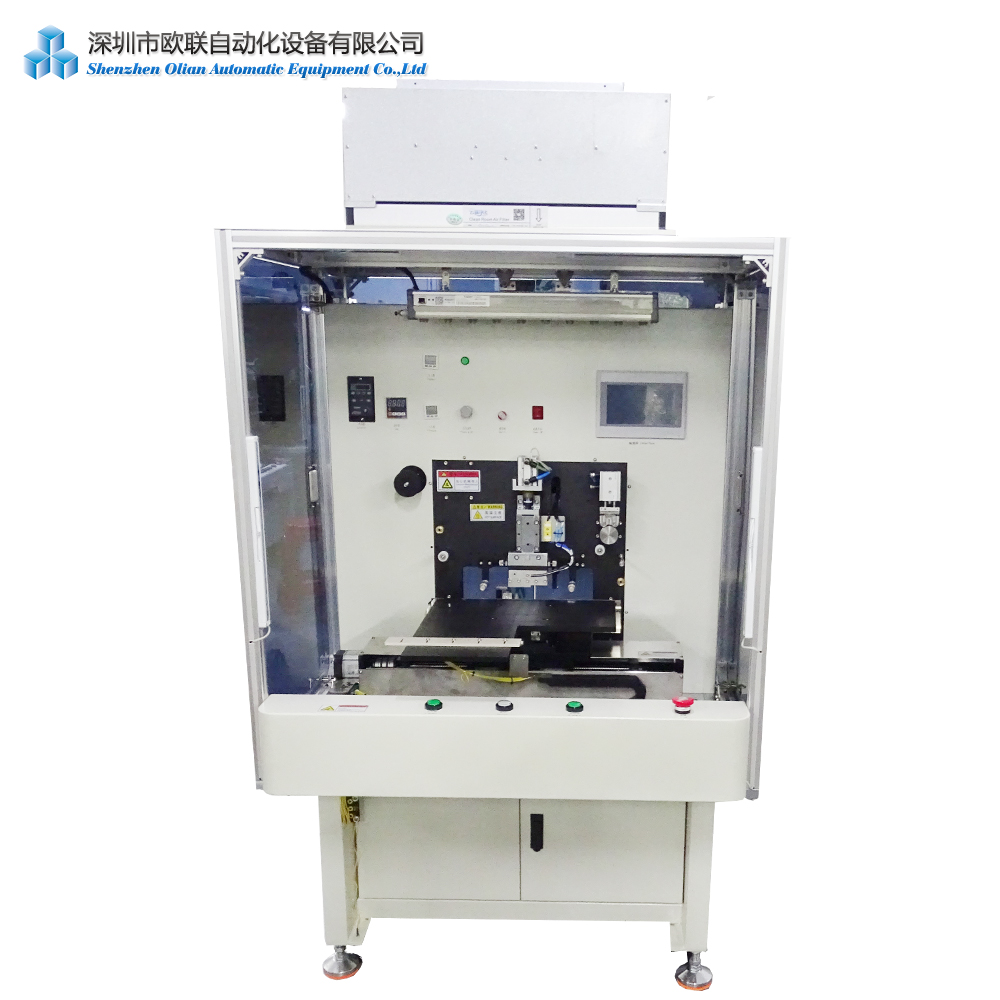

1.1 This equipment is a multi-segment ACF attaching machine, which can attach conductive film (ACF) on PCB, LCD, LED, etc. The picking and placing of PCB, LCD, LED and other products is done manually, and attaching heat The pressure and ACF length control is automatically completed by the equipment. 1. 2 It can be attached in 1-10 positions on one side.

Equipment production capacity: about 4.5sec, calculated according to a single payment position: about 800pcs/hour

Product qualification rate: ≥98% (defective materials are not counted)

1) Manually place the Panel on the Panel workbench

2) Press the vacuum button of the Panel workbench, and the Panel is adsorbed on the Panel workbench

3) Press the start button with both hands, the Panel workbench moves forward to the pressing position, and the hot pressing head drops

4) The hot press head heats the ACF on the Panel. After the set hot press time is up, the hot press head rises, the peeling device peels off the ACF, and the platform moves 2nd, 3rd…attach (according to the set attachment position)

5) Finish attaching

6) The Panel workbench is moved back to the feeding position, and the ACF is rolled over the set length, and the cutting is completed. 7) Manually remove the hot-pressed product 8) The attachment of the second product repeats the above 1)~6) Steps

Pressing accuracy: X: ±0.2, Y: ±0.2mm

Number of fit segments: 10 segments can be pasted.

1. The equipment is controlled by PLC, and the length of the tape is controlled by a high-precision stepping motor;

2. The equipment adopts semi-shearing (only cuts the ACF but not the centrifugal membrane), and the shearing depth and position can be adjusted freely;

4. The number of sides to be attached to a product, the number of sections on each side, and the attachment position of each section can be freely set according to requirements;

5. Using universal template design, product switching is easier;

6. The longest ACF attached to each section can be as long as 90mm;

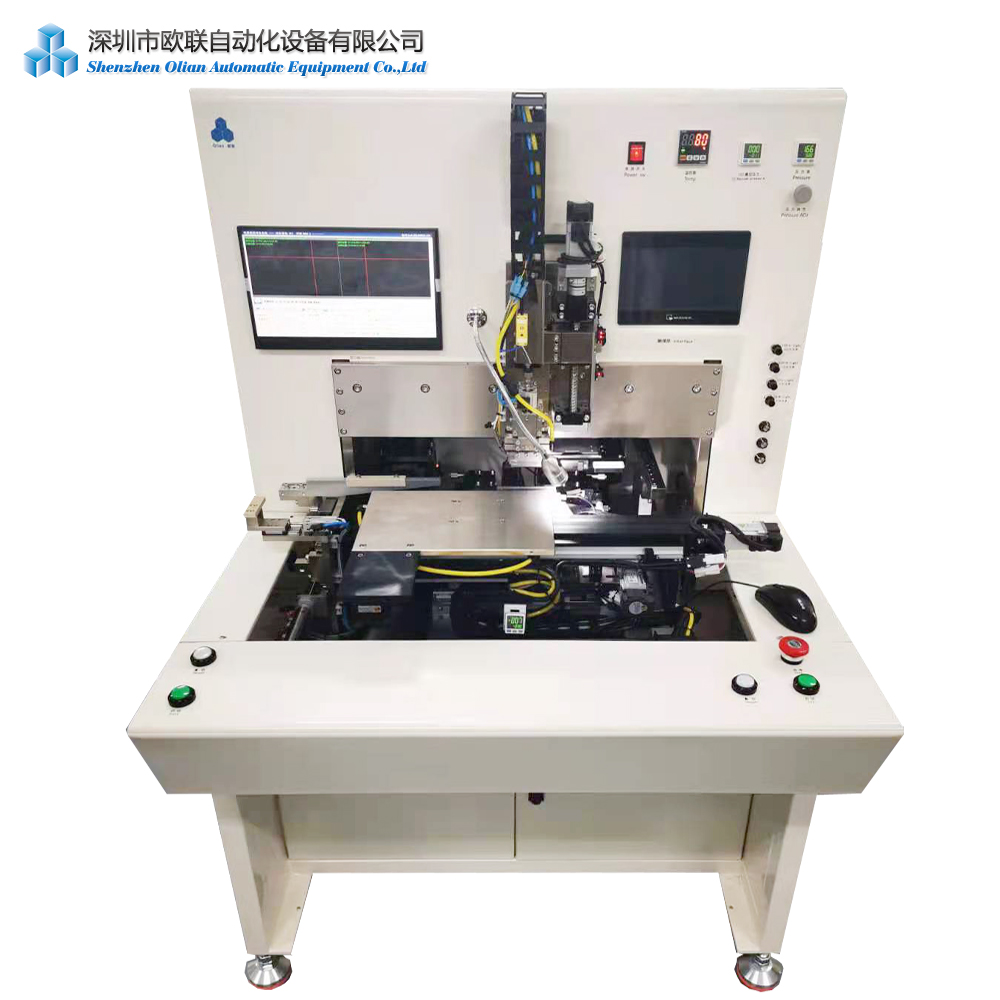

This equipment for high-precision IC TO STN-LCD, COLOR STN-LCD, TFT-LCD, OLED-LCD and flexible OLED fully automatic alignment and pre-bonding. It is mainly used for IC rework and small batch production.

This device is a manual bonding machine, which is a device that performs bonding again on the Panel that has been pre-attached to the IC to connect the IC to the corresponding circuit of the Panel. Suitable for 1″~15.6″ Panel hot pressing.

Applicable LCD size:2~15.6 inch STN/CSTN/TFT-LCD (the platform can be expanded to 17 inches);

Capacity:About 1200 tablets/hour;

Panel thickness:0.3~1.1mm;

FPC pressing range:6~80mm;

Mounting accuracy:±0.002mm;

Indenter specifications:40*5mm, can be changed according to customer requirements;

Flatness of hot pressing head:±5μm;

heating method:Thermostat control;

Temperature range of indenter:RT-400℃;

Back pressure temperature range:RT-150℃;

Temperature accuracy:±3℃;

Pressure accuracy:0.001MPa

Product fixing method:Vacuum adsorption;

Air consumption:0.3 cubic meters per minute;

working pressure:0.4~0.6Mpa;

power supply:220V, 50HZ, 2400W;

Total weight:550Kg;

Dimensions:L800*W840*H1310(720);

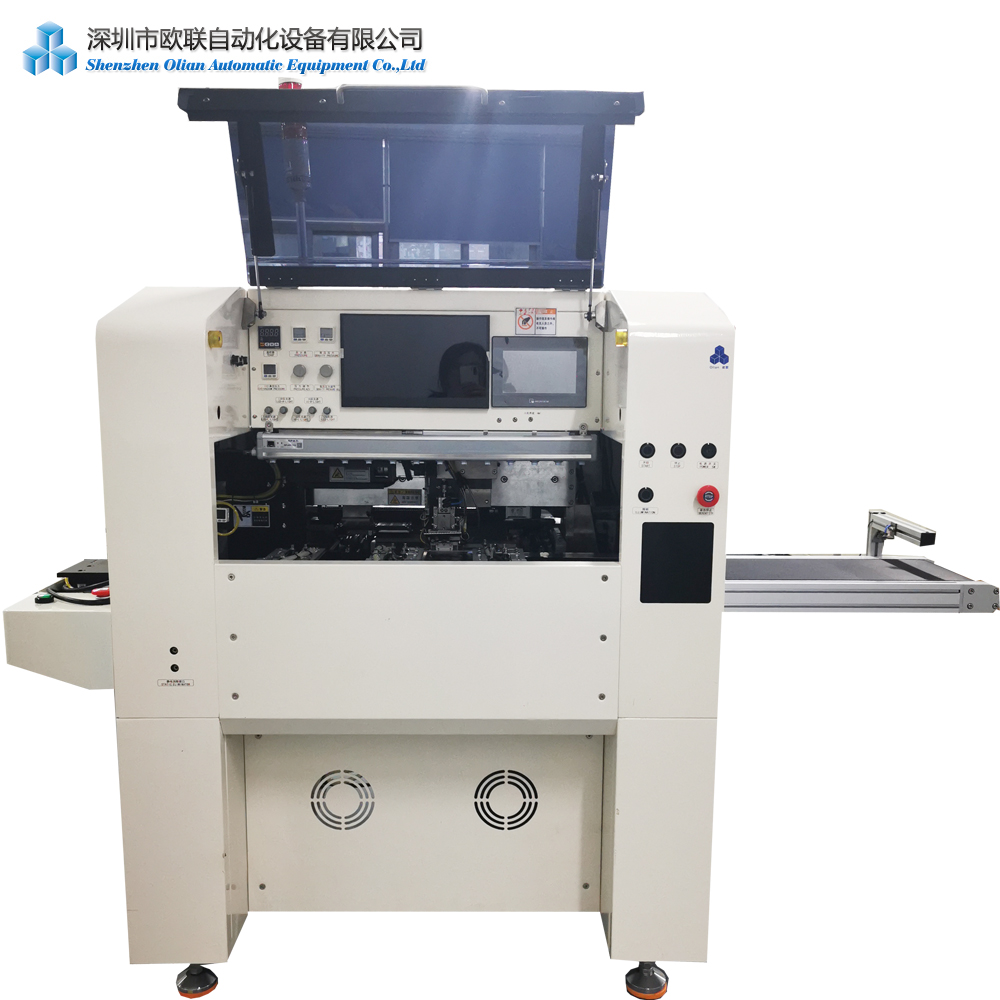

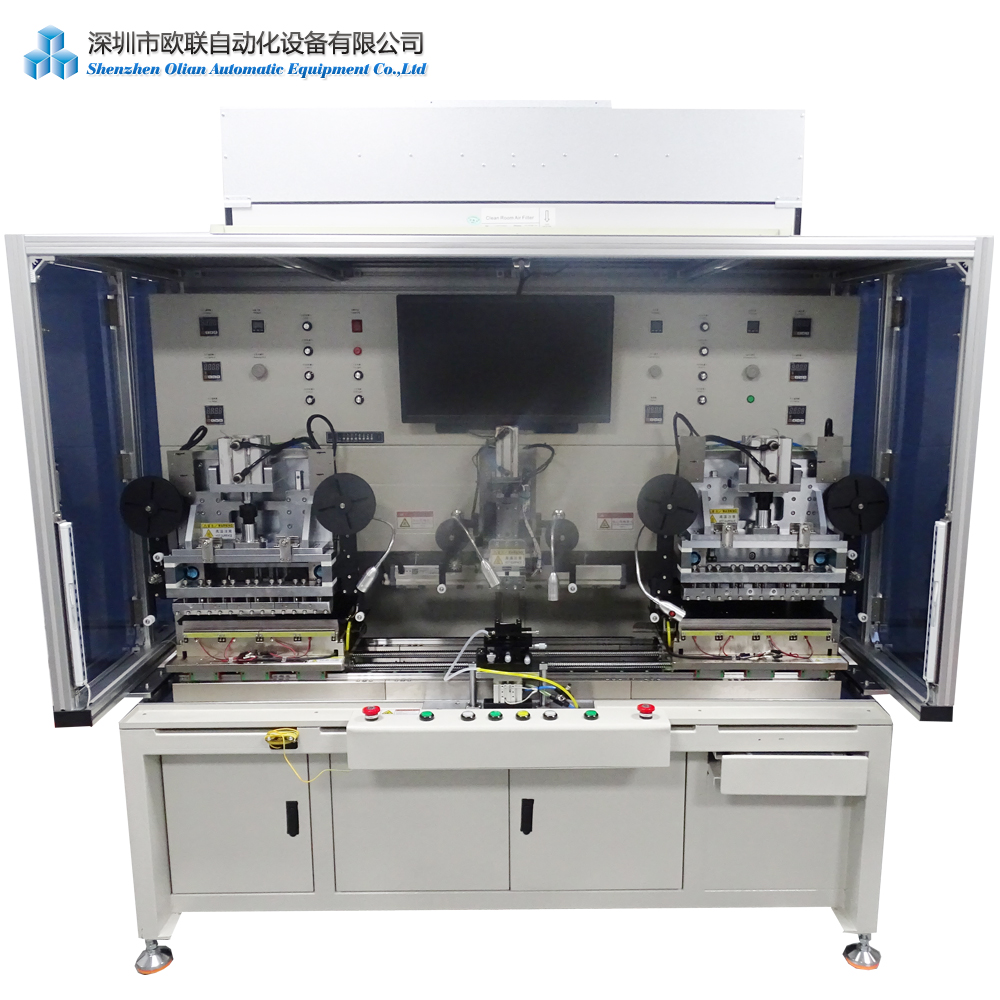

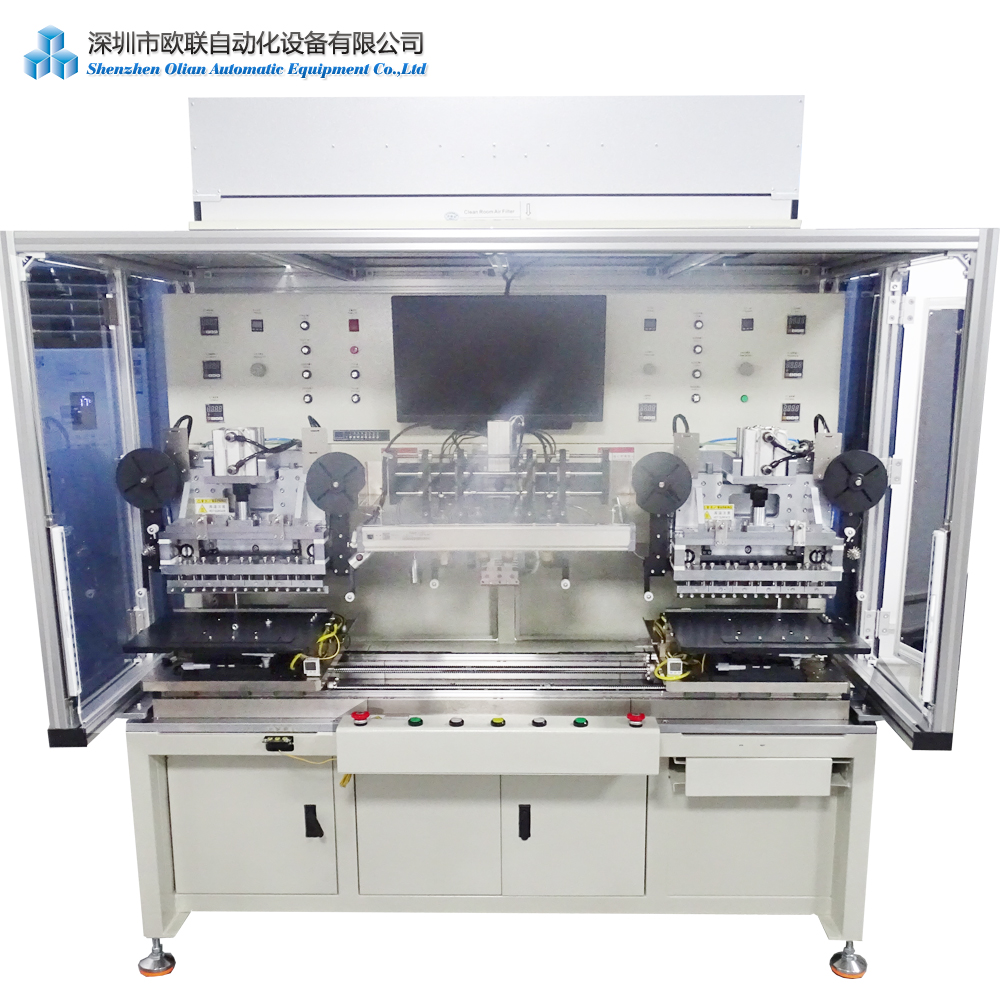

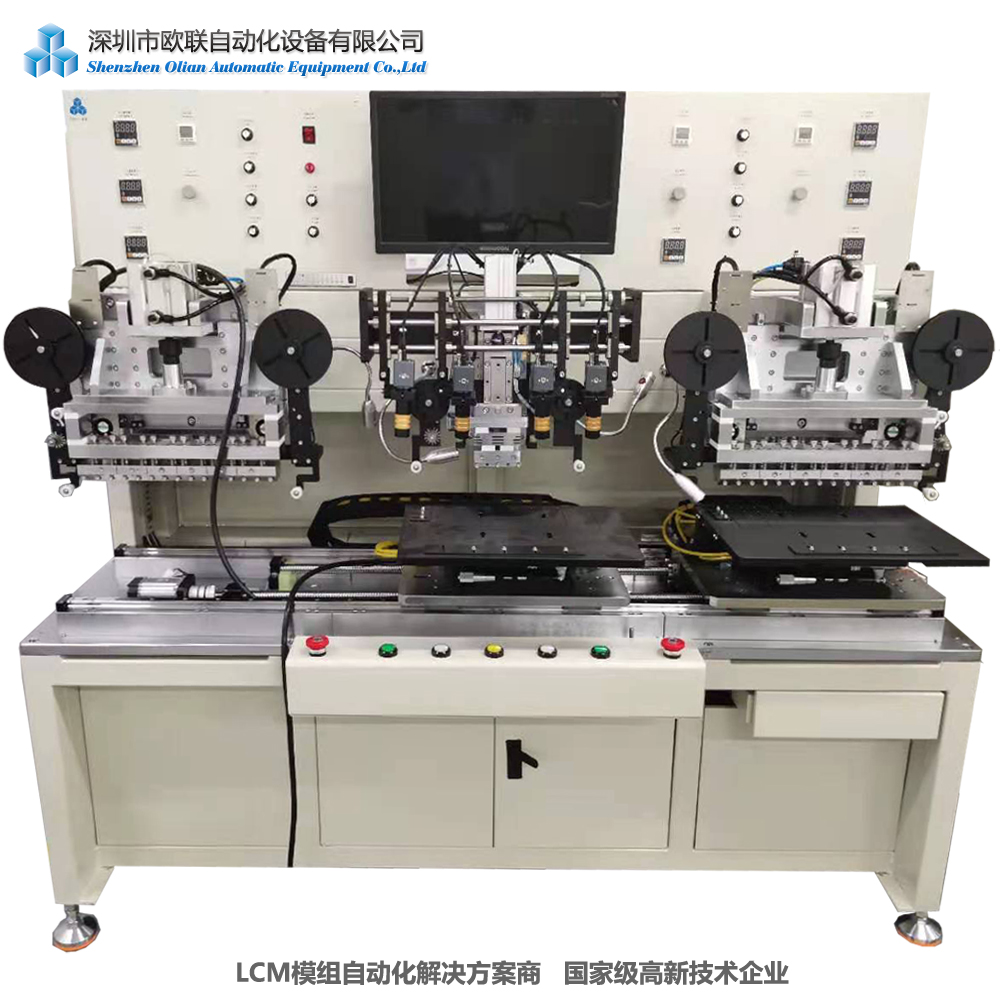

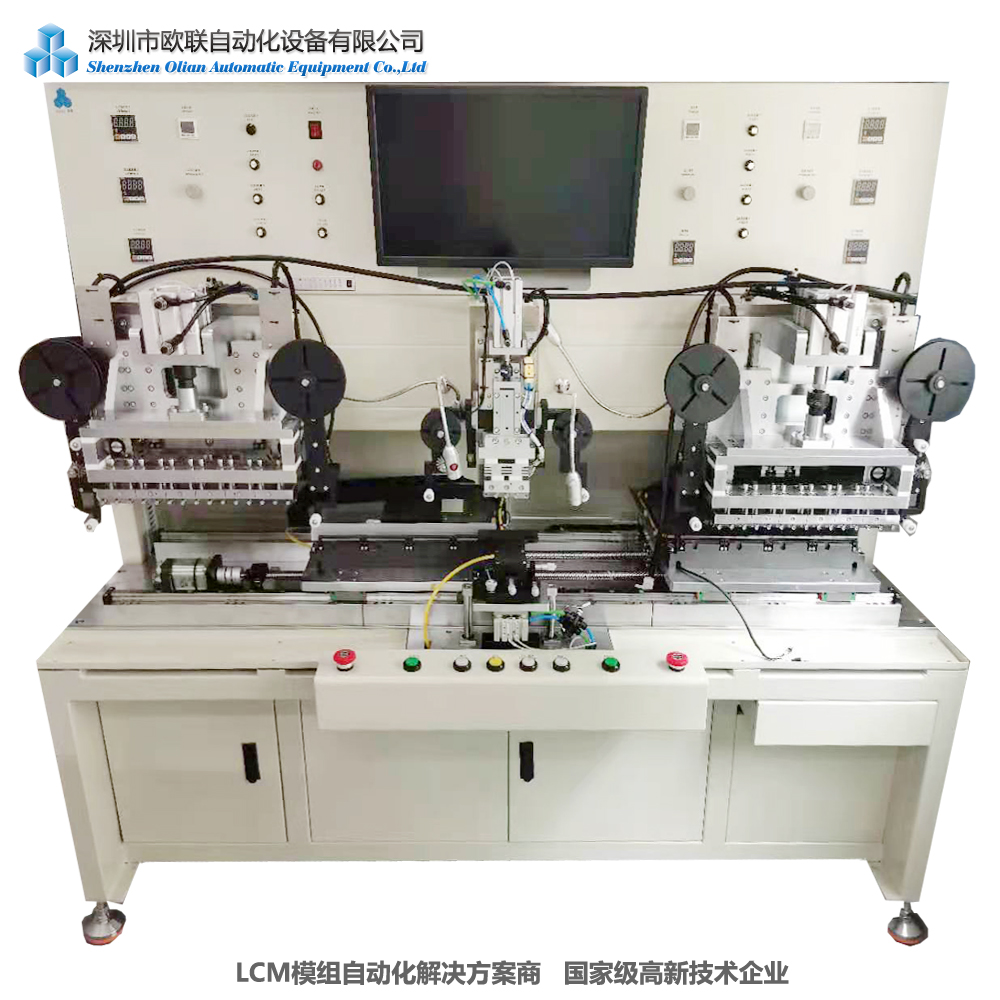

15.6Inch single side multi-segment FOB / FOG constant temperature bonding machine OL-F156

1.1 This equipment is a semi-automatic hot press bonding machine. It is a device for bonding the FPC to the Panel on which the conductive film (ACF) has been attached. It is done automatically by the device.

1.2 Suitable for bonding of FOG, FOB, OGS products.

Product qualification rate: ≥98%

1) Manually place the Panel on the Panel workbench

2) Press the vacuum button of the Panel workbench, and the Panel is adsorbed on the Panel workbench

3) Place the FPC to be hot-pressed on the FPC workbench, and initially position it with the Panel and vacuum adsorption.

4) The operator looks at the display on the MONITOR to perform alignment work.

5) The operator presses the start button with both hands, and the indenter presses down. Complete pre-compression The device moves to the next position and repeats 3) and 4) until all pre-compression positions are completed.

6) After the pre-compression is completed, the platform automatically moves to the current pressure position, and the current pressure head drops. After the current pressure time is up, the current pressure head rises and the hot pressing of a product ends. ,

7) Manually remove the hot-pressed Module and repeat 1)~7) to produce the next product.

9) The PCB and FPC operations are the same.

Pressing accuracy: PCB: X: ±10um Y: ±10um OLB:X: ±5um Y: ±5um

Shenzhen Olian is a Professional LCD/LED/OLED bonding Machine Manufacturer. We do the Research&Develop&Design&Make&Sell the best and latest IC/COG/COB/COF/COP/FPC/FOG/FOB/FOF/TAB/OLB/ACF/ Bonding Machine/bonder and tools for TV/Mobilephone/Laptop/Watch/Touch and other Screens.We also offer all the bonding machine parts and all the accessories.