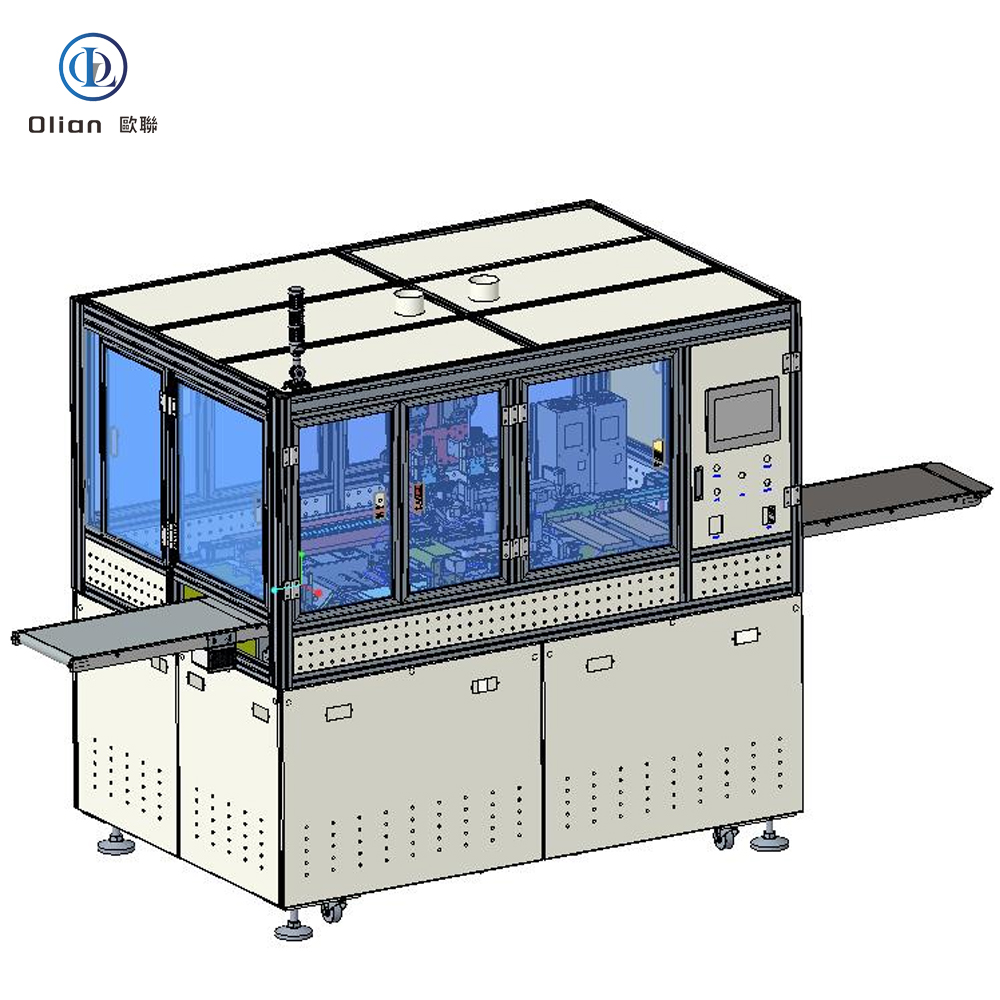

OL-TH800 Automatic Drag Welding Machine

In the realm of modern industrial manufacturing, particularly within the electronics and precision instrument sectors, welding processes play a pivotal role in product quality and production efficiency. The OL-TH800 Automatic Drag Welding Machine emerges as a cutting-edge solution, designed to deliver high-precision welding with remarkable automation and reliability.

I. Equipment Overview

The OL-TH800 Automatic Drag Welding Machine is engineered for high-precision welding tasks, catering to products ranging from 3 to 7 inches in size. It is extensively used in the production of smartphones, tablets, and wearable devices, where precise welding is crucial. The machine’s advanced features make it an ideal choice for manufacturers seeking to enhance production efficiency and product quality.

II. Equipment Structure and Working Process

Equipment Structure

The OL-TH800 comprises several sophisticated components that协同工作 to ensure precise and efficient welding operations:

- Frame: The backbone of the machine, constructed from sturdy materials to ensure stability and durability throughout the welding process.

- Infeed Conveyor: Responsible for transporting materials into the welding area smoothly and accurately.

- Loading Manipulator: Equipped with advanced motion control systems to handle materials with precision.

- CCD Correction System: Utilizes high-resolution cameras and sophisticated algorithms to correct material positioning, ensuring alignment accuracy within ±0.05mm.

- Flipping Mechanism: Enables precise flipping of materials to facilitate welding on different surfaces.

- Welding Platforms: Four sets of positioning platforms that work in conjunction with two welding heads to achieve efficient and accurate welding.

- Welding Head Unit: Features high-frequency temperature-controlled heating for optimal welding performance.

- AOI (Automated Optical Inspection) CCD Component: Detects welding defects such as insufficient solder and solder bridging.

- Solder Residue Collection System: Maintains a clean welding environment by collecting solder residues.

- Control Unit: Houses the machine’s control systems, including a PLC and a 10″ touchscreen interface for operation and monitoring.

Working Process

The OL-TH800 follows a highly automated sequence to complete welding tasks:

- Material Handling: The loading manipulator picks up materials from the infeed conveyor and places them onto the welding platform.

- Position Correction: The CCD correction system adjusts the material position to ensure precise alignment.

- Flipping and Welding: Materials are flipped as needed to access different welding surfaces. The welding heads perform precise welding operations based on predefined parameters.

- Defect Detection: The AOI system inspects the welded joints for common defects, ensuring high-quality output.

- Residue Management: Solder residues are collected and managed to maintain a clean production environment.

- Outfeed: Welded products are transported to the next process via the outfeed conveyor, completing the automated cycle.

III. Equipment Advantages

High Degree of Automation

The OL-TH800 automates the entire welding process, from material handling and flipping to position correction and welding. This minimizes human intervention, reduces labor costs, and enhances production efficiency. The machine can also be integrated with upstream devices for seamless production flow.

Strong Compatibility

Designed to accommodate products ranging from 3 to 7 inches, the OL-TH800 offers versatility across various production tasks. This flexibility allows manufacturers to adapt quickly to different product requirements and market demands.

High Yield Rate

With an automated exhaust system and contact-free production process, the OL-TH800 significantly improves product yield rates. The reduced human contact minimizes the risk of contamination and damage.

Stable Performance

Adopting advanced domestic design concepts and high-quality components from Japan, South Korea, and Taiwan, the OL-TH800 ensures stable operation and a long service life. Strict quality control during component processing further guarantees reliability.

AOI Functionality

The integrated AOI system detects welding defects such as insufficient solder and solder bridging, ensuring high-quality output. This feature enhances overall product reliability and reduces post-production rework.

IV. Basic Specifications and Parameters

Product Specifications

- Product Size: Length 60-170 mm, Width 40-95 mm, Thickness 0.5-5.0 mm

- Positioning Accuracy: ±0.05 mm

- Working Cycle: 3.5 seconds per piece

- Defect Rate: ≤2% (excluding defects caused by incoming material issues)

- Model Change Time: 50 minutes for new models, 30 minutes for existing models

- Equipment Dimensions: Approximately L1960×W1300×H1850 mm

- Equipment Weight: Approximately 1300 kg

- Power Supply: 1Phase AC220V/50Hz/60A, Power 8KW

- Welding Parameters: Rated voltage 220V, Rated power 200W, Temperature range Room temp – 599°C, High-frequency temperature-controlled heating

- Compressed Air: Working pressure ≥0.4-0.6Mpa, Air consumption ≈200L/min

- Vacuum: Vacuum degree ≤-90Kpa, Vacuum flow ≈100L/min

- Operating Environment: Clean, dust-free cleanroom

FPC Specifications

- FOG FPC: Length <150 mm, Width <80 mm

- BLU FPC: Length <20 mm

- Solder Joint Dimensions: Pin width >0.4mm, Pin spacing >0.4mm, Number of Pins ≤4, Pin length <4mm

- Design Requirements: Equal spacing between FPC gold fingers on FOG and BLU, specific hole requirements for BLU FPC, and no deformation or bending.

V. Main Component Brands

The OL-TH800 incorporates high-quality components from reputable brands, including SMC/CKD/AirTAC for pneumatic components, Hui川/Xinjie for servo motors, Hui川 for PLC, TBI for ball screws, HIWIN/12K for guides, Hikvision/Dahua/Dehong for CCD and lenses, Weilong for touch screens, Zhengtai for relays, Mingwei for power supplies, and Panasonic/Tianguang for fiber optic sensors. These components ensure the equipment’s performance and reliability.

VI. Documentation and After-sales Service

The OL-TH800 comes with comprehensive documentation and after-sales support:

- Operation Manual: One copy provided, detailing equipment operation procedures and safety precautions.

- Training Content: Covers installation, operation, adjustment, maintenance, troubleshooting, and other precautions.

- After-sales Service: Includes one year of free service (excluding damages caused by human error) and lifelong technical support.

In summary, the OL-TH800 Automatic Drag Welding Machine stands out as a top-tier solution for modern industrial welding needs. Its high degree of automation, strong compatibility, stable performance, and comprehensive after-sales service make it an invaluable asset for manufacturers aiming to boost production efficiency and product quality.