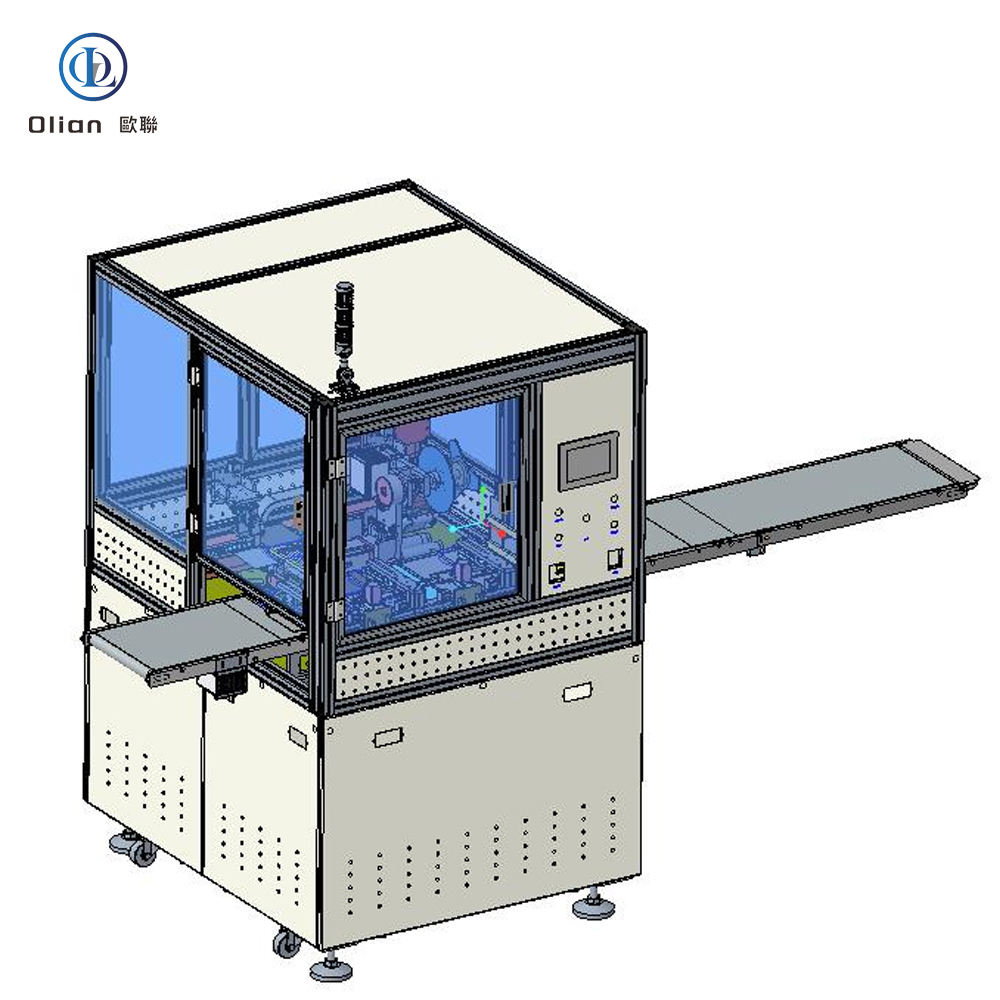

OL-TF800 Automatic Tape Attaching Machine

In modern industrial production, tape attaching processes are crucial for the manufacturing of electronic devices and precision instruments.

The OL-TF800 Automatic Tape Attaching Machine, as an advanced automated device.

offers efficient and precise tape attaching solutions with its outstanding performance and versatility.

I. Equipment Overview

The OL-TF800 Automatic Tape Attaching Machine is designed specifically for high-precision tape attaching tasks.

It can accommodate production requirements for products ranging from 0.96 to 8 inches.

making it widely applicable in the manufacturing of smartphones, tablets, wearable devices, and other electronics. It is especially suitable for production environments with high demands on attaching accuracy and efficiency.

II. Equipment Structure and Working Process

Equipment Structure

The OL-TF800 consists of several key components that work together to ensure efficient and precise operation:

- Frame: The main supporting structure of the equipment, made of sturdy welded square tubes and powder-coated for stability and durability.

- The upper part of the frame is constructed with aluminum profiles and acrylic panels.

- ensuring aesthetics and visibility for operators to monitor the operation status.

- Infeed Belt: Equipped with a speed-adjustable motor, synchronous belt, and anti-static black ring belt to ensure smooth and accurate material conveyance to the processing area.

- Loading and Unloading Manipulator: Achieves Z-axis vertical movement via cylinders and guides. and X-axis horizontal movement through servo motors and modules, enabling precise material handling.

- Attaching Platform: Driven by servo motors and modules in the Y-axis direction for accurate positioning. and equipped with cylinders and guides for X and Y-axis corrections to ensure precise tape application.

- Attaching Manipulator: Capable of multi-axis movements with X and Z-axis controlled by servo motors and modules for precise positioning, and actions like suction head lifting, tape feeding, and attaching performed by cylinders and guides.

- Tape Supply Unit: Uses a step motor for feeding, with a label sensor to detect tape position, a permanent magnet brake to control tension. and a photoelectric sensor to monitor material shortage.

- Outfeed Flipping (Optional): Achieves flipping via a rotary cylinder and Z-axis vertical movement through cylinders and guides, ensuring smooth product output.

- Outfeed Belt: Similar to the infeed belt, it transports attached products to the next process with a speed-adjustable motor. synchronous belt, and anti-static black ring belt.

- Control Unit: Features a 7″ touch screen with a Chinese interface, manual operation functions, and a three-color indicator light for monitoring operation status. ensuring stable and reliable equipment operation through PLC control.

Working Process

The OL-TF800 Automatic Tape Attaching Machine has a highly automated working process:

- Product Handling: The loading and unloading manipulator picks up products from the infeed belt and places them accurately on the attaching platform.

- Position Correction: The attaching platform adjusts the product position in the X and Y directions to ensure precise alignment during the attaching process.

- Tape Separation: The tape supply unit separates the tape from the roll and ensures correct position and tension through detection devices.

- Tape Attaching: The attaching manipulator applies the separated tape to the product according to the preset program, completing the attaching action.

- Outfeed Flipping (Optional): For products requiring flipping, the outfeed flipping device turns them over for subsequent processing or inspection.

- Outfeed Conveying: The attached products are transported to the next process via the outfeed belt, achieving efficient and stable automated production without manual intervention.

III. Equipment Advantages

High Degree of Automation

The OL-TF800 achieves full automation in product handling, position correction, tape separation, tape attaching, and outfeed flipping. This not only improves production efficiency and reduces human errors but also lowers labor costs. The equipment can be seamlessly integrated with upstream welding devices in the production line, forming a continuous and stable production process to enhance overall production efficiency and quality control.

Strong Compatibility

The equipment can accommodate products ranging from 0.96 to 8 inches, making it suitable for various production tasks, from small electronic components to larger products like tablets. This versatility allows the equipment to be used in diverse production environments, enabling flexible production and quick response to market changes and customer demands.

Stable and Reliable Performance

Adopting the most advanced domestic design concepts and high-quality components and parts from Japan, South Korea, and Taiwan, the OL-TF800 ensures overall stability and a long service life. The strict testing of key components guarantees reliable operation during extended, high-intensity use, reducing downtime and ensuring continuous production and product quality.

IV. Basic Specifications and Parameters

Equipment Description

The OL-TF800 has the following key specifications:

- Product Size: Length 28-180 mm, Width 14-100 mm, Thickness 0.5-5.0 mm

- FPC Size: Length <150 mm, Width <50 mm

- Anti-static Tape Roll Size: Width <100 mm, Outer Diameter <200 mm, Inner Diameter 76 mm

- Working Cycle: 3.5 seconds per piece

- Attaching Accuracy: ±0.5 mm

- Equipment Yield: ≥99%

- Model Change Time: 30 minutes for new models, 15 minutes for old models

- Equipment Dimensions: Approximately L1100×W1300×H1850 mm (excluding conveyor size)

- Equipment Weight: Approximately 850 kg

- Power Supply: 1Phase AC220V/50Hz/60A, Power 2.5KW, with a 2-meter-long power cord

- Compressed Air: Working Pressure ≥0.5-0.7Mpa, Air Consumption ≈120L/min, Air Hose Diameter 10mm

- Vacuum: Equipped with a self-contained vacuum pump

- Operating Environment: Clean, dust-free cleanroom

- Safety Protection: Interlocked safety design with buzzer alarm for errors or operator alerts

Machine Construction

The equipment is constructed with:

- One set each of frame, infeed belt, loading and unloading manipulator, attaching platform, attaching manipulator, tape supply unit, outfeed belt, and control unit

- One optional set of outfeed flipping device

Unit Specifications

- Frame: Covers the entire assembly, with a welded and powder-coated lower section, an aluminum profile and acrylic panel upper section, and a fluorescent light on top.

- Infeed Belt: Powered by a speed-adjustable motor and synchronous belt, with an anti-static black ring belt.

- Loading and Unloading Manipulator: Z-axis movement via cylinders and guides, X-axis via servo motors and modules.

- Attaching Platform: Y-axis movement via servo motors and modules, with cylinders and guides for X and Y-axis corrections.

- Attaching Manipulator: X and Z-axis movements via servo motors and modules, with cylinders and guides for suction head lifting, tape feeding, and attaching actions.

- Tape Supply Unit: Feeding via step motor, with label sensor for position detection, permanent magnet brake for tension control, and photoelectric sensor for material shortage detection.

- Outfeed Flipping: Flipping via rotary cylinder, Z-axis movement via cylinders and guides.

- Outfeed Belt: Similar to infeed belt, transports attached products to next process.

- Control Unit: Features a 7″ touch screen with Chinese interface, manual operation functions, and three-color indicator light, using PLC control for stable operation.

V. Main Component Brands

The equipment uses high-quality components from reputable brands, including SMC/CKD/AirTAC for pneumatic components, Xinjie/Hui川for servo motors, Panasonic/Hui川for PLC, TBI for ball screws, HIWIN/12K for guides, Weilong for touch screens, Zhengtai for relays, Mingwei for power supplies, Zhengtai for circuit breakers, and Panasonic/Tianguang for fiber optic sensors. These components ensure the equipment’s performance and reliability.

VI. Documentation and After-sales Service

The equipment comes with a comprehensive set of documentation and after-sales services:

- Operation Manual: One copy provided, detailing equipment operation procedures and safety precautions.

- Training Content: Covers installation, operation, adjustment, maintenance, troubleshooting, and other precautions.

- After-sales Service: Includes one year of free service (excluding damages caused by human error) and lifelong technical support.

In summary, the OL-TF800 Automatic Tape Attaching Machine is an ideal choice for modern industrial production with its high degree of automation, strong compatibility, stable performance, and comprehensive after-sales service, helping manufacturers improve production efficiency and product quality.