Advanced Flexible Display Bonding Dispensing Production Solution

In the rapidly evolving landscape of display technology, the production of advanced flexible OLED displays demands a highly sophisticated and versatile bonding and dispensing solution. Our Advanced Flexible Display Bonding Dispensing Production Solution is designed to meet these demands, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Advanced Flexible Display Bonding Dispensing Production Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple bonding technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

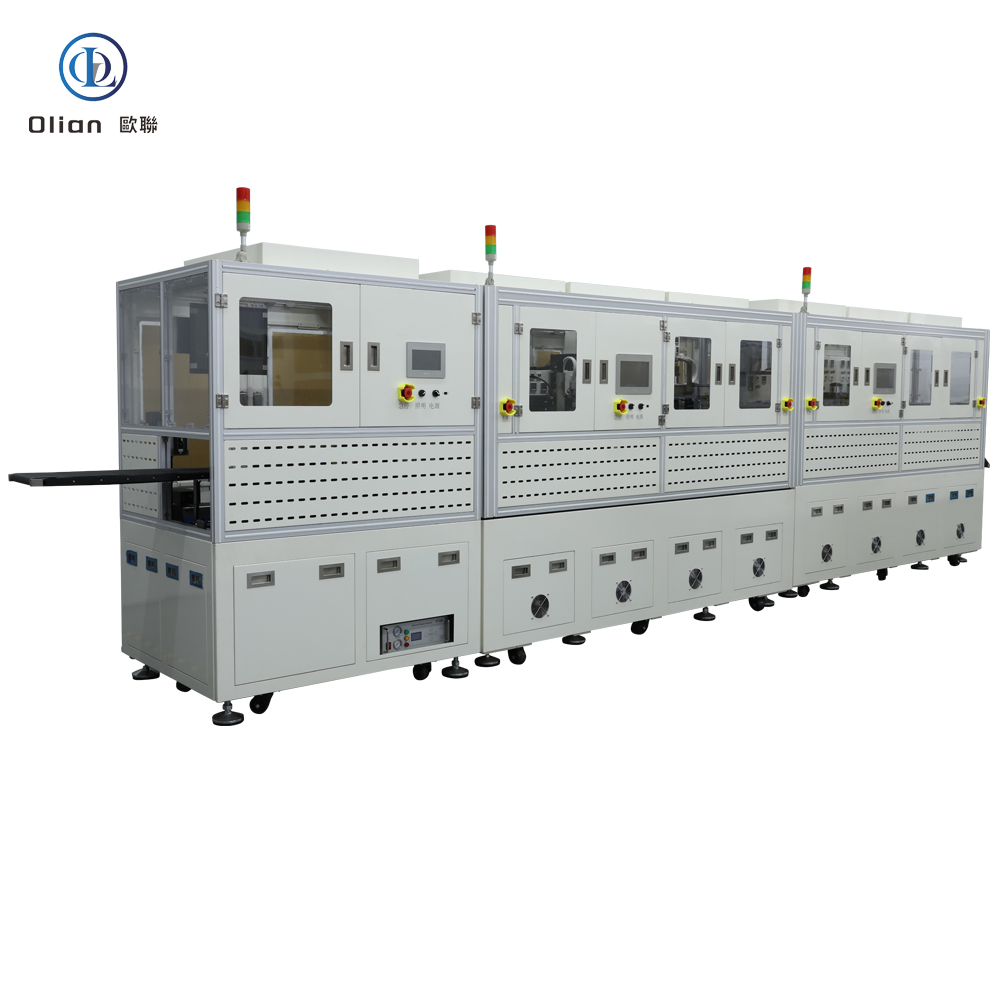

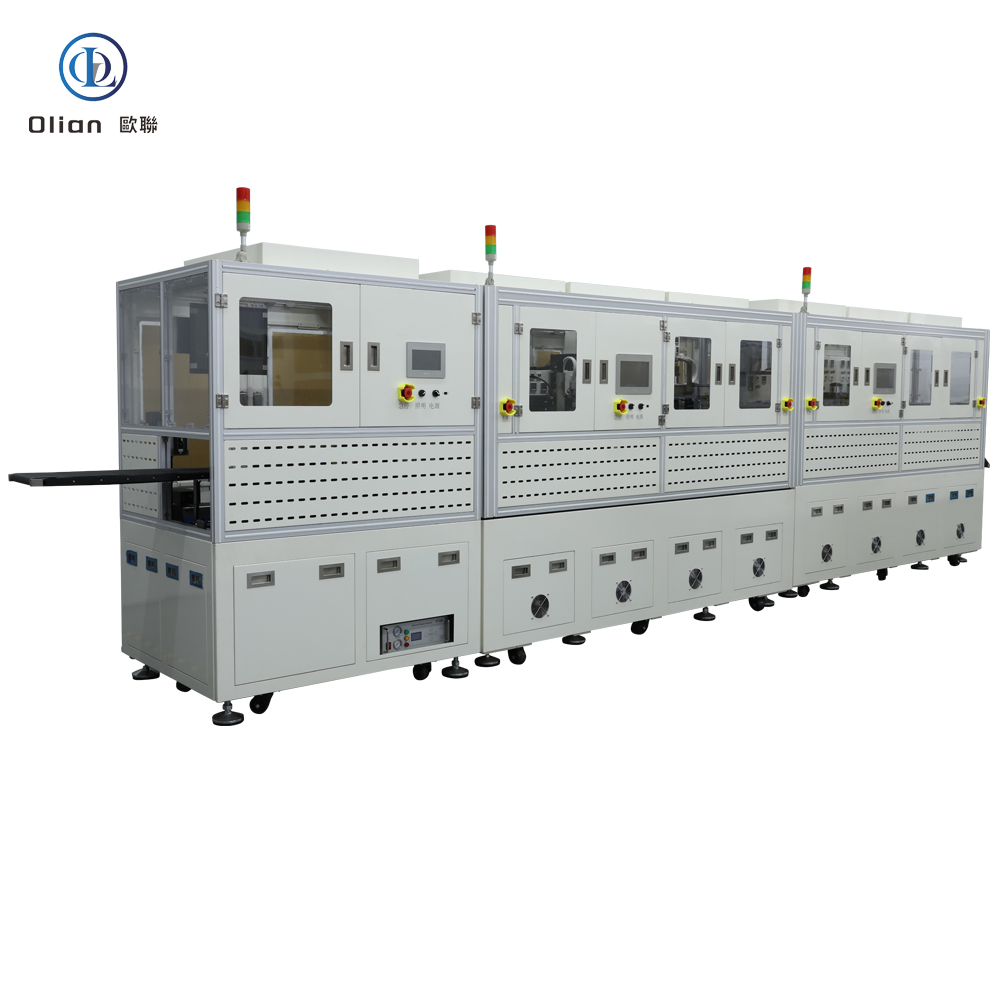

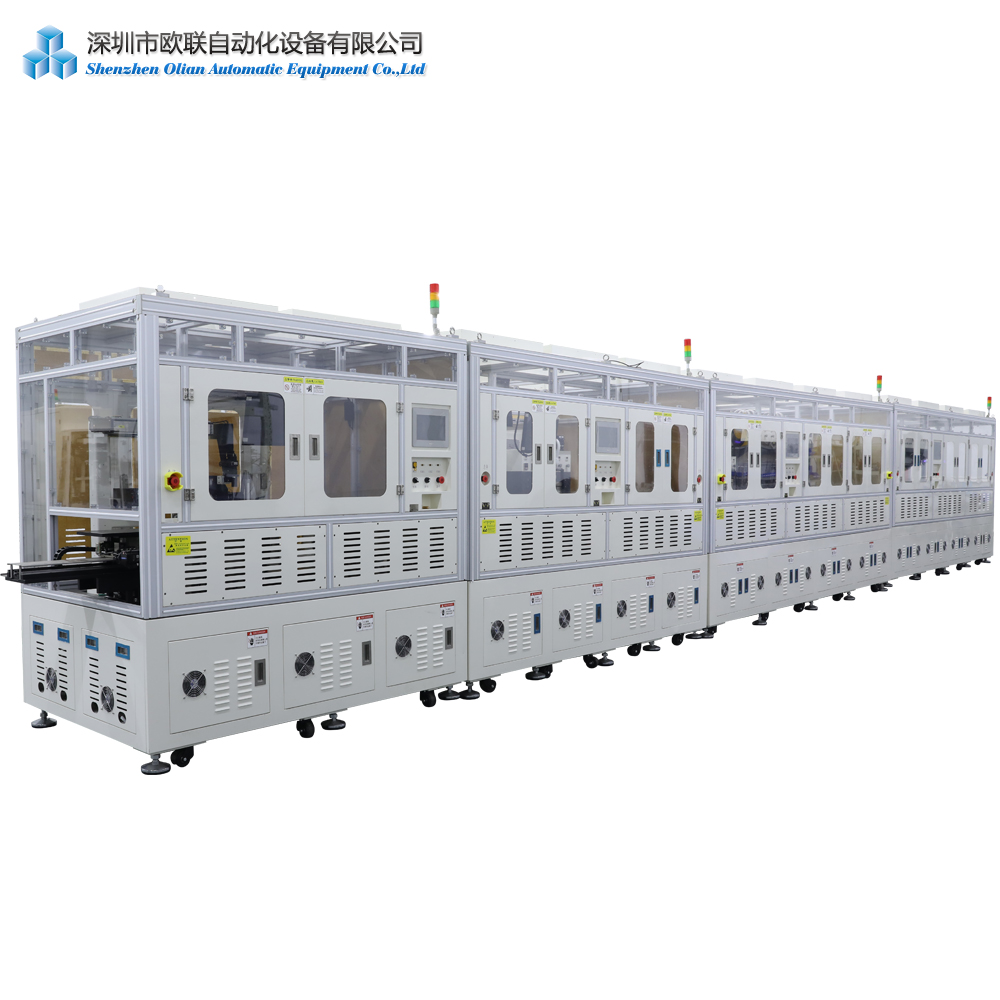

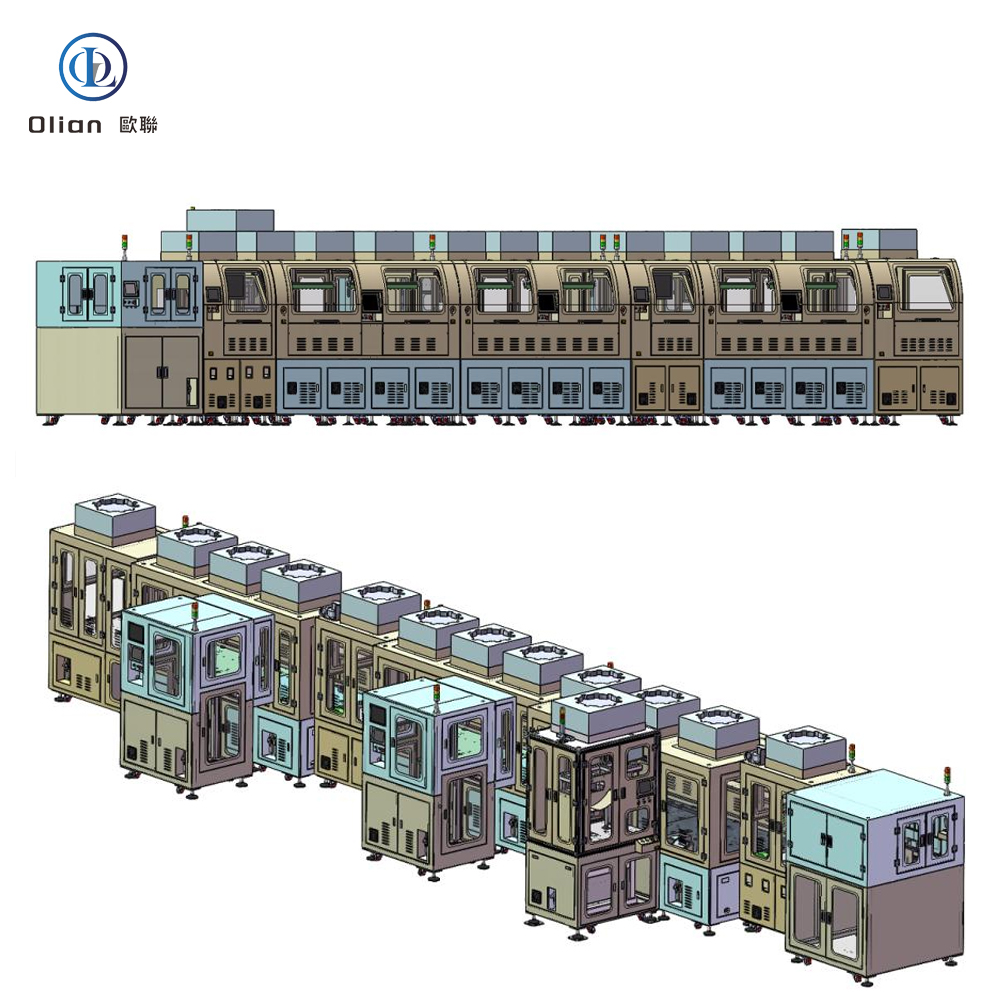

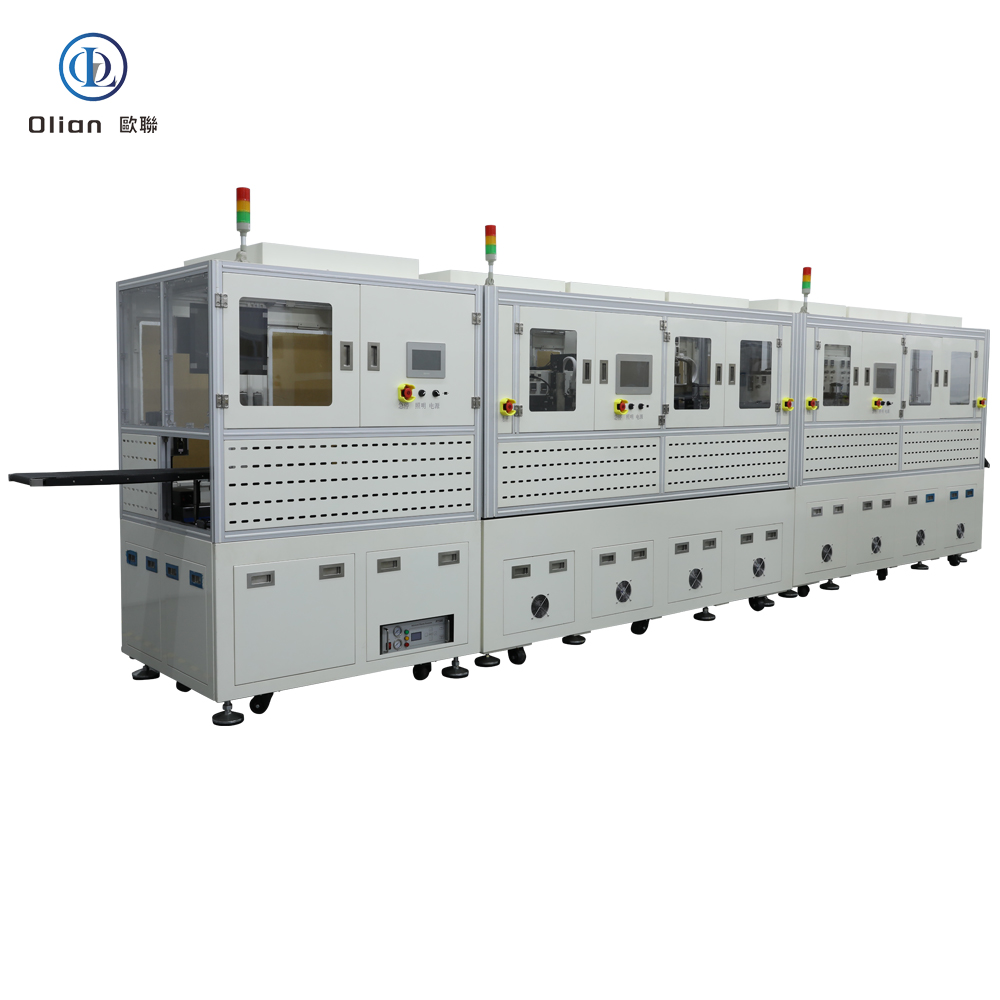

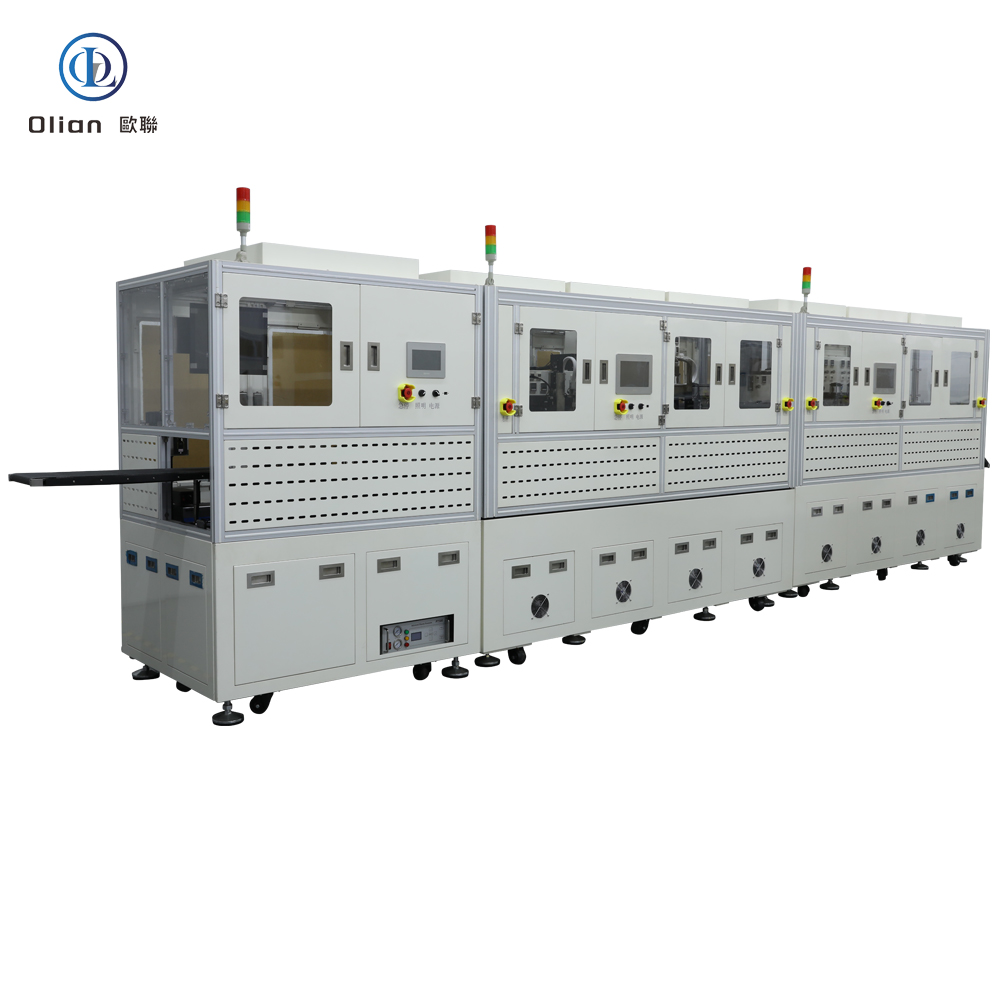

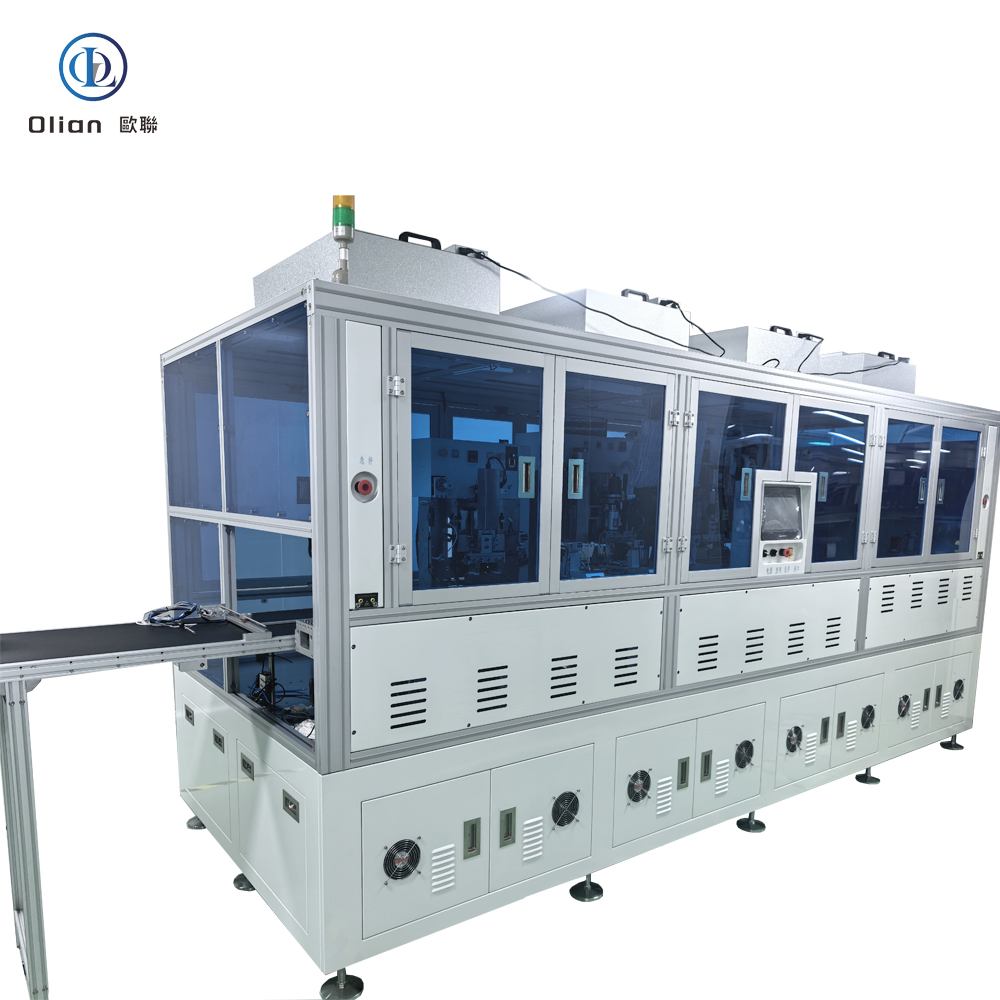

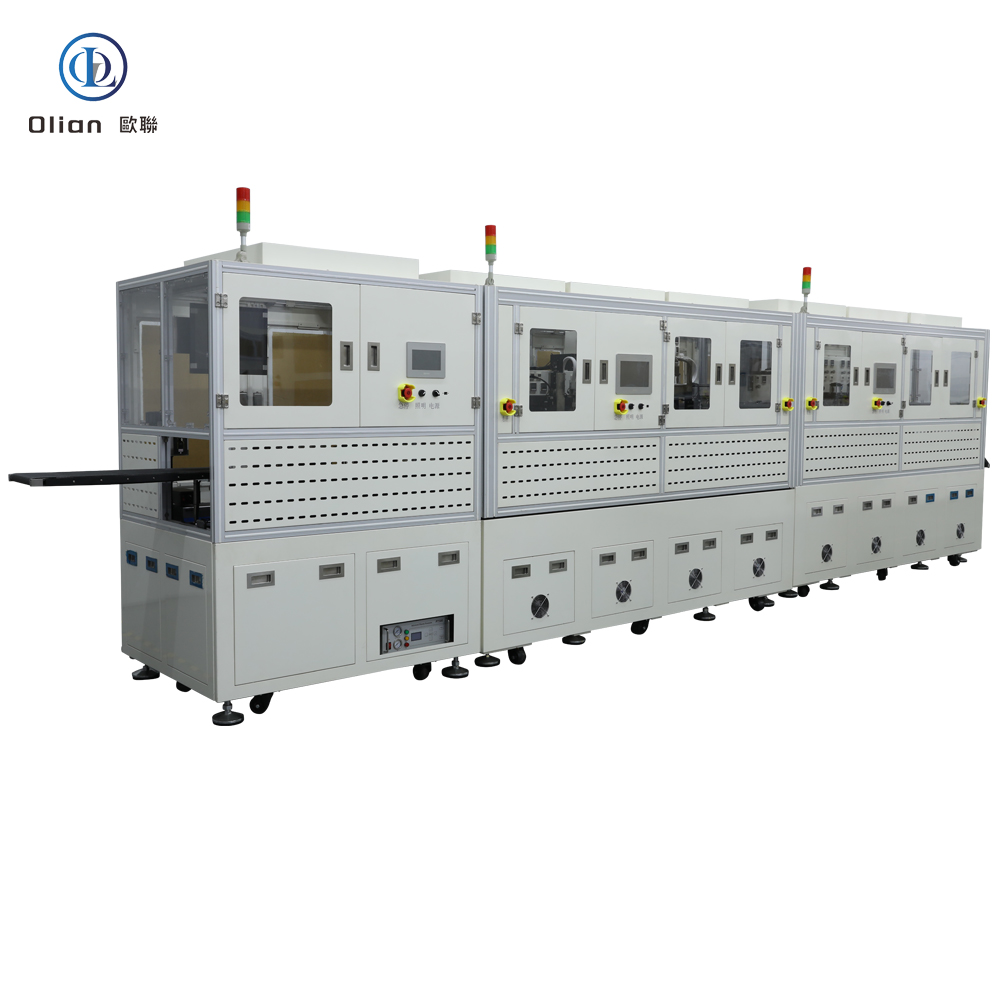

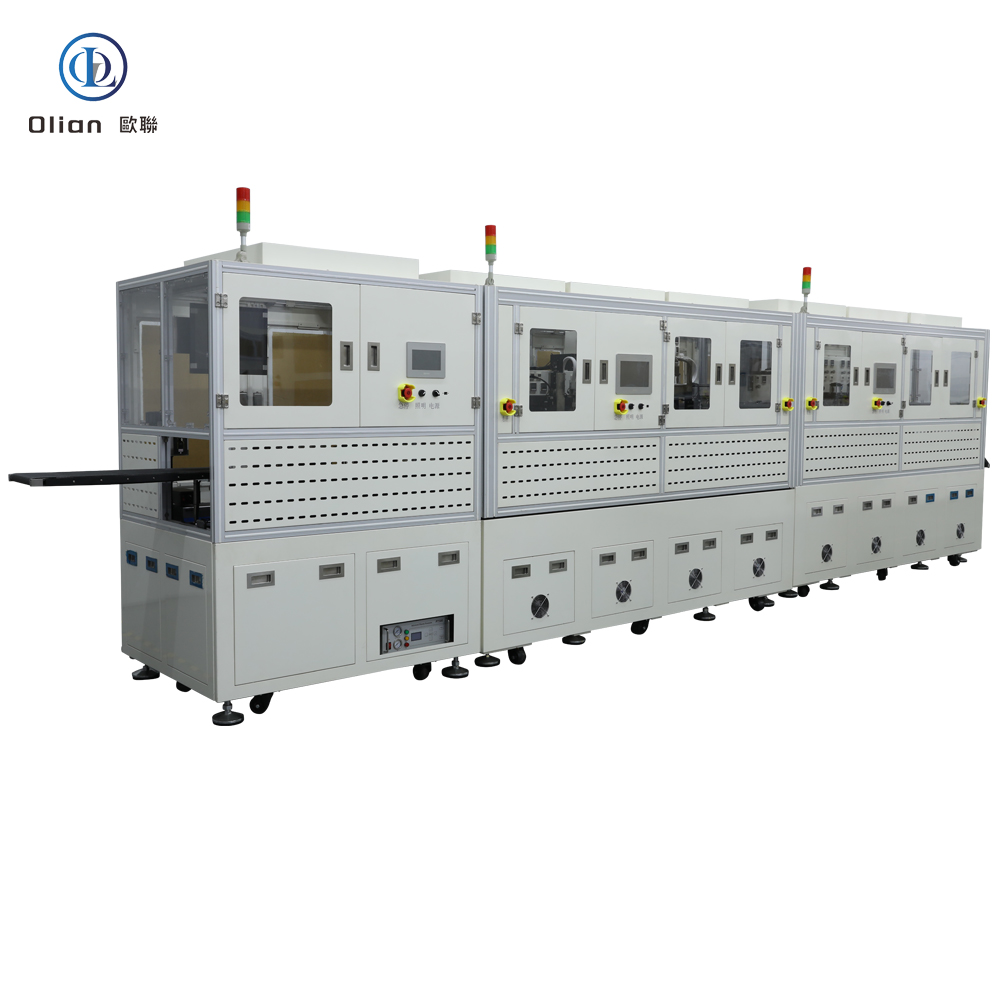

Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution

In the dynamic landscape of display technology, the production of mid-size displays for vehicles and notebooks requires a comprehensive and highly automated solution. Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is designed to meet the demands of both automotive and notebook display modules, offering a versatile and integrated approach to ensure high efficiency, precision, and adaptability.

Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is ideal for a wide range of smart display products, including:

Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

By integrating these advanced processes and technologies, our solution ensures high-quality, reliable, and efficient production of mid-size displays for a variety of applications.

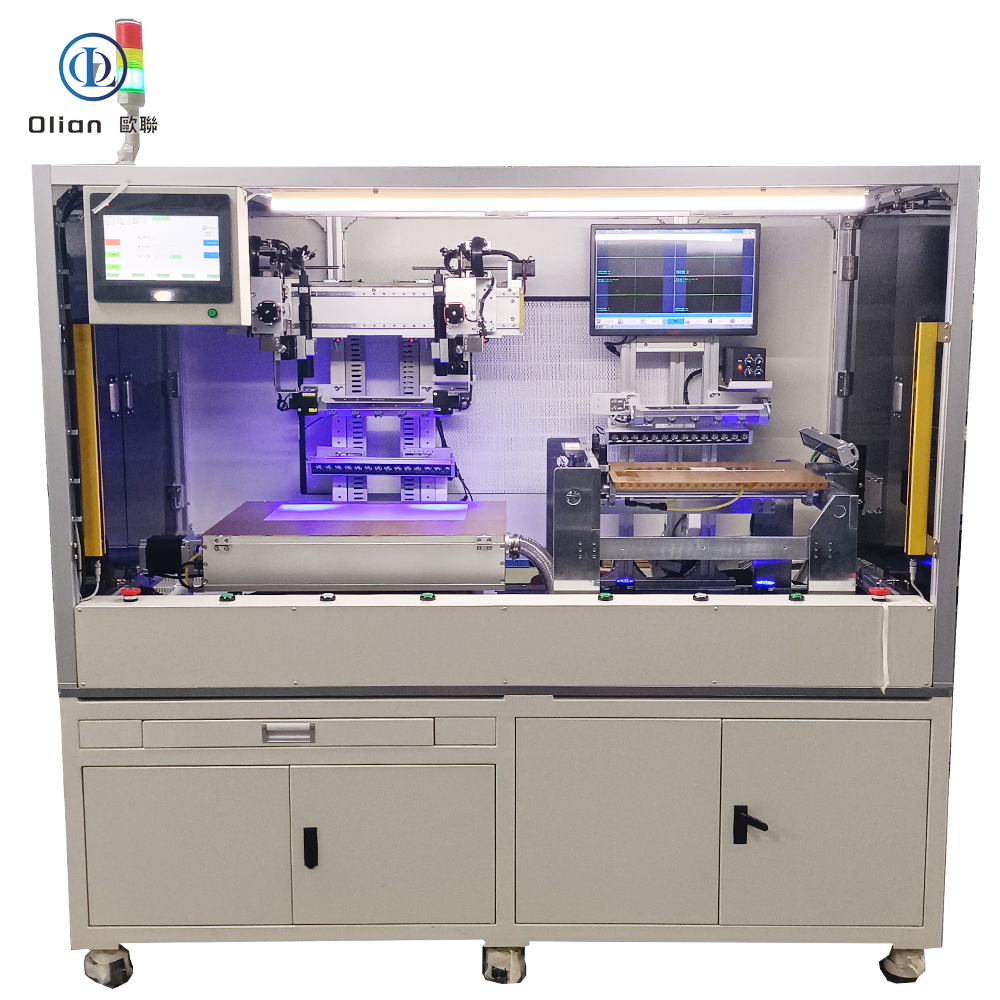

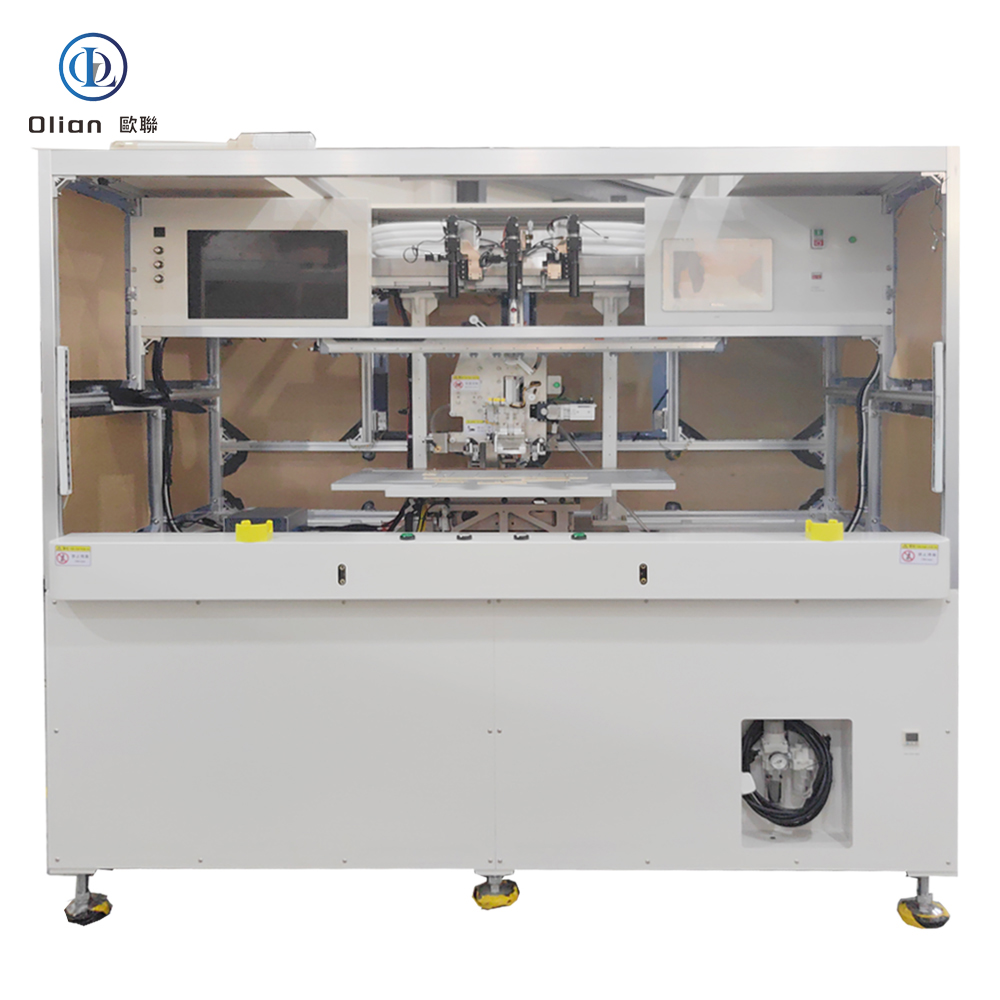

Electronic Paper Production Whole Line Solution

In the evolving market of display technology, the production of electronic paper (e-paper) for applications such as electronic labels and e-books requires a specialized and automated production line. Our Electronic Paper Production Whole Line Solution is designed to meet the demands of producing small to medium-sized e-paper displays, ranging from 0.96″ to 10.1″. This solution offers a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Electronic Paper Production Whole Line Solution is ideal for a wide range of smart display products, including:

Our Electronic Paper Production Whole Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

Backlight Assembly Equipment Process Solution for Mid-Size LCM Assembly

In the competitive landscape of display manufacturing, the production of mid-size Liquid Crystal Modules (LCMs) for applications such as tablets, notebooks, and automotive displays requires a specialized and automated backlight assembly solution. Our Backlight Assembly Equipment Process Solution is designed to meet the demands of producing LCMs ranging from 5” to 17.3”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Backlight Assembly Equipment Process Solution is ideal for a wide range of display products, including:

Our Backlight Assembly Equipment Process Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

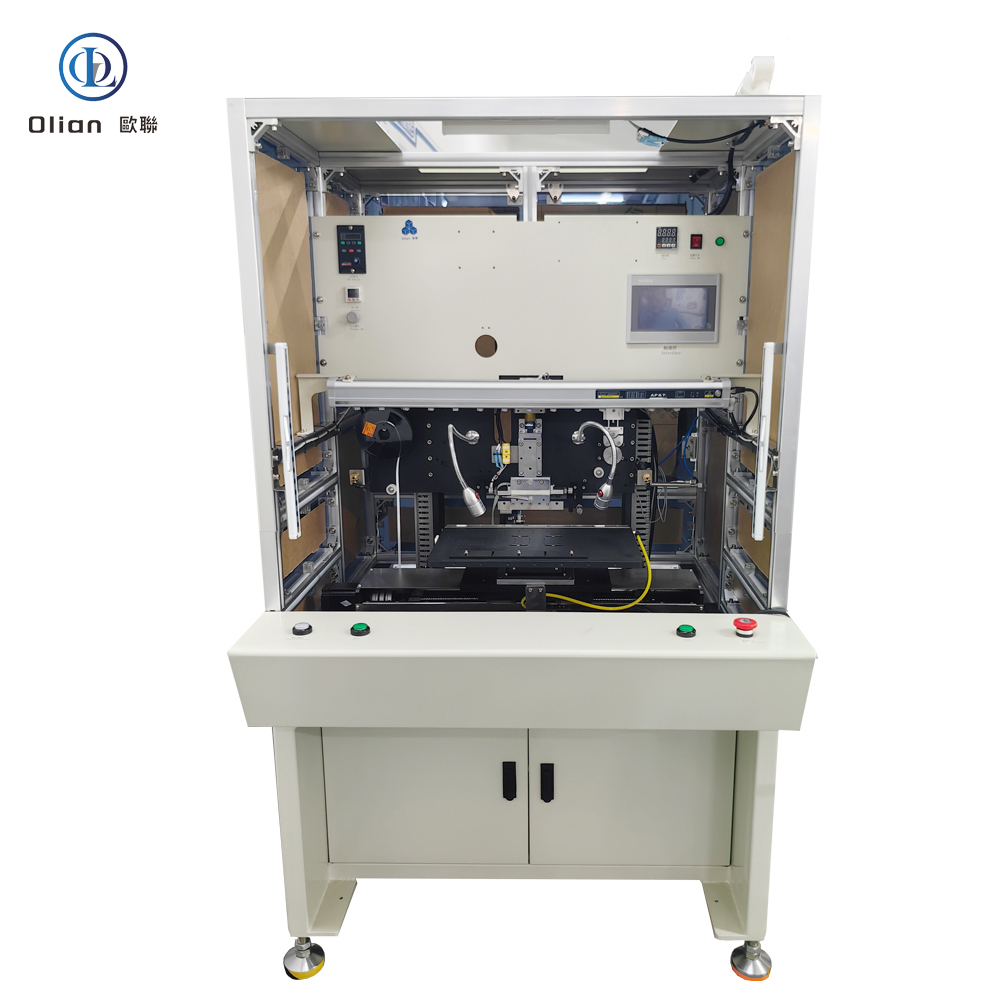

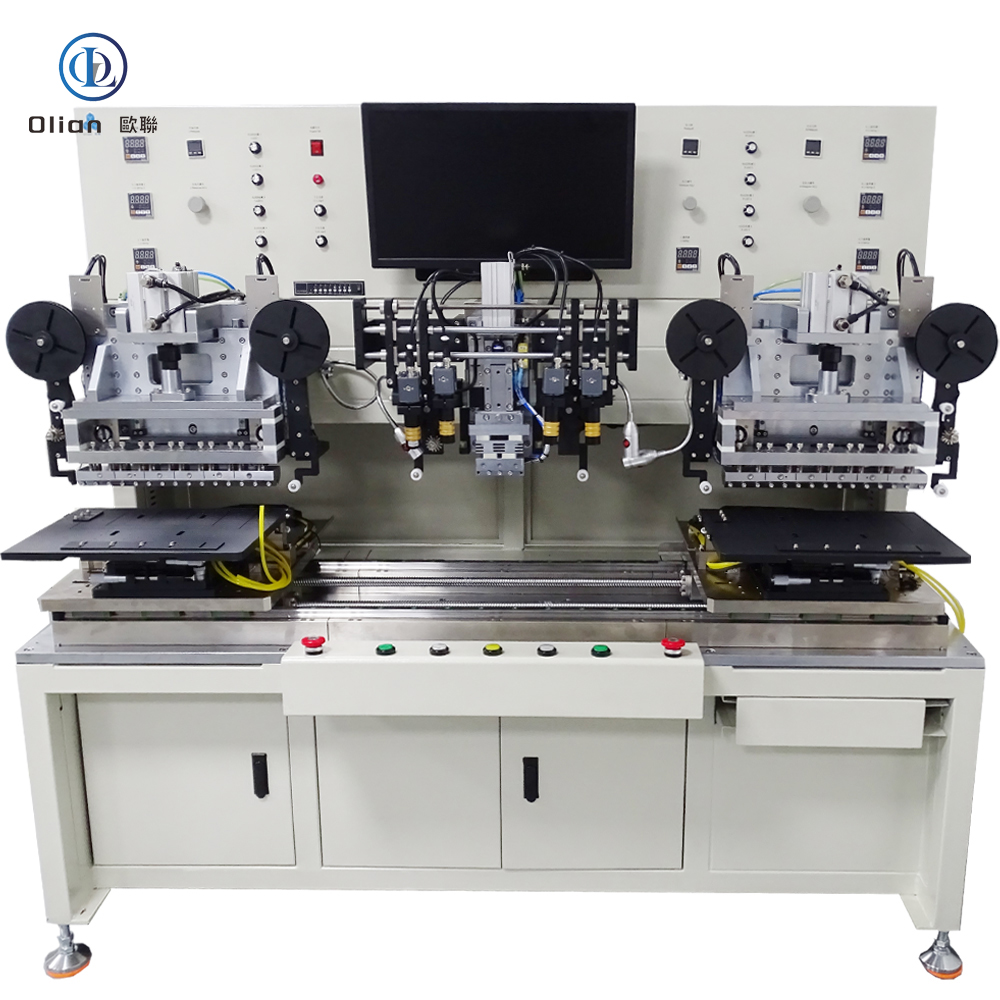

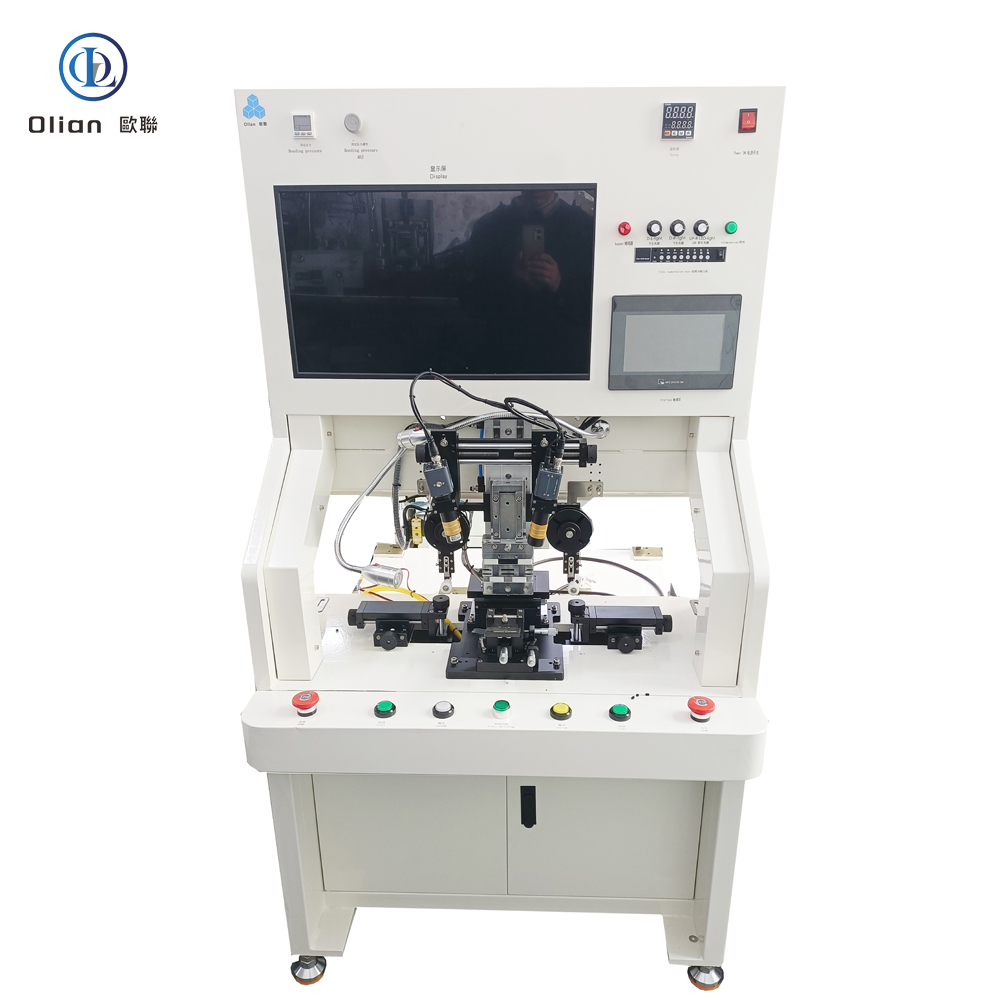

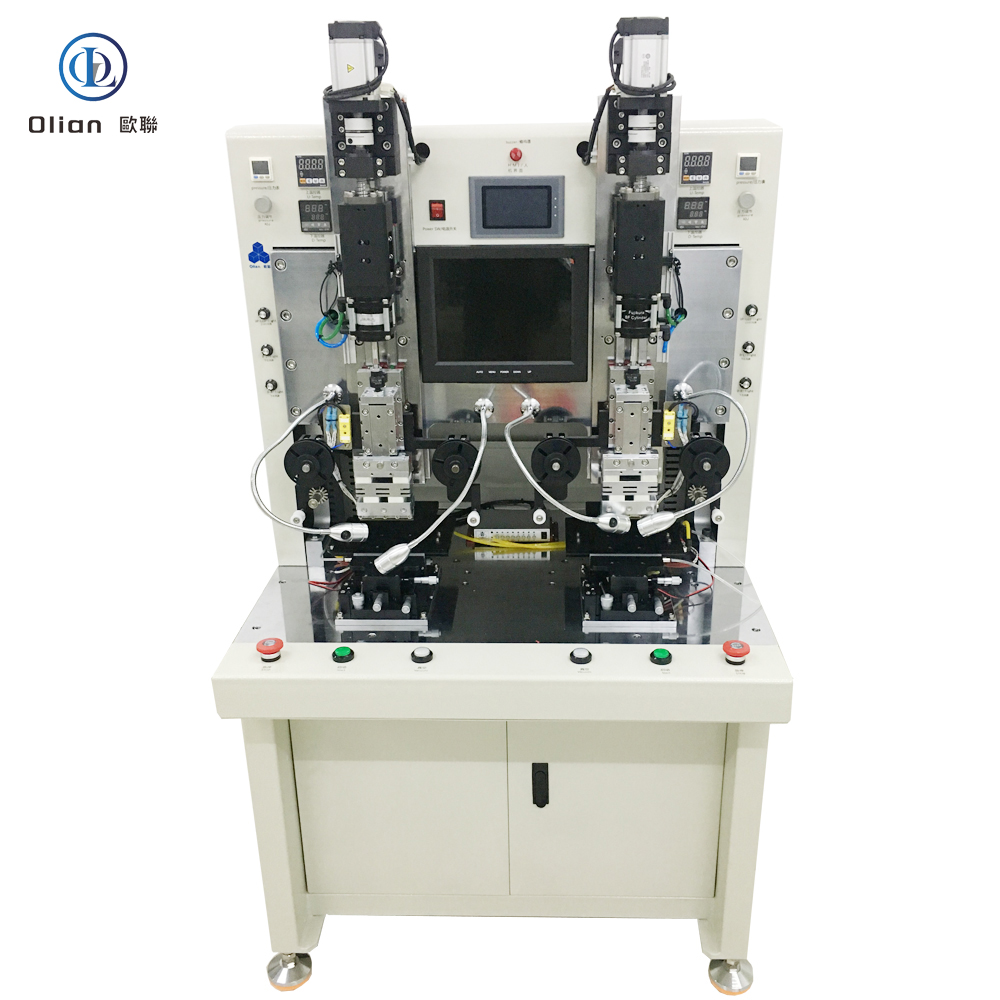

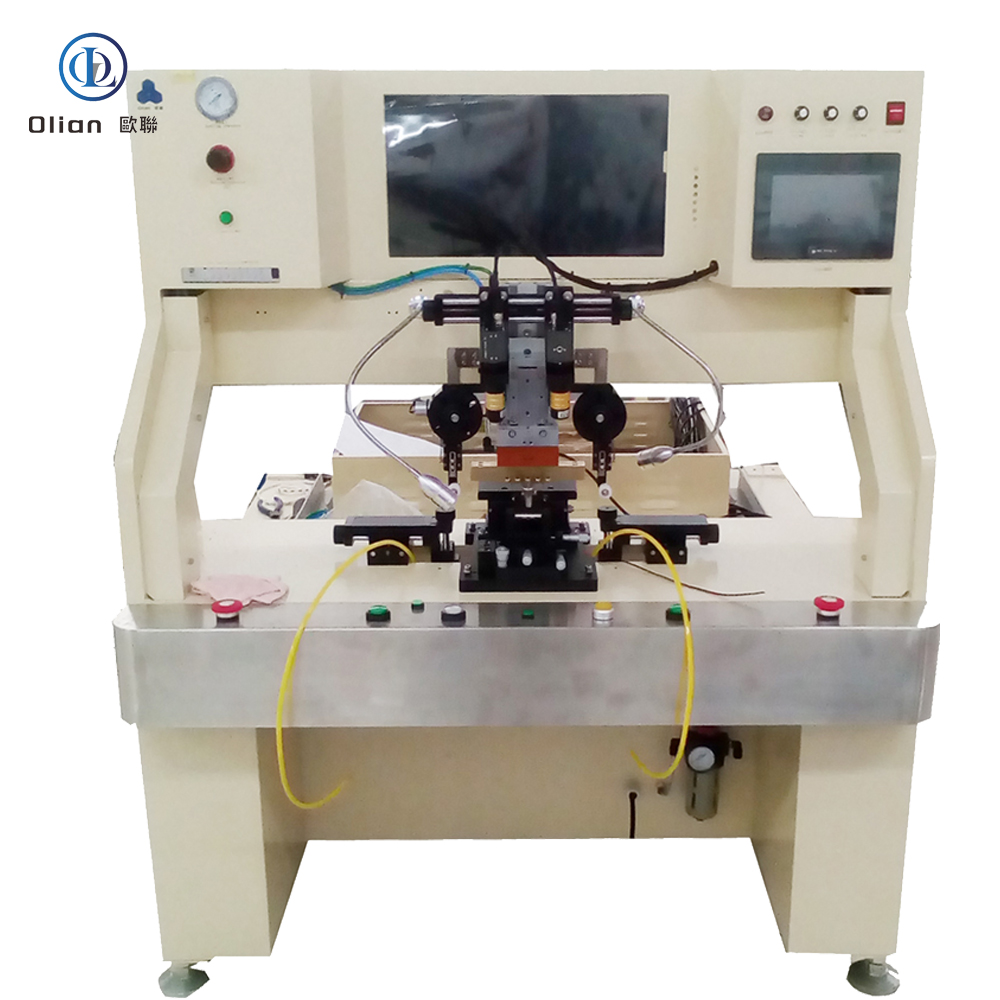

1-7 Inch Semi Automatic Bonding Machines

In the dynamic field of display manufacturing, the production of small to medium-sized Liquid Crystal Displays (LCDs) for applications such as tablets, notebooks, and automotive displays requires a specialized and semi-automated bonding solution. Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing LCDs ranging from 1” to 7”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

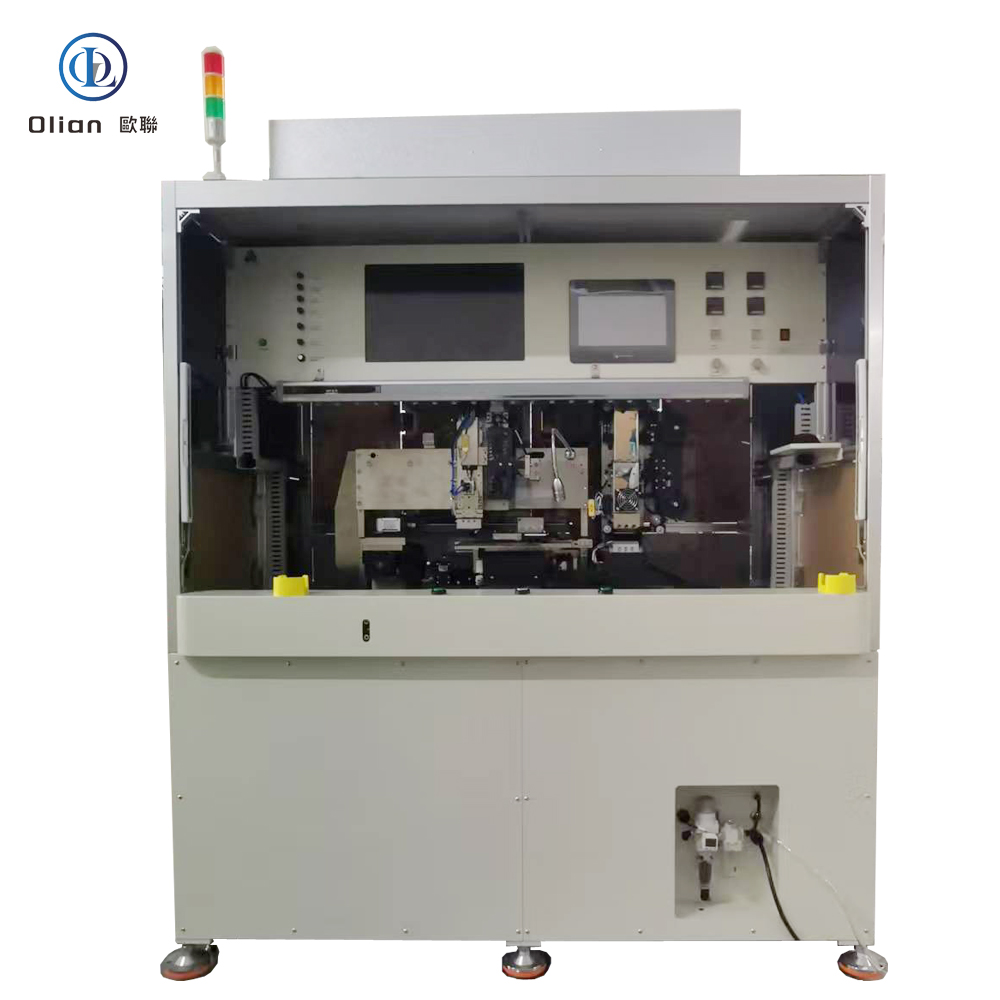

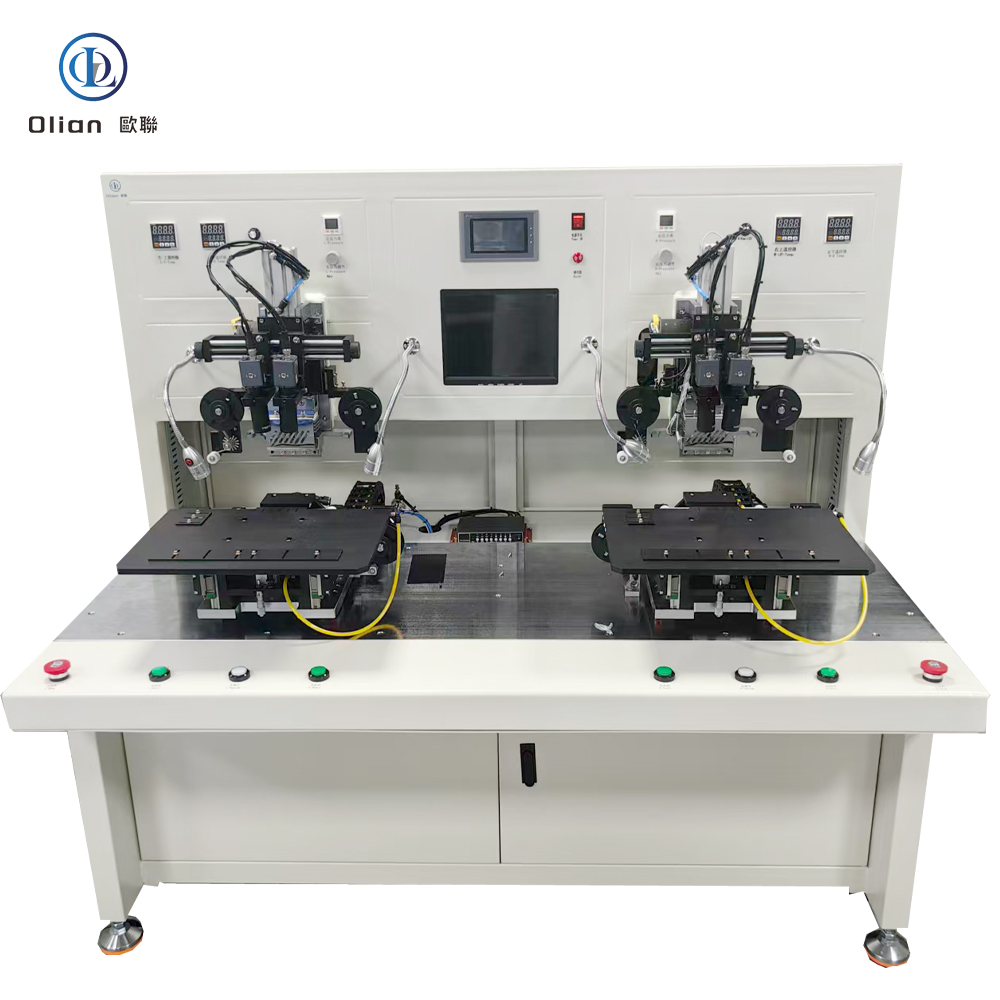

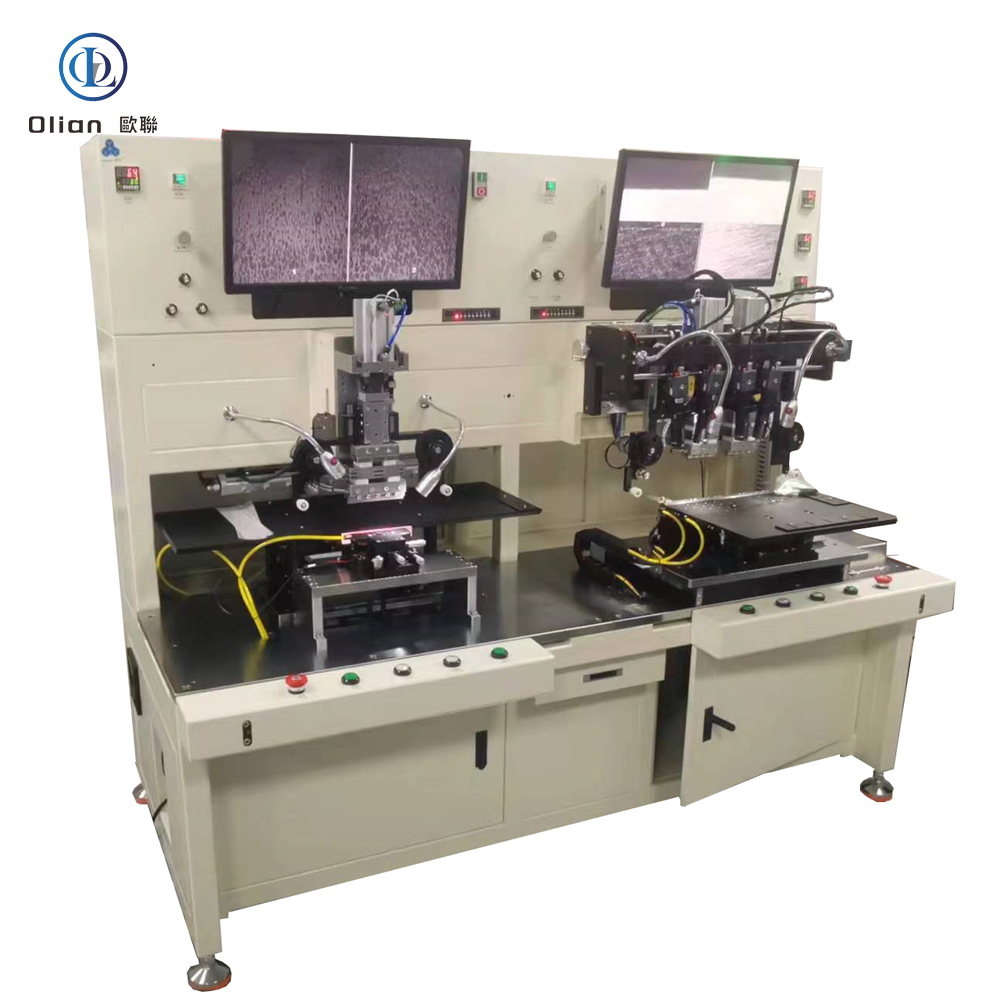

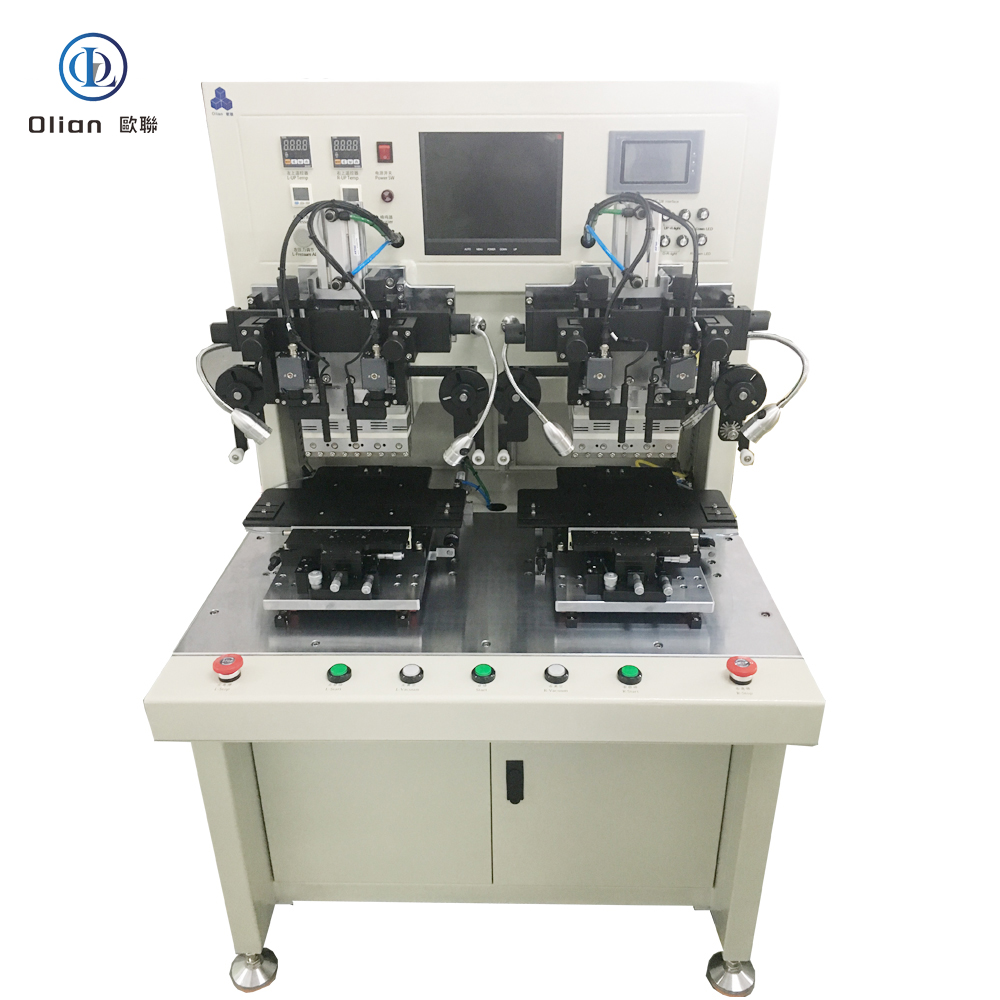

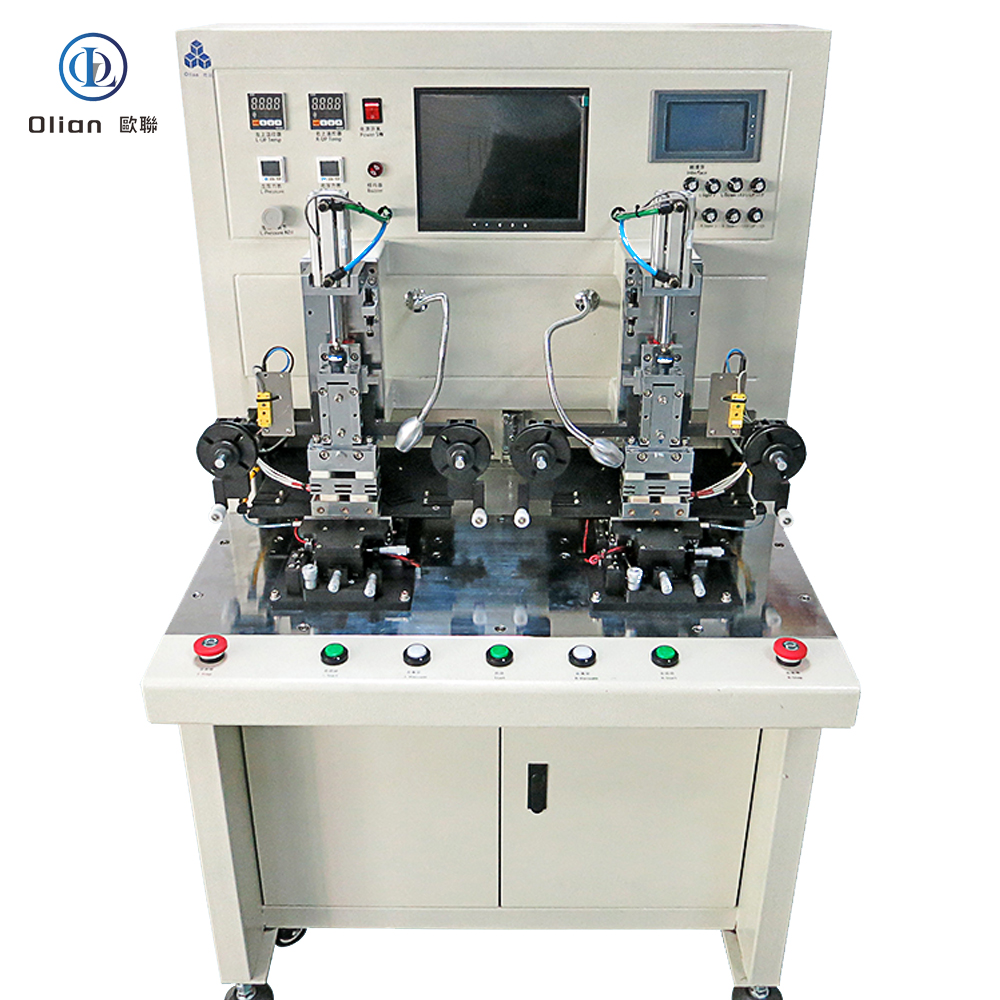

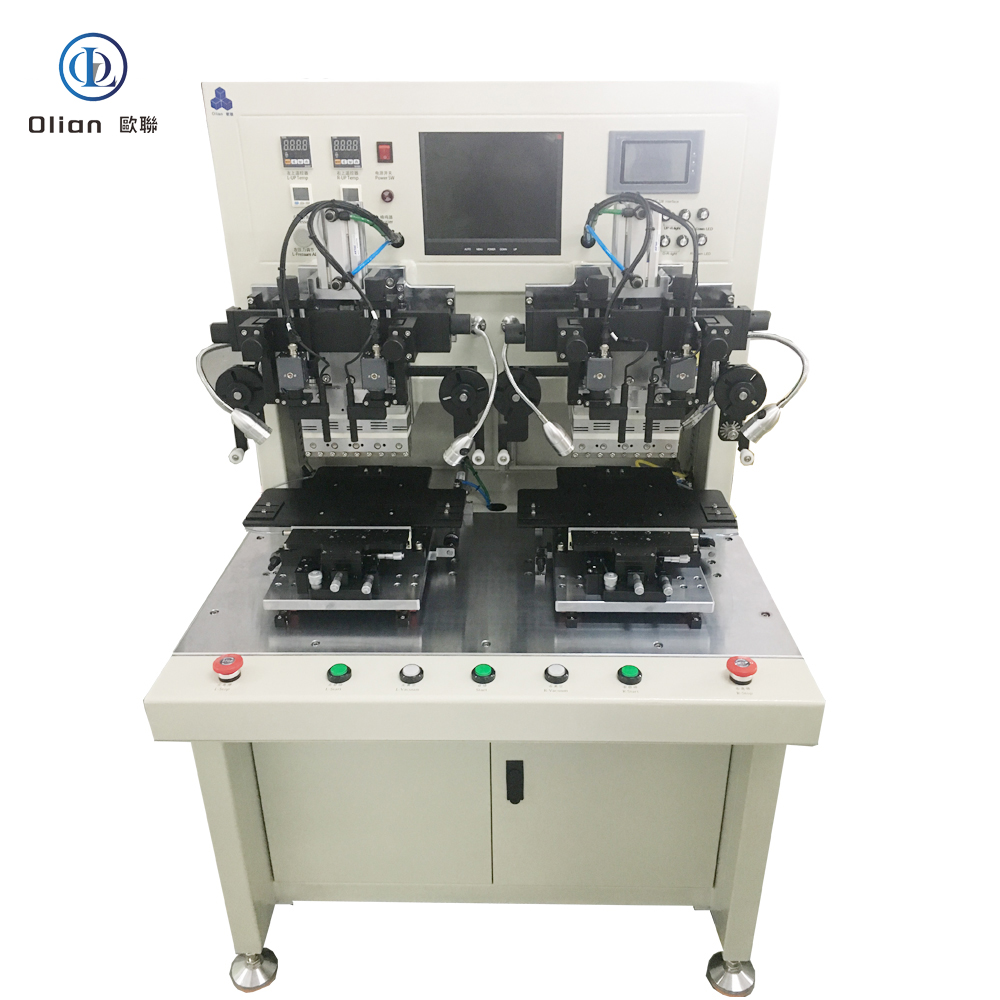

7-17 Inch Semi Automatic Bonding Machines Production Line Solution

In the competitive landscape of display manufacturing, the production of mid-size Liquid Crystal Modules (LCMs) for applications such as tablets, notebooks, and automotive displays requires a specialized and semi-automated bonding solution. Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing LCMs ranging from 7” to 17.3”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

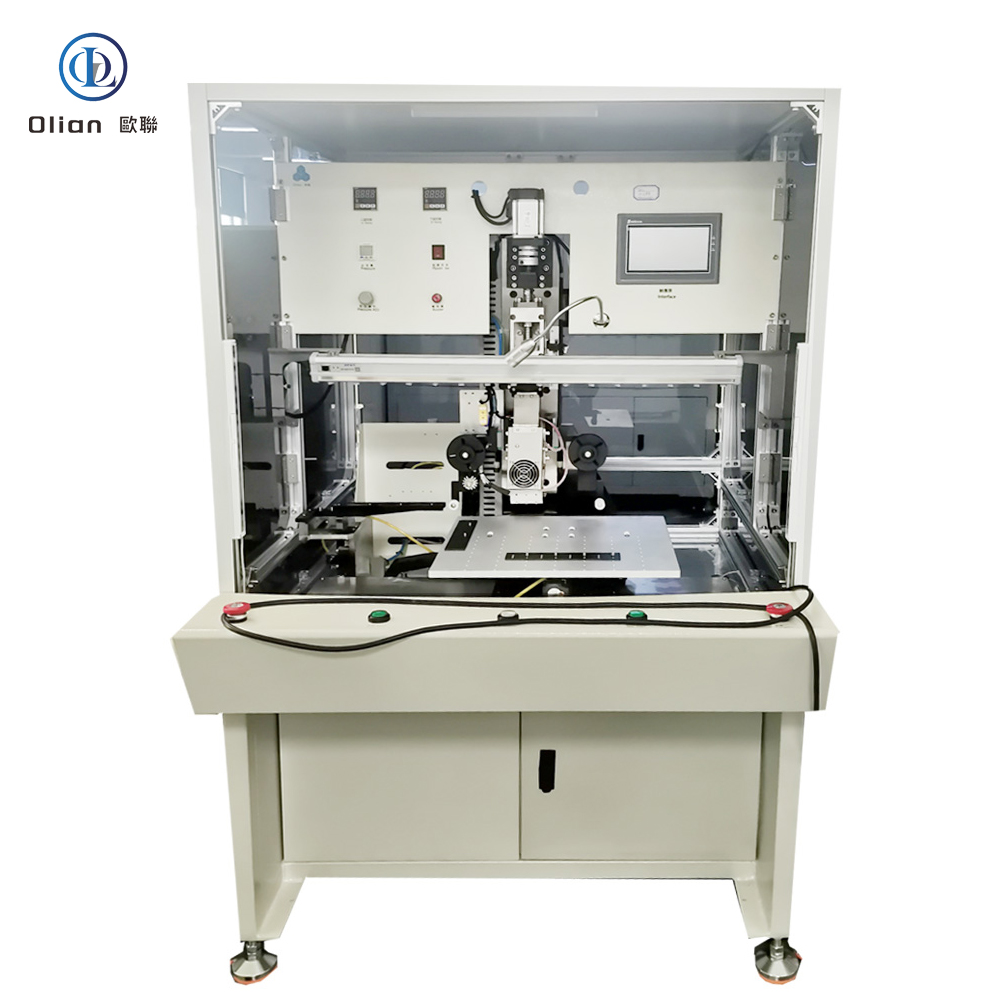

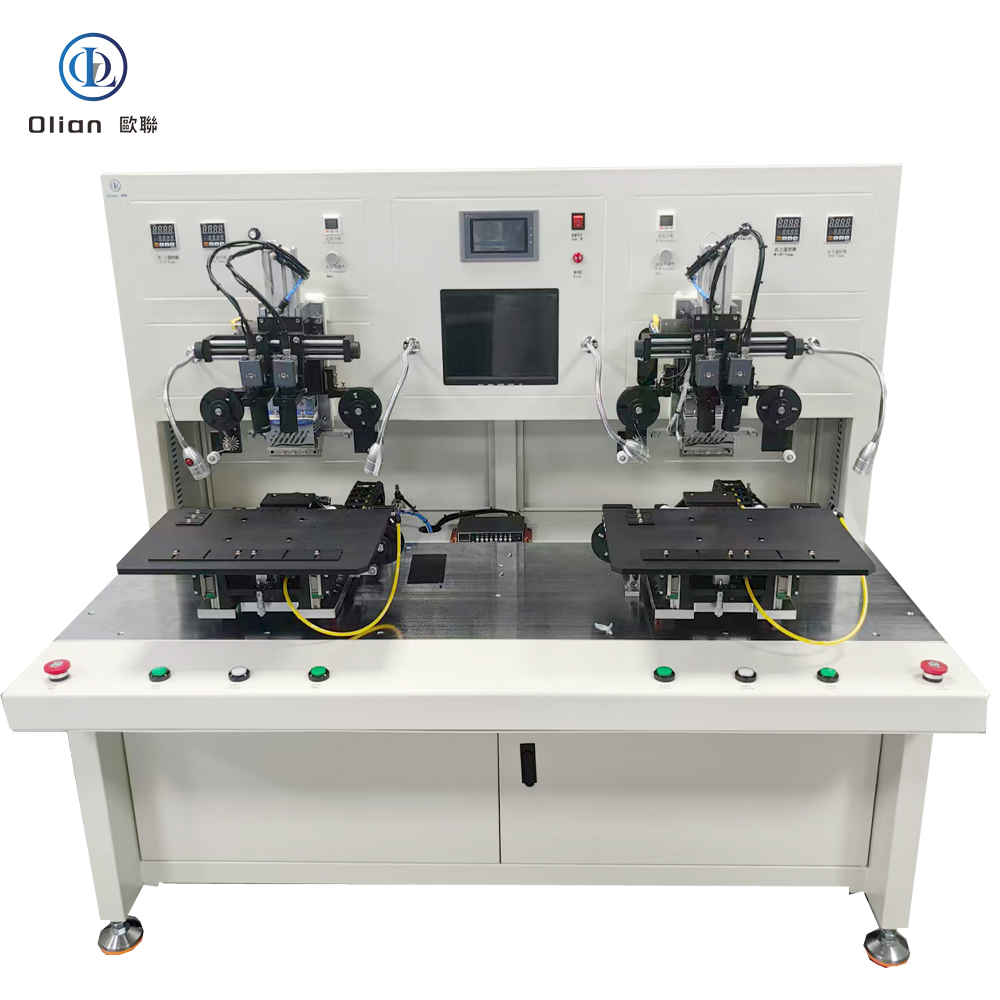

17-120 Inch Semi Automatic Bonding Machines Production Line Solution for TV/Touch Panels/Customized Products

In the rapidly evolving display manufacturing industry, the production of large-sized displays for applications such as TVs, touch panels, and customized products requires a specialized and semi-automated bonding solution. Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing large-sized Liquid Crystal Modules (LCMs) ranging from 17” to 120”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

The display manufacturing industry is on a remarkable journey of innovation and growth. Technologies like OLED, QLED, and MicroLED are pushing the boundaries of what screens can do, offering better resolution, color accuracy, and energy efficiency. However, challenges such as high costs, durability issues, and supply chain disruptions still need to be addressed. As research and collaboration continue, we can expect even more exciting advancements in the future.

Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

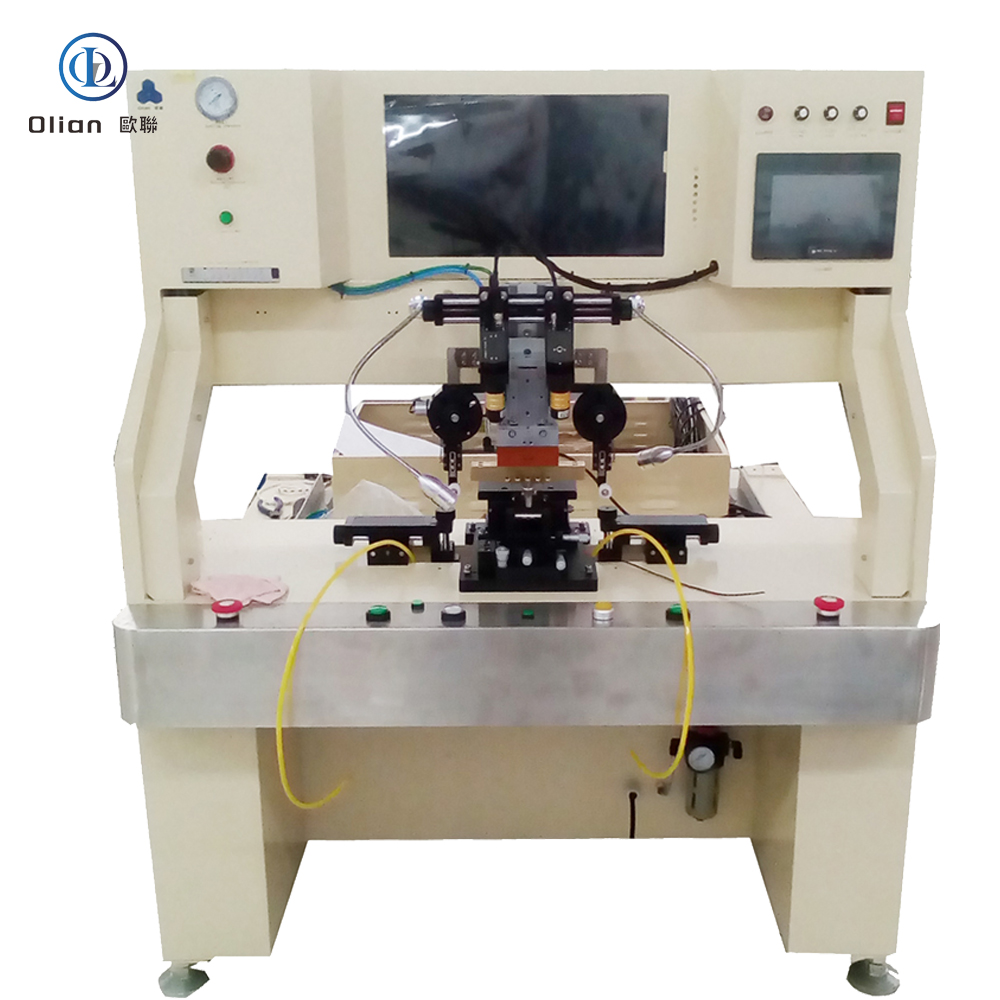

A TFOF bonder—short for Touch-Flex-On-Film bonder—is the precision heart that welds a touch-sensor flex tail directly onto a flexible polyimide film (PET or PI) using anisotropic conductive film (ACF) and controlled heat plus pressure. Every foldable OLED, curved automotive cluster, or transparent medical patch you touch has passed through such a bench. This guide explains physics, hardware, software, specs, applications, trends, and maintenance—so Google instantly ranks you for “TFOF bonder”, “TFOF bonding machine”, “manual TFOF bonder”, “ACF TFOF bonding”, and every high-value permutation.

Cycle time: < 3 s (bond only), 6–8 s (full loop).

TFOF bonder, TFOF bonding machine, manual TFOF bonder, ACF TFOF bonding, high-quality TFOF bonder manufacturer, Shenzhen Olian TFOF bonder, high-quality TFOF bonding machine supplier, high-quality COG TFOF bonder manufacturer, high-quality COF TFOF bonder supplier, high-quality FOG TFOF bonder supplier, high-quality pulse heat TFOF bonder, high-quality constant temperature TFOF bonder, high-quality AI vision TFOF bonder, IoT TFOF bonder, high-quality 8-K TV TFOF line manufacturer, high-quality foldable phone TFOF line supplier, high-quality automotive display TFOF line manufacturer, high-quality medical display TFOF line supplier.

A TFOF bonder is no longer a niche reel-fed press—it is the global, AI-driven, blockchain-audited gateway that turns flexible polyimide into the transparent touch layers, foldable phones, and curved automotive clusters that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s TFOF lines deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade.

When global display giants search for high-quality ACF hot-press machines, reliable manufacturers, or trusted suppliers, one name consistently surfaces at the top of every shortlist: Shenzhen Olian Automatic Equipment Co., Ltd.

From 1-inch wearable OLEDs to 100-inch 8-K TV source drivers, Olian’s fully automatic ACF hot-press bonding lines deliver 99.9 % yield at 1,000 UPH, micron-accurate alignment, and blockchain-audited traceability. This guide explains physics, hardware, software, specs, applications, trends, and maintenance—so Google instantly ranks you for “ACF hot-press machine manufacturer”, “Shenzhen Olian supplier”, “COG/COF/FOG hot-press supplier”, and every high-value permutation.

Cycle time: < 3 s (bond only), 6–8 s (full loop).

ACF hot-press machine, ACF hot press machine, high-quality ACF hot-press machine manufacturer, Shenzhen Olian ACF hot-press machine, high-quality ACF hot-press machine supplier, high-quality COG hot-press machine manufacturer, high-quality COF hot-press machine supplier, high-quality FOG hot-press machine supplier, high-quality pulse heat ACF hot-press machine, high-quality constant temperature ACF hot-press machine, high-quality AI vision ACF hot-press machine, high-quality IoT ACF hot-press machine, high-quality blockchain hash ACF hot-press machine, high-quality 1,000 UPH ACF hot-press machine, high-quality 99.9 % yield ACF hot-press machine, high-quality 8-K TV ACF hot-press line manufacturer, high-quality foldable phone ACF hot-press line supplier

A high-quality ACF hot-press machine from Shenzhen Olian Automatic Equipment Co., Ltd. is no longer a regional factory—it is the global, AI-driven, blockchain-audited gateway that turns instantaneous resistance heat into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian lines deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade.

When global display giants search for high-quality bonding machines, reliable manufacturers, or trusted suppliers, one name consistently surfaces at the top of every shortlist: Shenzhen Olian Automatic Equipment Co., Ltd.

From 1-inch wearable OLEDs to 100-inch 8-K TV source drivers, Olian’s fully automatic COG/COF/FOG/TFOG bonding lines deliver 99.9 % yield at 1,000 UPH, micron-accurate alignment, and blockchain-audited traceability. This guide explains physics, hardware, software, specs, applications, trends, and maintenance—so Google instantly ranks you for “high-quality bonding machines manufacturer”, “Shenzhen Olian supplier”, “COG bonding machine supplier”, and every high-value permutation.

Cycle time: < 3 s (bond only), 6–8 s (full loop).

high-quality bonding machines company manufacturer supplier, Shenzhen Olian automatic equipment, high-quality COG bonding machine manufacturer, high-quality COF bonding machine supplier, high-quality FOG bonding machine supplier, high-quality ACF bonding machine manufacturer, high-quality pulse heat bonder supplier, high-quality constant temperature bonder manufacturer, high-quality AI vision bonder supplier, high-quality IoT bonding machine manufacturer, high-quality blockchain hash bonder supplier, high-quality 1,000 UPH bonder manufacturer, high-quality 99.9 % yield bonder supplier, high-quality 8-K TV bonding line manufacturer, high-quality foldable phone bonding line supplier, high-quality automotive display bonding line manufacturer, high-quality medical display bonding line supplier, high-quality ISO 6 cleanroom bonder manufacturer, high-quality granite base bonder supplier, high-quality servo motor bonder manufacturer, high-quality voice-coil actuator bonder supplier, high-quality telecentric lens bonder manufacturer,

A high-quality bonding machines company, manufacturer, and supplier such as Shenzhen Olian Automatic Equipment Co., Ltd. is no longer a regional factory—it is the global, AI-driven, blockchain-audited gateway that turns micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian lines deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade.