In the dynamic world of electronics and display manufacturing, precision and reliability are paramount. Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, the right bonding machine is essential for ensuring high-quality connections and efficient production processes. Our company offers a wide range of state-of-the-art bonding machines designed to meet the diverse needs of modern manufacturing. Below is an overview of our product offerings, tailored to help you find the perfect solution for your specific requirements.

Our mobile phone bonding machines are designed to handle the precise assembly requirements of smartphones. These machines support various bonding processes, including COG (Chip on Glass), COF (Chip on Film), and FPC (Flexible Printed Circuit) bonding. They are equipped with high-definition microscopes, digital pressure gauges, and vacuum generators to ensure accurate alignment and reliable bonding

For the growing wearable technology market, our smart watch LCD bonding machines offer high precision and flexibility. These machines are ideal for bonding small LCD panels and flexible circuits, ensuring that your wearable devices are both durable and reliable

Our wearable equipment bonding machines are versatile and can handle a variety of components used in smartwatches, fitness trackers, and other wearable devices. These machines support multiple bonding processes, including COG, COF, and FOG (Film on Glass) bonding

Our TV panel bonding machines are designed for large-scale production of LCD and LED TV panels. These machines support high-speed bonding processes and are equipped with advanced features such as pulse heating and constant temperature control to ensure consistent bonding quality

For the production of Liquid Crystal Modules (LCMs) and LCD modules, our bonding machines offer high precision and reliability. These machines support various bonding processes, including COG, FOG, and OLB (Outer Lead Bonding), and are suitable for both small and large-scale production

Our flat panel display bonding machines are designed to handle a wide range of display sizes and types, from small wearable devices to large TV panels. These machines are equipped with advanced vision systems and precise temperature control to ensure high-quality bonding

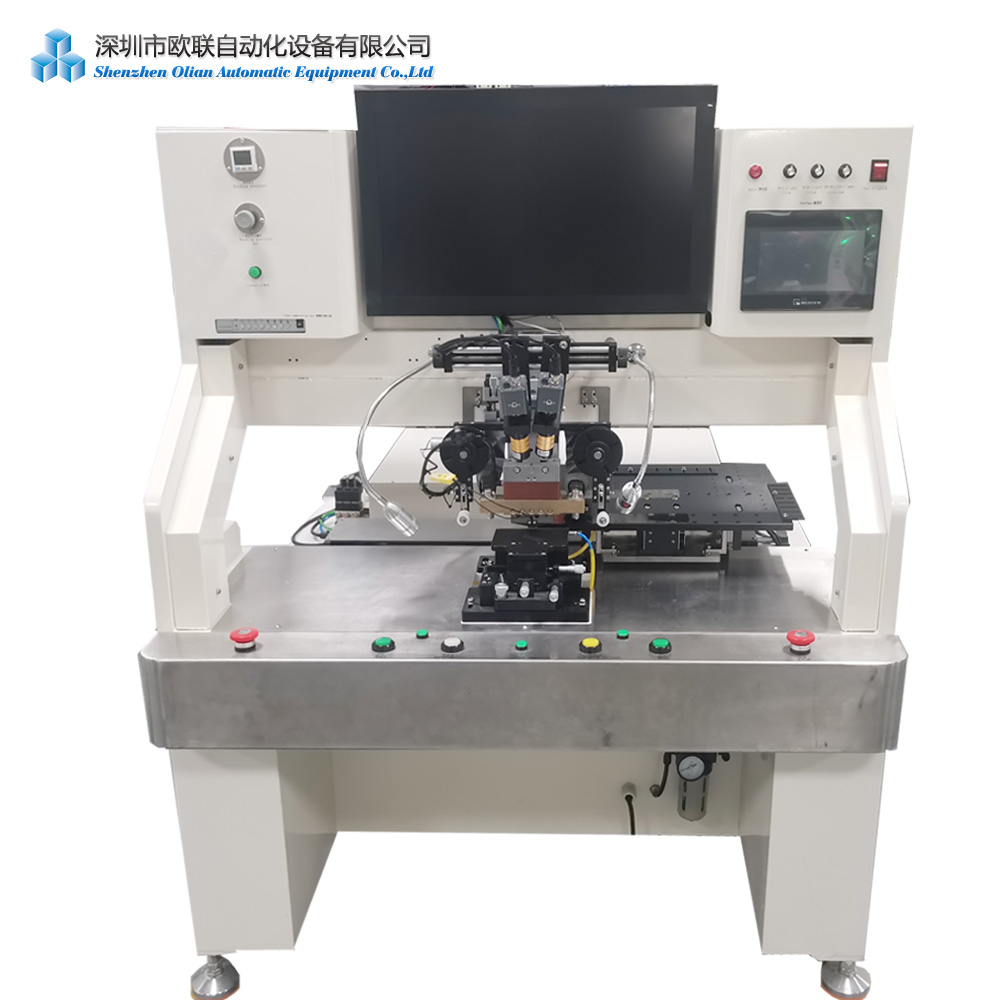

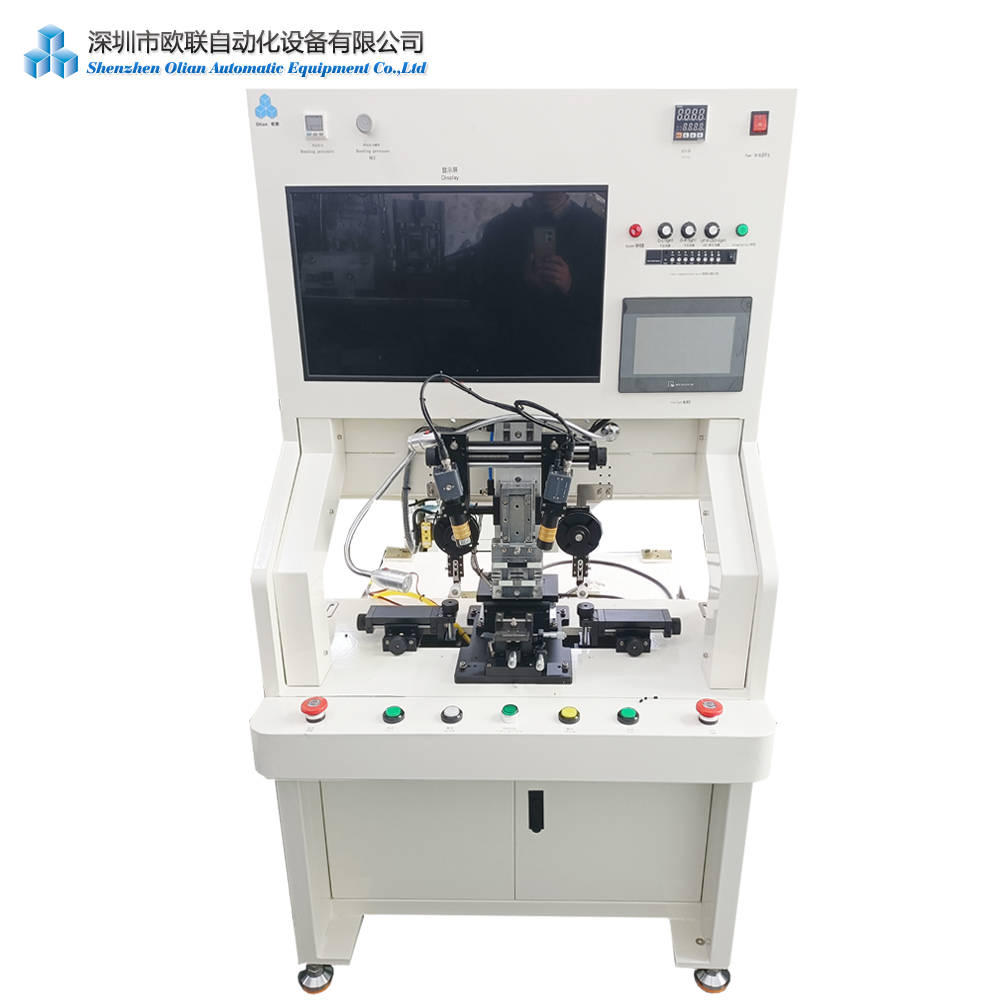

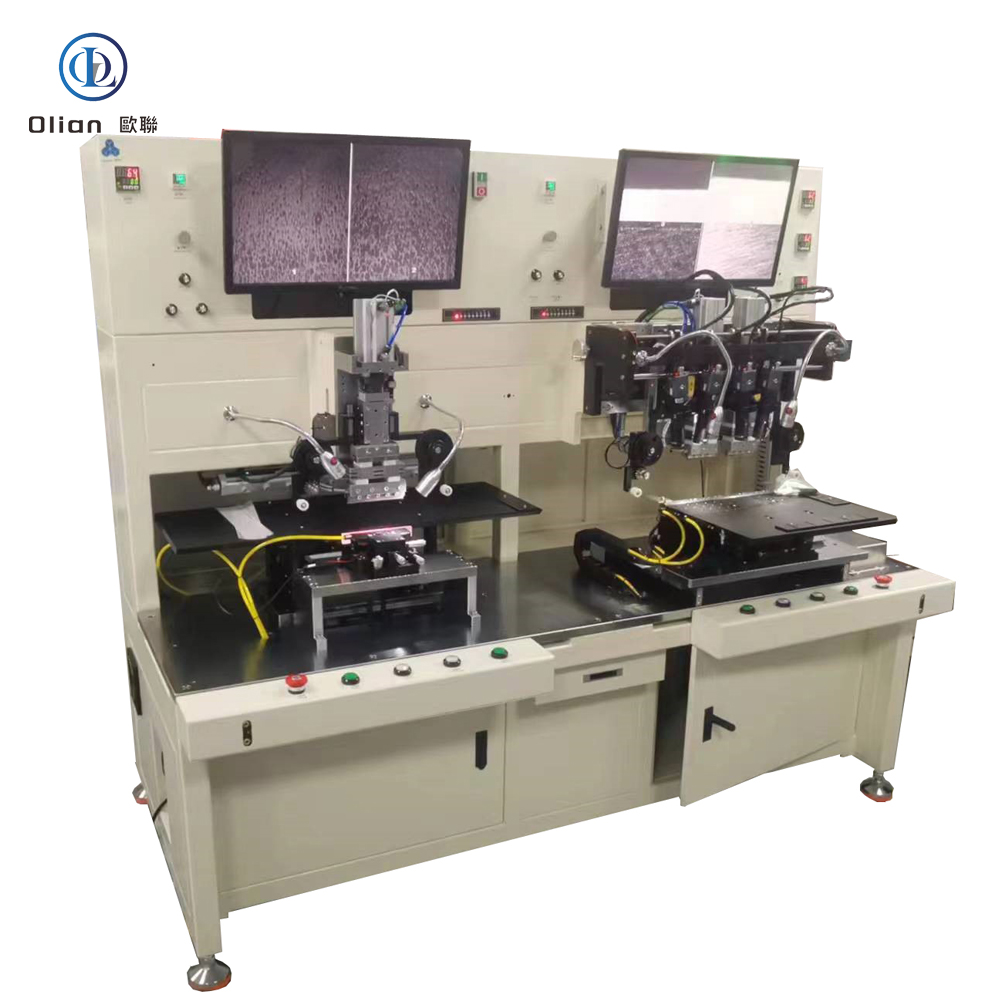

Our COG (Chip on Glass), COP (Chip on Plastic), and COF (Chip on Film) bonding machines are designed for high-precision bonding of integrated circuits (ICs) and flexible printed circuits (FPCs) to various substrates. These machines offer both semi-automatic and fully automatic configurations, making them suitable for a wide range of production volumes

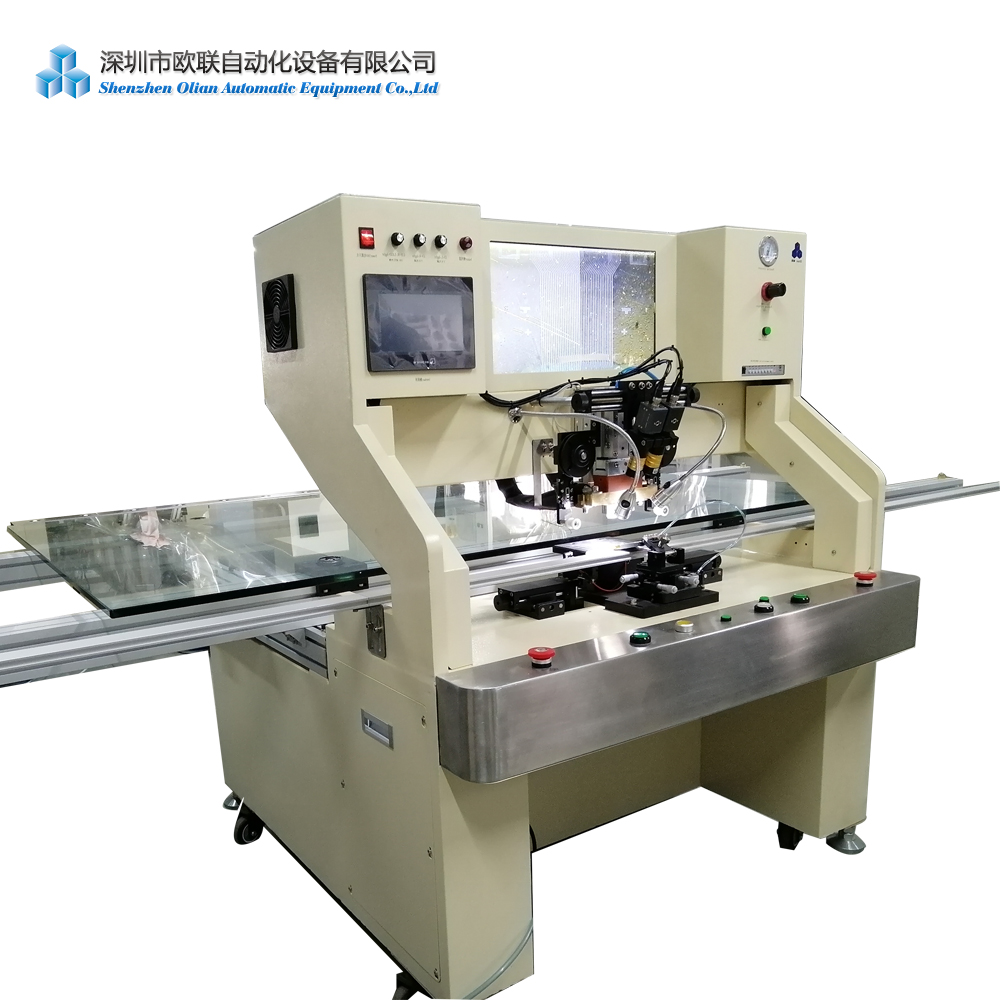

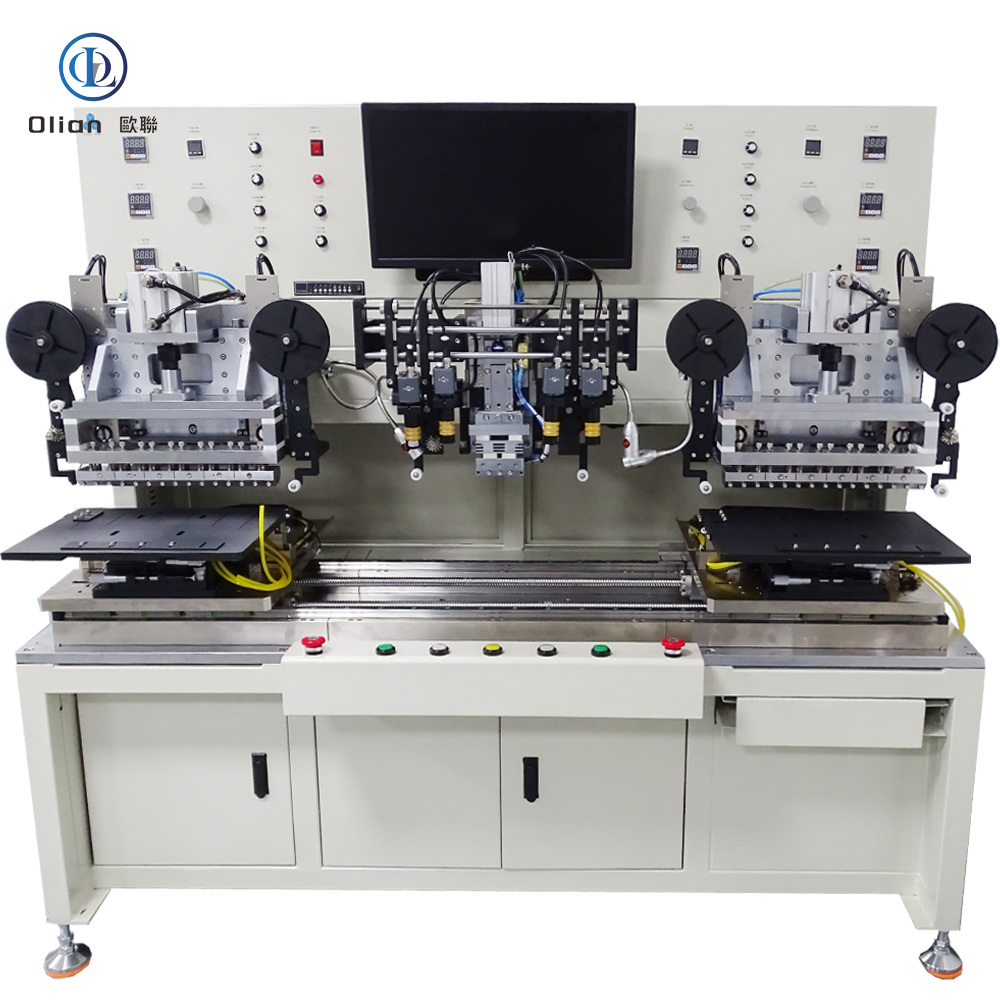

Our FOG (Film on Glass), FOB (Film on Board), and FOF (Film on Film) bonding machines are designed for bonding flexible circuits to various substrates. These machines support both pulse heating and constant temperature bonding processes, ensuring reliable connections in your display assemblies

Our TAB (Tape Automated Bonding), OLB (Outer Lead Bonding), and IC bonding machines are versatile tools for bonding integrated circuits and other components. These machines offer high precision and reliability, making them ideal for a wide range of electronic manufacturing applications

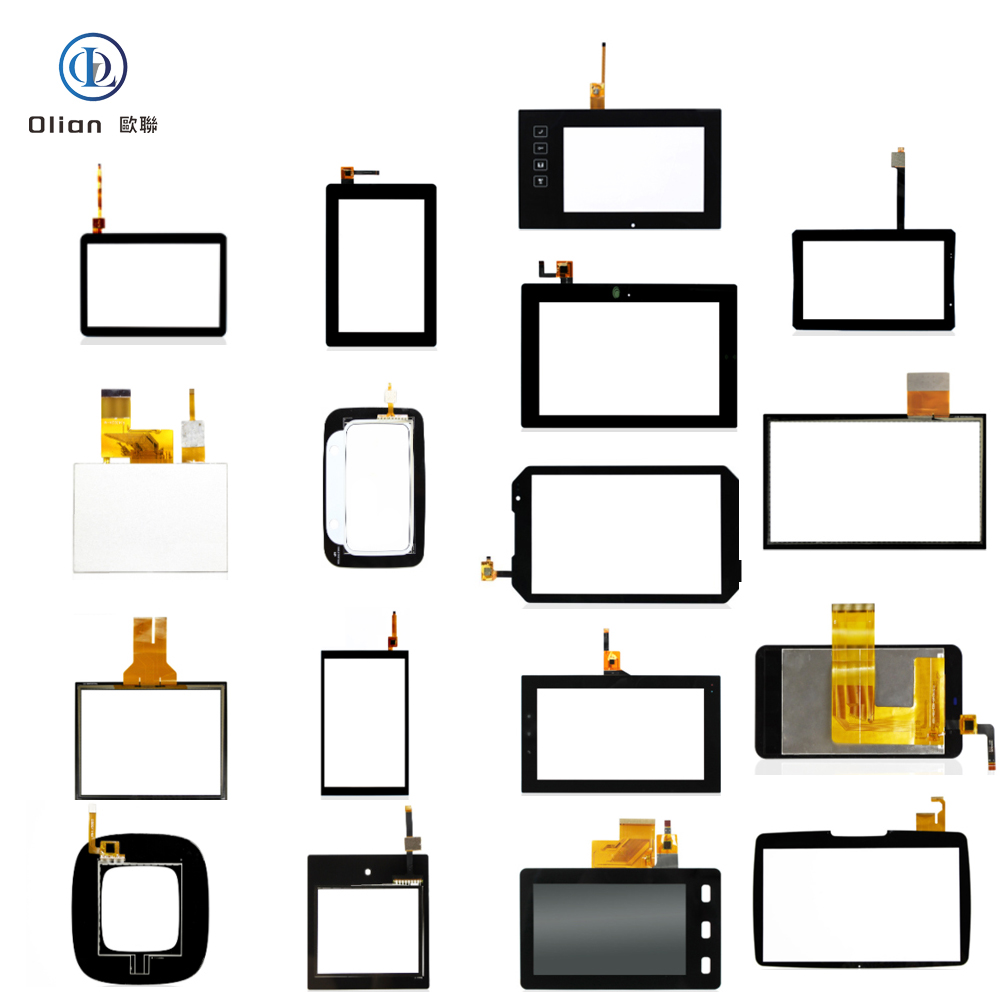

Our FPC (Flexible Printed Circuit), glass, and touch panel bonding machines are designed to handle the specific requirements of flexible circuits and touch-sensitive displays. These machines support various bonding processes, including COG, FOG, and COF bonding, and are equipped with advanced features such as high-definition microscopes and precise temperature control

For advanced display technologies such as OLED, Mini LED, and Micro LED, our bonding machines offer high precision and reliability. These machines are designed to handle the specific requirements of these advanced displays, ensuring high-quality connections and efficient production

Our Zebra paper and flex cable bonding machines are designed for bonding components to Zebra paper and flexible cables. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are crucial

Our bonding machines are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key features of our machines include:

Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our comprehensive range of bonding machines is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality connections and efficient production processes. Contact us today to find the perfect bonding machine for your application.

In the rapidly evolving world of display technology, bonding machines play a crucial role in the assembly and manufacturing of various electronic components and displays. Our company is proud to offer a wide range of advanced bonding solutions tailored to meet the diverse needs of the industry. Whether you are looking to bond integrated circuits, flexible printed circuits, or other components, we have the right machine for you.

ACF bonders are essential for bonding two substrates, such as LCDs, PCBs, and FPCs, using Anisotropic Conductive Film (ACF). These machines are available in both constant heat and pulse heat systems, with vision alignment capabilities for precise bonding

. They are widely used in applications like COB (Chip on Board), COF (Chip on Film), COG (Chip on Glass), COP (Chip on Panel), FOB (Film on Board), and FOG (Film on Glass).

COG bonders are specifically designed for attaching integrated circuits (ICs) directly onto glass substrates. These machines ensure high precision and reliability, making them ideal for the production of LCD panels used in consumer electronics, automotive displays, and industrial applications

. Our COG bonders come in both pre-bonding and main-bonding configurations, with options for manual or automated loading.

Similar to COG bonders, COP bonders are used for bonding ICs directly onto display panels. They are particularly useful for flexible AMOLED production, offering advanced functions to ensure high bonding quality and productivity

.

COF bonders are designed for bonding ICs onto flexible films. These machines are versatile and can be used for various applications, including COF on glass, COF on board, and COF on film bonding

. They are available in both manual and automatic configurations, with options for single or dual heads.

FOG bonders are used for bonding flexible printed circuits (FPCs) onto glass substrates. These machines come in both pulse heat and constant heat versions, with top-bottom alignment systems for precise bonding

. They are suitable for a wide range of applications, including LCD and OLED panel manufacturing.

FOB bonders are designed for bonding FPCs onto PCBs. They offer similar features to FOG bonders, including precise alignment and reliable bonding capabilities

. These machines are essential for applications where flexibility and compactness are required.

FOF bonders are used for bonding FPCs onto other FPCs. These machines are particularly useful in applications where space is limited and flexibility is crucial

. They offer high precision and reliability, ensuring a strong and stable connection between the components.

TAB bonders are used for bonding integrated circuits onto substrates using tape automated bonding techniques. These machines are known for their high precision and reliability, making them ideal for a wide range of electronic manufacturing applications

.

OLB bonders are used for bonding the outer leads of integrated circuits onto substrates. These machines are essential for ensuring a reliable connection between the IC and the display panel

. They offer high precision and reliability, making them a crucial part of the display manufacturing process.

IC bonders are versatile machines used for bonding integrated circuits onto various substrates. They are available in both manual and automated configurations, with options for single or dual heads

. These machines are essential for a wide range of electronic manufacturing applications.

FPC bonders are designed for bonding flexible printed circuits onto various substrates. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are required

. They are available in both manual and automated configurations, with options for single or dual heads.

Glass bonders are used for bonding components directly onto glass substrates. These machines are essential for the production of LCD and OLED panels, offering high precision and reliability

. They are available in both manual and automated configurations, with options for single or dual heads.

LCD panel bonders are specifically designed for the assembly of LCD panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

LED panel bonders are used for bonding components onto LED panels. These machines offer high precision and reliability, making them ideal for applications where brightness and efficiency are crucial

. They are available in both manual and automated configurations, with options for single or dual heads.

Mini LED bonders are designed for the assembly of Mini LED panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

Micro LED bonders are used for the assembly of Micro LED panels. These machines offer extremely high precision and reliability, making them ideal for applications where brightness, efficiency, and resolution are crucial

. They are available in both manual and automated configurations, with options for single or dual heads.

Zebra paper bonders are used for bonding components onto Zebra paper. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are required

. They are available in both manual and automated configurations, with options for single or dual heads.

Touch panel FPC bonders are specifically designed for bonding flexible printed circuits onto touch panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

Our company offers a comprehensive range of bonding machines designed to meet the diverse needs of the display manufacturing industry. From ACF bonders to Micro LED bonders, we have the right machine for every application. Our machines are known for their high precision, reliability, and versatility, making them ideal for a wide range of electronic manufacturing applications. We are committed to providing our customers with the best possible solutions and support to ensure their success in the competitive world of display technology.

In the modern electronics repair industry, having the right tools and machines is crucial for efficiently repairing and refurbishing LCD and LED screens, especially for TVs and other large displays. Our company offers a wide range of advanced repair machines and bonding equipment designed to meet the diverse needs of professionals in this field. Whether you are repairing LCD TVs, smartphones, or other display devices, our products are designed to provide high precision, reliability, and efficiency.

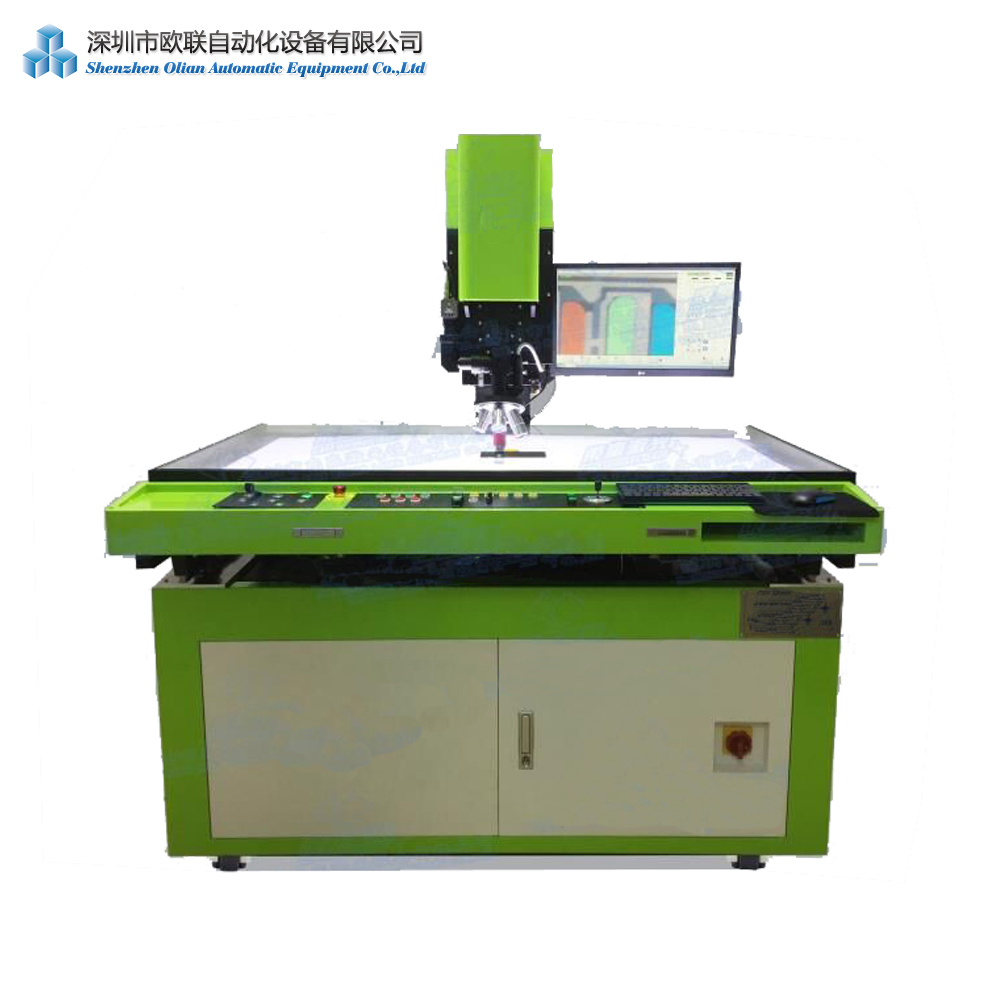

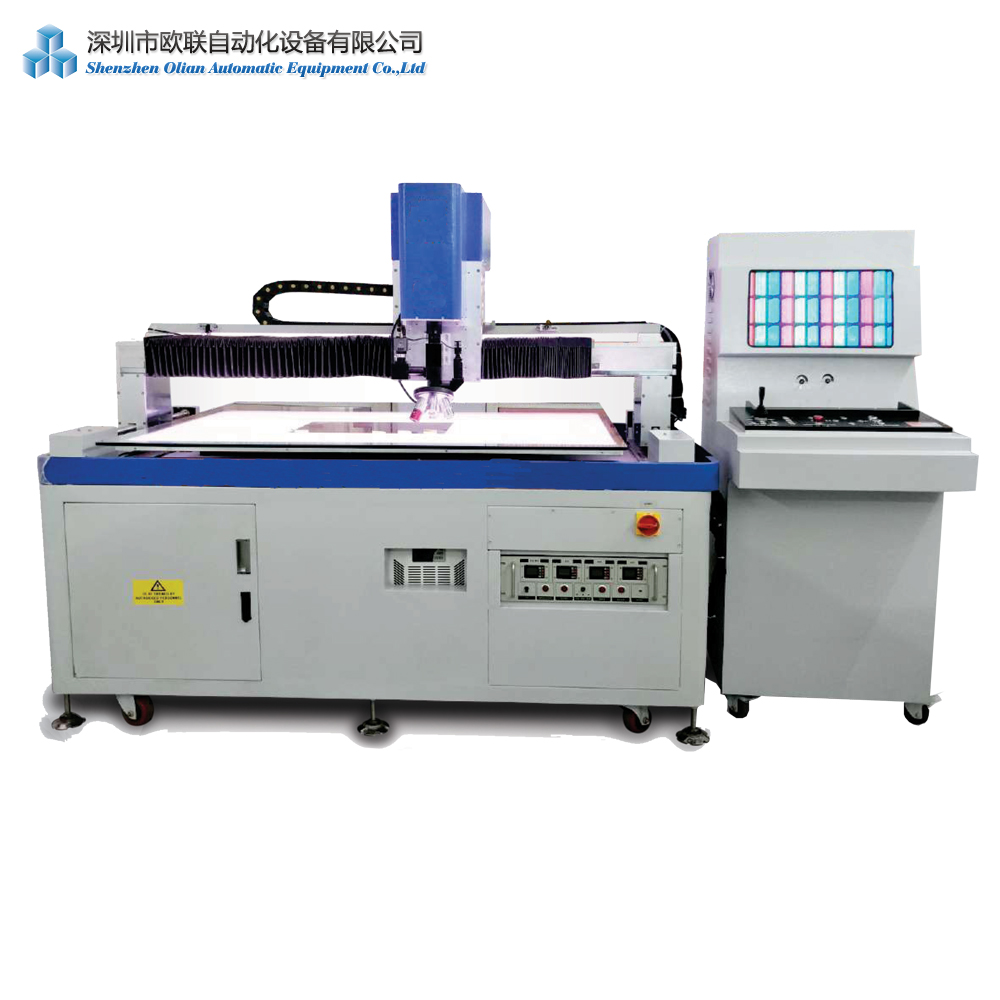

Our LCD screen laser repair machines are designed to efficiently repair a variety of defects in LCD panels, including vertical lines, horizontal lines, black screens, and more. These machines use high-frequency pulse laser beams to cut and trim micron-sized semiconductor circuit components, especially passivation layers (silicon oxide/nitride) and metal interconnects

They are suitable for repairing LCD screens in TVs, PCs, touch teaching machines, splicing screens, notebooks, digital devices, and car displays

Our COF (Chip-On-Film) bonding machines are essential for repairing and assembling LCD and LED panels. These machines are used to bond integrated circuits (ICs) to flexible film substrates, enabling compact designs and high-resolution displays

They are widely used in the repair and manufacturing of TVs, laptops, mobile phones, and tablets

Our FOB (FPC on Board) and FOG (FPC on Glass) bonding machines are designed for bonding flexible printed circuits (FPCs) to PCBs and glass substrates. These machines offer high precision and reliability, making them ideal for applications requiring flexible and compact designs

Our hot bar pressing machines are designed for soldering FPCs, PCBs, LED displays, and other electronic components. These machines use pulse heating technology to achieve accurate temperature control, making them suitable for temperature-critical applications

Our LCD panel rework and repair equipment includes a variety of machines designed to refurbish and repair LCD panels. These machines are capable of repairing a wide range of defects, including vertical and horizontal lines, black screens, and more

Our products are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key reasons to choose our products include:

Whether you are repairing LCD TVs, smartphones, or other display devices, our comprehensive range of repair machines and bonding equipment is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality repairs and efficient production processes. Contact us today to find the perfect solution for your application.

In the electronics manufacturing industry, particularly in the ACF (Anisotropic Conductive Film) bonding process, a variety of testing machines and equipment are essential to ensure the quality and reliability of the final products. These machines play a crucial role in the production line, from initial material inspection to final product testing. Here is a comprehensive overview of the testing instruments and equipment used in ACF bonding processes:

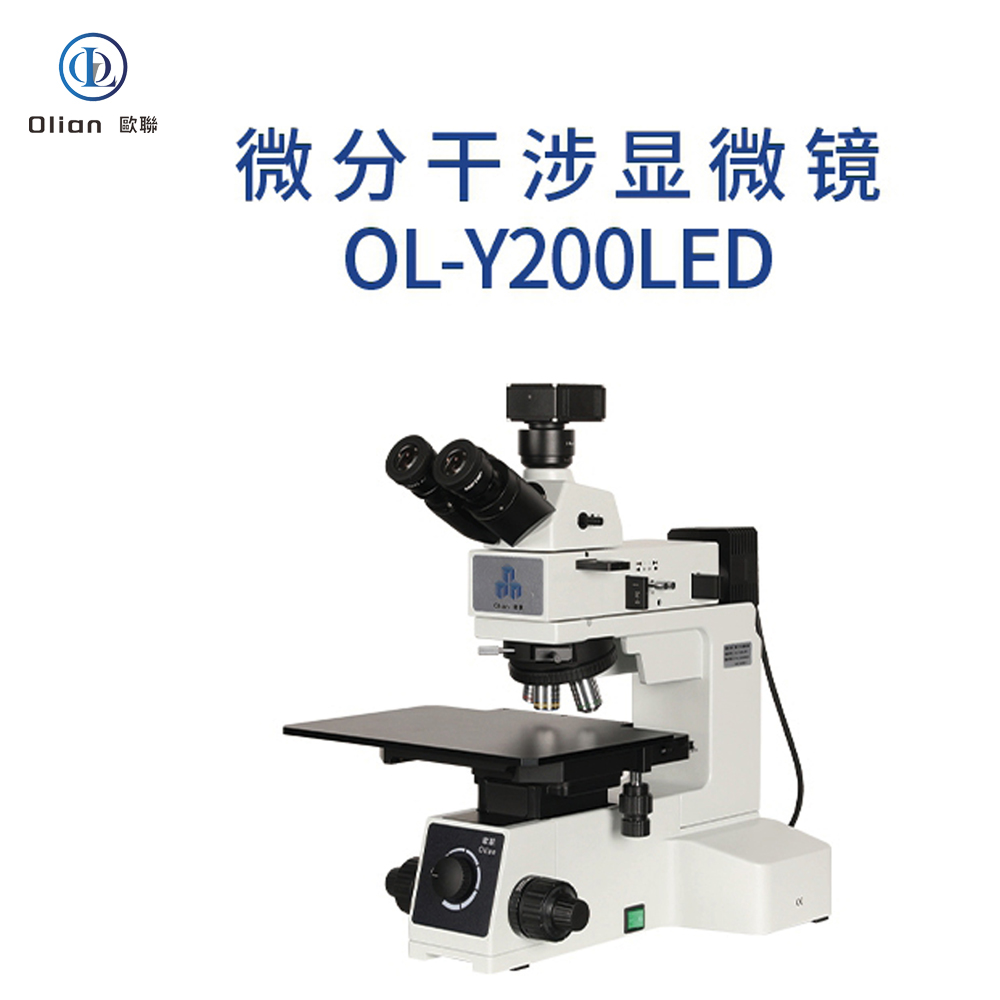

Interferometer Microscope: Interferometer microscopes are used to analyze the surface topography of materials with high precision. They are essential for inspecting the quality of ACF and the bonding surfaces of components. By using optical interference, these microscopes can detect minute surface irregularities that might affect the bonding process.

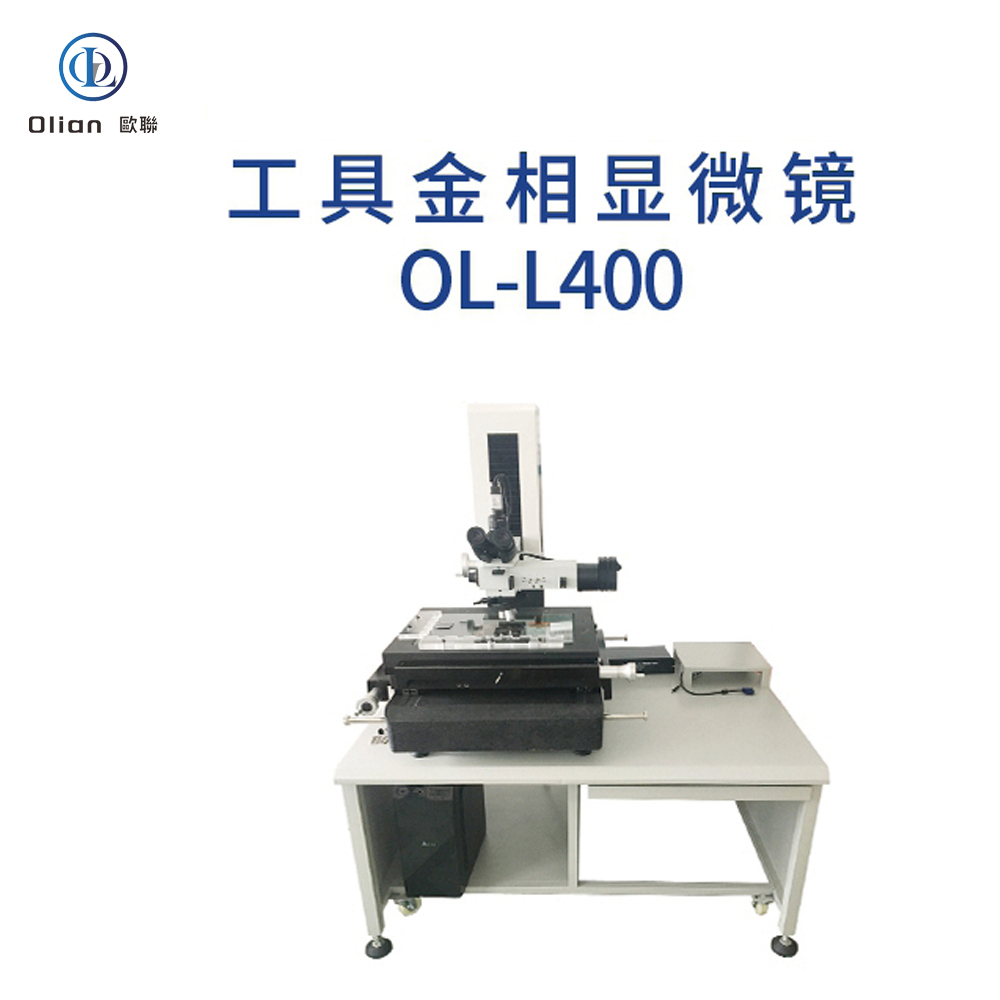

Metallographic Microscope: Metallographic microscopes are designed to examine the microstructure of metals and alloys. In the context of ACF bonding, they are used to analyze the metallurgical properties of the bonding sites. This helps in understanding the compatibility of the materials and the effectiveness of the bonding process.

Lens Inspection Microscope: Lens inspection microscopes are used to inspect and analyze optical components, such as the lenses used in display devices. They ensure that the optical properties of the components are maintained after the bonding process. High-resolution imaging helps in detecting any defects that might have occurred during bonding.

Tool Microscope: Tool microscopes are used for measuring and inspecting the dimensions and geometry of tools and mechanical parts. In ACF bonding, they are used to verify the alignment and precision of the bonding equipment. This ensures that the bonding process is accurate and consistent.

Temperature Testing Instrument: Temperature testing instruments are crucial for monitoring and controlling the temperature during the ACF bonding process. They ensure that the bonding temperature is maintained within the specified range, which is critical for the quality of the bond. These instruments can be contact or non-contact types, providing real-time temperature data.

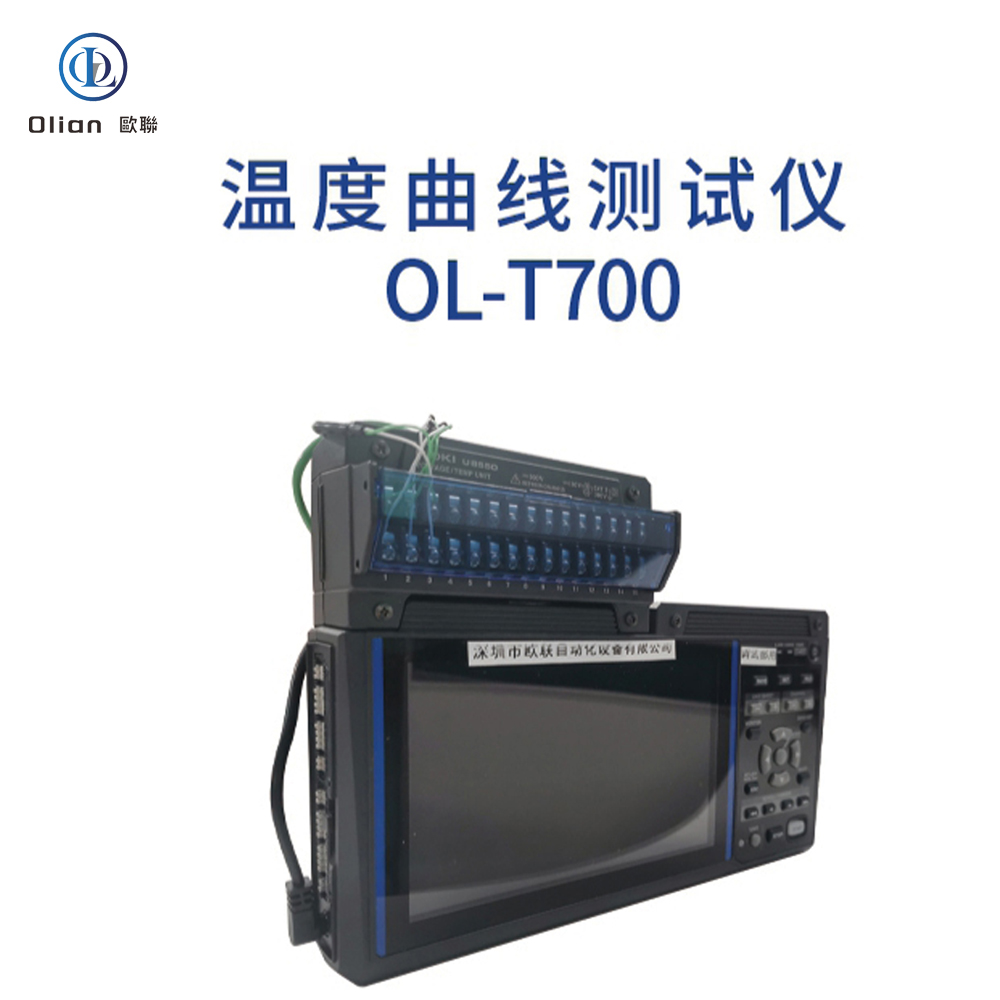

Temperature Curve Testing Instrument: Temperature curve testing instruments measure and record temperature changes over time. They are used to analyze the thermal behavior of the bonding process and to optimize the temperature profile. This helps in achieving a consistent and reliable bond quality.

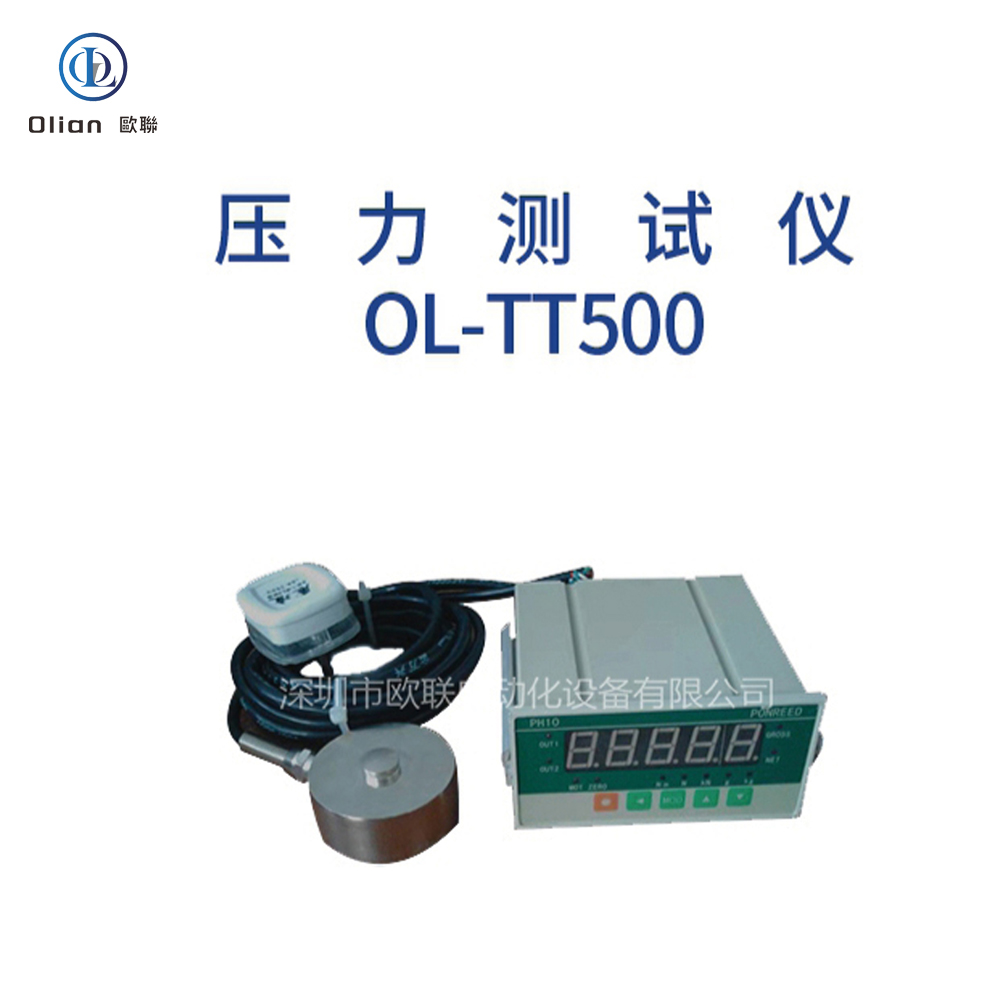

Pressure Testing Device: Pressure testing devices are used to measure and control the pressure applied during the ACF bonding process. They ensure that the pressure is uniform and within the specified limits, which is essential for a strong and durable bond. These devices can handle a wide range of pressures and provide precise control.

Tensile Testing Machine: Tensile testing machines are used to measure the tensile strength of the bonds created by the ACF process. They apply tensile force to the bonded components and measure the response. This helps in determining the mechanical strength of the bonds and ensuring that they can withstand the required forces.

High Temperature High Humidity Testing Chamber: These chambers simulate high temperature and high humidity conditions to test the adaptability and reliability of the bonded products. They are used to evaluate the long-term performance of the products under extreme environmental conditions.

Cold Hot Shock Testing Chamber: Cold hot shock testing chambers rapidly change the temperature to simulate extreme temperature variations. They are used to test the thermal shock resistance of the bonded products, ensuring that they can withstand rapid temperature changes without failure.

Salt Spray Testing Chamber: Salt spray testing chambers simulate a corrosive environment to test the corrosion resistance of the bonded products. This is particularly important for products that will be used in harsh environments, such as automotive and marine applications.

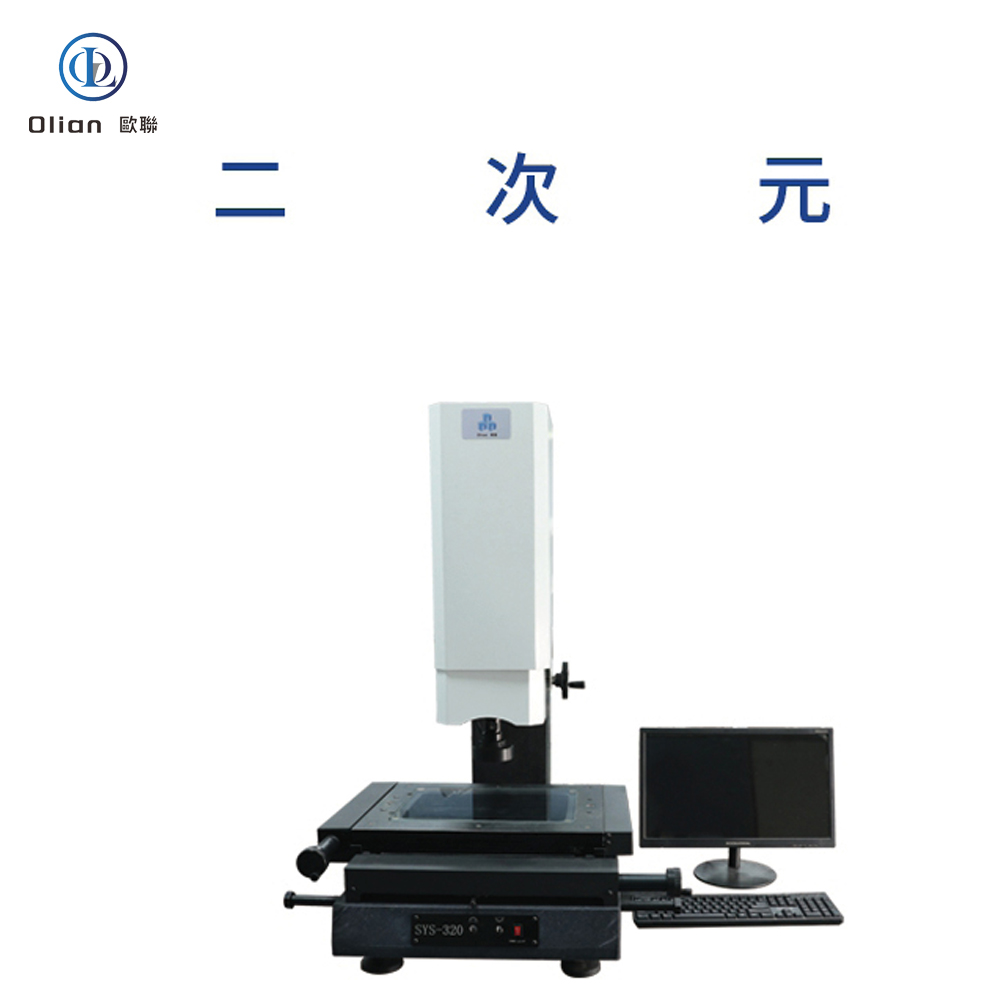

2D Measuring Instrument: 2D measuring instruments use optical imaging and image processing to measure two-dimensional dimensions with high precision. They are used to verify the dimensional accuracy of the components before and after the bonding process. This ensures that the components meet the required specifications.

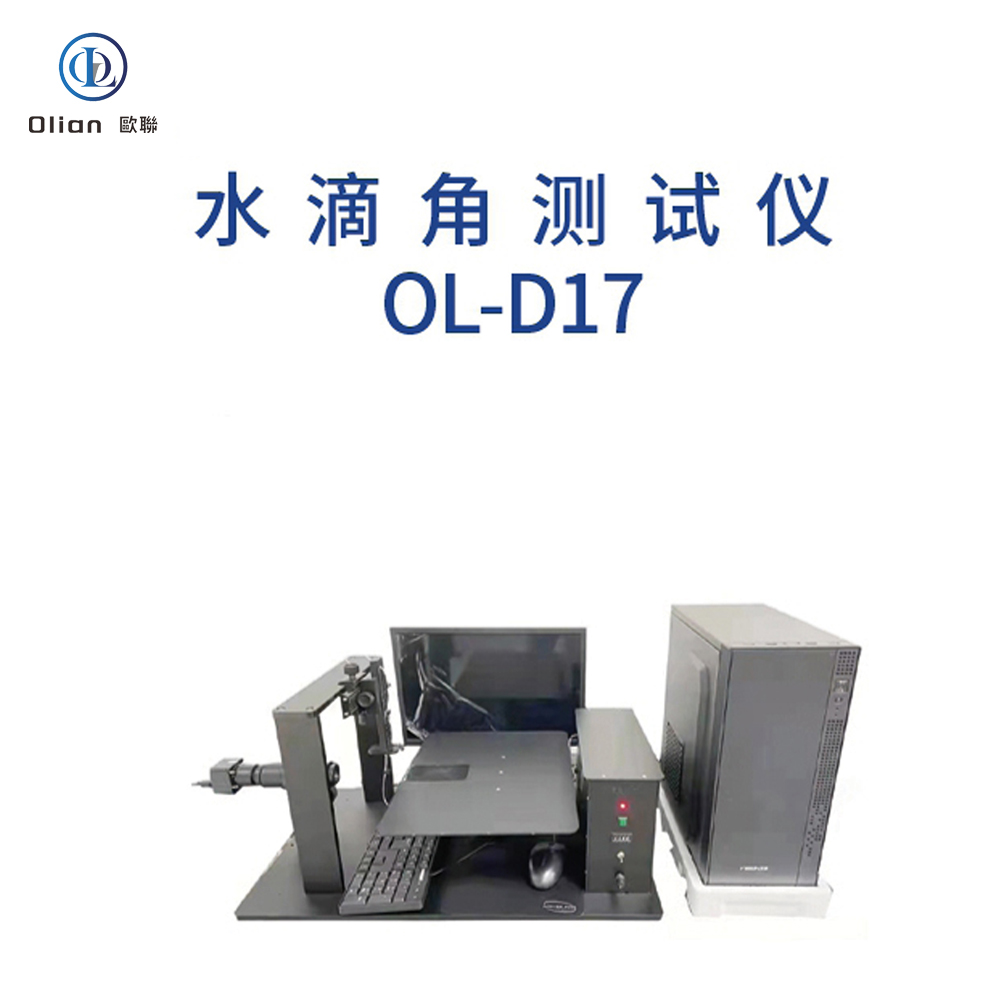

Contact Angle Meter: Contact angle meters measure the contact angle of a liquid on a solid surface, providing information about surface wettability and adhesion. In ACF bonding, they are used to evaluate the surface properties of the bonding sites, ensuring that the ACF can adhere properly.

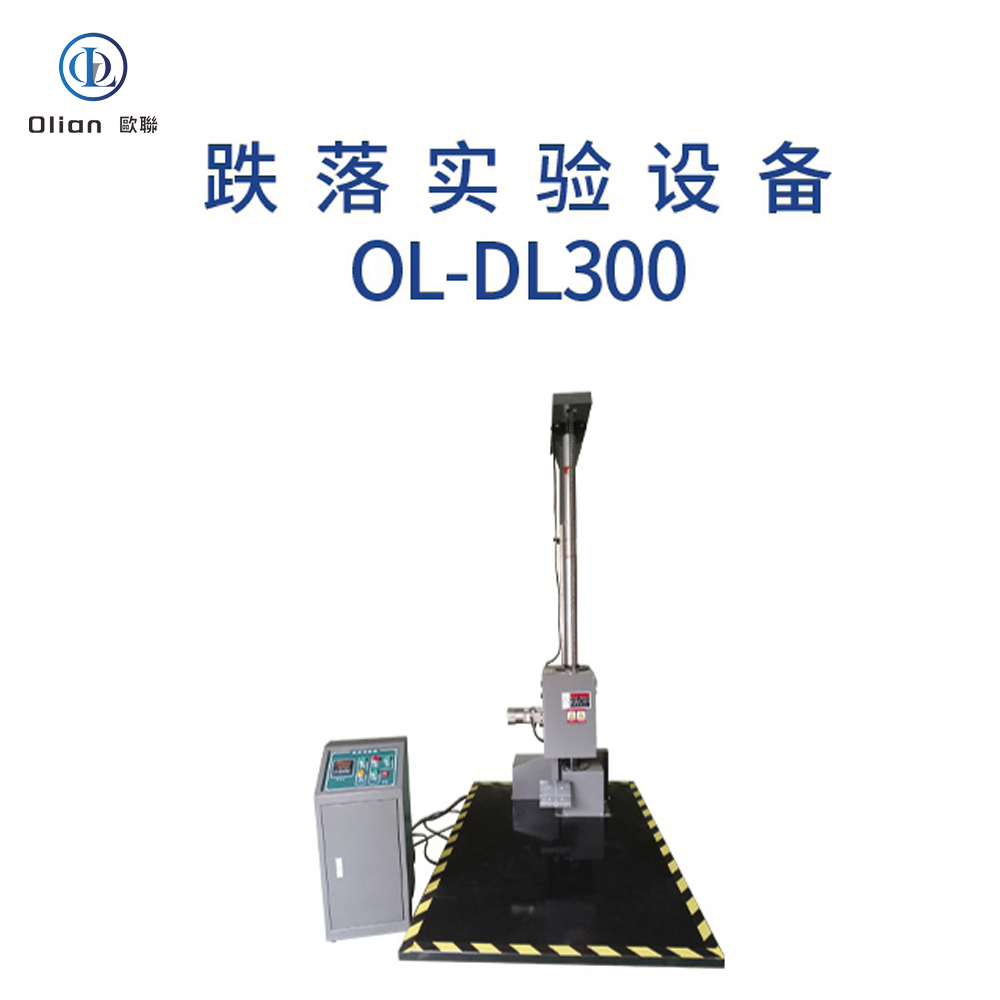

Drop Tester: Drop testers simulate the impact of dropping products to test their durability and shock resistance. They are used to ensure that the bonded products can withstand accidental drops during handling and transportation.

Vibration Testing Machine: Vibration testing machines simulate various vibration conditions to test the vibration resistance and reliability of the bonded products. They are used to ensure that the products can operate reliably in vibrating environments, such as in automotive and aerospace applications.

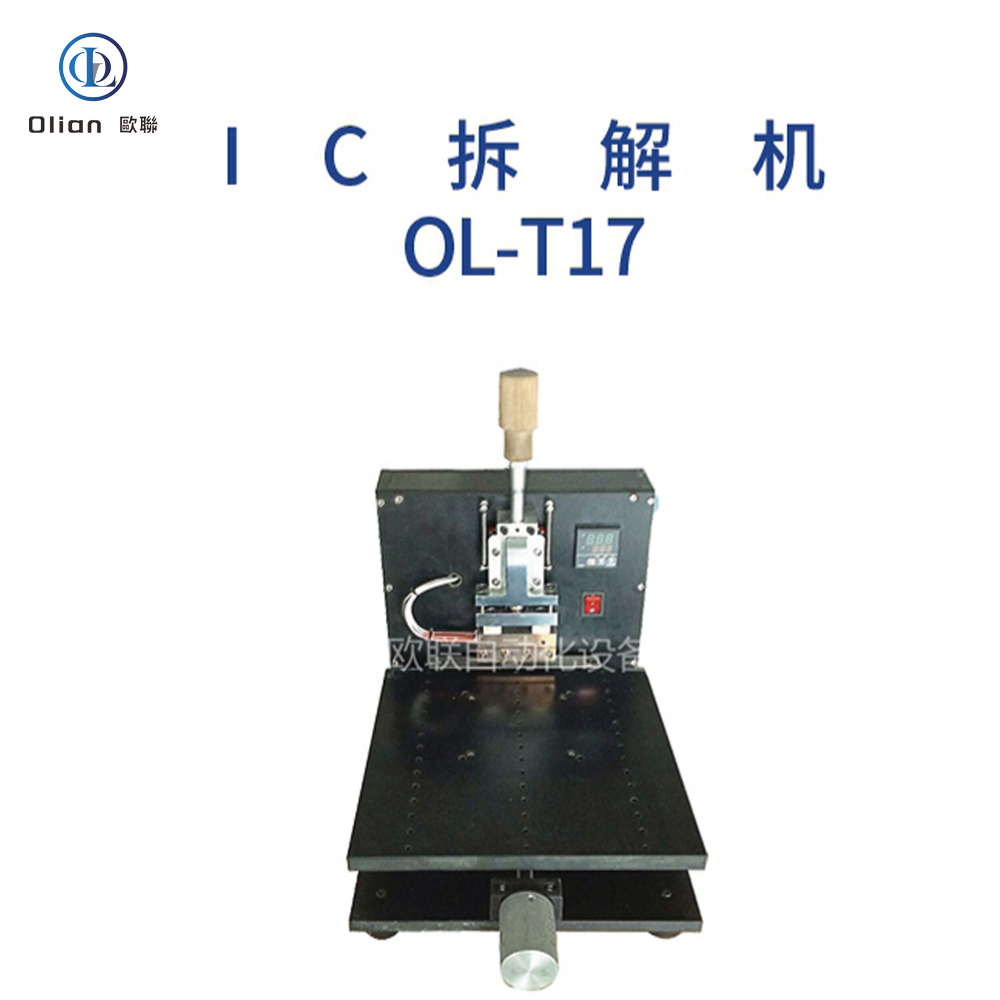

IC Disassembly Machine: IC disassembly machines are used to carefully remove integrated circuits (ICs) from their substrates without causing damage. This is crucial for repair and rework processes in the electronics industry.

IC Removal Machine: IC removal machines are designed to safely and efficiently remove ICs from printed circuit boards (PCBs). They are essential for maintaining the integrity of the board and the components during the repair process.

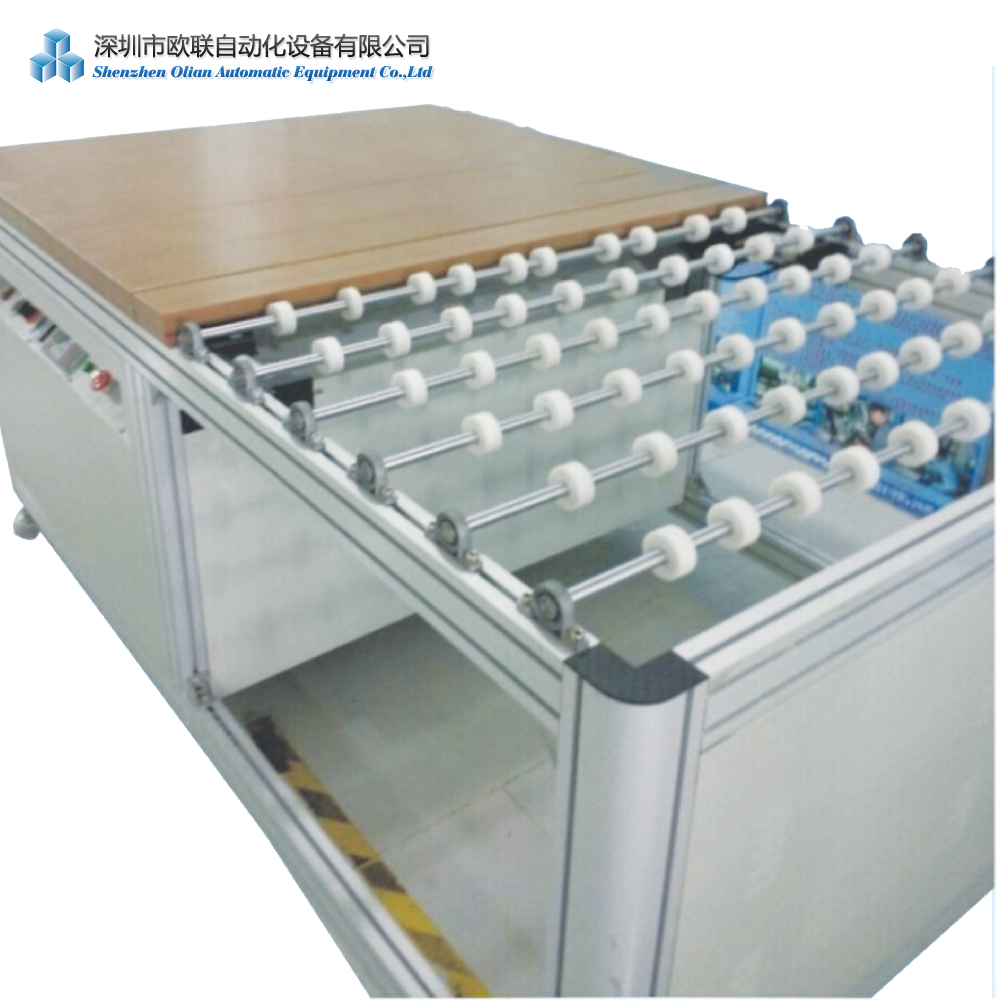

ACF Cutting Machine: ACF cutting machines are used to cut the ACF tape to the required length and shape. These machines ensure that the ACF tape is accurately cut and positioned for the bonding process.

ACF Bonding Machine: ACF bonding machines are used to bond the ACF tape to the substrates (LCD, PCB, Flex, COF, IC Chip, FPC, etc.) using appropriate temperature, pressure, and time. These machines are available in various configurations, including constant heat systems and pulse heat systems, to meet different bonding requirements.

ACF Pre-Bonding Machine: ACF pre-bonding machines are used to pre-bond ICs or COF on the panel that has been attached to the ACF. The pick and place of the panel is achieved manually, and the pre-alignment is automatically completed by the equipment.

ACF Final Bonding Machine: ACF final bonding machines perform the main bonding on the LCD glass with IC, cable, or COF pre-pressed. The operator manually loads and unloads the products, while the ACF bonding is automatically performed by the machine.

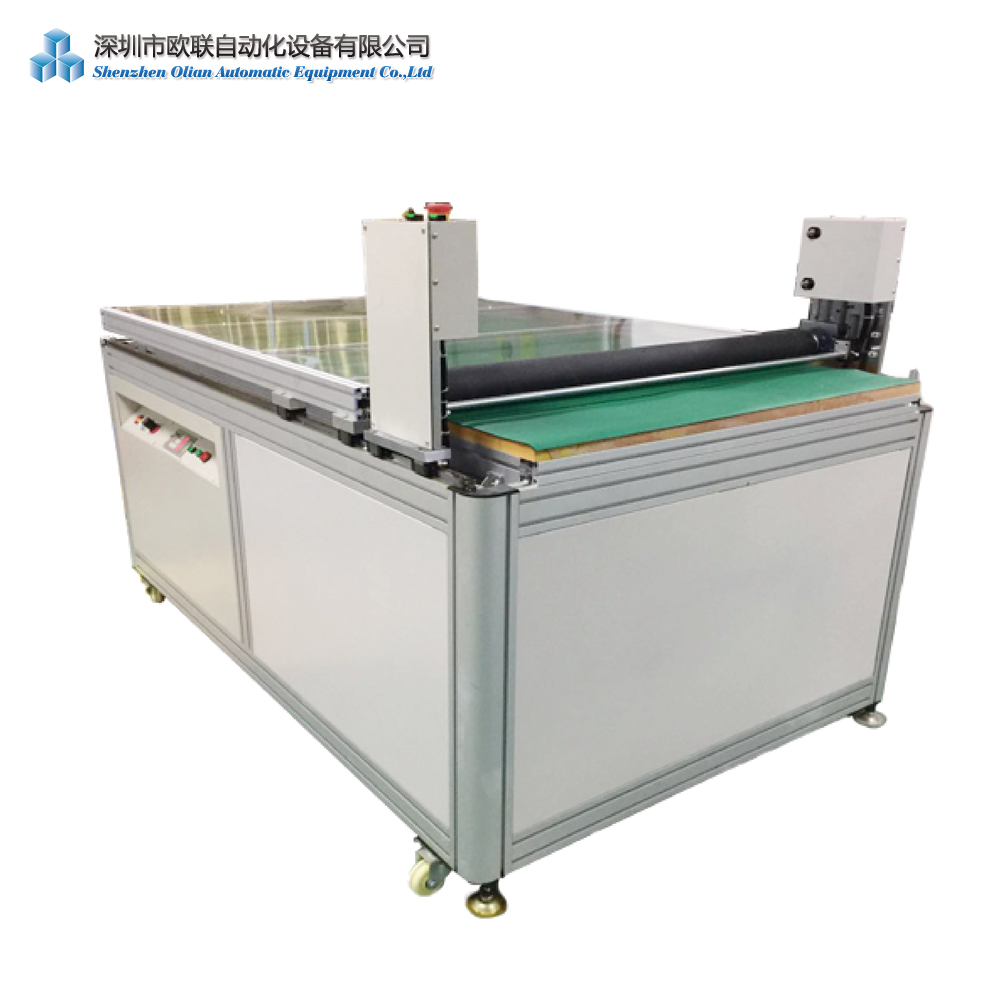

Top-Bottom Alignment Bonding Machine: Top-bottom alignment bonding machines are used to bond FPC/Zebra paper on the PCB/Glass with the ACF attached. The pick and place and alignment of the PCB/Panel are done manually, and the ACF bonding is done automatically. These machines are suitable for 1″ to 12″ flat glass and flexible screen products bonding.

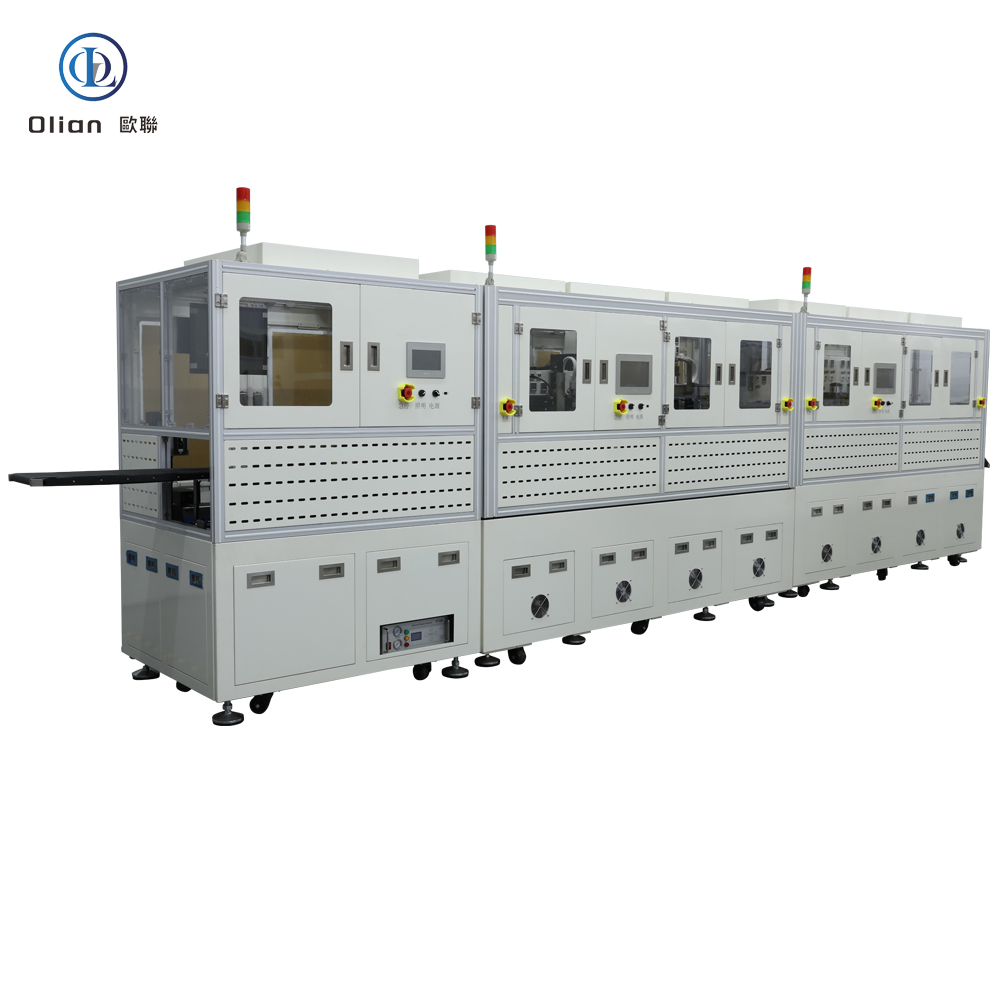

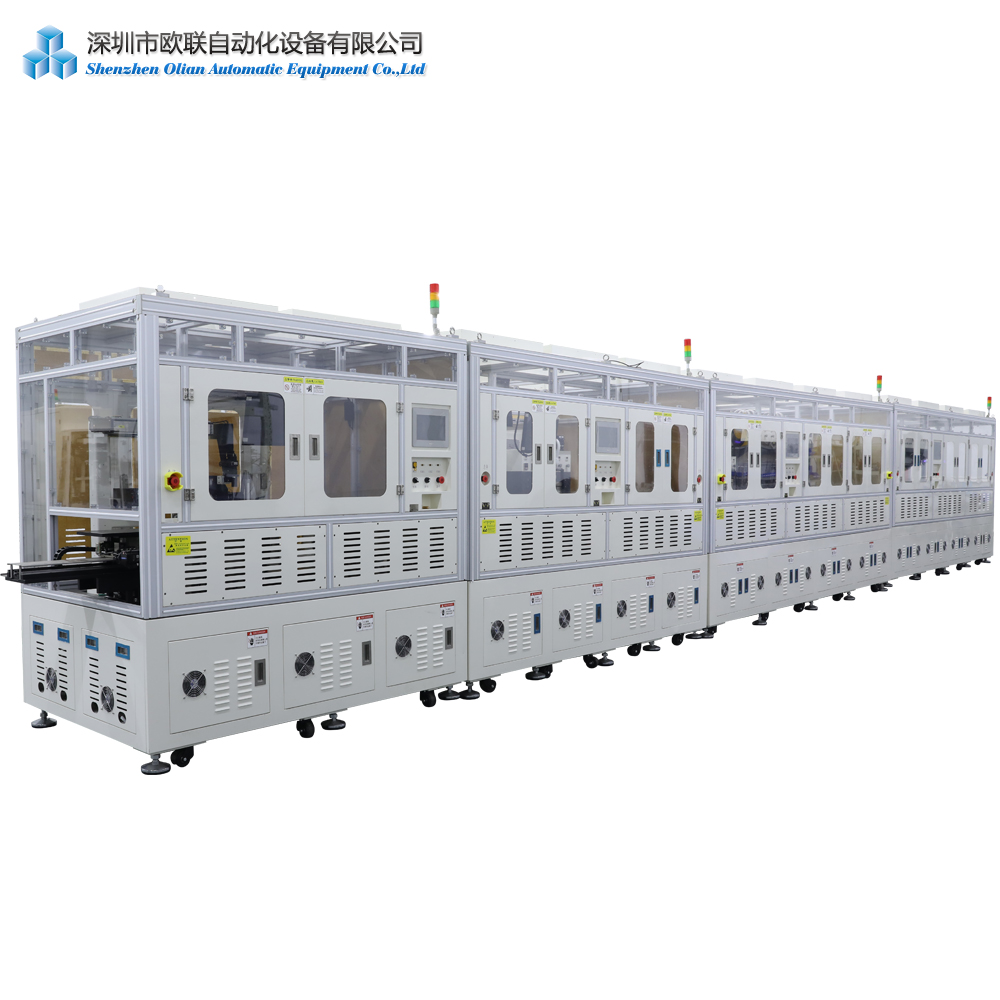

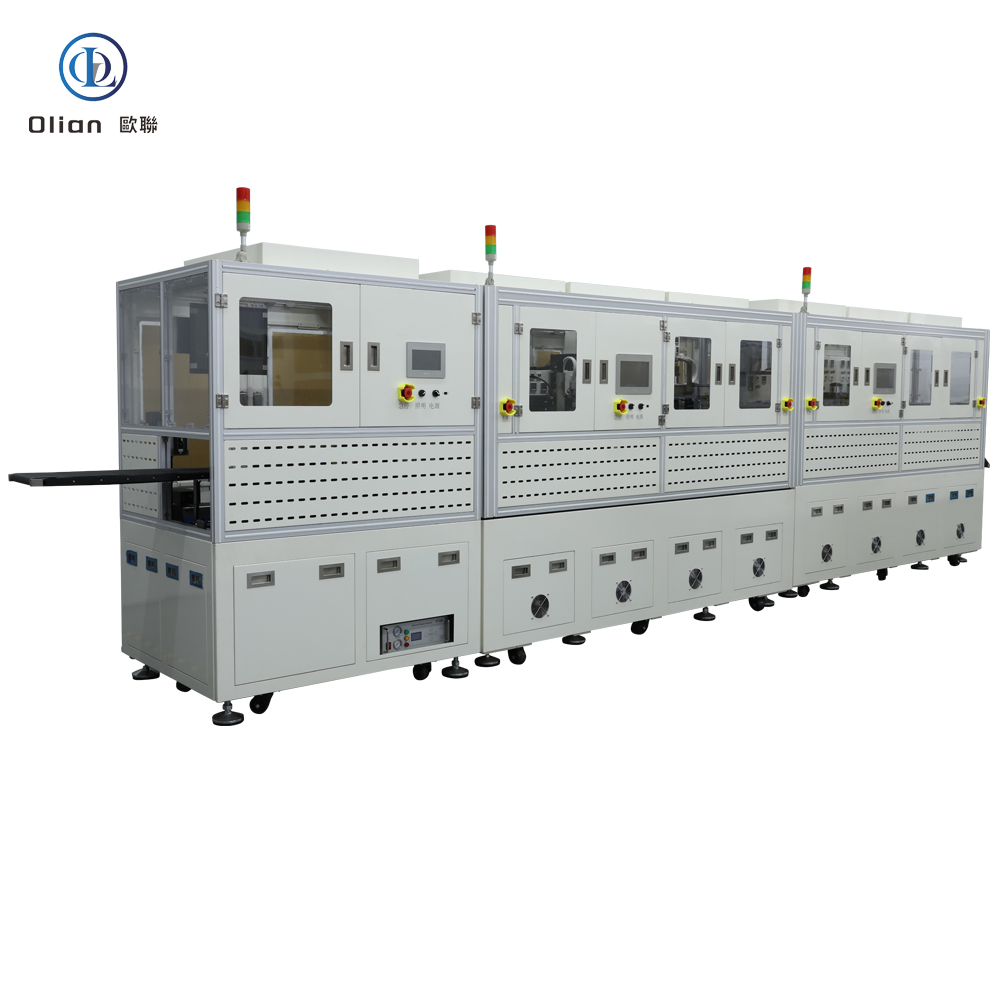

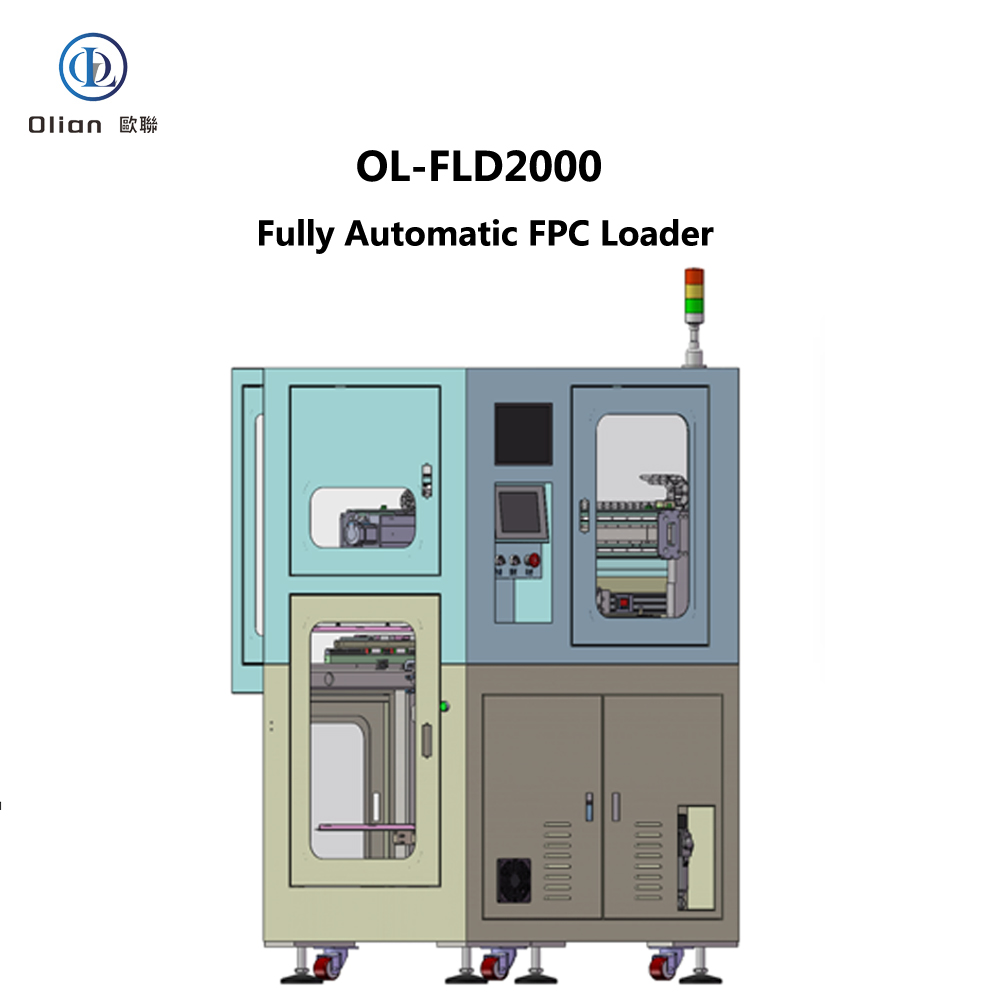

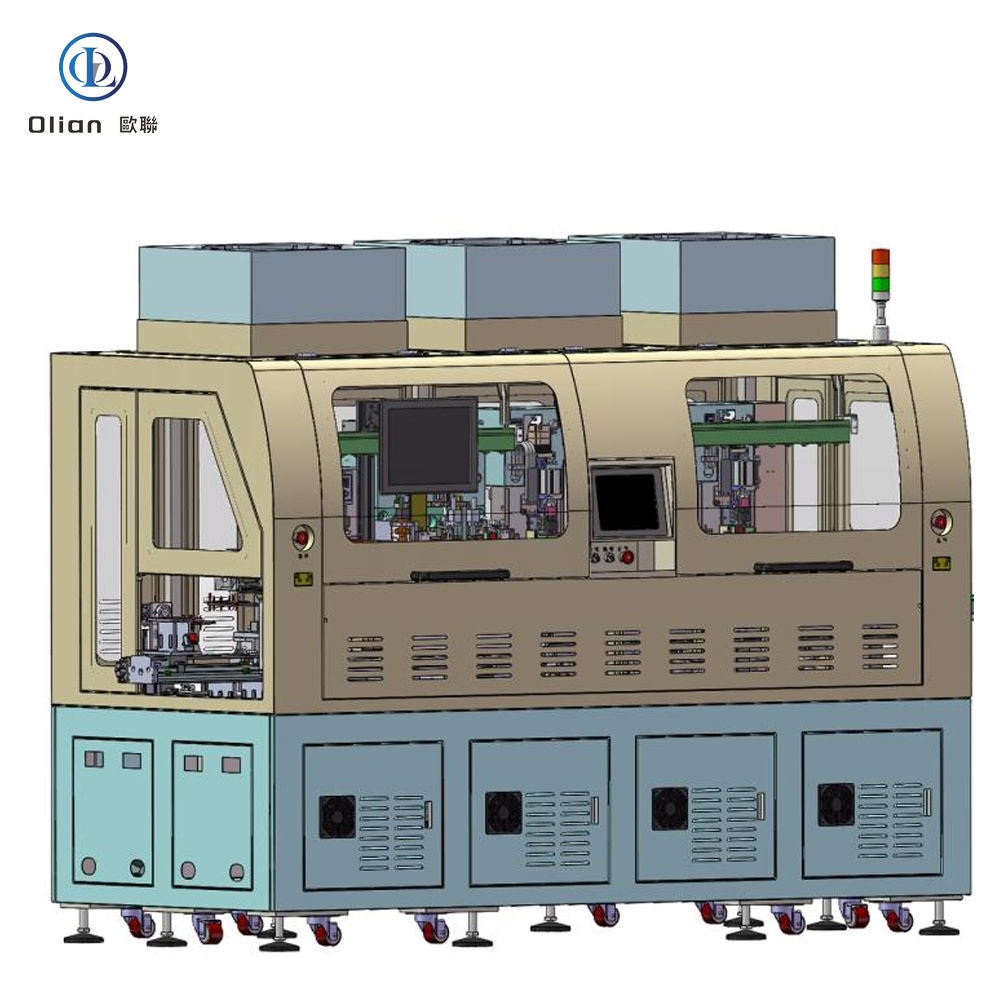

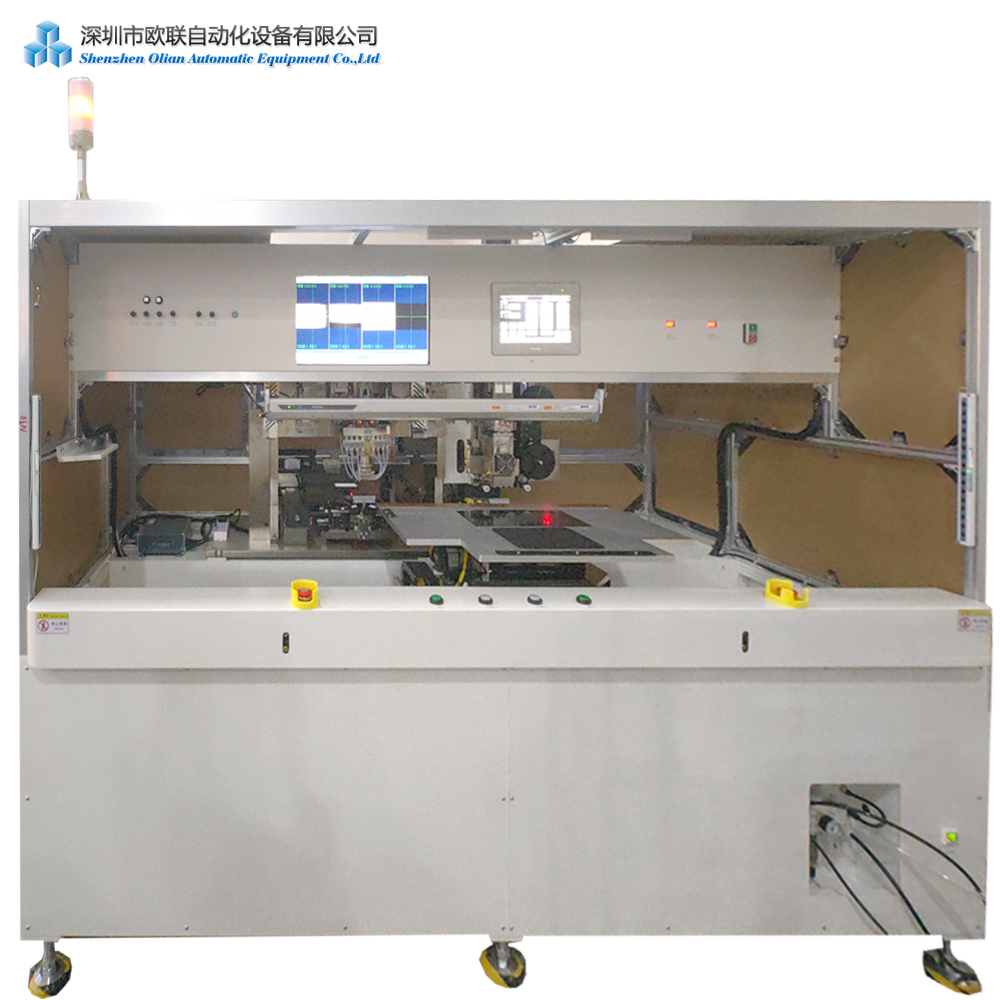

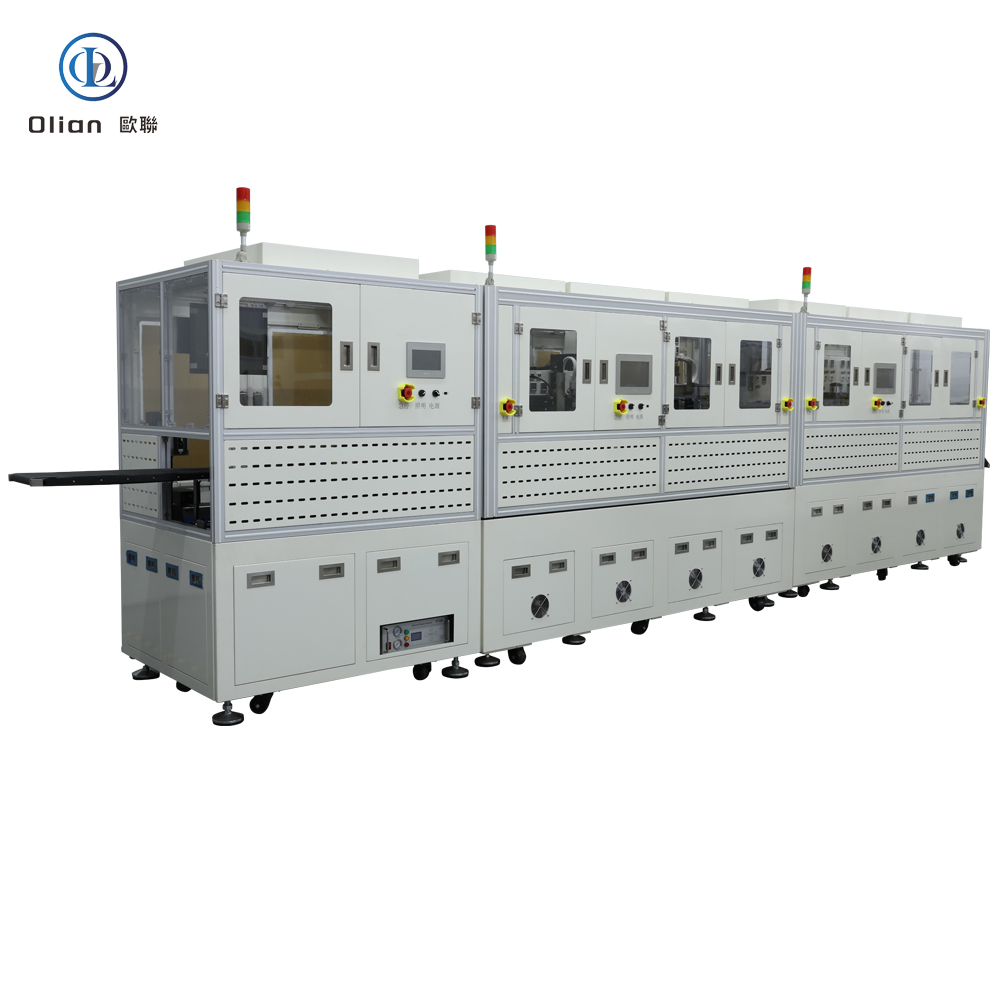

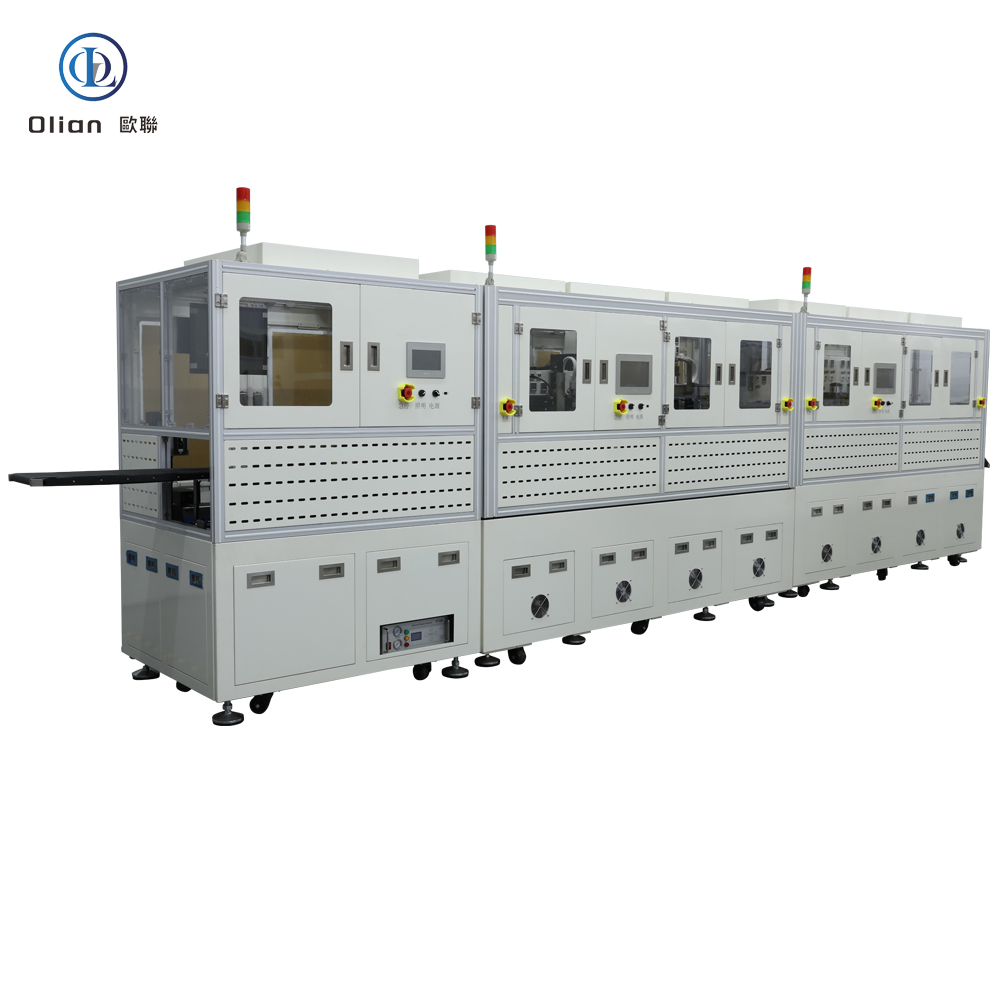

A fully automatic ACF bonding line includes multiple machines working together to automate the entire bonding process. This includes substrates loading machines, terminal cleaning machines, fully automatic COG/COF/COP bonding machines, and fully automatic COF punching machines.

In conclusion, the ACF bonding process relies on a suite of sophisticated testing machines and equipment to ensure the quality and reliability of the final products. Each type of testing equipment plays a critical role in different stages of the production process, from initial material inspection to final product testing. By using these machines, manufacturers can optimize their processes, reduce defects, and ensure that their products meet the highest standards of quality and performance.

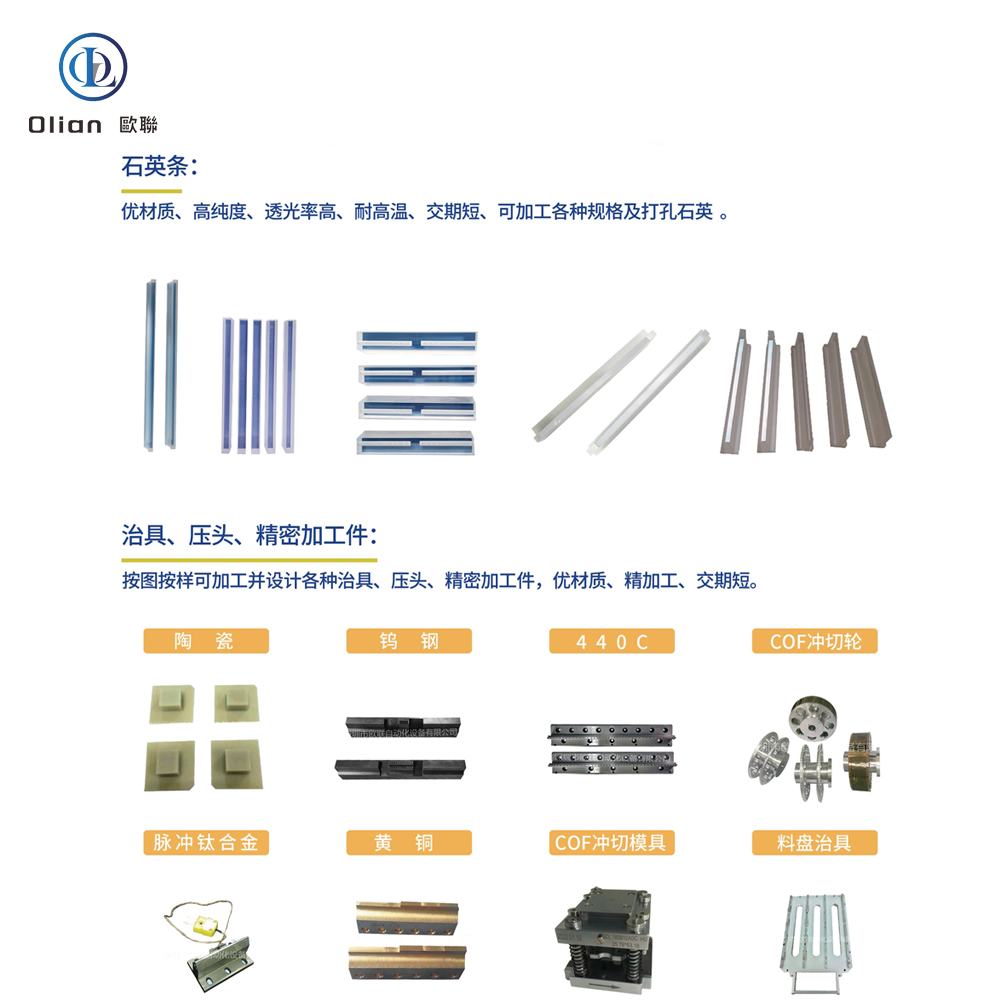

In the ACF (Anisotropic Conductive Film) bonding process, a variety of parts and accessories are used to ensure the quality and reliability of the final products. These components play a crucial role in the production line, from initial material preparation to final product testing. Here is a comprehensive overview of the parts and accessories used in ACF bonding processes:

ACF Tape is the core material used in the ACF bonding process. It is an epoxy adhesive system filled with conductive particles that provide electrical interconnection between pads through the film thickness (z-direction). The conductive particles are distributed far apart to ensure electrical insulation in the plane direction (X&Y) of the film. ACF tape is available in various models and is specific to the application for which it is designed. For example, ACF designed for flex-on-glass (FOG) assembly is usually not suitable for chip-on-glass (COG) or chip-on-film (COF) applications.

The Hot Bar or Thermode is the primary tool used to apply heat and pressure during the ACF bonding process. Hot bar bonding systems are designed to heat the hot bar to a specific temperature using low voltage electricity, which temperature is fed back to the controller via a thermocouple. The hot bar is brought into contact with the ACF film over the bonding pad, heated to the bonding temperature, and held for a specified time. This process produces the connection between the ACF tape and the components.

Bonding Heads are designed to hold the components and position the ACF tape correctly with the conductive pads on the PCB or other components. They ensure that the bonding process is accurate and consistent. Bonding heads can be manual or automated, depending on the specific requirements of the bonding process.

ACF Cutting Machines are used to cut the ACF tape to the required length and shape. These machines ensure that the ACF tape is accurately cut and positioned for the bonding process. The cutting is done using the half-cut method, where only the actual ACF material is cut, and the cover-layer is used for tape transport.

Pre-Bonding Machines are used to pre-bond ICs or COF on the panel that has been attached to the ACF. The pick and place of the panel is achieved manually, and the pre-alignment is automatically completed by the equipment.

Final Bonding Machines perform the main bonding on the LCD glass with IC, cable, or COF pre-pressed. The operator manually loads and unloads the products, while the ACF bonding is automatically performed by the machine.

Top-Bottom Alignment Bonding Machines are used to bond FPC/Zebra paper on the PCB/Glass with the ACF attached. The pick and place and alignment of the PCB/Panel are done manually, and the ACF bonding is done automatically. These machines are suitable for 1″ to 12″ flat glass and flexible screen products bonding.

A Fully Automatic ACF Bonding Line includes multiple machines working together to automate the entire bonding process. This includes substrates loading machines, terminal cleaning machines, fully automatic COG/COF/COP bonding machines, and fully automatic COF punching machines.

Testing and Inspection Equipment is used to ensure the quality and reliability of the bonded products. This includes microscopes for surface inspection, temperature and pressure testers, and environmental testing chambers to simulate various conditions.

ACF bonding is widely used in various industries, including mobile phone manufacturing, automotive, LCD production, mobile computers, TV manufacturing, open cell panels, touch panels, smart watches, and pads. It is also used in research labs focusing on LCD/LED/OLED/MICRO LED/MINI LED displays.

ACF bonding offers several benefits, including:

In conclusion, the ACF bonding process relies on a suite of sophisticated parts and accessories to ensure the quality and reliability of the final products. Each component plays a critical role in different stages of the production process, from initial material preparation to final product testing. By using these parts and accessories, manufacturers can optimize their processes, reduce defects, and ensure that their products meet the highest standards of quality and performance.

FOG FOP FOF FOB T-FOG FPC Flex Cable Bonding Machine are essential in the manufacturing of electronic devices, particularly for attaching flexible printed circuits (FPCs) or flexible flat cables (FFCs) to various substrates. These machines ensure a seamless and robust connection between the flexible cable and the electronic components, playing a crucial role in the production of devices like smartphones, tablets, and automotive displays.

Flex cable bonding machines can be classified based on their specific applications and the type of bonding process they perform:

Flex cable bonding machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

Flex cable bonding machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, flex cable bonding technology continues to play a crucial role in the electronics industry.

Chip bonding machines are essential in the electronics manufacturing industry, particularly for attaching integrated circuits (ICs) to various substrates. These machines ensure a seamless and robust connection between the ICs and the substrates, playing a crucial role in the production of devices like smartphones, tablets, and automotive displays. The different types of chip bonding machines, including COG (Chip On Glass), COP (Chip On Plastic), COF (Chip On Film), and COB (Chip On Board), are designed to meet specific requirements and applications.

Chip bonding machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

Chip bonding machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, chip bonding technology continues to play a crucial role in the electronics industry.

Smart Wear LCD OLED Bonding Production Whole Line Solution

In the rapidly evolving field of smart wear technology, the production of LCD and OLED display modules requires a comprehensive and integrated approach to ensure high efficiency, quality control, and adaptability to market demands. Our Smart Wear LCD OLED Bonding Production Whole Line Solution is designed to meet these challenges by providing a seamless and intelligent manufacturing process.

Glass Loading (玻璃上料)

Automated Glass Loading: The process begins with the automated loading of glass substrates into the production line. This step ensures that the substrates are handled with precision and care, reducing the risk of damage.

Plasma Cleaning (等离子清洗)

High-Purity Cleaning: The glass substrates are cleaned using a plasma cleaning process to remove any contaminants. This step is crucial for ensuring a high-quality bond and reducing defects.

COG (Chip on Glass) and COF (Chip on Film) Bonding

Driver IC Attachment: COG and COF processes are used to attach driver ICs directly to the glass substrate (COG) or to a flexible film (COF) which is then bonded to the glass. These processes ensure a stable and reliable connection, enhancing the performance of the display.

FOG (Film on Glass) and FOF (Film on Film) Bonding

FPC Bonding: FOG and FOF processes involve bonding flexible printed circuits (FPCs) to the glass substrate or to other FPCs. This step is essential for connecting the display module to the mainboard and other components.

Impedance Testing (阻抗测试)

Quality Assurance: Impedance testing is performed to ensure that the electrical connections are stable and reliable. This step is crucial for identifying and correcting any electrical issues before proceeding to the next stage of production.

RT (Room Temperature Curing)

Adhesive Curing: Room temperature curing is used to set the adhesives used in the bonding processes. This ensures that the components are securely attached without the need for high-temperature processes that could damage sensitive materials.

AOI (Automated Optical Inspection)

Quality Control: AOI systems use high-resolution cameras to inspect the display modules for defects. This process ensures that only high-quality products proceed to the next stage of production.

Dispensing (点胶)

Adhesive Application: Precision dispensing machines apply adhesives to the components to ensure a strong bond. This step is crucial for the durability and reliability of the display modules.

Drying (晾干)

Adhesive Drying: After dispensing, the adhesives are allowed to dry under controlled conditions. This ensures that the components are securely bonded and the display modules are ready for further assembly.

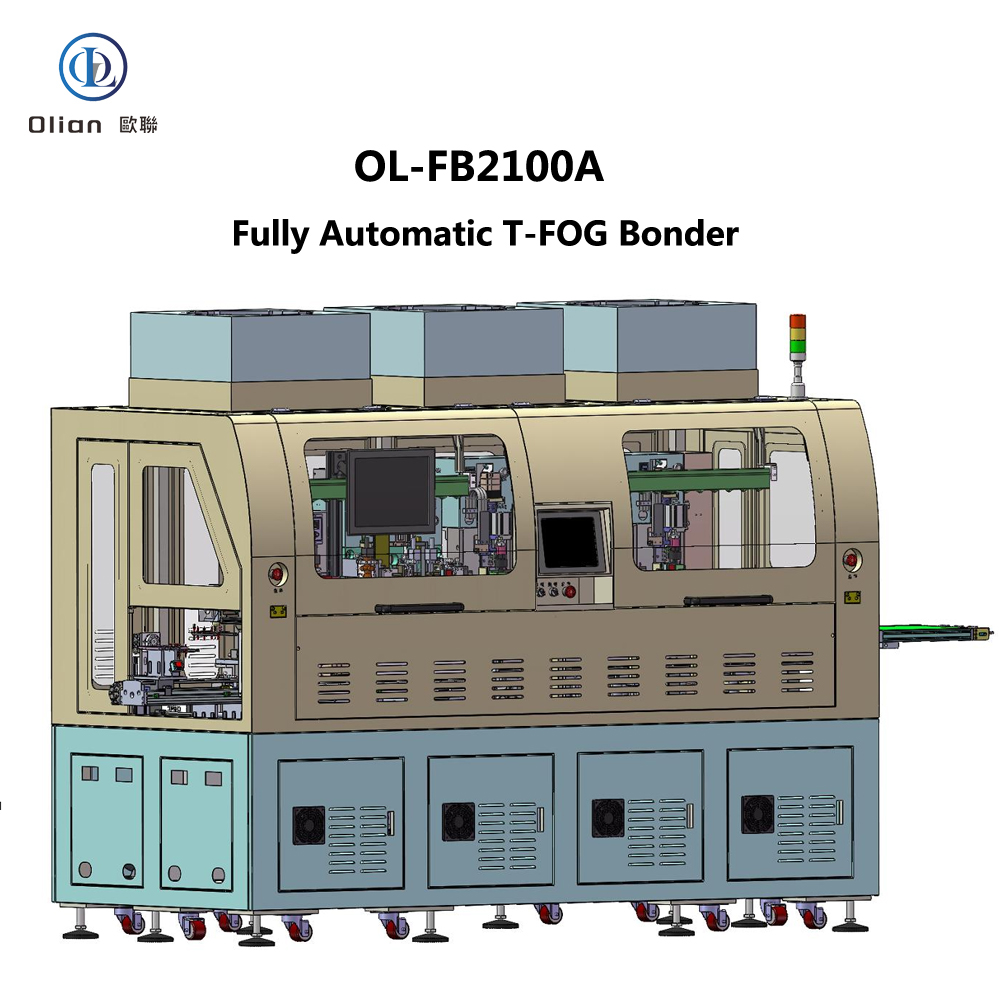

TFOG (Thermal Film on Glass)

Thermal Bonding: TFOG processes use heat to bond films to the glass substrate. This step is essential for creating a strong and durable bond, especially in high-stress applications.

Final Dispensing (点胶)

Sealing and Protection: Final dispensing of adhesives is used to seal and protect the display modules. This ensures that the modules are resistant to environmental factors such as dust and moisture.

Our Smart Wear LCD OLED Bonding Production Whole Line Solution is ideal for a wide range of smart wear devices, including:

These devices require high touch sensitivity, durability, and clear displays, making our solution particularly beneficial for these applications.

With our comprehensive Smart Wear LCD OLED Bonding Production Whole Line Solution, manufacturers can achieve high-quality, durable, and responsive displays in their smart wear devices. Our solution combines advanced manufacturing techniques, precision inspection systems, and customizable processes to meet the diverse needs of the smart wear market. By choosing our solution, you can ensure that your smart wear devices stand out in terms of performance and user experience.

Mobile Phones, Tablets, and Industrial Control Products Whole Line Solution for TFT Displays

In the highly competitive and rapidly evolving market of consumer electronics and industrial control systems, the production of TFT displays for mobile phones, tablets, and industrial control products requires a comprehensive and highly automated solution. Our Whole Line Solution for TFT displays is designed to meet the stringent demands of these sectors, ensuring high-quality, reliable, and efficient production processes.

Our Whole Line Solution for TFT displays is ideal for a wide range of products, including:

These devices require high touch sensitivity, durability, and clear displays, making our solution particularly beneficial for these applications.

With our comprehensive Whole Line Solution for TFT displays, manufacturers can achieve high-quality, durable, and responsive displays in their products. Our solution combines advanced manufacturing techniques, precision inspection systems, and customizable processes to meet the diverse needs of the market. By choosing our solution, you can ensure that your products stand out in terms of performance and user experience.