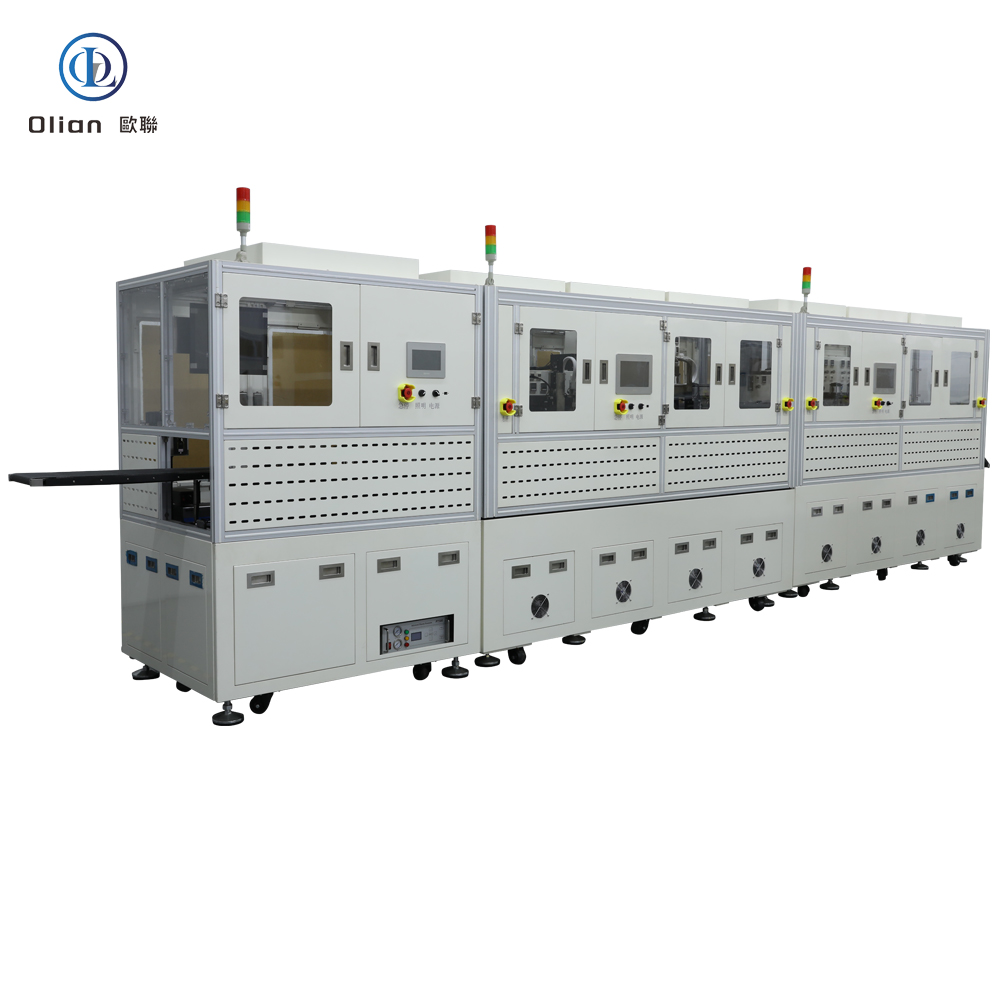

Fully automatic ACF (Anisotropic Conductive Film) bonding machine production line is a sophisticated system designed to streamline the process of bonding electronic components using ACF.

This technology is crucial in the manufacturing of various electronic devices, particularly those involving LCD panels, PCBs, and other high-density electronic assemblies.

Key Components and Features

The production line typically consists of several integrated modules, each responsible for a specific step in the bonding process:

- ACF Application Module: This module applies the ACF to the substrate. It ensures precise placement and alignment of the film, which is critical for achieving reliable electrical connections.

- Component Alignment Module: Before bonding, components such as FPCs (Flexible Printed Circuits) or ICs (Integrated Circuits) are accurately aligned with the ACF on the substrate. Advanced vision systems are often used to ensure high alignment accuracy.

- Bonding Module: The core of the production line, this module applies heat and pressure to the assembly, causing the ACF to bond the components to the substrate. The bonding process is carefully controlled to ensure optimal temperature and pressure profiles, which are crucial for the quality and reliability of the bond.

- Inspection Module: After bonding, the assembly is inspected to verify the quality of the bond. This can include visual inspection or more advanced techniques such as electrical testing to ensure that all connections are properly made.

Applications

The fully automatic ACF bonding machine production line is widely used in various industries, including:

- Consumer Electronics: For manufacturing LCD panels in smartphones, tablets, and TVs, where high precision and reliability are essential.

- Automotive Electronics: Used in the production of vehicle displays and other electronic components that require robust and reliable connections.

- Industrial and Medical Equipment: For creating high-performance displays and electronic systems used in industrial machinery and medical devices.

Market Analysis and Industry Trends

The market for ACF bonding machines is driven by the increasing demand for smaller, more efficient electronic devices. As technology continues to advance, the need for more precise and reliable bonding processes is growing

This has led to the development of more sophisticated and automated bonding machines that can handle higher production volumes and more complex assemblies.

Future trends in the industry include the integration of AI and machine learning technologies to further enhance the precision and efficiency of the bonding process.

Additionally, there is a growing focus on developing environmentally friendly materials and processes to reduce the environmental impact of electronic manufacturing

In summary, the fully automatic ACF bonding machine production line is a vital tool in modern electronics manufacturing.

It offers a high degree of precision, reliability, and efficiency, making it an essential component in the production of high-quality electronic devices.