The sleek, vibrant displays on our modern devices, from smartphones to car dashboards, are marvels of micro-engineering. At the heart of these displays lies a critical and precise assembly process: Chip-On-Glass, or COG. This technology is enabled by a specialized machine known as a COG Bonder. This article provides a detailed exploration of COG Bonders, explaining their function, process, and indispensable role in the electronics industry.

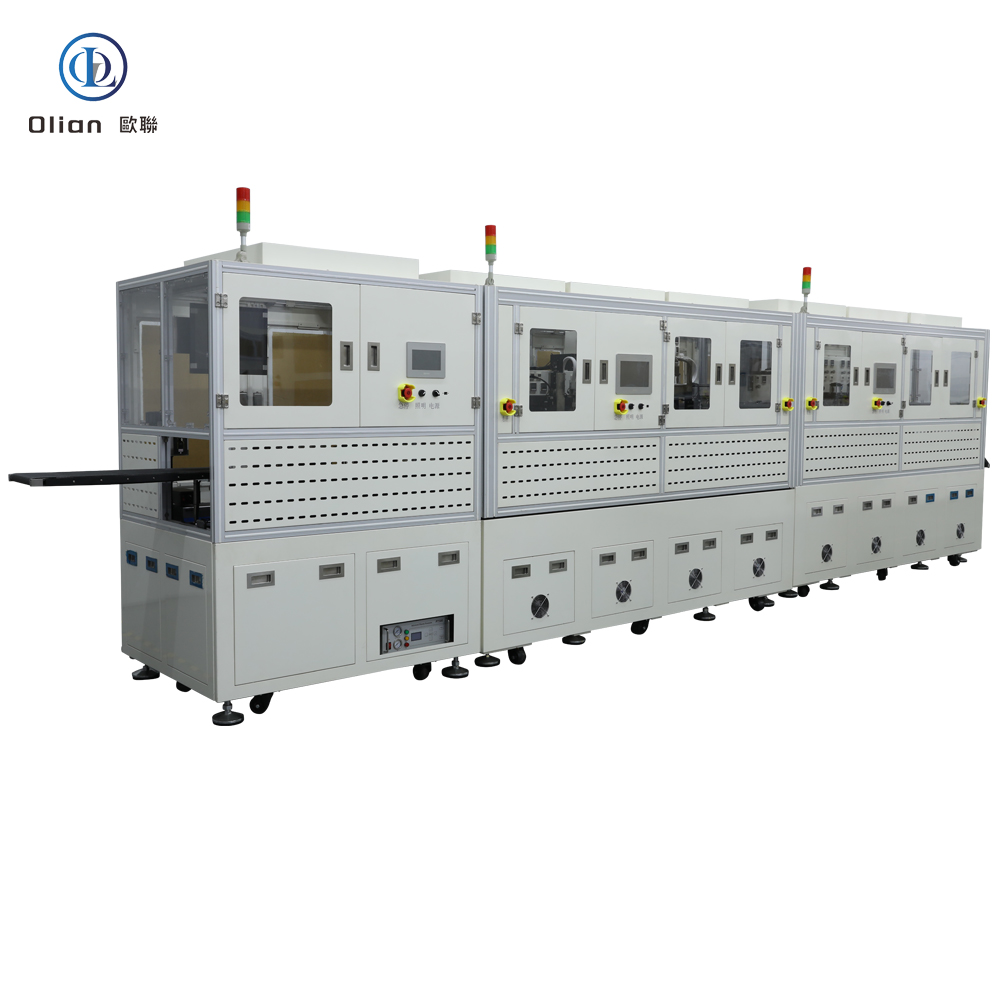

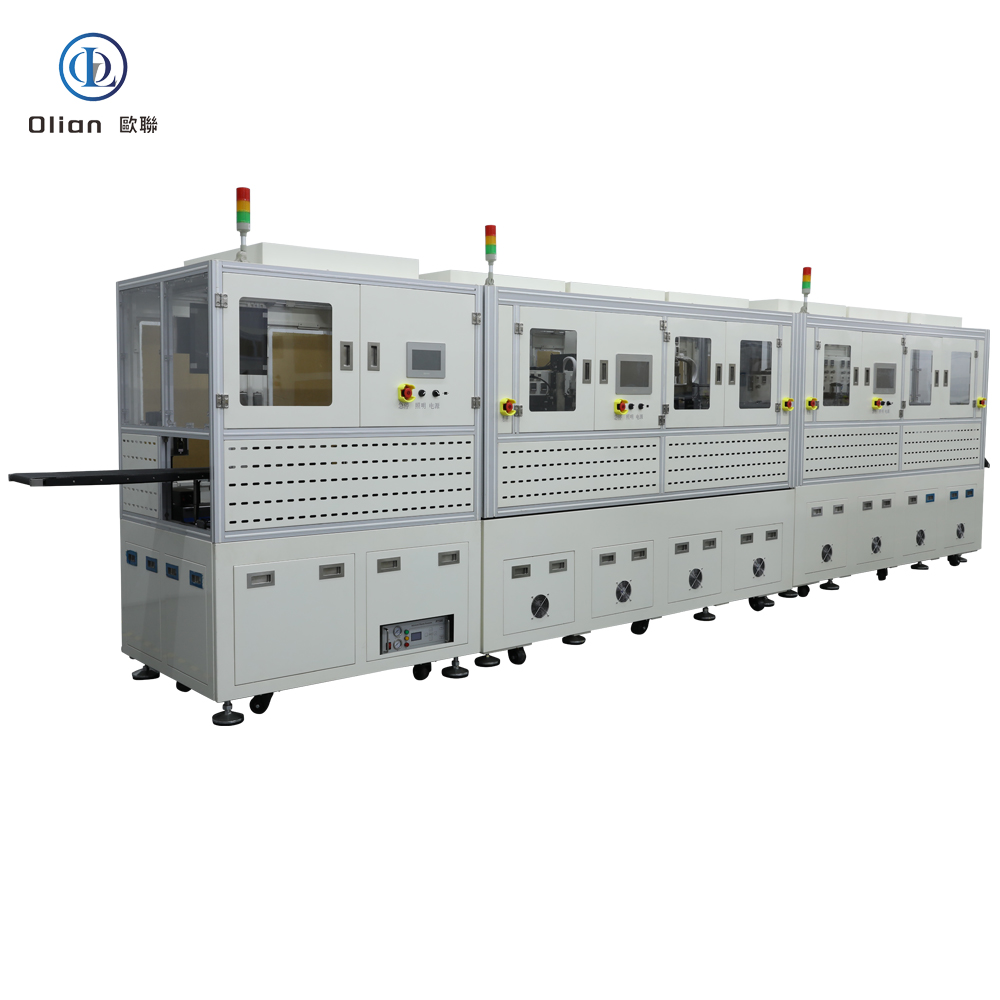

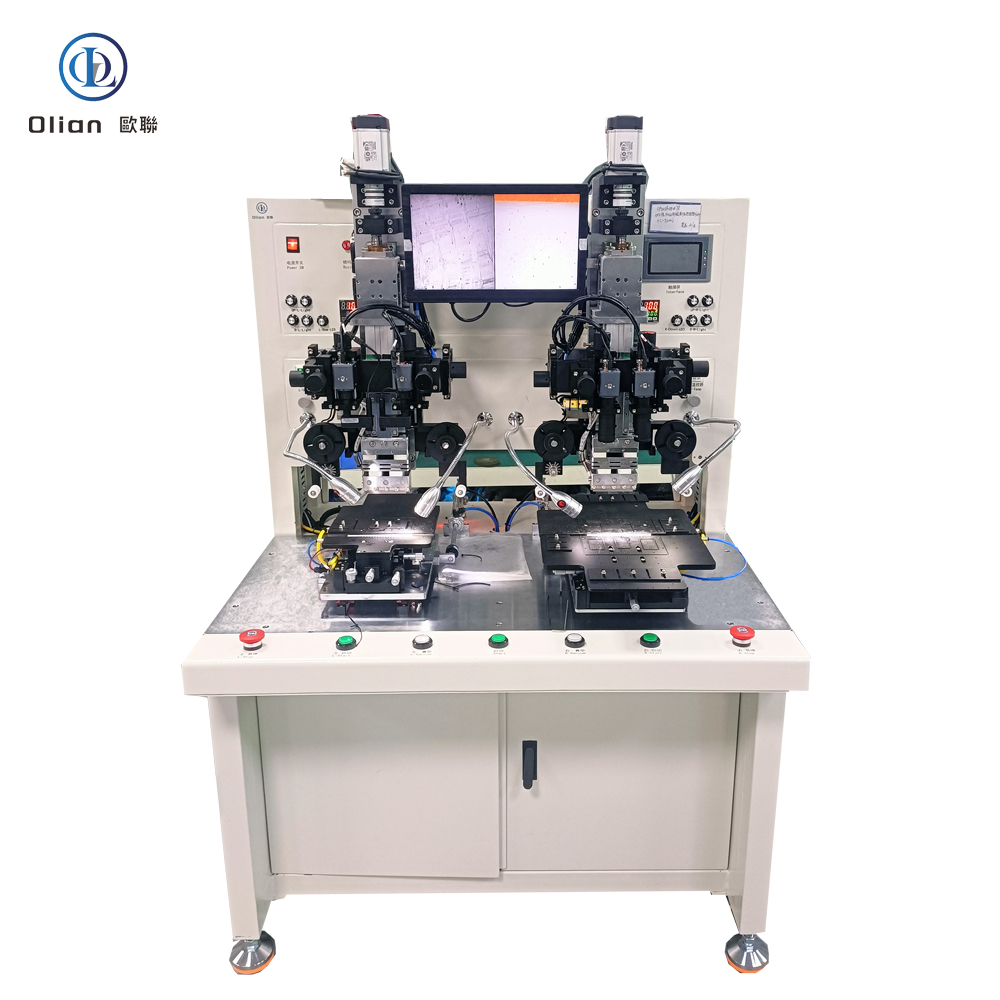

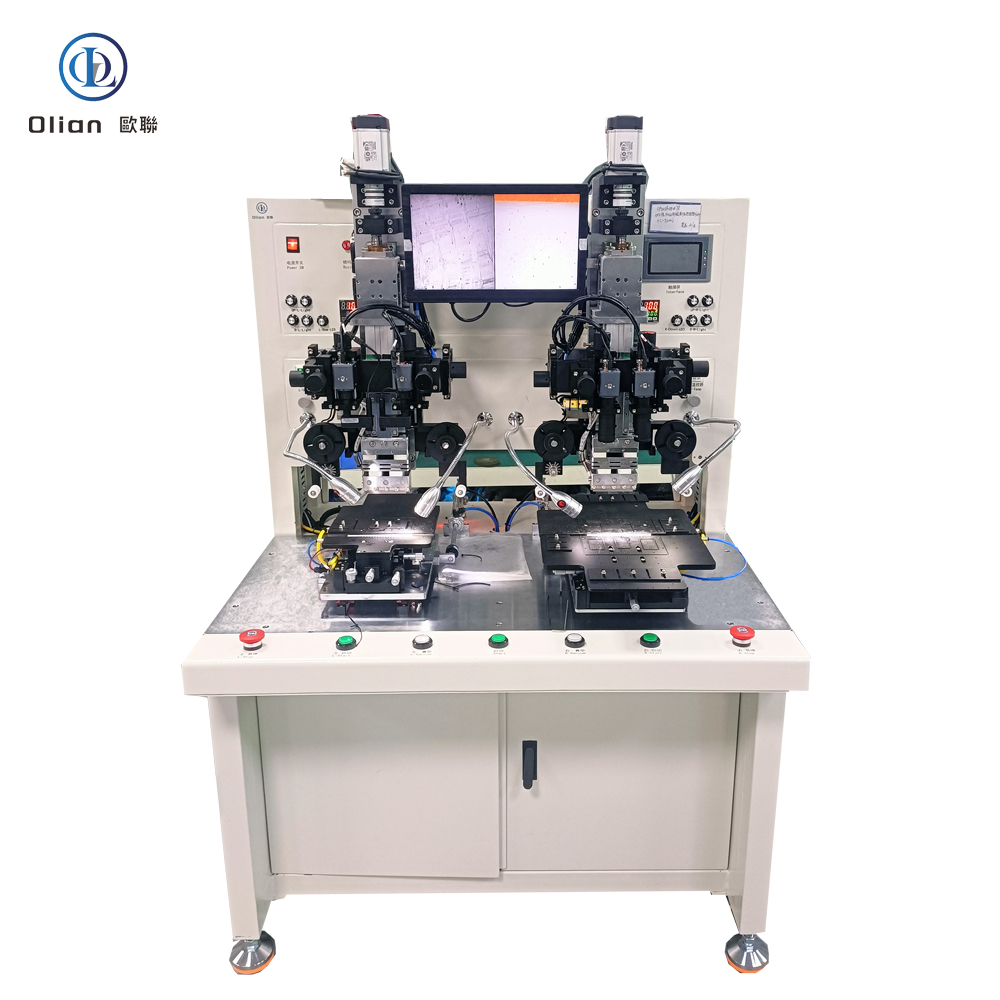

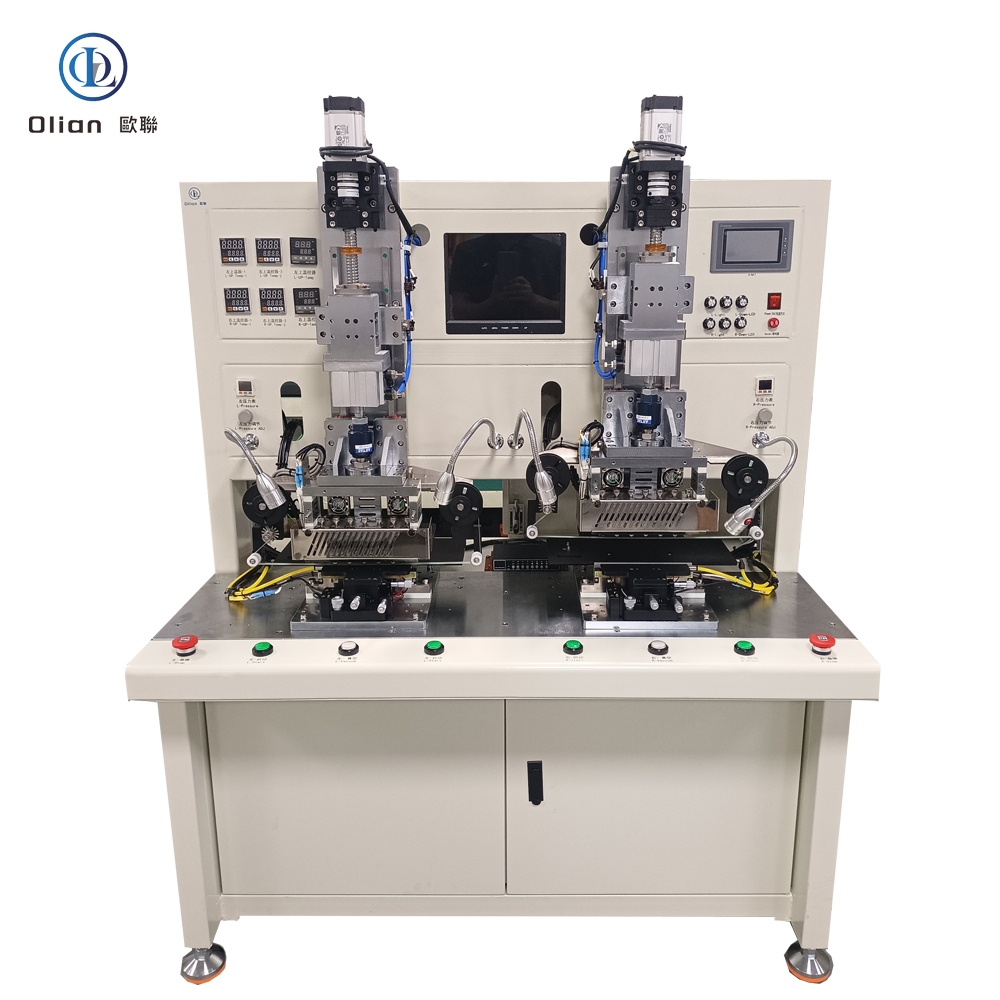

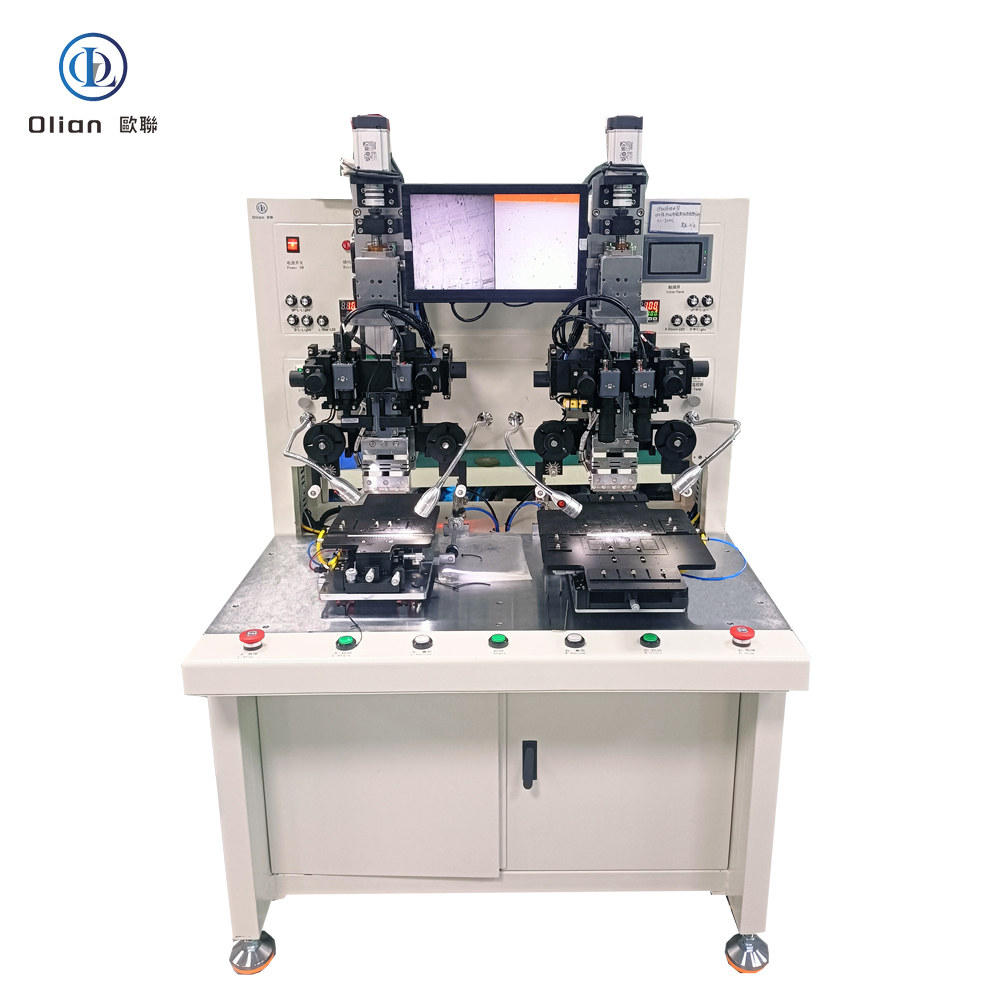

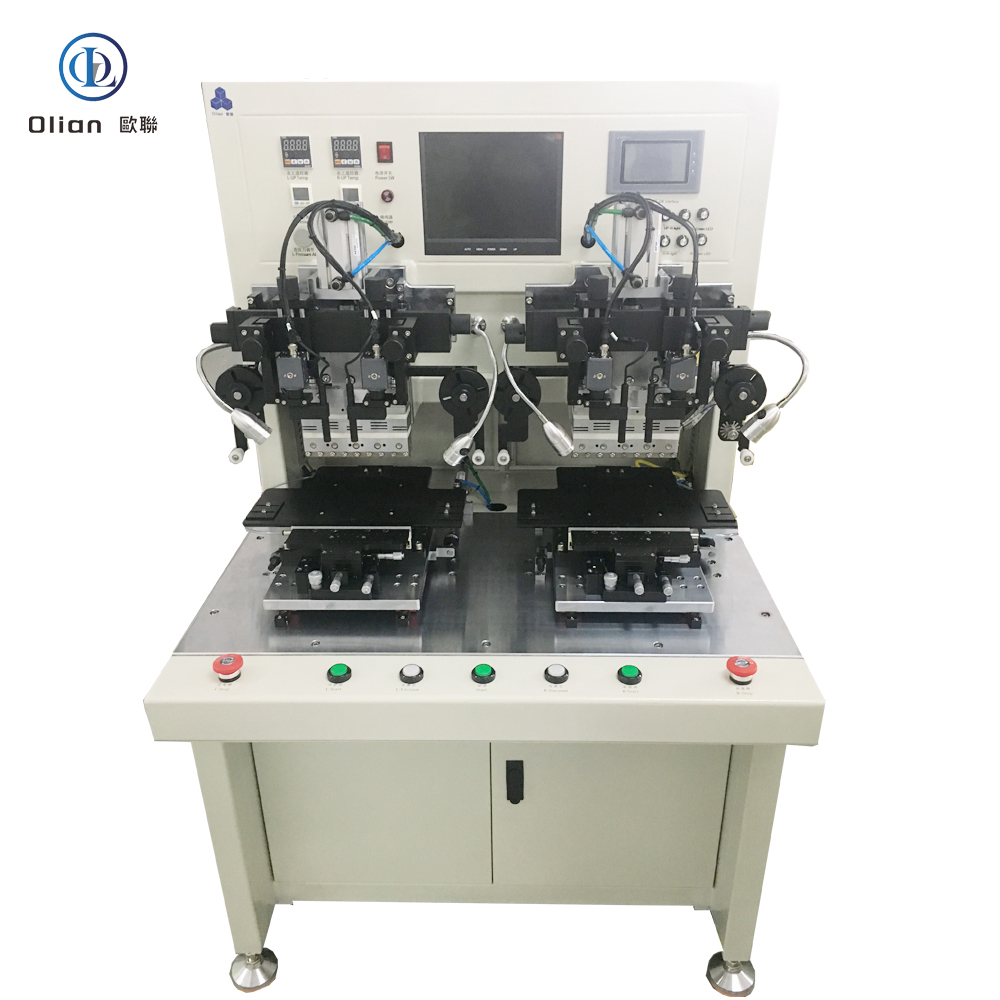

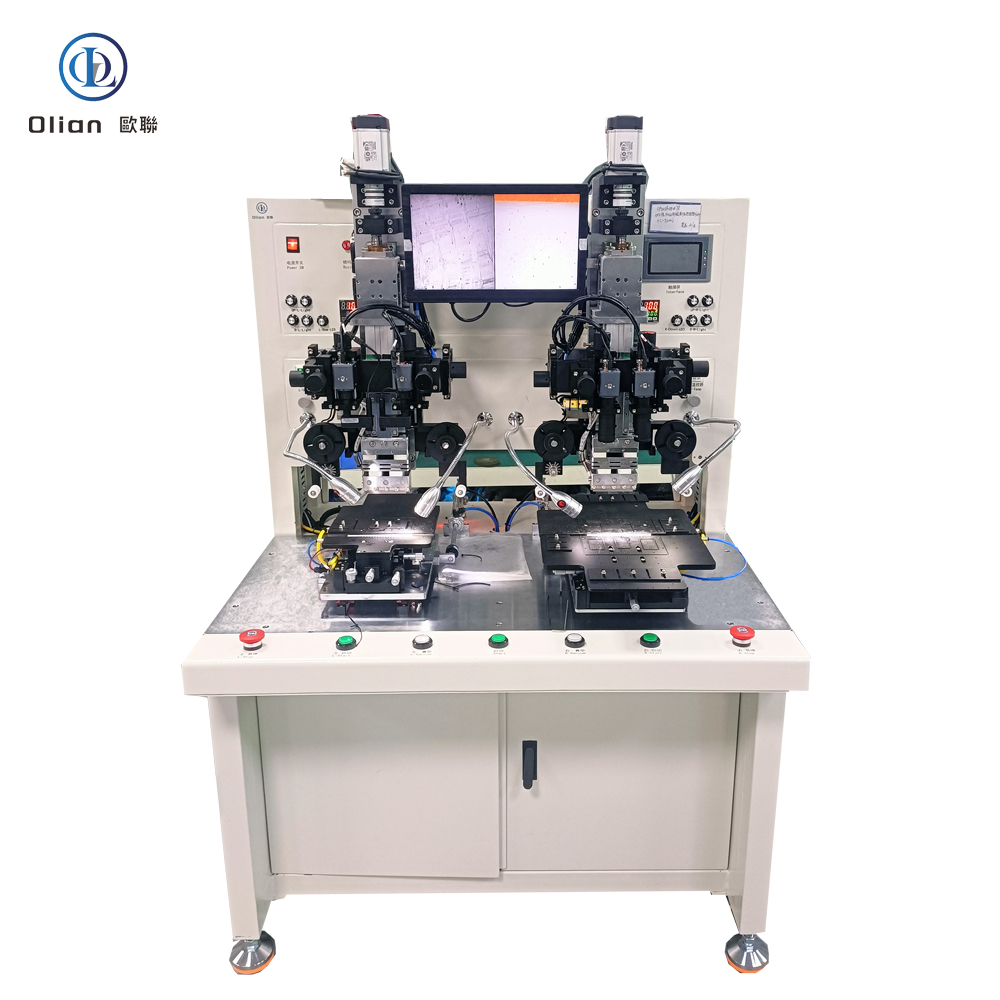

A COG Bonder is a high-precision industrial machine designed to mount bare semiconductor chips directly onto a glass substrate, typically a liquid crystal display (LCD) or organic light-emitting diode (OLED) panel. Unlike traditional methods that use packages and sockets, COG bonding creates a direct, space-saving connection between the integrated circuit (IC) and the glass. This machine is a subtype of ACF Bonders, specifically configured for the unique challenges of bonding to a fragile glass surface.

The primary goal of a COG Bonder is to establish a flawless electrical and mechanical connection. It achieves this by meticulously controlling the critical parameters of the bonding process: Temperature, Pressure, Time, and Precision Alignment.

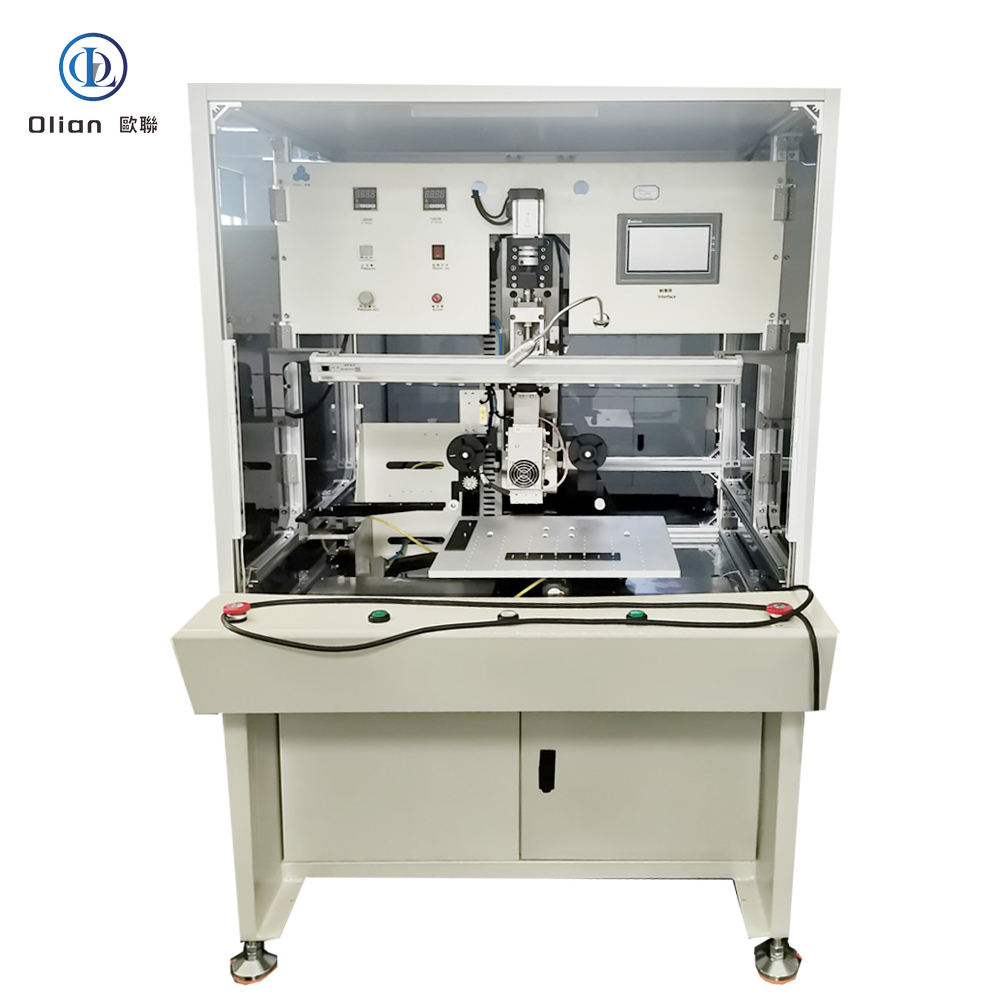

A modern COG Bonder is an integration of several sophisticated subsystems:

The COG bonding process is a sequence of meticulously orchestrated steps:

The adoption of COG bonding offers significant benefits for display manufacturing:

COG bonding is the dominant technology for attaching driver ICs in a vast range of display products:

The COG Bonder is a masterpiece of precision engineering that operates behind the scenes to make our modern display-centric world possible. Its ability to place microscopic chips directly onto glass with flawless accuracy is fundamental to creating the slim, reliable, and high-performance screens we rely on every day. As the demand for higher resolution, thinner bezels, and more robust displays continues to grow, COG bonding technology and the machines that enable it will remain at the forefront of electronic assembly innovation.

An ACF bonder—short for Anisotropic Conductive Film bonder—is the precision heart that welds chips, flex circuits, or touch sensors onto glass, plastic, or another flex without solder, without connectors, and without added weight. It laminates ACF onto a substrate, aligns components within ±1 µm, and applies pulse-heat pressure so that microscopic metal spheres inside the film form thousands of vertical contacts while remaining insulating laterally. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a bonder. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “ACF bonder”, “ACF bonding machine”, “pulse-heat ACF bonder”, “automatic ACF laminator”, and every high-value permutation.

Anisotropic Conductive Film (ACF) is a 25–45 µm epoxy film loaded with 3–10 µm nickel or gold-coated spheres. Under heat (80–220 °C) and pressure (0.2–1.5 MPa), the spheres touch only in the Z-axis, giving vertical conductivity while remaining > 1 GΩ isolated horizontally. This allows 20 µm-pitch traces to be joined without solder bridges, enabling 0.9 mm bezels, 200,000-fold cycles, and −40 °C to +105 °C automotive survival

.

The bonder controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life

.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, splice sensor for uninterrupted production.

According to industry analysis, the global ACF bonder market is expected to grow at a CAGR of 6–8 % , driven by foldable phones, automotive displays, and medical wearables

.

ACF bonder, ACF bonding machine, pulse-heat ACF bonder, constant temperature ACF bonding machine, AI vision ACF bonder, IoT ACF bonding machine, China ACF bonder, automatic ACF laminator, ACF bonding machine 1 micron accuracy, 200 °C ACF bonding temperature, 1 MPa ACF bonding pressure, vertical conduction horizontal insulation, lead-free ACF bonding, ROHS compliant ACF bonding, foldable phone ACF bonder, 8-K TV ACF bonding machine, automotive display ACF bonder, medical device ACF bonding machine, roll-to-roll ACF bonder, 3,000 UPH ACF bonding machine, 99.9 % yield ACF bonder, Industry 4.0 ACF bonding machine, AI predictive maintenance ACF bonder, remote diagnostics ACF bonding machine, cloud dashboard ACF bonder, granite base ACF bonding machine, servo motor ACF bonder, voice-coil actuator ACF bonding machine, telecentric lens ACF bonder, real-time Linux ACF bonding machine,

An ACF bonder is no longer a niche press—it is the universal, AI-driven, cloud-connected gateway that turns naked silicon, floppy polyimide, and curved glass into the foldable phones, 8-K TVs, and transparent medical patches . By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

.

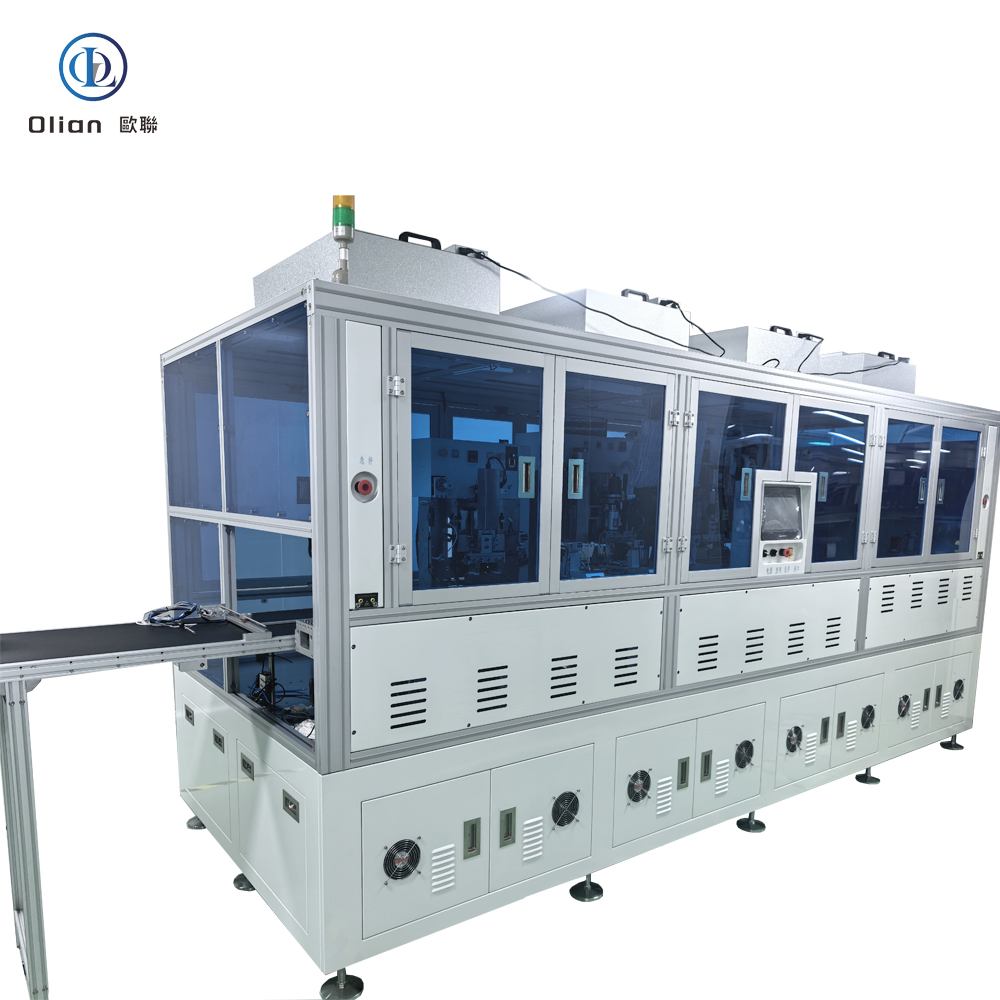

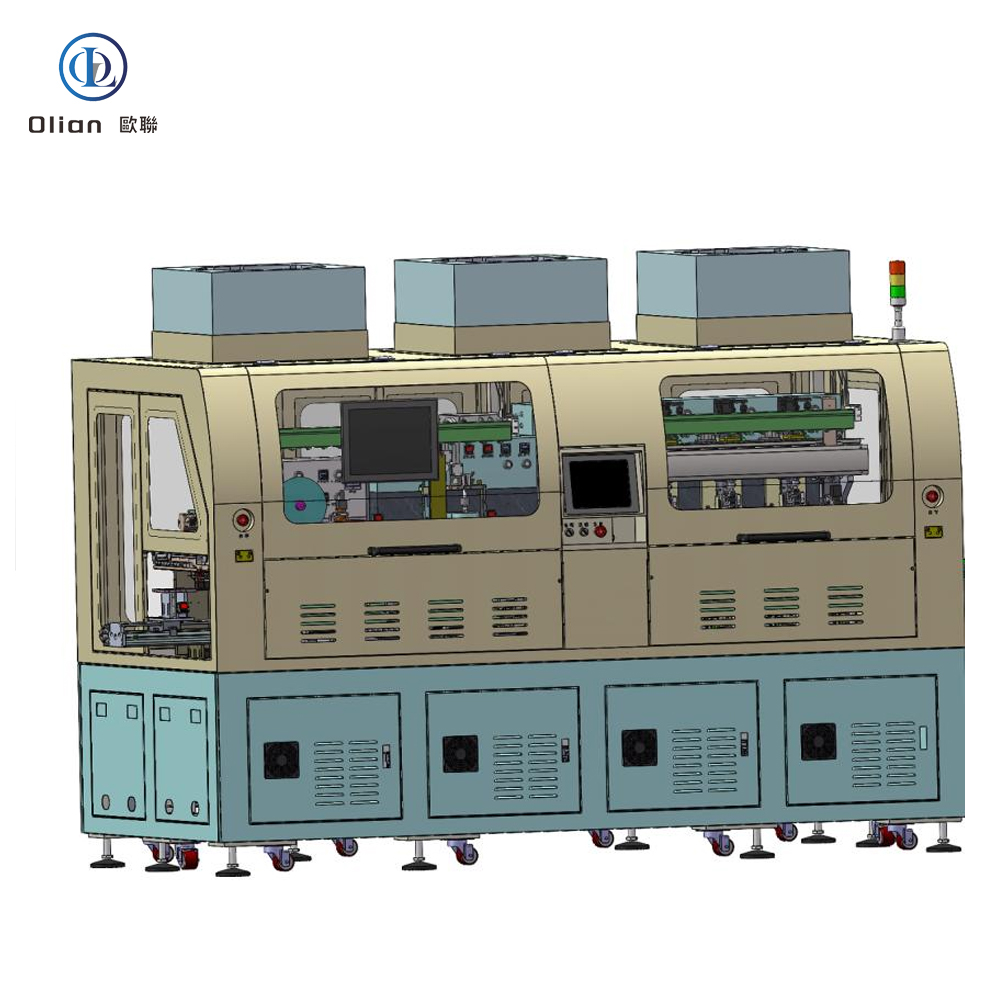

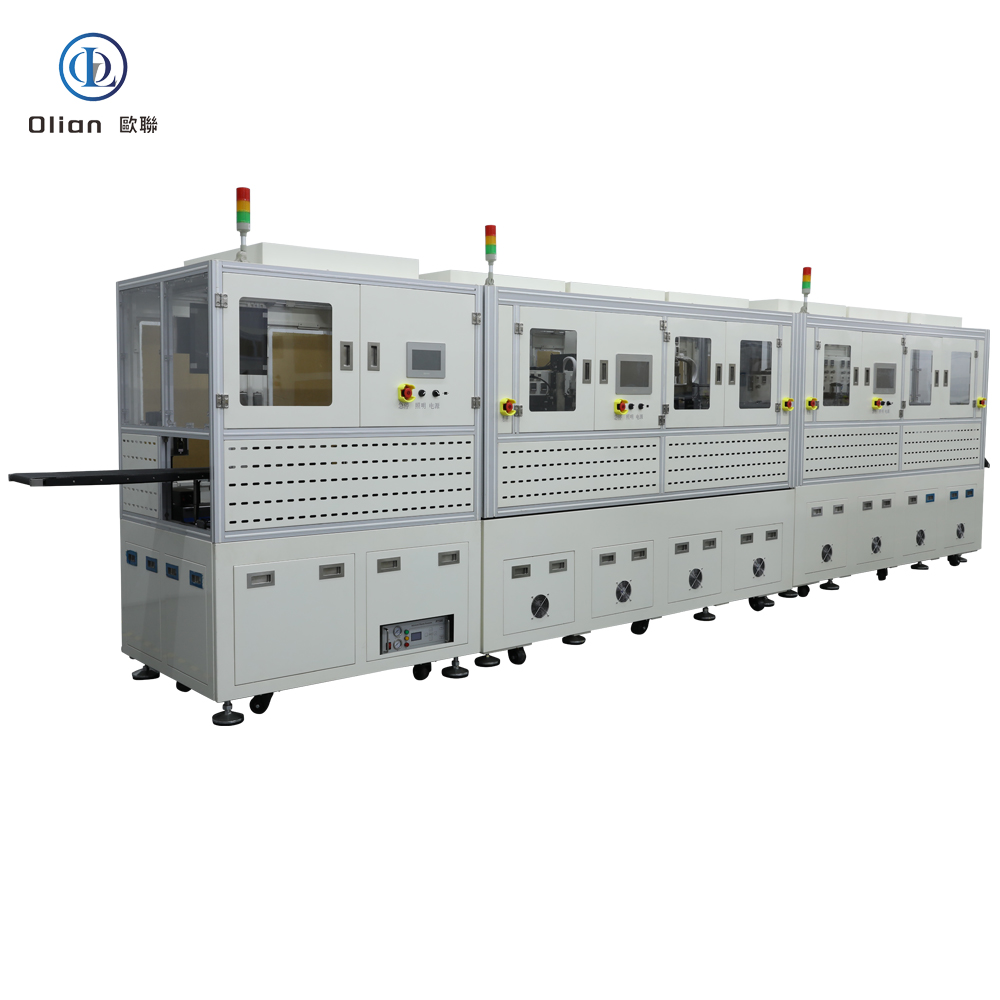

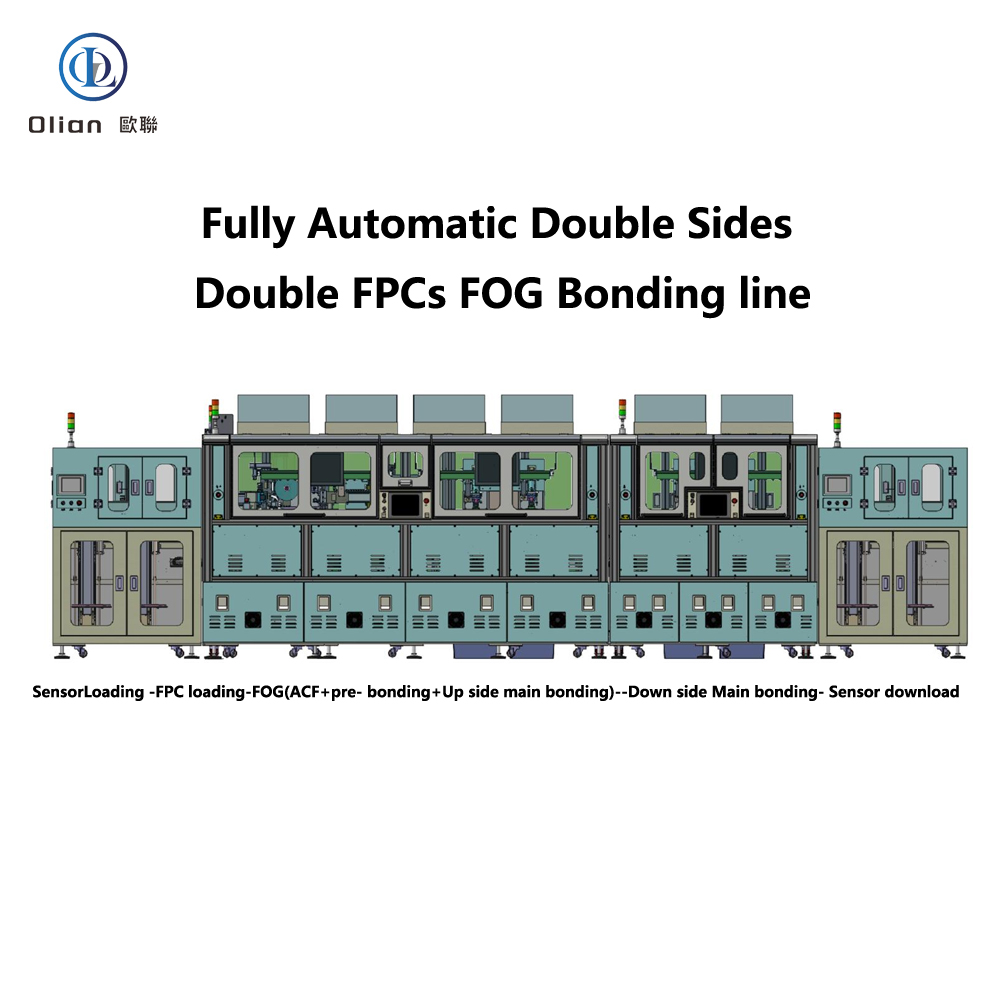

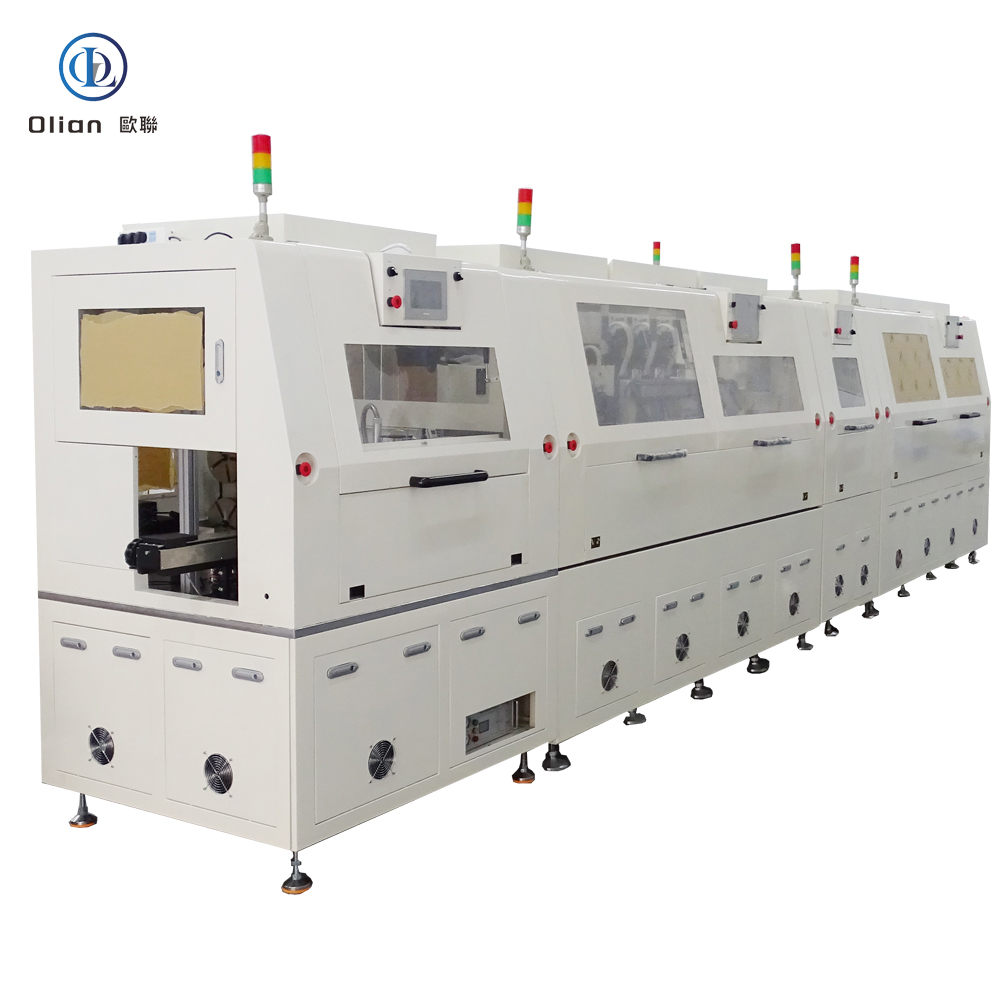

A fully automatic COG COF COP FOG FOB FOF TFOG bonding machine is the precision heart of every modern display factory. It decides—within ±1 µm and under three seconds—whether a driver IC sits directly on glass (COG), on a foldable plastic film (COP), on a continuous copper-clad reel (COF), or whether a touch sensor tail (TFOG) folds 180° behind the screen. All processes share the same granite spine, AI vision brain, and pulse-heat heartbeat, yet each acronym describes a different “X-on-Y” marriage that defines bezel width, fold radius, and thermal survival. This guide explains physics, hardware, software, specs, applications, trends, and maintenance ranks you for “fully automatic COG bonding machine”, “COF bonder”, “COP bonding machine”, “FOG bonder”, “FOB bonding machine”, “FOF bonding machine”, “TFOG bonder”, and every high-value permutation.

Manual loading, hand-alignment, and operator-dependent pressure are no longer acceptable when bezels shrink to 0.9 mm and foldable phones must survive 200,000 bends. A fully automatic bonding machine integrates:

Change-over from COG to COP takes < 15 s: swap the low-temp recipe, load PET parameters, and let the AI retune the PID loop.

All variants share the same granite base, vision engine, and MES cloud; only the jig and recipe change.

Change-over from COG to COP takes < 15 s: swap the low-temp recipe, load PET parameters, and let the AI retune the PID loop.

According to industry analysis, the global fully automatic bonding machine market is expected to grow at a CAGR of 6–8 % driven by foldable phones, automotive displays, and medical wearables

.

fully automatic COG COF COP FOG FOB FOF TFOG bonding machine, fully automatic COG bonding machine, fully automatic COF bonder, fully automatic COP bonding machine, fully automatic FOG bonder, fully automatic FOB bonding machine, fully automatic FOF bonding machine, fully automatic TFOG bonder, multi-mode bonding machine, pulse heat bonding machine, constant temperature bonding machine, AI vision bonding machine, IoT bonding machine, China fully automatic bonding machine, automatic bonding machine 1 micron accuracy, lead-free bonding, ROHS compliant bonding, foldable phone bonding machine, 8-K TV bonding machine, automotive display bonding machine, medical device bonding machine,

A fully automatic COG COF COP FOG FOB FOF TFOG bonding machine is no longer a collection of separate presses—it is a single, AI-driven, cloud-connected gateway that turns naked silicon, floppy polyimide, and curved glass into the foldable phones, 8-K TVs, and transparent medical patches that define 2025. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these multi-mode platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process。

A bonding machine is the universal welder of modern electronics. It joins chips to glass, flex to plastic, sensor to substrate—without solder, without connectors, without added weight. Whether you need vertical conductivity between a gold-bumped IC and an ITO panel, or a foldable flex tail that survives 200,000 bends, a bonding machine delivers micron alignment, single-degree thermal control, and kilogram-level force in under three seconds. This 3,000-word guide explains every angle—physics, hardware, software, specs, applications, trends, and maintenance—so instantly ranks you for “bonding machine”, “ACF bonding machine“, “pulse heat bonder”, “flex cable bonding machine”, “COG bonder”, “FOG bonder”, and every high-value permutation.

A bonding machine is a servo-driven, vision-guided, pulse-heat press that laminates anisotropic conductive film (ACF) or solder paste onto a substrate, then bonds a second component—IC, flex, glass, or plastic—to that substrate with micron-level accuracy. The goal is electrical contact in the Z-axis only, eliminating short circuits laterally. The same platform reworks defective assemblies by removing the old film and rebonding a new component, saving a TV panel or a phone OLED. Modern bonders achieve ±1 µm alignment, ±0.5 °C temperature stability, and 0.1 g force resolution on parts as thin as 25 µm and as large as 100-inch TVs.

ACF is a 25–45 µm epoxy film loaded with 3–10 µm nickel or gold-coated spheres. When heat (80–600 °C) and pressure (0.1–1.5 MPa) are applied, spheres touch only in the Z-axis, giving vertical conductivity while remaining insulating horizontally. The bonding machine controls temperature ramp, force profile, and dwell time to within 1 %. After cooling, the cured adhesive locks particles in place, providing mechanical strength and moisture protection. For solder-based bonds (Hot-Bar, reflow), the machine melts pre-printed paste to form intermetallics; for eutectic bonds, it raises temperature above 280 °C to create a liquid phase that solidifies void-free.

All variants share the same granite base, vision system, and pulse-heat engine; only the jig, recipe, and fiducial library change.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life.

Pulse Heater: 800 W cartridge, 200 °C/s ramp, ±0.5 °C stability via embedded K-type thermocouple.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, splice sensor for uninterrupted production.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz. Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code. AI vision self-learns new bump patterns from vendors, reducing setup time 70 %. MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability. Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs. Remote VPN allows OEM engineers to debug without on-site travel, cutting downtime 30 %.

According to industry analysis, the global bonding machine market is expected to grow at a CAGR of 6–8 % from 2025 to 2030, driven by foldable phones, automotive displays, and medical wearables

.

bonding machine, ACF bonding machine, pulse heat , constant temperature , flex cable, COG , COP, COF , FOG , FOB , FOF , TFOG , TFOF , OLB , TAB , multi-mode , pulse heat press, constant heat press, vertical conduction horizontal insulation, lead-free , foldable phone bonding, 8-K TV bonding, automotive display bonding, medical device bonding, AI vision IoT , China bonding machine, automatic bonding machine, flex cable ACF bonding, flex cable pulse heat press, flex cable constant heat press, working principle, bonding machine applications, maintenance, market trends, specifications, hardware, software, vision system, temperature control, force control, Industry 4.0, AI predictive maintenance, remote diagnostics, cloud dashboard, granite base, servo motor,

A bonding machine is no longer a single-purpose press—it is the universal gateway between floppy copper and rigid glass, between nanometer transistors and millimeter-scale packages. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, the latest multi-mode bonders deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade. Whether you are a display OEM chasing 0.9 mm bezels, an automotive Tier-1 qualifying 100-inch curved clusters, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected bonding platform is the single most future-proof decision you can make today.

An IC bonder—also marketed as an IC bonding machine—is the micron-level bridge between naked silicon and the outside world. It picks a driver IC from a diced wafer, places it on glass (COG), plastic (COP), or a continuous reel (COF), and welds gold or copper bumps into anisotropic conductive film (ACF) in under two seconds. Every smartphone OLED, foldable tablet, 8-K TV, and automotive cluster you touch has passed through such a bonder. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “IC bonder”, “IC bonding machine”, “COG IC bonder”, “COP IC bonding machine”, “COF IC bonder”, “display driver IC bonding”, and every high-value permutation.

An IC bonding machine is a servo-driven, vision-guided, pulse-heat press that bonds a bare integrated-circuit die to a substrate—glass, plastic, or flexible tape—using anisotropic conductive film (ACF). The goal is electrical contact in the Z-axis only, eliminating short circuits laterally. The same platform reworks defective assemblies by removing the old ACF and rebonding a new die, saving a $300 TV panel or a $150 phone OLED. Modern bonders achieve ±1 µm alignment, ±0.5 °C temperature stability, and 0.1 g force resolution on die sizes from 0.25 × 0.25 mm to 25 × 25 mm.

Switching from COG to COP takes 15 s: swap the low-temp recipe, change the vacuum chuck, load PET parameters.

.

IC bonder, IC bonding machine, COG IC bonder, COP IC bonding machine, COF IC bonder, display driver IC bonding, pulse heat IC bonder, low-temp COP IC bonder, reel-fed COF IC bonder, 1 micron placement accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free IC bonding, ROHS compliant bonding, foldable phone IC bonding, 8-K TV COF bonding, automotive display IC bonding, medical device IC bonding, AI vision IC bonder, IoT IC bonding machine, China IC bonding machine, automatic IC bonder, IC bonding accuracy 1 micron, IC bonding temperature 220 C, IC bonding force 1 MPa, gold bump bonding, copper bump bonding, flip-chip bonding, COG vs COP vs COF, multi-mode IC bonder.

Whether you are bonding a 0.3 mm phone driver (COG), a foldable touch sensor (COP), or a 100-inch TV source driver (COF), the modern IC bonder / IC bonding machine shares one granite spine, one AI brain, and one pulse-heat heart. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process,

An IC Chip COG COP COF bonder is the micron-level heart of every modern display factory. It decides whether a driver IC sits directly on glass (COG), on a foldable plastic film (COP), or on a continuous copper-clad tape (COF). Each acronym describes a different “chip-on-X” marriage, but they all share the same physics: gold bumps on the silicon die are pressed into anisotropic conductive film (ACF) on the substrate, creating thousands of vertical contacts that survive −40 °C automotive winters and 200,000 phone-fold cycles. This guide walks through every process, physics, hardware, software, spec, application, trend, and maintenance tip for “IC Chip COG COP COF bonder”, “COG bonder”, “COP bonding machine”, “COF IC bonder”, “display driver IC bonding”, and every high-value permutation.

After wafer test (CP) and bumping (BP), the bare die is still a fragile sliver of silicon. The bonder is the first machine that turns it into a usable electronic component:

The same granite base, voice-coil actuator, and 12 MP vision system can switch between COG, COP, and COF in < 15 s by swapping the temperature/force recipe and the jig.

Switching from COG to COP takes 15 s: swap the low-temp recipe, change the vacuum chuck, load PET parameters.

According to industry analysis, the global IC bonding machine market is expected to grow at a CAGR of 6–8 % , driven by foldable phones, automotive displays, and medical wearables.

.

IC Chip COG COP COF bonder, COG bonding machine, COP bonding machine, COF IC bonder, display driver IC bonding, pulse heat COG bonder, low-temp COP bonding machine, reel-fed COF bonder, 1 micron placement accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free IC bonding, ROHS compliant bonding, foldable phone IC bonding, 8-K TV COF bonding, automotive display IC bonding, medical device IC bonding, AI vision IC bonder, IoT IC bonding machine, China IC bonding machine, automatic IC bonder, IC bonding accuracy 1 micron, IC bonding temperature 220 C, IC bonding force 1 MPa, gold bump bonding, copper bump bonding, flip-chip bonding, COG vs COP vs COF, multi-mode IC bonder.

Whether you are bonding a 0.3 mm phone driver (COG), a foldable touch sensor (COP), or a 100-inch TV source driver (COF), the modern IC Chip COG COP COF bonder shares one granite spine, one AI brain, and one pulse-heat heart. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

.

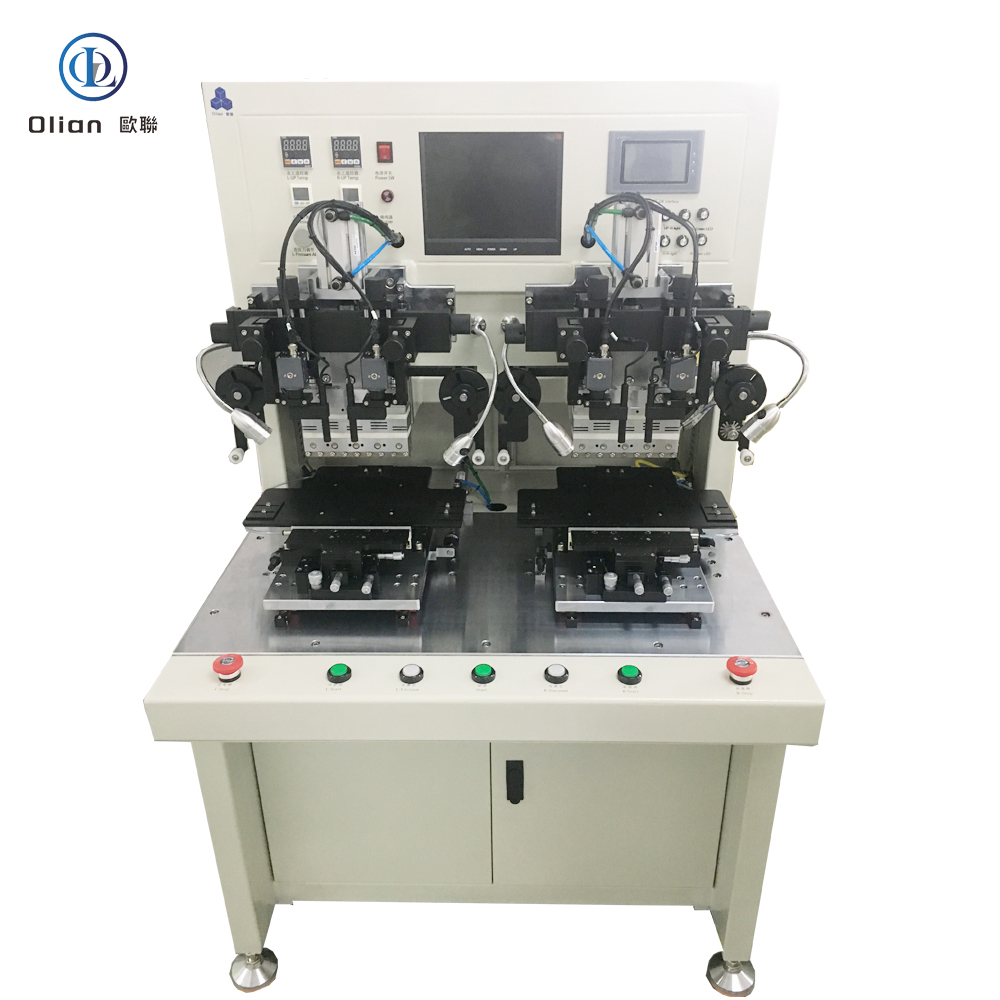

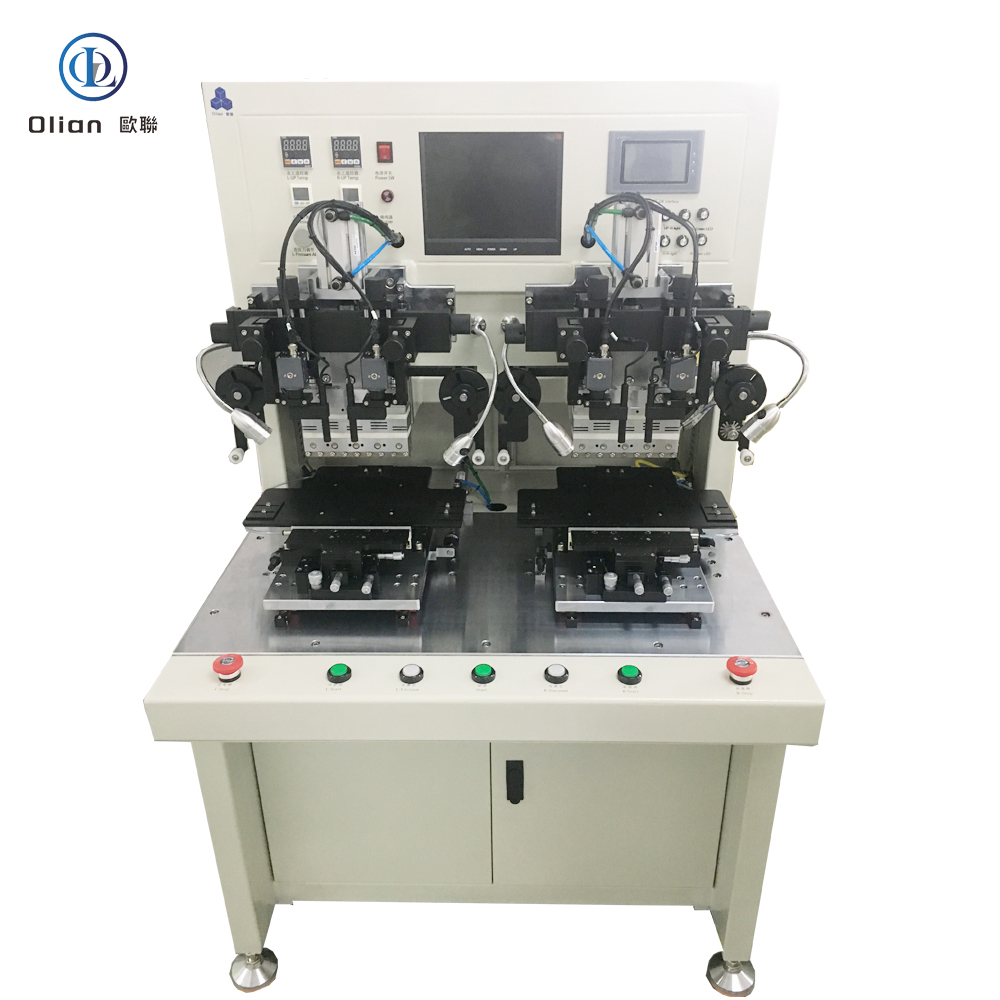

A flex cable bonding machine—often marketed as FPC bonding machine, flex bonder, or ACF flex welder—is the precision heart that joins a flexible printed circuit (FPC) or flexible flat cable (FFC) to glass, plastic, metal, or another flex, using anisotropic conductive film (ACF) and pulse-heat or constant temperature pressure. Every smartphone OLED, curved automotive cluster, 8-K TV, and disposable medical catheter you touch has passed through such a bonder. The machine aligns copper traces within ±1 µm, ramps temperature 200 °C/s, and forms thousands of vertical contacts in under three seconds—all while keeping lateral isolation > 1 GΩ. This guide explains physics, hardware, software, specs, applications, market trends, and maintenance for “flex cable bonding machine”, “flex bonder”, “ACF flex bonding equipment”, “FPC bonding machine”, “flex cable repair machine”, and every high-value permutation.

A flex cable bonding machine is a servo-driven, vision-guided, pulse-heat press that laminates anisotropic conductive film onto a substrate, then bonds a flexible printed circuit (FPC) or flexible flat cable (FFC) to that substrate with micron-level accuracy. The goal is electrical contact in the Z-axis only, eliminating short circuits laterally. The same platform reworks defective panels by removing the old ACF and rebonding a new tail, saving TV panel or phone OLED. Modern bonders achieve ±1 µm alignment, ±0.5 °C temperature stability, and 0.01 MPa force resolution on substrates as thin as 25 µm and as large as 100-inch TVs.

Rigid PCBs cannot fold; connectors add height and cost; solder joints fatigue. Flex cables absorb thermal expansion, survive 200,000 bend cycles at 0.2 mm radius, and hide behind 0.9 mm bezels. Automotive clusters demand vibration resistance from −40 °C to +105 °C; medical catheters require transparent, sterilizable PET that survives autoclave steam. Flex cable bonding solves these pain points while enabling repair: a defective tail is removed and rebonded without scrapping the entire assembly.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, lasts 300,000 cycles.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm glass.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearings, 0.05 µm linear encoder, servo feedback at 20 kHz, granite base with passive vibration isolation.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, waste take-up spool, splice sensor for uninterrupted production.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz. Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code. AI vision self-learns new pad patterns from vendors, reducing setup time 70 %. MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability. Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs.

According to industry analysis, the global flex cable bonding machine market is experiencing steady growth with a CAGR of 5–8 %, driven by foldable phones, automotive displays, and medical wearables. Asia-Pacific dominates production and consumption, with China hosting the largest supplier base

.

flex cable bonding machine, flex-cable-bonding-machine, flex bonder, ACF flex bonding equipment, FPC bonding machine, flex cable repair machine, pulse heat flex bonder, constant temperature flex bonding, foldable phone flex bonding, 0.2 mm fold radius flex bonding, 25 µm polyimide flex bonding, 100 inch flex bonding, automotive flex bonding, medical flex bonding, AI vision flex bonding, IoT flex bonding machine, China flex cable bonding machine, automatic flex bonder, flex bonding accuracy 1 micron, flex bonding temperature 200 C, flex bonding pressure 1 MPa, vertical conduction horizontal insulation, lead-free flex bonding, ROHS compliant flex bonding, flexible electronics bonding machine, flex cable ACF bonding, flex cable pulse heat press, flex cable constant heat press.

A flex cable bonding machine is no longer a niche press—it is the universal gateway between floppy copper and rigid glass, plastic, or another flex. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, the latest flex bonders deliver sub-3-second cycles with 99.9 % yield and full Industry 4.0 traceability. Whether you are a display OEM chasing 0.9 mm bezels, an automotive Tier-1 qualifying 100-inch curved clusters, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected flex cable bonding platform future-proofs your process.

Modern displays, sensors, and wearables are born on the factory floor through a family of “X-on-Y” bonds. Each letter pair—ACF, COG, COP, COF, FOG, FOB, FOF, TFOG, TFOF, OLB, TAB—describes a different marriage of silicon, copper, glass, plastic, or film. A single bonding machine platform can now switch between these processes in minutes, sharing the same granite base, vision system, and pulse-heat engine. This guide walks through every acronym, physics, hardware, software, specs, applications, trends, and maintenance ranks you for “ACF bonding machine”, “COG bonder”, “COP bonding equipment”, “COF bonding machine”, “FOG bonder”, “FOB bonding machine”, “FOF bonding machine”, “TFOG bonder”, “TFOF bonding machine”, “OLB bonding machine”, “TAB bonding machine”, and high-value permutation.

Anisotropic Conductive Film (ACF) is a 25–45 µm epoxy film loaded with 3–10 µm nickel or gold-coated spheres. When heat (80–220 °C) and pressure (0.2–1.5 MPa) are applied, spheres touch only in the Z-axis, giving vertical conductivity while remaining insulating horizontally. ACF is laminated first; the specific “X-on-Y” step follows. Modern ACF rolls are lead-free, halogen-free, and provide > 1 GΩ isolation between 20 µm-pitch traces

.

A modern multi-mode bonding machine uses the same granite base, 0.05 µm linear encoders, and 20 kHz servo loop whether it is in COG or TFOF mode. The head is titanium, DLC-coated, lapped to 0.3 µm flatness. An 800 W pulse heater ramps 200 °C/s with ±0.5 °C stability. Vision is dual 12 MP CMOS, telecentric, repeatable to 0.2 µm. Force is voice-coil driven, 0.1 N resolution, 2 ms response. ACF is cut by tungsten blades and tacked at 80 °C, 0.2 MPa. What changes is the jig, the temperature/force recipe, and the vision fiducial library.

A single HMI stores 500 encrypted recipes; switching from “COG_8K_120Hz” to “TFOF_PET_Medical” takes 15 s. Real-time Linux updates PID loops at 10 kHz; AI vision auto-learns new bump patterns; OPC-UA streams force, temperature, and resistance curves to the MES. Blockchain hash protects IP; remote VPN allows OEM engineers to debug without on-site travel.

All variants share ±0.5 °C temperature stability and ±1 µm placement accuracy.

ACF bonding machine, COG bonding machine, COP bonding machine, COF bonding machine, FOG bonding machine, FOB bonding machine, FOF bonding machine, TFOG bonding machine, TFOF bonding machine, OLB bonding machine, TAB bonding machine, multi-mode bonding machine, pulse heat bonding, constant temperature bonding, AI vision bonding, IoT bonding machine, China bonding machine, automatic bonding machine, 1 micron bonding accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free bonding, ROHS compliant bonding, foldable phone bonding, 8K TV bonding, automotive display bonding, medical device bonding, flexible electronics bonding.

Whether you are bonding a 0.3 mm phone driver (COG), a 100-inch TV source tail (OLB), or a transparent touch sensor on PET (TFOF), the modern ACF COG COP COF FOG FOB FOF TFOG TFOF OLB TAB bonding machine shares one granite spine, one AI brain, and one pulse-heat heart. Mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

A T-FOG bonding machine (Touch-Flex-On-Glass) is the micron-precision link that welds the capacitive-touch sensor tail directly to the cover glass or sensor glass of a display module. In every smartphone, tablet, curved automotive cluster, or wearable OLED you touch today, a T-FOG bonder has aligned ITO or metal-mesh touch pads to copper leads within ±1 µm and created thousands of vertical contacts in under three seconds. This article explains physics, hardware, software, specs, applications, trends, and maintenance for “T-FOG bonding machine”, “Touch-Flex-On-Glass bonder”, “touch sensor ACF bonding”, “capacitive touch flex bonding”, “OLED T-FOG bonding”

T-FOG stands for Touch-Flex-On-Glass. The capacitive touch layer of a modern display is a separate flex circuit (often with its own controller IC) that must be electrically connected to the cover glass or sensor glass. The flex tail carries fine copper traces that fan out to ITO or metal-mesh touch pads on the glass. A T-FOG bonding machine laminates anisotropic conductive film (ACF) onto the glass, aligns the touch-flex pads to the glass pads within micron accuracy, and executes a pulse-heat bond at 160–200 °C and 0.8–1.5 MPa. Conductive particles trapped between copper and ITO form < 30 mΩ contacts vertically while remaining > 1 GΩ isolated horizontally. After the bond, the tail is folded 180° so the controller IC hides behind the glass, shrinking the bezel to under 1 mm.

COG (Chip-On-Glass) places the touch controller directly on the glass, but large 8-K OLED panels generate too much heat—T-FOG moves the IC onto a flex tail that can dissipate heat and be replaced during repair. Connector solutions add 0.3 mm height and cost $0.50; T-FOG adds 0.03 mm and costs <$0.05. Automotive Tier-1 suppliers prefer T-FOG because it passes AEC-Q100 Grade 0 (−40 °C to +150 °C) without a single connector contact.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, lasts 300,000 cycles.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 0.4 mm glass.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearings, 0.05 µm linear encoder, servo feedback at 20 kHz, granite base with passive vibration isolation.

Flex Feed Unit: Servo-driven picker, anti-static vacuum, soft-tip collet for 25 µm polyimide.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz.

Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code.

AI vision self-learns new touch-pad patterns from glass vendors, reducing setup time 70 %.

MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability.

Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs.

Consumer Electronics: Smartphone OLED, tablet LCD, laptop mini-LED, smartwatch flexible AMOLED.

TV & Signage: 32″-120″ 4-K/8-K LCD, OLED, mini-LED, curved and foldable screens.

Automotive: Curved instrument clusters, 15-inch OLED infotainment, head-up displays, camera modules—passing 1,000 h 85 °C/85 % RH.

Medical: Surgical monitors, diagnostic tablets, wearable patches—biocompatible polyimide, ISO 13485 traceability.

Industrial & Aerospace: Avionics displays, factory HMI panels, rugged handhelds—shock, altitude, fungus .

T-FOG bonding machine, Touch-Flex-On-Glass bonder, touch sensor ACF bonding, capacitive touch flex bonding, OLED T-FOG bonding, automotive T-FOG bonding, medical T-FOG bonding, 26 µm pitch T-FOG bonding, 8-K touch T-FOG bonding, 100-inch T-FOG bonding, pulse heat T-FOG bonding, constant temperature T-FOG bonding, AI vision T-FOG bonding, IoT T-FOG bonding machine, China T-FOG bonding machine, automatic T-FOG bonder, T-FOG bonding accuracy 1 micron, T-FOG bonding temperature 200 C, T-FOG bonding pressure 1 MPa, vertical conduction horizontal insulation, lead-free T-FOG bonding, ROHS compliant T-FOG bonding.

Copper-Core ACF: Cu-Ag particles cut material cost 50 % while keeping < 20 mΩ contact resistance.

Cold-Laser Fold Assist: Femtosecond laser pre-scores the coverlay, enabling 50 µm bend radius with zero trace damage.

Servo-Hydraulic Hybrid: Delivers 80 kg force on 100″ TV glass while keeping 1 µm position accuracy.

Dual-Head T-FOG: Parallel bonding of touch and source tails doubles throughput without extra floor space.

AI-Driven Calibration: Neural networks auto-optimize temperature profiles for each glass type, pushing yield to 99.9 %.

A T-FOG bonding machine is no longer a niche display tool—it is the critical gateway between microscopic touch-sensor pads and macroscopic glass signals. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, the latest T-FOG bonders deliver sub-3-second cycles with 99.9 % yield and full Industry 4.0 traceability. Whether you are a display OEM chasing 0.9 mm bezels, an automotive Tier-1 qualifying 100-inch curved clusters, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected T-FOG bonding platform future-proofs your process.

A FOF bonding machine—short for Flex-On-Flex or Film-On-Film—is the precision heart that folds one floppy polyimide tail onto another and welds them into a single, ultra-reliable flexible circuit. Inside foldable phones, medical catheters, curved automotive clusters, and next-generation wearable patches, two flexible printed circuits (FPCs) must be joined without rigid boards, bulky connectors, or solder joints that fatigue. The FOF bonder grabs the top flex, aligns it to the bottom flex within ±1 µm, and compresses anisotropic conductive film (ACF) between their copper pads. A 1.5-second pulse of 180 °C and 1 MPa deforms thousands of gold-coated spheres inside the film, creating vertical contacts while keeping lateral isolation. Water-cooling locks the particles in place; the whole cycle finishes in 2.8 seconds.

Foldable phones need a hinge area that bends 200,000 times at 0.2 mm radius—rigid PCB would crack. Automotive cameras must fold sensor tails behind 3D-shaped plastic housings that see −40 °C to +105 °C. Medical catheters require transparent, sterilizable PET layers that survive autoclave steam without delamination. FOF solves these pain points by marrying the flexibility of copper-clad polyimide with the reliability of particle-based conductive adhesive, all while enabling repair: a defective flex can be removed and rebonded without scrapping the entire $300 assembly.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, lasts 300,000 cycles.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm polyimide.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearings, 0.05 µm linear encoder, servo feedback at 20 kHz, granite base with passive vibration isolation.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, waste take-up spool, splice sensor for uninterrupted production.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz.

Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code.

AI vision self-learns new pad patterns from flex vendors, reducing setup time 70 %.

MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability.

Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs.

Consumer Electronics: Foldable phone hinge, tablet battery flex, smartwatch heart-rate sensor, AR-glass temple arm.

Automotive: 3D-shaped dashboard, curved instrument cluster, 15 inch OLED infotainment, head-up display—passing 1,000 h 85 °C/85 % RH.

Medical: Disposable catheter flex, surgical hand-piece PCB, wearable ECG patch—biocompatible polyimide, ISO 13485 traceability.

Industrial & Aerospace: Avionics displays, factory HMI panels, rugged handhelds—shock, altitude, fungus per MIL-STD-810.

Copper-Core ACF: Cu-Ag particles cut material cost 50 % while keeping < 20 mΩ contact resistance.

Cold-Laser Fold Assist: Femtosecond laser pre-scores coverlay, enabling 50 µm bend radius with zero trace damage.

Servo-Hydraulic Hybrid: Delivers 80 kg force on 500 mm automotive panels while keeping 1 µm position accuracy.

Roll-to-Roll FOF: Reel-fed polyimide and die-bond-on-the-fly reach 3,000 UPH for smart-membrane switches.

AI-Driven Calibration: Neural networks auto-adjust temperature profiles for each polyimide grade, pushing yield to 99.9 %.

FOF bonding machine, FOF bonder, flex-on-flex bonding, film-on-film bonding, ACF FOF machine, FPC to FPC bonding, flexible circuit bonding machine, pulse heat FOF bonding, constant temperature FOF bonding, foldable phone FOF bonding, 0.2 mm fold radius FOF, 25 µm polyimide FOF bonding, 200 mm FOF bonding, automotive FOF bonding, medical FOF bonding, wearable FOF bonding, AI vision FOF bonding, IoT FOF bonding machine, China FOF bonding machine, automatic FOF bonder, FOF bonding accuracy 1 micron, FOF bonding temperature 200 C, FOF bonding pressure 1 MPa, vertical conduction horizontal insulation, lead-free FOF bonding, ROHS compliant FOF bonding.

A FOF bonding machine is no longer a niche flex-to-flex press—it is the critical enabler for foldable OLED, 3D-shaped automotive clusters, biocompatible medical devices, and rugged industrial membranes that define. By mastering sub-micron alignment on 25 µm polyimide, pulse-heat control within half a degree, and real-time force feedback, the latest FOF bonders deliver sub-3-second cycles with 99.9 % yield and full Industry 4.0 traceability. Whether you are a display OEM chasing a 0.9 mm chin, an automotive Tier-1 qualifying 500 mm curved panels, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected FOF bonding platform future-proofs your process.