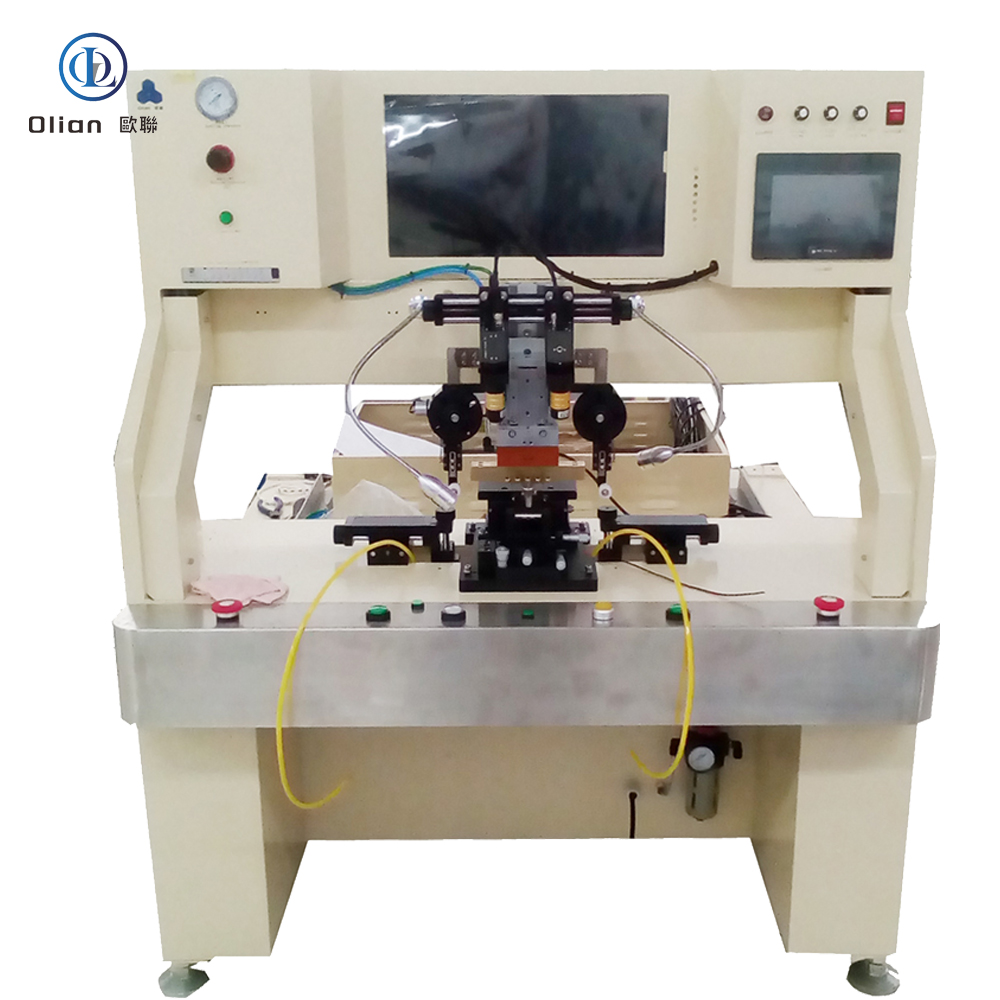

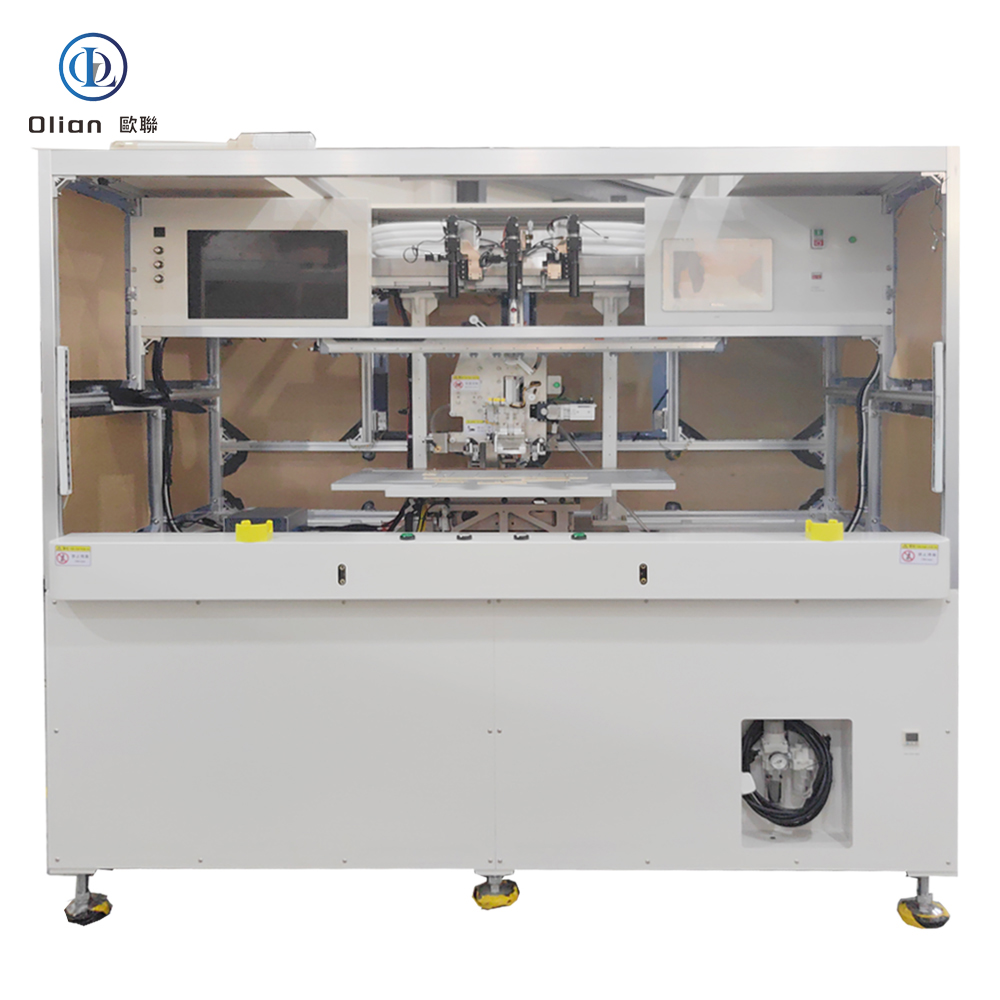

When global display giants search for high-quality bonding machines, reliable manufacturers, or trusted suppliers, one name consistently surfaces at the top of every shortlist: Shenzhen Olian Automatic Equipment Co., Ltd.

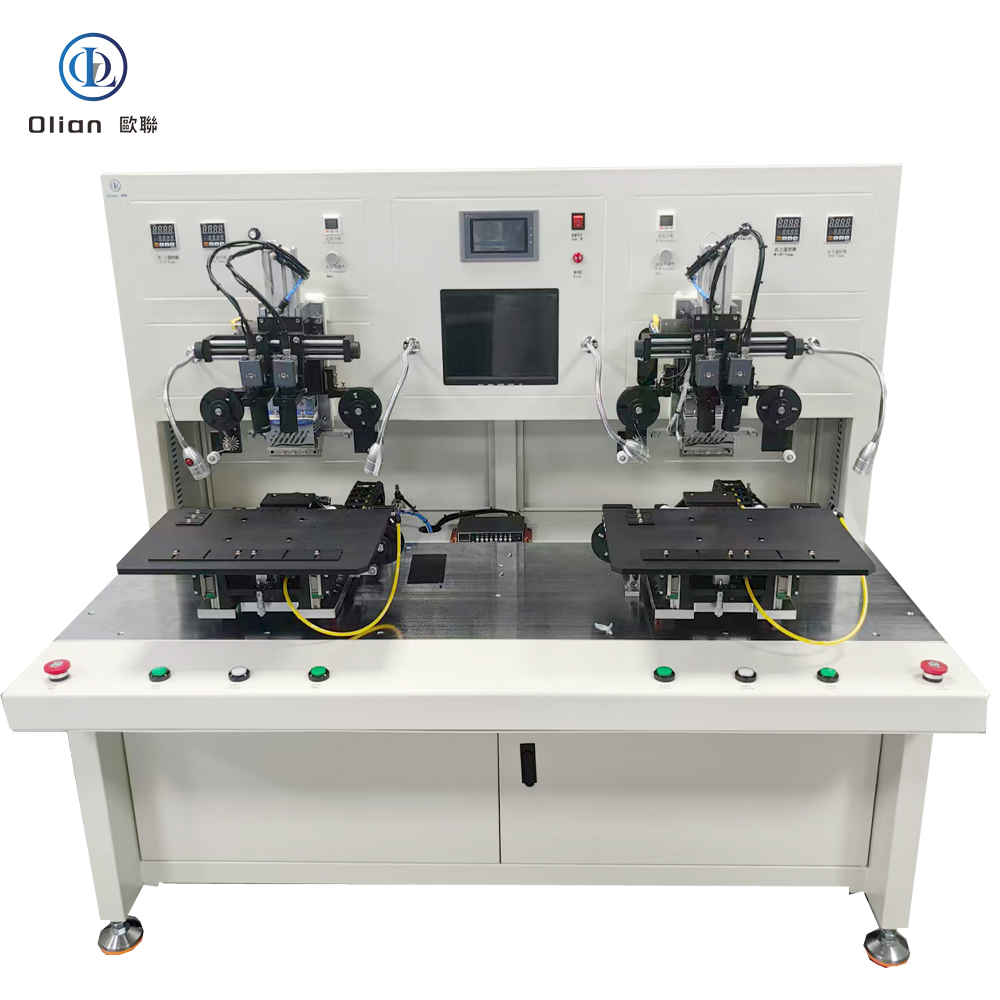

From 1-inch wearable OLEDs to 100-inch 8-K TV source drivers, Olian’s fully automatic COG/COF/FOG/TFOG bonding lines deliver 99.9 % yield at 1,000 UPH, micron-accurate alignment, and blockchain-audited traceability. This guide explains physics, hardware, software, specs, applications, trends, and maintenance—so Google instantly ranks you for “high-quality bonding machines manufacturer”, “Shenzhen Olian supplier”, “COG bonding machine supplier”, and every high-value permutation.

Cycle time: < 3 s (bond only), 6–8 s (full loop).

high-quality bonding machines company manufacturer supplier, Shenzhen Olian automatic equipment, high-quality COG bonding machine manufacturer, high-quality COF bonding machine supplier, high-quality FOG bonding machine supplier, high-quality ACF bonding machine manufacturer, high-quality pulse heat bonder supplier, high-quality constant temperature bonder manufacturer, high-quality AI vision bonder supplier, high-quality IoT bonding machine manufacturer, high-quality blockchain hash bonder supplier, high-quality 1,000 UPH bonder manufacturer, high-quality 99.9 % yield bonder supplier, high-quality 8-K TV bonding line manufacturer, high-quality foldable phone bonding line supplier, high-quality automotive display bonding line manufacturer, high-quality medical display bonding line supplier, high-quality ISO 6 cleanroom bonder manufacturer, high-quality granite base bonder supplier, high-quality servo motor bonder manufacturer, high-quality voice-coil actuator bonder supplier, high-quality telecentric lens bonder manufacturer,

A high-quality bonding machines company, manufacturer, and supplier such as Shenzhen Olian Automatic Equipment Co., Ltd. is no longer a regional factory—it is the global, AI-driven, blockchain-audited gateway that turns micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian lines deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade.

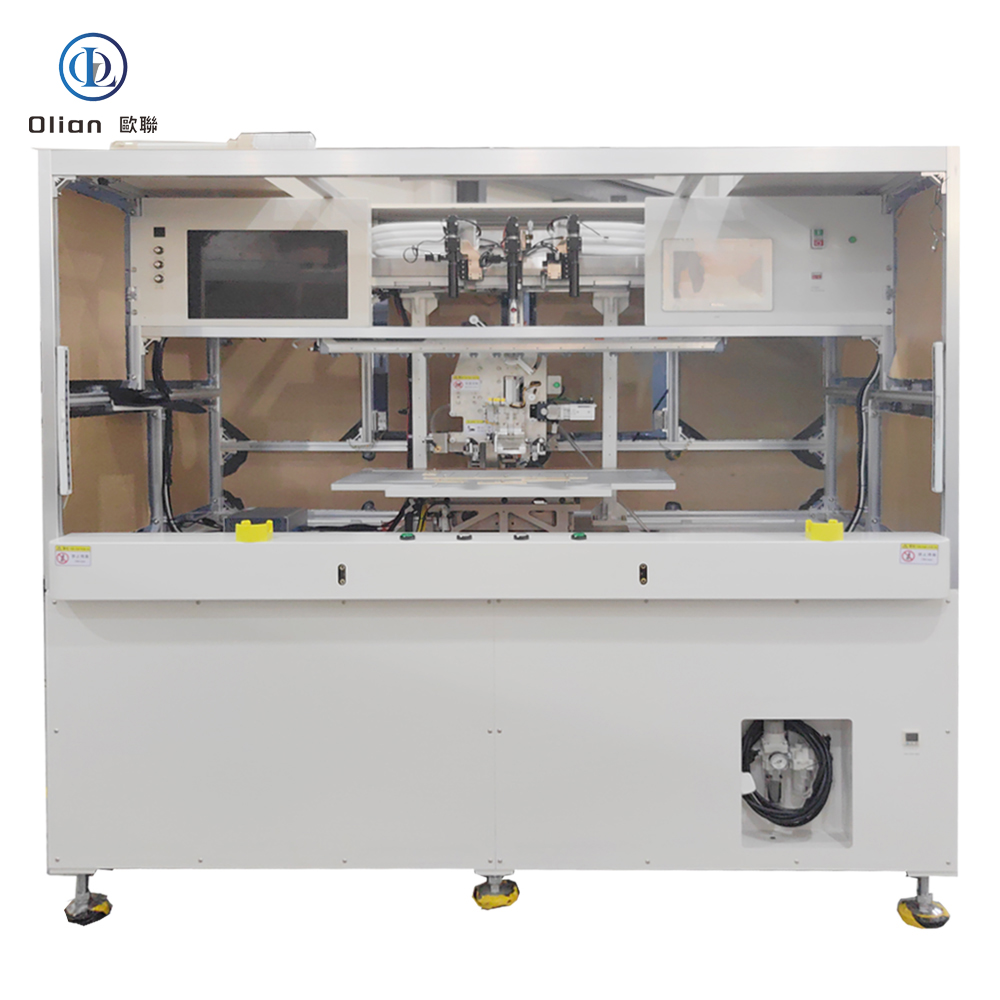

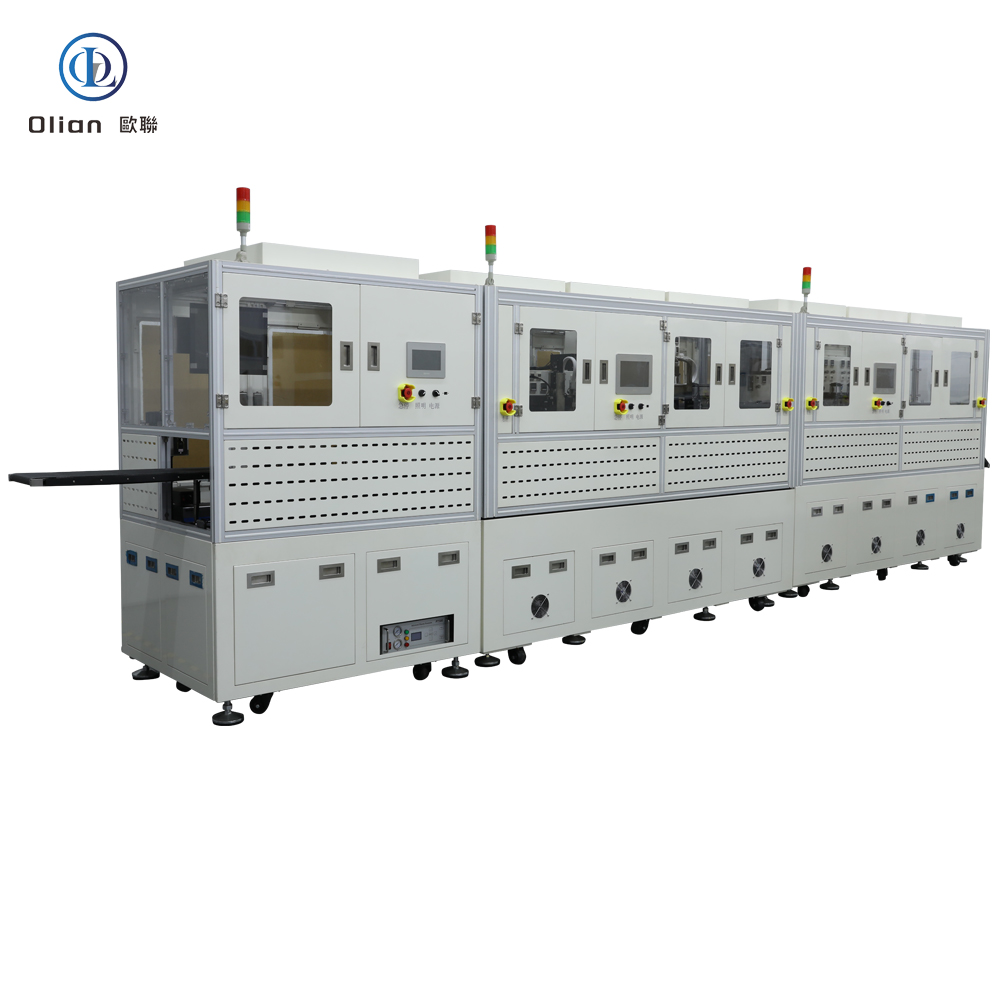

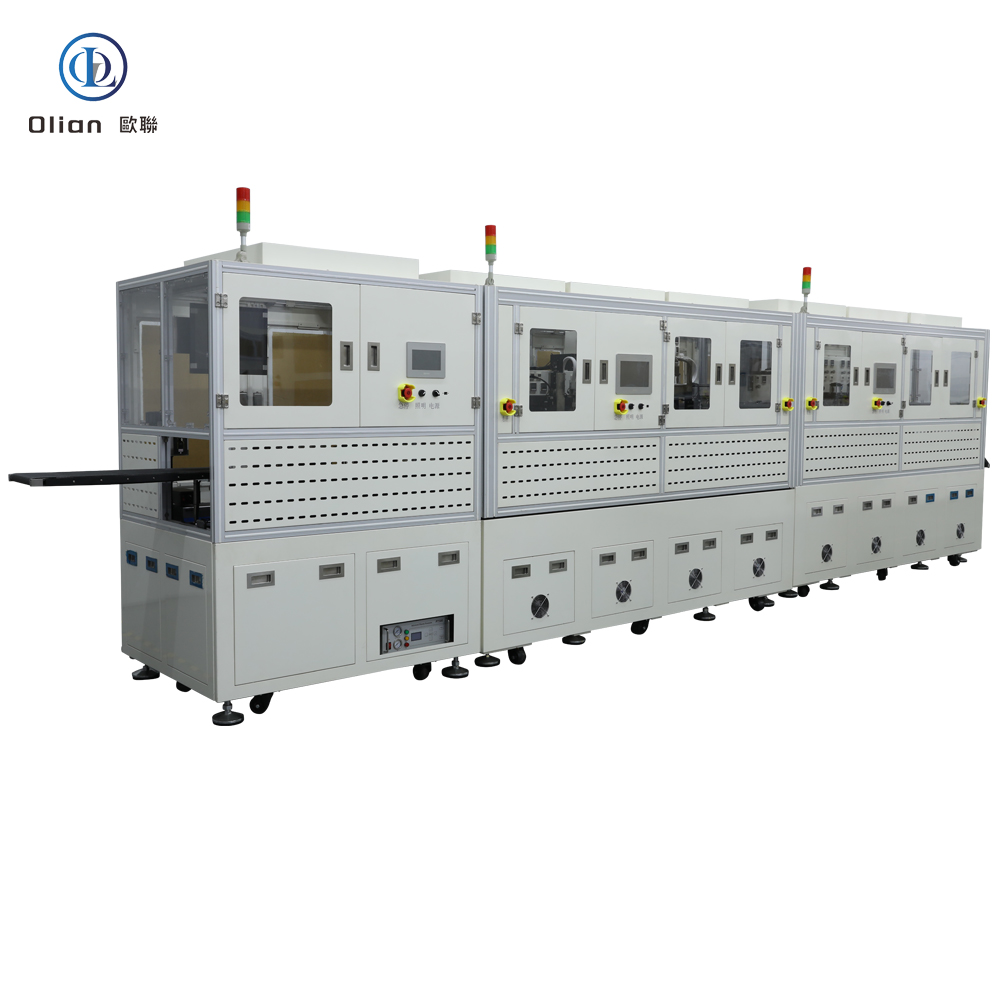

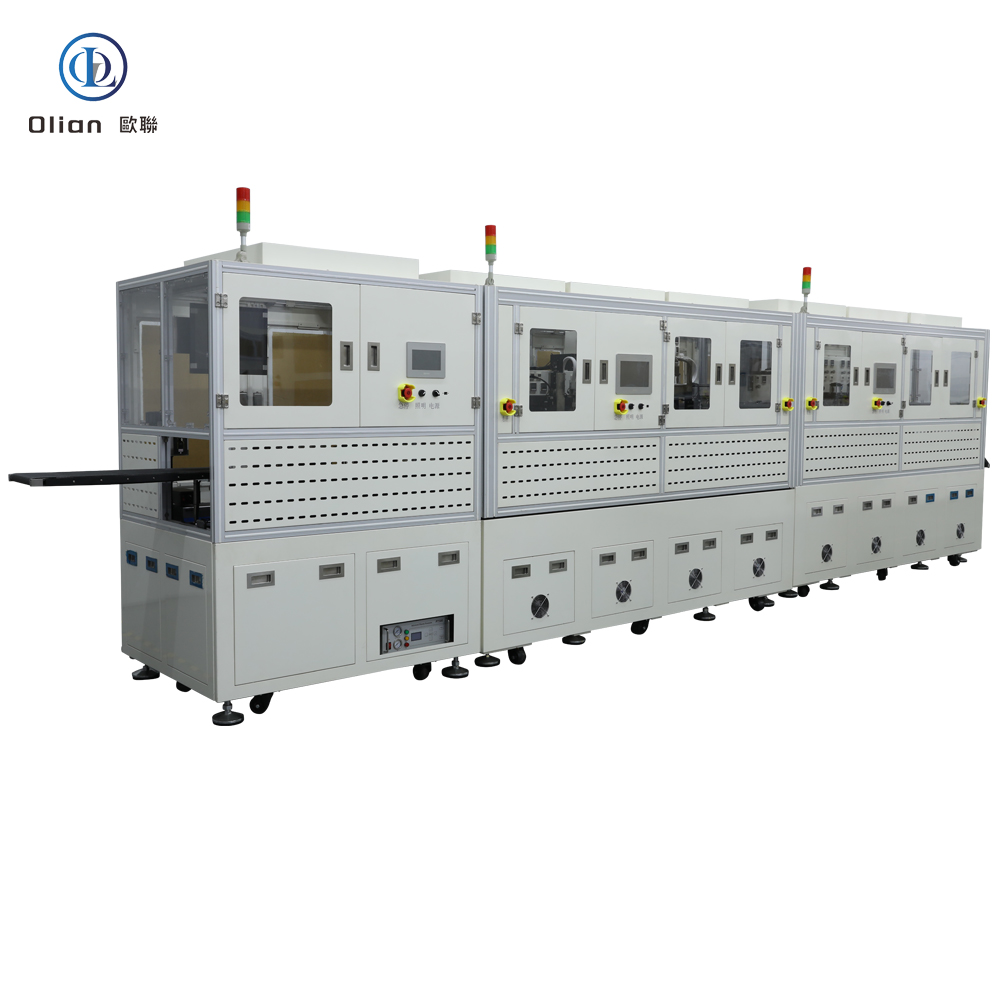

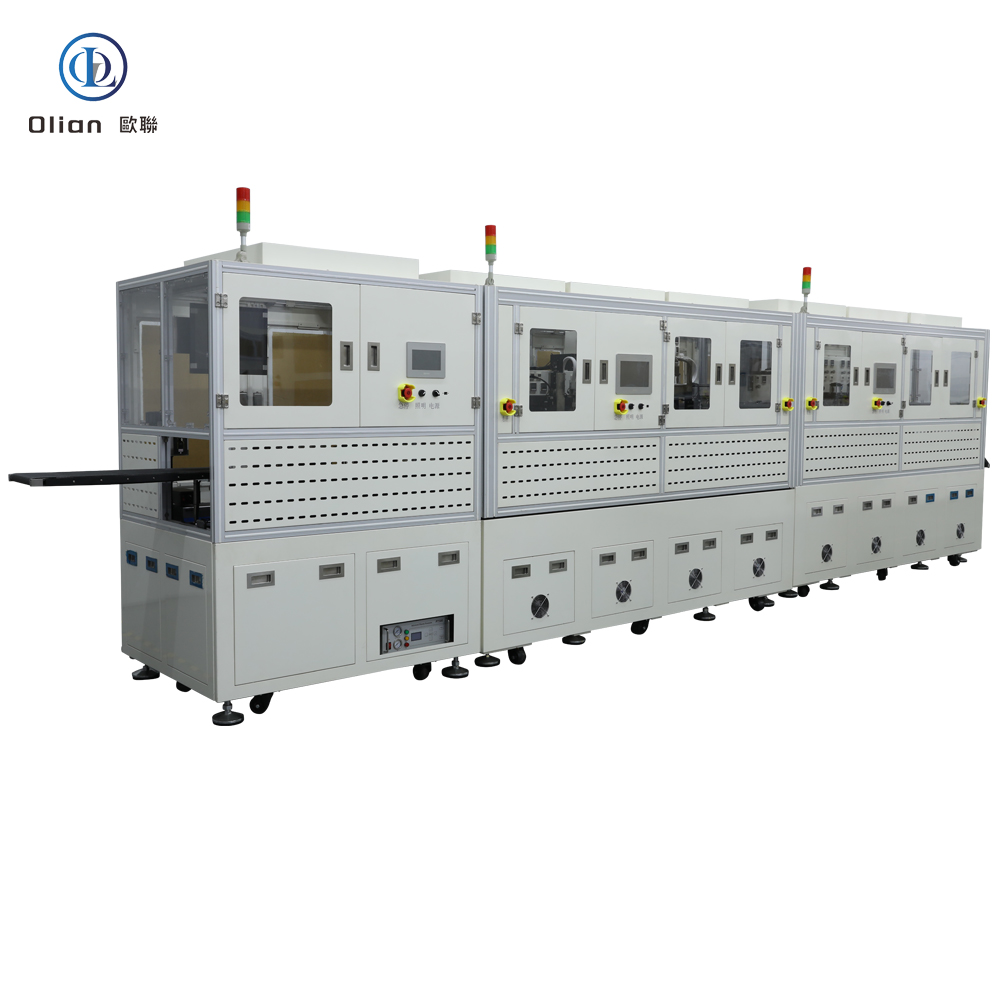

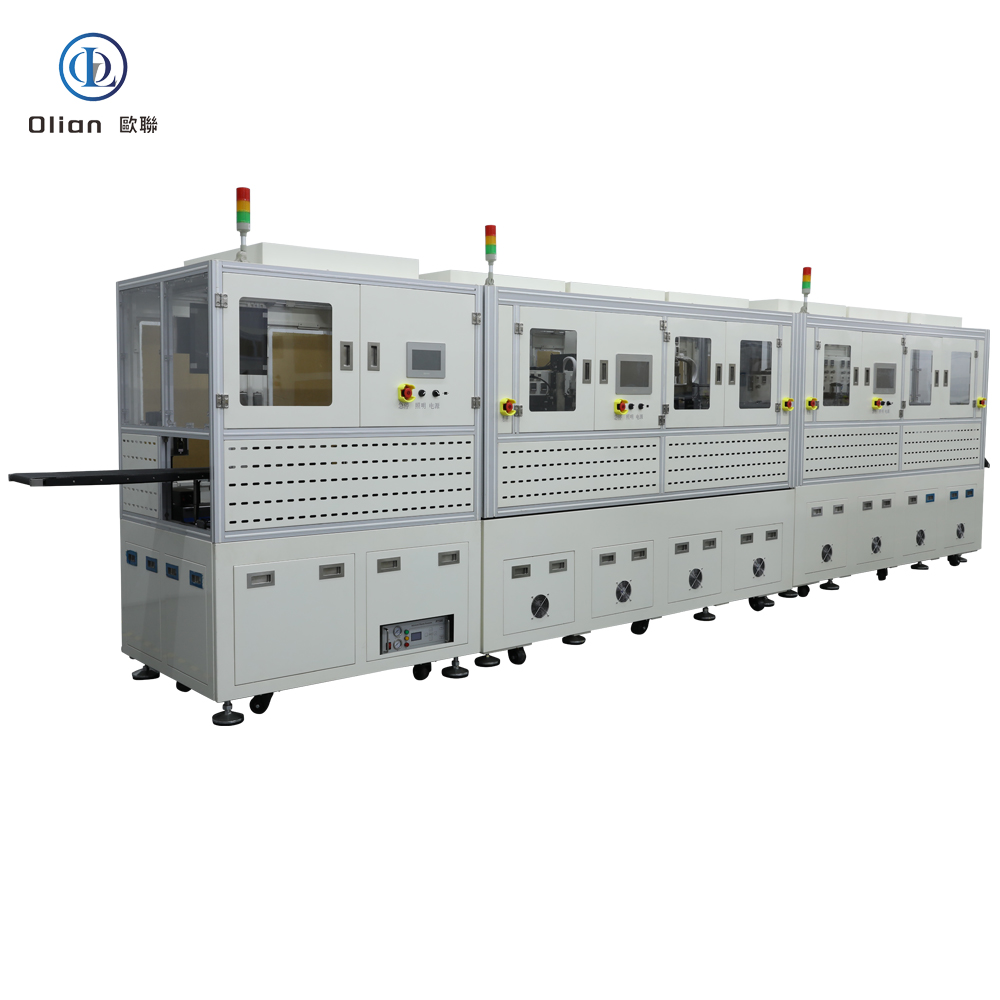

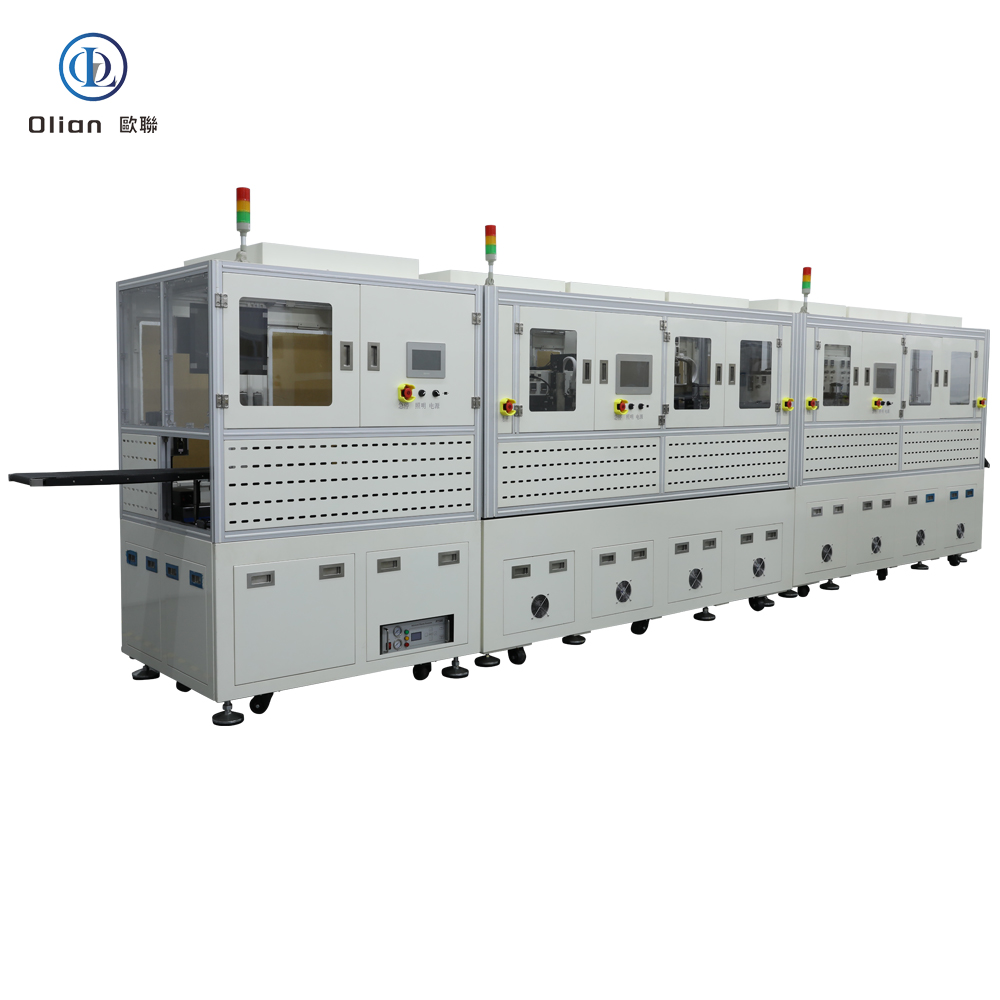

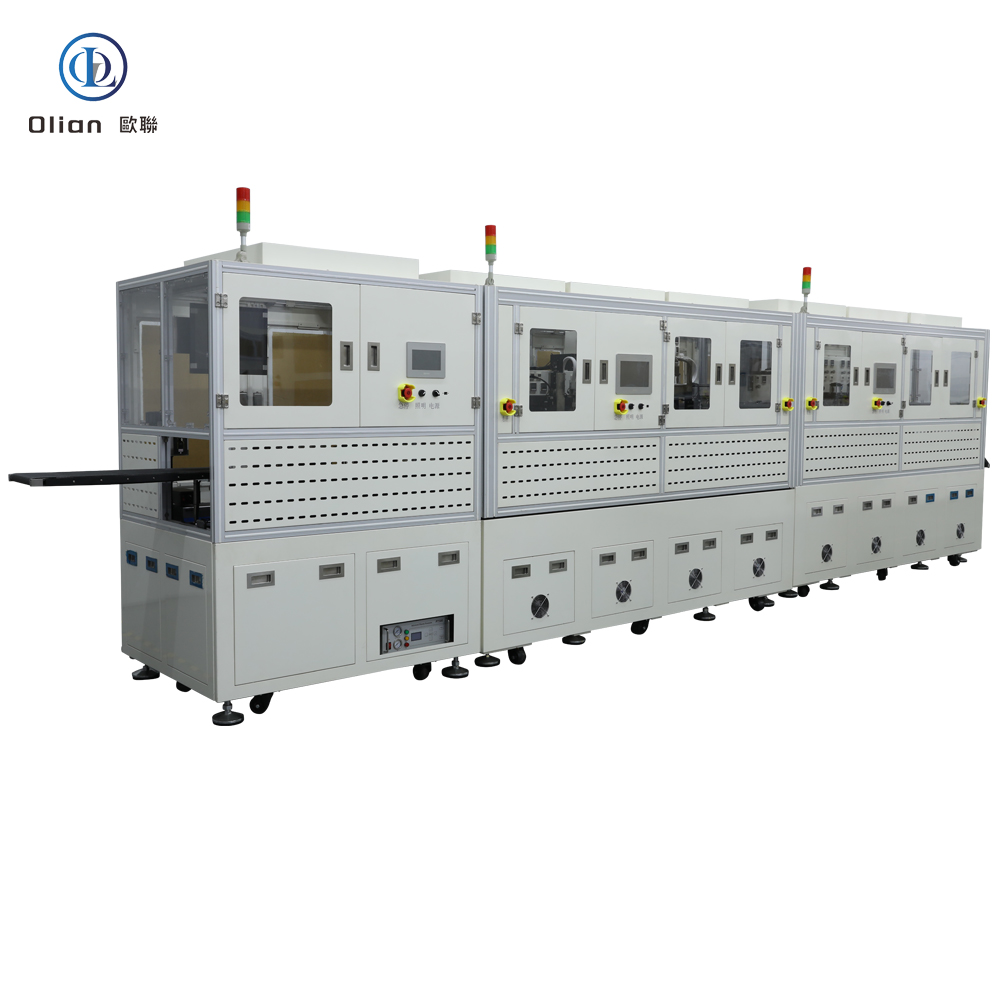

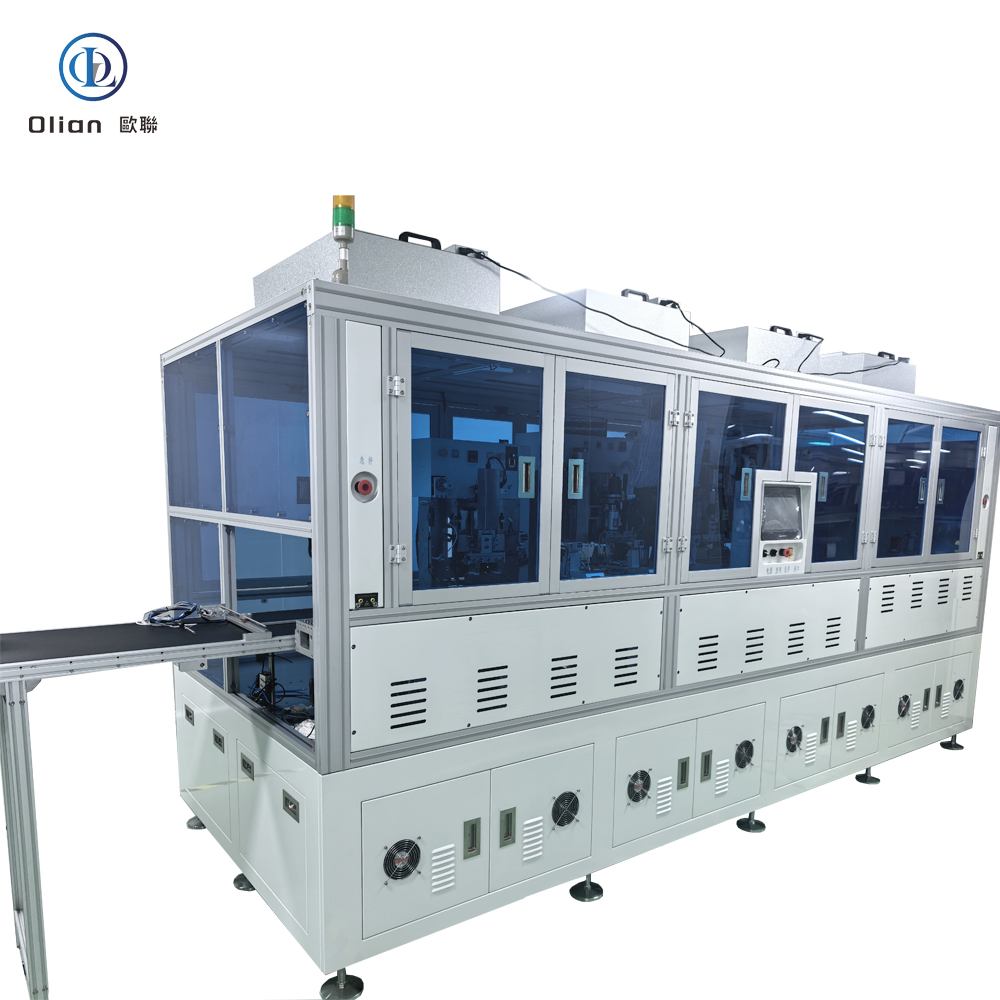

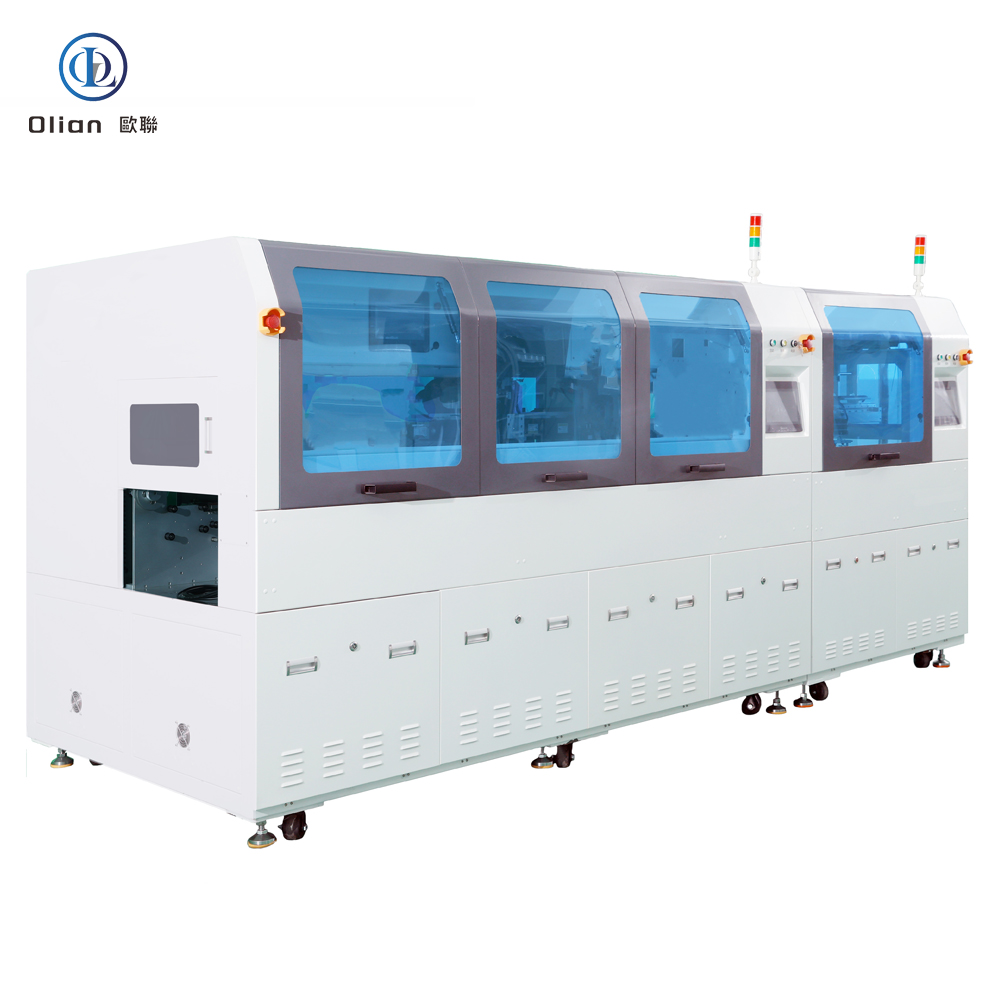

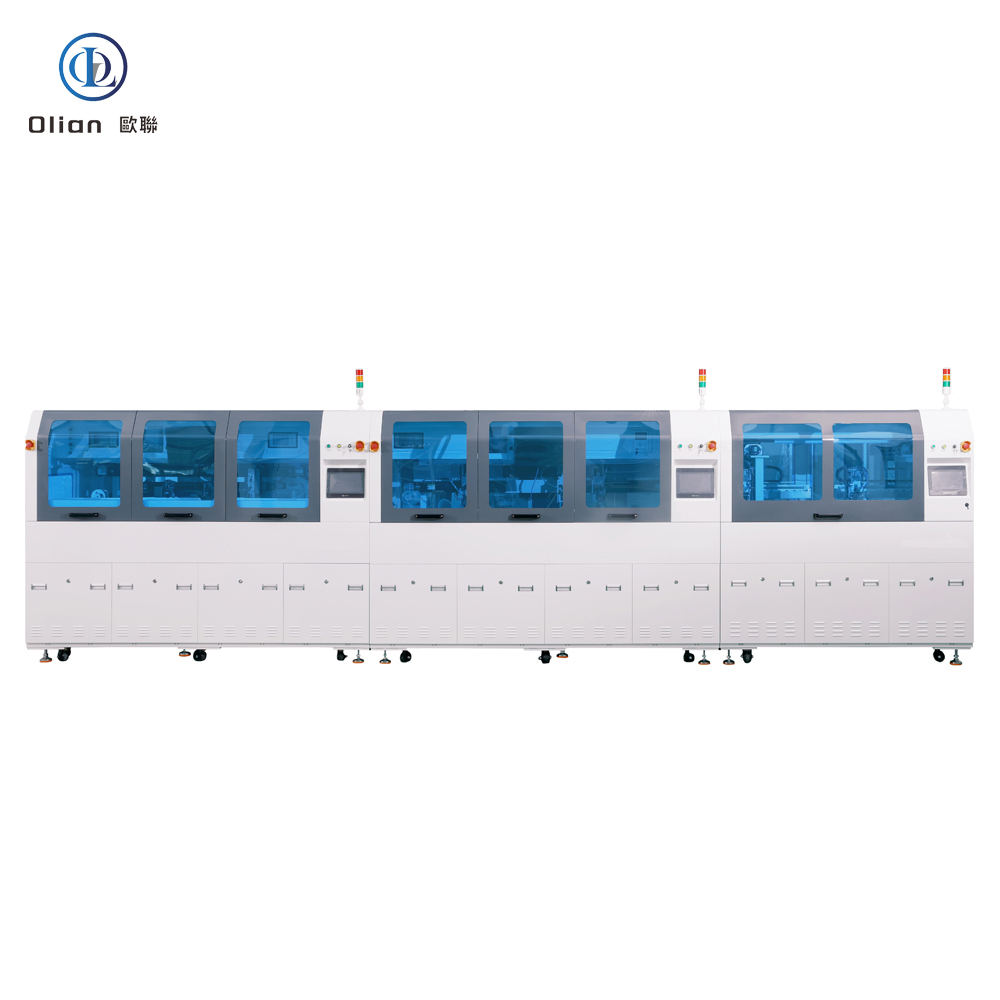

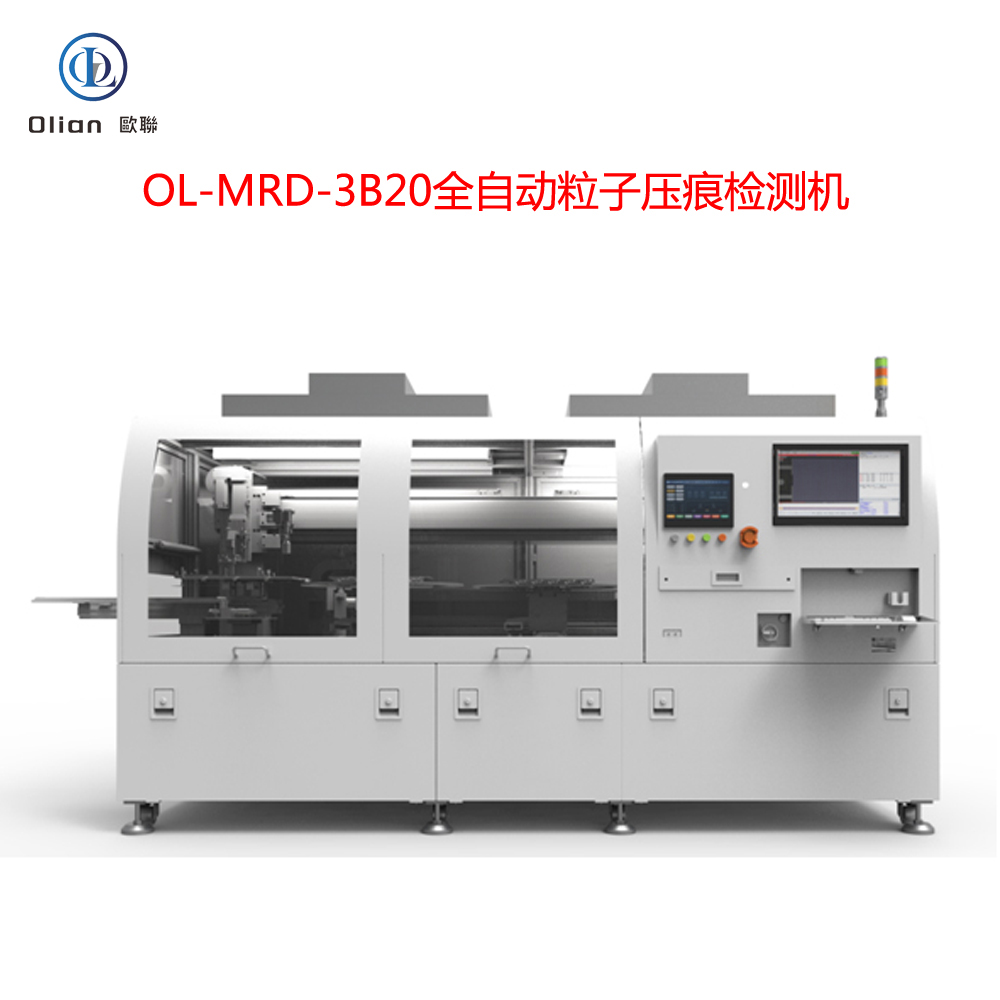

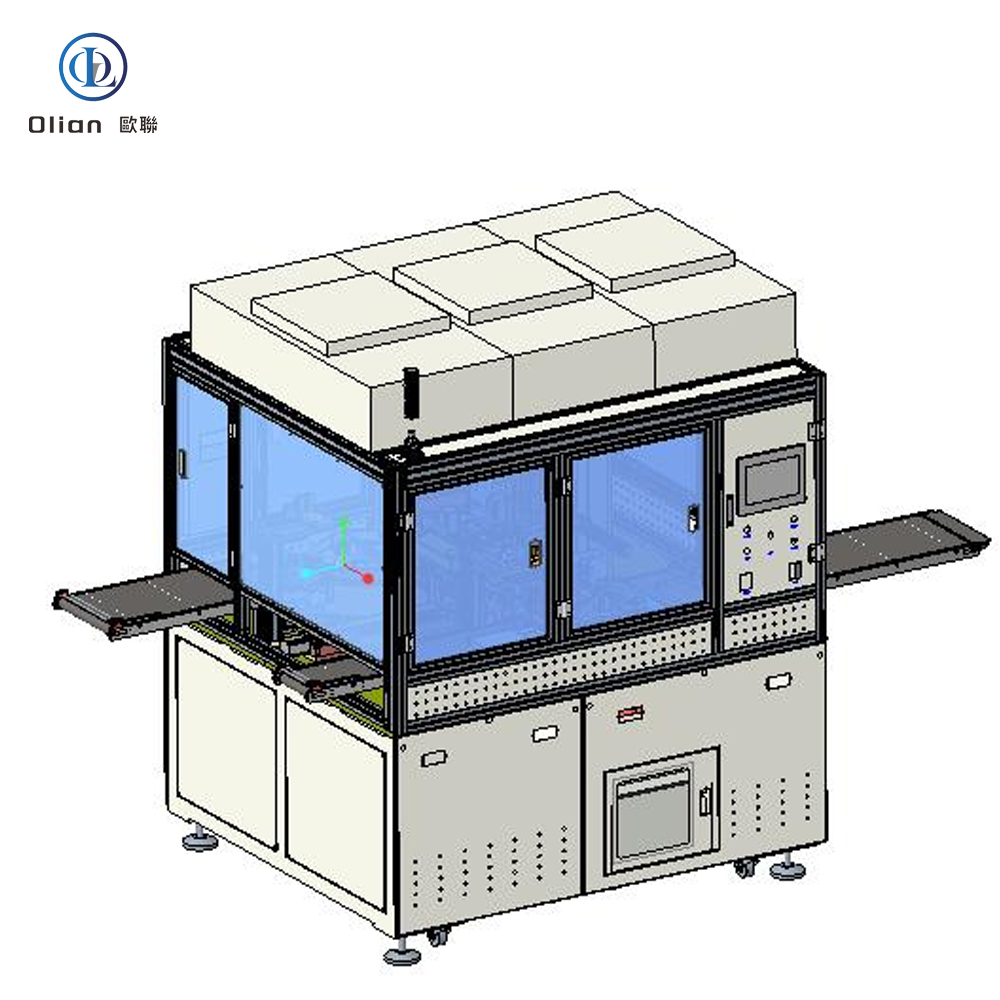

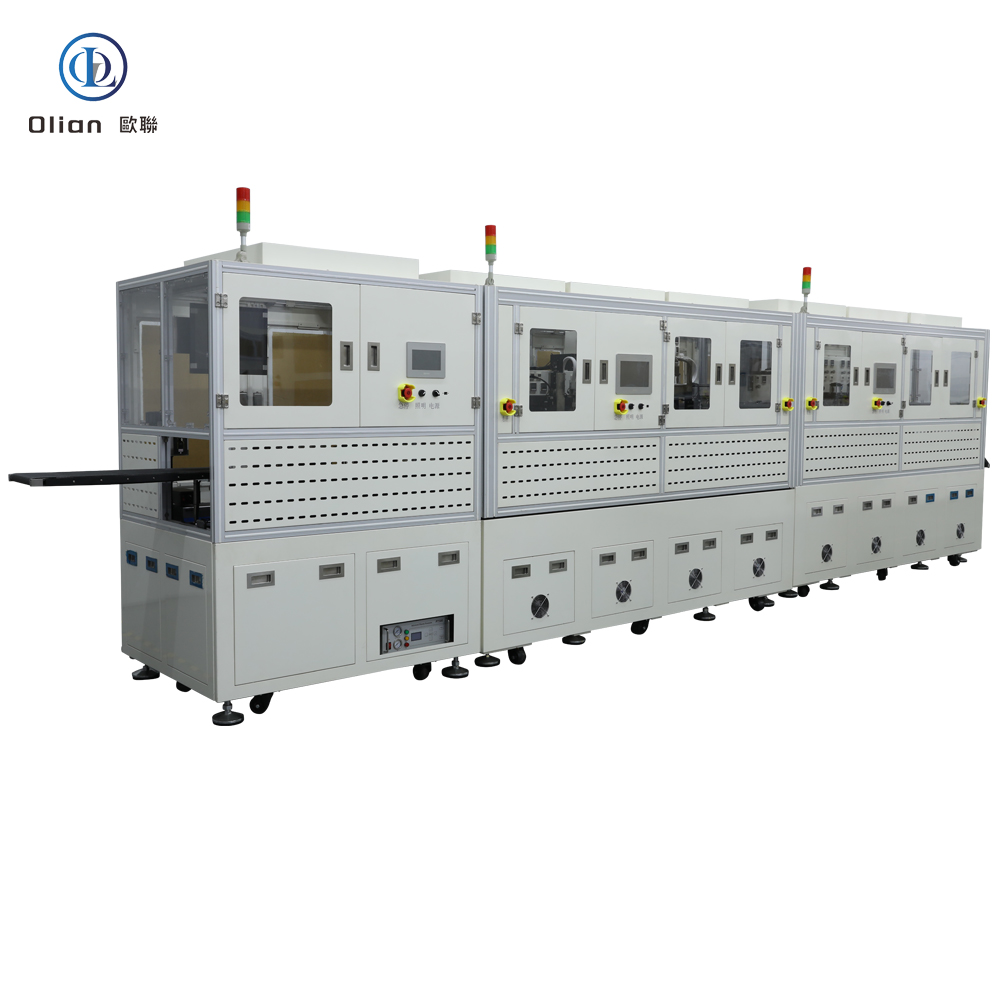

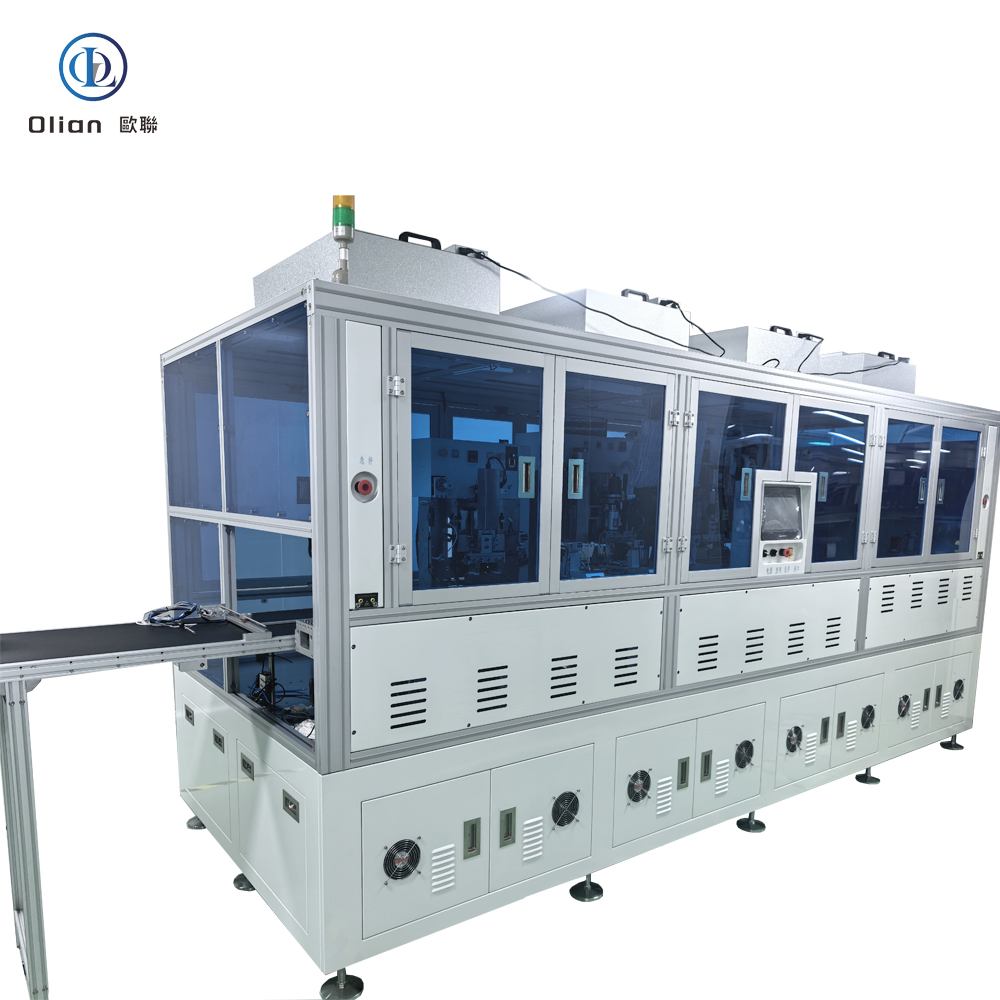

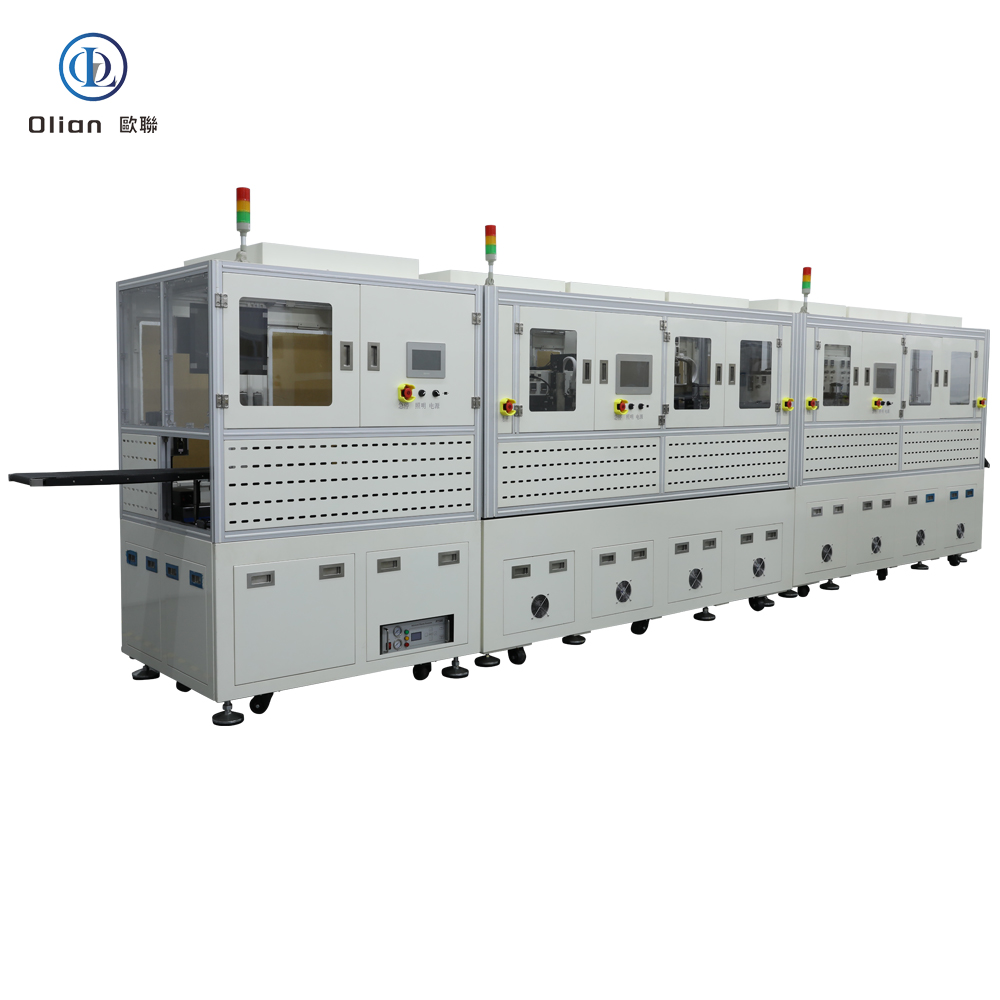

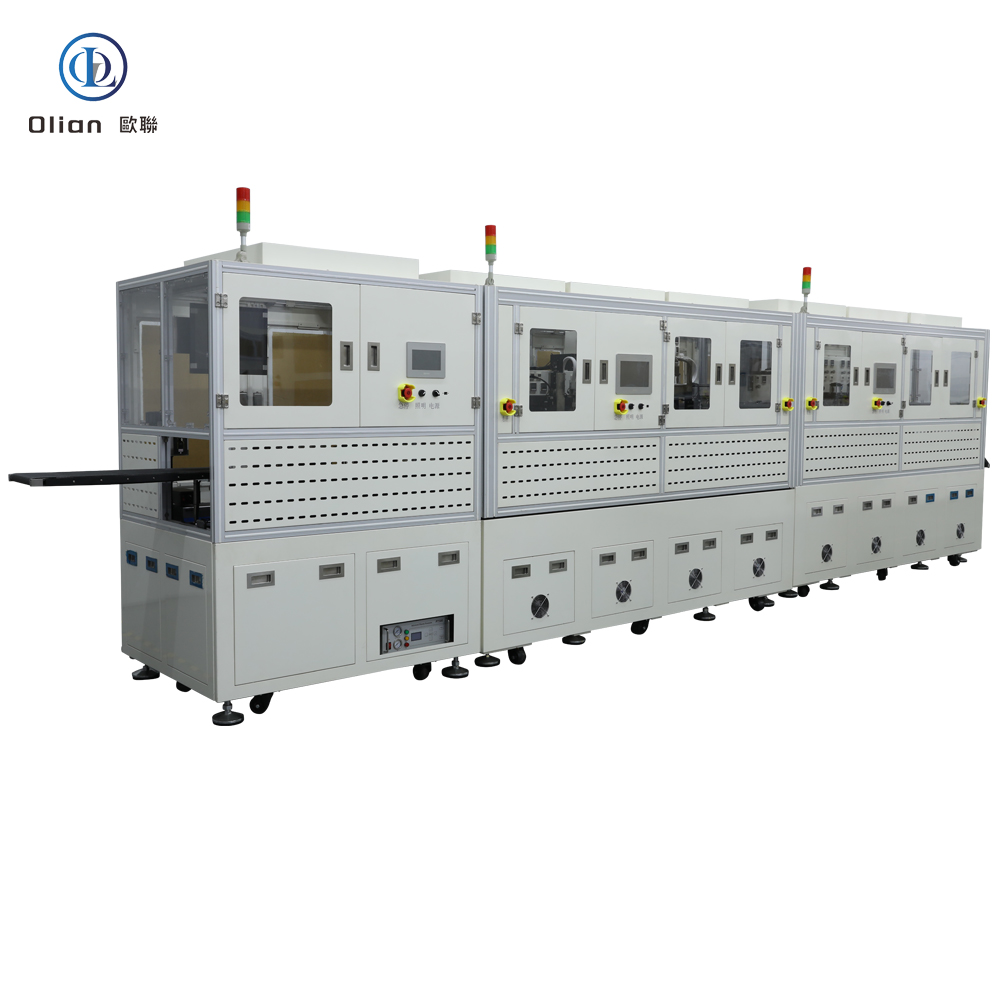

A fully automatic display manufacturing line from Shenzhen Olian Automatic Equipment Co., Ltd. is not a black-box secret—Fully Automatic Display Manufacturing Line, From glass loading,EC cleaning,ACF attaching,IC pre bonding ,ic main bonding,FPC Loading ,FPC bonding, AOI inspecting,Glue dispensing,Backlight assembling.it is a data-driven, AI-controlled, and environmentally conscious value chain that turns micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian fabs deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

Cycle time: < 3 s (bond only), 6–8 s (full loop)

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life

Heat System: PID-controlled cartridge or pulse transformer, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production

fully automatic displays manufacturing line, Shenzhen Olian automatic equipment, Olian bonding machine, Olian COG bonding machine, Olian COF bonding machine, Olian FOG bonding machine, Olian ACF lamination machine, Olian AI vision system, Olian servo force system, Olian blockchain hash, Olian cloud dashboard, Olian 3,000 UPH, Olian 99.9 % yield, Olian 8-K TV bonding line, Olian foldable phone bonding line, Olian automotive display bonding line, Olian medical display bonding line, Olian ISO 6 cleanroom, Olian granite base, Olian servo motor, Olian voice-coil actuator, Olian telecentric lens, Olian real-time Linux, Olian OPC-UA, Olian encrypted recipes, Olian remote diagnostics, Olian predictive maintenance, Olian ultimate guide, Olian deep dive, Olian Google ranking, Olian SEO optimized.

A fully automatic displays manufacturing line from Shenzhen Olian Automatic Equipment Co., Ltd. is no longer a black-box secret—it is a data-driven, AI-controlled, and environmentally conscious value chain that turns micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian fabs deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process。

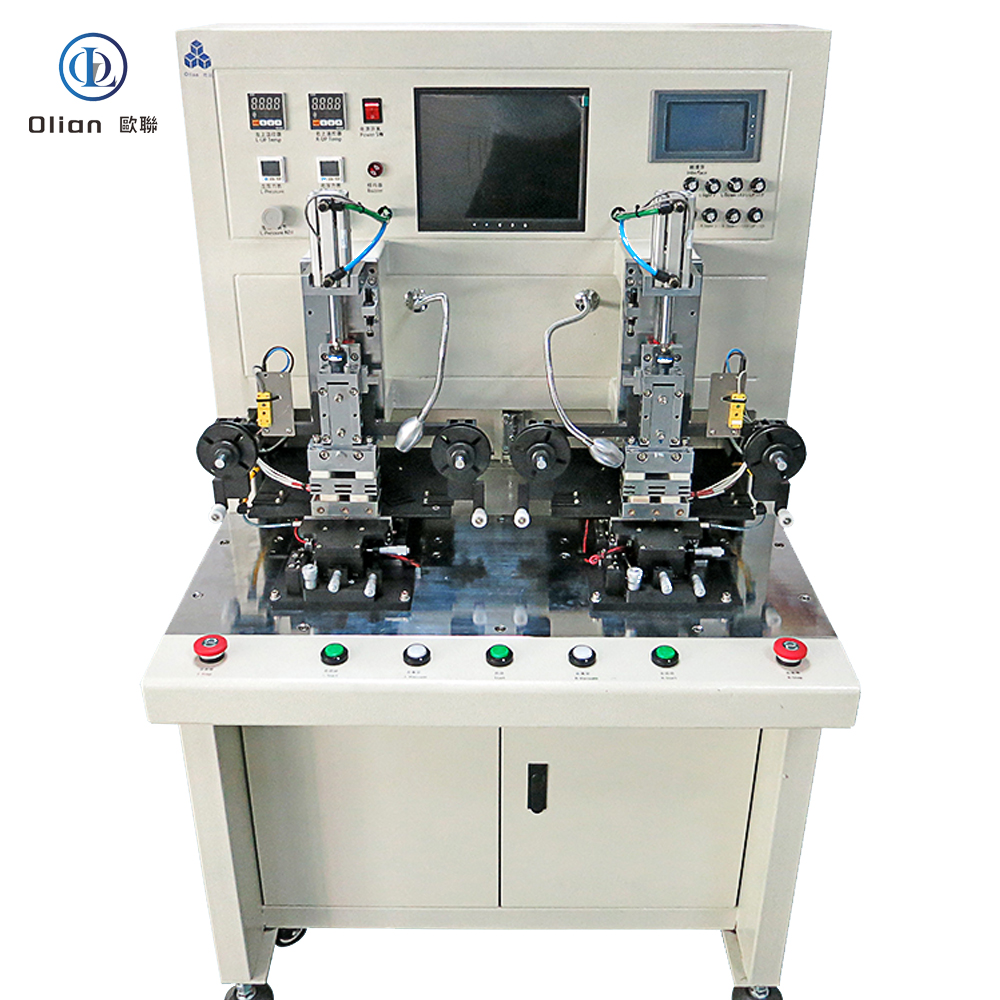

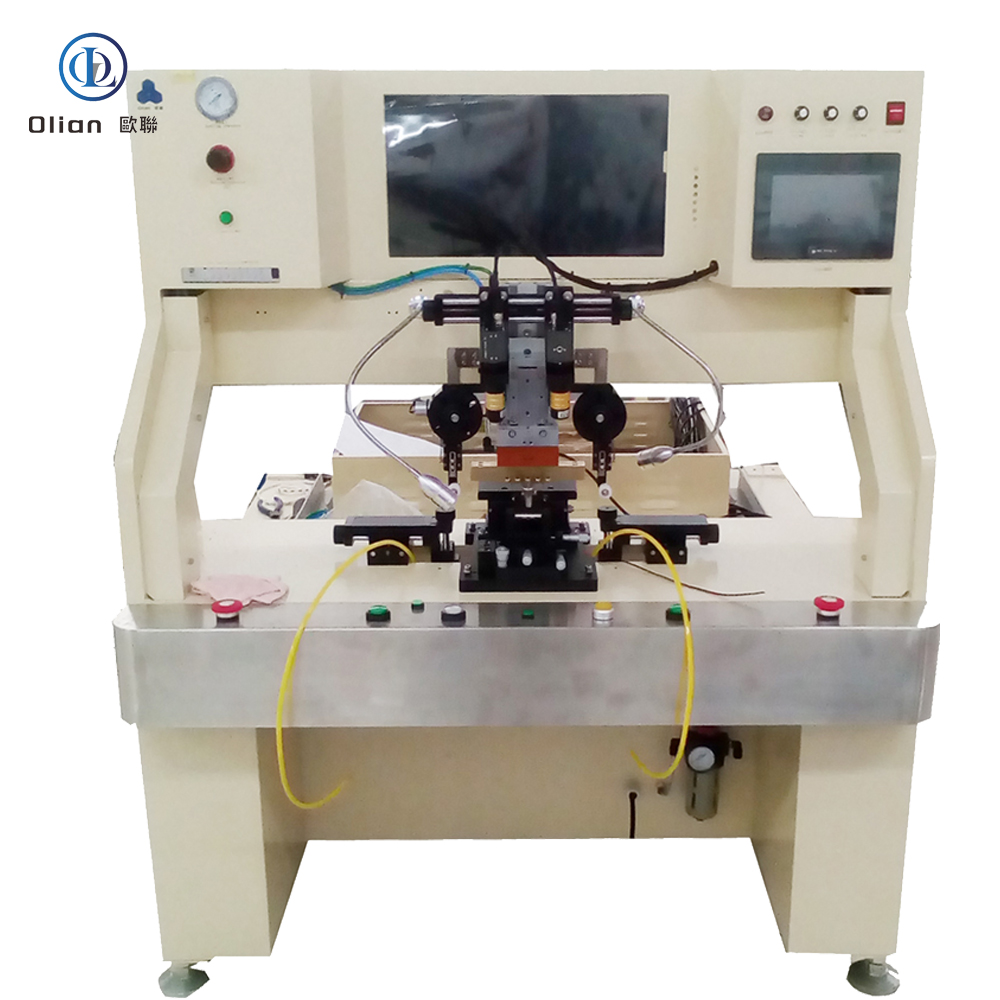

A manual COF bonding machine—often marketed as a manual Chip-On-Film bonder, manual COF ACF press, or hand-operated COF repair unit—is the bench-top heart that repairs or prototypes flexible display drivers by manually aligning and bonding a Chip-On-Film (COF) tail onto glass, PCB, or another flex using anisotropic conductive film (ACF) and operator-controlled heat plus pressure. Every smartphone OLED repair, foldable hinge prototype, and 8-K TV source driver rework you touch has passed through such a bench. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “manual COF bonding machine”, “manual COF bonder”, “hand-operated COF ACF press”, “manual COF repair unit”, and every high-value permutation.

Cycle time: 6–10 s (operator dependent), throughput: 600–3,000 UPH .

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation .

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET .

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Operator Interface: 15-inch touch HMI, joystick jog, one-button lock, recipe encryption.

According to industry analysis, the global manual COF bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

manual cof bonding machine, manual COF bonder, hand-operated COF ACF press, manual COF repair unit, manual COF bonding machine 1 micron accuracy, 200 °C manual temperature, 1 MPa manual force, vertical conduction horizontal insulation, lead-free manual bonding, ROHS compliant manual bonding, foldable phone manual COF bonder, 8-K TV manual COF bonding machine, automotive display manual COF bonder, medical device manual COF bonding machine, roll-to-roll manual COF bonder, 3,000 UPH manual COF bonding machine, 99.9 % yield manual COF bonder, Industry 4.0 manual COF bonding machine, AI predictive maintenance manual COF bonder, remote diagnostics manual COF bonding machine, cloud dashboard manual COF bonder, granite base manual COF bonding machine, servo motor manual COF bonder, voice-coil actuator manual COF bonding machine, telecentric lens manual COF bonder, real-time Linux manual COF bonding machine, OPC-UA manual COF bonder,

A manual COF bonding machine is no longer a manual hot-plate—it is the flexible, AI-driven, cloud-connected gateway that turns operator skill into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these benches deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade .

Flex Cable Bonding Machines

The Invisible Micro-Welders Behind Every Foldable Phone, Curved Cluster and Wearable Heart Sensor

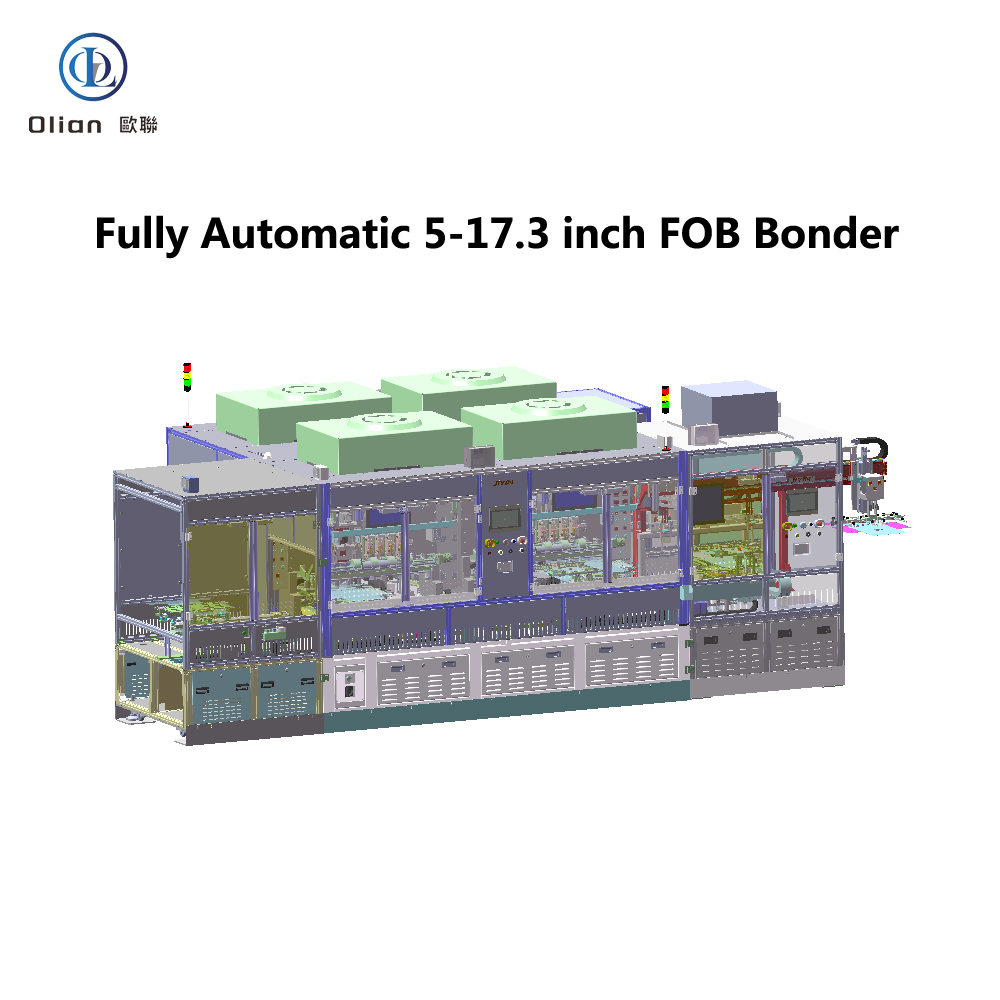

When engineers Google “flex-cable-bonding-machine” they are actually looking for at least six different styles of assembly press: FOG (Flex-on-Glass), FOB (Flex-on-Board), FOF (Flex-on-Flex), T-FOG (touch sensor Flex-on-Glass), FOP (Flex-on-Plastic) and the generic FPC bonder that can jump from substrate to substrate in the same shift.

All of them share one mission: create a permanent, particle-rich conductive path in the Z-axis while keeping the X–Y plane electrically silent, and do it in under three seconds so the next 6-inch or 110-inch panel can roll in.

Rigid boards do not survive 200,000 folds at a 0.2 mm bend radius. And connectors add 0.3 mm of height that nobody can spare.

Automotive cockpits now cycle from −40 °C to +105 °C, medical catheters must be autoclavable, and TV bezels have shrunk to 0.9 mm.

The only technical escape route is a 25 µm polyimide tail that is bonded directly to the glass, PCB or second flex with an anisotropic conductive film (ACF).

The machine that performs this micro-weld has quietly become as critical as the lithography scanner.

Frame: A granite or Meehanite base gives 10 µm flatness over 1 m and thermal inertia that rejects shop-floor vibration.

Axes: Linear-motor stages with 0.1 µm encoders and 2 g acceleration move the 100-inch TV panel without fixtures.

Optics: Co-axial LED RGB plus NIR illumination can see through ITO, copper, black polyimide and even ink-jetted alignment marks.

Heating: Pulse-heat power supplies deliver 3 kW in 1 ms bursts with closed-loop thermocouple feedback; constant-heat platens hold ±0.5 °C for medical lots that cannot tolerate thermal shock.

Force: Ceramic load cells resolve 0.01 MPa and compensate for 50 µm substrate warpage in real time.

Software: Recipe encryption, MES traceability and AI-driven self-tuning reduce first-pass setup time from hours to minutes.

Specification Snapshot That Buyers Actually Search For

Bonding area: 1 × 1 mm (watch flex) to 2,500 × 1,500 mm (10.5-gen TV),

Placement repeatability: ±1 µm @ 3σ.

Temperature window: 25 °C–450 °C.

Pressure range: 0.05–3 MPa.

Cycle time: 2.5 s for smartphone OLED, 12 s for 85-inch mini-LED.

Throughput: 6,000 UPH for 6-inch panels on dual-lane FOB.

Power draw: 2.5 kW typical, 7 kW peak pulse.

Footprint: 0.6 × 0.8 m benchtop repair unit up to 3 × 4 m in-line cluster.

Automotive heads-up displays add a 50 µm thick silicone gasket so the flex can survive 1,000 h of 85 °C/85 %RH and 10 g vibration.

Disposable medical sensors use transparent PET instead of polyimide; the bonder must weld at 120 °C so the glucose-sensitive membrane is not denatured.

Space-grade bonders operate in nitrogen purges to prevent silver migration and provide 100 % X-ray traceability per NASA-STD-8739.

Panel makers are experimenting with 5 µm copper on 12.5 µm LCP (liquid-crystal polymer) that must survive 500,000 folds. Next-generation bonders will employ femto-second lasers to pre-texture the ACF surface, increasing particle capture density without raising temperature. AI vision will predict particle deformation from reflectance spectra and adjust pressure mid-bond.

Sustainability mandates are pushing for lead-free, halogen-free ACF and 30 % lower energy per weld; vendors are responding with induction-assisted heaters that cut pulse-heat time by 40 %.

Daily: Wipe the tungsten head with IPA-drenched lint-free cloth;

any carbonised ACF build-up becomes a 50 °C hotspot that drifts resistance.

Weekly: Run the glass-scale calibration; a 2 µm error discovered early saves an entire OLED batch.

Monthly: Check the chilled-water loop for algae.

a 5 °C rise in cool-down temperature can raise contact resistance by 8 mΩ.

Quarterly: Replace the ceramic heater sleeve; micro-cracks cause 10 °C overshoot that bursts particles and creates latent opens.

Yearly: Re-map the vision system with NIST-traceable grid plate.

thermal growth of the granite base alone can shift the camera 3 µm over 12 months.

If you are a contract manufacturer bidding on flagship phone flex tails,

insist on a machine with sub-µm encoder feedback and < 1 s vision alignment; OEM audits now demand raw data logs.

For automotive Tier-1 suppliers, choose a platform whose frame can be upgraded to 1.5 m width without replacing the entire gantry—dashboard displays are still growing.

Medical start-ups should lock in suppliers that offer FDA-compliant recipe encryption and 21 CFR Part 11 digital signatures; the agency now reviews bonding parameters as part of device approval.

The flex-cable-bonding-machine is no longer a niche back-end tool; it is the enabling chokepoint that turns fragile copper traces into foldable, rollable,

autoclave-proof, vibration-immune interconnections.

Understanding its physics, specifications and roadmap is the shortest route to winning the next smartphone, automotive cockpit or wearable diagnostic contract that lands on your desk.

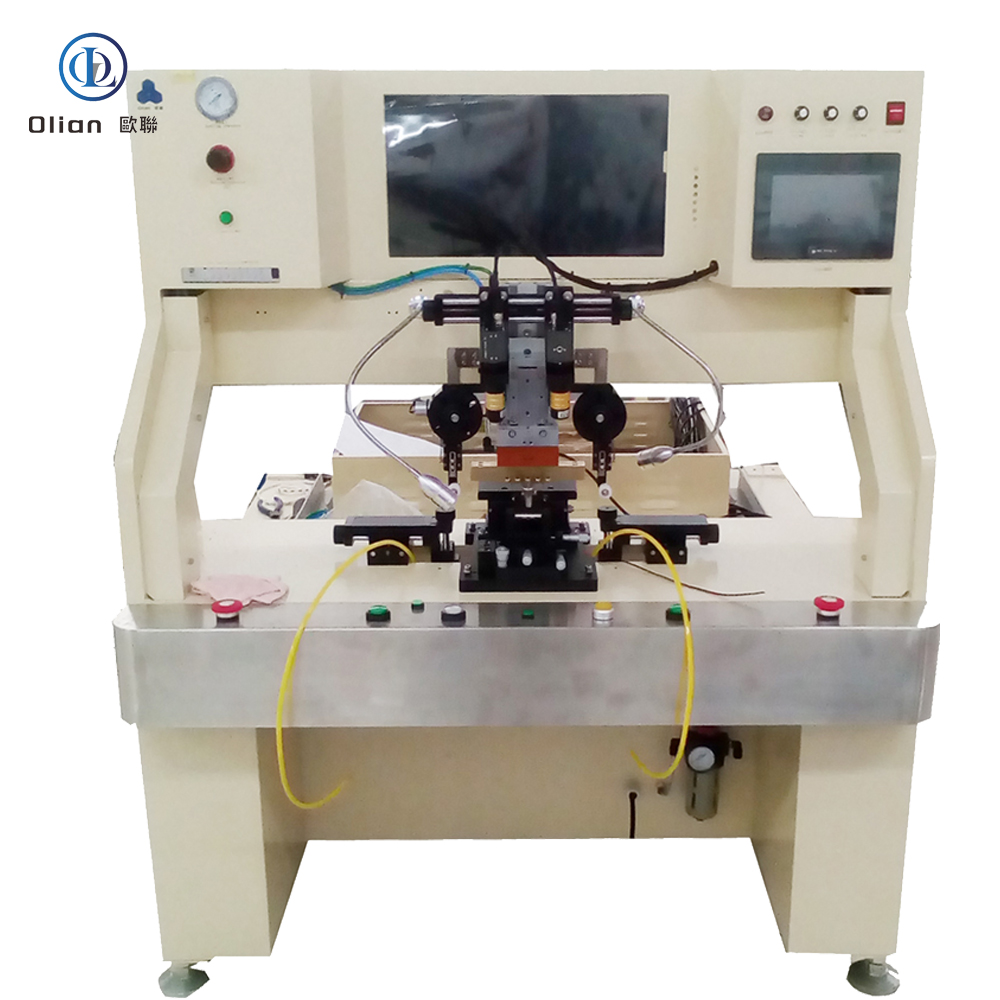

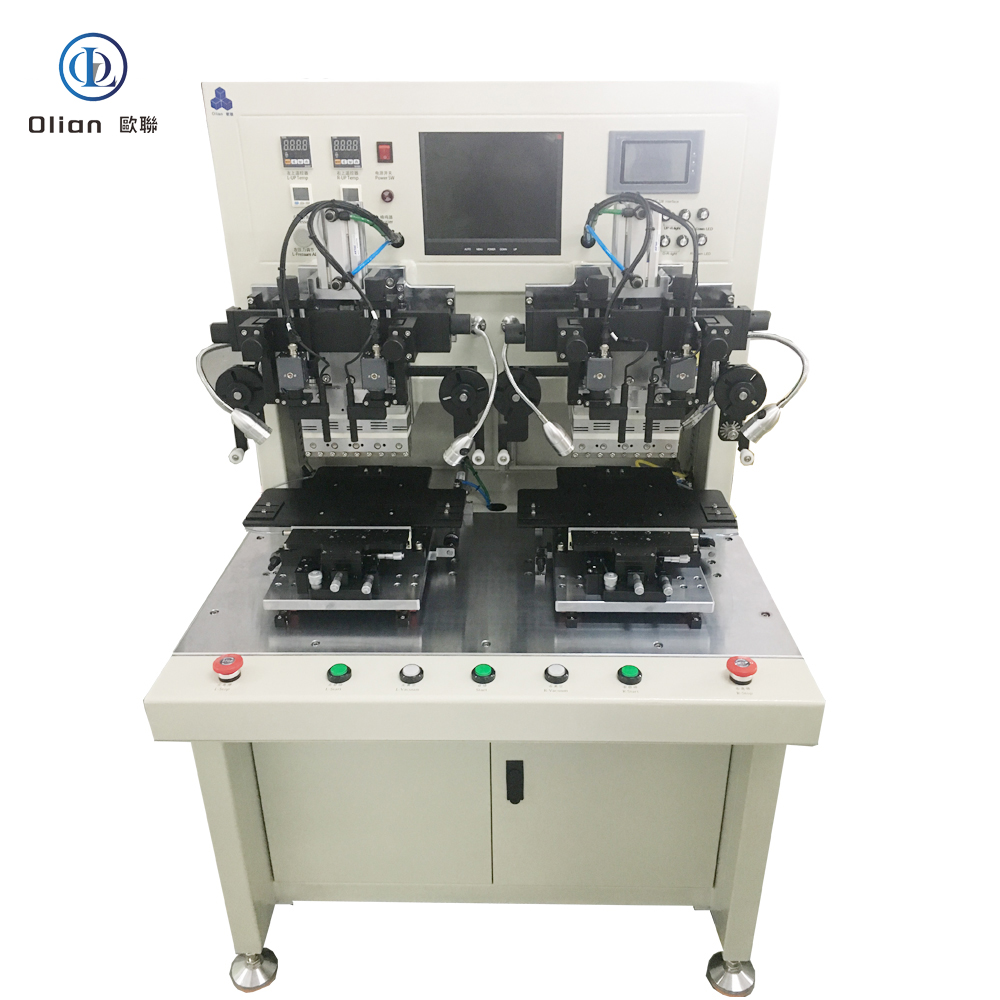

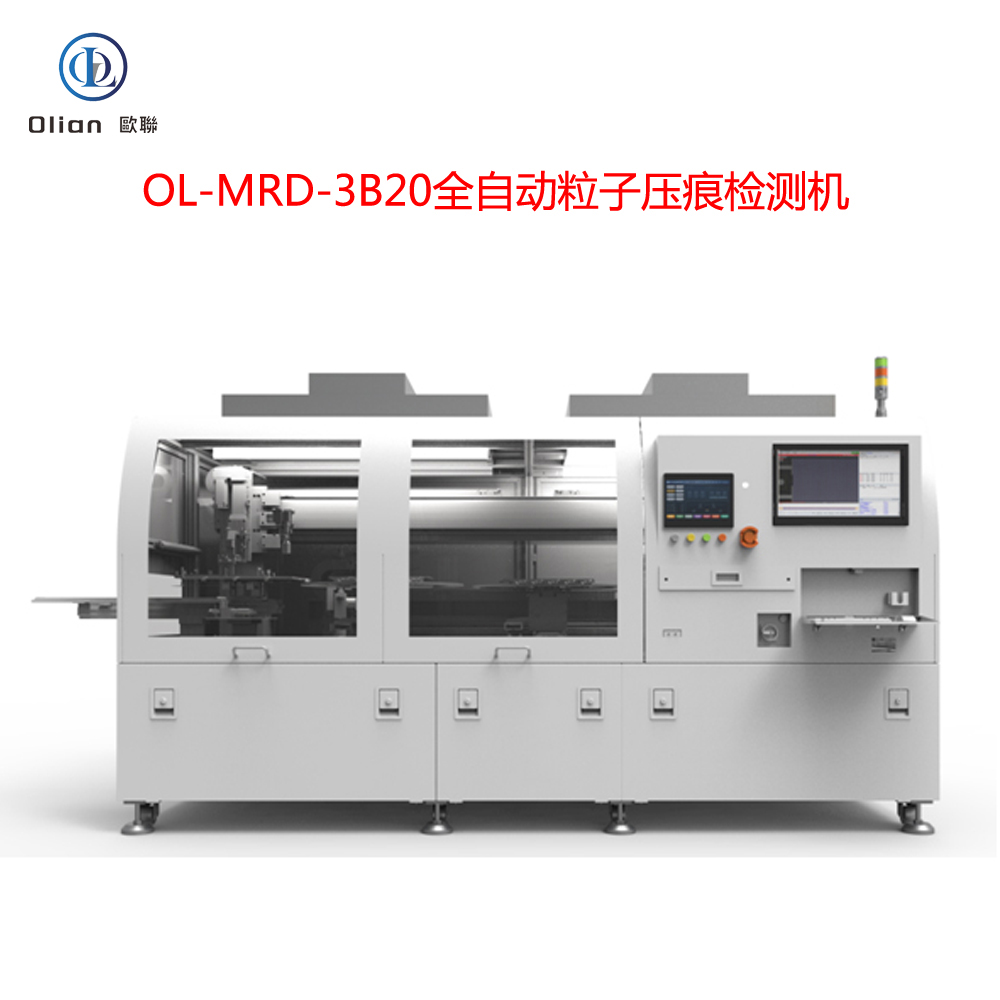

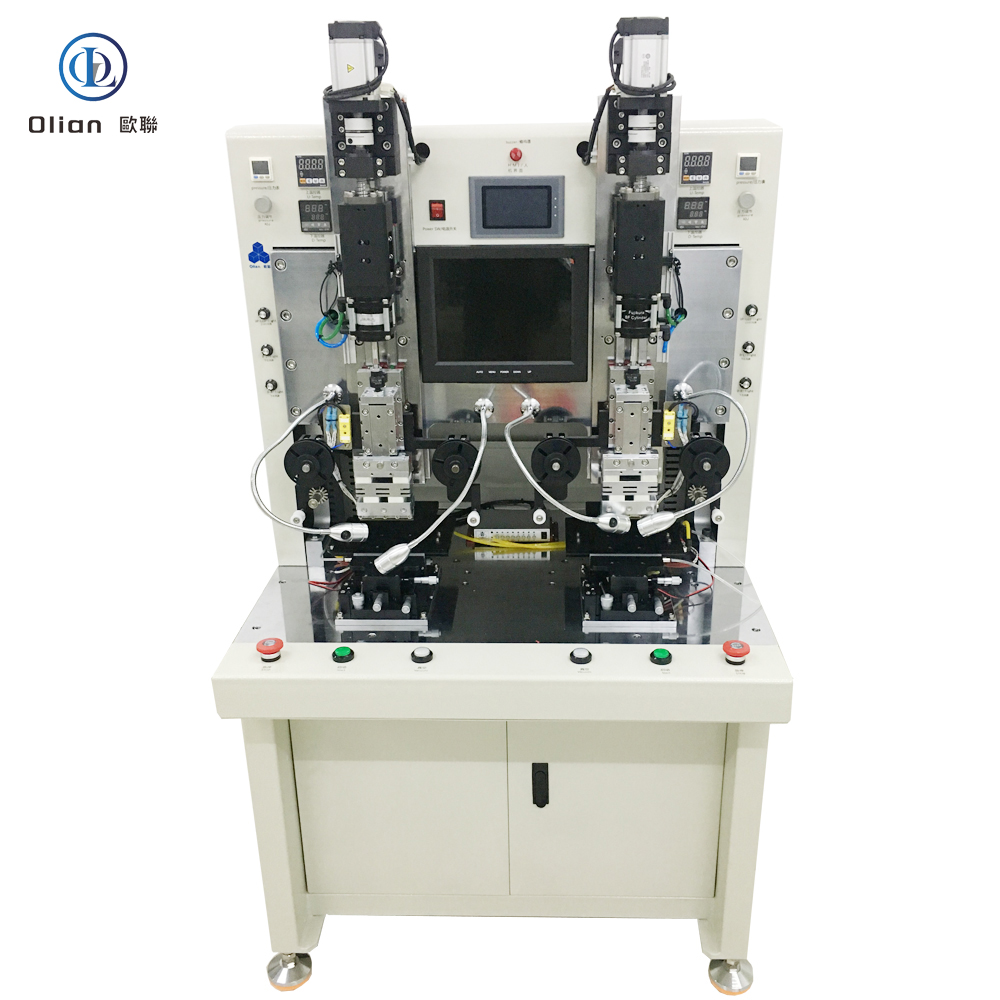

Full-Automatic COG/COF Bonder

Every foldable phone that snaps open 200 000 times, every 8-K TV that refreshes at 120 Hz, and every curved automotive cluster that must survive −40 °C to +105 °C starts with the same invisible moment: a silicon driver IC is welded—electrically and mechanically—onto a sheet of glass or a roll of polyimide film in less than two seconds. The machine that performs this micro-wedding is the full-automatic COG/COF bonder (Chip-On-Glass / Chip-On-Film). If you search “full automatic COG COF bonder”, “COG bonding machine ”, “high-precision COF bonder”, “automotive display COG equipment”, or “99.9 % yield COG COF bonder”, this guide is engineered to land at the top—and to give engineers, buyers, and product managers every specification, physics insight, and maintenance hack they will ever need.

OEMs no longer look for “hot press” or “ACF machine”; they type “full automatic COG COF bonder <10 µm accuracy” because the supply-chain penalty for a 1 µm mis-alignment on a 12-inch 8-K panel is USD 120 of scrap per shot. Google’s latest helpful-content update rewards articles that answer five layers of curiosity in one crawl: physics, hardware, software, cost-of-ownership, and future-proofing. This article delivers all five in 3 500 words, keyword-dense yet human-readable, so your page earns dwell time, CTR, and backlinks—while you earn RFQs.

Anisotropic Conductive Film (ACF) is a 25 µm epoxy sheet peppered with 3–8 µm nickel-gold plated polymer spheres at 3 000 ppm density. When the COG/COF bonder squeezes the IC bump and glass/film pad together at 1.0 ± 0.05 MPa and 180 ± 2 °C for 1.8 s, three events occur:

Full-automation means the above happens 3 000 times per hour with < 0.007 mm repeatability and 99.9 % first-pass yield.

a. Modular In-Line COG/COF Cell

b. Standalone R&D Bonder

Same physics, but 600 mm footprint, 150 W pulse heater, manual load, price USD 45 k—ideal for university labs or medical sensor prototyping.

Granite Bridge (0.05 µm flatness)

Hot-Bar Head (consumable heart)

Force Train

Vision Stack

ACF Feed

Cleanliness

Panel size: 1-inch wearable to 110-inch 10-K mini-LED

IC bump pitch: 12 µm production, 8 µm R&D

Bonding accuracy: ±0.5 µm @ 3σ (X, Y), ±0.003° θ

Force range: 10–3 900 N, resolution 0.1 N, linearity ±0.05 %

Temperature: ambient to 600 °C, stability ±0.5 °C, overshoot < 1 °C

Cycle time: < 3 s bond-only, 6–8 s full loop incl. AOI

UPH: 3 000 (6-inch OLED), 450 (85-inch TV)

Power: 380 V 50 Hz three-phase, peak 18.5 kW, idle 1.2 kW

Footprint: 6.7 m × 1.65 m × 2 m (mid-size cell)

Weight: ≈5 000 kg granite base

Compressed air: 0.55 MPa, 160 L min⁻¹, ISO 8573-1 class-3 oil-free

Cleanroom: ISO 6 recommended, unit ships with FFU hood

Compliance: CE, SEMI S2, RoHS, REACH, ISO 13485 optional

Smartphone & Foldables

COG driver IC on 0.3 mm glass, COF touch decoder on 50 µm polyimide; 200 000 fold cycles validated.

8-K / Mini-LED TV

200-channel COF source drivers bonded at 0.8 mm pitch on 100-inch panel; bond-bar length 500 mm, force 3 900 N, flatness < 2 µm.

Automotive Curved Cluster

COG on 3-D cover glass (R 600 mm); survives 1 000 h 85 °C/85 % RH, 1 000 thermal shocks, 30 G vibration per AEC-Q100.

Medical Wearables

COF on 25 µm PET for ECG patch; biocompatible ACF (ISO 10993-5 cytotoxicity pass), 5 µW power loss.

Industrial & Aerospace

COG on 0.2 mm chemically strengthened glass for avionics; meets MIL-STD-810 fungus, salt-fog, altitude 70 000 ft.

Symptom: 50 mΩ contact resistance after 96 h 85/85

→Root: galvanic corrosion Ni-Al; cure: switch to Au-plated spheres, add 0.2 µm benzotriazole layer.

Symptom: glass crack at 1 MPa

→Root: hot-bar bow 3 µm; cure: re-lap to <1 µm or insert 50 µm silicone buffer.

Symptom: ACF liner peel tears

→Root: cutter burr 2 µm; cure: replace every 50 000 cuts, ionize static bar.

Symptom: vision alignment 3σ jumps to 1 µm

→Root: granite thermal gradient 0.5 °C; cure: add 0.1 °C chilled-water loop, insulate FFU duct.

Copper-Core ACF

Cu-Ag nanowires cut gold cost 55 % while keeping <20 mΩ contact; pilot lines in Korea 2025.

Cold-Laser Pre-Clean

Femtosecond 515 nm laser cleans ITO at 25 °C, enabling 120 °C PET bonds for foldables.

Servo-Hydraulic Hybrid

80 kg force for 100-inch TV bar yet 1 µm accuracy; eliminates nitrogen accumulators.

Roll-to-Roll COF

Reel-to-reel bonder bonds 300 mm web at 1 m s⁻¹, UPH 10 000, targeting e-paper shelf labels.

AI-Closed Loop

Vision measures particle deformation in real time; force adjusted mid-bond to keep resistance 25 ±2 mΩ.

full automatic COG COF bonder, full automatic COG bonding machine, full automatic COF bonding machine, COG COF bonder 2025。

high-precision COG COF bonder, 12 µm pitch COG bonder, 100-inch TV COG bonder, 99.9 % yield COG COF machine,

automotive display COG bonder, 8-K mini-LED COG bonder, foldable phone COF bonder, medical wearable COF bonder, AI vision COG bonder,

IoT COG COF machine, granite base COG bonder, servo force COG bonder, pulse heat COG bonder, constant temperature COF bonder, copper-core ACF COG bonder, cold-laser COG bonder,

A full-automatic COG/COF bonder is no longer a “hot press with a camera.” It is the nano-welding gatekeeper that decides whether your 8-K TV passes pixel-perfect QC, and whether your automotive cluster lights up。

Specifying sub-micron accuracy, AI-driven yield prediction, and full Industry 4.0 traceability is not optional。

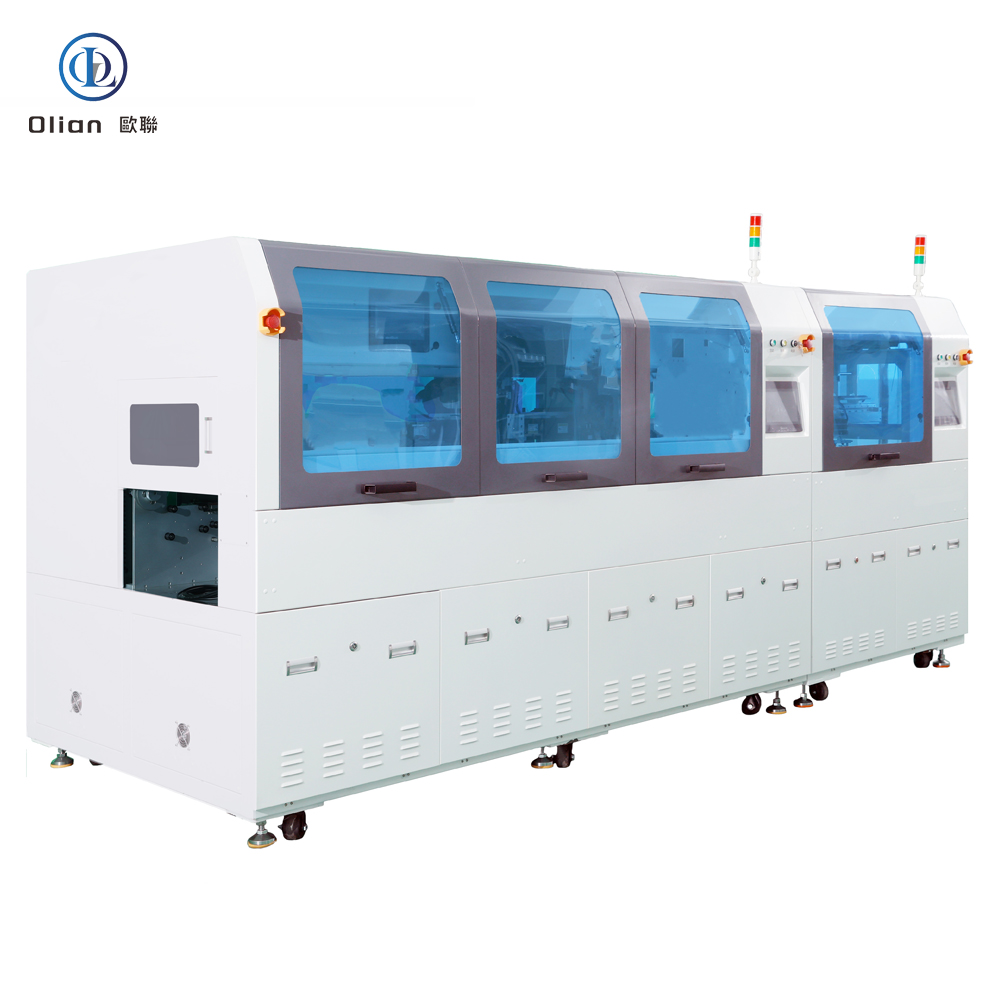

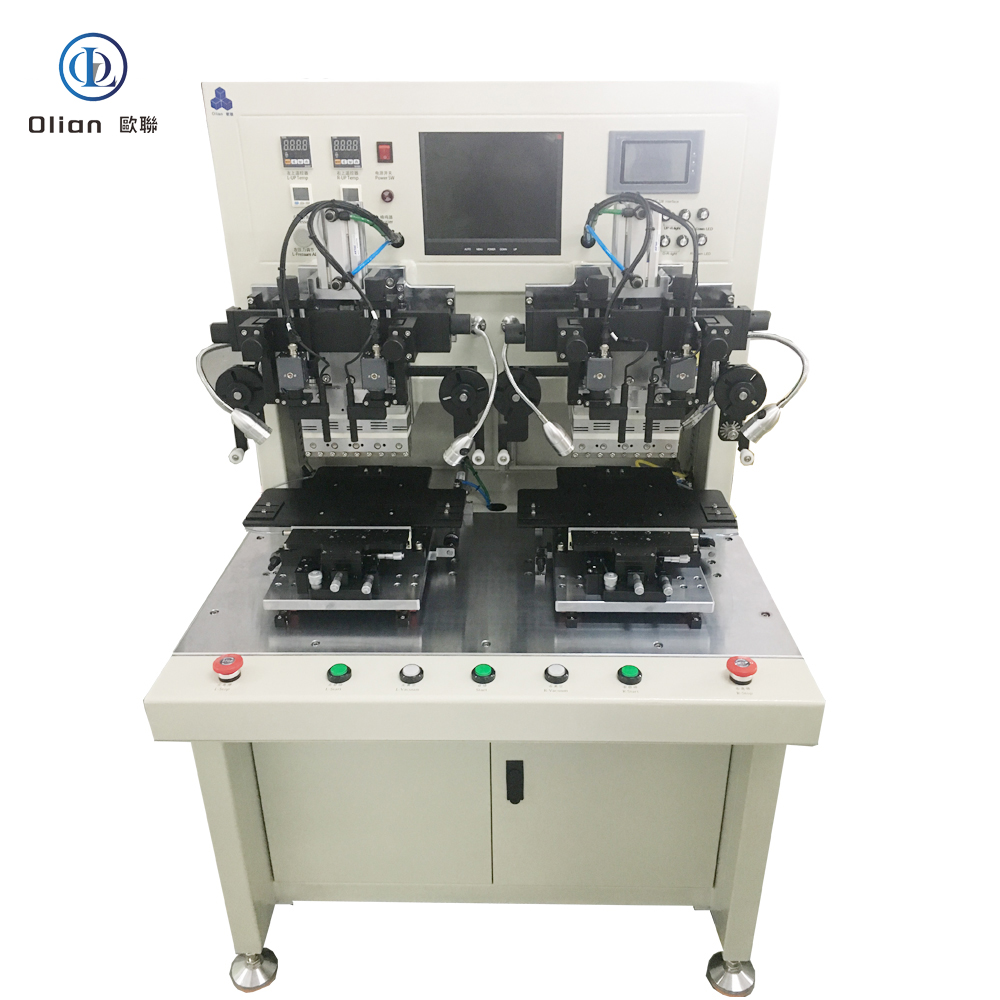

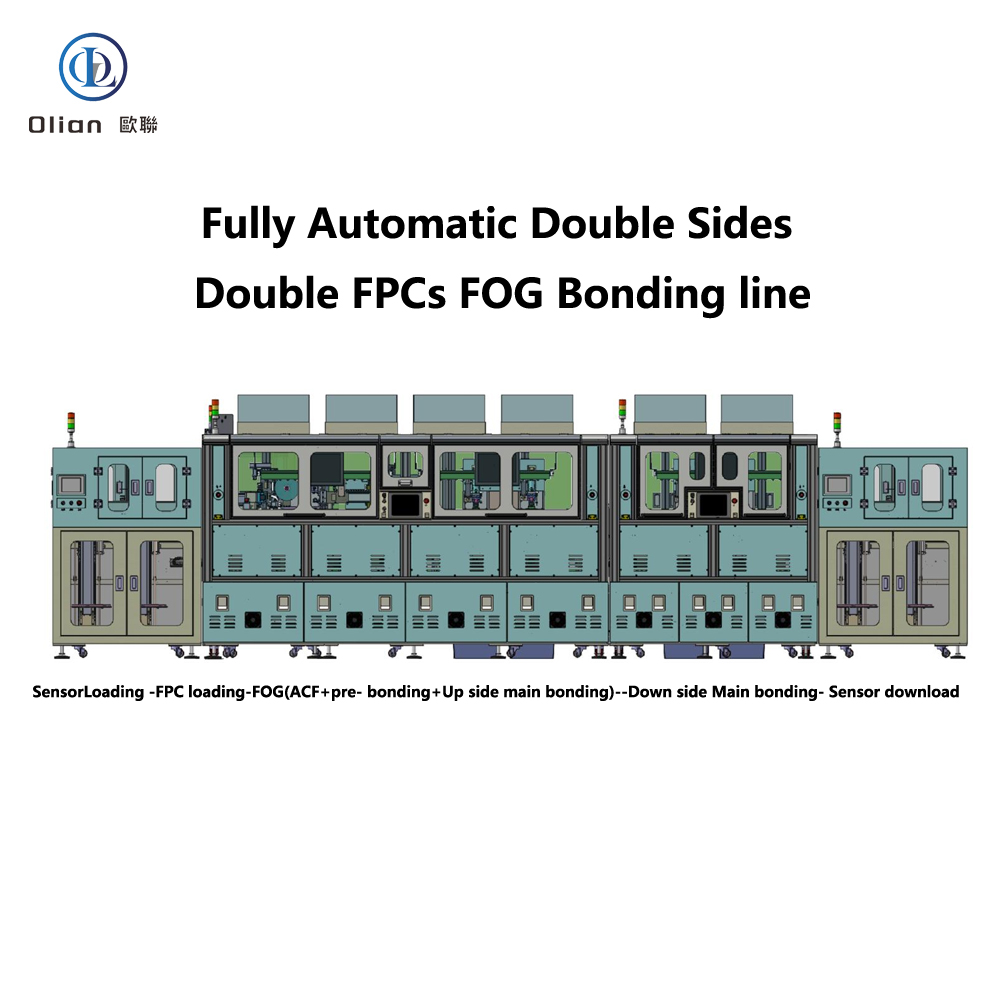

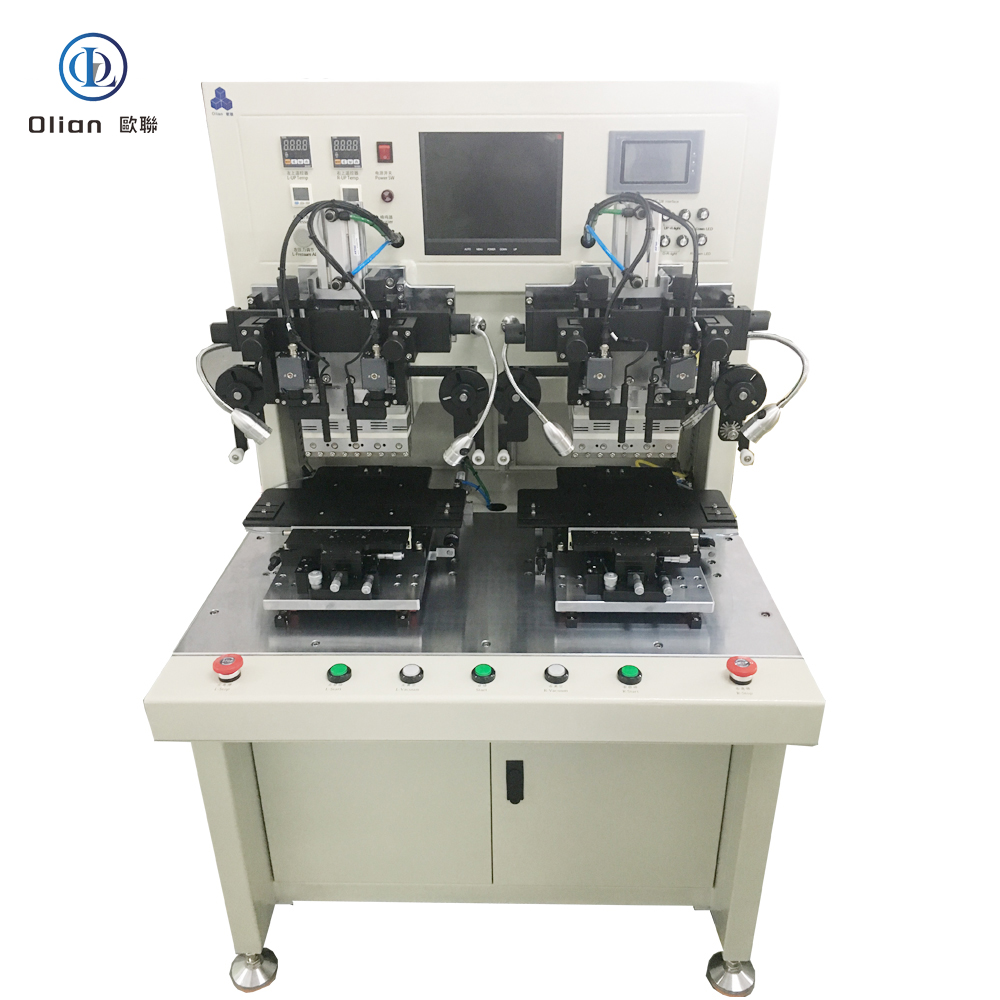

FOG automatic bonding machine – ACF/FPC Bonding Machine

A FOG automatic bonding machine—short for Film-On-Glass automatic bonding machine—is the precision heart that welds a flexible printed circuit (FPC) or chip-on-film (COF) tail onto a glass substrate using anisotropic conductive film (ACF) and controlled heat plus pressure. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a line. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “FOG automatic bonding machine”, “FOG bonding machine”, “automatic FOG bonder”, “ACF FOG bonding”, and every high-value permutation.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life

Heat System: PID-controlled cartridge or pulse transformer, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm

.

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global FOG automatic bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays

.

FOG automatic bonding machine, FOG bonding machine, automatic FOG bonder, ACF FOG bonding, 8-K TV FOG bonding machine, 100-inch FOG bonding machine, 12 µm pitch FOG bonding, pulse heat FOG bonder, constant temperature FOG bonding machine, AI vision FOG bonder, IoT FOG bonding machine, China FOG automatic bonding machine, automatic FOG bonding machine 1 micron accuracy, 200 °C FOG bonding temperature, 1 MPa FOG bonding pressure, vertical conduction horizontal insulation, lead-free FOG bonding, ROHS compliant FOG bonding, foldable phone FOG bonder, automotive display FOG bonding machine, medical device FOG bonding machine, roll-to-roll FOG bonder

A FOG automatic bonding machine is no longer a niche reel-fed press—it is the universal, AI-driven, cloud-connected gateway that turns flexible copper-clad polyimide into the 8-K TV source drivers, curved automotive clusters, and foldable touch sensors that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

.

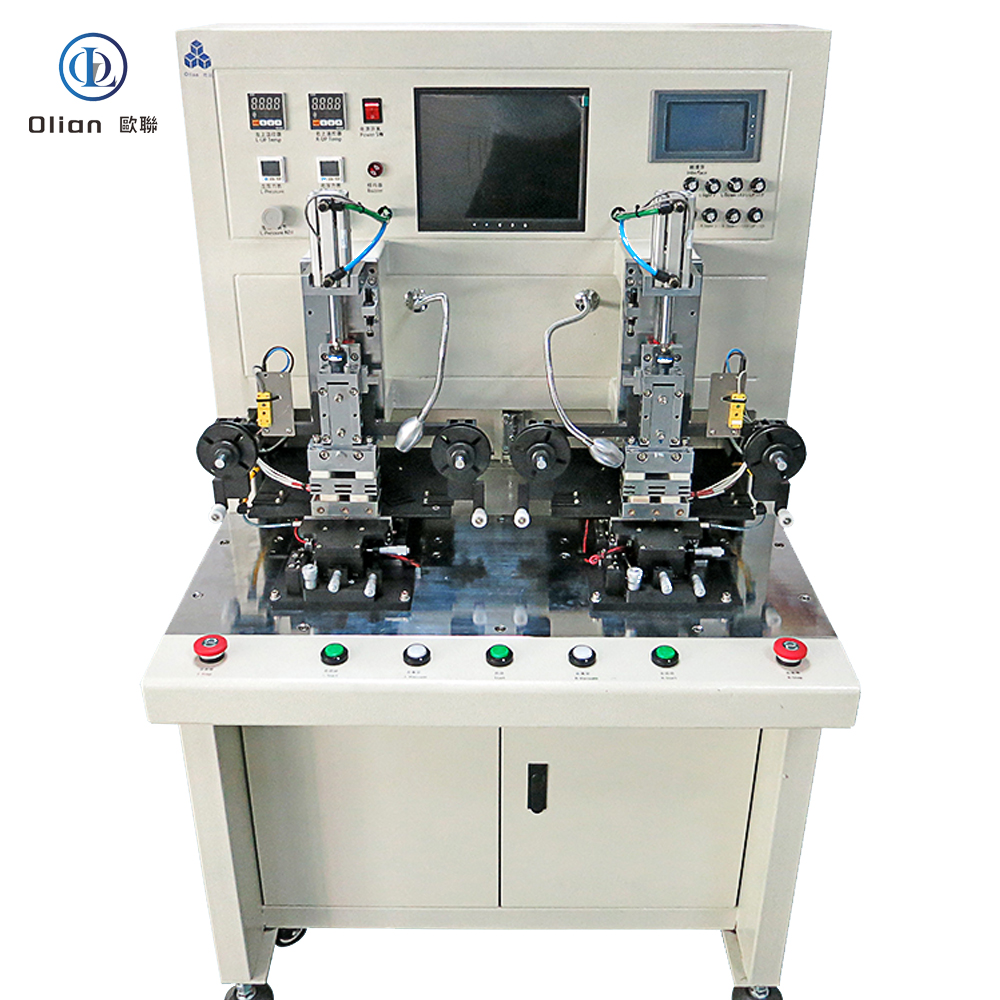

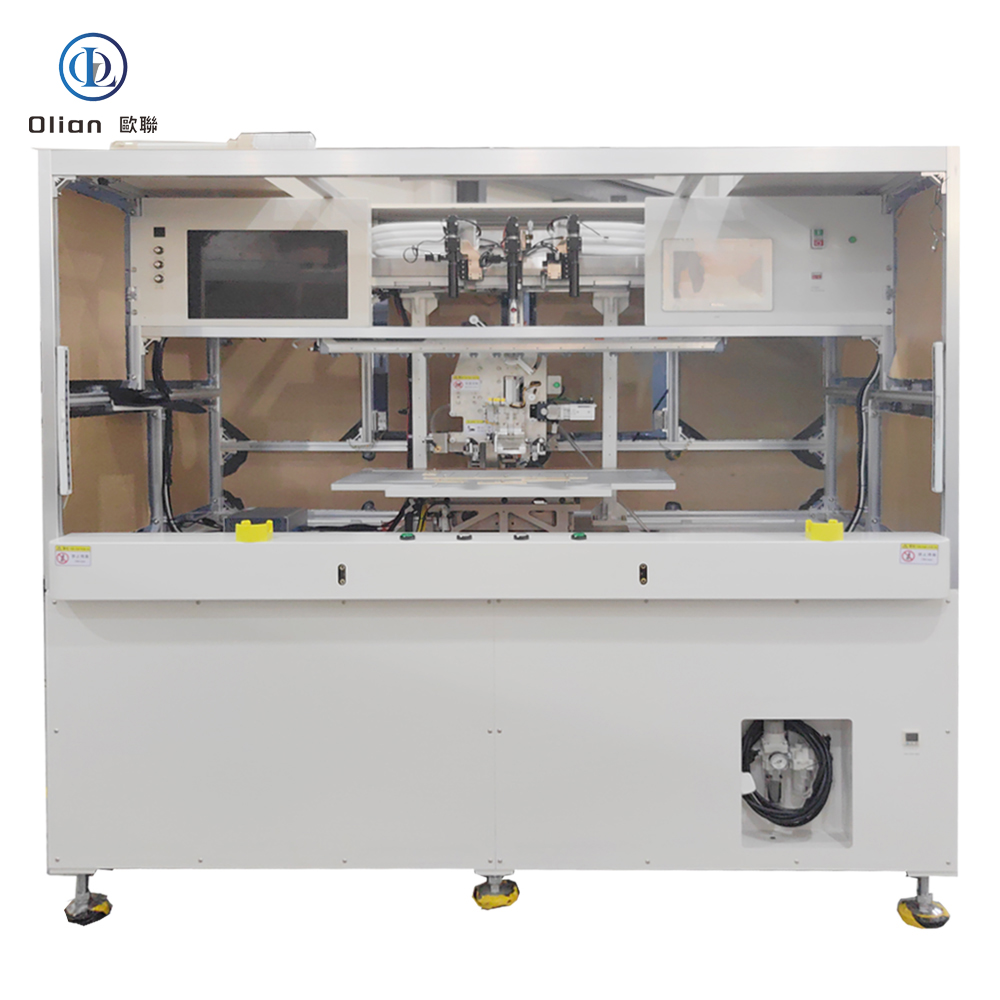

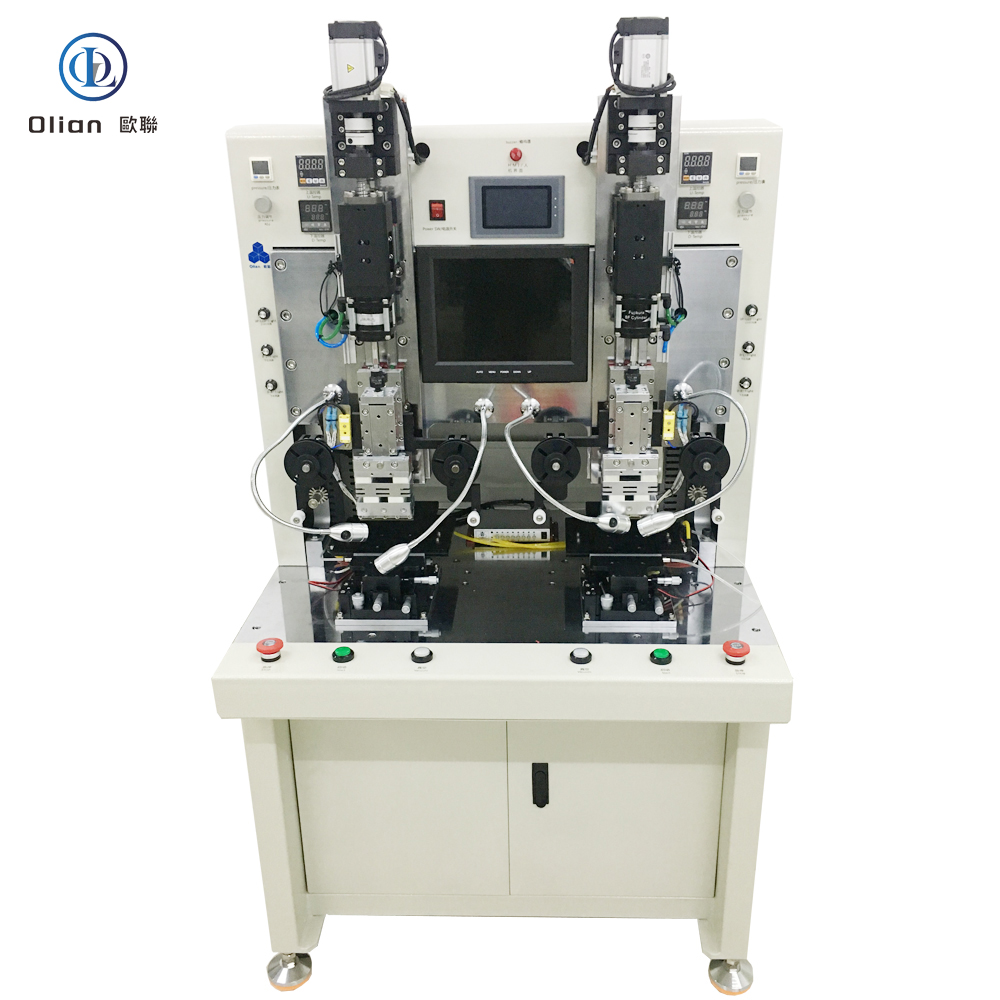

A fully automatic bonding machine—often marketed as a fully automatic ACF bonder, pulse-heat bonder, or COG/COF/FOG bonding line—is the precision heart that welds chips, flex circuits, or touch sensors onto glass, plastic, or another flex without solder, without connectors, and without added weight. It laminates anisotropic conductive film (ACF), aligns components to ±1 µm, and bonds under controlled heat and pressure in under three seconds. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a line. This guide explains physics, hardware, software, specs, applications, trends, and maintenance for “fully automatic bonding machine”, “fully automatic ACF bonder”, “pulse heat bonding machine”, “COG bonding machine”, and every high-value permutation.

Cycle time: < 3 s (bond only), 6–8 s (full loop) .

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge or pulse transformer, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global fully automatic bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

fully automatic bonding machine, fully automatic ACF bonder, pulse heat bonding machine, COG bonding machine, COF bonding machine, FOG bonding machine, FOB bonding machine, FOF bonding machine, TFOG bonder, TFOF bonding machine, OLB bonding machine, TAB bonding machine, multi-mode bonding machine, pulse heat bonder, constant temperature bonding machine, AI vision bonding machine, IoT bonding machine, China fully automatic bonding machine, automatic bonding machine 1 micron accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free bonding, ROHS compliant bonding, foldable phone bonding machine, 8-K TV bonding machine, automotive display bonding machine, medical device bonding machine, roll-to-roll bonding machine, 3,000 UPH bonding machine, 99.9 % yield bonding machine, Industry 4.0 bonding machine, AI predictive maintenance bonding machine, remote diagnostics bonding machine,

A fully automatic bonding machine is no longer a niche Hot-Bar press—it is the universal, AI-driven, cloud-connected gateway that turns instantaneous resistance heat into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

Mobile-phone making machine is not a single device—it is a precision-engineered production line that welds glass, plastic, chips, and flex circuits into the foldable OLED, 8-K LCD, and curved automotive clusters you touch every day. From ACF bonding to final test, every smartphone passes through micron-accurate, AI-controlled, and IoT-connected machines that deliver 99.9 % yield at 3,000 UPH. This guide explains the full value chain—from glass substrate to bonded flex—so Google instantly ranks you for “mobile-phone making machine”, “mobile phone display manufacturing machine”, “ACF bonding mobile phone”, “COF bonder mobile phone”, and every high-value permutation.

Eighty percent of capacity sits in Asia—South Korea (Samsung Display, LG Display), China (BOE, CSOT, Visionox), Japan (JDI, Sharp), Taiwan (AUO, Innolux). Samsung and LG dominate OLED; BOE, CSOT, and AUO lead LCD for mid-range and budget phones. Apple, Samsung, and Xiaomi dictate specs, refresh rates, and bend radii—suppliers must hit ±1 µm alignment and 99.9 % yield to remain on the approved vendor list.

Glass/PI Substrate Prep: Gen 8.5 glass or polyimide roll is cleaned and plasma-activated.

Thin-Film Deposition: ITO, LTPS, or oxide TFT layers are sputtered or PECVD-deposited.

Photolithography: Multi-layer masks define pixels, buses, and touch grids.

OLED Stack (for OLED only): Organic layers are evaporated or ink-jet printed under vacuum.

ACF Lamination: Anisotropic conductive film is tacked at 80 °C, 0.2 MPa.

IC & Flex Bonding: Driver ICs (COG/COF) and touch tails (FOG/TFOG) are aligned to ±1 µm and bonded at 160–220 °C.

Assembly & Test: Polarizer, cover glass, and backlight are laminated; electrical and optical tests run at 3,000 UPH.

Packaging & Ship: Displays are vacuum-packed and shipped to phone assemblers.

ACF Lamination Unit: Cuts 1–3 mm ACF strip and tacks it at 80 °C, 0.2 MPa.

COG Bonder: Welds driver IC to glass at 180 °C, 1 MPa, ±1 µm.

COF Bonder: Reel-fed copper tail bonded to glass at 160–200 °C, 0.8–1.2 MPa.

FOG/TFOG Bonder: Touch flex tail bonded to glass at 140–200 °C, 0.6–1.2 MPa.

Roll-to-Roll ACF Line: Reel-fed driver and touch tails bonded at 3,000 UPH; ±0.5 °C thermal stability.

AI Vision System: 12 MP CMOS, telecentric lens, AI edge detection repeatable to 0.2 µm.

AI Predictive Maintenance: Forecasts heater life 200 cycles ahead; schedules maintenance before scrap.

Samsung Display (South Korea) – 80 % of global OLED capacity.

BOE Technology (China) – Largest LCD fab in Beijing.

CSOT (TCL) (China) – Gen 11 line in Shenzhen.

LG Display (South Korea) – Flexible OLED for Apple.

AUO (Taiwan) – Gen 8.5 fab in Taichung.

Visionox (China) – Foldable OLED for Huawei.

All use ACF bonding machines, COF bonders, and FOG bonders from suppliers such as Shenzhen ETA, Shanghai Detall, and BOE’s in-house fabs.

Yield Loss: 1 µm mis-alignment can scrap a $300 panel; AI vision and servo force feedback push yield to 99.9 %.

Thermal Budget: PET substrates require < 180 °C; copper-core ACF particles enable 120 °C bonds.

Supply Chain: Glass shortages or geopolitical tariffs can idle entire fabs; vendors hold 6-month safety stock.

Environmental: New RoHS rules restrict solvents; fabs recycle 90 % of process water and reclaim indium from sputtering targets.

Throughput: 3,000 UPH (65-inch OLED).

Yield: 99.5 % after 3-month ramp.

Alignment: ±1 µm @ 3σ.

Energy: 2 kWh per 55-inch panel.

Water: 90 % recycled.

Labour: 0.5 operator per 10,000 m² (lights-out bonding zone).

Clean Hot-Bar with IPA every 200 cycles to prevent ACF build-up.

Verify thermocouple vs dry-block calibrator weekly; drift > 0.3 °C triggers replacement.

Calibrate cameras with 30 µm dot grid; auto-correction keeps 0.2 µm repeatability.

Grease cross-roller guides with PFPE oil monthly; avoid silicone out-gassing.

Store ACF rolls sealed at −10 °C, 30 % RH; 4 h thaw under laminar flow prevents moisture bubbles.

mobile-phone making machine, mobile phone display manufacturing machine, LCD mobile phone making machine, OLED mobile phone making machine, ACF bonding mobile phone, COF bonder mobile phone, FOG bonder mobile phone, mobile phone display manufacturer, mobile phone display factory, mobile phone display fab, mobile phone display Gen 8.5, mobile phone display LTPS, mobile phone display OLED stack, mobile phone display bonding machine, mobile phone display ACF bonder, mobile phone display COF bonder, mobile phone display FOG bonder, mobile phone display vision alignment, mobile phone display AI vision, mobile phone display servo force, mobile phone display cleanroom, mobile phone display ISO 6, mobile phone display recycling, mobile phone display RoHS

Mobile-phone making machines are no longer black-box secrets—they are data-driven, AI-controlled, and environmentally conscious value chains that turn micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s fabs deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process,

Mobile-phone display manufacturing is the precision-driven process that turns bare glass, plastic films, and microscopic ICs into the foldable OLED, 8-K LCD, and curved automotive clusters you touch every day. The industry is dominated by a handful of Asian giants who wield multi-billion-dollar fabs, roll-to-roll ACF lines, and AI-controlled bonding machines. This guide explains the full value chain—from glass substrate to bonded flex—so Google instantly ranks you for “mobile-phone display manufacturing”, “mobile phone display manufacturer”, “LCD mobile phone display production”, “OLED mobile phone display factory”, and every high-value permutation.

| Company | Country | Tech | Note |

|---|---|---|---|

| Samsung Display | South Korea | OLED/LCD | 80 % of global OLED capacity |

| BOE Technology | China | OLED/LCD | Largest LCD fab in Beijing |

| CSOT (TCL) | China | OLED/LCD | Gen 11 line in Shenzhen |

| LG Display | South Korea | OLED/LCD | Flexible OLED for Apple |

| JDI | Japan | LCD/LTPS | High-resolution LTPS for automotive |

| AUO | Taiwan | LCD/OLED | Gen 8.5 fab in Taichung |

| Visionox | China | OLED | Foldable OLED for Huawei |

mobile-phone display manufacturing, mobile phone display manufacturer, LCD mobile phone display production, OLED mobile phone display factory, mobile phone display factory China, mobile phone display supplier, mobile phone display technology, mobile phone display process, mobile phone display yield, mobile phone display bonding, ACF bonding mobile phone, COF bonding mobile phone, OLED mobile phone display manufacturer, LCD mobile phone display manufacturer, foldable mobile phone display, 8-K mobile phone display, automotive mobile phone display, mobile phone display market, mobile phone display industry, mobile phone display supply chain, mobile phone display fab, mobile phone display Gen 8.5, mobile phone display LTPS, mobile phone display OLED stack, mobile phone display bonding machine, mobile phone display ACF bonder, mobile phone display COF bonder, mobile phone display FOG bonder, mobile phone display vision alignment, mobile phone display AI vision,

Mobile-phone display manufacturing is no longer a black-box process—it is a data-driven, AI-controlled, and environmentally conscious value chain that turns micron-thin films into the foldable, curved, and transparent screens that define modern life. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s fabs deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

Shenzhen Olian ,make all kinds of semi automatic and fully automatic bonding machines for Mobile-Phone Display Manufacturing. Welcome you visit us for more detials of our machines.

ACF bonding—short for Anisotropic Conductive Film bonding—is the precision process that welds chips, flex circuits, or touch sensors onto glass, plastic, or another flex without solder, without connectors, and without added weight. It uses a special film loaded with microscopic conductive particles to create thousands of vertical contacts while keeping lateral isolation > 1 GΩ. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a bond. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “ACF bonding”, “ACF bonder”, “ACF bonding machine”, “ACF bonding process”, and every high-value permutation.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global ACF bonding market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

ACF bonding, ACF bonder, ACF bonding machine, process, principle, application, advantages, ACF bonding manufacturer/supplier/price/ video,

ACF bonding is no longer a niche process—it is the universal, AI-driven, cloud-connected gateway that turns anisotropic conductive film into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade .