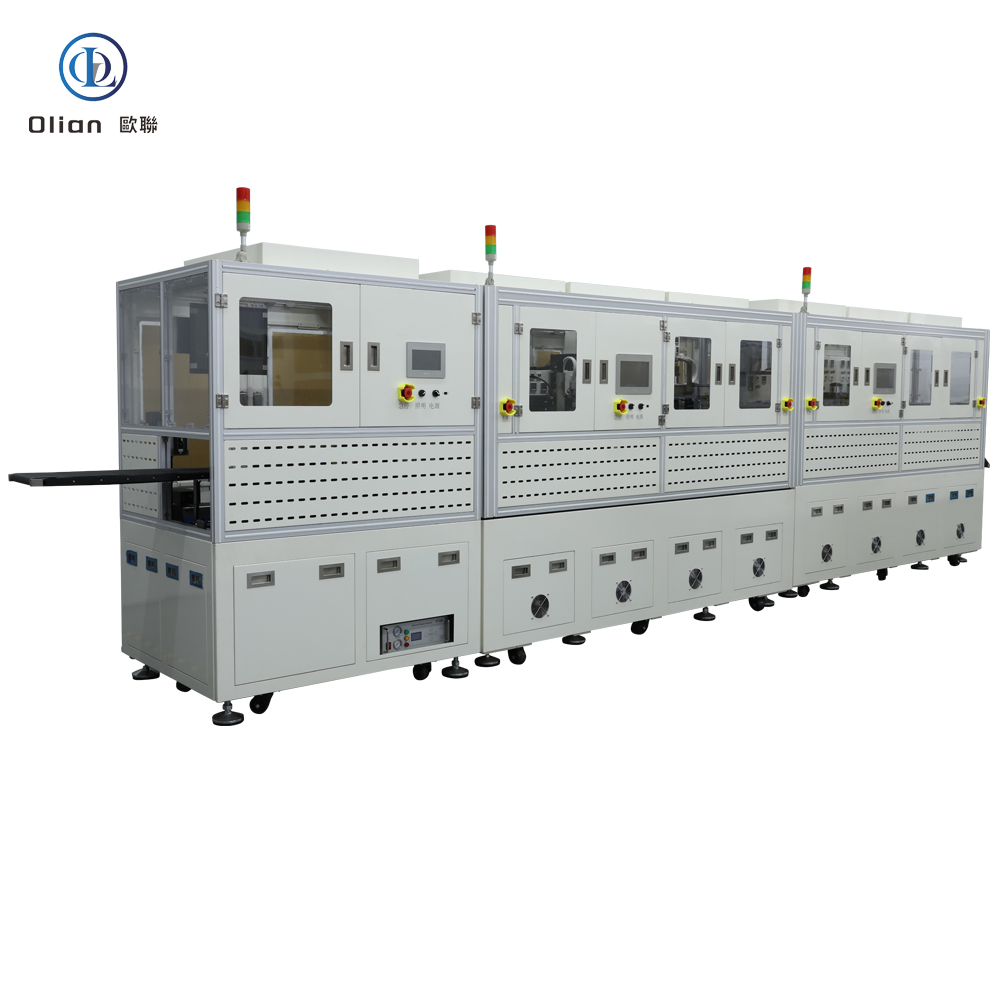

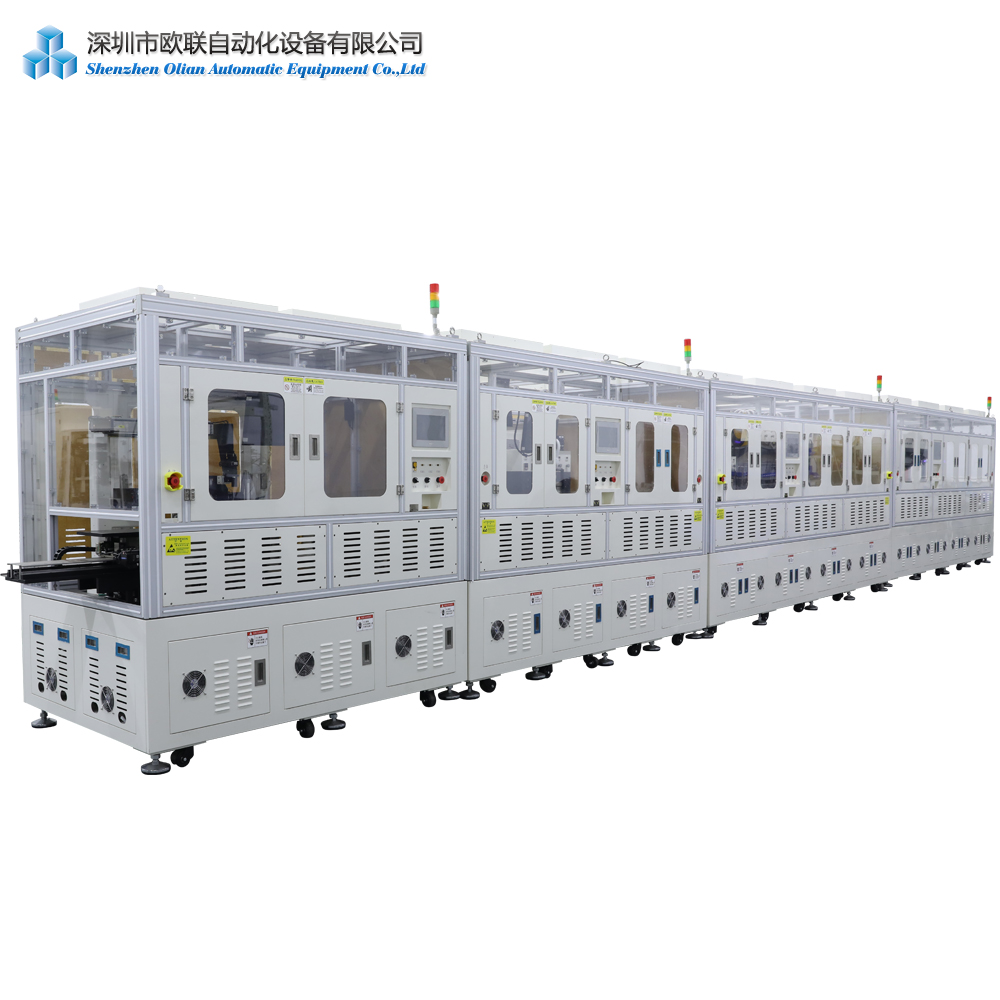

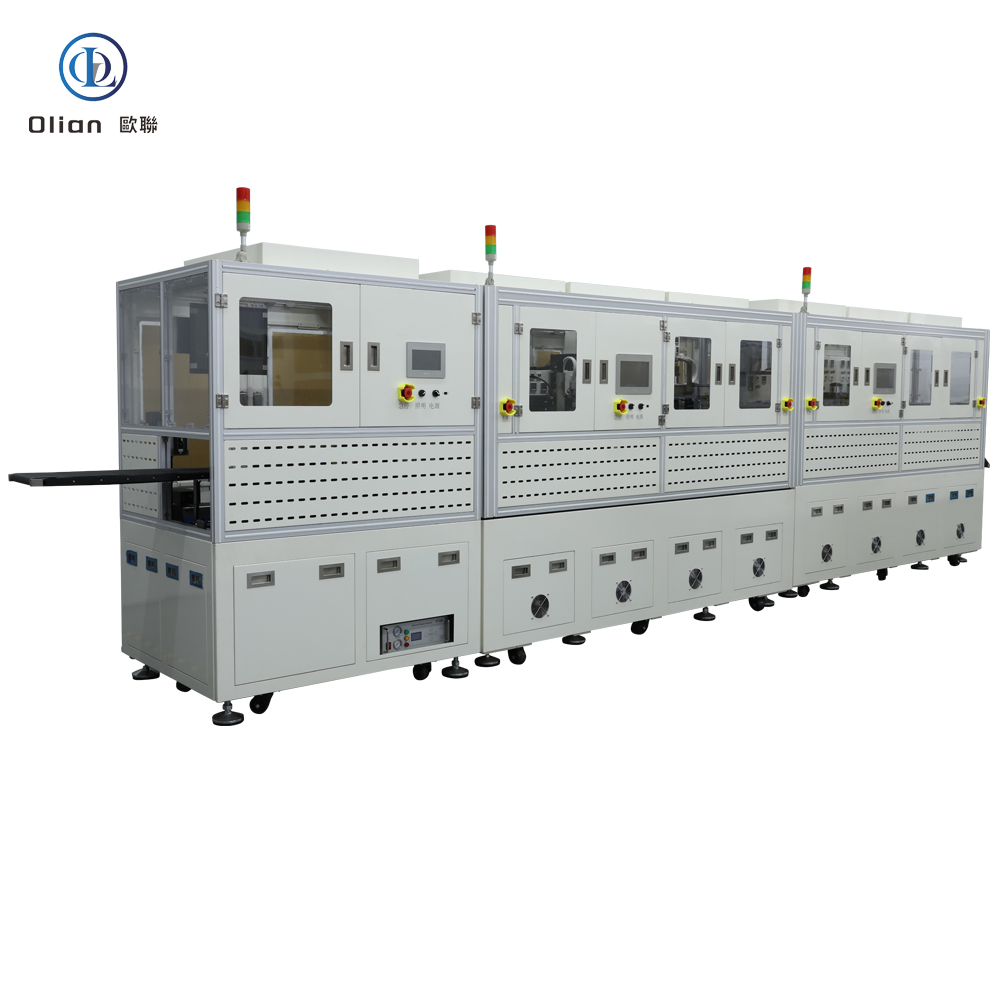

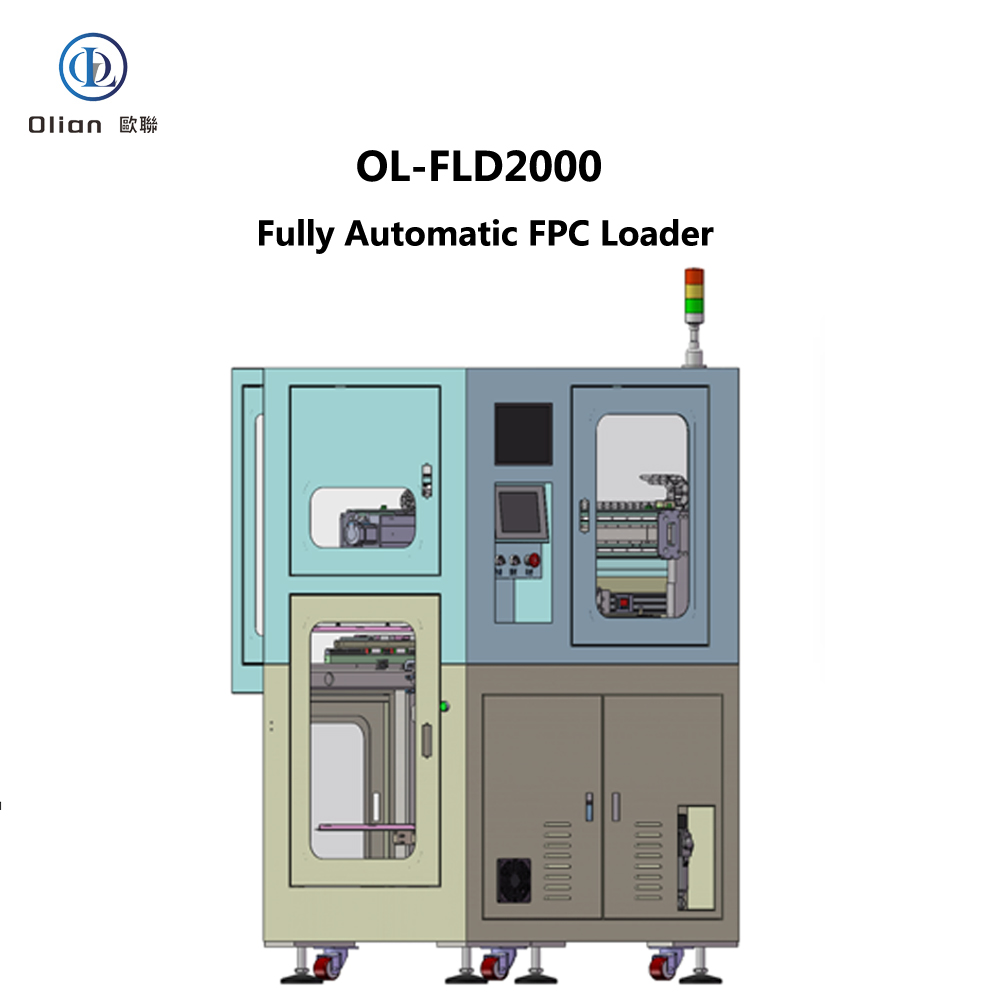

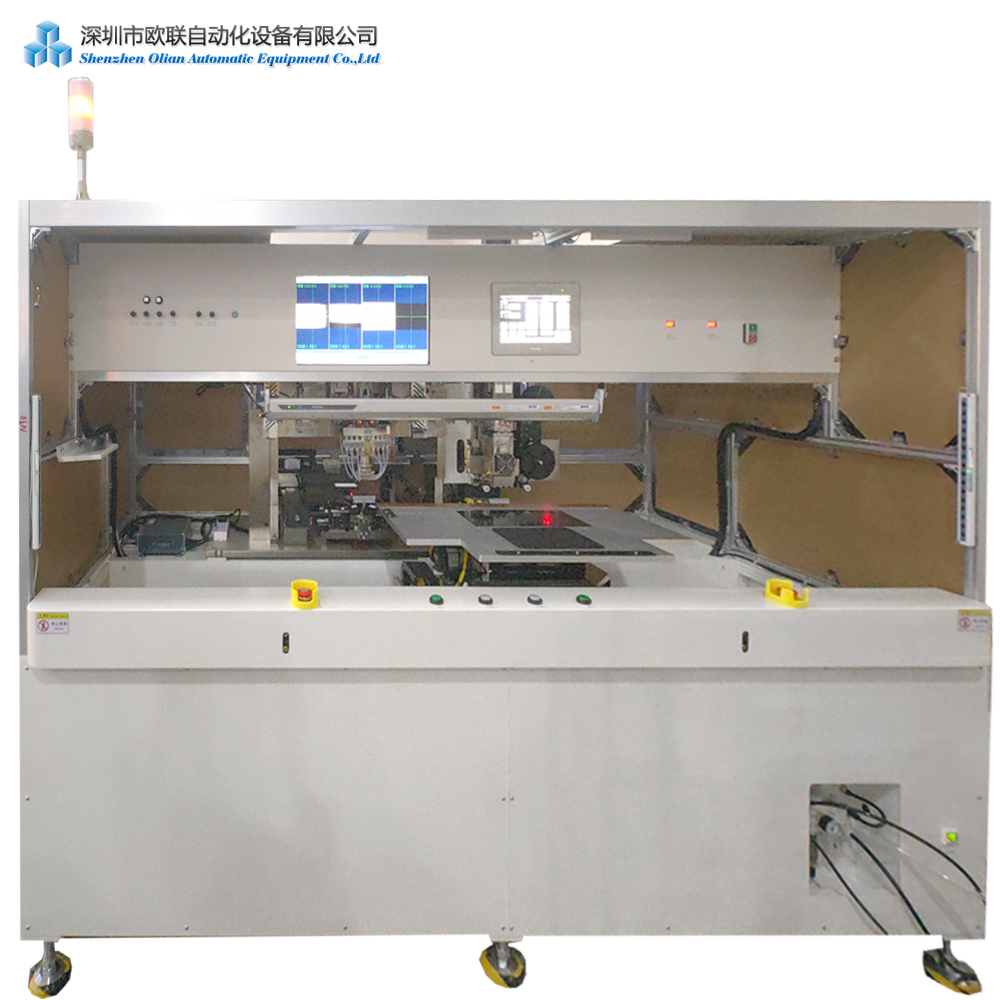

5-17.3″ Mid-Size Display Module Automation Solution: LOAD/EC/COG/FOG/FPC Feeding System

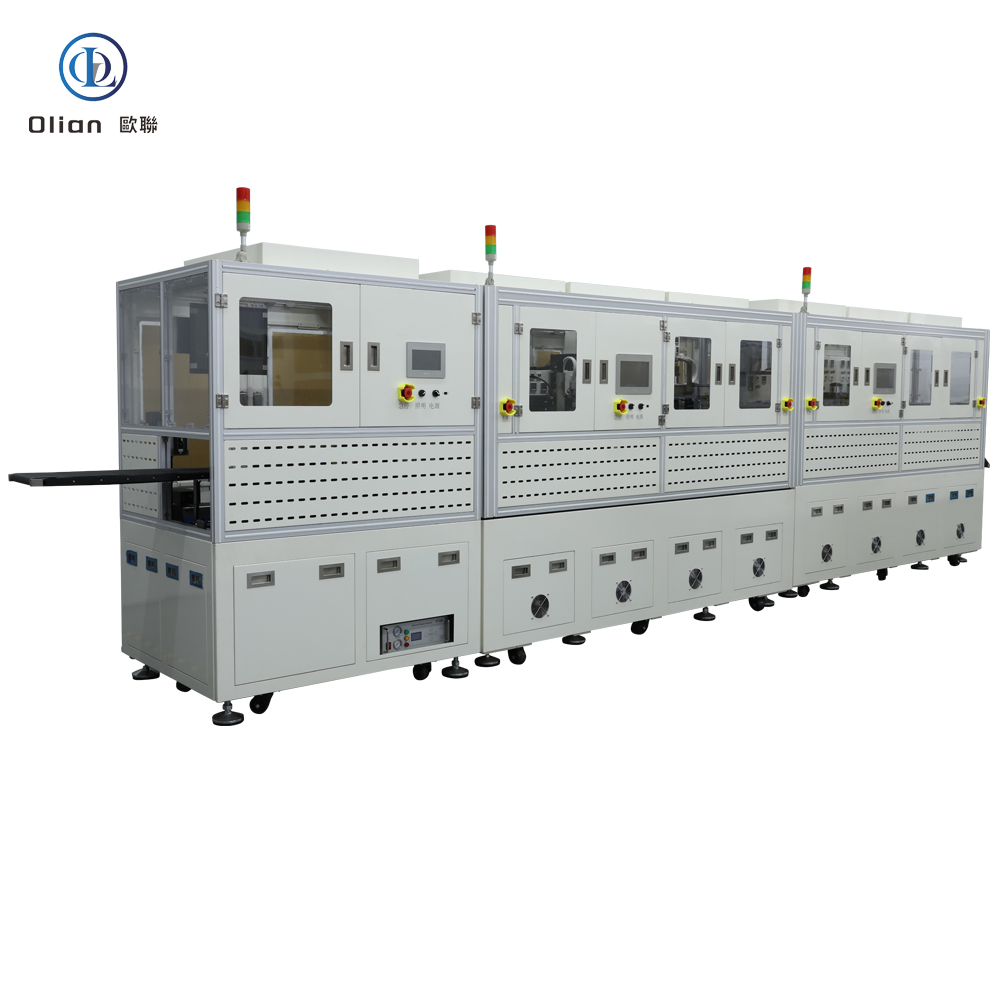

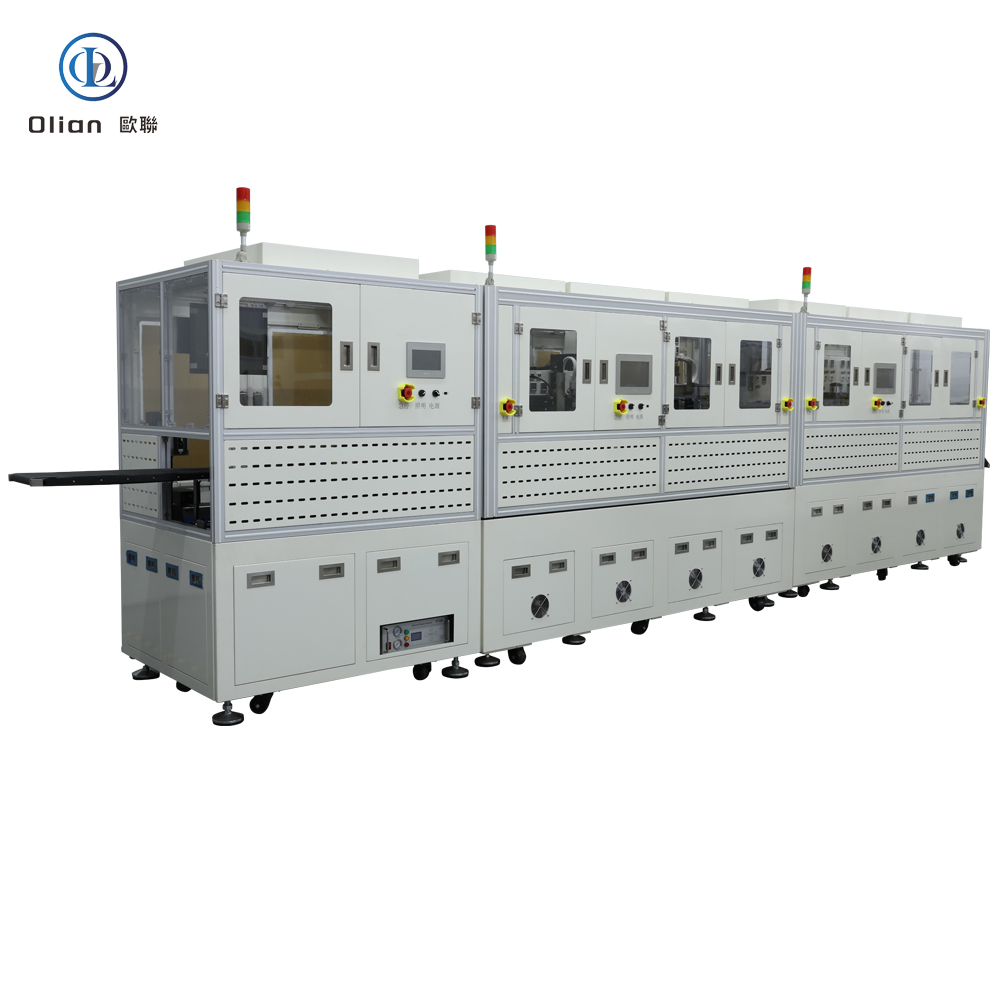

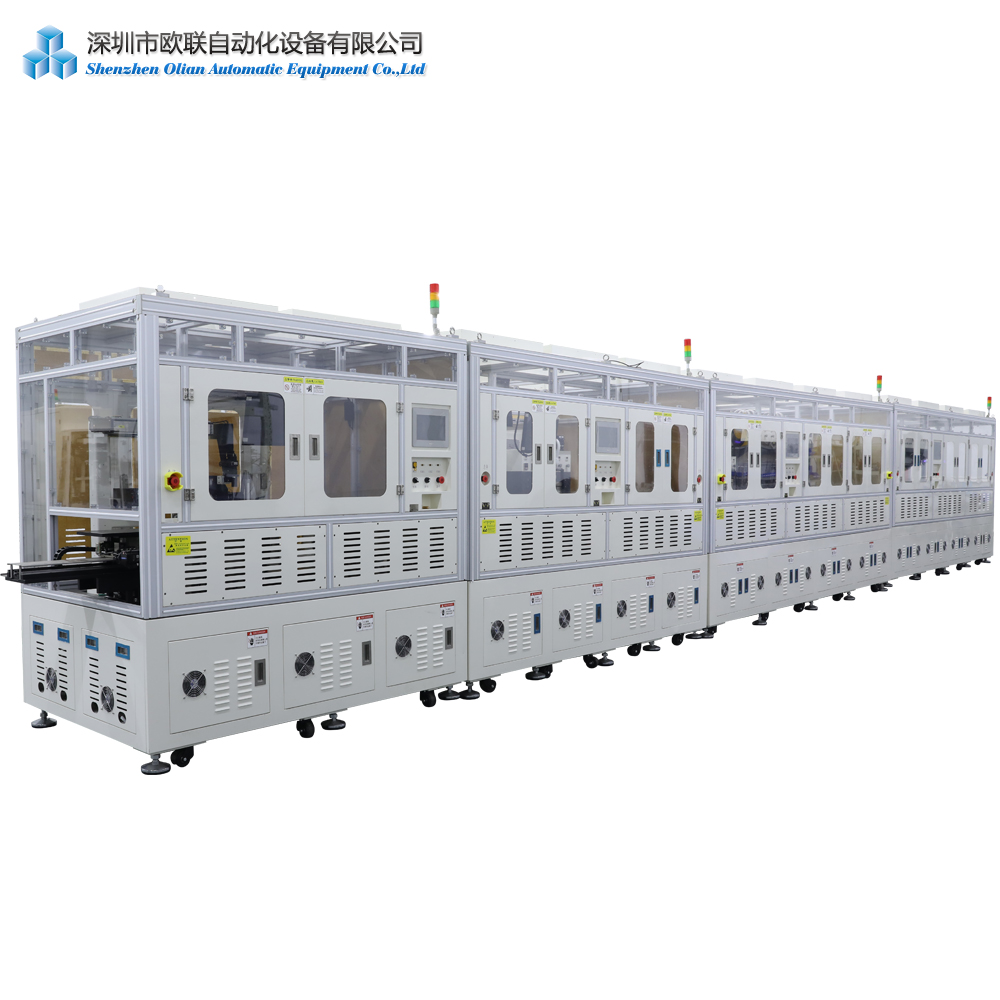

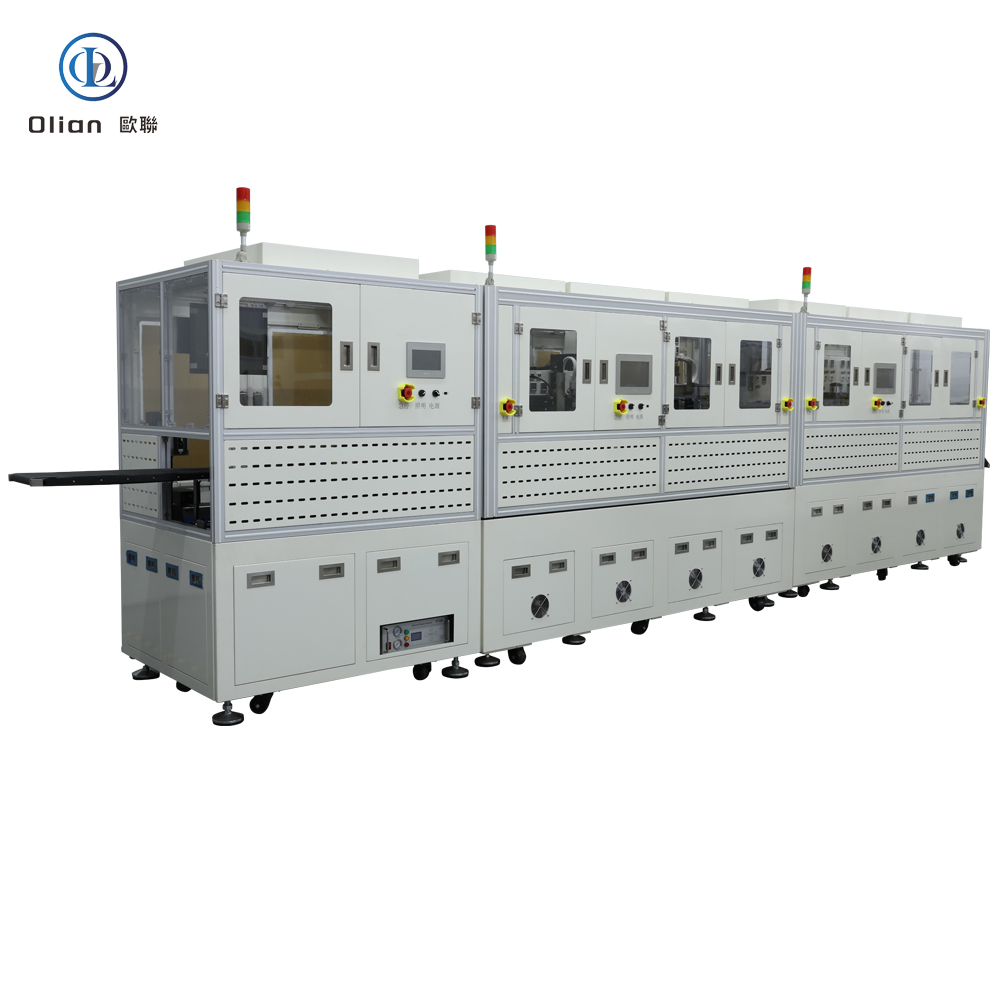

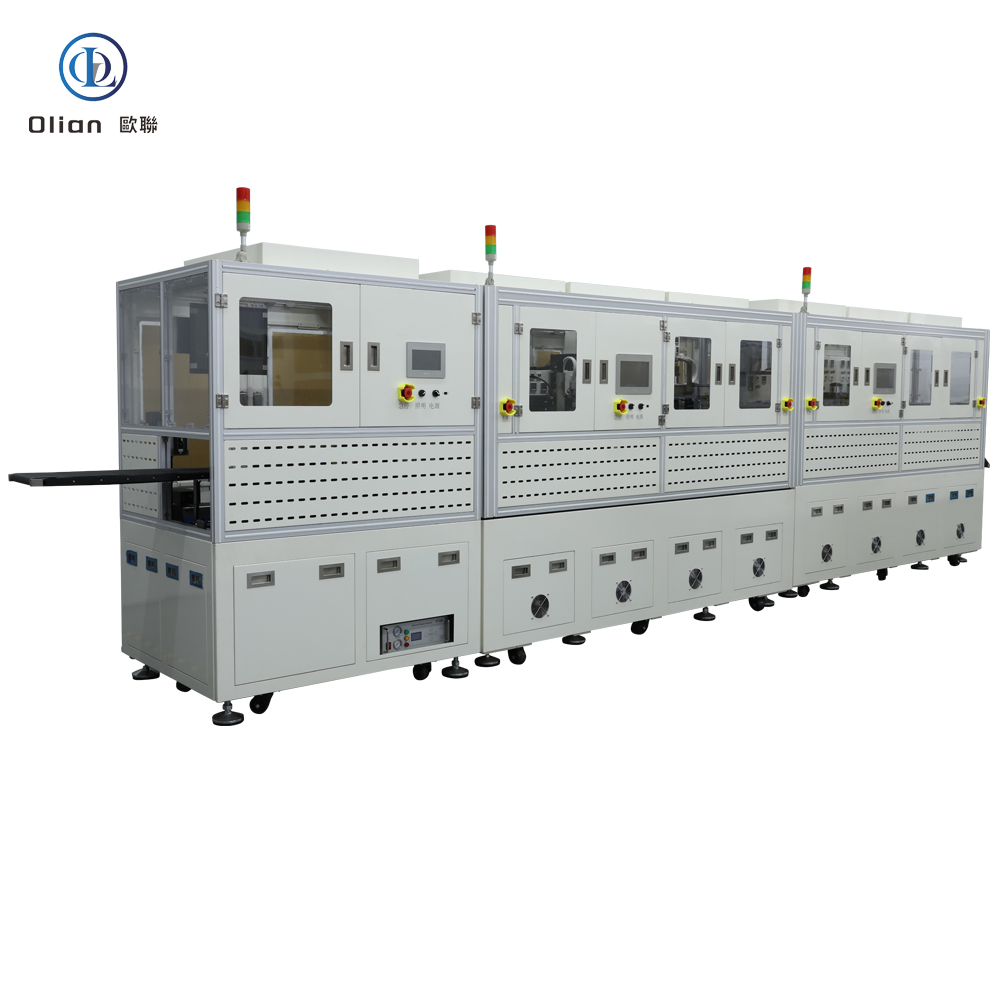

This document presents a comprehensive automation solution for the production of mid-size display modules (5-17.3 inches), focusing on the integration of various equipment for high-precision and high-efficiency manufacturing. The solution includes panel loading, terminal cleaning, COG (Chip on Glass) and FOG (FPC on Glass) bonding, as well as FPC (Flexible Printed Circuit) feeding. Each component is designed to work seamlessly with others to ensure smooth production flow and superior product quality.

This automation solution for mid-size display modules offers a comprehensive approach to efficient and precise manufacturing. By integrating advanced technologies and equipment, it ensures high yield, superior quality, and cost-effectiveness, making it ideal for modern display production environments.

TFT displays manufacturing glass cutting laminating bonding dispensing assembling testing packing processes detailed introduction to each process and equipment situation:

Glass loading is the process of placing the cut glass substrates into designated fixtures or carriers to prepare them for subsequent processes such as electronic cleaning and bonding. It ensures the glass substrates are properly positioned and secured for further processing.

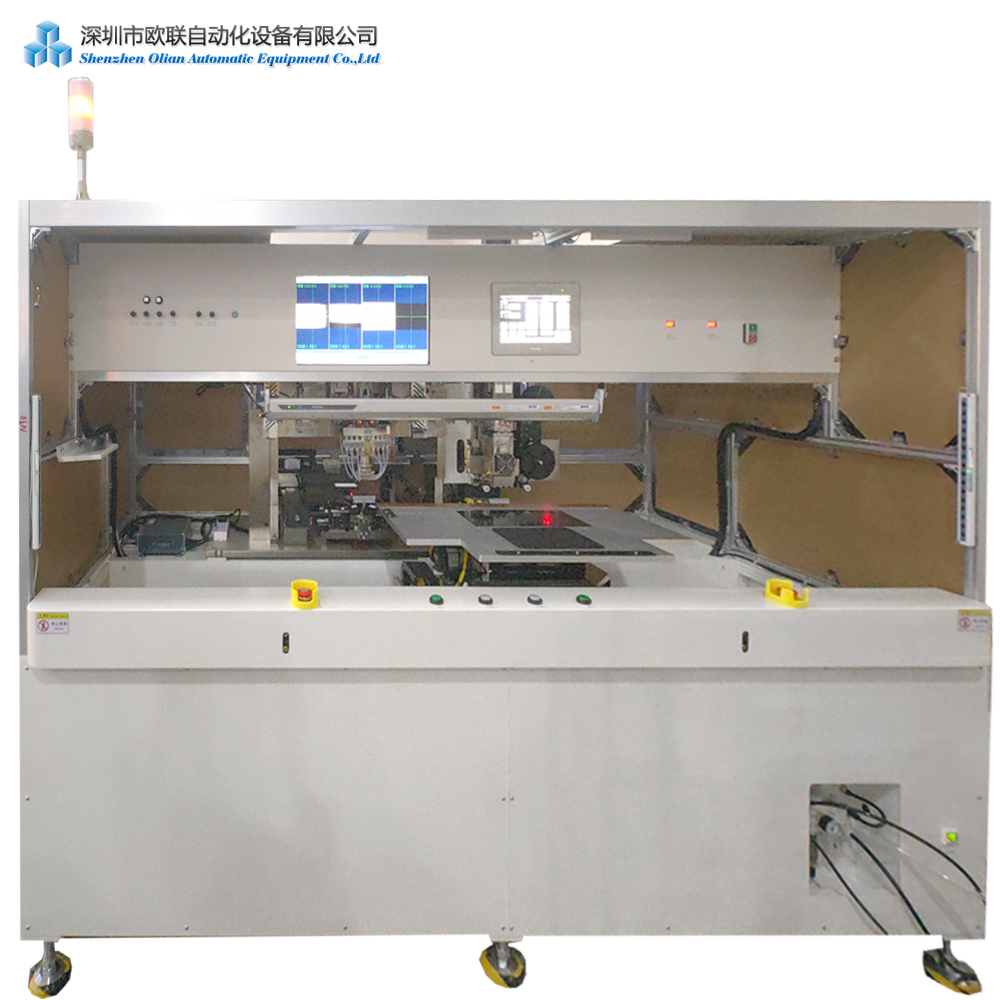

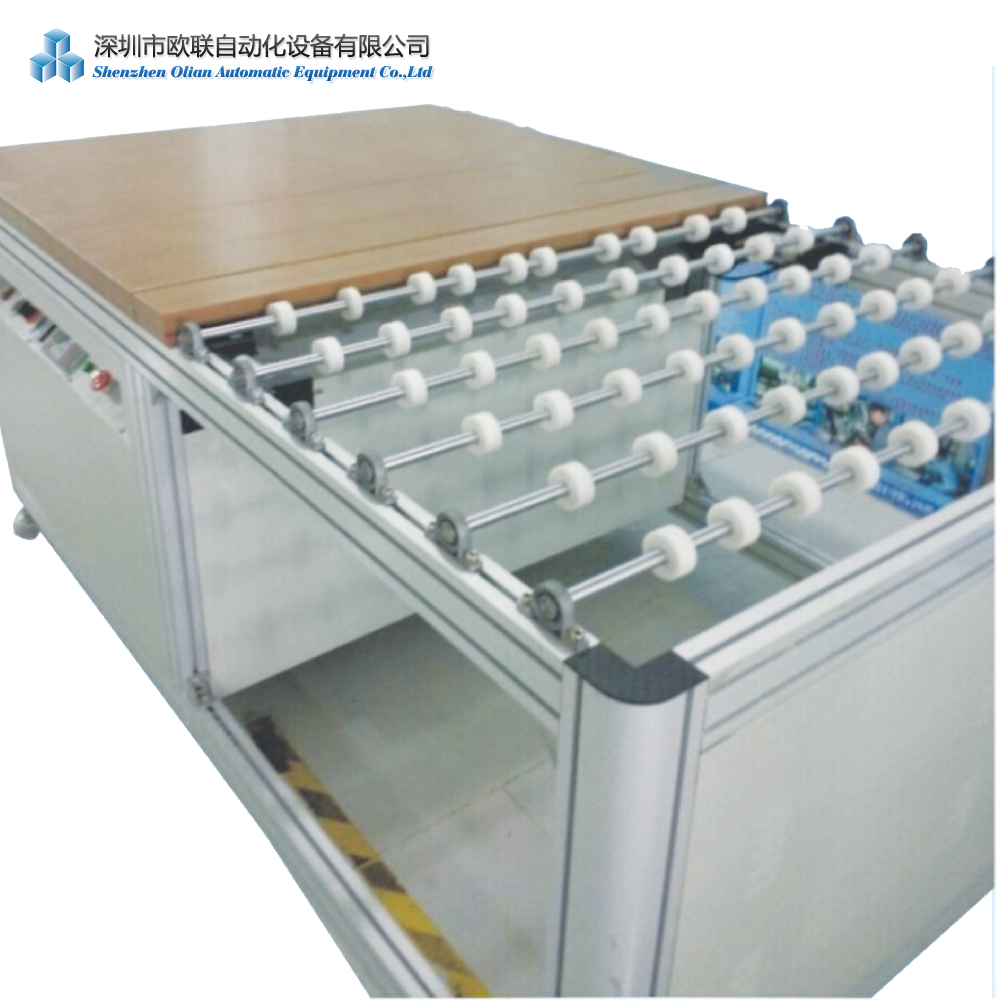

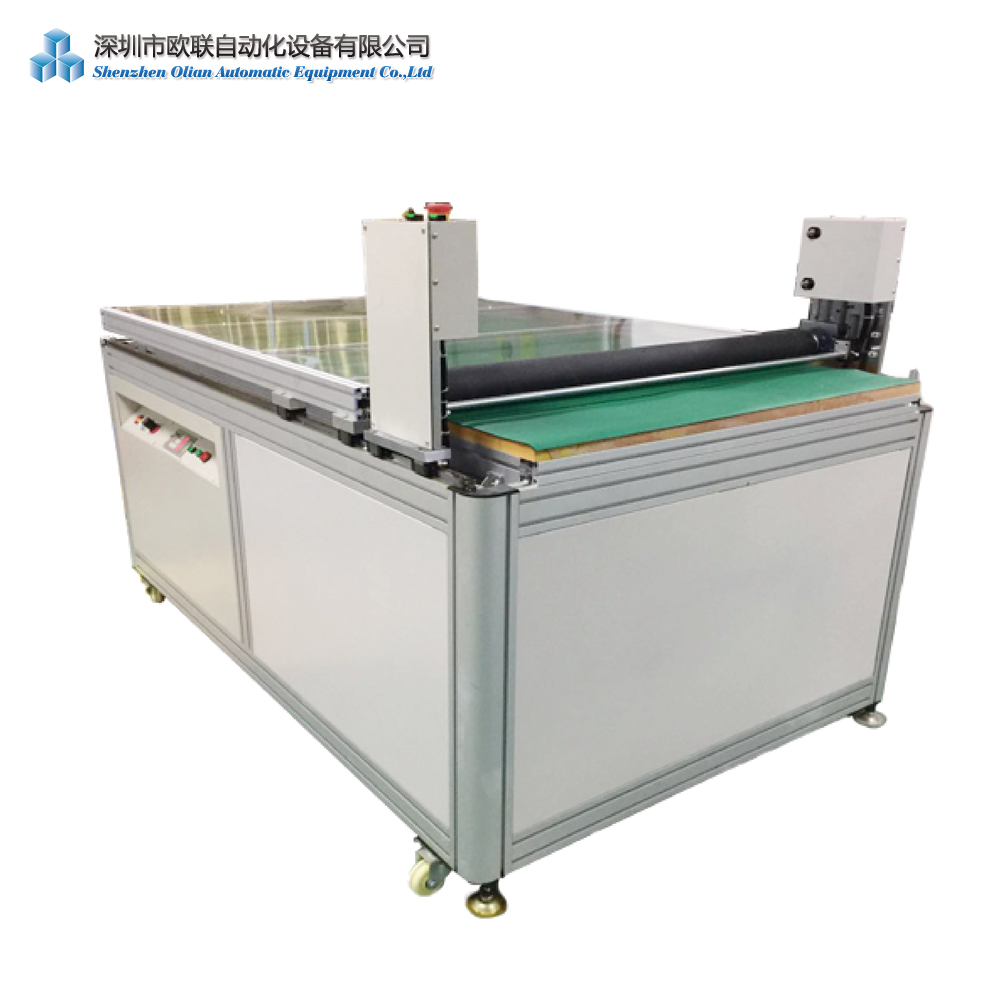

The glass loading machine is designed to handle glass substrates with care. It has a precise positioning system to place the glass substrates into the fixtures accurately. The machine may also feature automated arms or conveyors to transport the glass substrates efficiently while minimizing manual handling and potential damage.

Electronic cleaning is used to remove contaminants such as dust, organic residues, and ions from the surface of the glass substrates or polarizing plates. This helps improve the bonding quality and reliability in subsequent processes, preventing issues like poor adhesion or electrical shorts.

The electronic cleaning machine typically uses a combination of ultrasonic waves, deionized water, and chemical cleaning agents to thoroughly clean the glass substrates or polarizing plates. It has a closed cleaning chamber to prevent re – contamination and a drying system to quickly dry the cleaned substrates after cleaning.

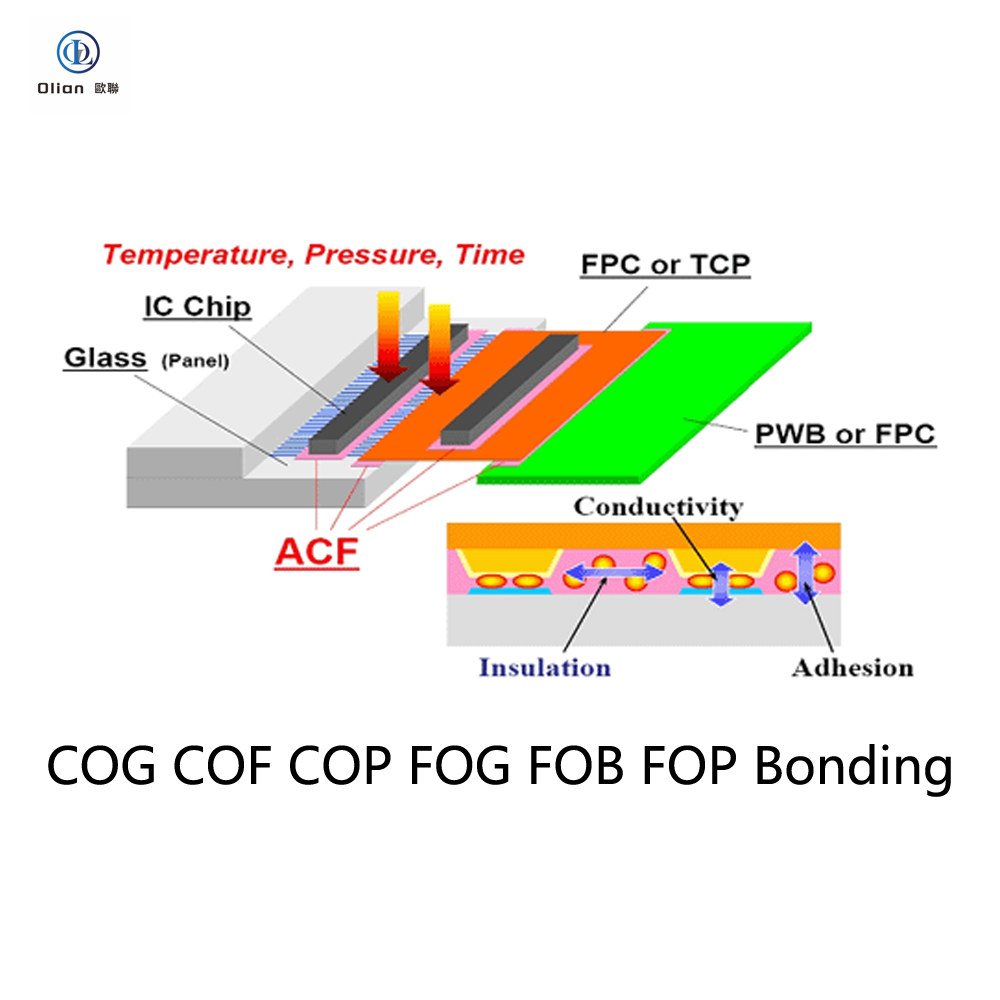

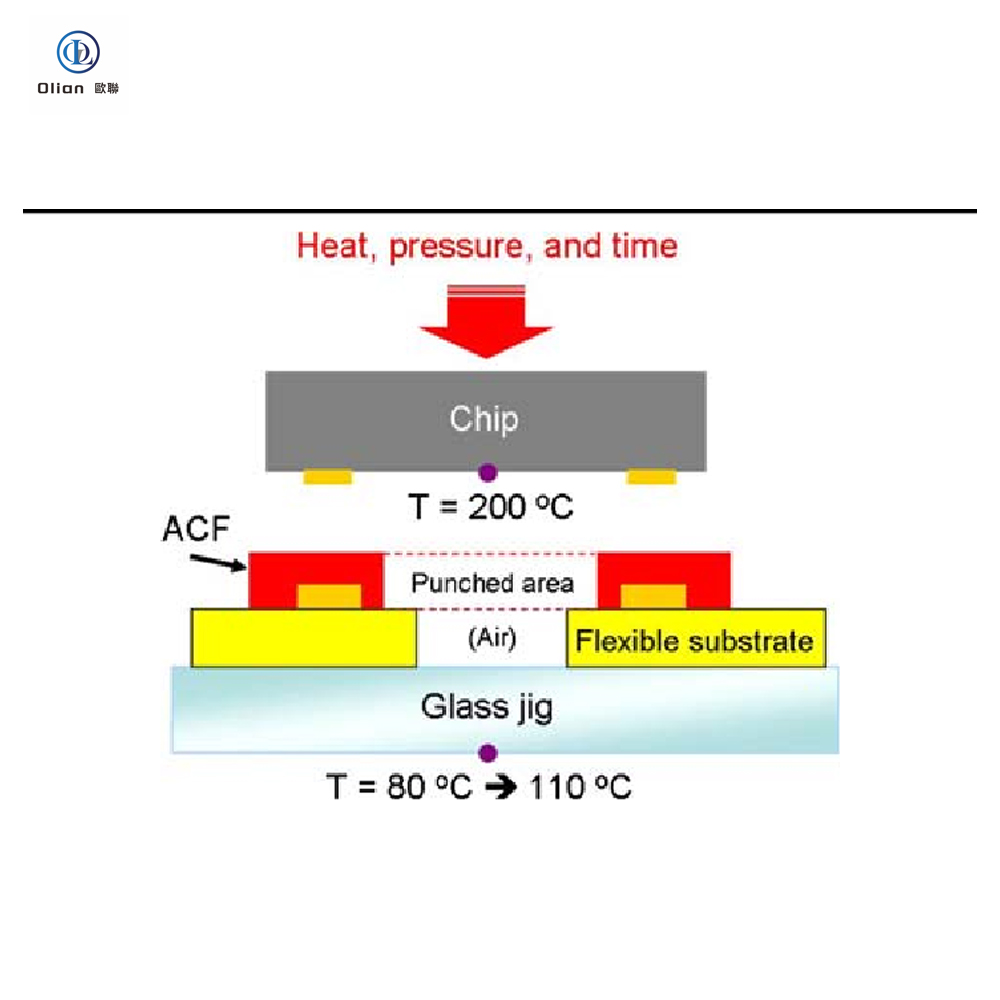

The driver IC is directly bonded to the glass substrate of the TFT – LCD panel. This process is characterized by high precision and small bonding area, offering advantages such as fast production speed and good electrical performance.

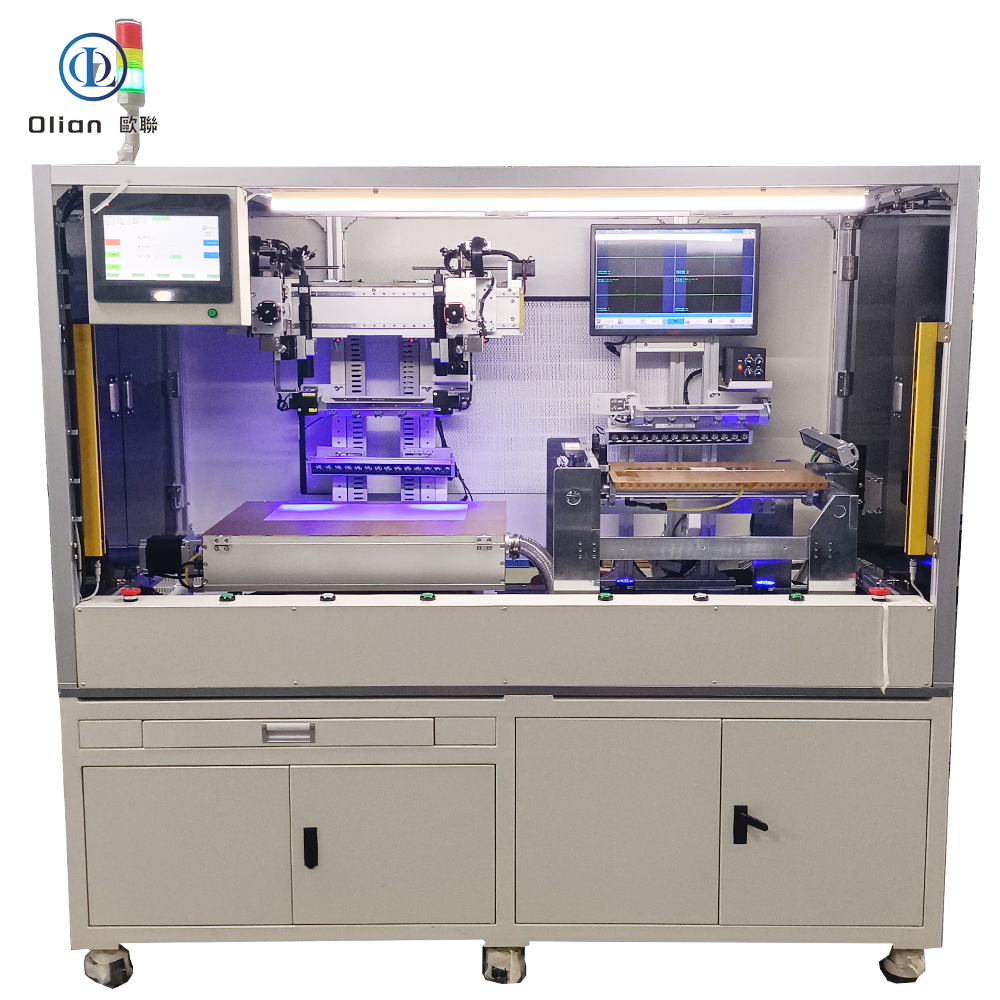

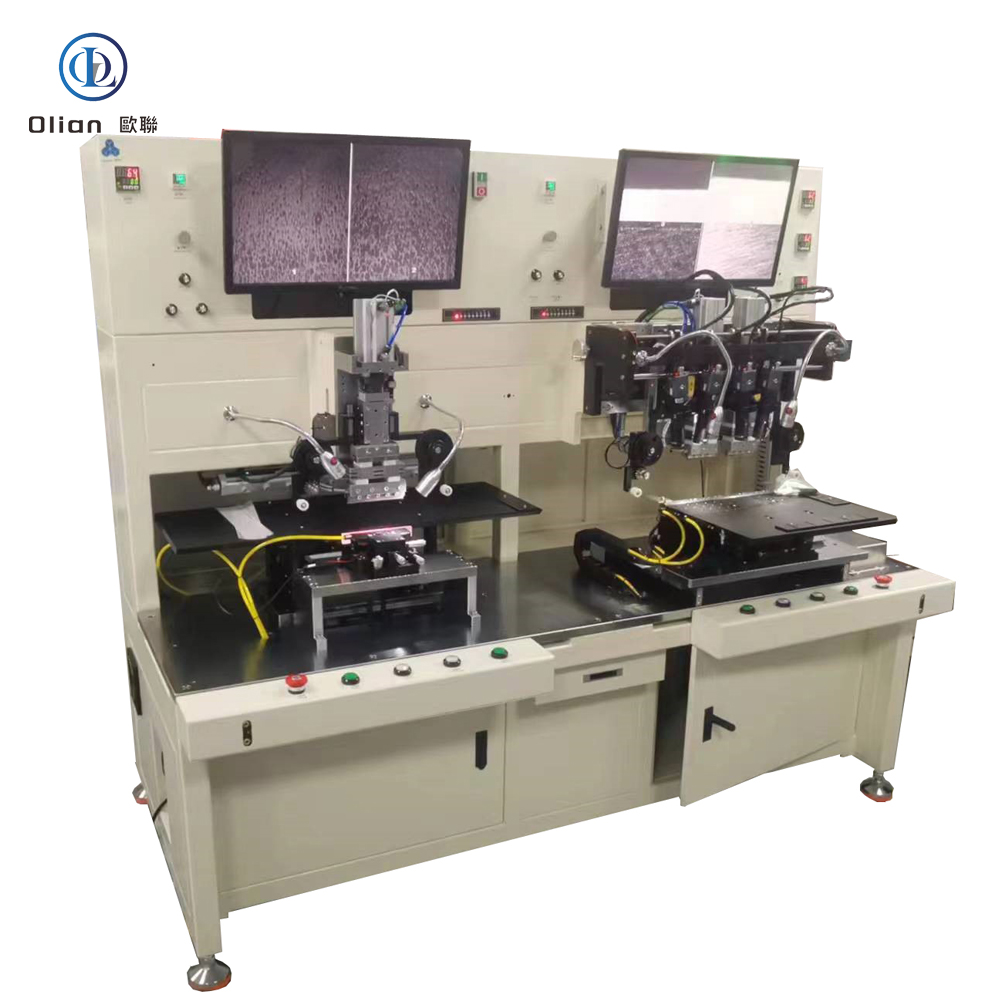

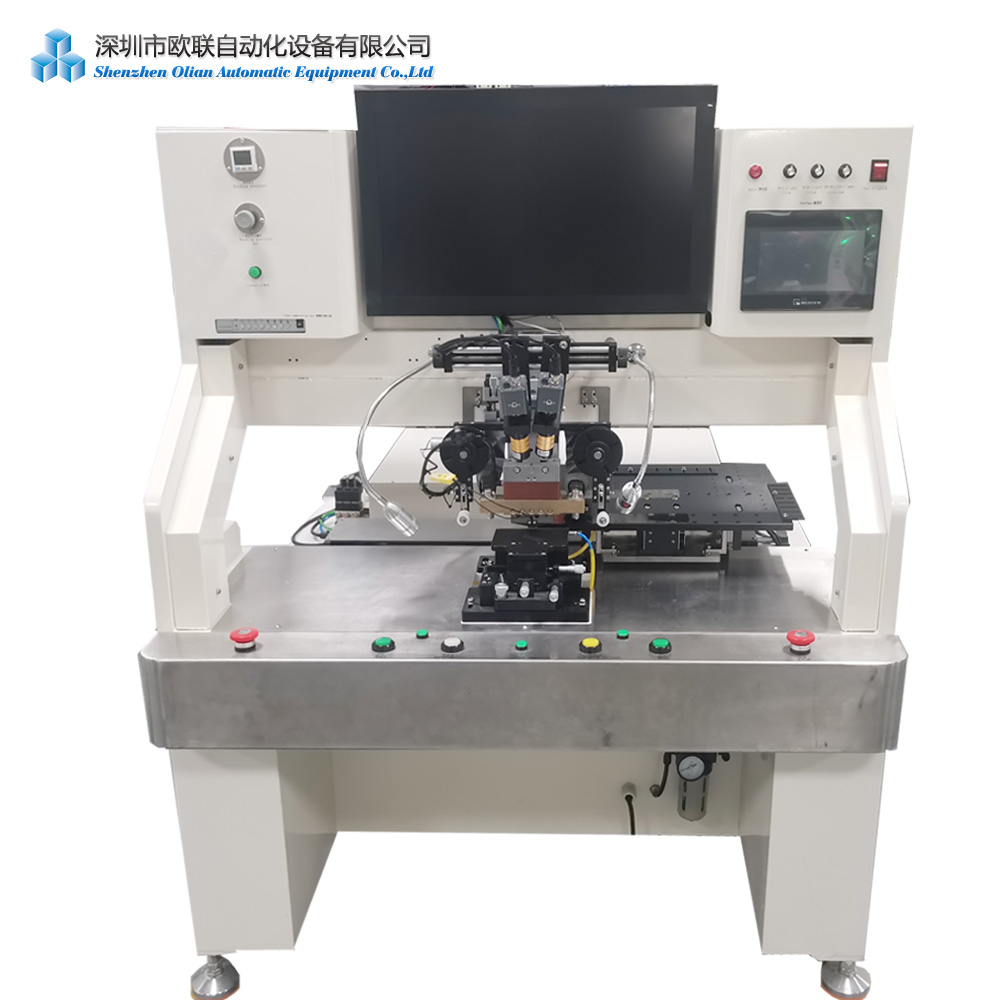

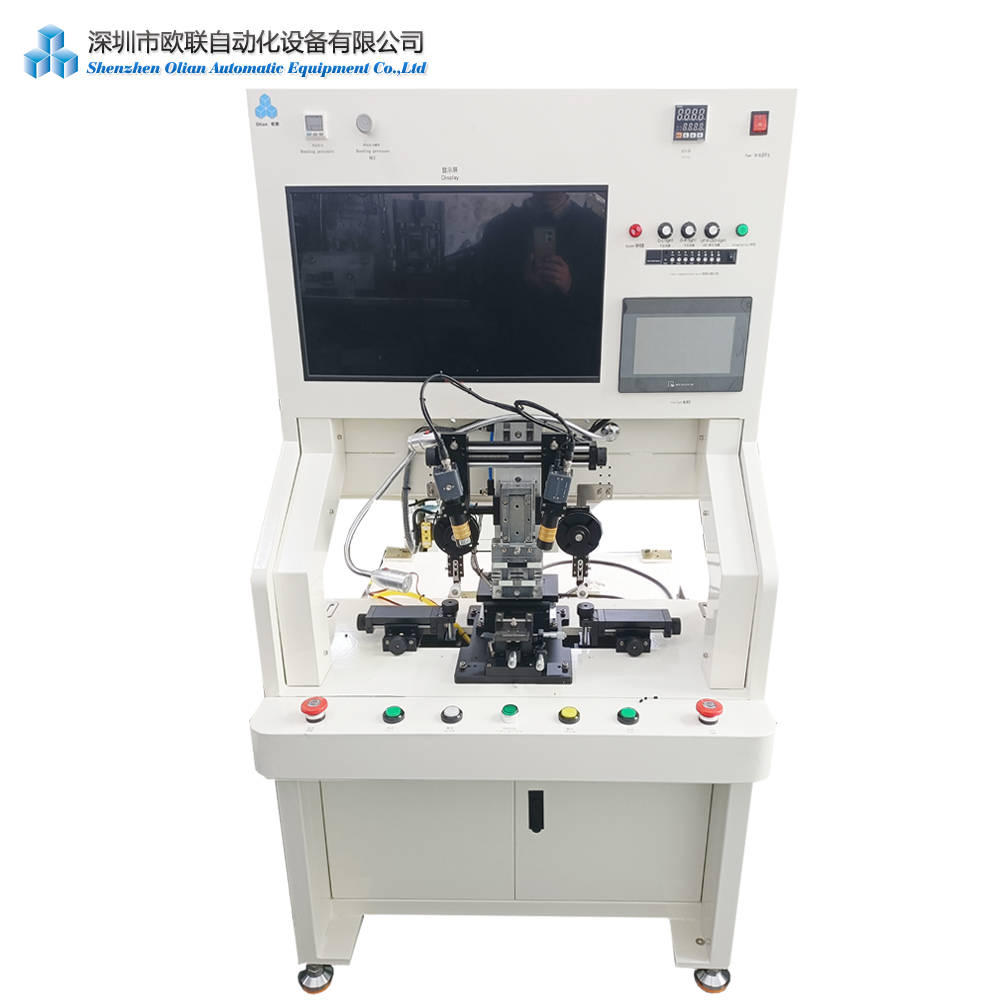

Equipment – COG Bonding Machine: The COG bonding machine uses a high – precision alignment system to accurately position the driver IC relative to the glass substrate. Its heating and pressing mechanism ensures a stable connection between the driver IC and the glass substrate. The machine also has a vision system for precise alignment and a temperature – and – pressure control system to ensure bonding quality.

The driver IC is first bonded to a flexible film and then connected to the TFT – LCD panel. It offers better flexibility and reliability, suitable for lightweight and thin display devices.

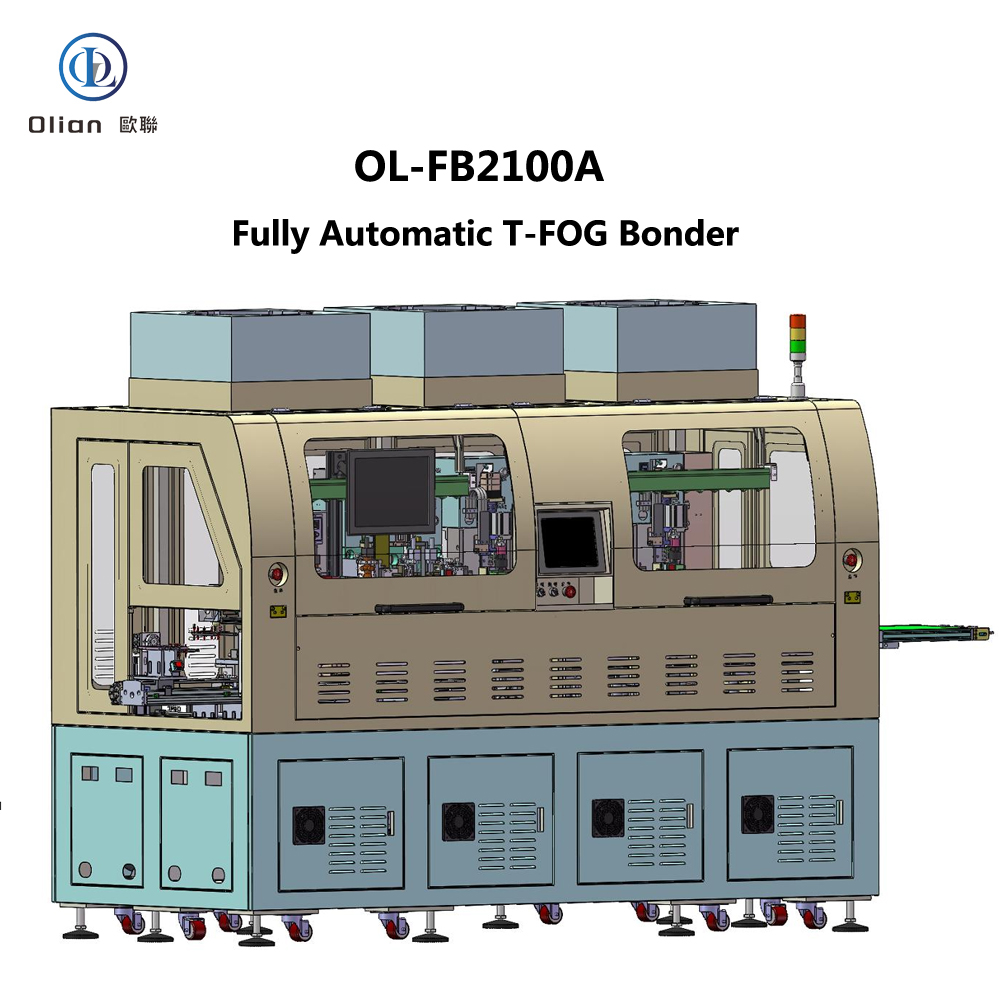

Equipment – FOG Bonding Machine: The FOG bonding machine is designed to handle flexible films and perform high – precision bonding. It has a complex structure and advanced to technology ensure reliable connections between the driver IC and the panel. Its alignment system accurately positions the flexible film and driver IC on the panel.

After the bonding process, automated optical inspection is used to detect defects in the bonding quality, such as misalignment, missing bonds, and insufficient bonding. This helps to promptly identify and correct bonding issues, improving production yield.

Equipment – Bonding AOI Machine: The bonding AOI machine uses high – resolution cameras and advanced image processing software to capture images of the bonding area and compare them with the standard template. It can accurately detect various bonding defects and has a fast inspection speed, capable of meeting the high – speed production requirements of the production line.

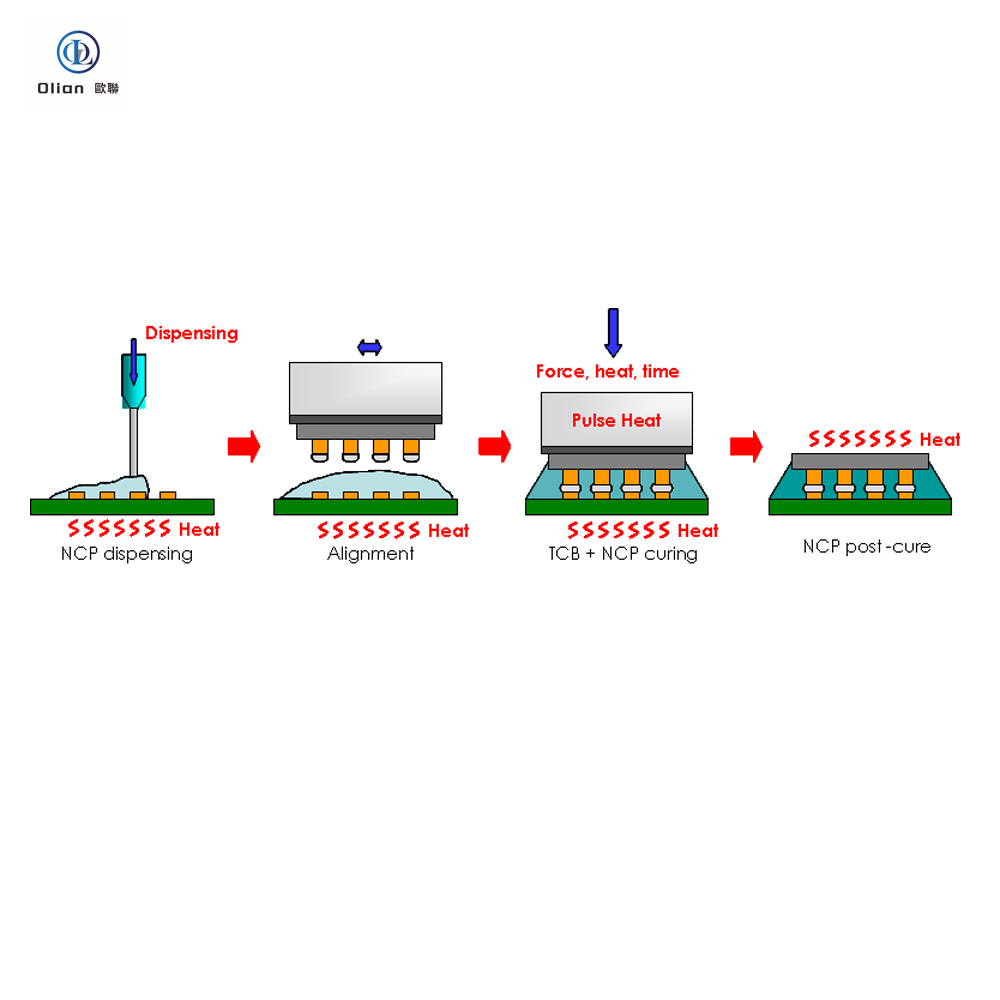

Adhesive is applied to the bonding area to enhance bonding the strength and reliability between the driver IC and the panel. The glue dispenser must ensure precise glue – dispensing quantity and uniform glue – dispensing.

Equipment – Glue Dispensing Machine: The glue dispensing machine has a high – precision dispensing system that can accurately control the glue – dispensing quantity and pattern. Its dispensing nozzle can move precisely to dispense adhesive on the designated bonding area. The machine can also adjust the glue – dispensing parameters according to different adhesives and bonding requirements.

This process applies an under – layer adhesive to the bonding area to further enhance the bonding strength and reliability. It also helps to prevent moisture and impurities from invading the bonding area, improving the product’s stability and reliability.

Equipment – ULD Machine: The ULD machine is similar to the glue dispensing machine in structure but specializes in applying under – layer adhesives. It can accurately dispense under – layer adhesives on the bonding area and has a heating and curing system to rapidly cure the adhesive, improving production efficiency.

Display Screen Production lines,

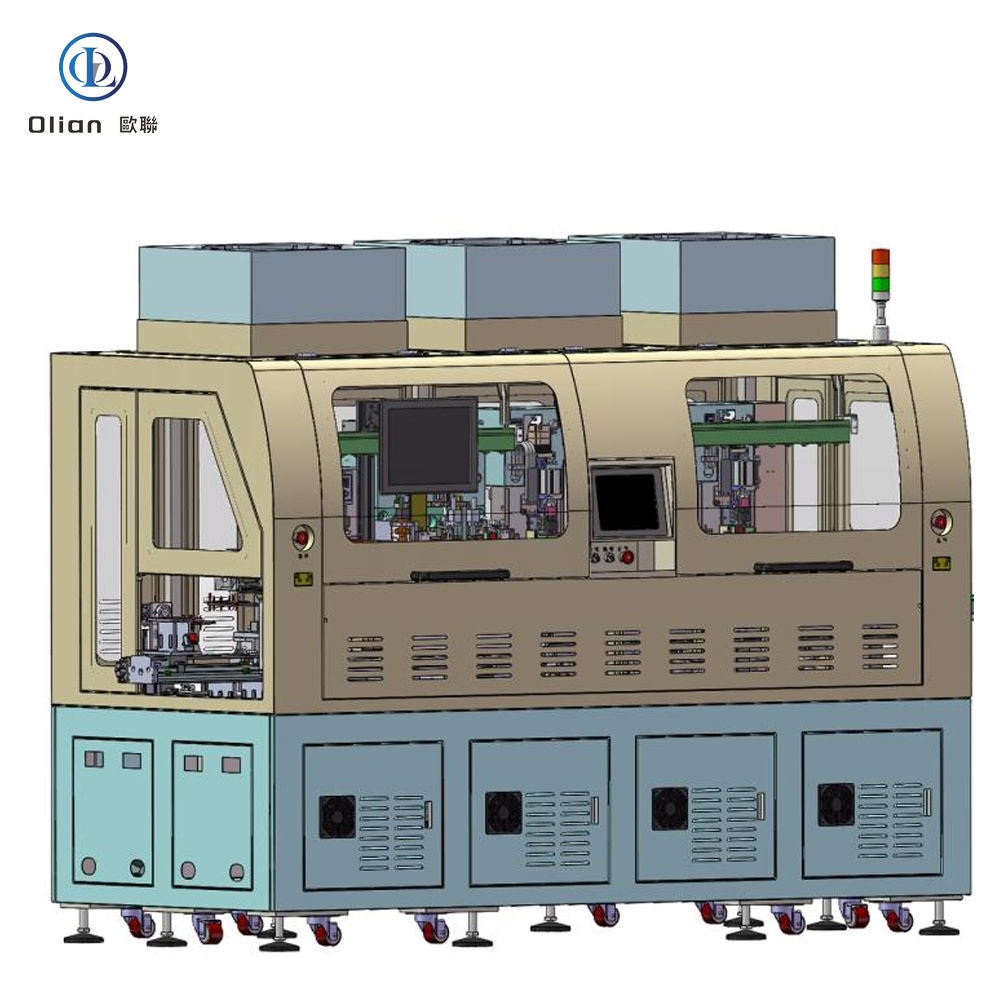

Display Screen Production lines,In the dynamic world of electronics manufacturing, Shenzhen Olian offers a comprehensive range of solutions designed to meet the high-precision requirements of modern display and electronic component production. From flexible screen glue field production to intelligent locomotive and notebook product lines, our solutions are tailored to enhance efficiency, reliability, and quality.

Our high-level flexible screen glue field production solutions are designed for the precise application of adhesives in the production of flexible OLED displays. These solutions support a combination of COG/FOG, COF/FOF, and COP/FOP processes, ensuring high-quality connections and efficient production

For the manufacturing of intelligent locomotive and notebook products, Shenzhen Olian provides advanced production line solutions. These solutions are designed to handle the specific requirements of these products, ensuring high precision and reliability in every step of the manufacturing process

Our display product line solutions cover a wide range of processes, including bonding, laminating, and dispensing. These solutions are suitable for various display technologies such as LCD, OLED, Mini LED, and Micro LED. They are designed to ensure high-quality connections and efficient production, making them ideal for manufacturers of smartphone screens, wearable devices, large TV panels, and advanced OLED displays

For commercial display screens, Shenzhen Olian offers flexible bonding production line solutions. These solutions are designed to handle the specific requirements of large-format displays, ensuring high precision and reliability. They are suitable for a variety of applications, including advertising displays, public information displays, and industrial control systems

Our electronic paper line solutions include laminating, bonding, and dispensing field line solutions. These solutions are designed to meet the high-precision requirements of E-paper displays, ensuring high-quality connections and efficient production. They are suitable for a variety of applications, including e-readers, smart labels, and public information displays

Shenzhen Olian provides comprehensive solutions for backlight leading, laminated film, shading, and wrapping line equipment. These solutions are designed to ensure high precision and reliability in the production of displays, making them ideal for manufacturers of smartphone screens, large TV panels, and other advanced displays

Our fingerprint module under the screen bond spot glue and AOI intelligent detection field solutions are designed to ensure high precision and reliability in the production of fingerprint modules. These solutions support high-precision bonding and intelligent detection, making them ideal for manufacturers of smartphone screens and other advanced displays

For the production of optical clear adhesive (OCA) and optical clear resin (OCR) fits, Shenzhen Olian offers automatic production solutions. These solutions are designed to ensure high precision and reliability, making them ideal for manufacturers of smartphone screens, wearable devices, and other advanced displays

Our FPC covering film, EMI automatic laminating, and FPC exposure special equipment field solutions are designed to meet the high-precision requirements of flexible printed circuit (FPC) production. These solutions ensure high-quality connections and efficient production, making them ideal for manufacturers of smartphone screens, wearable devices, and other advanced displays

Finally, Shenzhen Olian provides comprehensive solutions for 3C product inspection and packaging production lines. These solutions are designed to ensure high precision and reliability in the inspection and packaging of 3C products, making them ideal for manufacturers of smartphones, tablets, and other electronic devices

By choosing Shenzhen Olian, you benefit from:

In conclusion, Shenzhen Olian’s Display Screen Production lines, comprehensive solutions for high-level flexible screen glue field production and beyond offer a reliable and efficient approach to modern display and electronic component manufacturing. Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, Shenzhen Olian’s solutions can help you achieve high-quality, efficient, and reliable production processes.

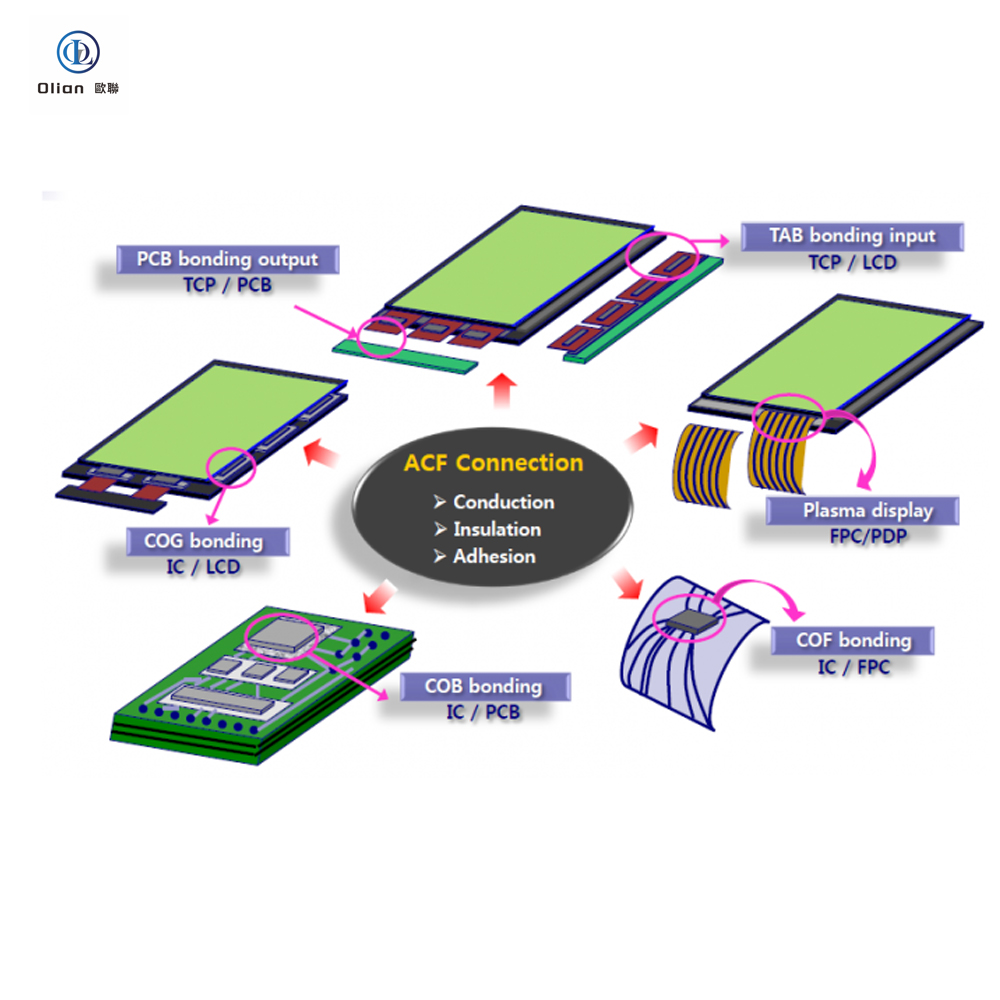

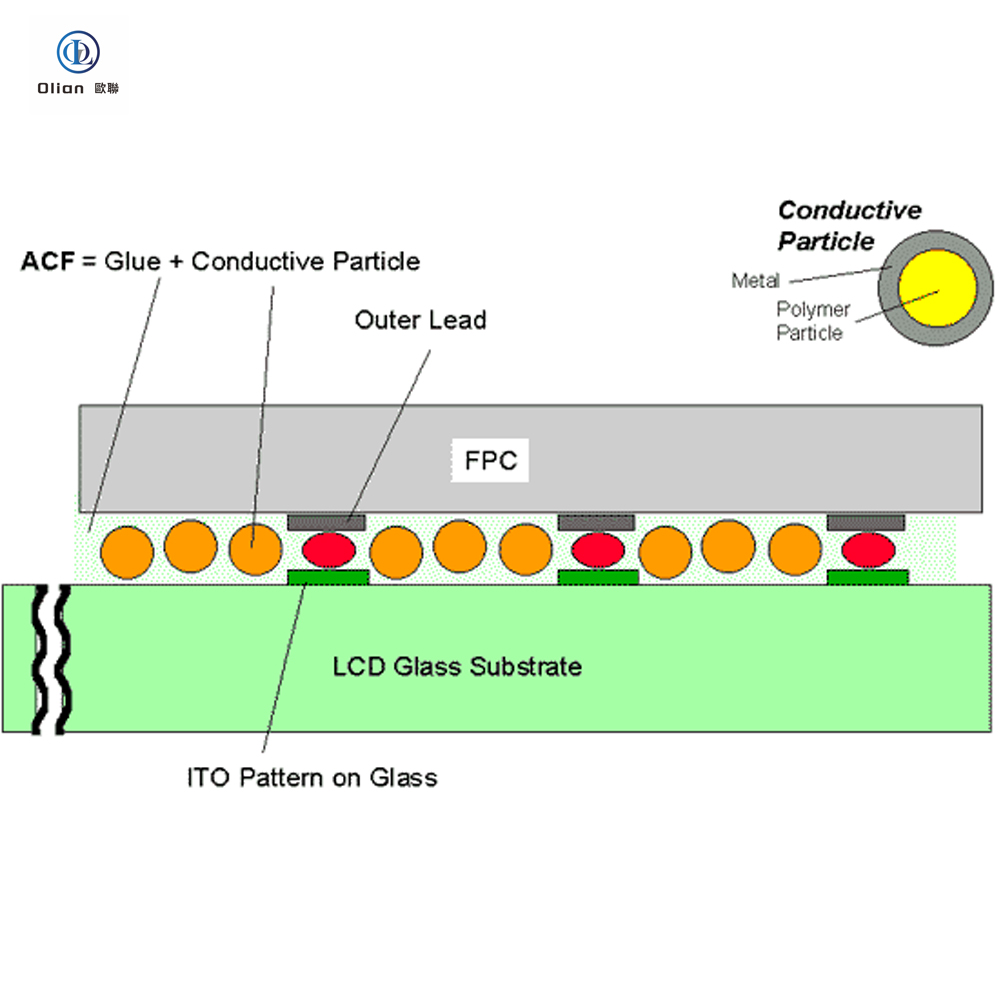

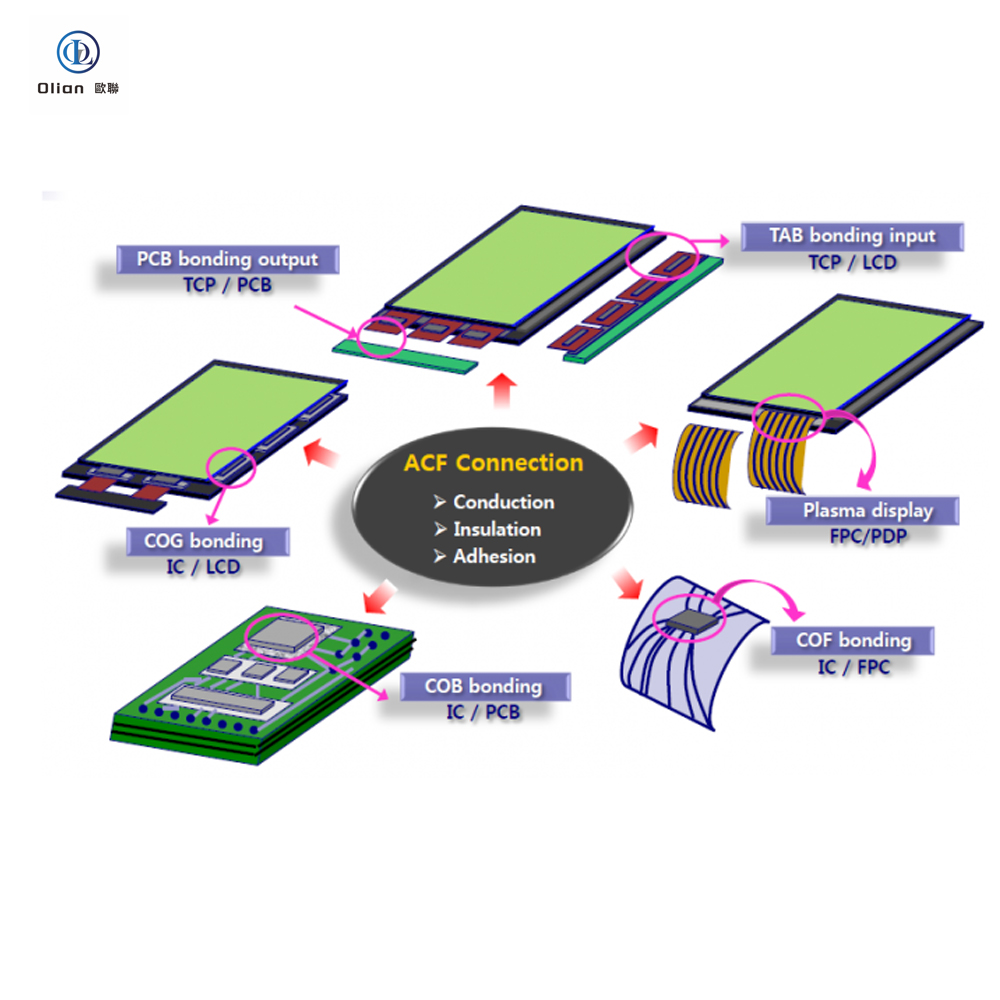

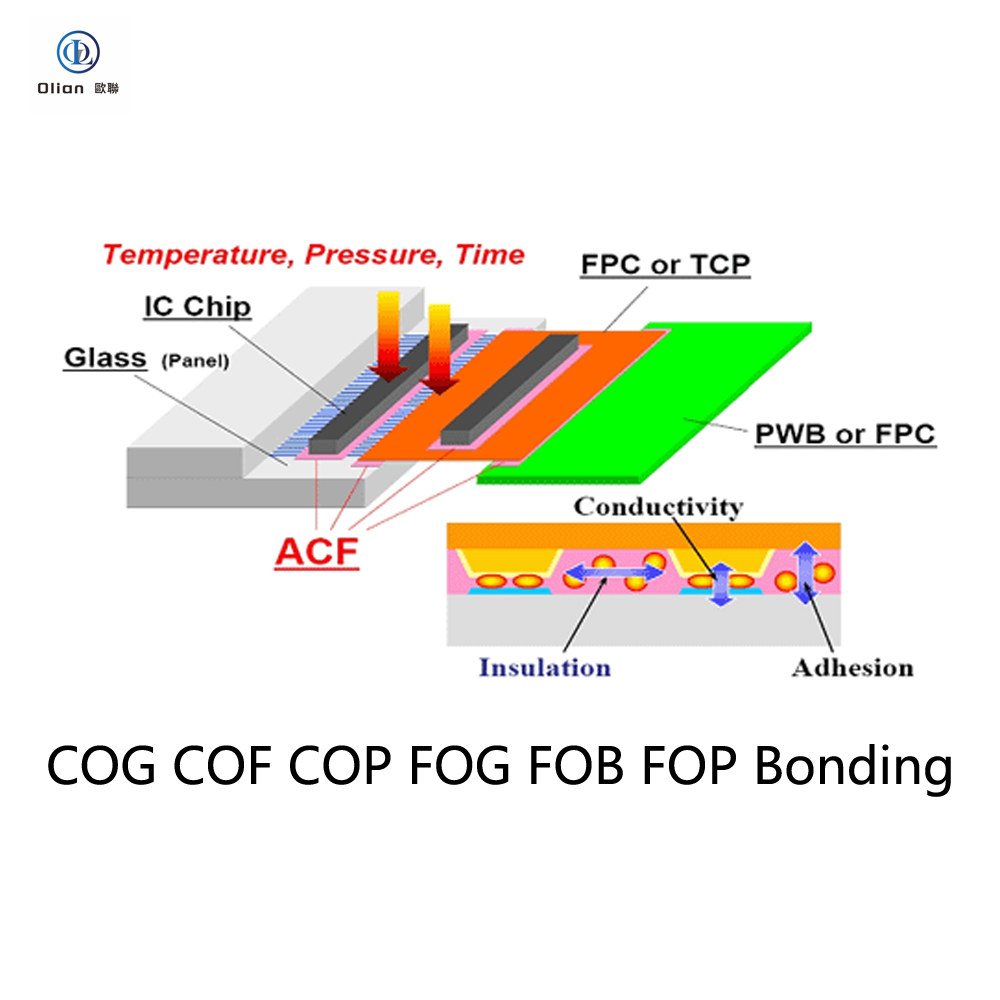

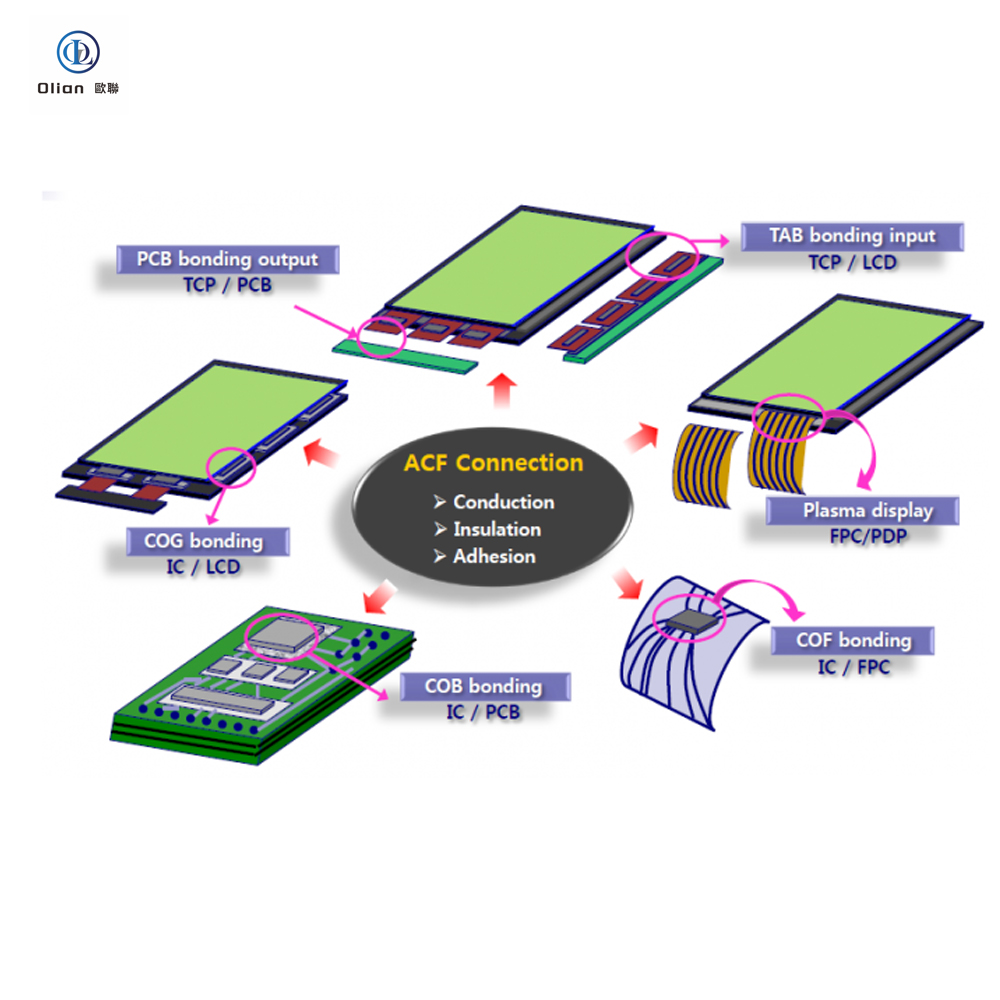

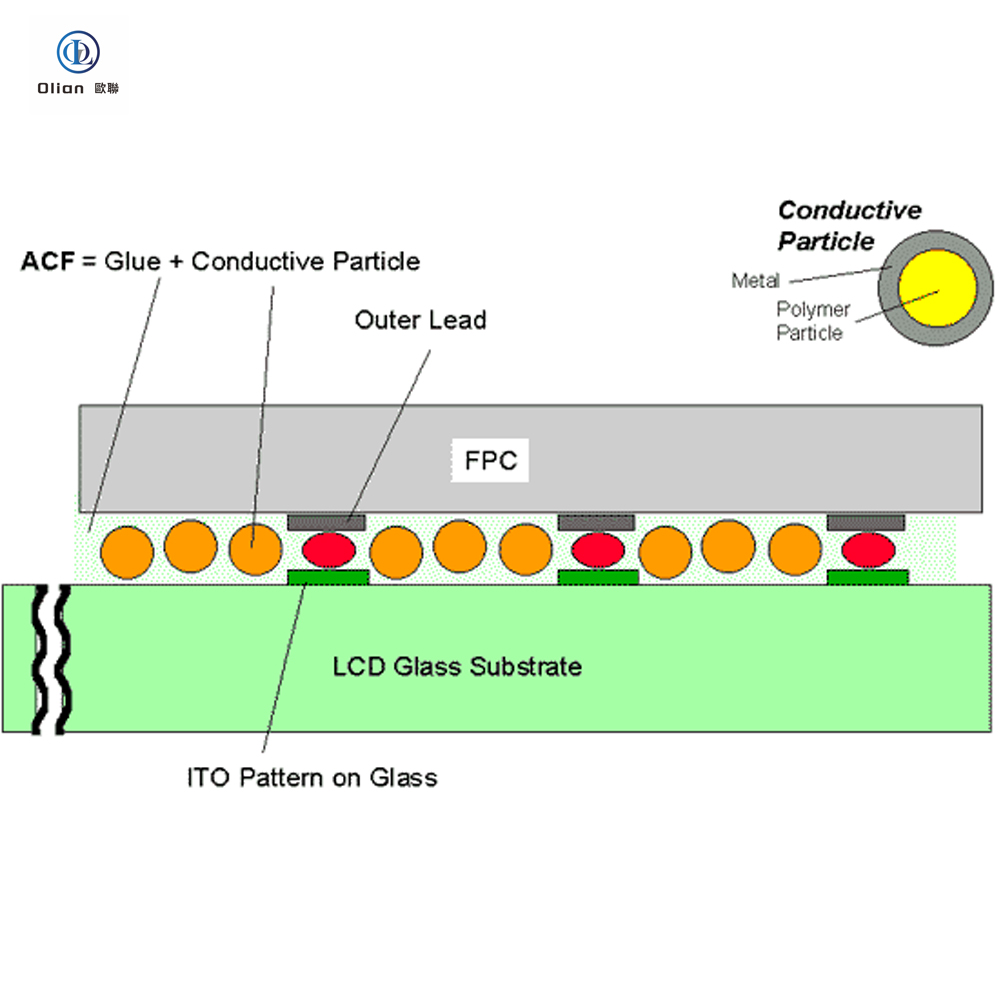

Anisotropic Conductive Films (ACF) have a wide range of applications in modern electronics, including the following key areas:

Chip-on-Glass (COG): ACF is used to bond driver ICs directly onto the glass substrate of liquid crystal displays (LCDs), enabling high-resolution and high-quality images.

Chip-on-Flex (COF): ACF facilitates the connection between chips and flexible circuits, allowing for compact and flexible designs in devices such as mobile phones and tablets.

Flip-Chip Bonding: ACF provides reliable electrical connections in flip-chip packaging, where the chip is mounted directly onto the substrate with the active side facing down.

LCDs and OLEDs: ACF is essential for bonding driver ICs to the display panels in both LCDs and organic light-emitting diode (OLED) displays, ensuring stable electrical connections and high image quality.

Micro LED Displays: ACF is used to bond micro LED chips to the display substrate, enabling high-brightness and high-efficiency displays.

Light-Emitting Diodes (LEDs): ACF is used to bond LED chips to the substrate, providing efficient electrical connections and improving the overall performance of the LEDs.

Photovoltaic Cells: ACF can be used to bond photovoltaic cells to the substrate, enhancing the electrical conductivity and reliability of the solar panels.

Flexible Printed Circuits (FPCs): ACF is used to bond FPCs to various substrates, such as glass or other flexible materials, enabling the development of flexible and foldable electronic devices.

Wearable Devices: ACF is used in wearable devices such as smartwatches, fitness trackers, and smart clothing, providing reliable and flexible connections .

Sensors: ACF is used to bond sensors to glass or ceramic substrates, enabling high-precision and high-reliability sensor connections.

Smart Cards and RFID: ACF is used in smart cards and RFID tags.

providing secure and reliable electrical connections for data storage and transmission.

Automotive Electronics: ACF is used in automotive applications such as dashboard displays,

infotainment systems, and sensor connections, providing reliable and durable connections under harsh environmental conditions.

Industrial Equipment: ACF is used in industrial equipment for connections between electronic components and substrates,

ensuring high reliability and performance in demanding industrial environments.

Medical Equipment: ACF is used in medical devices such as electrosurgical knives,

endoscopic imagers, and medical packaging, providing reliable and safe electrical connections.

Wearable Medical Devices: ACF is used in wearable medical devices such as health monitoring devices and wearable sensors, enabling comfortable and reliable connections.

These applications demonstrate the versatility and importance of ACF in modern electronics, enabling the development of compact,

high-performance, and reliable electronic devices across various industries.

In the dynamic world of electronics and display manufacturing, precision and reliability are paramount. Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, the right bonding machine is essential for ensuring high-quality connections and efficient production processes. Our company offers a wide range of state-of-the-art bonding machines designed to meet the diverse needs of modern manufacturing. Below is an overview of our product offerings, tailored to help you find the perfect solution for your specific requirements.

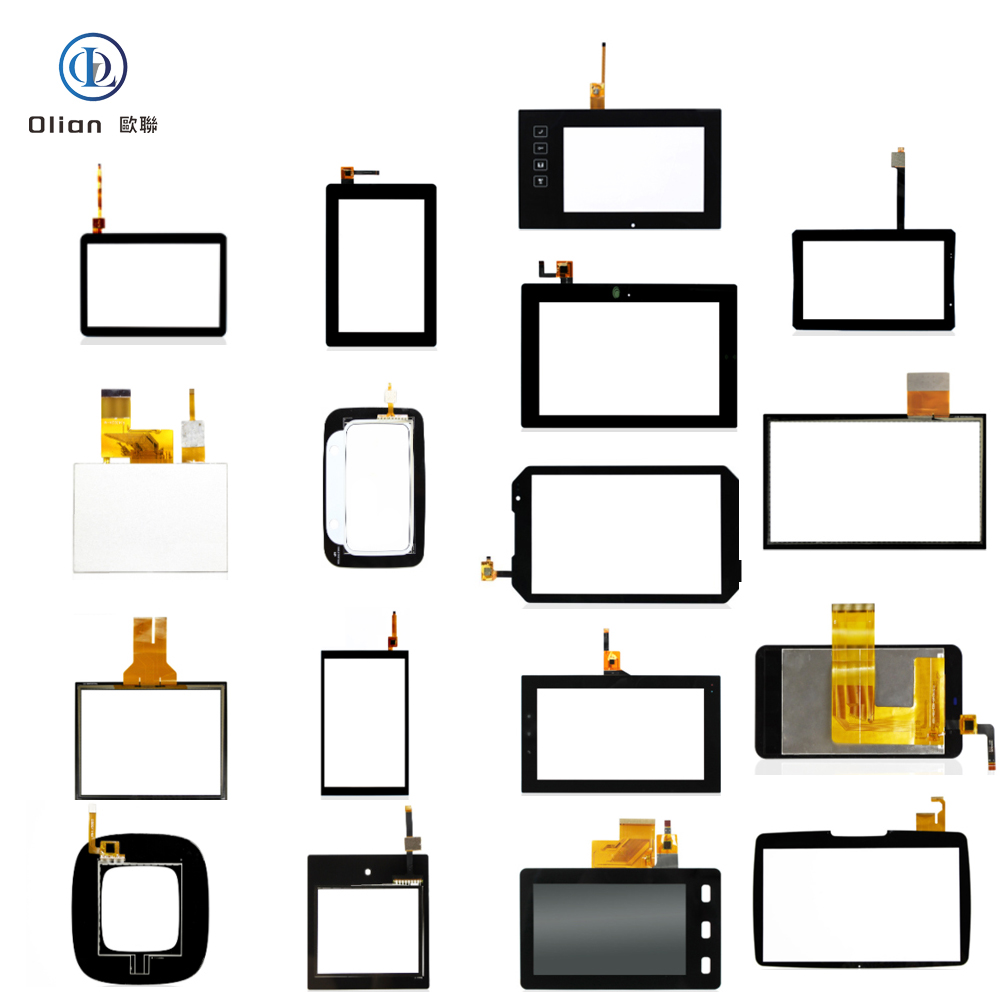

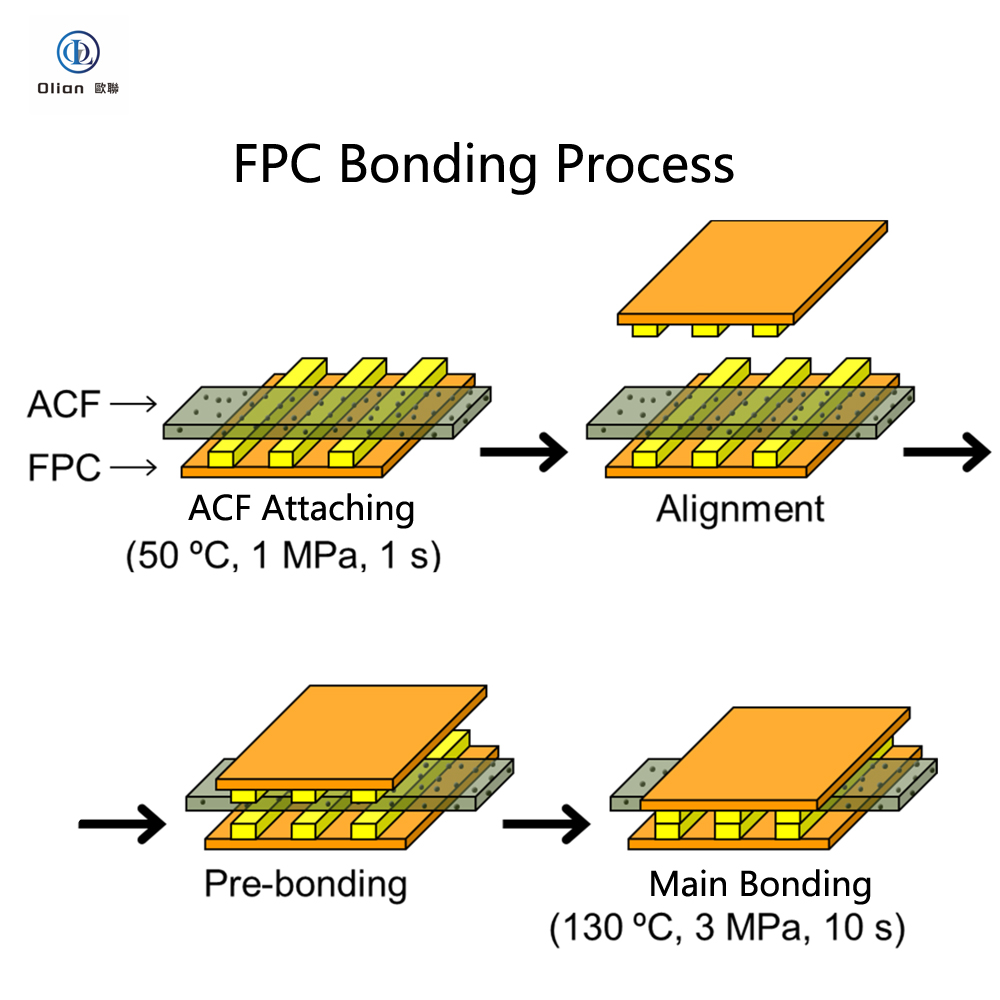

Our mobile phone bonding machines are designed to handle the precise assembly requirements of smartphones. These machines support various bonding processes, including COG (Chip on Glass), COF (Chip on Film), and FPC (Flexible Printed Circuit) bonding. They are equipped with high-definition microscopes, digital pressure gauges, and vacuum generators to ensure accurate alignment and reliable bonding

For the growing wearable technology market, our smart watch LCD bonding machines offer high precision and flexibility. These machines are ideal for bonding small LCD panels and flexible circuits, ensuring that your wearable devices are both durable and reliable

Our wearable equipment bonding machines are versatile and can handle a variety of components used in smartwatches, fitness trackers, and other wearable devices. These machines support multiple bonding processes, including COG, COF, and FOG (Film on Glass) bonding

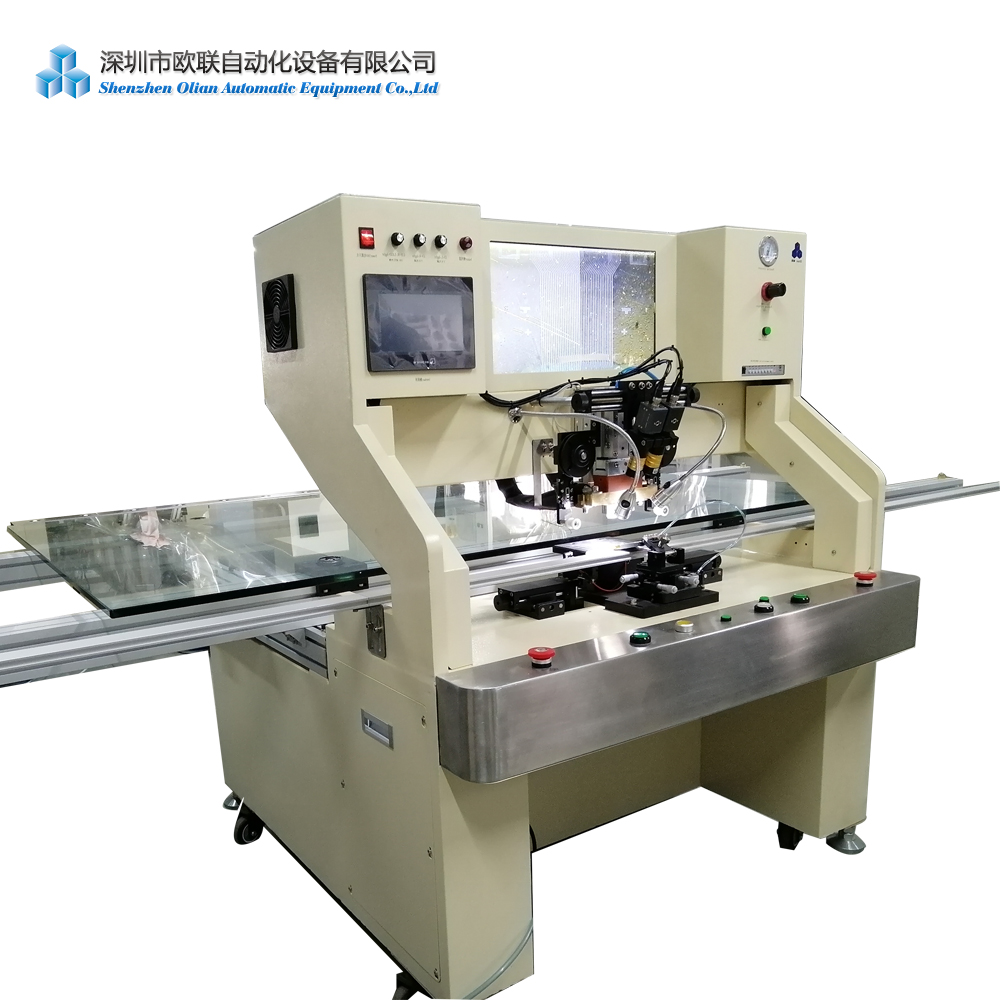

Our TV panel bonding machines are designed for large-scale production of LCD and LED TV panels. These machines support high-speed bonding processes and are equipped with advanced features such as pulse heating and constant temperature control to ensure consistent bonding quality

For the production of Liquid Crystal Modules (LCMs) and LCD modules, our bonding machines offer high precision and reliability. These machines support various bonding processes, including COG, FOG, and OLB (Outer Lead Bonding), and are suitable for both small and large-scale production

Our flat panel display bonding machines are designed to handle a wide range of display sizes and types, from small wearable devices to large TV panels. These machines are equipped with advanced vision systems and precise temperature control to ensure high-quality bonding

Our COG (Chip on Glass), COP (Chip on Plastic), and COF (Chip on Film) bonding machines are designed for high-precision bonding of integrated circuits (ICs) and flexible printed circuits (FPCs) to various substrates. These machines offer both semi-automatic and fully automatic configurations, making them suitable for a wide range of production volumes

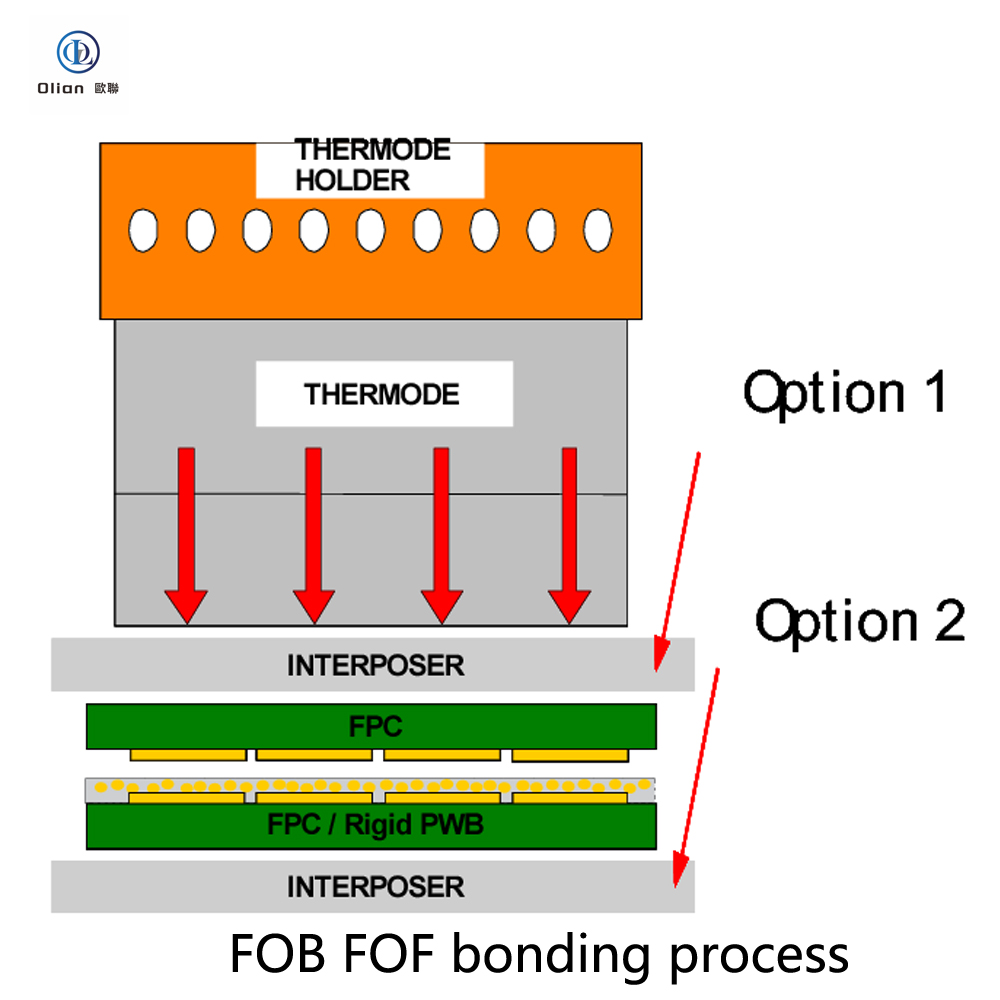

Our FOG (Film on Glass), FOB (Film on Board), and FOF (Film on Film) bonding machines are designed for bonding flexible circuits to various substrates. These machines support both pulse heating and constant temperature bonding processes, ensuring reliable connections in your display assemblies

Our TAB (Tape Automated Bonding), OLB (Outer Lead Bonding), and IC bonding machines are versatile tools for bonding integrated circuits and other components. These machines offer high precision and reliability, making them ideal for a wide range of electronic manufacturing applications

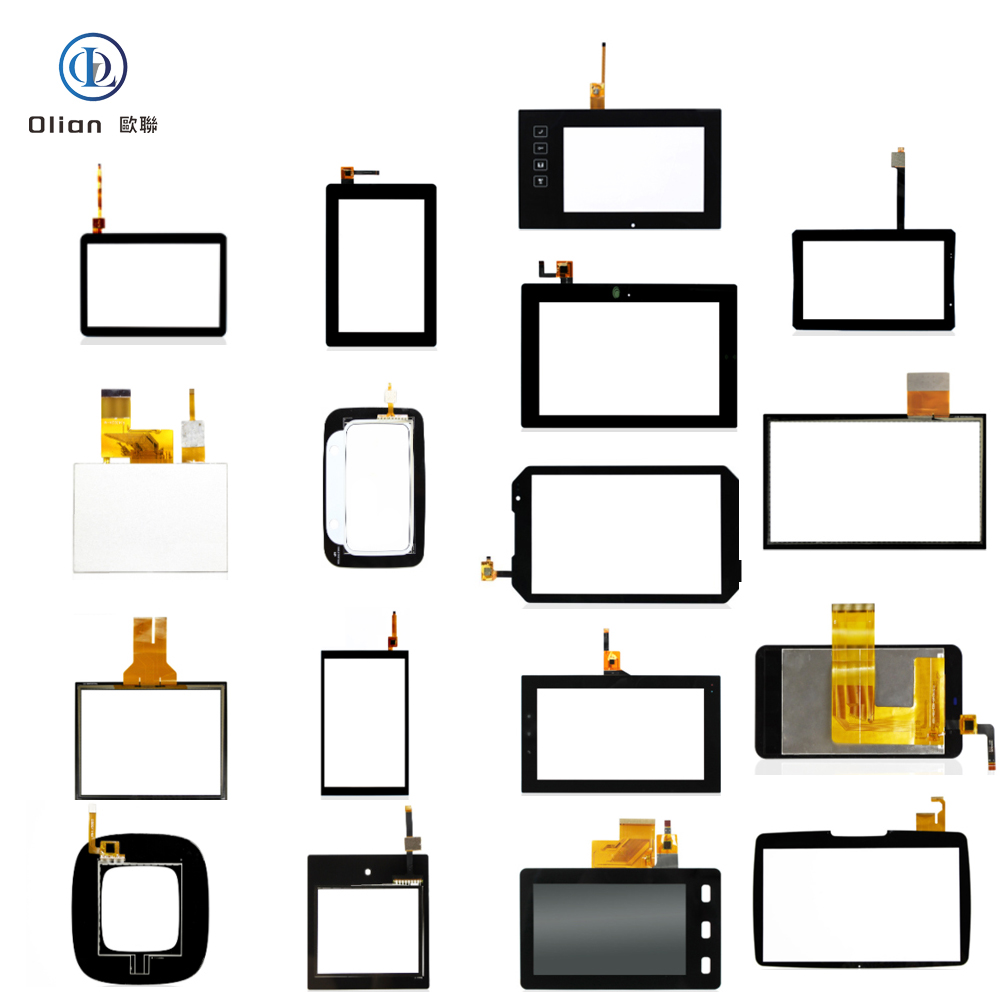

Our FPC (Flexible Printed Circuit), glass, and touch panel bonding machines are designed to handle the specific requirements of flexible circuits and touch-sensitive displays. These machines support various bonding processes, including COG, FOG, and COF bonding, and are equipped with advanced features such as high-definition microscopes and precise temperature control

For advanced display technologies such as OLED, Mini LED, and Micro LED, our bonding machines offer high precision and reliability. These machines are designed to handle the specific requirements of these advanced displays, ensuring high-quality connections and efficient production

Our Zebra paper and flex cable bonding machines are designed for bonding components to Zebra paper and flexible cables. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are crucial

Our bonding machines are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key features of our machines include:

Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our comprehensive range of bonding machines is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality connections and efficient production processes. Contact us today to find the perfect bonding machine for your application.

In the rapidly evolving world of display technology, bonding machines play a crucial role in the assembly and manufacturing of various electronic components and displays. Our company is proud to offer a wide range of advanced bonding solutions tailored to meet the diverse needs of the industry. Whether you are looking to bond integrated circuits, flexible printed circuits, or other components, we have the right machine for you.

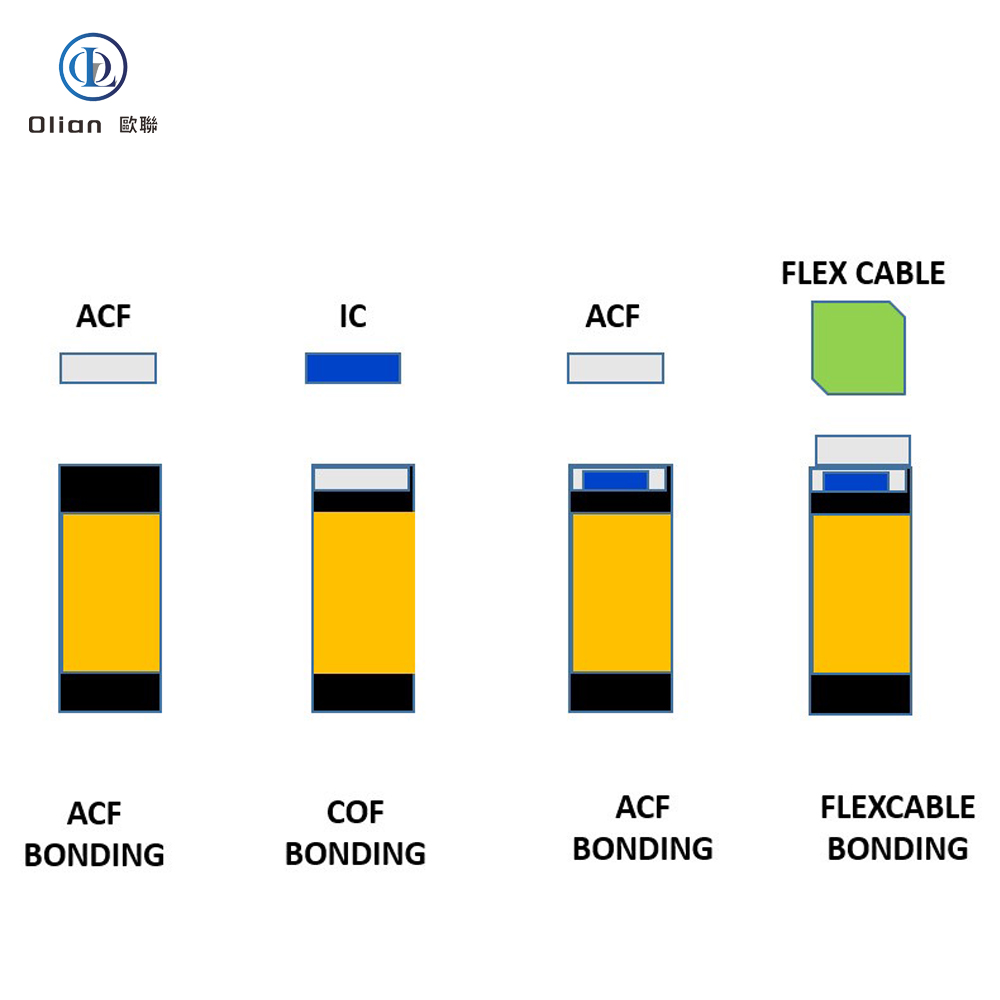

ACF bonders are essential for bonding two substrates, such as LCDs, PCBs, and FPCs, using Anisotropic Conductive Film (ACF). These machines are available in both constant heat and pulse heat systems, with vision alignment capabilities for precise bonding

. They are widely used in applications like COB (Chip on Board), COF (Chip on Film), COG (Chip on Glass), COP (Chip on Panel), FOB (Film on Board), and FOG (Film on Glass).

COG bonders are specifically designed for attaching integrated circuits (ICs) directly onto glass substrates. These machines ensure high precision and reliability, making them ideal for the production of LCD panels used in consumer electronics, automotive displays, and industrial applications

. Our COG bonders come in both pre-bonding and main-bonding configurations, with options for manual or automated loading.

Similar to COG bonders, COP bonders are used for bonding ICs directly onto display panels. They are particularly useful for flexible AMOLED production, offering advanced functions to ensure high bonding quality and productivity

.

COF bonders are designed for bonding ICs onto flexible films. These machines are versatile and can be used for various applications, including COF on glass, COF on board, and COF on film bonding

. They are available in both manual and automatic configurations, with options for single or dual heads.

FOG bonders are used for bonding flexible printed circuits (FPCs) onto glass substrates. These machines come in both pulse heat and constant heat versions, with top-bottom alignment systems for precise bonding

. They are suitable for a wide range of applications, including LCD and OLED panel manufacturing.

FOB bonders are designed for bonding FPCs onto PCBs. They offer similar features to FOG bonders, including precise alignment and reliable bonding capabilities

. These machines are essential for applications where flexibility and compactness are required.

FOF bonders are used for bonding FPCs onto other FPCs. These machines are particularly useful in applications where space is limited and flexibility is crucial

. They offer high precision and reliability, ensuring a strong and stable connection between the components.

TAB bonders are used for bonding integrated circuits onto substrates using tape automated bonding techniques. These machines are known for their high precision and reliability, making them ideal for a wide range of electronic manufacturing applications

.

OLB bonders are used for bonding the outer leads of integrated circuits onto substrates. These machines are essential for ensuring a reliable connection between the IC and the display panel

. They offer high precision and reliability, making them a crucial part of the display manufacturing process.

IC bonders are versatile machines used for bonding integrated circuits onto various substrates. They are available in both manual and automated configurations, with options for single or dual heads

. These machines are essential for a wide range of electronic manufacturing applications.

FPC bonders are designed for bonding flexible printed circuits onto various substrates. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are required

. They are available in both manual and automated configurations, with options for single or dual heads.

Glass bonders are used for bonding components directly onto glass substrates. These machines are essential for the production of LCD and OLED panels, offering high precision and reliability

. They are available in both manual and automated configurations, with options for single or dual heads.

LCD panel bonders are specifically designed for the assembly of LCD panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

LED panel bonders are used for bonding components onto LED panels. These machines offer high precision and reliability, making them ideal for applications where brightness and efficiency are crucial

. They are available in both manual and automated configurations, with options for single or dual heads.

Mini LED bonders are designed for the assembly of Mini LED panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

Micro LED bonders are used for the assembly of Micro LED panels. These machines offer extremely high precision and reliability, making them ideal for applications where brightness, efficiency, and resolution are crucial

. They are available in both manual and automated configurations, with options for single or dual heads.

Zebra paper bonders are used for bonding components onto Zebra paper. These machines offer high precision and reliability, making them ideal for applications where flexibility and compactness are required

. They are available in both manual and automated configurations, with options for single or dual heads.

Touch panel FPC bonders are specifically designed for bonding flexible printed circuits onto touch panels. These machines offer high precision and reliability, ensuring a strong and stable connection between the components

. They are available in both manual and automated configurations, with options for single or dual heads.

Our company offers a comprehensive range of bonding machines designed to meet the diverse needs of the display manufacturing industry. From ACF bonders to Micro LED bonders, we have the right machine for every application. Our machines are known for their high precision, reliability, and versatility, making them ideal for a wide range of electronic manufacturing applications. We are committed to providing our customers with the best possible solutions and support to ensure their success in the competitive world of display technology.

In the modern electronics repair industry, having the right tools and machines is crucial for efficiently repairing and refurbishing LCD and LED screens, especially for TVs and other large displays. Our company offers a wide range of advanced repair machines and bonding equipment designed to meet the diverse needs of professionals in this field. Whether you are repairing LCD TVs, smartphones, or other display devices, our products are designed to provide high precision, reliability, and efficiency.

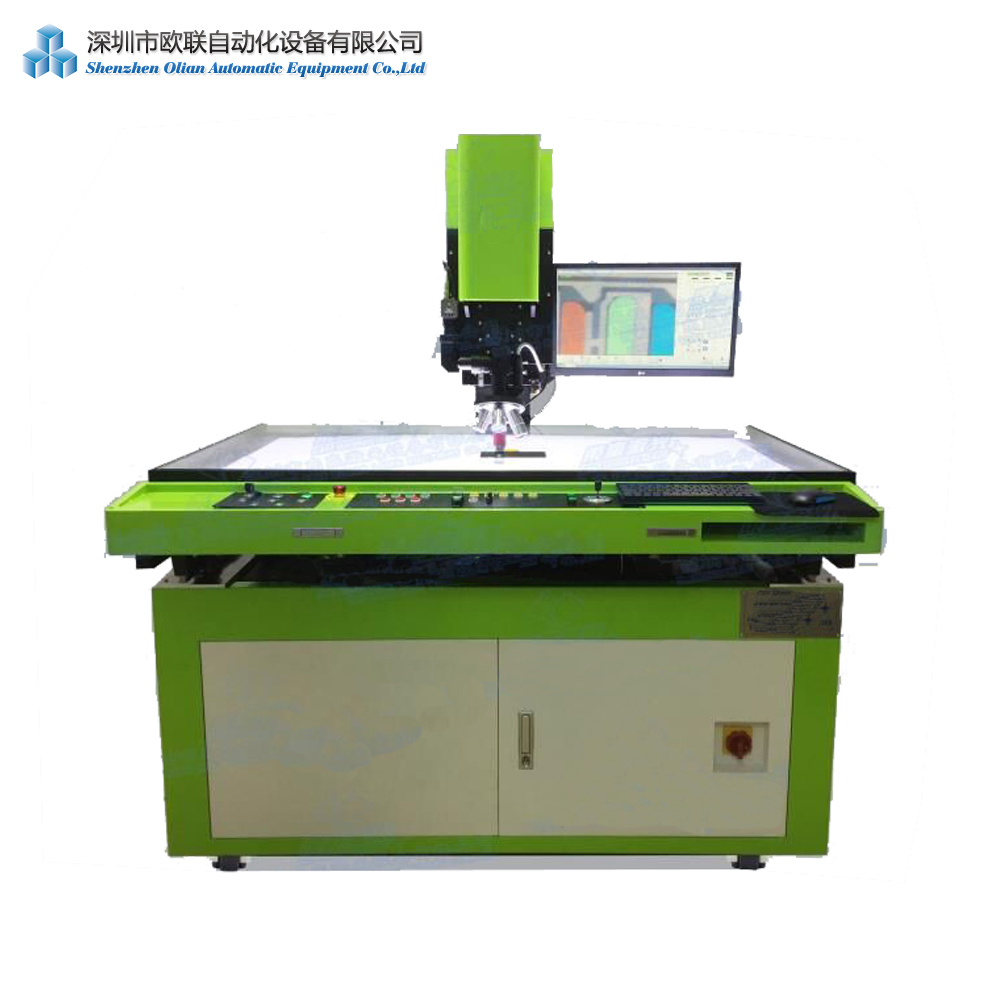

Our LCD screen laser repair machines are designed to efficiently repair a variety of defects in LCD panels, including vertical lines, horizontal lines, black screens, and more. These machines use high-frequency pulse laser beams to cut and trim micron-sized semiconductor circuit components, especially passivation layers (silicon oxide/nitride) and metal interconnects

They are suitable for repairing LCD screens in TVs, PCs, touch teaching machines, splicing screens, notebooks, digital devices, and car displays

Our COF (Chip-On-Film) bonding machines are essential for repairing and assembling LCD and LED panels. These machines are used to bond integrated circuits (ICs) to flexible film substrates, enabling compact designs and high-resolution displays

They are widely used in the repair and manufacturing of TVs, laptops, mobile phones, and tablets

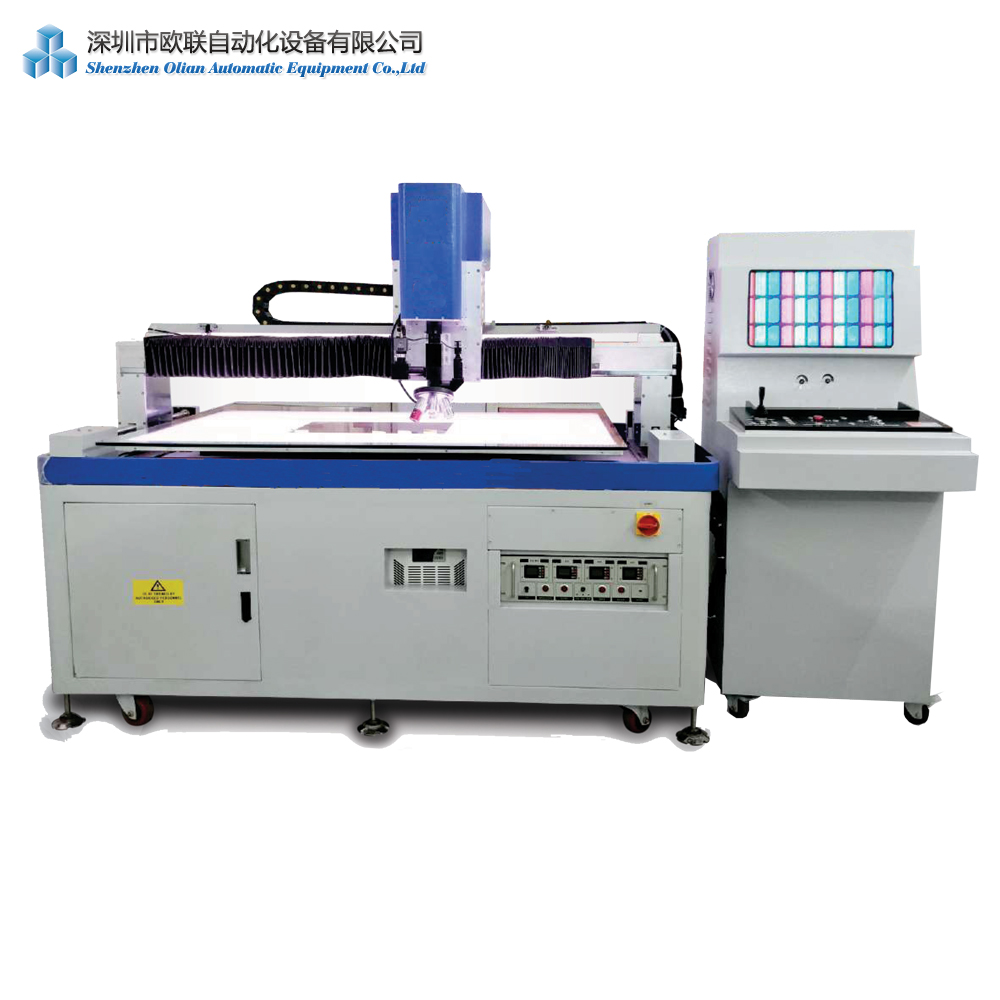

Our FOB (FPC on Board) and FOG (FPC on Glass) bonding machines are designed for bonding flexible printed circuits (FPCs) to PCBs and glass substrates. These machines offer high precision and reliability, making them ideal for applications requiring flexible and compact designs

Our hot bar pressing machines are designed for soldering FPCs, PCBs, LED displays, and other electronic components. These machines use pulse heating technology to achieve accurate temperature control, making them suitable for temperature-critical applications

Our LCD panel rework and repair equipment includes a variety of machines designed to refurbish and repair LCD panels. These machines are capable of repairing a wide range of defects, including vertical and horizontal lines, black screens, and more

Our products are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key reasons to choose our products include:

Whether you are repairing LCD TVs, smartphones, or other display devices, our comprehensive range of repair machines and bonding equipment is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality repairs and efficient production processes. Contact us today to find the perfect solution for your application.