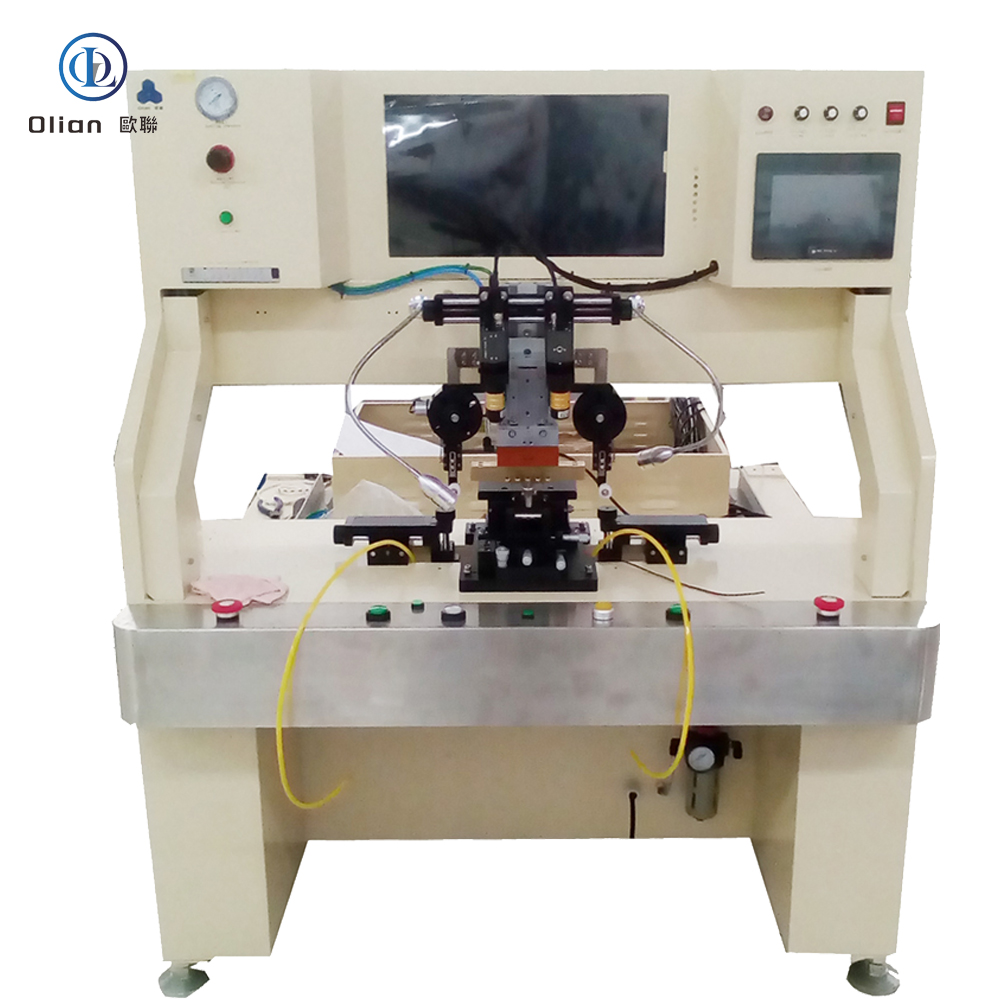

Automatic FOB Bonder OL-PB3000

Equipment Overview

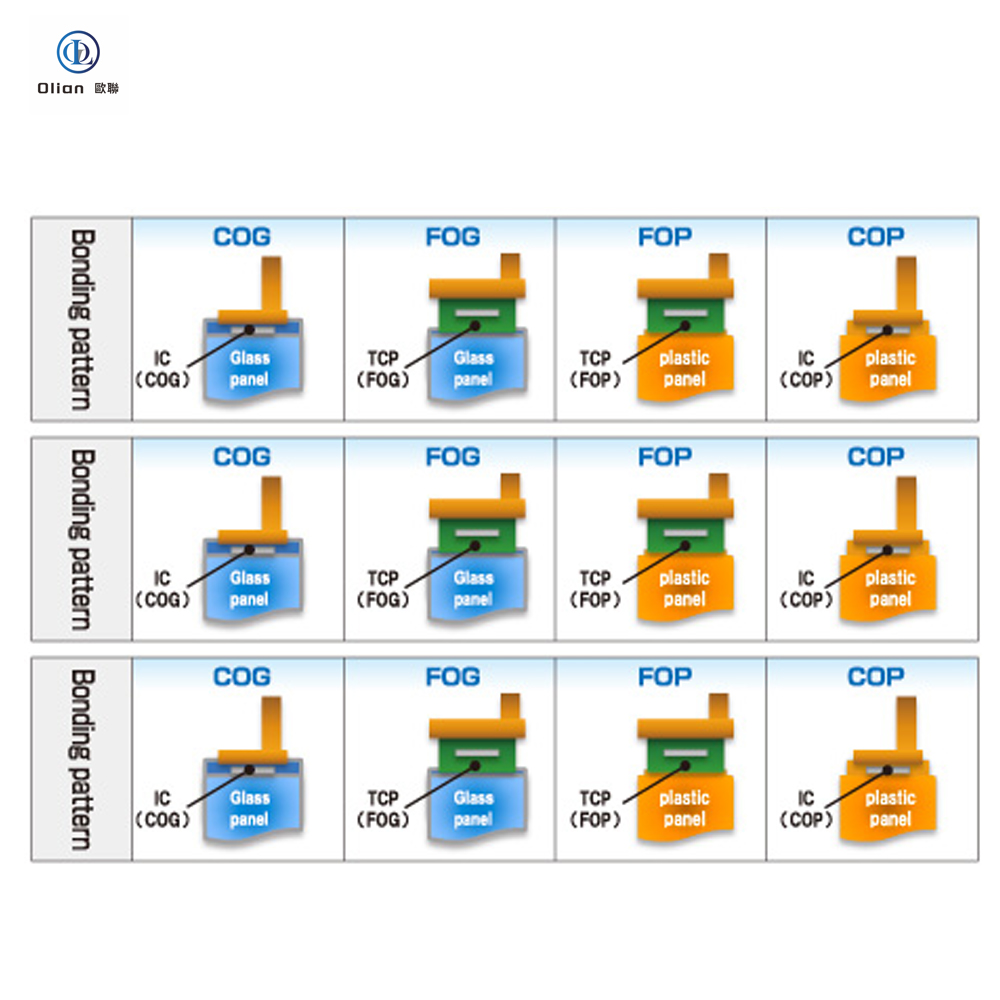

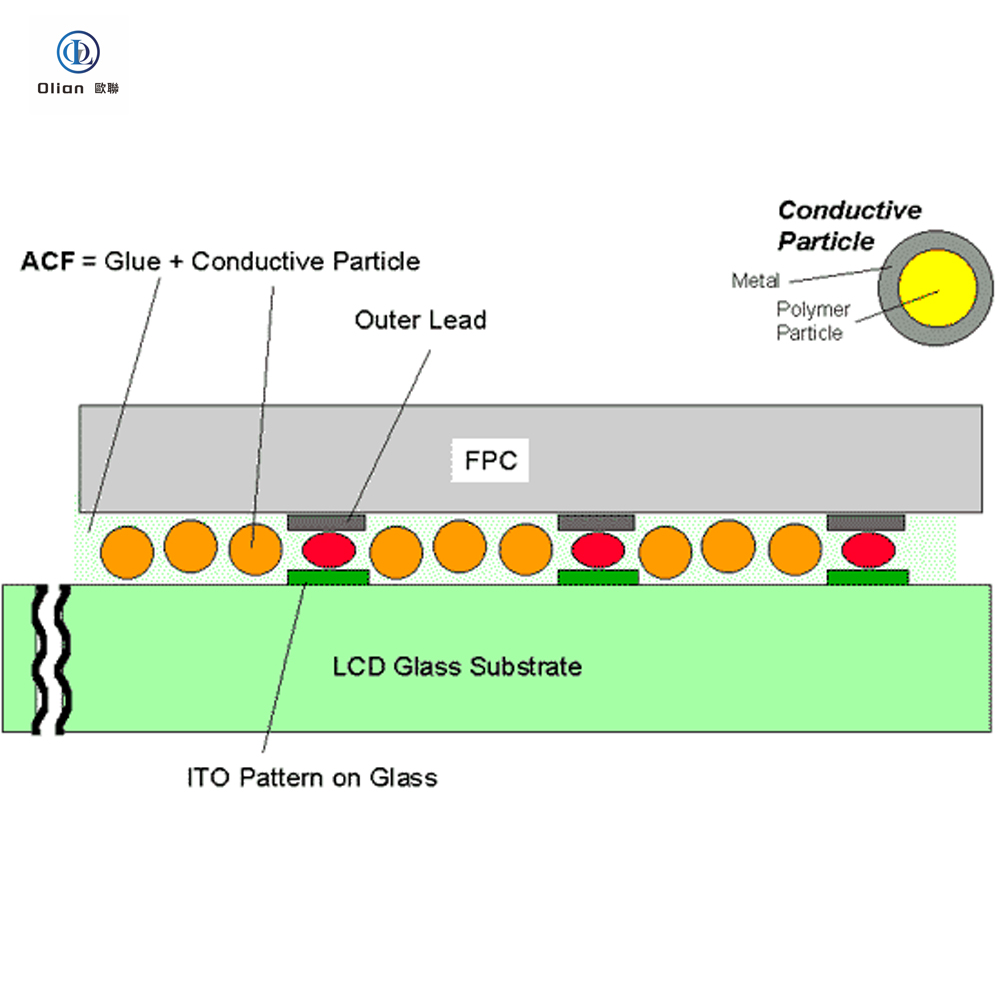

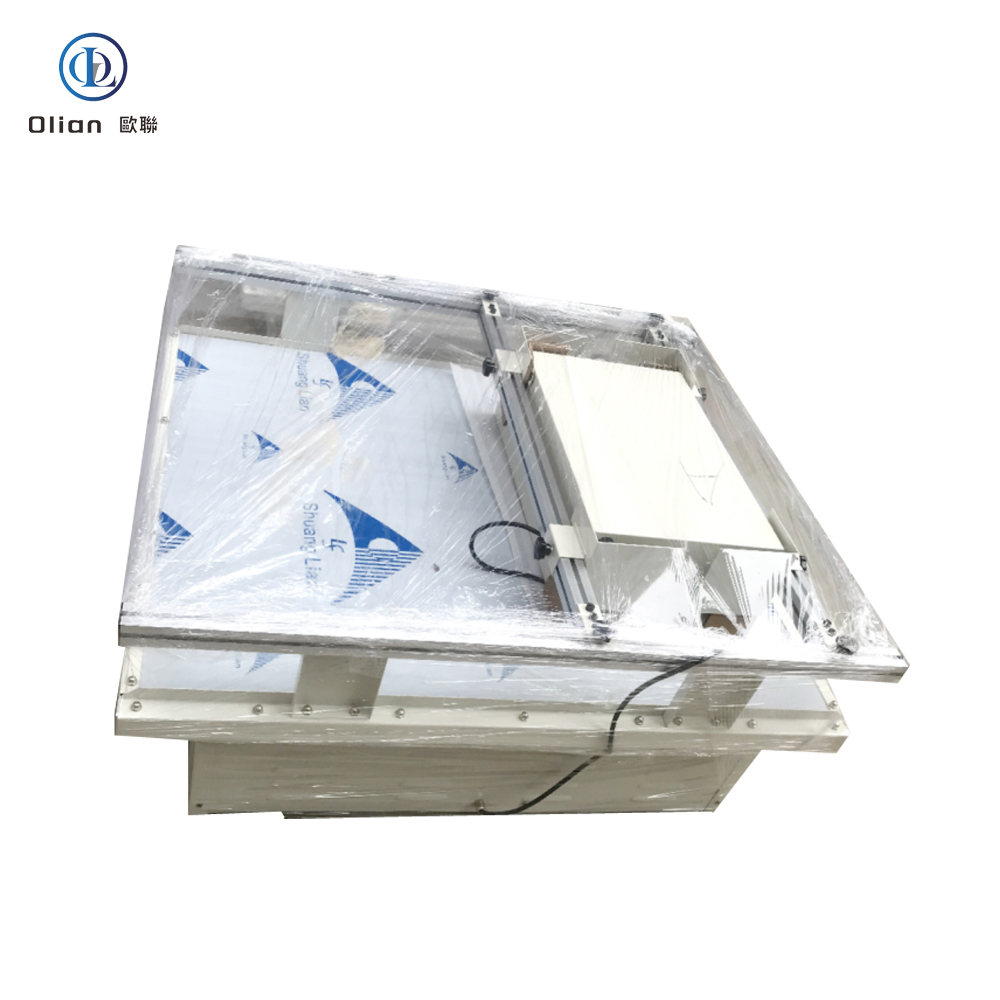

The OL-PB3000 Automatic FOB Bonder, manufactured by Shenzhen Olian Automatic Equipment Co., Ltd., is a cutting-edge device designed for the automatic PCB loading, ACF (Anisotropic Conductive Film) attachment, alignment, and thermal compression between FOG (Flexible On Glass) products and PCB (Printed Circuit Board) in LCD products ranging from 5.5″ to 17.3″. This equipment is compatible with single-edge multi-segment FPC (Flexible Printed Circuit) products and can be integrated with other machines from the same company to form a production line.

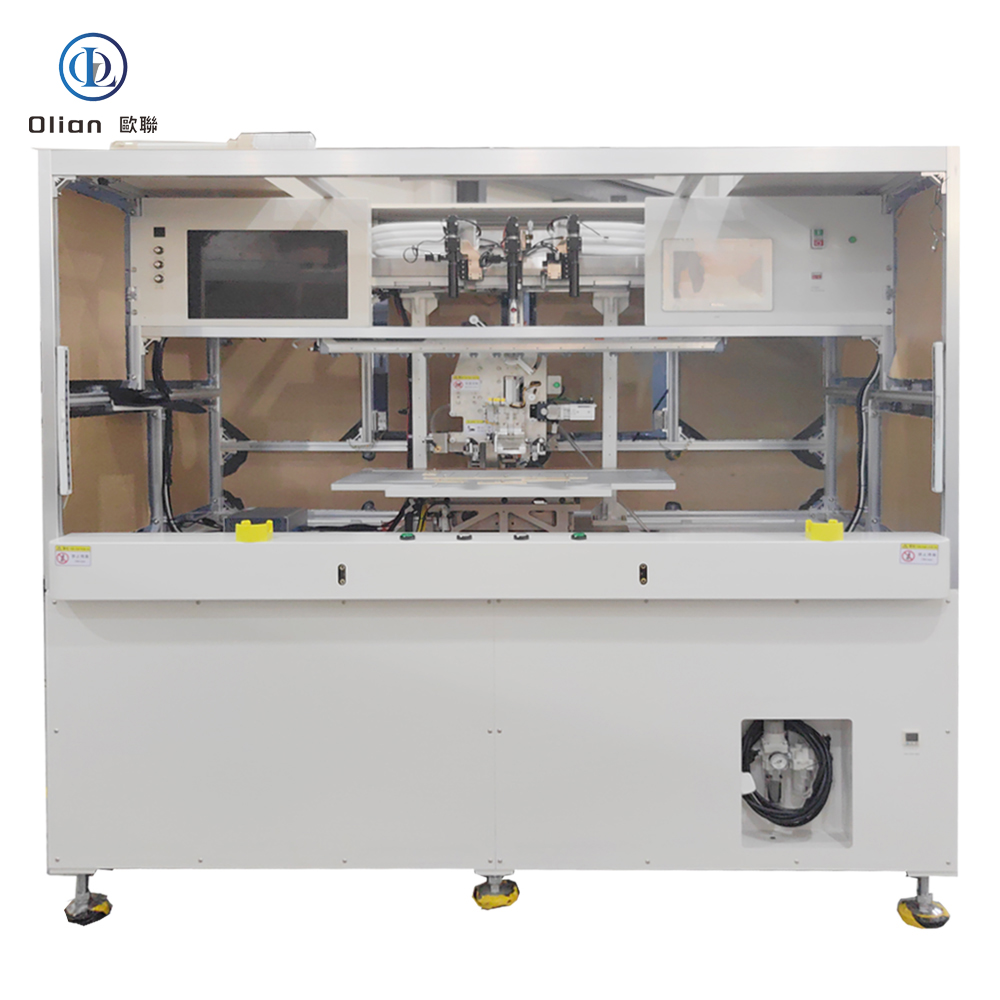

Device Structure and Workflow

The device consists of several key components, including PCB loading, FOG loading, pre-main pressing platform, detection platform, and an outfeeding system. Its workflow starts with PCB loading, followed by FOG loading. Then, the PCB undergoes plasma cleaning. Subsequently, the FOG is transferred to the pre-main pressing platform, and the PCB is also moved to this platform. After alignment between FOG and PCB, the main pressing process takes place. Post pressing, the product undergoes various detection processes. If any deviation is detected, the product is discharged through a belt. If the product passes the detection, it is handed over to the subsequent machine or outfed.

Applicable Product Specifications

The OL-PB3000 accommodates LCD dimensions from 100mm×100mm to 380mm×380mm. The FPC & COF (Chip On Film) dimensions range from 20mm×20mm to 80mm×80mm, with a maximum of 6 FPC & COF units on a single edge and a center distance of≥60mm. The PCB length can be 70 – 380mm, width 10 – 60mm, with a maximum of 1 PCB. The maximum finished product size is 480mm. The ACF can be of the reel type, with 2 or 3 layers. The ACF attachment length is 5 – 80mm, and the width is 0.3 – 5mm, adjustable for different widths. The ACF reel has an inner diameter of 18mm or 25mm, and the maximum reel diameter is 200mm.

Machine Performance Indicators

The OL-PB3000 boasts high-precision production capabilities. The ACF attachment accuracy is X:±0.15mm, Y:±0.1mm. The FOB main pressing accuracy is X: ±25um, Y:±30um. The production cycle is≤10sec/pcs, with the ACF setting time≤0.5sec and the main pressing setting time≤10sec. It is suitable for FOB bonding of single-edge 1 – 6 FPC products. When switching to a new model, the time required is≤90min, and for existing models, it’s≤50min, depending on the engineer’s proficiency.

Process Parameter Specifications

The temperature control for ACF-bonding ranges from RT (Room Temperature) to 120℃, and for main-bonding, it’s RT to 400℃. The heating method for the pressing head is constant heat, with temperature control via PID (Proportional Integral Derivative) control and touch screen settings. The temperature error on the pressing head surface is±5℃, using K-type thermocouples. The time setting for ACF-bonding is 0.1 – 9.9Sec, and for main-bonding, it’s 0.1 – 99.9Sec. The pressure regulation range for ACF-bonding is 10 – 150N, and for main-bonding, it’s 20 – 600N. Pressure regulation for ACF is via a precision pressure regulator, while for main pressing, it’s controlled by a proportional valve and touch screen adjustments.

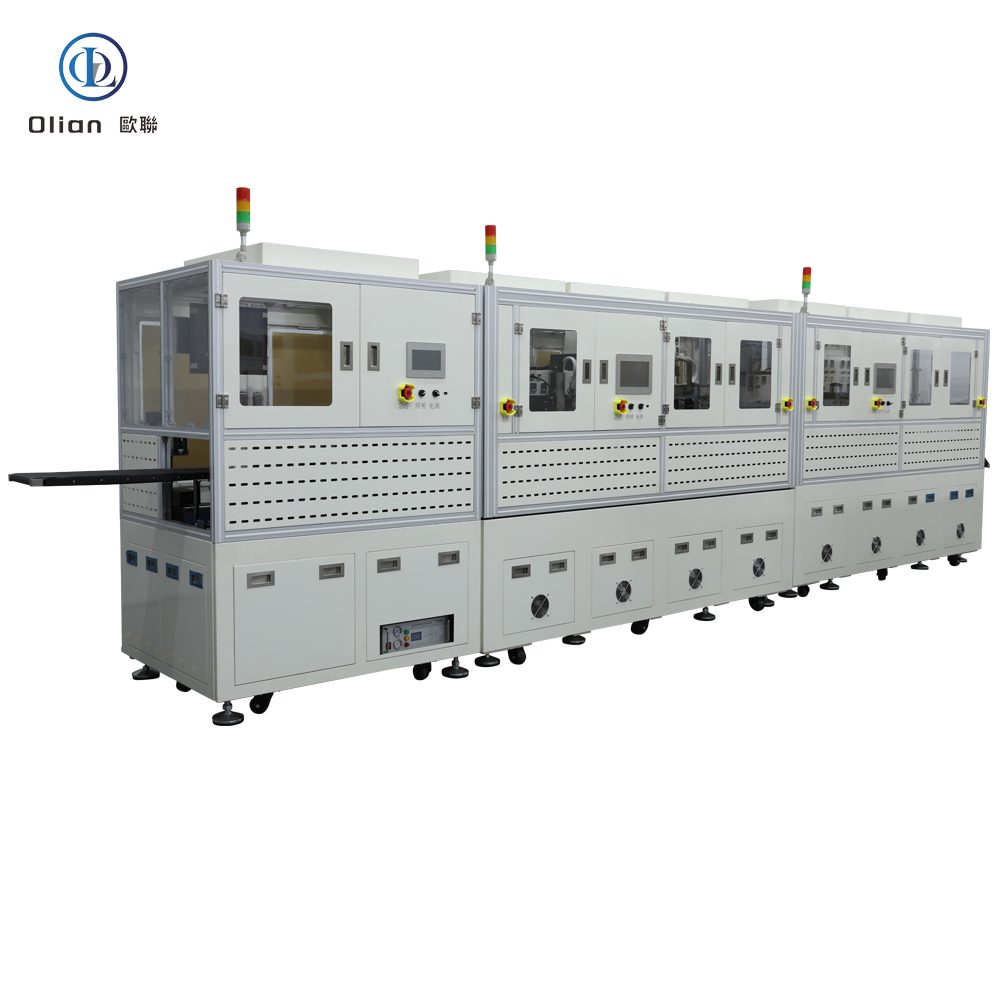

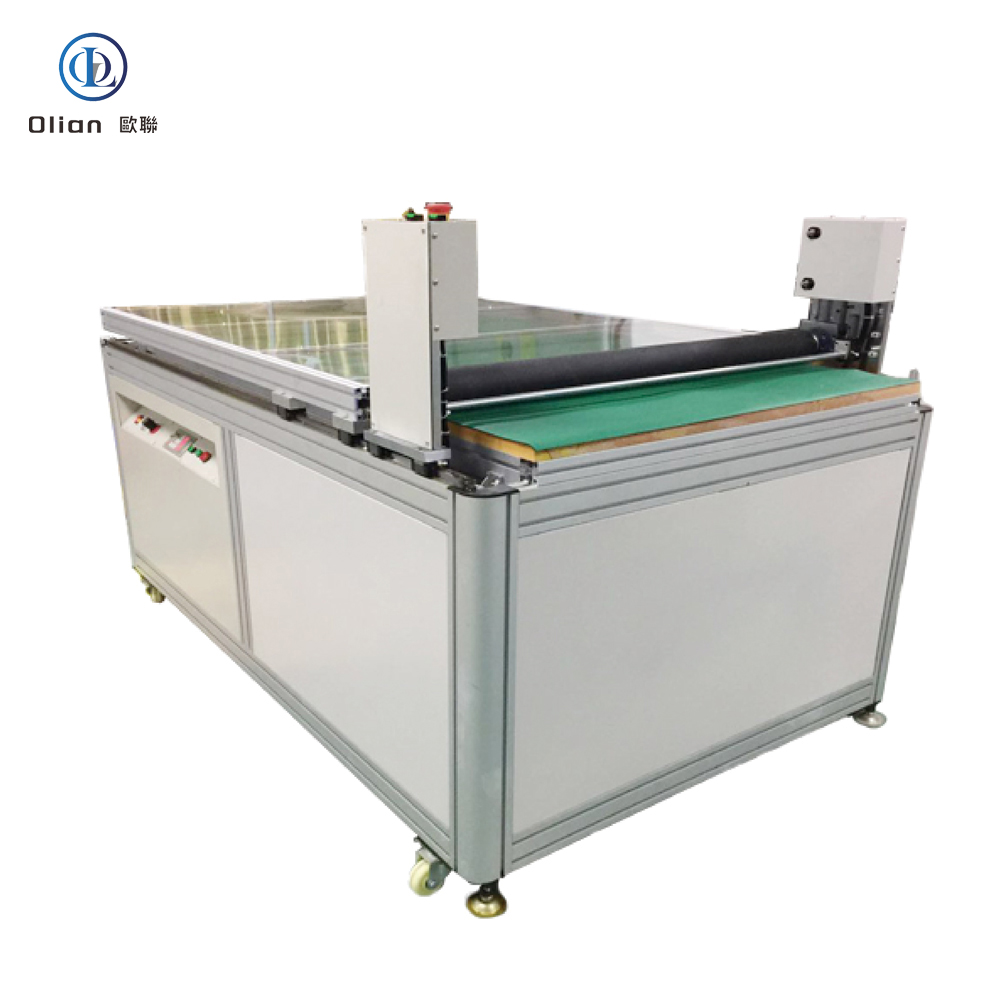

Overall Machine Specifications

The machine dimensions are approximately 4400mm (length) ×2000mm (width) ×1900mm (height), with a working height of 1000mm. It weighs around 3000KG and comes in ivory white. It requires a cleanroom environment of class 1000 or below. The power supply is three-phase 380V. The machine has a maximum power of 15KW. The air source requirement is a clean compressed air of≥0.5 – 0.7MPa, with a consumption of≈200L/min. The machine is equipped with a vacuum pump (200L/min) and a storage tank. It also features an exhaust system with a centralized silencer. For safety, it has an emergency stop button with a protective cover, interlocking design, and alarm systems.

Equipment Unit Specifications

The PCB loading section uses tray loading with a tray size range of 400x500mm (max) and 250x250mm (min), and a maximum stack height of 400mm.

The FOG loading can be via belt, platform, or upstream machine integration, with offline unloading. The outfeeding section can directly connect with downstream machines.

The FOG mechanical hands are equipped with vacuum groups and quantity selectable according to product dimensions, with vacuum value digital displays.

The X-axis is driven by linear motor, θ-axis by servo + harmonic reducer, and Z-axis by slide cylinder lifting.

The ACF unit features automatic semi-cutting, with cutting depth adjustable via a micrometer.

The ACF stage includes platform vacuum, material, and flatness specifications.

The ACF detection part uses a CCD vision system.

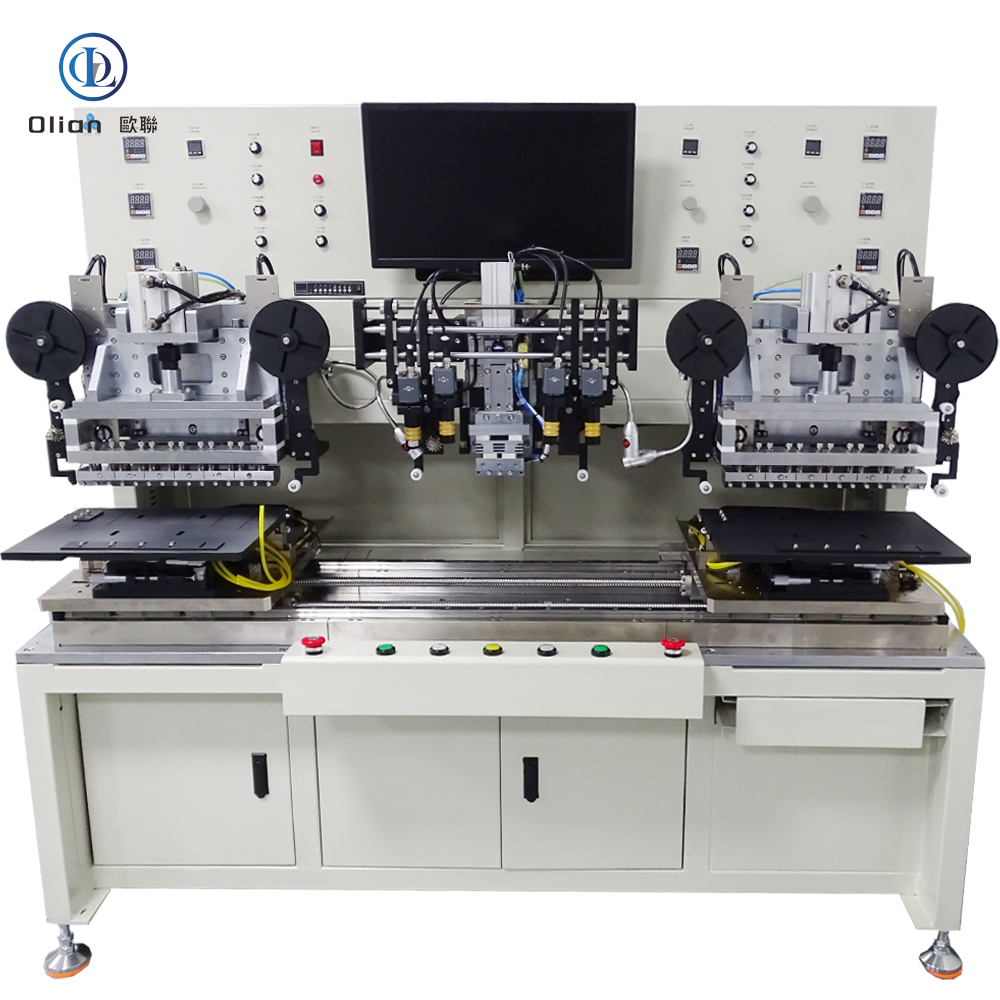

The pre-main pressing unit has 4 pressing heads per group, driven by servo + cylinder + guide rail.

The pre-main pressing stage involves Y1-axis, X-axis, Y2-axis, FOG-Z-axis, and PCB-Z-axis movements, all driven by servo motors.

The pre-main pressing alignment CCD uses linear motor + guide rail for X-axis movement.

The main pressing backup part has specific material, size, and surface flatness requirements.

The buffer material supply part involves step motor-driven rotation, manual width adjustment, and sensor detection for material exhaustion.

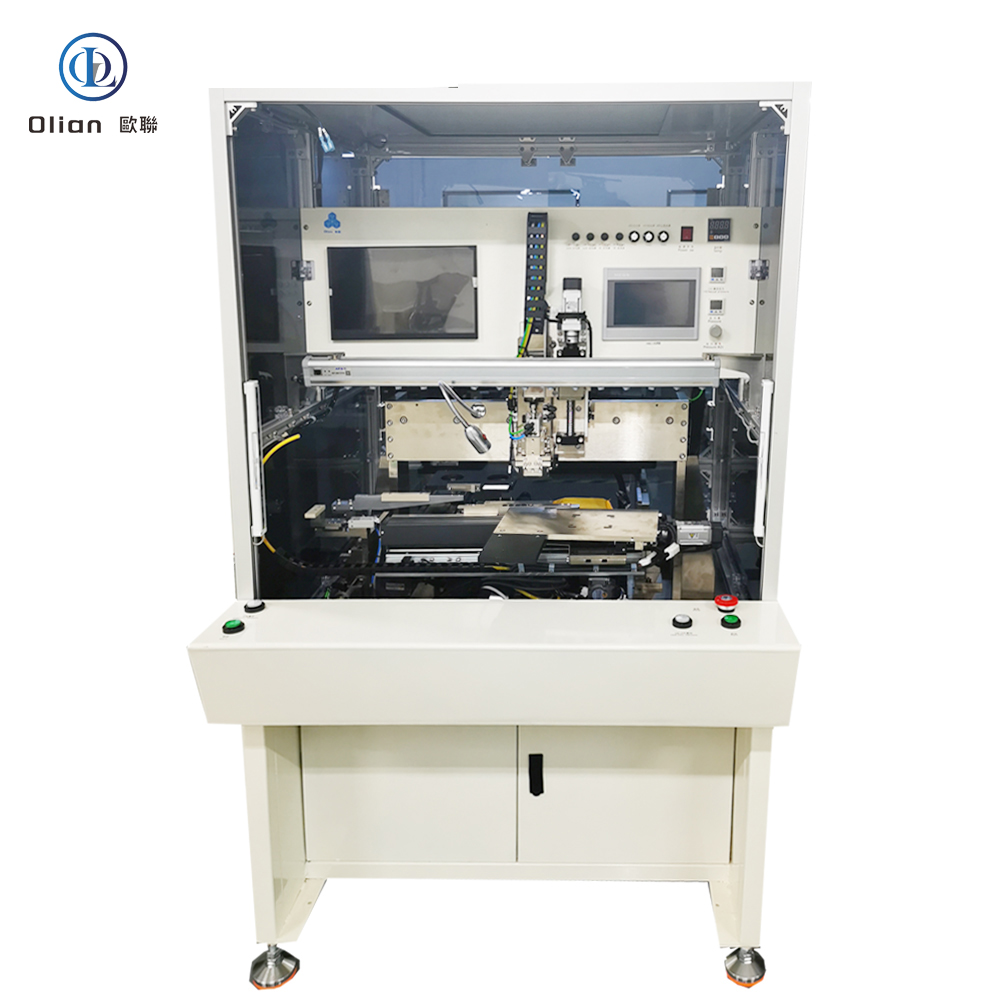

Image Processing and Control Unit

The image processing unit employs the Boss system with multiple CCD cameras, same-axis light barrels, and different magnifications and field of views for various detection parts. The control unit uses PLC control with a touch screen interface supporting manual and automatic modes. It displays working parameters and can store data for 100 varieties. It also has emergency stop buttons, power switches, lighting switches, door interlock functions, and a three-color operation indicator light.

File Documentation and After-sales Service

The company provides an operation manual and offers training on equipment installation, operation, calibration, parameter setting, maintenance, and troubleshooting. It also includes one year of free after-sales service (excluding damages caused by human error) and lifelong technical support.

Major Component Brands

The OL-PB3000 utilizes high-quality components from renowned brands, such as Servo motors from Rite,丝杆 from THK and 上银, DDR from雅克贝斯,导轨 from THK and 上银, pneumatic elements from SMC and 亚德客, PLC from Keyence, touch screens from Weilin, sensors from Meiji, switch power supplies from Mingwei, circuit breakers and contactors from Schneider and 士林, and drag chains from igus.

In summary, the OL-FB3000 Automatic FOB Bonder is a high-precision, efficient, and reliable device designed to meet the stringent requirements of LCD product manufacturing. With its advanced technology, robust performance, and comprehensive after-sales service, it is an ideal choice for businesses in the electronics manufacturing industry seeking to enhance production efficiency and product quality.