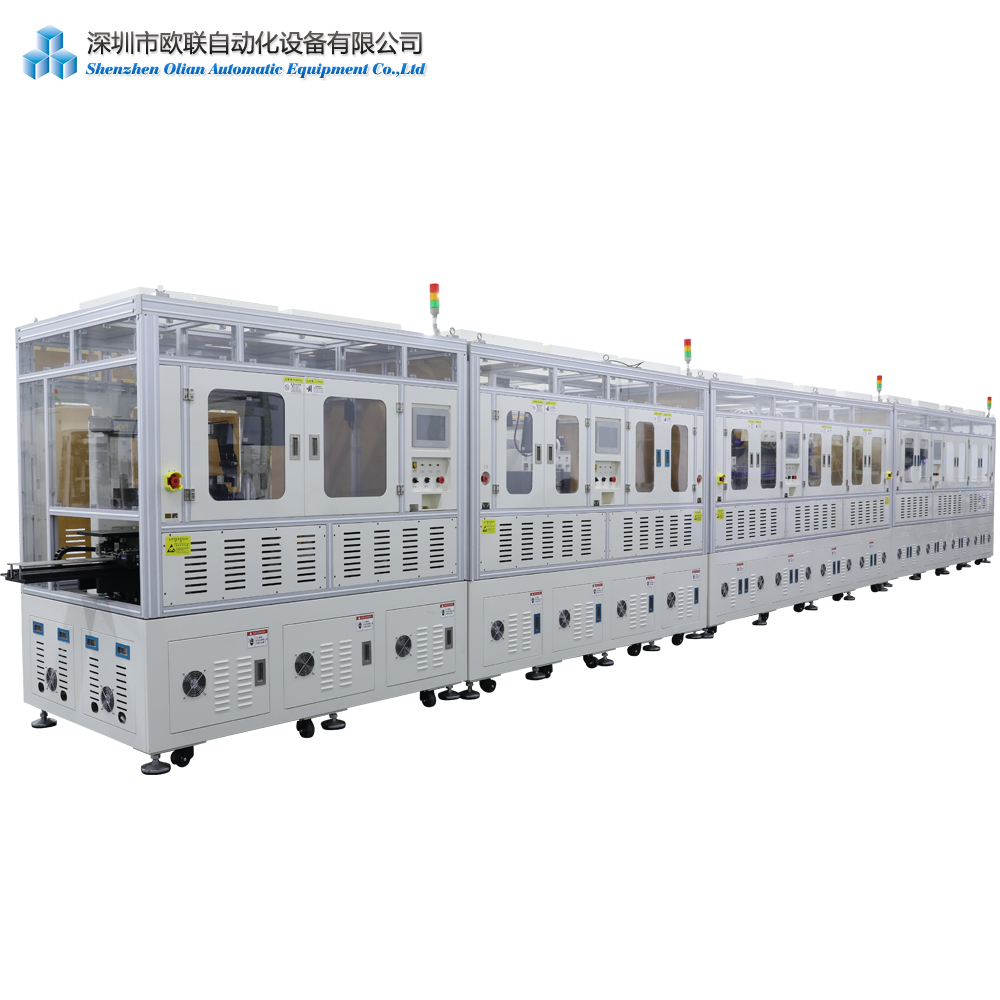

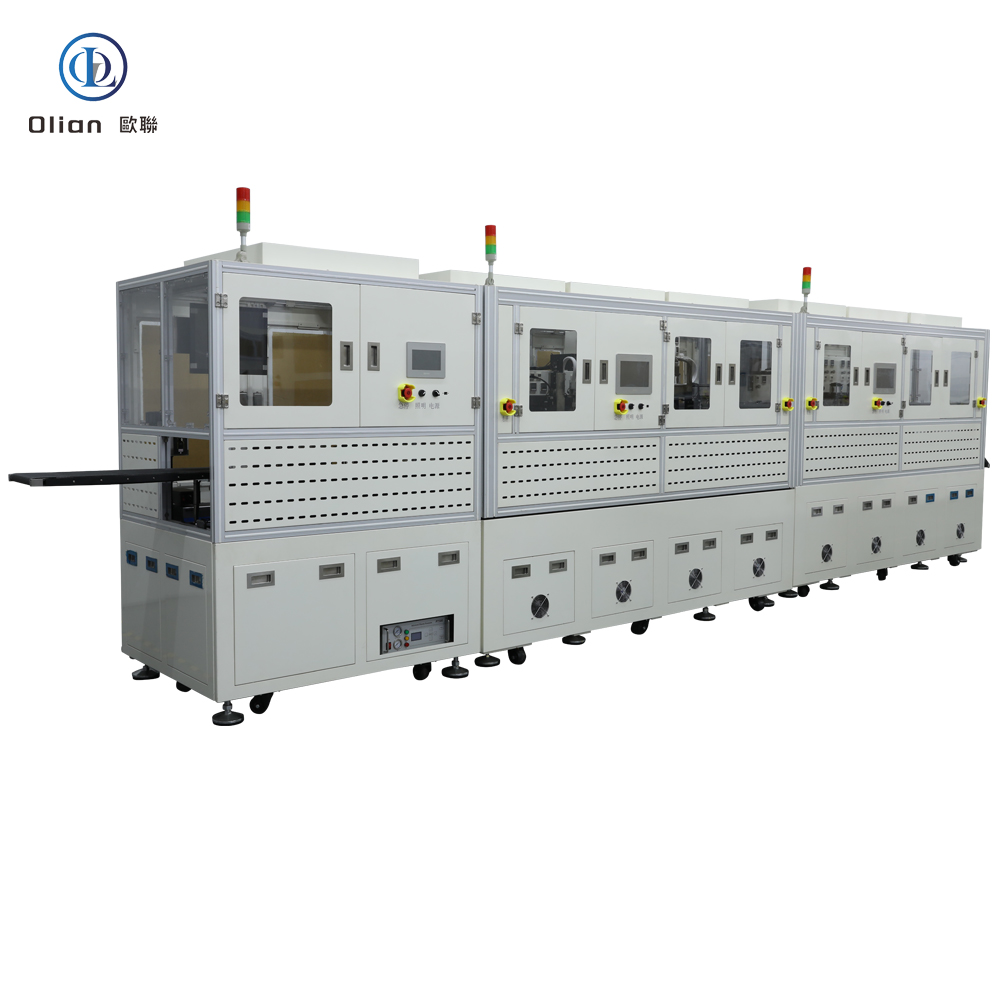

COG bonding machine

A COG bonding machine is the micro-surgical robot of the display world.

COG—Chip-On-Glass—means the bare driver IC is flipped, aligned, and permanently fused directly to the glass substrate of an LCD, OLED, or mini-LED panel.

Because the chip sits on the glass instead of a flexible circuit, bezels shrink, signal paths shorten, and phones, tablets, laptops, TVs, automotive clusters, and medical monitors become thinner, lighter, and more reliable.

High-value keywords: “COG bonding machine”, “Chip on Glass bonder”, “LCD IC bonding equipment”, “ACF COG machine”, “pulse heat COG bonder”, “narrow bezel bonding”, “smartphone display bonding”, “automotive COG bonding”, and many more.

A COG bonding machine is a high-precision pulse-heat press that picks up a gold-bumped driver IC, places it face-down on a glass substrate, and bonds it through anisotropic conductive film (ACF) in one three-second cycle.

The film contains 3–5 µm nickel or gold-coated plastic spheres.

Heat and pressure trap particles between IC bump and glass pad, creating thousands of vertical contacts while remaining insulated laterally.

The result is a permanent, flexible, lead-free interconnect that survives −40 °C to +85 °C thermal shock, 1,000-cycle bend tests, and 95 % humidity at 65 °C for 1,000 h.

Modern COG bonders achieve ±1 µm alignment, ±0.3 °C temperature stability, and 0.1 kg force resolution on panels from 1 inch smartwatches to 17 inch automotive displays.

COG eliminates the flexible printed circuit entirely.

Signal length from IC to pixel column drops 50 %, reducing EMI at 120 Hz and 240 Hz refresh rates.

Because the IC overhangs only 0.3 mm beyond the active area, bezels shrink to 0.9 mm, enabling edge-to-edge smartphones and seamless multi-screen video walls.

Cost drops: no flex, no connector, less copper.

Yield rises: fewer solder joints, no FPC misalignment.

Rework is possible: a laser can remove a defective IC and rebond a new one in under two minutes

Bonding Head: Titanium alloy, diamond-lapped to 0.5 µm flatness, plasma-nitrided to 70 HRC, anti-stick coating lasts 100,000 cycles.

Heater Cartridge: 400 W, ramp rate 150 °C/s, embedded K-type thermocouple accuracy ±0.3 °C.

Force Actuator: Voice-coil or servo motor with 16-bit encoder, 0.1 N resolution, 5 ms settling time.

Vision System: 12 MP CMOS cameras, telecentric lens, coaxial LED ring light, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearing, 0.05 µm linear encoder, feedback loop at 10 kHz, vibration isolation granite base.

Software: Windows real-time kernel, recipe encryption, SECS/GEM for semiconductor fabs, OPC-UA for Industry 4.0 dashboards.

Smartphones & Tablets: COG bonds the display driver and touch controller in iPhone, Galaxy, and iPad lines, enabling 1 mm side bezels.

Laptops & Monitors: 240 Hz gaming panels use COG to cut latency and electromagnetic noise.

Automotive: Curved instrument clusters and 12.3 inch center stacks rely on COG for vibration resistance from −40 °C to +105 °C.

TV & Signage: 4K and 8K LCD/mini-LED TVs bond source drivers on both top and bottom edges; COG shrinks frame width to 6 mm.

Medical: Surgical displays and portable ultrasound units demand zero flex cable failure; COG delivers 99.97 % reliability.

Industrial & Military: Avionics and factory HMI panels use COG for shock, altitude, and fungus resistance

COG bonding machine, Chip on Glass bonder, LCD IC bonding equipment, ACF COG machine, pulse heat COG bonder, narrow bezel bonding, smartphone display bonding, automotive COG bonding, TV driver IC bonding, 8K display bonding, micro-bump bonding, flip chip glass bonding, lead-free IC bonding, ROHS compliant bonding, China COG bonding machine, automatic COG bonder, COG vs COF comparison, COG bonding accuracy 1 micron, COG bonding temperature 220 C, COG bonding pressure

AI Predictive Alignment: Neural networks pre-heat the stage to cancel thermal expansion, pushing accuracy to ±0.5 µm.

IoT Yield Analytics: Every bond uploads temperature, force, and resistance to the cloud; big data predicts heater failure one week early.

Green ACF: Copper-core particles replace gold, cutting material cost 50 % while maintaining < 30 mΩ contact resistance.

Cold-Laser Assist: Femtosecond laser cleans bumps at room temperature, allowing polyimide-friendly 120 °C bond profiles.

Micro-LED Bridge: Same COG platform bonds 20 µm × 20 µm micro-LED dies onto glass backplanes for next-generation emissive displays.

Servo-Hydraulic Hybrid: Delivers 80 kg force for 100″ TV panels while keeping 1 µm position accuracy.

A COG bonding machine is no longer a niche tool—it is the beating heart of every slim-bezel smartphone, every 240 Hz gaming monitor, and every curved automotive cluster you will touch .

By mastering sub-micron alignment, single-degree thermal control, and ton-class force feedback, the latest COG bonders deliver 3-second cycles with 99.97 % yield and full Industry 4.0 traceability.

Whether you are a display OEM chasing 0.9 mm bezels, a TV repair center , or a micro-LED start-up prototyping next-gen emissive screens, investing in an AI-enhanced, IoT-connected COG bonding platform future-proofs your process.

Shenzhen Olian is professional in design & assembly&sales&service for all kinds of COG bonding machine. Welcome to feel free visit us in shenzhen of China.