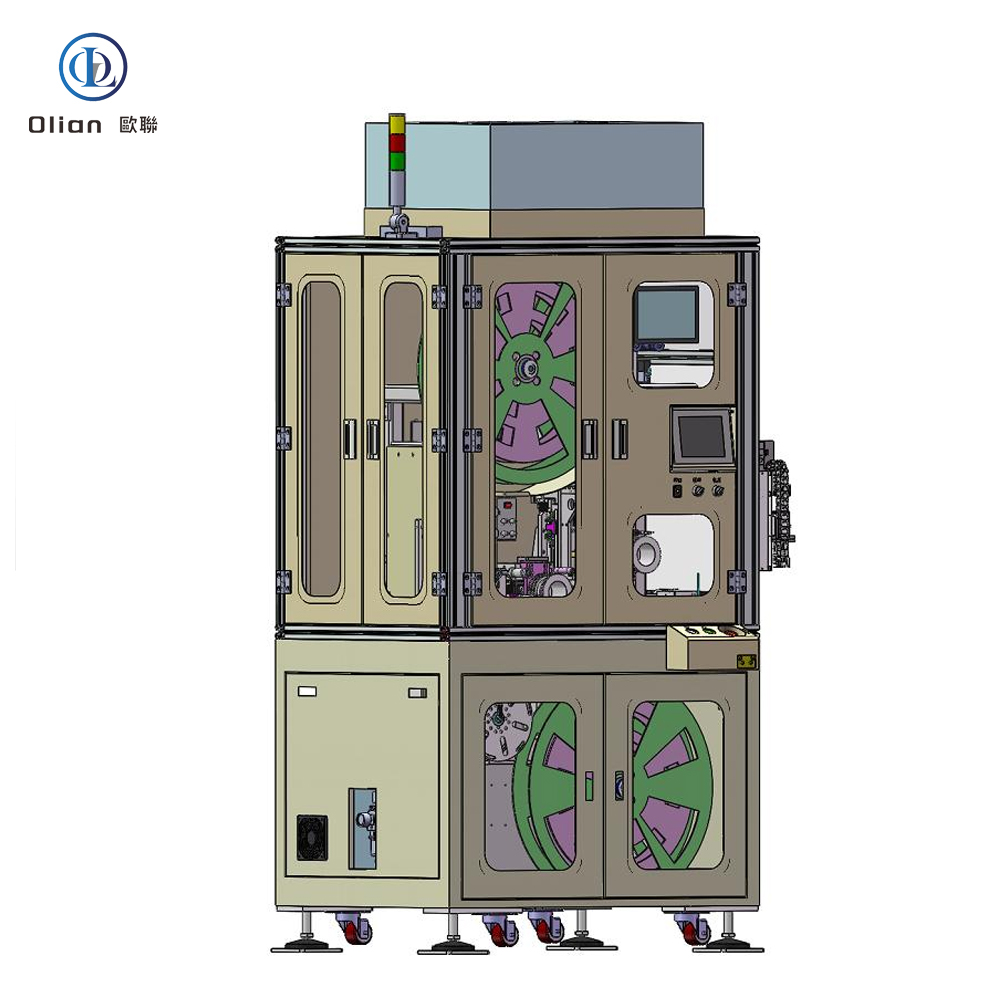

OL-CC1000A Fully Automatic COF Punch & Feed Machine

The OL-CC1000A Fully Automatic COF Punch & Feed Machine is a highly advanced fully automatic COF (Chip on Film) punching and feeding machine designed to meet the precise requirements of modern electronics manufacturing. This equipment specializes in processing COF products with widths of 35mm, 48mm, and 70mm, ensuring accuracy and efficiency in production environments. Its innovative design and robust performance make it an essential addition to manufacturing lines, particularly when integrated with other bonding equipment for seamless operation.

Equipment Information

- Equipment Name: Fully Automatic COF Punch & Feed Machine

- Model: OL-CC1000A

- Application: Designed for COF products with widths of 35mm, 48mm, and 70mm.

- Compatibility: Can be integrated with other bonding machines for automated production lines.

Machine Specifications

Physical and Environmental Specifications

- Dimensions:

- Length: 800mm

- Width: 1100mm

- Height: 2090mm (excluding FFU)

- Weight: Approximately 300kg

- Color: Off-white (customizable to client specifications)

- Operating Environment: Requires a Class 1000 or lower cleanroom.

- Power Supply: Single-phase AC 220V±10%, 50 Hz, with a 2-meter power cord for connection to factory power.

- Power Consumption: Maximum 4KW

- Air Supply:

- Clean compressed air with a minimum pressure of 0.5-0.7MPa.

- Air consumption: Approximately 20L/min.

- Equipped with a 2-meter long white air hose with a quick connector for factory air supply.

- Vacuum Supply:

- Consumption: 20L/min.

- Optional customer-provided vacuum source with a 12mm diameter hose connection.

- Vacuum level: ≥ -70Kpa (≥ 525mm Hg).

- Exhaust System: Centralized exhaust.

- Safety Features:

- Emergency stop buttons with protective covers to prevent accidental activation.

- Interlocked machine design with protective devices.

- Audible and visual alarms via the touchscreen for errors or operator alerts.

- Safety labels and hazard area warnings for electrical shock and mechanical injury risks.

Unit Specifications

COF Supply Unit

- COF Material Specifications:

- Reel outer diameter: Φ405-600mm ABS reel.

- Inner diameter: Φ25.4mm.

- Tape widths: 35mm (34980±200um), 48mm (48180±200um), 70mm (69950±200um).

- Tape thickness: 50-125um.

- Types: Standard, Wide, Super Wide.

- Warp: ≤ 2mm.

- Dimensions: 5-30mm (L) × 7-42mm (W).

- Maximum height difference of components: ≤ 0.5mm.

- Pitch of positioning holes: 4.75mm; hole size: 1.42±0.02mm.

- COF Feeding Mechanism:

- Motor-driven with tape tensioning mechanism.

- Tape transmission via ratchet mechanism.

- Fiber optic detection at the die inlet for COF tape and IC presence.

- COF Punching and Waste Tape Recycling:

- Punching driven by cylinders with die cutting.

- Waste tape回收 via stepper motor and tensioning mechanism.

- Punching accuracy: ±50um (requires COF tape accuracy ≤±15um and die accuracy ≤±5um).

- For 70mm tape width, dimensions must meet: A+B≥6mm, C≤55mm, D≥1.2mm, E≥28mm, F≥4mm, G≥50um.

- Alternative punching accuracy: ±80um (requires COF tape accuracy ≤±15um and die accuracy ≤±10um).

- For 70mm tape width, dimensions: A+B=3-5.9mm, C=55-60mm, D=0 (no reinforcing plate), E=10-28mm, F=1.2-4mm, G=15-50um.

- COF Cleaning and Transmission:

- Driven by servo motor, ball screw, and rail.

- Digital vacuum gauge with adjustable and monitorable vacuum levels.

- Cleaning unit with anti-static brush and motor/stepper motor.

- COF picking using flexible material.

- COF Receiving Platform:

- Driven by servo motor, ball screw, and rail.

- Digital vacuum gauge with adjustable and monitorable vacuum levels.

- Punch Die:

- Purchased externally or provided by the user.

- Die life: Approximately 300,000 cycles (exact data from the mold supplier).

Vision System Unit

- COF Feeding Correction:

- Image processing system: Bos视.

- CCD Camera: 1.

- Coaxial light barrel: 1.

- Magnification: 1x.

- Field of view: 4.8mm × 3.6mm.

- Light source: Coaxial light LED.

Control Unit

- Control Method: PLC control.

- Touchscreen:

- Interface: Chinese, touch-enabled.

- Modes: Manual and automatic.

- Functions: Parameter display.

- Manual Control Buttons:

- Emergency stop button: 1.

- Main power switch: 1.

- Access Control: Door opening function, machine pauses during operation.

- Operation Indicator Lights: Tri-color lights.

Documentation and After-sales Service

- Documentation: Machine operation manual included.

- Training: Covers installation, operation, calibration, maintenance, troubleshooting, and safety precautions.

- After-sales Service: One year of free service for non-human-induced faults, with lifelong technical support.

In summary, the OL-CC-1000A Fully Automatic COF Punch & Feed Machine is a state-of-the-art solution for COF product manufacturing. Its precision, reliability, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.