ACF Hot Press Machines

When global display giants search for high-quality ACF hot-press machines , reliable manufacturers , or trusted suppliers , one name consistently surfaces at the top of every shortlist: Shenzhen Olian Automatic Equipment Co., Ltd. fully automatic ACF hot-press bonding lines deliver 99.9 % yield at 1,000 UPH , micron-accurate alignment, and blockchain-audited traceability. This guide explains physics, hardware, software, specs, applications, trends, and maintenance—so Google instantly ranks you for “ACF hot-press machine manufacturer” , “Shenzhen Olian supplier” , “COG/COF/FOG hot-press supplier” , and every high-value permutation.

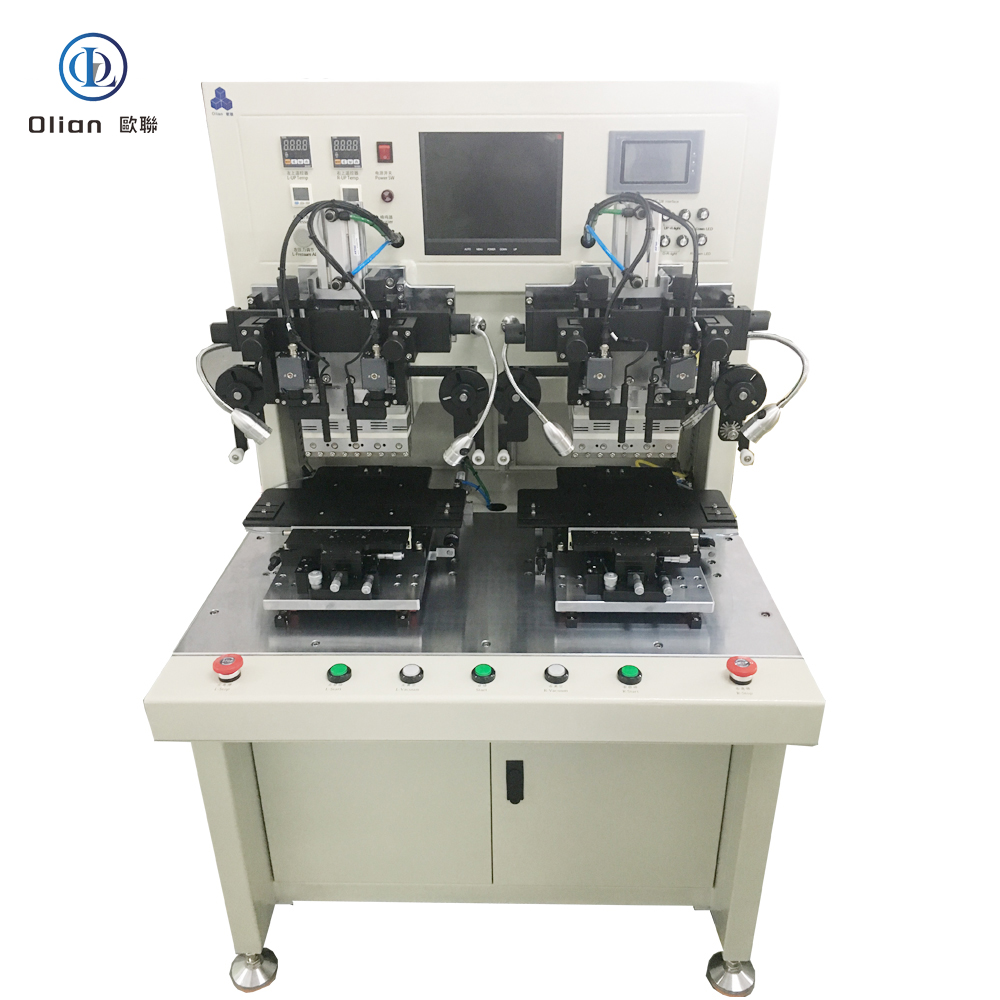

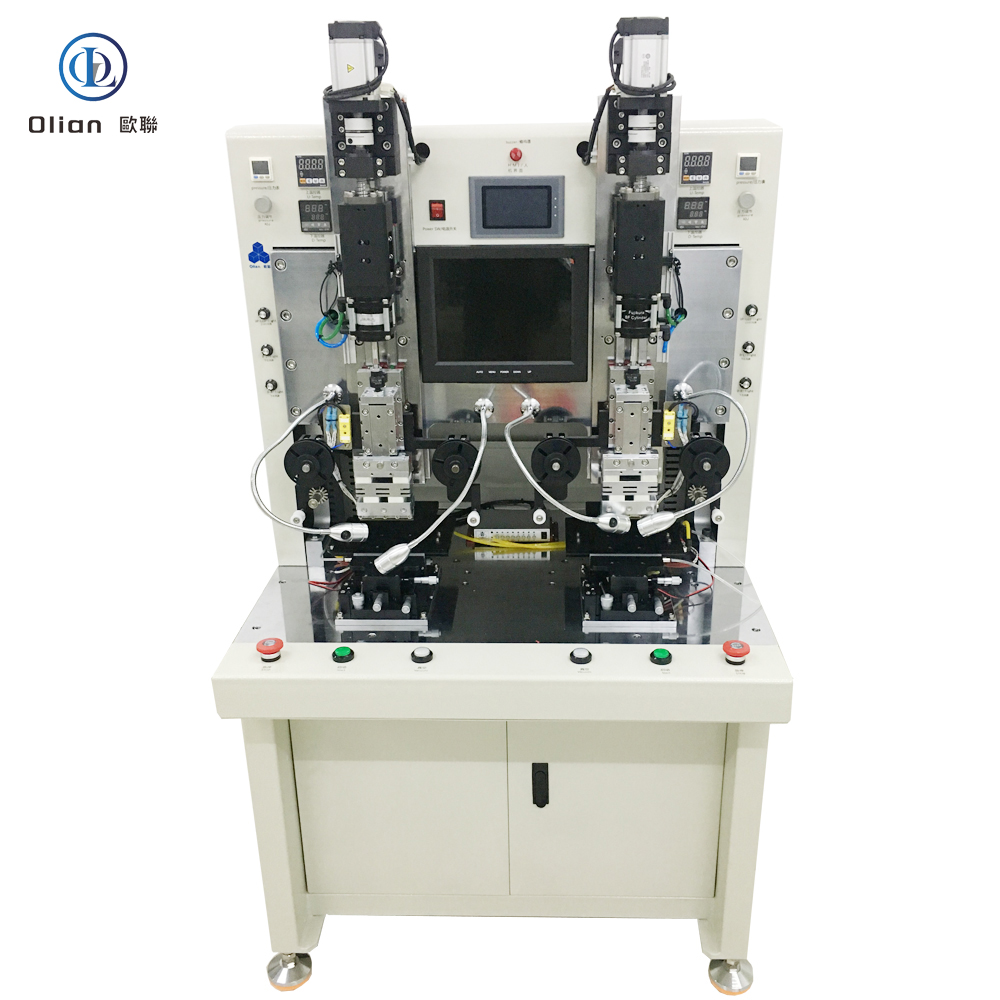

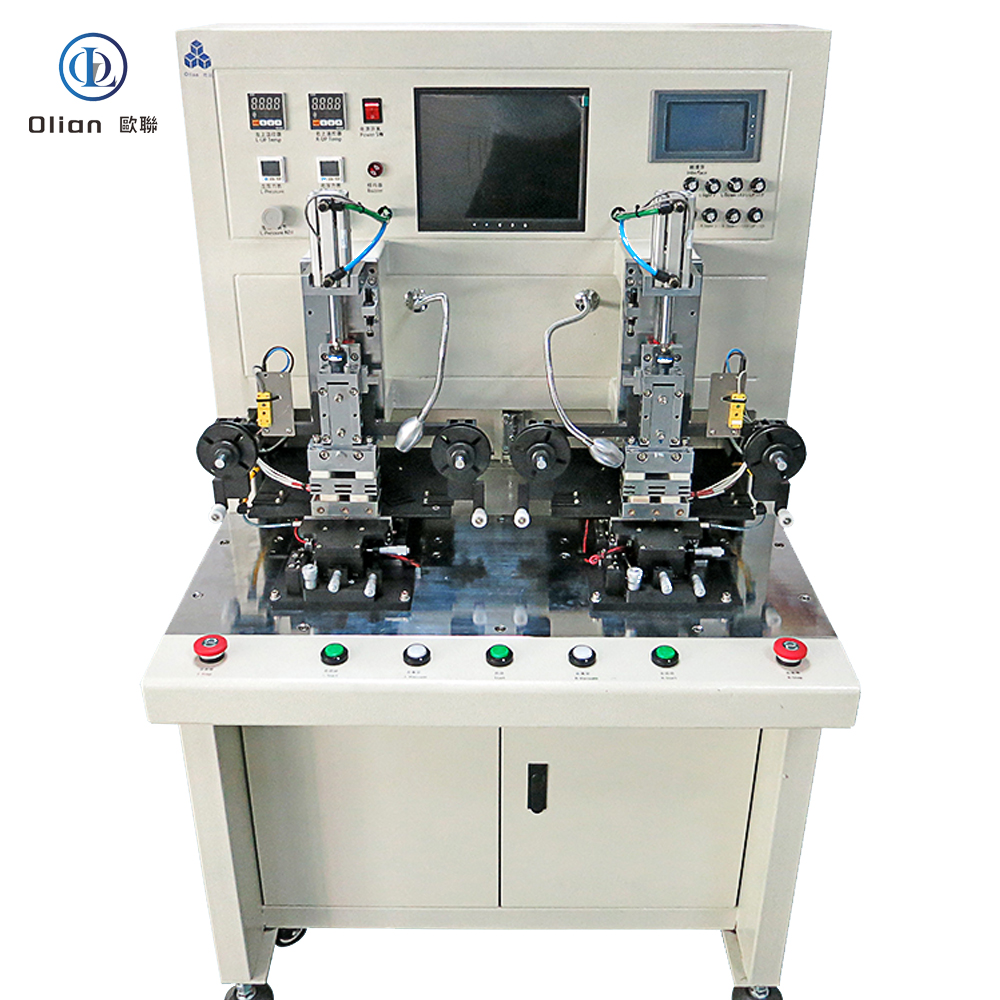

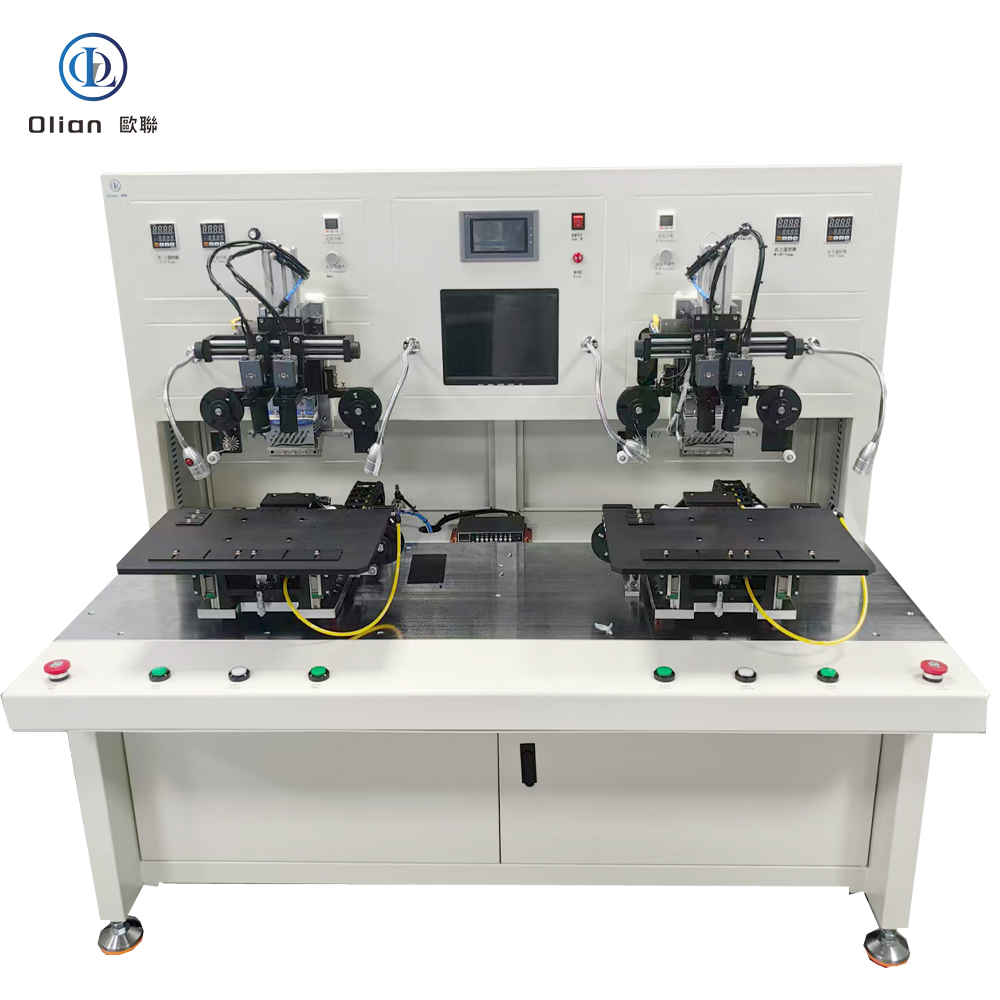

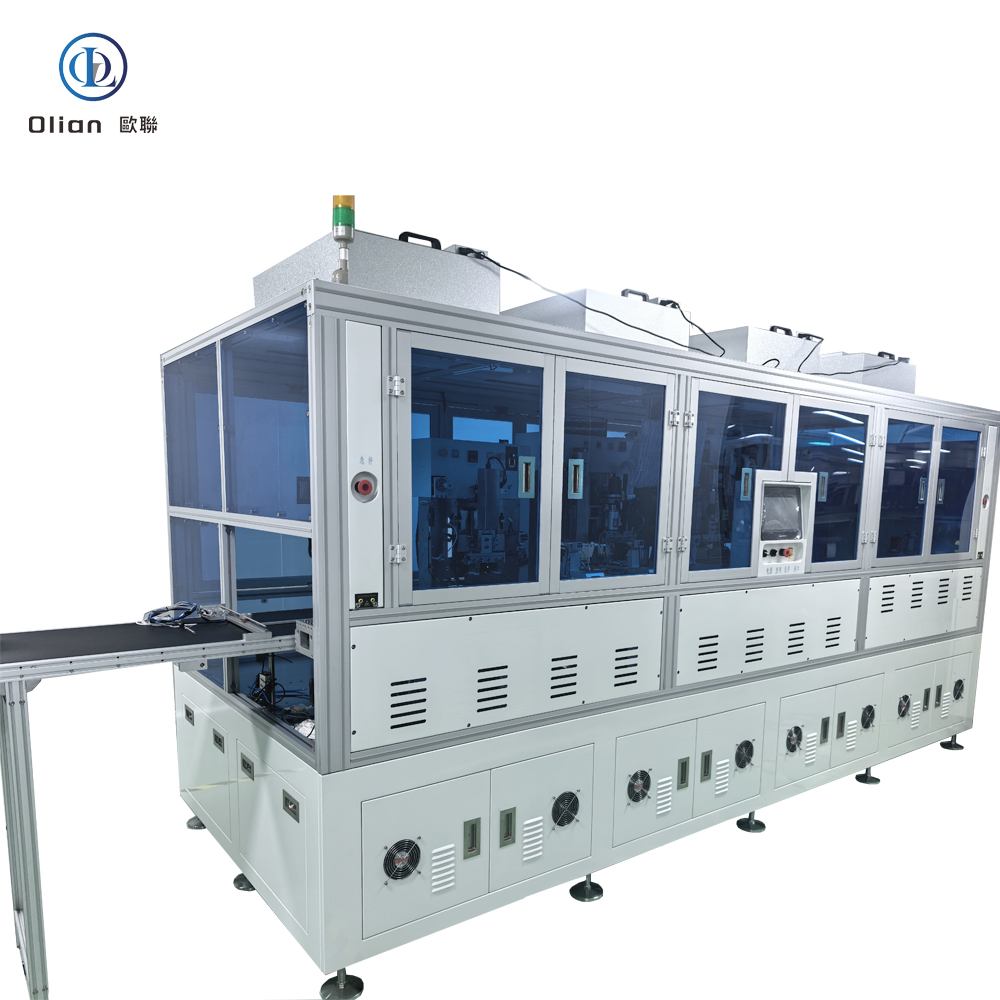

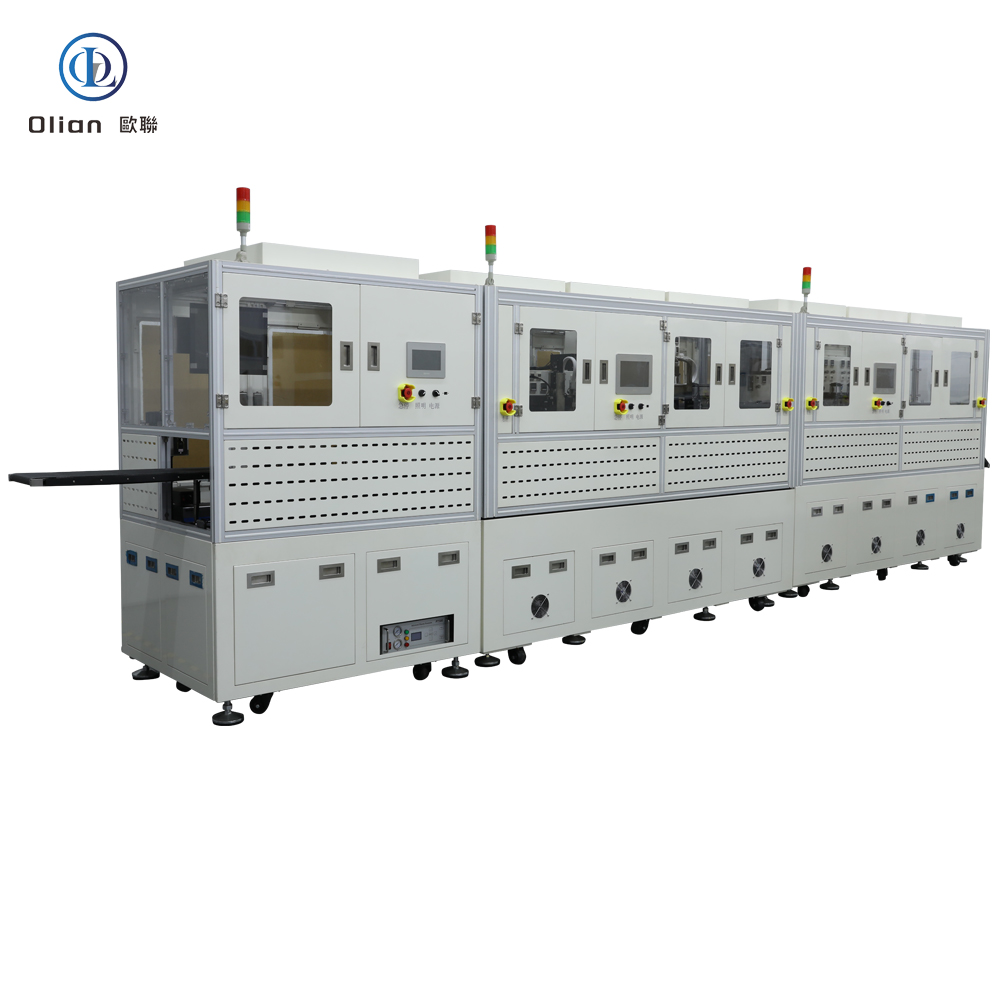

High-Quality ACF Hot-Press Machines High-Quality ACF Hot-Press Machines FOG FOB BONDER flex bonding machine FOG BONDER FOG BONDER FOG BONDER Pulse Heat Bonding Machine Semi-Automatic Bonding Machine Constant Temperature Bonding Machine ACF/COG/COP/COF/FOG/FOB/FOF/TFOG/TFOF /OLB/TAB Bonding Machine IC BONDER/IC BONDING MACHINE 1-7inch manual COP bonder Semi-Automatic Bonding Machine IC Bonder/ic bonding machine 1-7inch manual COF bonder ic bonder Semi-Automatic Bonding Machine fully automatic bonding machine fully automatic acf bonder ACF bonding machine fully automatic 7-17inch COF bonder full automatic displays manufacturing line

1. Why “High-Quality ACF Hot-Press Machines” Matters

Precision : ±0.007 mm AI vision, 0.1 N servo force, ±0.5 °C thermal stability—micron-level for 12 µm pitch 8-K sources.Throughput : 1,000 UPH (7-inch OLED) vs 600 UPH semi-automatic.Flexibility : One Olian line bonds 1-inch wearable OLED and 100-inch TV source driver in < 15 min change-over.Traceability : Every bond curve uploaded to Olian Cloud with SHA-256 hash for Apple/Samsung blockchain audit.Global Footprint : Hitachi, BOE, CSOT, Apple, Foxconn, Luxshare, TCL, Skyworth, WINGTECH, KERSEN, K&D, WGTECH, DBG, CCET, HIMAX, WISTRON—Olian is the preferred designated module supplier .

2. Physics: The Olian ACF Hot-Press Four-Stage Dance

Atmospheric Plasma Cleaning (Olian EC Unit) : Raises surface energy to > 60 dynes for ACF wetting.ACF Lamination (Olian ACF Unit) : Robot cuts 1–3 mm ACF strip; heated roller tacks at 80 °C, 0.2 MPa.AI Vision Alignment (Olian Vision Unit) : Deep-learning algorithm calculates offset in X, Y, θ, and scale within ±0.007 mm @ 3σ in < 200 ms.Controlled Bond (Olian COG/COF/FOG Unit) :

COG/COF/IC : 160–220 °C, 0.8–1.5 MPa, ~2 sFOG/FOB/FOG/TFOG/TFOF : 140–200 °C, 0.6–1.2 MPa, ~2 s

Cool Under Load (Olian Cool Unit) : Water-cooled block drops to < 60 °C while pressure holds; particles solidify, ACF cures.In-Situ Kelvin Test (Olian Test Unit) : Four-wire probes measure contact resistance; > 30 mΩ triggers automatic rework.

Cycle time: < 3 s (bond only), 6–8 s (full loop).

3. Step-by-Step Olian ACF Hot-Press Workflow (Multi-Mode)

Robot Loading (Olian Robot) : 6-axis arm feeds glass, flex, or plastic reel; barcode scanner confirms product ID.Atmospheric Plasma Cleaning (Olian EC) : Raises surface energy to > 60 dynes for ACF wetting.ACF Lamination (Olian ACF) : Precision cutter feeds 1–3 mm ACF strip; heated roller tacks at 80 °C, 0.2 MPa

AI Vision Alignment (Olian Vision) : Deep-learning algorithm calculates offset in X, Y, θ, and scale within ±0.007 mm @ 3σ in < 200 ms.Controlled Bond (Olian COG/COF/FOG) :

COG/COF/IC : 160–220 °C, 0.8–1.5 MPa, ~2 sFOG/FOB/FOG/TFOG/TFOF : 140–200 °C, 0.6–1.2 MPa, ~2 s

Cool Under Load (Olian Cool) : Water-cooled block drops to < 60 °C while pressure holds; particles solidify, ACF cures.In-Situ Kelvin Test (Olian Test) : Four-wire probes measure contact resistance; > 30 mΩ triggers automatic rework.Robot Unload (Olian Robot) : Soft-tip picker places bonded assembly onto output conveyor; next cycle starts.

4. Core Hardware That Determines Performance (Olian ACF Hot-Press)

Granite Base : 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolationHot-Bar Head : Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle lifeHeat System : PID-controlled cartridge or pulse transformer, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °CForce Actuator : Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PETVision System : 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µmReel Feed Unit : Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production

5. Software & Industry 4.0 Integration (Olian ACF Hot-Press)

Recipe Vault : 500 encrypted programs per QR code; cloud backup with SHA-256 blockchain hashAI Predictor : Forecasts heater life 200 cycles ahead; schedules maintenance before scrapRemote VPN : OEM engineers debug without on-site travel; downtime cut 30 %Cloud Dashboard : Real-time Cpk, resistance drift, and yield predictions; MES uploads every bond curve

6. Technical Specifications Buyers Compare (Olian ACF Hot-Press)

Panel Size : 10.1–21 in (standard), 55 in+ (custom)Bar Size : 50 × 1.4 × 10 mm (standard) up to 500 × 5 × 20 mm (TV source)Force Range : 10–3,900 N, resolution 0.1 NTemperature Window : Room to 600 °C, stability ±0.5 °C, overshoot < 1 °CCycle Time : < 3 s (bond only), 6–8 s (full loop)Pitch Capability : Down to 12 µm for 8-K source driversPower : Single-phase 220 V ±10 %, peak 4 kWCleanroom : ISO 6 recommended; laminar-flow hood integrated

7. Market Trends

Copper-Core ACF : Cu-Ag spheres cut gold cost 50 % while keeping < 20 mΩ contactCold-Laser Assist : Femtosecond laser pre-cleans ITO at 25 °C, enabling 120 °C PET bondsAI Yield Predictor : Neural networks forecast particle-trap probability, pushing yield to 99.9 %Servo-Hydraulic Hybrid : 80 kg force for 100-inch TV bar while maintaining 1 µm accuracyRoll-to-Roll Fully Automatic : Reel-fed driver and touch tails bonded at 3,000 UPH

8. Applications Across All Olian ACF Hot-Press Types

Consumer Electronics : Smartphone OLED (COG + TFOG), foldable hinge (FOF), tablet battery tail (FOB)TV & Signage : 32″-100″ 4-K/8-K LCD, OLED, mini-LED—COF source + OLB gate + TFOG touchMedical : Surgical monitors, portable ultrasound, wearable ECG patches—biocompatible polyimide, ISO 13485 traceabilityIndustrial & Aerospace : Avionics displays, factory HMI panels, rugged handhelds—shock, altitude, fungus per MIL-STD-810

9. Daily Maintenance for 99 % Uptime (Olian ACF Hot-Press)

Clean Hot-Bar with IPA every 200 cycles to prevent ACF build-up.

Verify thermocouple vs dry-block calibrator weekly; drift > 0.3 °C triggers replacement.

Calibrate cameras with 30 µm dot grid; auto-correction keeps 0.2 µm repeatability.

Grease cross-roller guides with PFPE oil monthly; avoid silicone that out-gasses.

Store ACF rolls sealed at −10 °C, 30 % RH; 4 h thaw under laminar flow prevents moisture bubbles.

10. SEO Keyword Integration

ACF hot-press machine, ACF hot press machine, high-quality ACF hot-press machine manufacturer, Shenzhen Olian ACF hot-press machine, high-quality ACF hot-press machine supplier, high-quality COG hot-press machine manufacturer, high-quality COF hot-press machine supplier, high-quality FOG hot-press machine supplier, high-quality pulse heat ACF hot-press machine, high-quality constant temperature ACF hot-press machine, high-quality AI vision ACF hot-press machine, high-quality IoT ACF hot-press machine, high-quality blockchain hash ACF hot-press machine, high-quality 1,000 UPH ACF hot-press machine, high-quality 99.9 % yield ACF hot-press machine, high-quality 8-K TV ACF hot-press line manufacturer, high-quality foldable phone ACF hot-press line supplier

11. Conclusion

A high-quality ACF hot-press machine from Shenzhen Olian Automatic Equipment Co., Ltd. is no longer a regional factory—it is the global, AI-driven, blockchain-audited gateway that turns instantaneous resistance heat into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, today’s Olian lines deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade.

2 comments so far

Cheapest BacklinksPosted on11:20 上午 - 12 月 11, 2025

As a Newbie, I am constantly browsing online for articles that can be of assistance to me. Thank you

ObsidianPosted on11:25 上午 - 12 月 12, 2025

I precisely wished to thank you very much all over again. I do not know the things I could possibly have achieved in the absence of those advice shared by you on that area. It became the daunting circumstance for me personally, nevertheless taking note of a new well-written strategy you processed it made me to cry over happiness. I’m happy for this advice and thus have high hopes you find out what a powerful job that you’re putting in training other individuals thru your webblog. Most probably you’ve never got to know all of us.