Chip bonding machines are essential in the electronics manufacturing industry, particularly for attaching integrated circuits (ICs) to various substrates. These machines ensure a seamless and robust connection between the ICs and the substrates, playing a crucial role in the production of devices like smartphones, tablets, and automotive displays. The different types of chip bonding machines, including COG (Chip On Glass), COP (Chip On Plastic), COF (Chip On Film), and COB (Chip On Board), are designed to meet specific requirements and applications.

Chip bonding machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

Chip bonding machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, chip bonding technology continues to play a crucial role in the electronics industry.

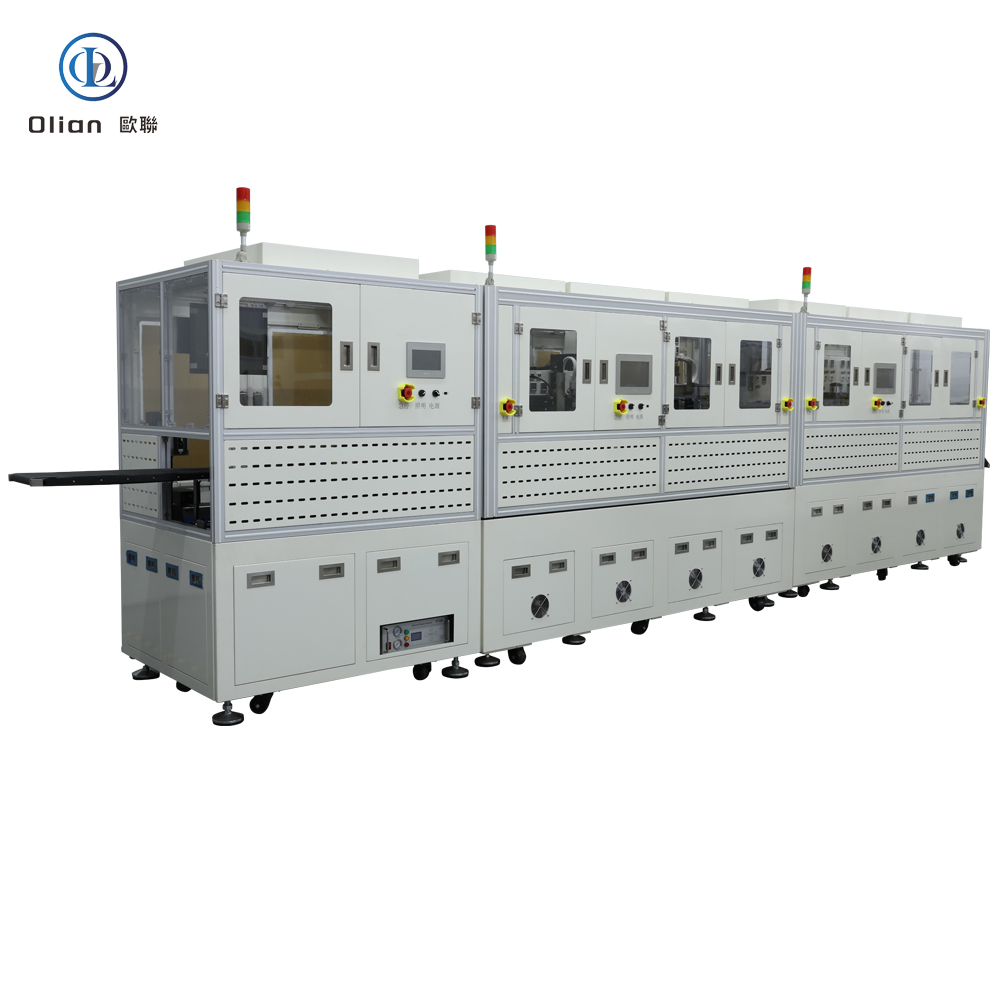

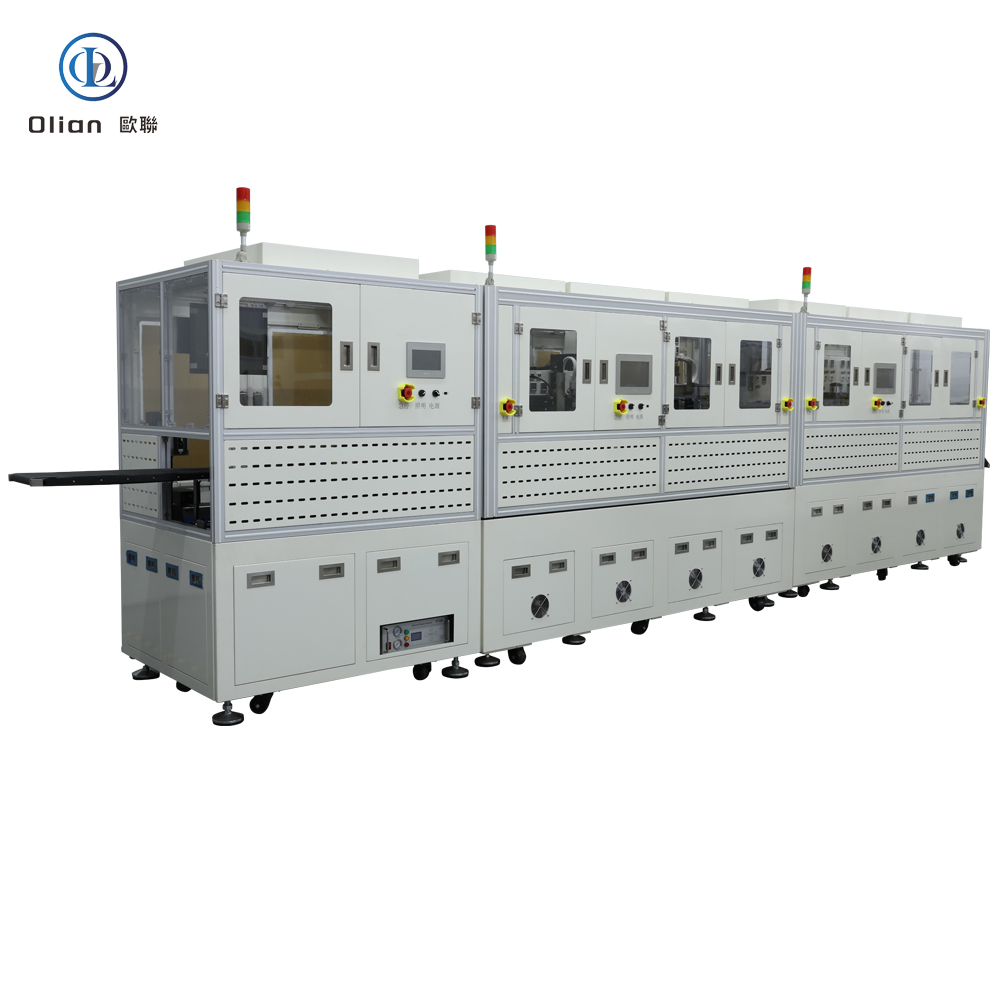

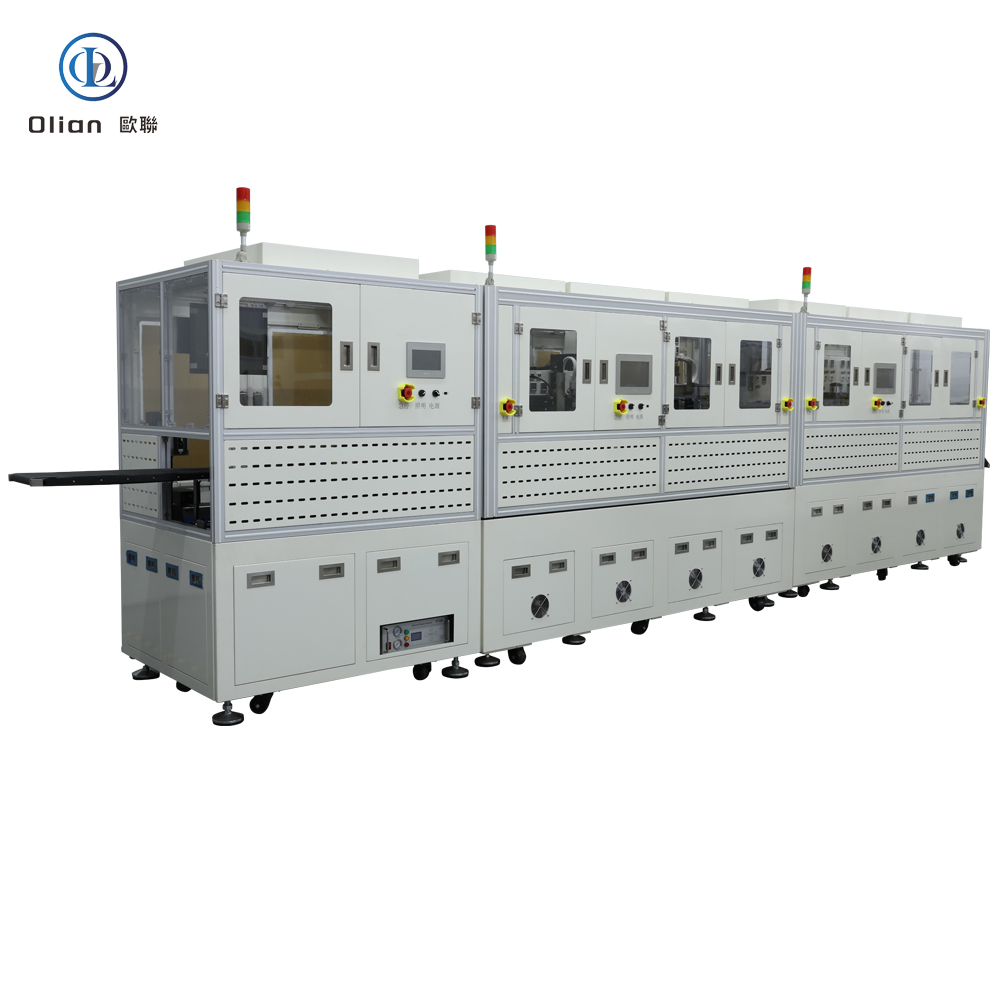

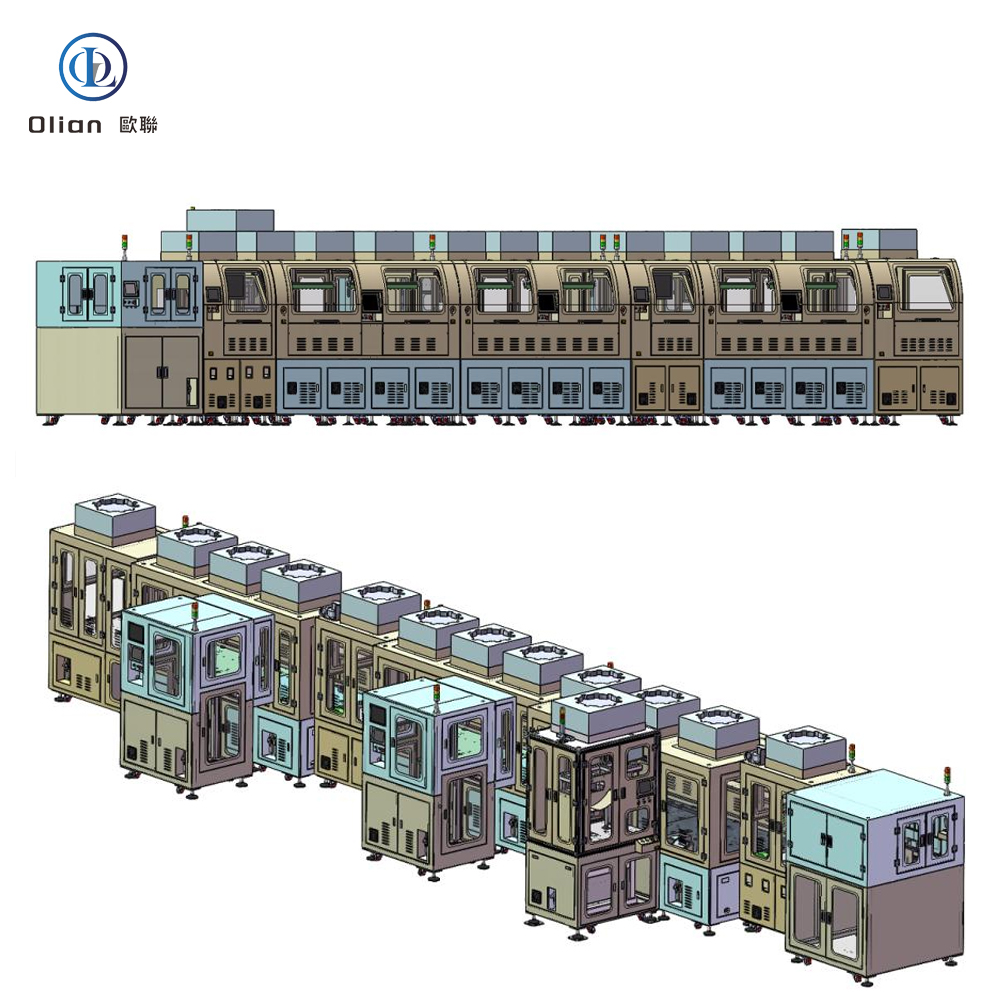

Smart Wear LCD OLED Bonding Production Whole Line Solution

In the rapidly evolving field of smart wear technology, the production of LCD and OLED display modules requires a comprehensive and integrated approach to ensure high efficiency, quality control, and adaptability to market demands. Our Smart Wear LCD OLED Bonding Production Whole Line Solution is designed to meet these challenges by providing a seamless and intelligent manufacturing process.

Glass Loading (玻璃上料)

Automated Glass Loading: The process begins with the automated loading of glass substrates into the production line. This step ensures that the substrates are handled with precision and care, reducing the risk of damage.

Plasma Cleaning (等离子清洗)

High-Purity Cleaning: The glass substrates are cleaned using a plasma cleaning process to remove any contaminants. This step is crucial for ensuring a high-quality bond and reducing defects.

COG (Chip on Glass) and COF (Chip on Film) Bonding

Driver IC Attachment: COG and COF processes are used to attach driver ICs directly to the glass substrate (COG) or to a flexible film (COF) which is then bonded to the glass. These processes ensure a stable and reliable connection, enhancing the performance of the display.

FOG (Film on Glass) and FOF (Film on Film) Bonding

FPC Bonding: FOG and FOF processes involve bonding flexible printed circuits (FPCs) to the glass substrate or to other FPCs. This step is essential for connecting the display module to the mainboard and other components.

Impedance Testing (阻抗测试)

Quality Assurance: Impedance testing is performed to ensure that the electrical connections are stable and reliable. This step is crucial for identifying and correcting any electrical issues before proceeding to the next stage of production.

RT (Room Temperature Curing)

Adhesive Curing: Room temperature curing is used to set the adhesives used in the bonding processes. This ensures that the components are securely attached without the need for high-temperature processes that could damage sensitive materials.

AOI (Automated Optical Inspection)

Quality Control: AOI systems use high-resolution cameras to inspect the display modules for defects. This process ensures that only high-quality products proceed to the next stage of production.

Dispensing (点胶)

Adhesive Application: Precision dispensing machines apply adhesives to the components to ensure a strong bond. This step is crucial for the durability and reliability of the display modules.

Drying (晾干)

Adhesive Drying: After dispensing, the adhesives are allowed to dry under controlled conditions. This ensures that the components are securely bonded and the display modules are ready for further assembly.

TFOG (Thermal Film on Glass)

Thermal Bonding: TFOG processes use heat to bond films to the glass substrate. This step is essential for creating a strong and durable bond, especially in high-stress applications.

Final Dispensing (点胶)

Sealing and Protection: Final dispensing of adhesives is used to seal and protect the display modules. This ensures that the modules are resistant to environmental factors such as dust and moisture.

Our Smart Wear LCD OLED Bonding Production Whole Line Solution is ideal for a wide range of smart wear devices, including:

These devices require high touch sensitivity, durability, and clear displays, making our solution particularly beneficial for these applications.

With our comprehensive Smart Wear LCD OLED Bonding Production Whole Line Solution, manufacturers can achieve high-quality, durable, and responsive displays in their smart wear devices. Our solution combines advanced manufacturing techniques, precision inspection systems, and customizable processes to meet the diverse needs of the smart wear market. By choosing our solution, you can ensure that your smart wear devices stand out in terms of performance and user experience.

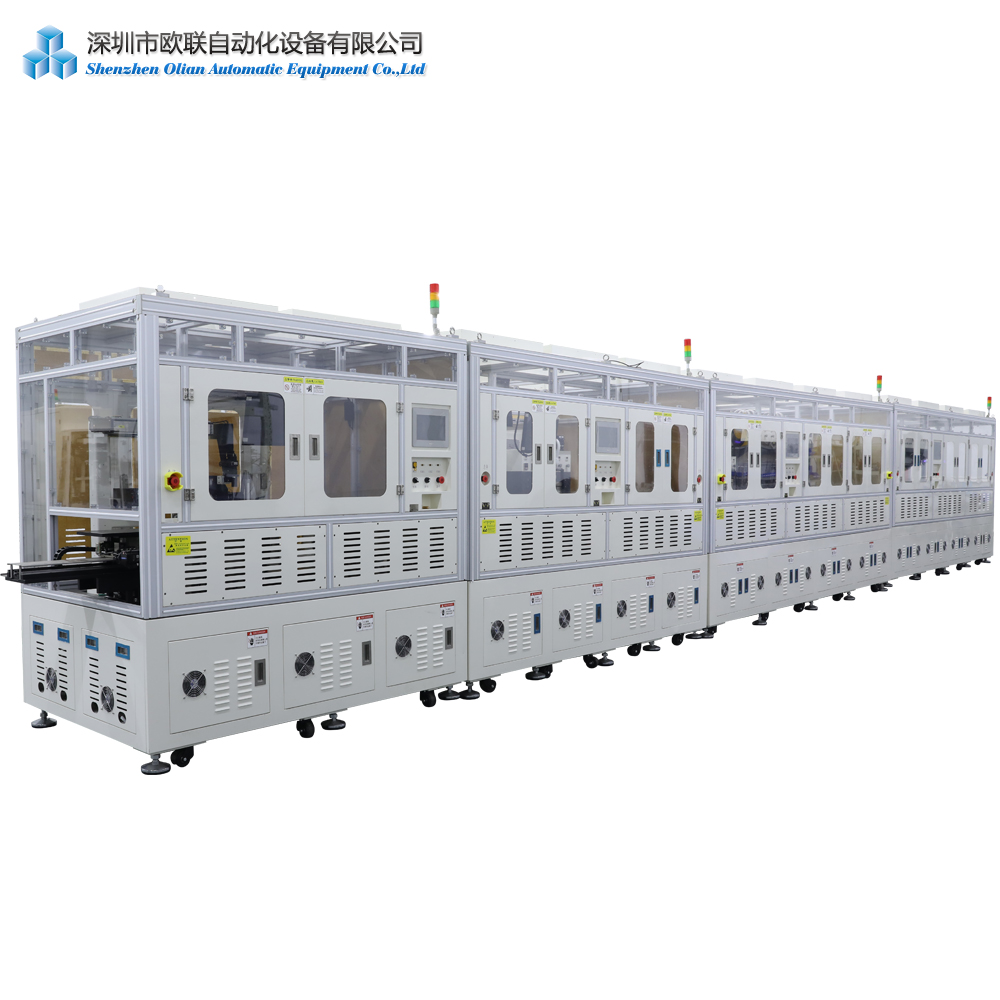

Mobile Phones, Tablets, and Industrial Control Products Whole Line Solution for TFT Displays

In the highly competitive and rapidly evolving market of consumer electronics and industrial control systems, the production of TFT displays for mobile phones, tablets, and industrial control products requires a comprehensive and highly automated solution. Our Whole Line Solution for TFT displays is designed to meet the stringent demands of these sectors, ensuring high-quality, reliable, and efficient production processes.

Our Whole Line Solution for TFT displays is ideal for a wide range of products, including:

These devices require high touch sensitivity, durability, and clear displays, making our solution particularly beneficial for these applications.

With our comprehensive Whole Line Solution for TFT displays, manufacturers can achieve high-quality, durable, and responsive displays in their products. Our solution combines advanced manufacturing techniques, precision inspection systems, and customizable processes to meet the diverse needs of the market. By choosing our solution, you can ensure that your products stand out in terms of performance and user experience.

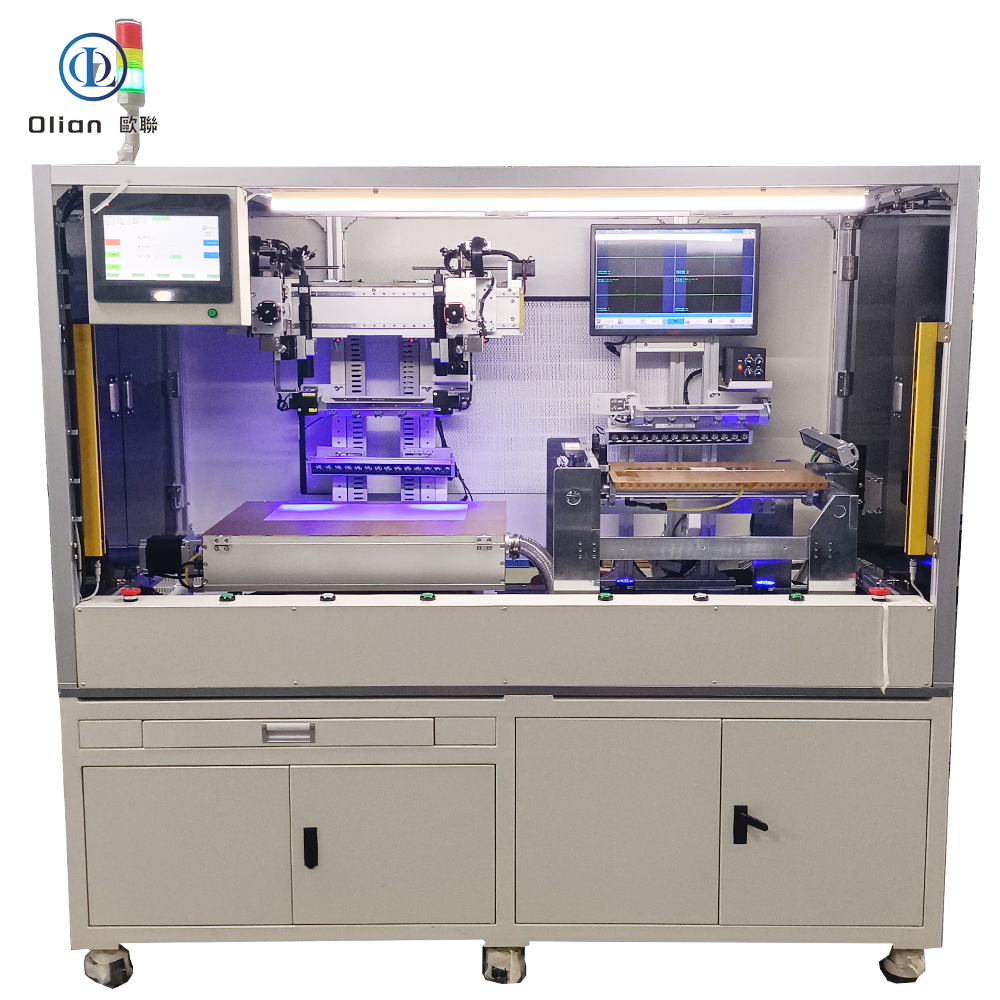

Advanced Flexible Display Bonding Dispensing Production Solution

In the rapidly evolving landscape of display technology, the production of advanced flexible OLED displays demands a highly sophisticated and versatile bonding and dispensing solution. Our Advanced Flexible Display Bonding Dispensing Production Solution is designed to meet these demands, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Advanced Flexible Display Bonding Dispensing Production Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple bonding technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

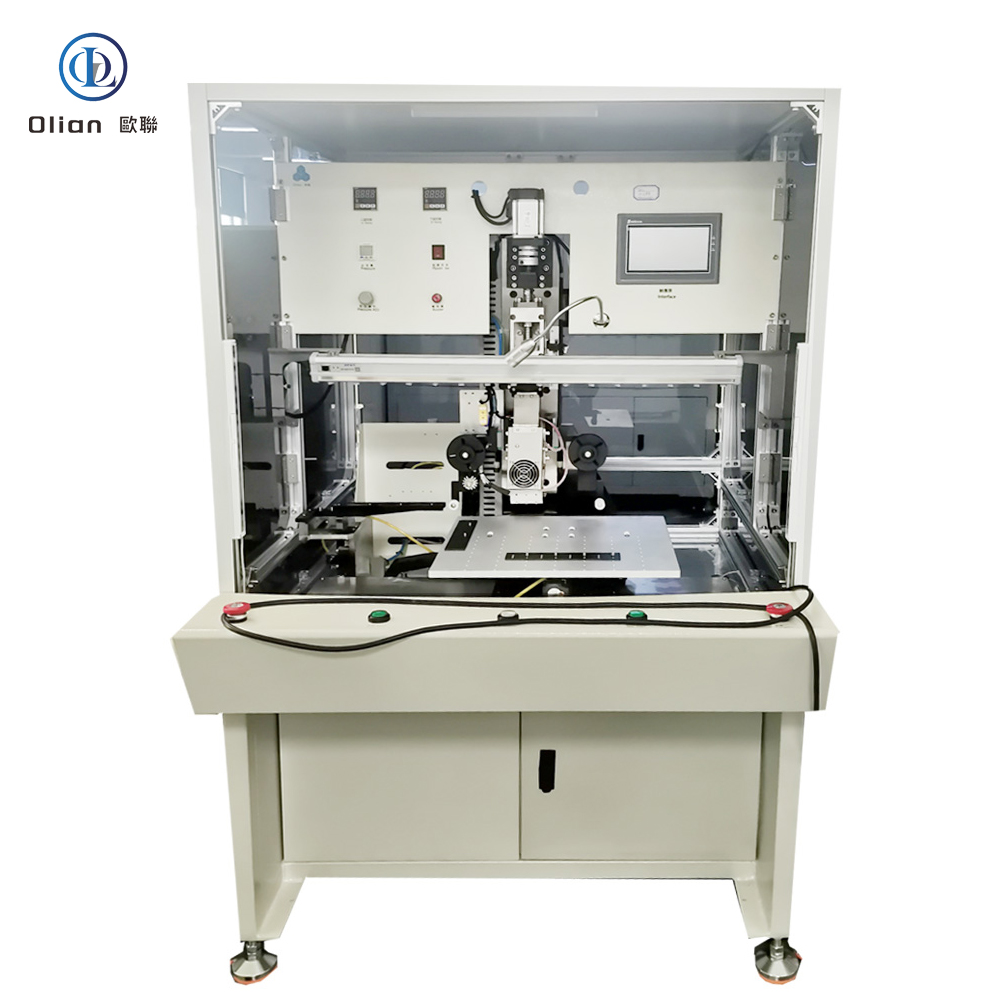

Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution

In the dynamic landscape of display technology, the production of mid-size displays for vehicles and notebooks requires a comprehensive and highly automated solution. Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is designed to meet the demands of both automotive and notebook display modules, offering a versatile and integrated approach to ensure high efficiency, precision, and adaptability.

Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is ideal for a wide range of smart display products, including:

Our Mid Size 7-17 Inch Vehicle Display and Notebook Whole Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

By integrating these advanced processes and technologies, our solution ensures high-quality, reliable, and efficient production of mid-size displays for a variety of applications.

Electronic Paper Production Whole Line Solution

In the evolving market of display technology, the production of electronic paper (e-paper) for applications such as electronic labels and e-books requires a specialized and automated production line. Our Electronic Paper Production Whole Line Solution is designed to meet the demands of producing small to medium-sized e-paper displays, ranging from 0.96″ to 10.1″. This solution offers a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Electronic Paper Production Whole Line Solution is ideal for a wide range of smart display products, including:

Our Electronic Paper Production Whole Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

Backlight Assembly Equipment Process Solution for Mid-Size LCM Assembly

In the competitive landscape of display manufacturing, the production of mid-size Liquid Crystal Modules (LCMs) for applications such as tablets, notebooks, and automotive displays requires a specialized and automated backlight assembly solution. Our Backlight Assembly Equipment Process Solution is designed to meet the demands of producing LCMs ranging from 5” to 17.3”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our Backlight Assembly Equipment Process Solution is ideal for a wide range of display products, including:

Our Backlight Assembly Equipment Process Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

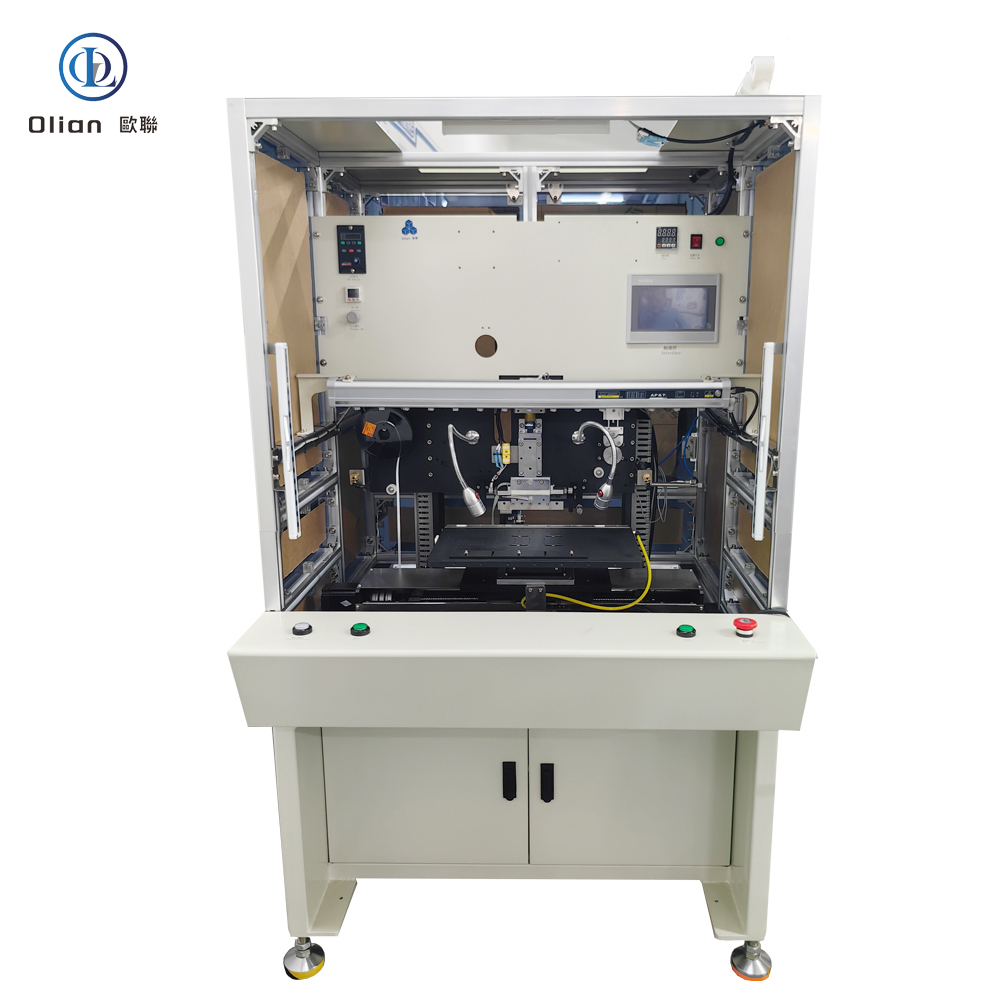

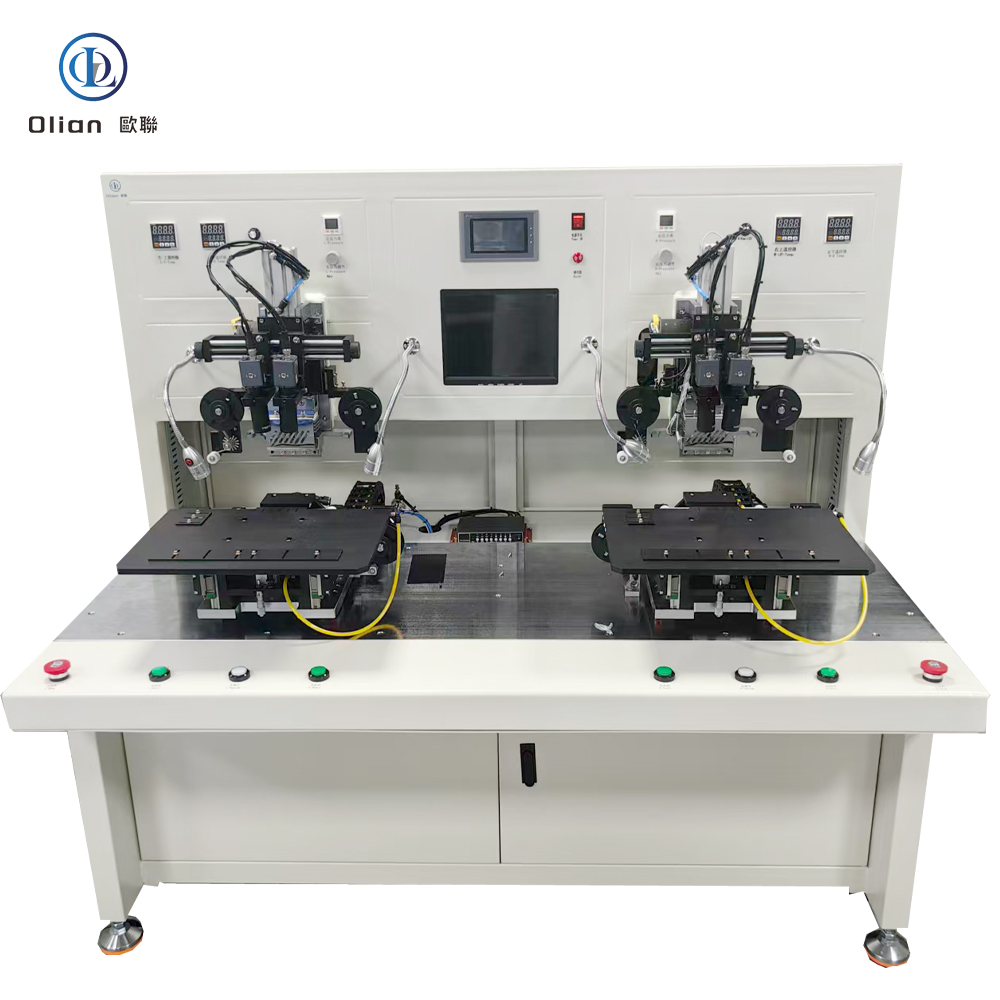

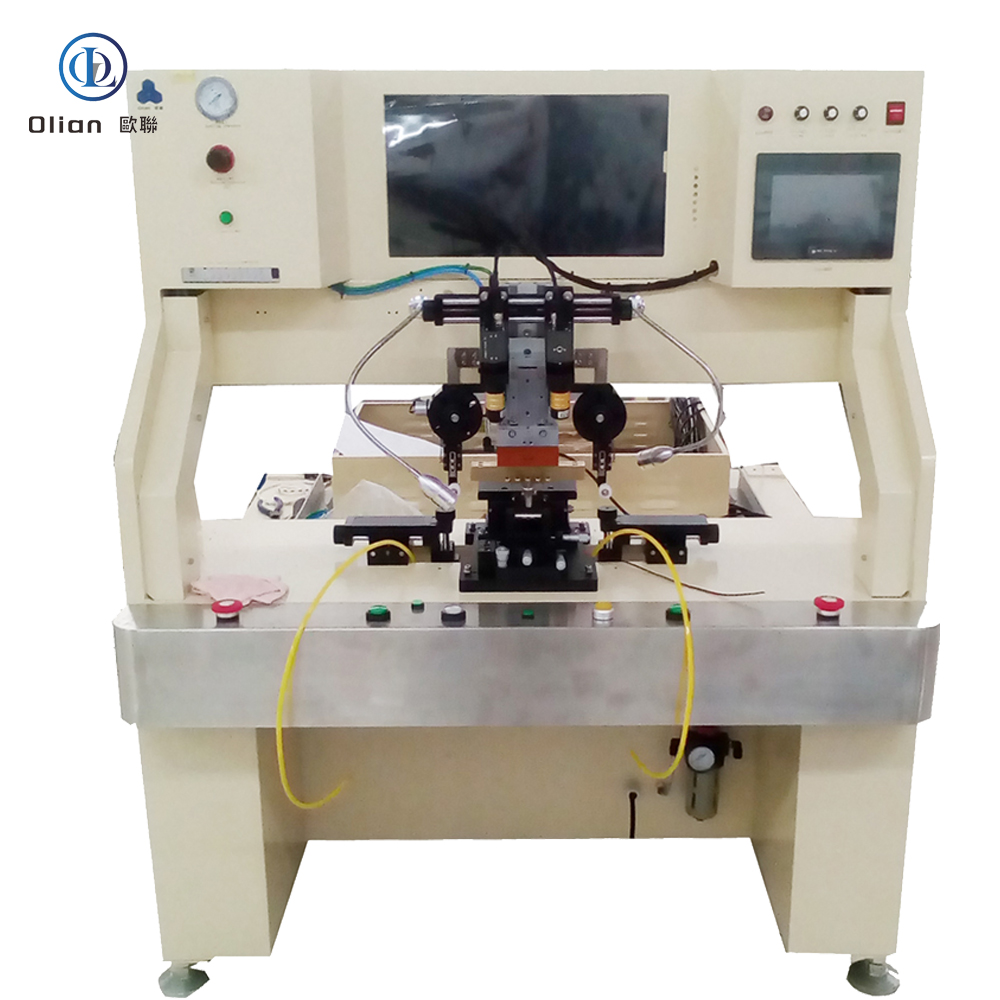

1-7 Inch Semi Automatic Bonding Machines

In the dynamic field of display manufacturing, the production of small to medium-sized Liquid Crystal Displays (LCDs) for applications such as tablets, notebooks, and automotive displays requires a specialized and semi-automated bonding solution. Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing LCDs ranging from 1” to 7”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

Our 1-7 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

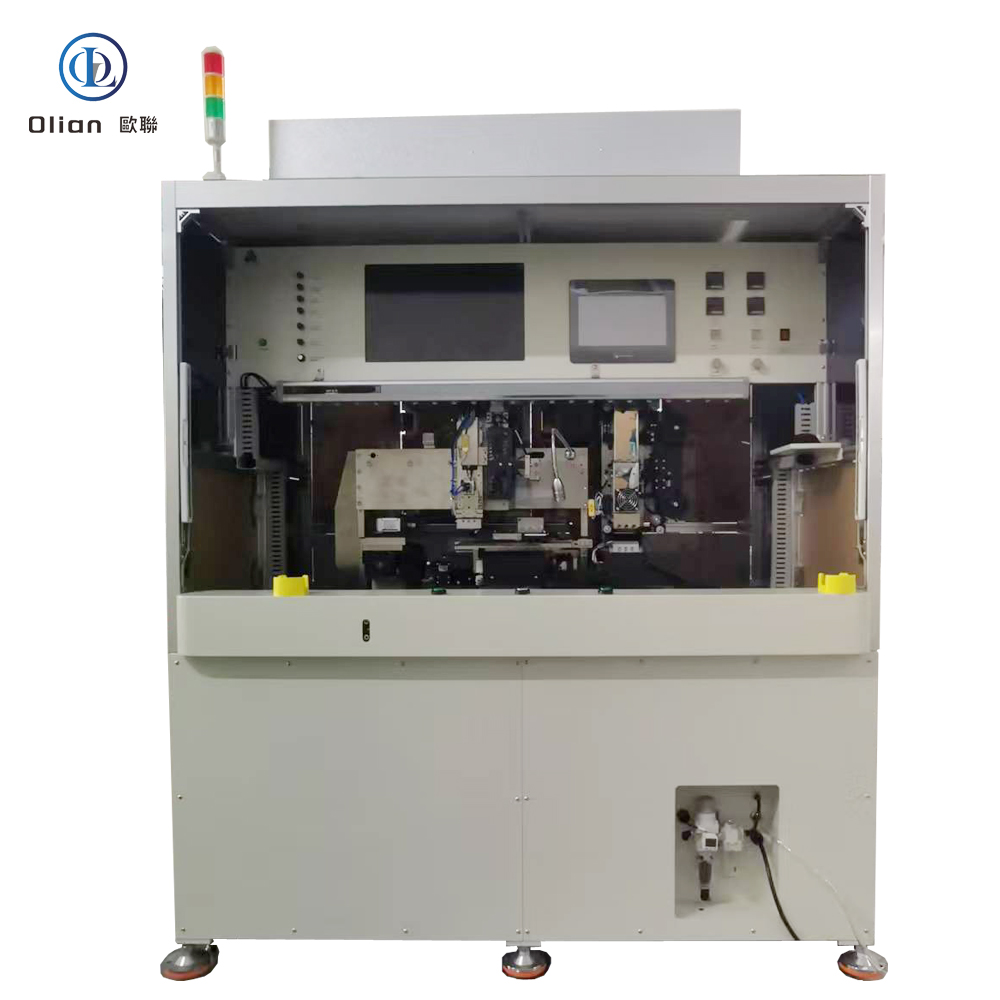

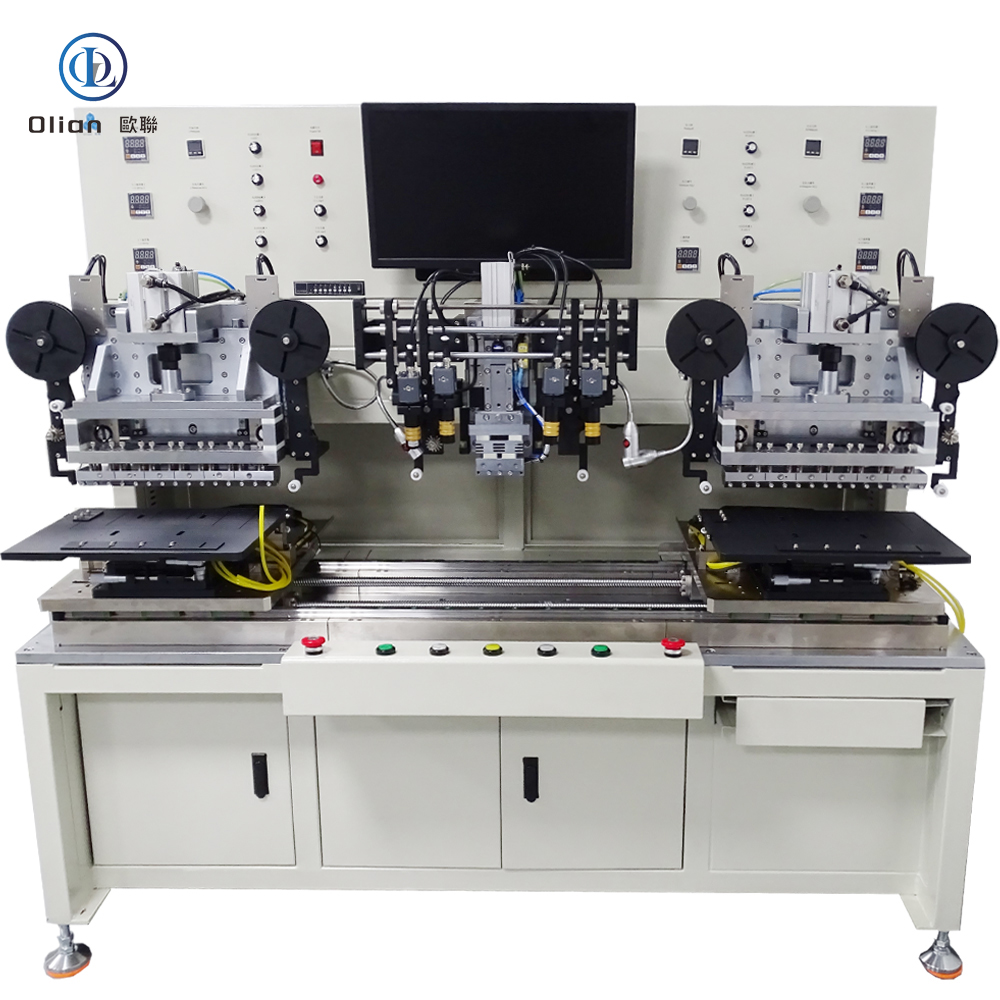

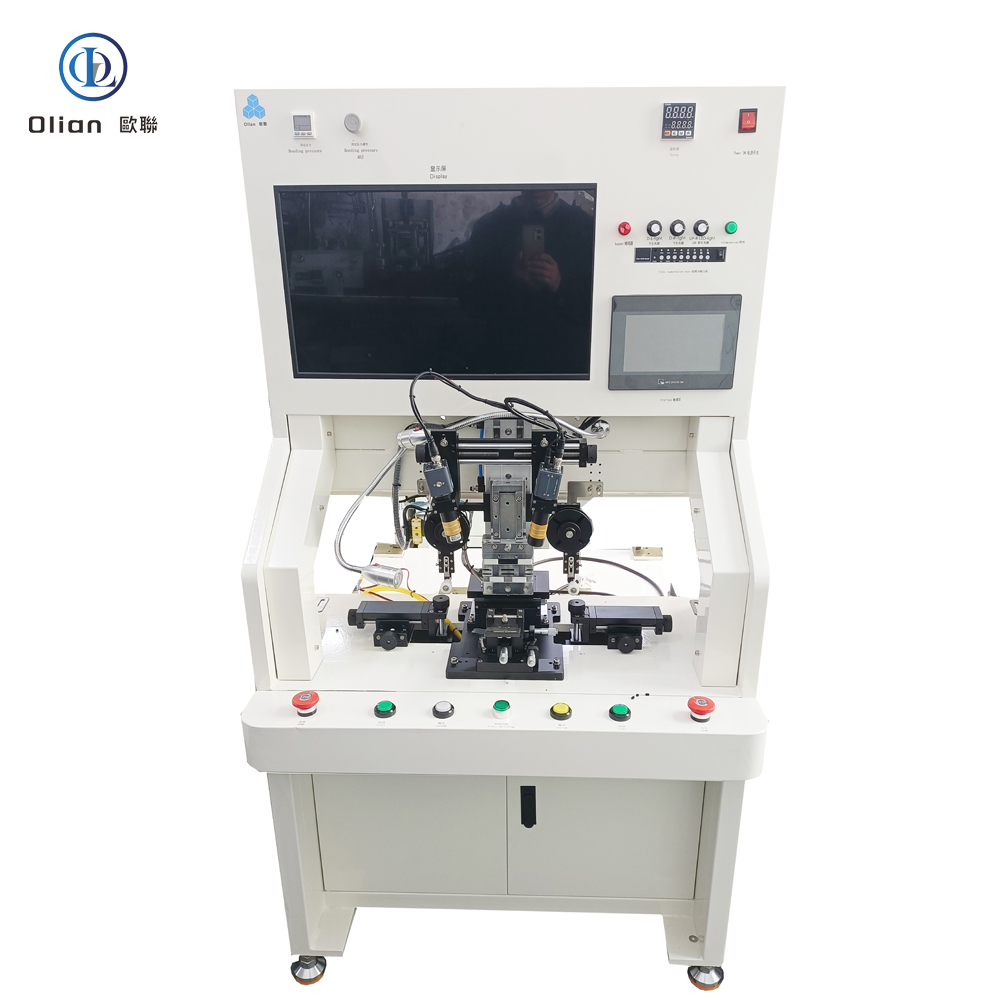

7-17 Inch Semi Automatic Bonding Machines Production Line Solution

In the competitive landscape of display manufacturing, the production of mid-size Liquid Crystal Modules (LCMs) for applications such as tablets, notebooks, and automotive displays requires a specialized and semi-automated bonding solution. Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing LCMs ranging from 7” to 17.3”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

Our 7-17 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.

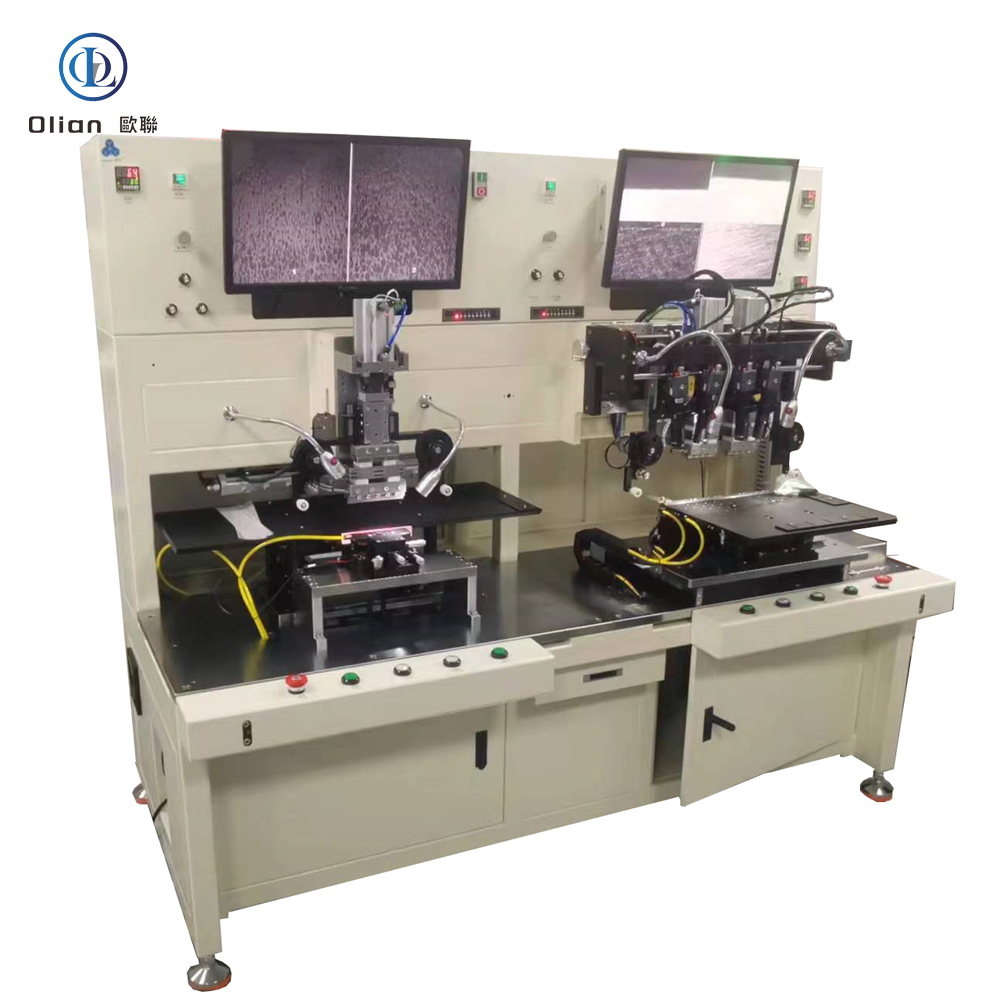

17-120 Inch Semi Automatic Bonding Machines Production Line Solution for TV/Touch Panels/Customized Products

In the rapidly evolving display manufacturing industry, the production of large-sized displays for applications such as TVs, touch panels, and customized products requires a specialized and semi-automated bonding solution. Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the demands of producing large-sized Liquid Crystal Modules (LCMs) ranging from 17” to 120”, offering a comprehensive and integrated approach to ensure high efficiency, precision, and adaptability.

Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is ideal for a wide range of display products, including:

The display manufacturing industry is on a remarkable journey of innovation and growth. Technologies like OLED, QLED, and MicroLED are pushing the boundaries of what screens can do, offering better resolution, color accuracy, and energy efficiency. However, challenges such as high costs, durability issues, and supply chain disruptions still need to be addressed. As research and collaboration continue, we can expect even more exciting advancements in the future.

Our 17-120 Inch Semi Automatic Bonding Machines Production Line Solution is designed to meet the future demands of the display industry, offering a versatile, high-precision, and efficient production process. By integrating multiple advanced technologies and ensuring high-quality standards, our solution is ideal for manufacturers looking to produce a wide range of advanced display modules. Choose our solution to stay ahead in the competitive market and deliver top-quality products.