TFT panel produce processes from bonding to backlight assembly.

1. Cutting Process

- Process Introduction: In this stage, large – sized TFT – LCD glass substrates or polarizing plates are cut into smaller pieces according to the required dimensions of the display module. High – precision cutting is crucial to ensure the edges of the cut pieces are smooth and free of cracks or defects, which affects the quality and yield of subsequent processes.

- Equipment – Cutting Machine: Equipped with high – precision cutting blades or laser cutting heads, the cutting machine can accurately cut glass substrates and polarizing plates. Its positioning system ensures precise alignment of the cutting lines with the preset dimensions. Some advanced cutting machines also feature automatic feeding and discharging functions to improve production efficiency.

2. SB AOI (Automated Optical Inspection) Process

- Process Introduction: This process uses automated optical inspection equipment to detect defects on the surface of the TFT – LCD panel after cutting, such as scratches, particles, and polarity direction. It helps to identify and eliminate defective products early in the production line, reducing production costs and improving overall product quality.

- Equipment – AOI Machine: The AOI machine is equipped with high – resolution cameras and advanced image processing software. It can quickly capture images of the panel surface and compare them with the standard template to identify defects. Its inspection speed can be adjusted according to the size and resolution of the panel, and it has a high detection accuracy rate.

3. POL Attach Process

- Process Introduction: Polarizing plates are thin layers that allow light to pass through either horizontally or vertically. In this process, the polarizing plate is bonded to the surface of the TFT – LCD panel. The bonding must be accurate and free of bubbles or wrinkles to ensure the display effect of the LCD screen.

- Equipment – POL Attaching Machine: The POL attaching machine has a high – precision alignment system to precisely position the polarizing plate on the panel. Its pressing mechanism ensures uniform pressure during bonding, and the heating system helps the adhesive cure, enhancing the bonding strength between the polarizing plate and the panel.

4. Autoclave Process

- Process Introduction: The autoclave process is used to further strengthen the bonding between the polarizing plate and the panel. By applying high – temperature and high – pressure conditions, the air bubbles and impurities within the bonding layer are eliminated, improving the bonding quality and reliability of the polarizing plate.

- Equipment – Autoclave Machine: The autoclave machine is a sealed pressure vessel that can precisely control temperature and pressure parameters. It evenly heats and pressurizes the panels placed inside, ensuring uniform treatment of each panel. Its control system can set different temperature and pressure curves according to the characteristics of the panels and polarizing plates.

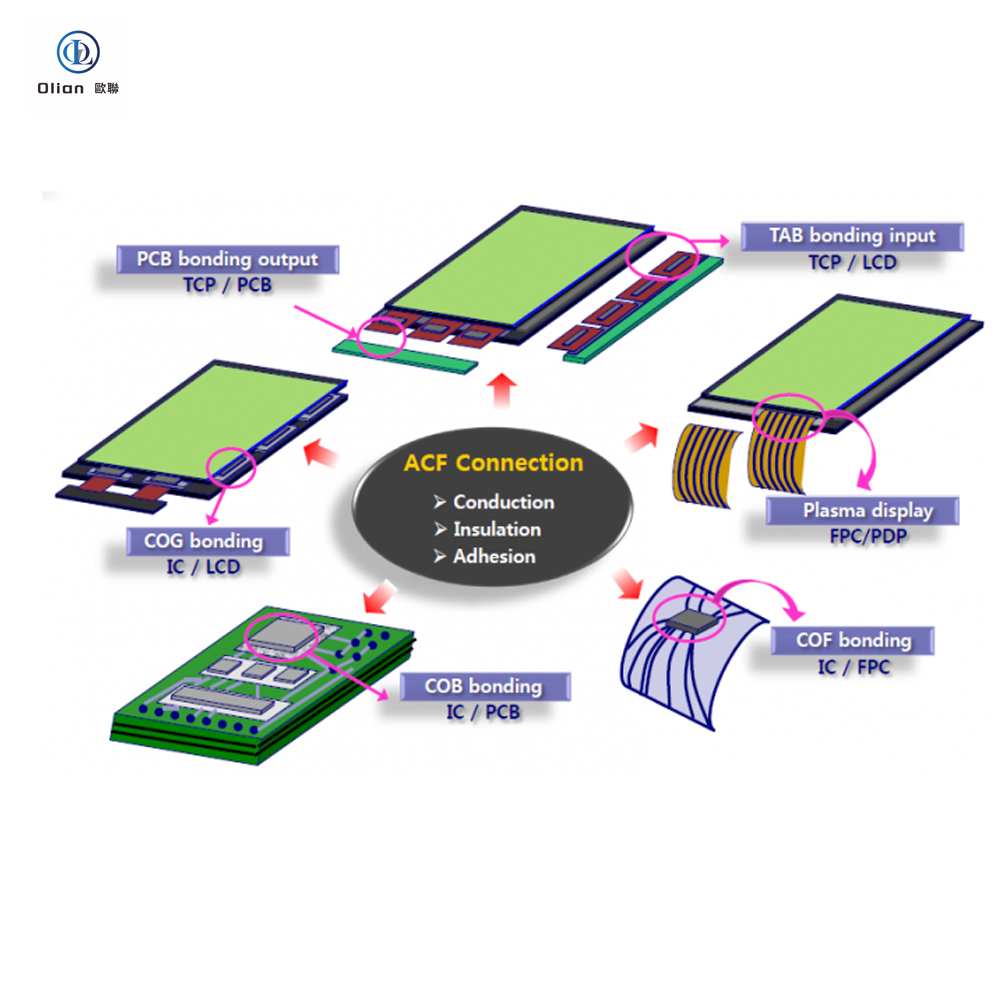

5. Bonding Process (LD/EC+COG+FOG+Bonding AOI+Glue dispenser+ULD)

- LD (Glass Loading) Process: Glass loading is the process of placing the cut glass substrates into designated fixtures or carriers to prepare them for subsequent processes such as electronic cleaning and bonding. It ensures the glass substrates are properly positioned and secured for further processing.

- Equipment – Glass Loading Machine: The glass loading machine is designed to handle glass substrates with care. It has a precise positioning system to place the glass substrates into the fixtures accurately. The machine may also feature automated arms or conveyors to transport the glass substrates efficiently while minimizing manual handling and potential damage.

- EC (Electronic Cleaning) Process: Electronic cleaning is used to remove contaminants such as dust, organic residues, and ions from the surface of the glass substrates or polarizing plates. This helps improve the bonding quality and reliability in subsequent processes, preventing issues like poor adhesion or electrical shorts.

- Equipment – Electronic Cleaning Machine: The electronic cleaning machine typically uses a combination of ultrasonic waves, deionized water, and chemical cleaning agents to thoroughly clean the glass substrates or polarizing plates. It has a closed cleaning chamber to prevent re – contamination and a drying system to quickly dry the cleaned substrates after cleaning.

- COG (Chip – on – Glass) Process: The driver IC is directly bonded to the glass substrate of the TFT – LCD panel. This process is characterized by high precision and small bonding area, offering advantages such as fast production speed and good electrical performance.

- Equipment – COG Bonding Machine: The COG bonding machine uses a high – precision alignment system to accurately position the driver IC relative to the glass substrate. Its heating and pressing mechanism ensures a stable connection between the driver IC and the glass substrate. The machine also has a vision system for precise alignment and a temperature – and – pressure control system to ensure bonding quality.

- FOG (Film – on – Glass) Process: The driver IC is first bonded to a flexible film and then connected to the TFT – LCD panel. It offers better flexibility and reliability, suitable for lightweight and thin display devices.

- Equipment – FOG Bonding Machine: The FOG bonding machine is designed to handle flexible films and perform high – precision bonding. It has a complex structure and advanced to technology ensure reliable connections between the driver IC and the panel. Its alignment system accurately positions the flexible film and driver IC on the panel.

- Bonding AOI Process: After the bonding process, automated optical inspection is used to detect defects in the bonding quality, such as misalignment, missing bonds, and insufficient bonding. This helps to promptly identify and correct bonding issues, improving production yield.

- Equipment – Bonding AOI Machine: The bonding AOI machine uses high – resolution cameras and advanced image processing software to capture images of the bonding area and compare them with the standard template. It can accurately detect various bonding defects and has a fast inspection speed, capable of meeting the high – speed production requirements of the production line.

- Glue Dispensing Process: Adhesive is applied to the bonding area to enhance bonding the strength and reliability between the driver IC and the panel. The glue dispenser must ensure precise glue – dispensing quantity and uniform glue – dispensing.

- Equipment – Glue Dispensing Machine: The glue dispensing machine has a high – precision dispensing system that can accurately control the glue – dispensing quantity and pattern. Its dispensing nozzle can move precisely to dispense adhesive on the designated bonding area. The machine can also adjust the glue – dispensing parameters according to different adhesives and bonding requirements.

- ULD (Under – Layer Dispensing) Process: This process applies an under – layer adhesive to the bonding area to further enhance the bonding strength and reliability. It also helps to prevent moisture and impurities from invading the bonding area, improving the product’s stability and reliability.

- Equipment – ULD Machine: The ULD machine is similar to the glue dispensing machine in structure but specializes in applying under – layer adhesives. It can accurately dispense under – layer adhesives on the bonding area and has a heating and curing system to rapidly cure the adhesive, improving production efficiency.

6. PWB (Printed Wiring Board) Process

- Process Introduction: In this process, the printed wiring board is assembled and connected to the TFT – LCD panel. The PWB serves as the carrier of the electrical circuit, connecting various components of the display module and enabling signal transmission and power supply.

- Equipment – PWB Assembly Machine: The PWB assembly machine includes functions such as component placement and soldering. It uses high – precision placement heads to accurately position components on the PWB and employs automated soldering equipment to ensure reliable soldering connections. The machine also has an inspection system to detect defects in the PWB assembly.

7. Oven Process

- Process Introduction: The oven process is used to cure adhesives or other materials used in the bonding and assembly processes. By heating, the adhesives can fully cure, enhancing bonding strength and reliability. It also helps to remove residual solvents and impurities, improving product quality.

- Equipment – Oven: The oven has a temperature control system that can precisely regulate the temperature and heating time according to different process requirements. It provides a uniform heating environment to ensure uniform curing of the adhesives on each panel. The oven also has a ventilation system to timely exhaust volatile substances during the heating process.

8. Optical Bonding Process

- Process Introduction: Optical bonding is the process of filling the gap between the TFT – LCD panel and the cover glass with an optical adhesive. This eliminates air gaps between the two, reducing light reflection and refraction, improving display clarity and brightness, and enhancing the product’s resistance to external impacts and vibrations.

- Equipment – Optical Bonding Machine: The optical bonding machine has a high – precision dispensing system to accurately dispense optical adhesive between the panel and the cover glass. Its pressing mechanism ensures uniform pressure during bonding, and the machine is equipped with a degassing system to remove bubbles within the adhesive. Some optical bonding machines also have a UV curing system to rapidly cure the adhesive using ultraviolet light.

9. Auto Clave Process

- Process Introduction: Similar to the autoclave process in the POL attach stage, this process further strengthens the bonding between the optical adhesive and the panel and cover glass through high – temperature and high – pressure conditions. It eliminates bubbles and impurities within the bonding layer, improving the bonding quality and reliability.

- Equipment – Autoclave Machine: The autoclave machine used in this stage is similar to that in the POL attach stage but may have different parameter settings. It can precisely control the temperature and pressure to meet the requirements of the optical bonding process. Its control system can set different temperature and pressure curves according to the characteristics of the optical adhesive and the panels.

10. Backlight Assembly Process

- Process Introduction: The backlight assembly process involves assembling the backlight module, including components such as the light guide plate, reflective film, diffusion film, and prism film. The backlight module provides uniform backlight for the TFT – LCD panel, ensuring accurate display of images. The assembly of the backlight module must be precise to ensure uniform light distribution and high brightness.

- Equipment – Backlight Assembly Machine: The backlight assembly machine has functions such as automatic placement and lamination. It accurately positions the components of the backlight module and uses lamination technology to bond them together. The machine can adjust the placement parameters according to the size and thickness of the backlight module components to ensure assembly quality.

11. FI AOI (Final Inspection AOI) Process

- Process Introduction: As the final stage of the production line, FI AOI conducts a comprehensive optical inspection of the assembled TFT – LCD display module. It detects defects such as display abnormalities, brightness unevenness, and pixel defects to ensure the product meets quality standards before delivery.

- Equipment – FI AOI Machine: The FI AOI machine is equipped with high – resolution cameras and advanced image processing software. It can capture images of the display module from multiple angles and comprehensively evaluate the display quality. Its inspection accuracy is high, capable of detecting even minor defects. The machine also has a data analysis system to statistically analyze the defect data of the product, providing a basis for quality improvement.

12. Aging Process

- Process Introduction: The aging process subjects the TFT – LCD display module to prolonged operation under specific conditions (e.g., temperature, humidity, and voltage) to simulate long – term usage scenarios. This helps identify potential reliability issues, such as pixel aging and circuit instability, ensuring the product’s reliability and stability during actual use.

- Equipment – Aging Chamber: The aging chamber provides a stable and controllable environment, capable of regulating temperature and humidity and offering adjustable voltage and current. It can simultaneously age multiple display modules and has a monitoring system to real – time track the operating status of the modules during aging. Once abnormalities are detected, the system automatically alerts and takes protective measures.

13. Vacuum Packing Process

- Process Introduction: Vacuum packing is used to remove air from the packaging bag of the TFT – LCD display module, reducing the volume of the product and preventing oxidation and moisture damage during transportation and storage. It also offers certain protection against external impacts.

- Equipment – Vacuum Packing Machine: The vacuum packing machine has a vacuum chamber and a sealing system. It creates a vacuum environment within the chamber to extract air from the packaging bag and then seals the bag to ensure airtightness. The machine can adjust the vacuum degree and sealing parameters according to the size and material of the packaging bag to guarantee vacuum packing quality.

14. Carton Packaging Process

- Process Introduction: In this final stage, the vacuum – packed TFT – LCD display module is placed into a carton along with necessary accessories and documentation. The carton packaging provides further protection for the product during transportation and storage, preventing damage from external impacts and facilitating storage and transportation.

- Equipment – Carton Packaging Machine: The carton packaging machine has functions such as automatic carton forming, loading, and sealing. It can automatically form cartons according to the size of the product, load the product and accessories into the carton, and seal it. The machine can also print relevant information on the carton, such as product specifications and barcodes.

TFT LCD Module produce processes .

- Polarizer Lamination Machine(偏贴机)

This machine is used to automatically attach polarizing films onto substrates such as LCD or OLED panels. It ensures precise alignment and bonding to prevent defects like bubbles or particles.

- Glass Loading Machine(玻璃上料机)

This device automates the loading of glass substrates into production lines, improving efficiency and reducing manual handling errors.

- EC Cleaning Machine(EC清洗机)

This machine cleans the surface of glass or panels using detergents, ultrasonic waves, and hot air drying to remove contaminants and prepare the surface for subsequent processes.

- COG/COF Bonding Machine(COG/COF邦定机)

This equipment is used for bonding chips (COG) or flexible circuits (COF) onto glass panels, ensuring precise alignment and electrical connectivity in display manufacturing.

- FOG/FOF/FOP Bonding Machine(FOG/FOF/FOP邦定机)

This machine bonds flexible or printed circuits onto glass panels, facilitating electrical connections in display assembly processes.

- Fully Automatic Dispensing Machine(全自动点胶机)

This device precisely dispenses adhesives or conductive materials onto substrates, ensuring uniform application and high accuracy in bonding processes.

- FPC Loading Machine(FPC上料机)

This machine automates the loading of flexible printed circuits (FPC) into production lines, enhancing efficiency and reducing manual errors.

- TP Terminal Cleaning Machine(TP端子清洗机)

This equipment cleans the terminals of touch panels (TP) to remove contaminants and ensure reliable electrical connections.

- Fully Automatic F-FOG Bonding Machine(全自动F-FOG邦定机)

This machine bonds flexible circuits onto glass panels in flexible display manufacturing, ensuring precise alignment and connectivity.

- FPC Loading Machine(FPC上料机)

This device automates the loading of flexible printed circuits (FPC) into production lines, improving efficiency and reducing manual handling.

- T-FOG Dispensing Machine(T-FOG点胶机)

This machine precisely dispenses adhesives onto glass panels for flexible display manufacturing, ensuring uniform application and strong bonding.

- Automatic Back Adhesive Attaching Machine(自动背胶贴附机)

This equipment attaches back adhesives onto substrates, ensuring secure bonding and durability in display assembly.

- AOI Inspection Machine(AOI检测)

This automated optical inspection system detects defects such as bubbles, particles, or misalignments in the manufacturing process, ensuring high-quality production.