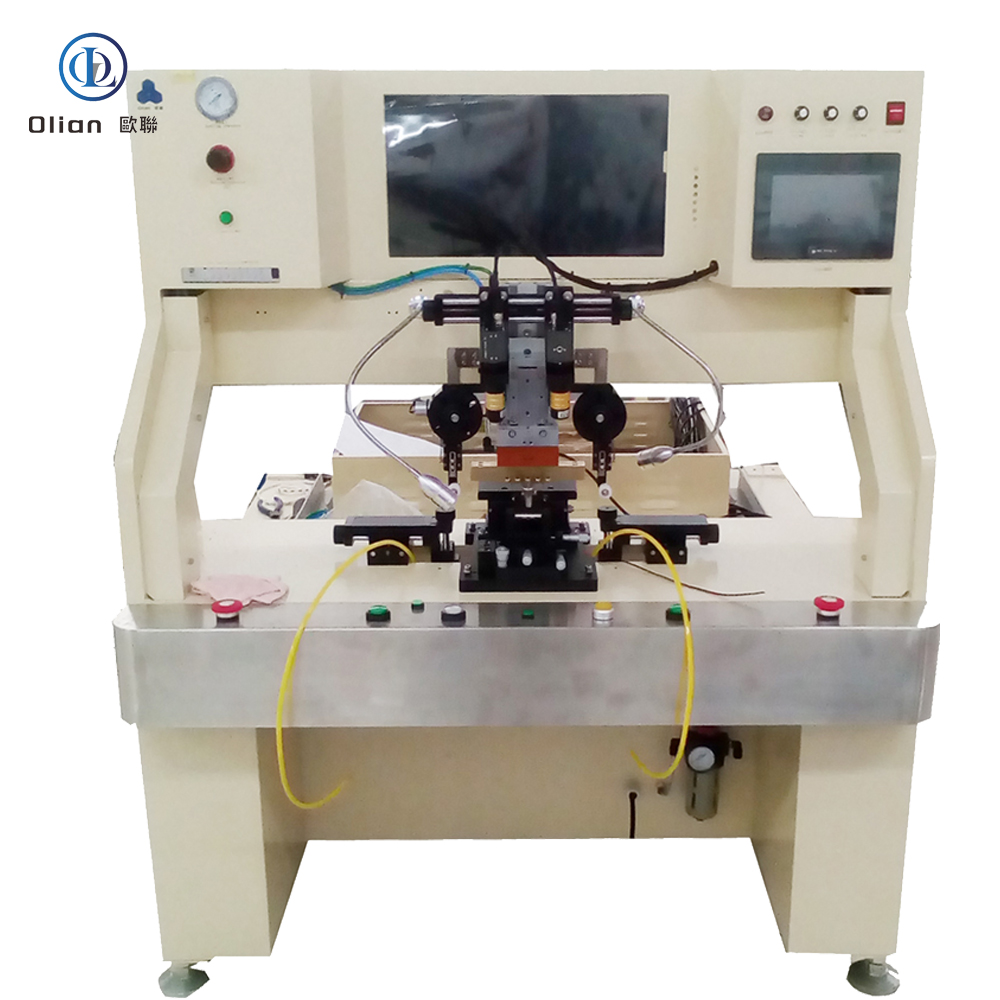

Manual COF Bonding Machine

A manual COF bonding machine —often marketed as a manual Chip-On-Film bonder , manual COF ACF press , or hand-operated COF repair unit —is the bench-top heart that repairs or prototypes flexible display drivers by manually aligning and bonding a Chip-On-Film (COF) tail onto glass, PCB, or another flex using anisotropic conductive film (ACF) and operator-controlled heat plus pressure . Every smartphone OLED repair, foldable hinge prototype, and 8-K TV source driver rework you touch has passed through such a bench. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “manual COF bonding machine”, “manual COF bonder”, “hand-operated COF ACF press”, “manual COF repair unit”, and every high-value permutation.

manual COF bonding machine manual COF bonding machine manual COF bonding machine 1-7inch manual COF bonder Pulse Heat Bonding Machine

1. Why “Manual COF” Matters

Cost vs. Throughput : Capex is ~40 % lower than fully automatic lines; ideal for 600–3,000 UPH .Flexibility : Operator can swap COF reels (8–70 mm) or glass sizes (1–55 in) in < 15 min .Repair & R&D : Manual alignment allows easy rework of defective units or small-batch validation .Skill Transfer : Technicians learn vision alignment and thermal profiling before upgrading to fully automatic lines .

2. Physics: The Manual Three-Stage Dance

Operator Load : Places glass/PCB on vacuum chuck; barcode confirms product ID.Manual ACF Lamination : Operator peels 1–3 mm ACF strip; tacks it at 80 °C, 0.2 MPa .Manual Vision Alignment : Operator jogs COF under live 12 MP camera; micrometer achieves ±0.003 mm .Manual Bond :

Pre-Bond (False Compression) : 60 °C, 0.1 MPa to tack COFMain Bond : 160–220 °C, 0.8–1.5 MPa, ~2 s

Manual Unload : Removes bonded assembly; next cycle starts.

Cycle time: 6–10 s (operator dependent), throughput: 600–3,000 UPH .

3. Step-by-Step Manual COF Workflow (Typical Bench Unit)

Operator Load : Places 1–55 in LCD/TFT/OLED or FPC on vacuum chuck; barcode confirms product ID.Atmospheric Plasma Cleaning : Raises surface energy to > 60 dynes for ACF wetting .Manual ACF Lamination : Operator peels 1–3 mm ACF strip; tacks it at 80 °C, 0.2 MPa .Manual Vision Alignment : Operator jogs COF under live 12 MP camera; micrometer achieves ±0.003 mm .Manual Bond :

Pre-Bond (False Compression) : 60 °C, 0.1 MPa to tack COFMain Bond : 160–220 °C, 0.8–1.5 MPa, ~2 s

Manual Unload : Removes bonded assembly; next cycle starts.

4. Core Hardware That Determines Performance (Manual COF)

Granite Base : 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation .Hot-Bar Head : Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .Heat System : PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .Force Actuator : Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET .Vision System : 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .Operator Interface : 15-inch touch HMI, joystick jog, one-button lock, recipe encryption.

5. Software & Industry 4.0 Integration (Manual COF)

Recipe Vault : 500 encrypted programs per QR code; cloud backup with blockchain hash.AI Predictor : Forecasts heater life 200 cycles ahead; schedules maintenance before scrap.Remote VPN : OEM engineers debug without on-site travel; downtime cut 30 %.Cloud Dashboard : Real-time Cpk, resistance drift, and yield predictions; MES uploads every bond curve.

6. Technical Specifications Buyers Compare (Manual COF)

Display Size : 1–55 inch (LCD, TFT, OLED, flexible OLED)IC/COF Size : 6 × 0.6 mm to 65 × 45 mmBonding Accuracy : ±0.003 mm (vision-guided)Temperature Window : RT–400 °C, stability ±0.5 °C, overshoot < 1 °CForce Window : 10–3,900 N, resolution 0.1 NCycle Time : 6–10 s (operator dependent)Throughput : 600–3,000 UPH (operator dependent)Power : Single-phase 220 V ±10 %, peak 4 kWCleanroom : ISO 6 recommended; laminar-flow hood integrated .

7. Market Trends

Copper-Core ACF : Cu-Ag spheres cut gold cost 50 % while keeping < 20 mΩ contact .Cold-Laser Assist : Femtosecond laser pre-cleans ITO at 25 °C, enabling 120 °C PET bonds .AI Yield Predictor : Neural networks forecast particle-trap probability, pushing yield to 99.9 % .Roll-to-Roll Manual : Reel-fed driver and touch tails bonded at 3,000 UPH .Micro-OLED : 12 µm pitch achieved on 0.15 mm bars .

According to industry analysis, the global manual COF bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

8. Applications Across All Manual COF Bond Types

Consumer Electronics : Smartphone OLED (COG + COF), foldable hinge (FOF), tablet battery tail (FOB) .TV & Signage : 32″-100″ 4-K/8-K LCD, OLED, mini-LED—COF source + OLB gate + TFOG touch .Medical : Surgical monitors, portable ultrasound, wearable ECG patches—biocompatible polyimide, ISO 13485 traceability .Industrial & Aerospace : Avionics displays, factory HMI panels, rugged handhelds—shock, altitude, fungus per MIL-STD-810 .

9. Daily Maintenance for 99 % Uptime (Manual COF)

Clean Hot-Bar with IPA every 200 cycles to prevent ACF build-up .

Verify thermocouple vs dry-block calibrator weekly; drift > 0.3 °C triggers replacement.

Calibrate cameras with 30 µm dot grid; auto-correction keeps 0.2 µm repeatability .

Grease cross-roller guides with PFPE oil monthly; avoid silicone that out-gasses.

Store ACF rolls sealed at −10 °C, 30 % RH; 4 h thaw under laminar flow prevents moisture bubbles.

10. SEO Keyword Integration

manual cof bonding machine, manual COF bonder, hand-operated COF ACF press, manual COF repair unit, manual COF bonding machine 1 micron accuracy, 200 °C manual temperature, 1 MPa manual force, vertical conduction horizontal insulation, lead-free manual bonding, ROHS compliant manual bonding, foldable phone manual COF bonder, 8-K TV manual COF bonding machine, automotive display manual COF bonder, medical device manual COF bonding machine, roll-to-roll manual COF bonder, 3,000 UPH manual COF bonding machine, 99.9 % yield manual COF bonder, Industry 4.0 manual COF bonding machine, AI predictive maintenance manual COF bonder, remote diagnostics manual COF bonding machine, cloud dashboard manual COF bonder, granite base manual COF bonding machine, servo motor manual COF bonder, voice-coil actuator manual COF bonding machine , telecentric lens manual COF bonder, real-time Linux manual COF bonding machine, OPC-UA manual COF bonder,

11. manual COF bonding machine Conclusion

A manual COF bonding machine is no longer a manual hot-plate—it is the flexible, AI-driven, cloud-connected gateway that turns operator skill into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these benches deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade .