A TAB bonding machine is the unsung hero inside every LCD television, laptop, tablet, and industrial monitor you use today. TAB—Tape Automated Bonding—refers to the process of bonding a driver IC mounted on a flexible polyimide tape to a glass or PCB substrate using anisotropic conductive film (ACF). The machine that performs this task must deliver micron-level alignment, single-degree temperature control, and kilogram-level pressure accuracy—all in under four seconds. High-value keywords like “TAB bonding machine”, “LCD TAB bonder”, “ACF TAB bonding”, “TV panel repair machine”, “pulse heat TAB bonding”, and more.

A TAB bonding machine is a high-precision pulse-heat press that bonds a driver IC mounted on a flexible tape to a glass or PCB substrate. The tape contains copper traces and is pre-bumped with gold or tin. ACF is used to create vertical conductivity between the bumps and the substrate while maintaining horizontal insulation. The result is a durable, flexible, and lead-free interconnect that survives thermal cycling, mechanical stress, and humidity. TAB bonding is widely used in LCD, LED, OLED, and QLED displays ranging from 5-inch smartphones to 100-inch TVs.

Although COG (Chip-On-Glass) and COF (Chip-On-Film) have gained popularity, TAB remains the go-to solution for large-size panels and repair markets. TAB allows the IC to be tested and burned-in before bonding, improving yield. The flexible tape absorbs thermal expansion mismatch between the IC and glass, enhancing reliability. TAB also enables repair: a defective IC can be removed and a new one bonded without scrapping the entire panel, saving hundreds of dollars per screen.

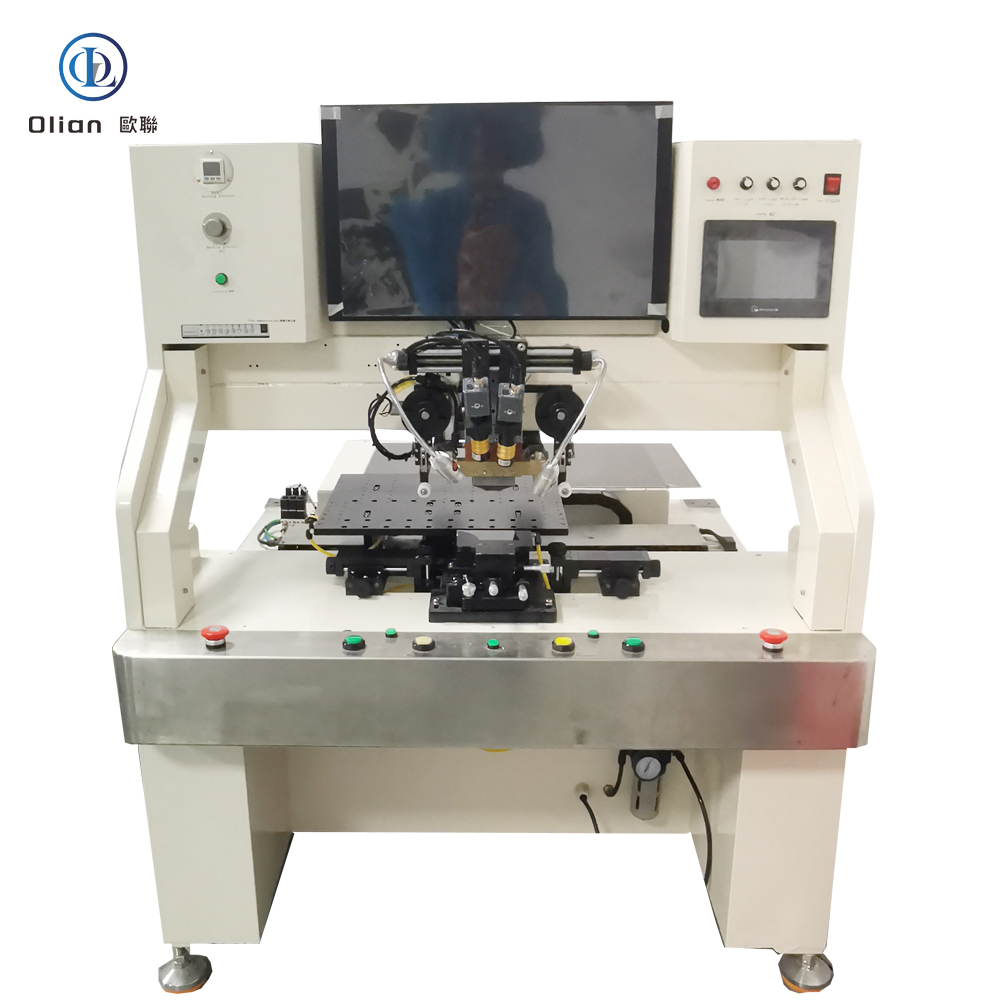

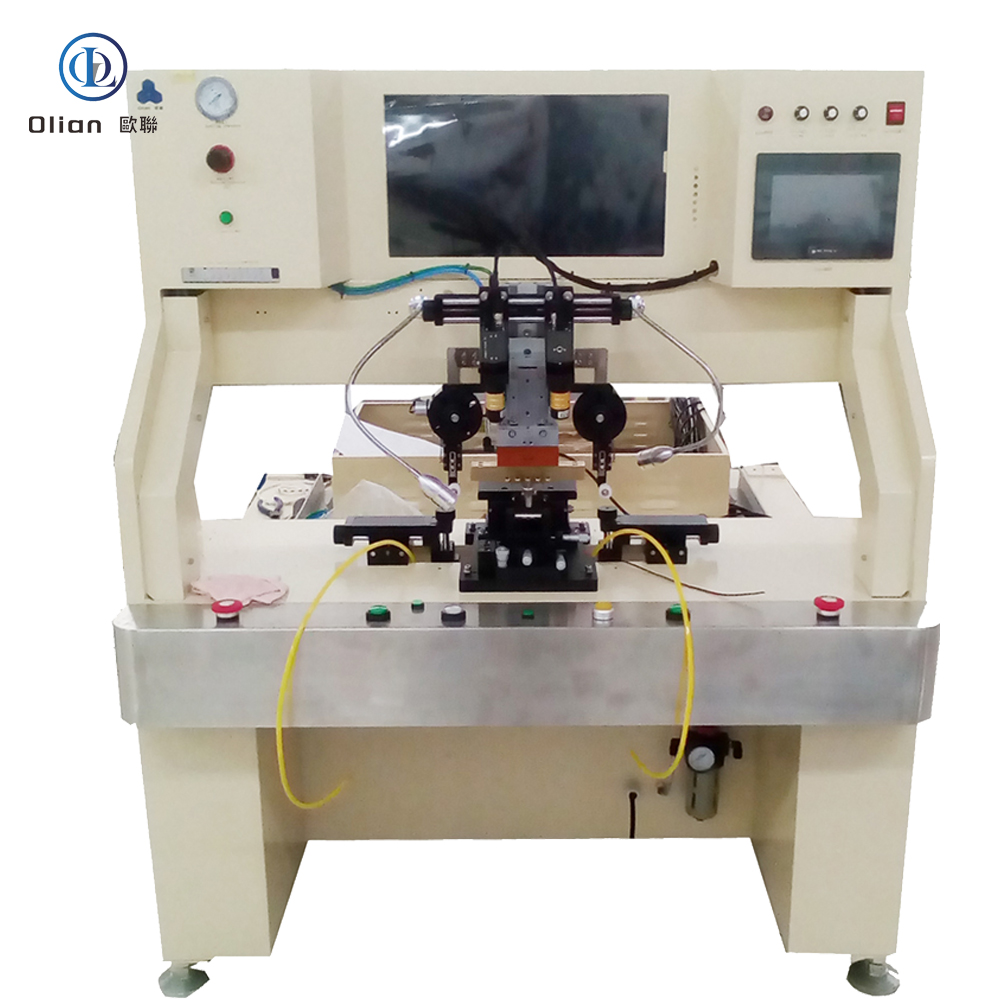

Bonding Head: Titanium alloy, lapped to 0.001 mm flatness, plasma-nitrided for durability.

Heater Cartridge: 400–800 W, ramp rate 150 °C/s, embedded thermocouple accuracy ±0.3 °C.

Force Actuator: SMC precision cylinder or voice-coil motor, 0.1 kg resolution, closed-loop control.

Vision System: Dual 12 MP CMOS cameras, telecentric lens, coaxial LED lighting, AI edge detection.

Motion Stage: Cross-roller guides, 0.1 µm linear encoder, servo feedback at 10 kHz.

Software: Panasonic or Siemens PLC, touch-screen HMI, recipe manager, data logging, SECS/GEM ready.

LCD TV Repair: Fixes vertical/horizontal lines, black bands, color lines, half-screen faults on 15″–100″ panels

.

Smartphones & Tablets: Bonds display driver and touch controller on mid-range devices.

Automotive: Repairs curved instrument clusters and infotainment screens.

Medical: Reworks patient monitors and diagnostic displays.

Industrial: Maintains HMI panels and outdoor kiosks.

TAB bonding machine, LCD TAB bonder, ACF TAB bonding, pulse heat TAB bonding, TV panel repair machine, 4K TAB bonding, 100 inch TAB bonding, COF vs TAB bonding, narrow bezel TAB bonding, China TAB bonding machine, automatic TAB bonder, TAB bonding accuracy 1.5 micron, TAB bonding temperature 220 C, TAB bonding pressure 1 MPa, LCD line repair machine, vertical line TAB bonding, horizontal line TAB bonding, black band repair, color line repair, OLED TAB bonding, QLED TAB bonding.

AI Vision: Deep-learning cameras auto-detect bump defects and adjust alignment on-the-fly.

IoT Monitoring: Cloud dashboards predict heater failure and schedule maintenance before scrap occurs.

Green ACF: Copper-core particles replace gold, cutting material cost 40 %.

Cold-Laser Assist: Femtosecond laser cleans bumps at room temperature, enabling 120 °C bond profiles for heat-sensitive OLED.

Servo-Hydraulic Hybrid: Delivers 80 kg force for 100″ TV TAB while keeping 1 µm position accuracy.

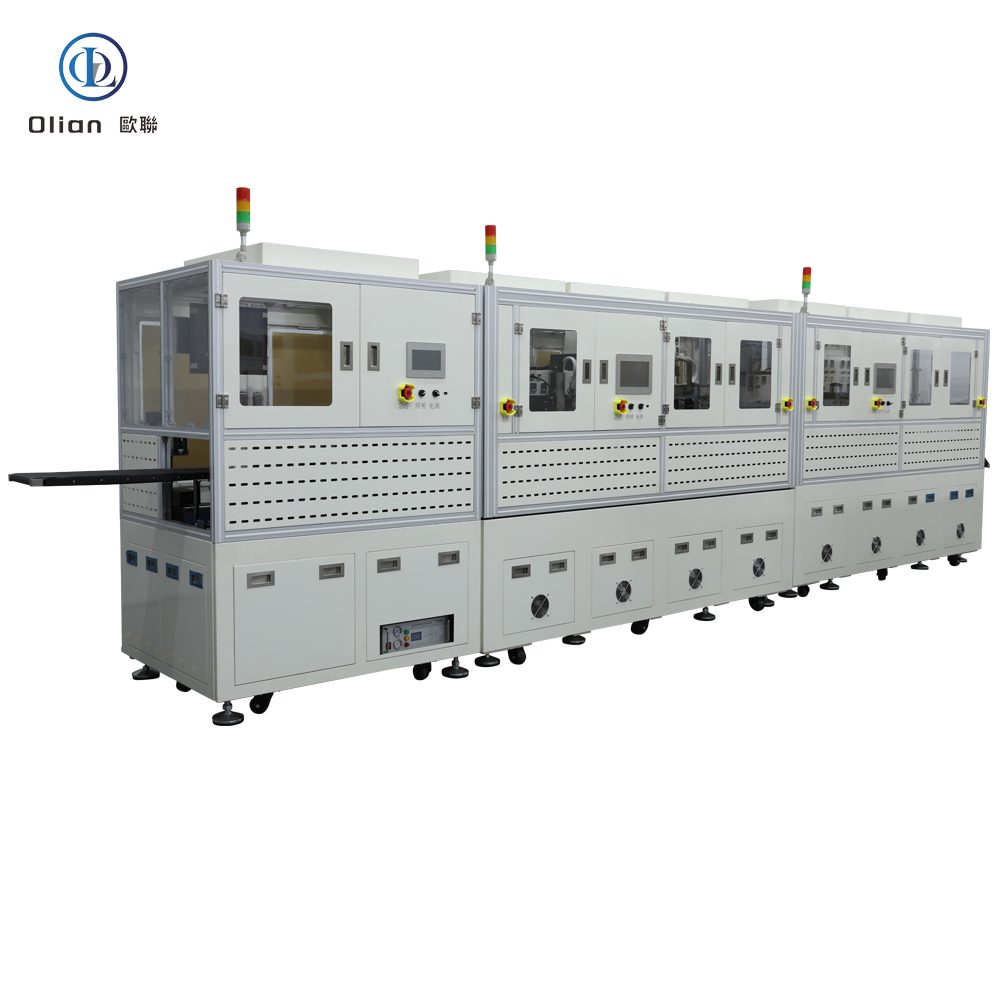

Dual-Head Systems: Parallel bonding of source and gate TABs doubles throughput without extra floor space.

A TAB bonding machine remains the backbone of LCD repair and large-panel manufacturing . By delivering micron alignment, pulse-heat precision, and flexible-tape reliability, TAB bonders save millions of dollars in scrap costs while enabling bezel-free designs and rugged automotive displays. Whether you run a high-volume TV factory or a boutique phone repair shop, investing in an AI-enhanced, IoT-ready TAB bonding platform future-proofs your process.