3-8 Inch Small-Size COP/FOP Bonding Line Solution

1. Company Overview Shenzhen Olian Automatic Equipment Co., Ltd., established in 2012, specializes in automation equipment for FPD flat-panel displays and next-generation flexible screens. As a national high-tech enterprise and “Specialized, Refined, Unique, Innovative” enterprise, Olian integrates R&D, production, sales, and service. Key highlights:

80+ professional R&D team with expertise in precision manufacturing.4,000㎡ facility featuring CNC machining centers (precision CNC, large surface grinders, lathes, milling machines) and a quality inspection center (Japanese-imported 2D measuring instruments, Olympus microscopes).2,100+ clients served globally, including partnerships with leading enterprises in China, Taiwan, Canada, South Korea, Singapore, India, and Vietnam.Core products : Full-process equipment for LCM module factories (bonding, AOI, dispensing, backlight, soldering), serving smartphones, e-tags, tablets, wearables, automotive displays, and smart factories.

2. Bonding Line Layout & Process Flow 2.1 Overall Wiring Scheme Scope : Fully automated EC/COP/FOP production line for small-size (3″–8″) single-IC, single-FPC products.

Key Stations :

FPC Handling : Loading platform → 1# ACF station → 1# Pre-Bond → Main-Bond (3 modules).Panel Processing : Loading → Plasma cleaning → ACF application → IC pre-bond alignment → Main bonding → Output.Quality Control : Dual CCD correction (pre-bond and main bond), ACF visual inspection, and USC (Ultrasonic Cleaning) optional.

Process Flow :

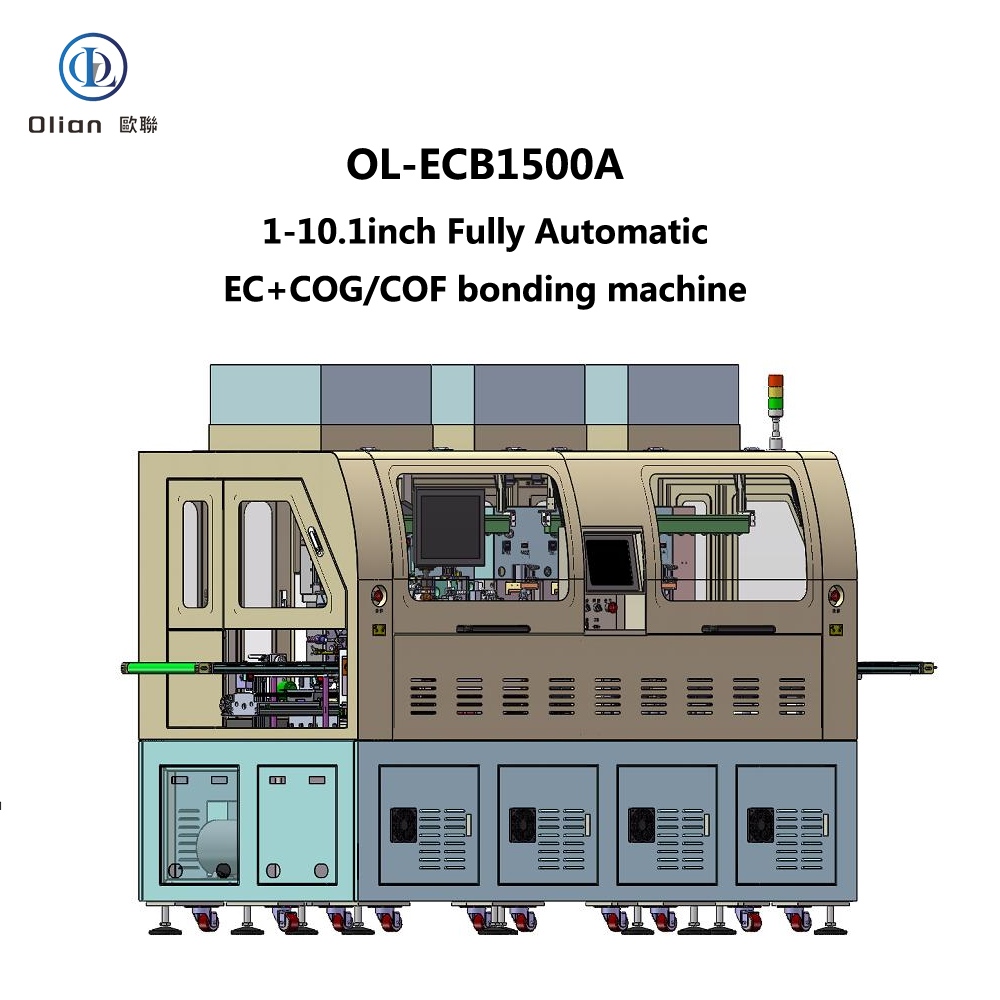

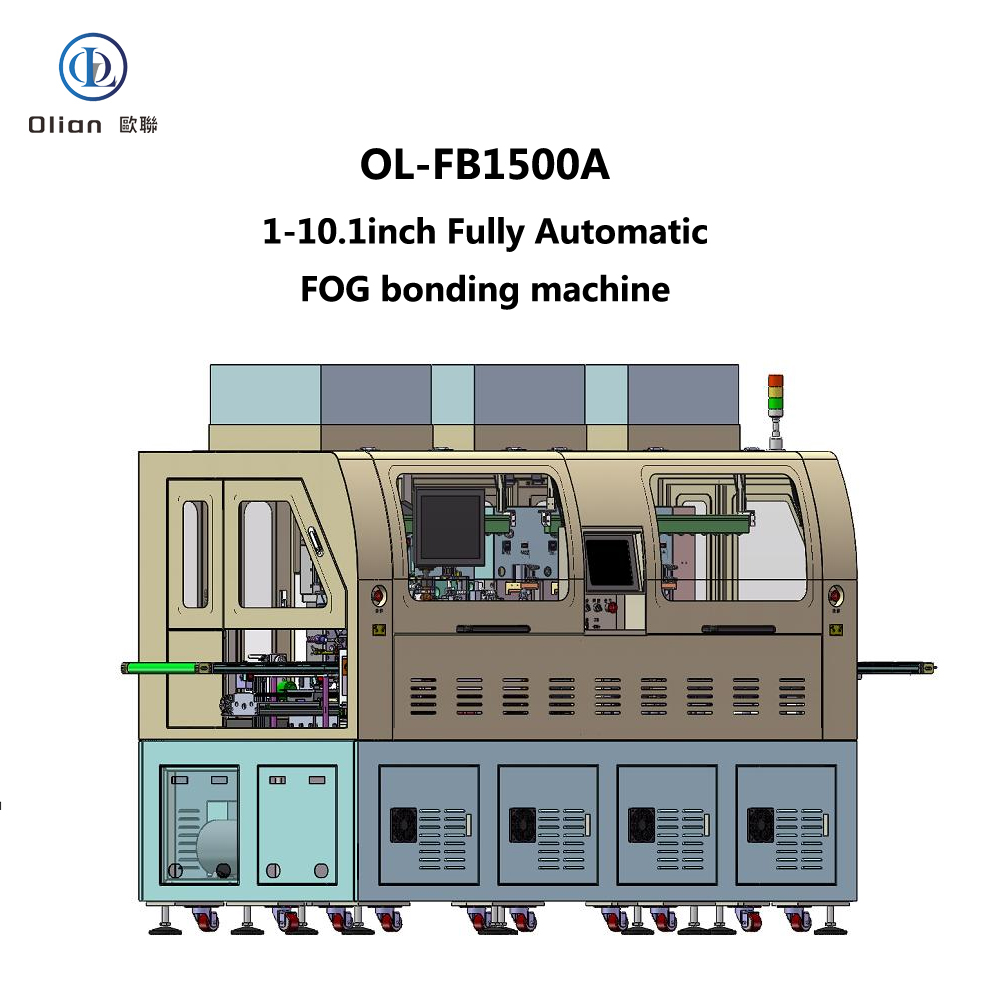

Panel Loading → Plasma Cleaning →ACF Application → COP Pre-Bond → COP Main Bonding FPC Loading → ACF Application On Panel → FOP Pre-Bond → FOP Main Bonding → Output 3. Equipment Specifications 3.1 COP Bonder (Chip-on-Panel Or Chip- on-Plastic)

Panel Range : 3″–8″ (65×30mm – 190×120mm), thickness: 0.3–0.5mm.IC Specifications : Single IC (5×0.6mm – 36×6mm).Precision :

ACF placement: X±0.15mm, Y±0.1mm

Total bonding accuracy: ±5μm

Cycle Time : 6 seconds per unit.Key Components :

ACF Head : SUS 440C, 4.0×60mm (pneumatic).Main Bonding Head : Ceramic/tungsten carbide, 5.0×40mm (servo + pneumatic).

Power & Size : 220V/50Hz/12.5kW; Dimensions: 3,250L × 1,500W × 1,800H mm (excl. FFU).

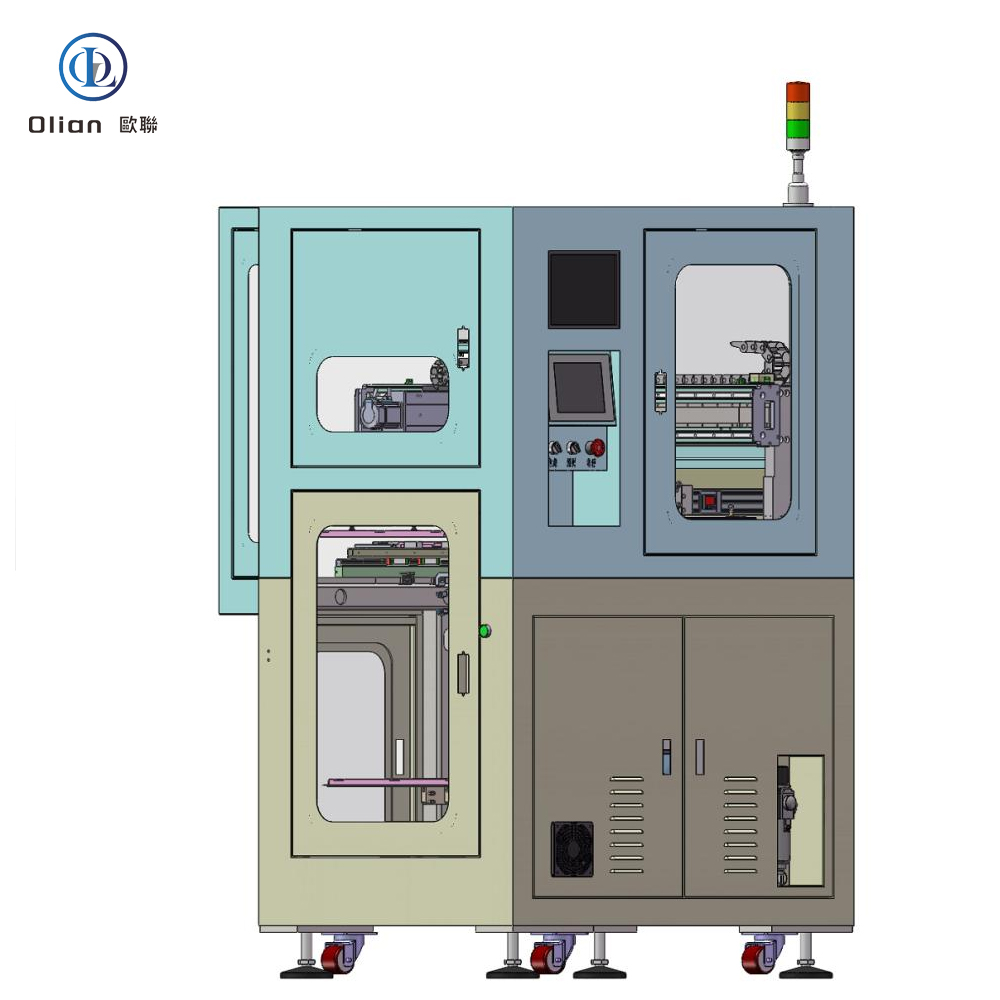

3.2 FOP Bonder (FPC-on-Panel or FPC-on-Plastic)

FPC Range : 10×14mm – 80×120mm (bonding area ≤60mm).Precision : ±15μm total accuracy.Cycle Time : 6 seconds (for 5.2″).Key Components :

Main Bonding Head : SUS 440C (×2, pneumatic).

Power & Size : 220V/50Hz/7.5kW; Dimensions: 2,500L × 1,300W × 1,800H mm (excl. FFU).

4. Technical Advantages 4.1 Precision & Efficiency

Linear Motor Robots : High-speed, low-vibration handling.CCD Vision System : Beijing Boshi for real-time alignment correction.Plasma Cleaning : SVD brand (15° water contact angle).

4.2 Component Quality

Critical Parts : Fuji/Servotronix servos, THK/HIWIN linear guides, SMC pneumatic components.Inspection Tools : Visual ACF detection, plasma treatment validation.

5. After-Sales & Quality Assurance 5.1 VIP Service

30-minute response time , 24/7 support.1-year warranty with free installation, training, and lifetime service.30-day defect resolution : Free replacement/refund if unresolved.

5.2 Quality Control System

Design : DQA (Design Quality Assurance) with safety and ESD compliance.Production : Strict assembly standards, precision calibration, and final testing per client specifications.

6. Certifications & Capabilities

Certifications : National High-Tech Enterprise (2022–2025), “Specialized, Refined, Unique, Innovative” (2024–2027), AAA Credit Enterprise.Patents : 10+ utility patents, software copyrights, and proprietary technologies.Production Capacity : 4,000+ equipment units delivered, 200+ automated lines deployed.

Contact Information whatsapp:+8618025364779

Empowering global display manufacturing with precision automation since 2012.

SEO Keywords : COP bonder, FOP bonder, LCM module automation, chip-on-panel equipment, flexible display bonding, Shenzhen automation company, high-precision bonder, Olian equipment,chip on plastic, fpc on plastic.

3 comments so far

LeahPosted on11:07 上午 - 12 月 30, 2025

best COP FOP bonding line,help us in the flexible amoled displays production.

DanielPosted on3:40 下午 - 1 月 3, 2026

3-8 Inch Small-Size COP/FOP Bonding Line

EloisePosted on6:40 下午 - 1 月 11, 2026

COP FOP bonder for OLED panels, good machines for future.