Wearable Device Display Manufacturing Line: Enabling the Future of Compact, Flexible, and High-Performance Wearables

As wearable technology continues to evolve—from smartwatches and fitness trackers to AR glasses and health monitoring patches—the demand for compact, durable, flexible, and energy-efficient displays has surged. At the core of this innovation lies the Wearable Device Display Manufacturing Line, a highly sophisticated, precision-driven production system engineered to meet the unique challenges of small-form-factor, curved, and often flexible displays used in modern wearables.

This advanced manufacturing line integrates cutting-edge automation, micro-assembly technologies, and stringent quality control systems to deliver high-yield, reliable, and aesthetically pleasing displays that seamlessly blend form and function.

Wearable devices require displays that are not only visually clear and responsive but also lightweight, power-efficient, and mechanically robust. Traditional rigid displays are increasingly being replaced by flexible OLED, micro-LED, and even electronic paper (e-Paper) technologies that conform to the human body and withstand constant movement and environmental stress.

The Wearable Device Display Manufacturing Line is specifically designed to handle these advanced display types, supporting both rigid and flexible substrates, ultra-thin components, and miniaturized packaging.

1. Cleanroom-Compatible Automation

○ Operates in Class 100–1000 cleanrooms to prevent particle contamination.

○ Robotic arms with nano-precision handling ensure safe transfer of fragile display panels.

2. Substrate Preparation and Cleaning

○ Advanced cleaning modules (brush, plasma, adhesive roller) remove micro-contaminants.

○ Surface activation improves adhesion for lamination and bonding processes.

3. Flexible Display Lamination

○ High-accuracy alignment systems bond flexible OLED or micro-LED panels to curved or flexible backplanes.

○ UV curing and thermal pressing ensure strong, bubble-free lamination.

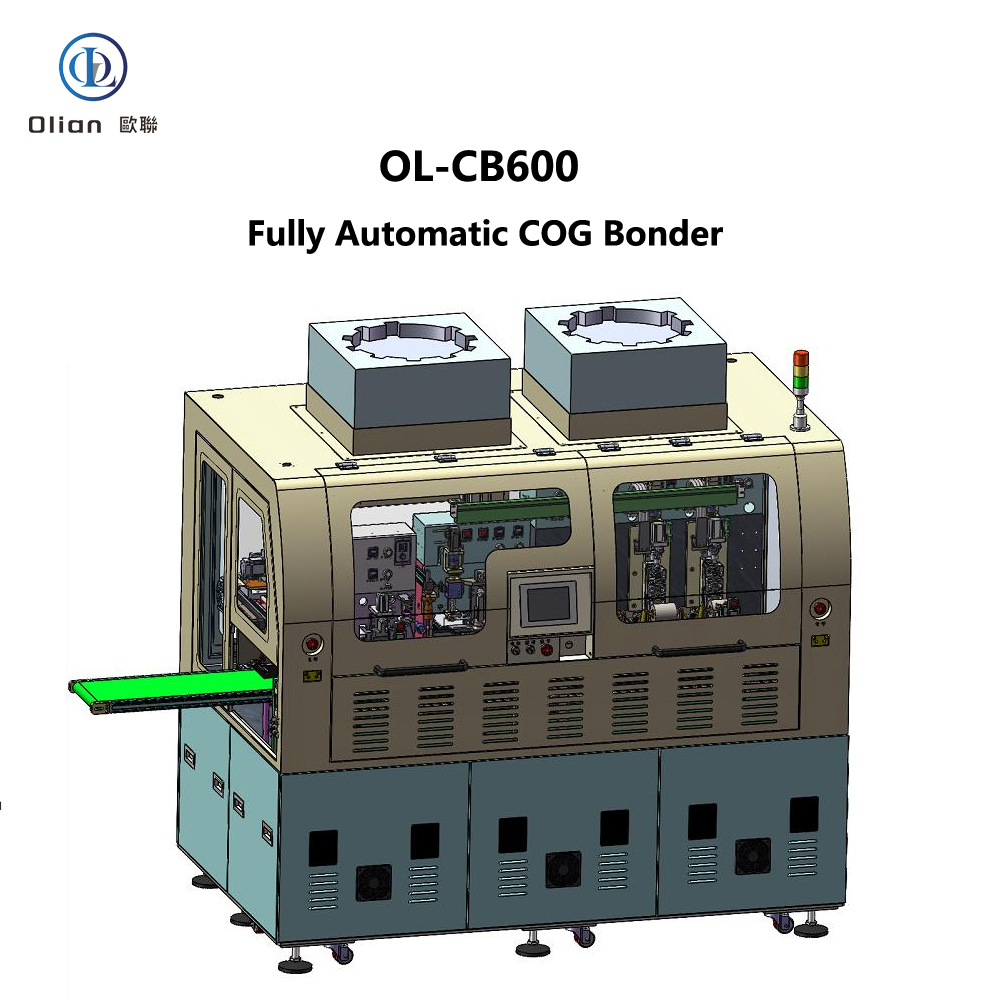

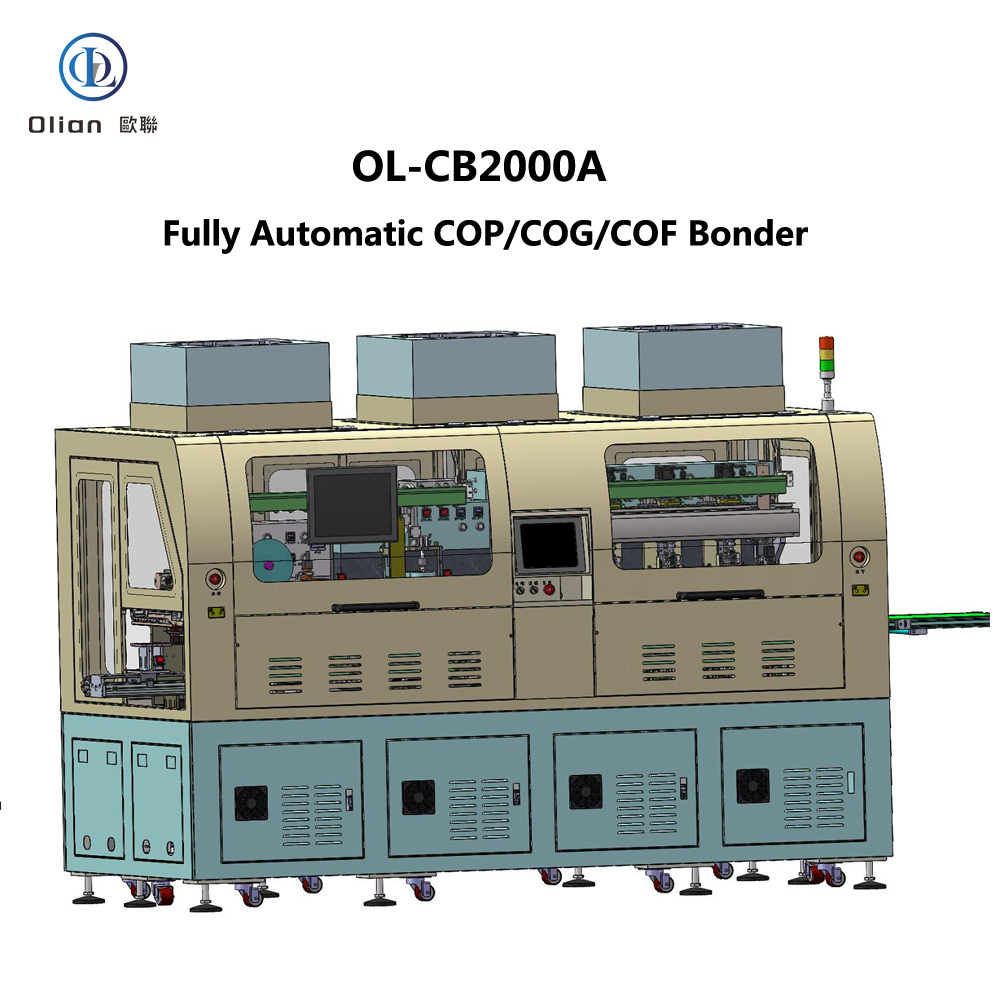

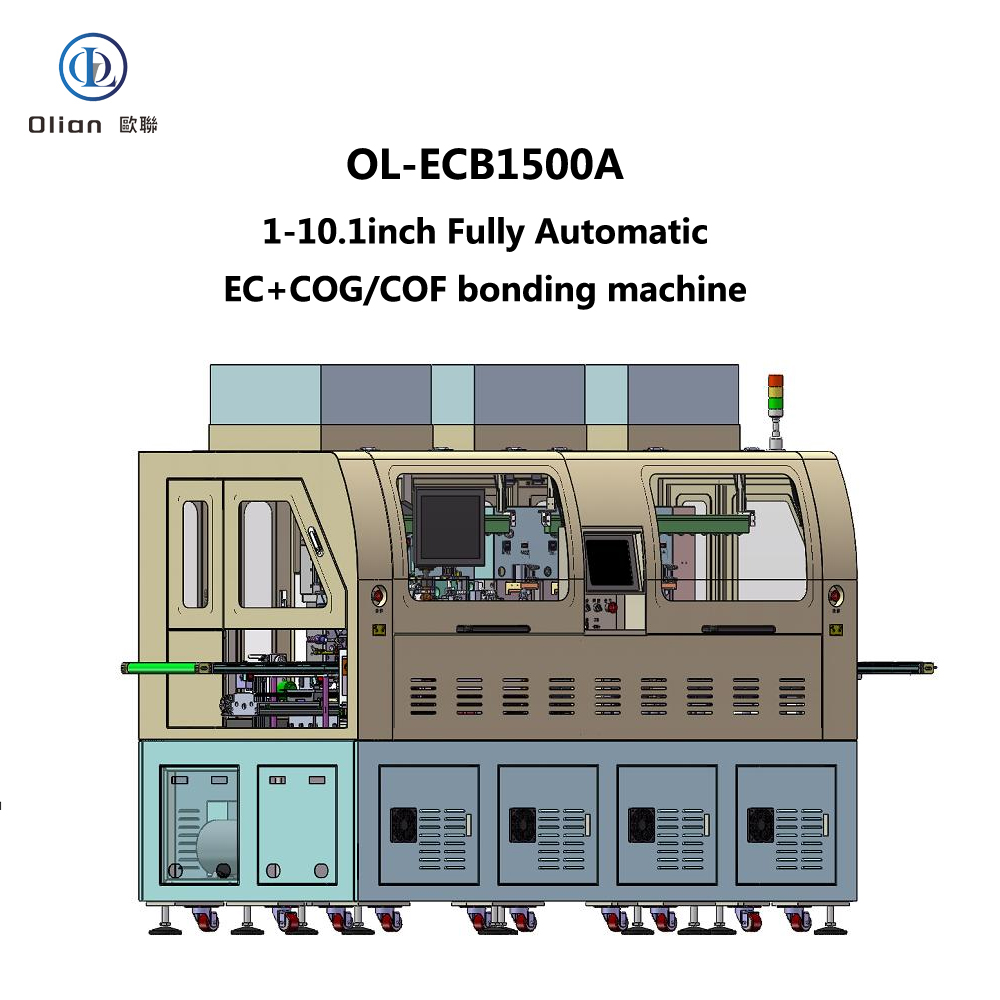

4. COG (Chip-on-Glass) and COF (Chip-on-Film) Bonding

○ Driver ICs are bonded directly onto display substrates using anisotropic conductive film (ACF).

○ Thermocompression equipment ensures reliable electrical connections with sub-micron precision.

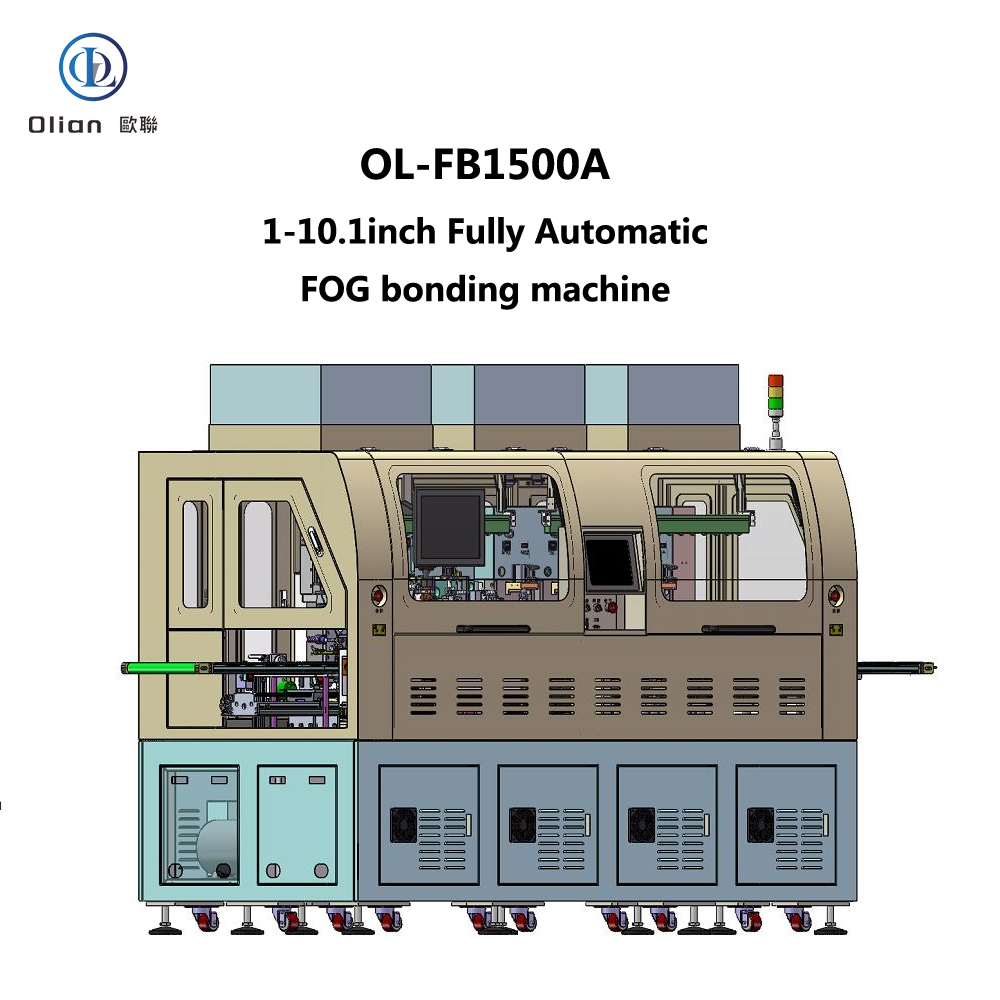

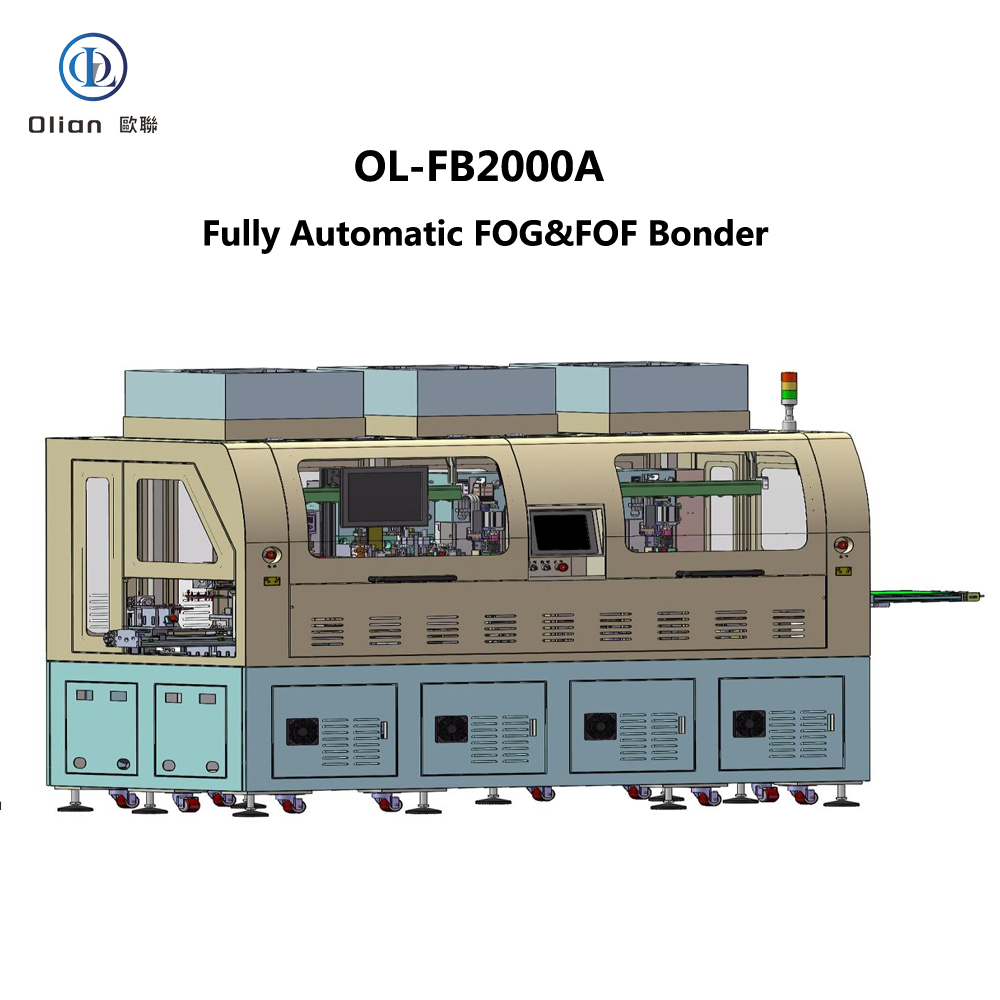

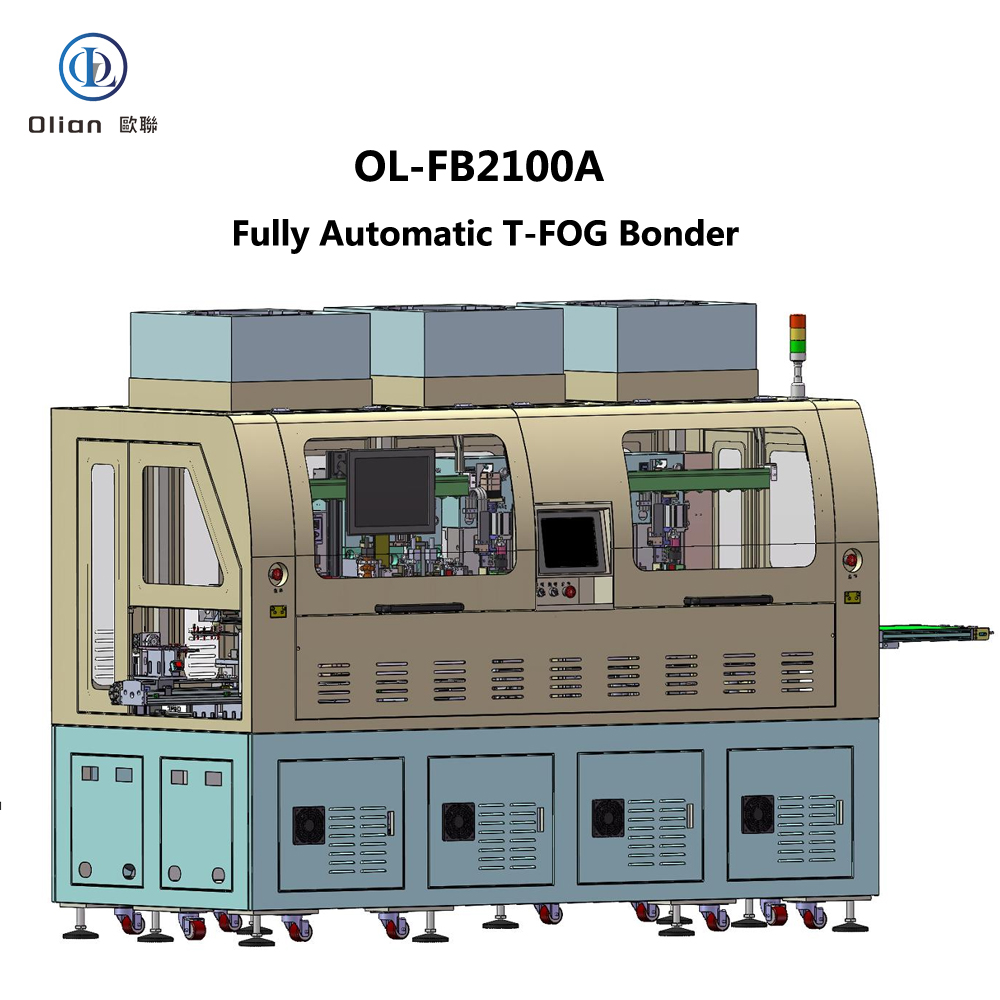

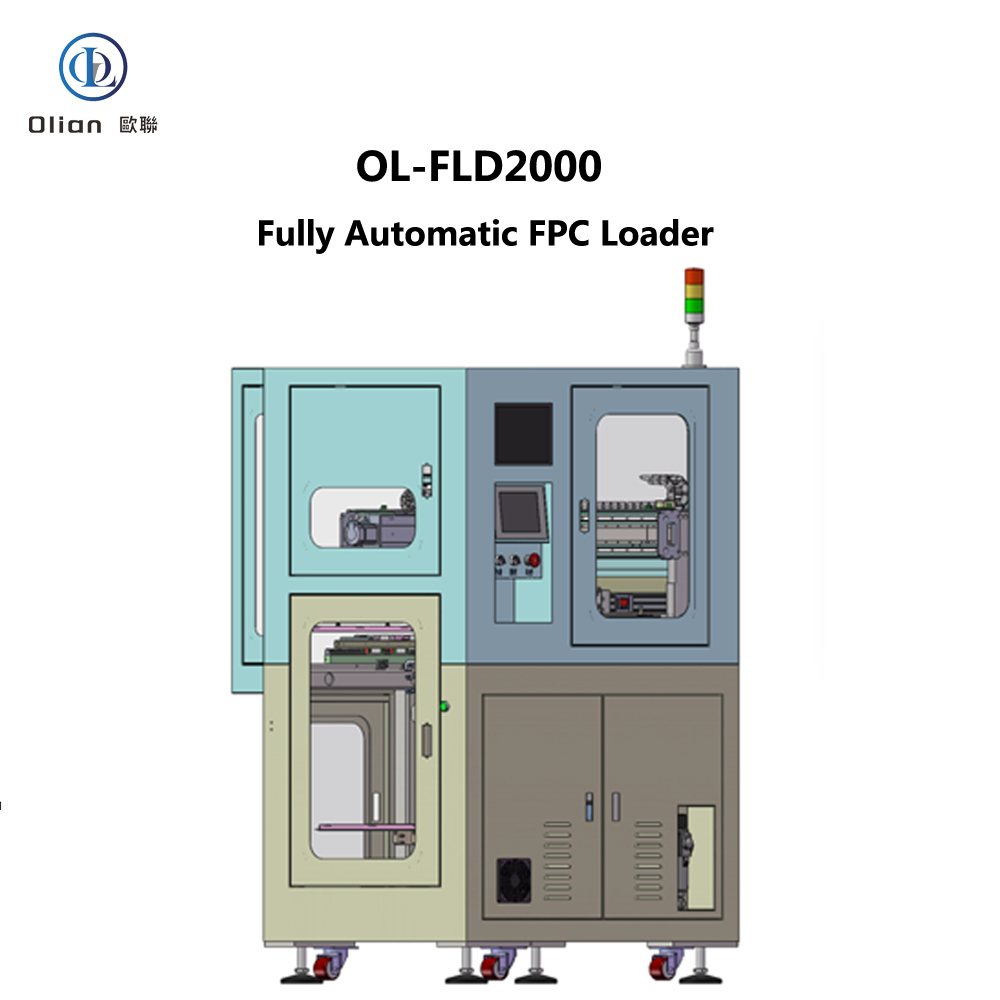

5. FPC (Flexible Printed Circuit) Integration

○ FPCs connect the display to the main control board, enabling signal and power transmission.

○ Automated bonding ensures consistent quality and durability.

6. Curved and 3D Forming (for Curved Displays)

○ Specialized molds and thermal forming equipment shape rigid or semi-flexible displays into curved forms for smartwatches and AR devices.

○ Stress simulation and real-time monitoring prevent cracking or delamination.

7. Automated Optical Inspection (AOI) and Defect Detection

○ High-resolution CCD and AI-powered vision systems detect pixel defects, misalignments, and bonding flaws.

○ Real-time feedback enables immediate process correction.

8. Aging and Reliability Testing

○ Modules undergo extended power cycling, temperature/humidity stress, and bend testing (for flexible displays).

○ Ensures long-term performance under real-world conditions.

9. Final Assembly and Packaging

○ Integration with touch sensors, cover lenses, and protective films.

○ Anti-static, shock-resistant packaging for downstream assembly.

● High Flexibility: Supports multiple display technologies (OLED, micro-LED, e-Paper) and form factors (round, square, curved, flexible).

● Ultra-Precision Handling: Capable of processing displays as small as 1 inch with micron-level accuracy.

● Low Particle Generation Design: Minimizes contamination in sensitive micro-display assemblies.

● Smart Manufacturing Integration: Fully compatible with SECS/GEM, MES, and IoT platforms for real-time monitoring, traceability, and predictive maintenance.

● Energy and Material Efficiency: Optimized processes reduce waste and power consumption, aligning with sustainable manufacturing goals.

● Scalability: Designed for both high-volume mass production and small-batch customization.

● Smartwatches & Fitness Trackers: High-brightness, always-on displays.

● AR/VR Headsets: Micro-displays with high pixel density and fast response.

● Smart Glasses: Transparent or near-eye displays for navigation and notifications.

● Health Monitoring Patches: Flexible, skin-conformable displays for real-time biometrics.

● Fashion-Tech & Smart Jewelry: Miniaturized, aesthetically integrated displays.

At Olian Automatic, we specialize in designing and delivering turnkey Wearable Device Display Manufacturing Lines that combine precision, reliability, and intelligence. Our solutions are built to support the rapid innovation cycles of the wearable industry, enabling manufacturers to bring next-generation products to market faster, with higher quality and lower total cost of ownership.

From concept to full-scale production, our engineering team works closely with clients to customize workflows, integrate advanced inspection systems, and ensure seamless compatibility with existing production ecosystems.

Welcome to visit us ,Wechat/whatsapp:+86 18025364779,Zack wu

Keywords: Wearable Display, Display Manufacturing Line, Flexible OLED, Micro-LED, COG Bonding, COF Bonding, FPC Integration, AOI, Automated Inspection, Smart Manufacturing, SECS/GEM, MES, Curved Display, Miniaturized Display, Wearable Technology, AR/VR Display, Health Monitoring Display, Precision Assembly, Cleanroom Automation, Flexible Electronics

Tags: Wearable Devices, Display Manufacturing, OLED, Micro-LED, Flexible Display, Smart Factory, Automation, Precision Engineering, IoT, AR/VR, Health Tech, Consumer Electronics, Mini-Display, Advanced Bonding, AOI, SECS/GEM, Sustainable Manufacturing

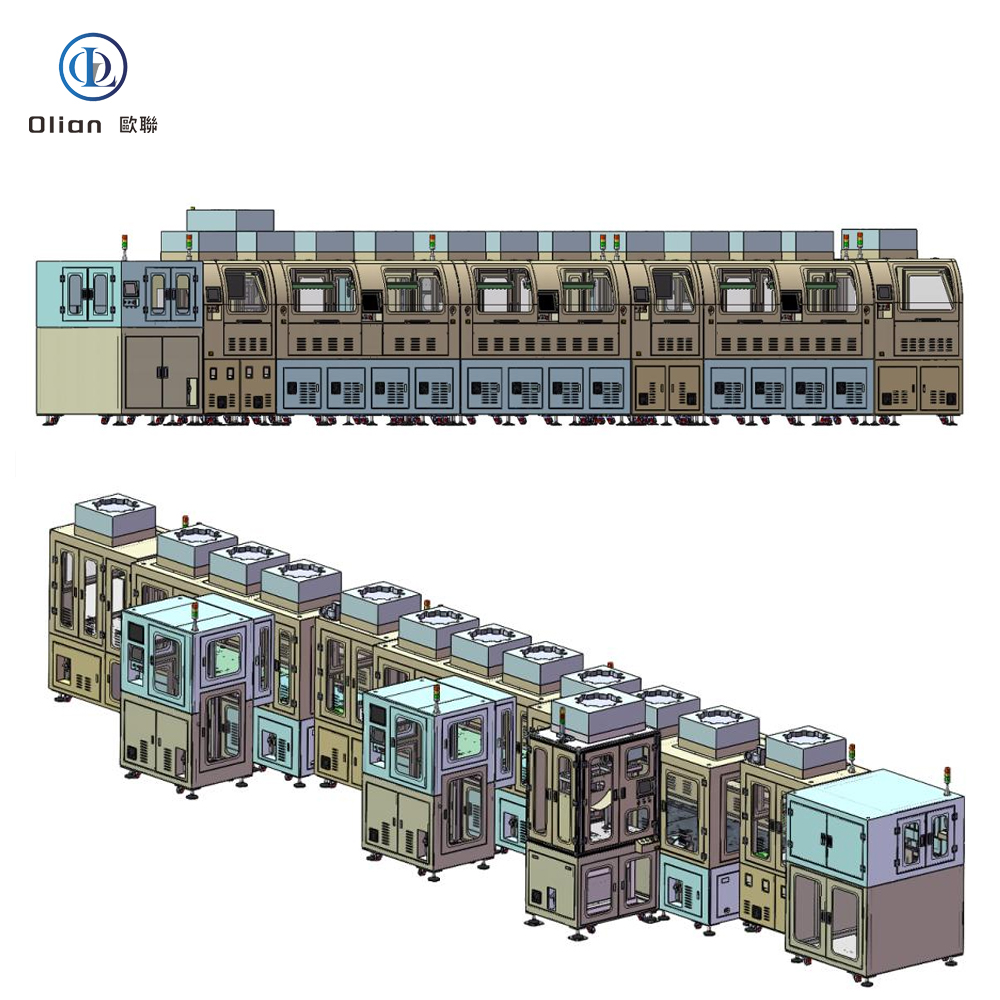

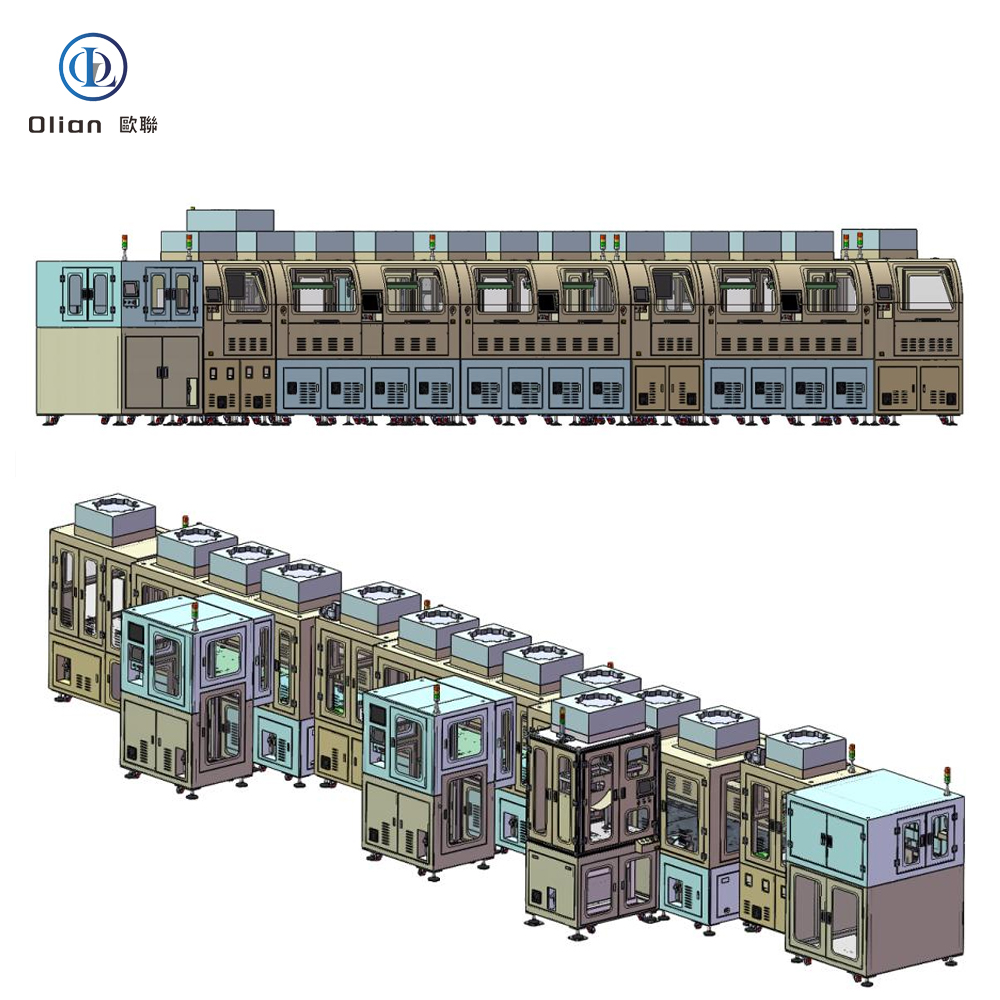

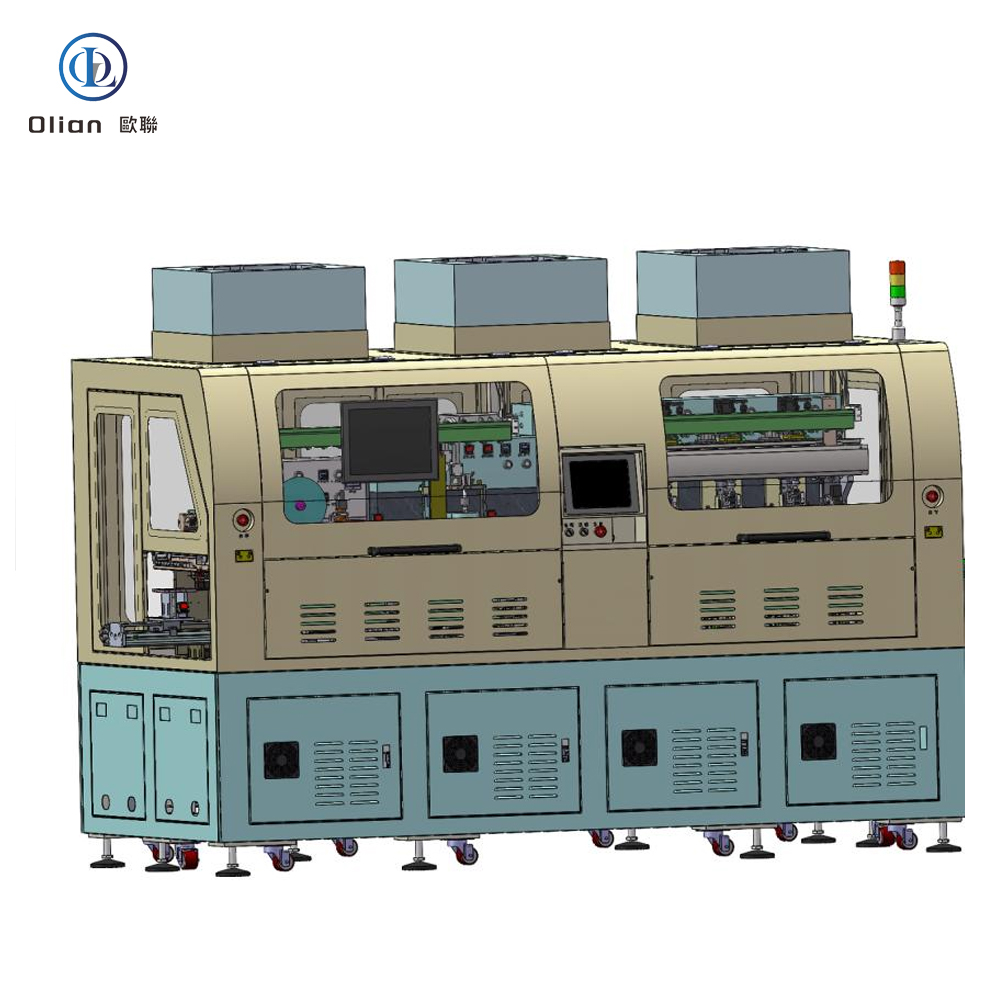

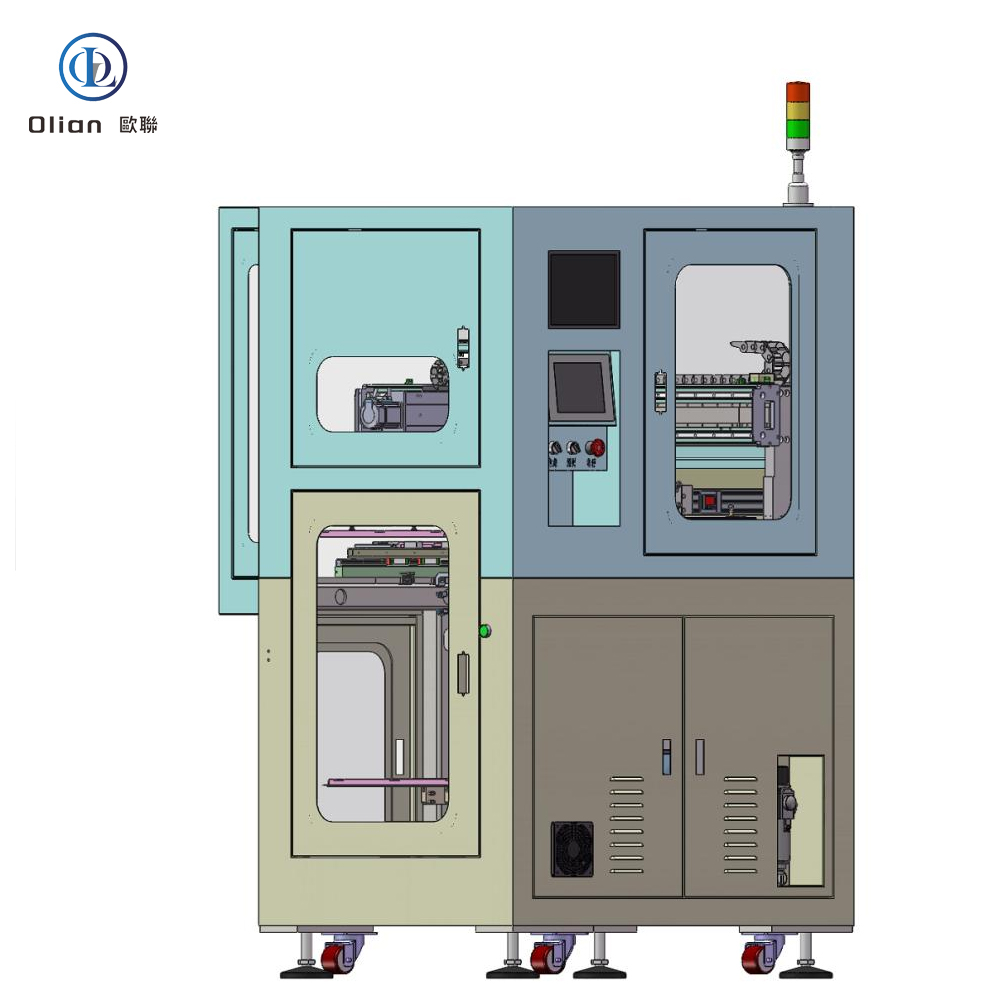

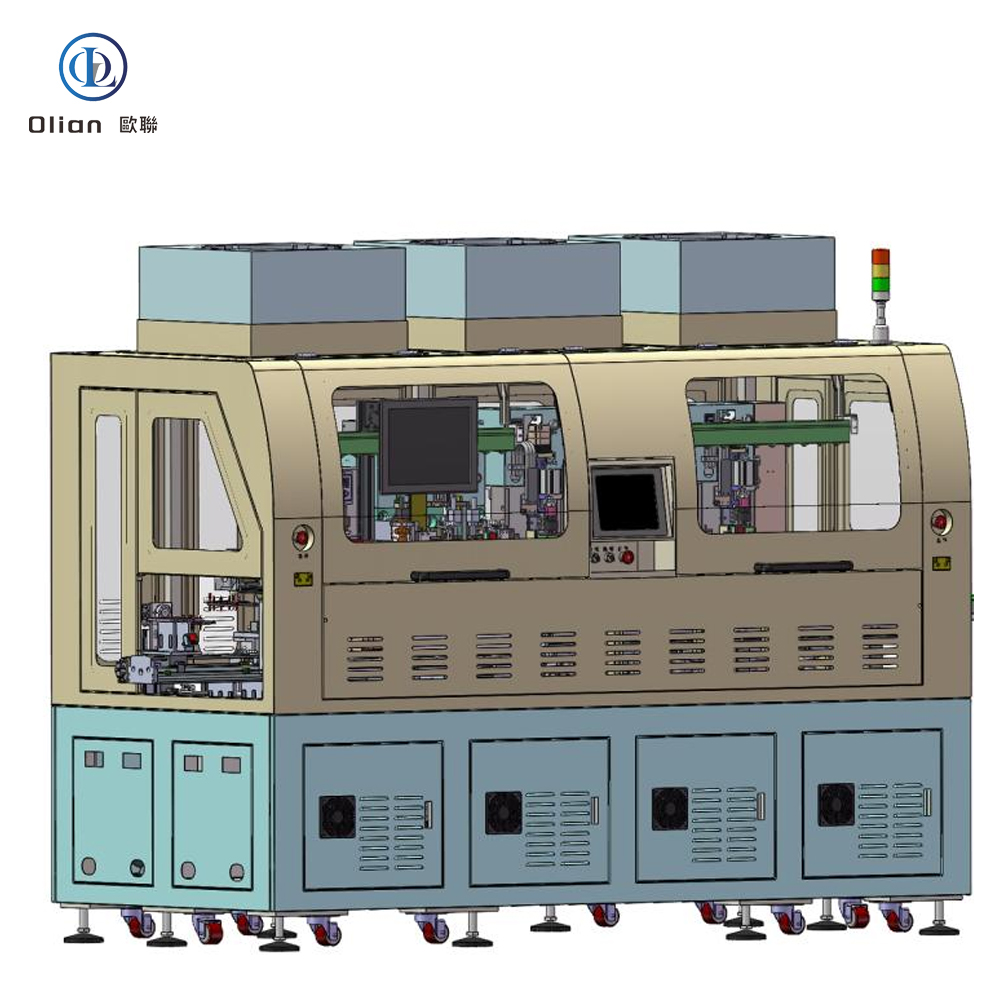

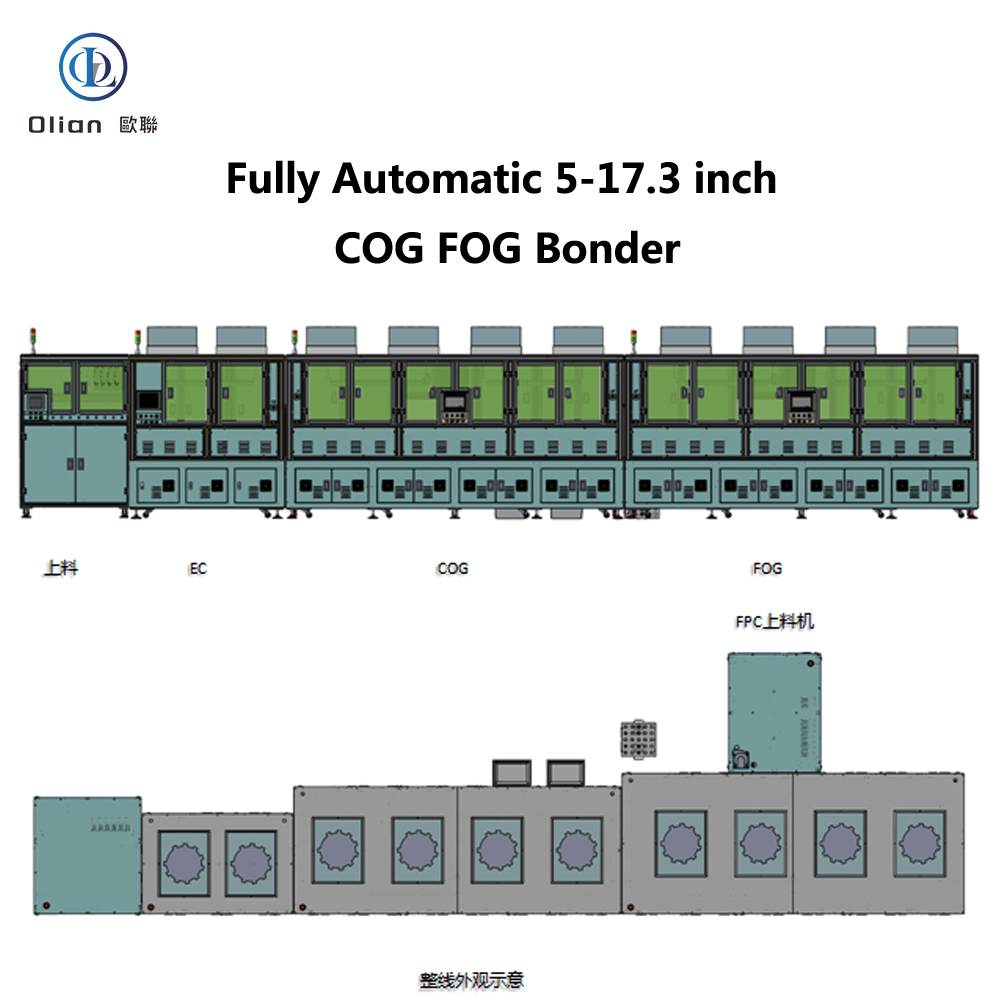

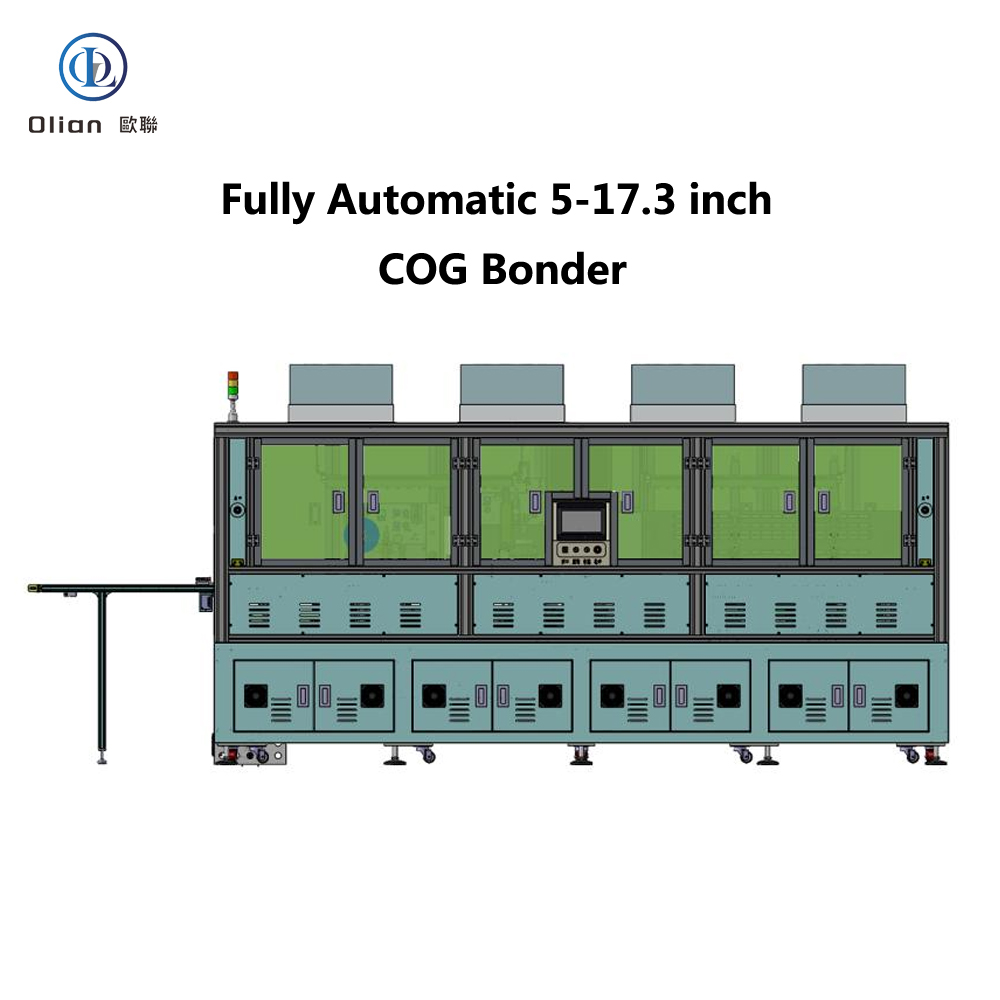

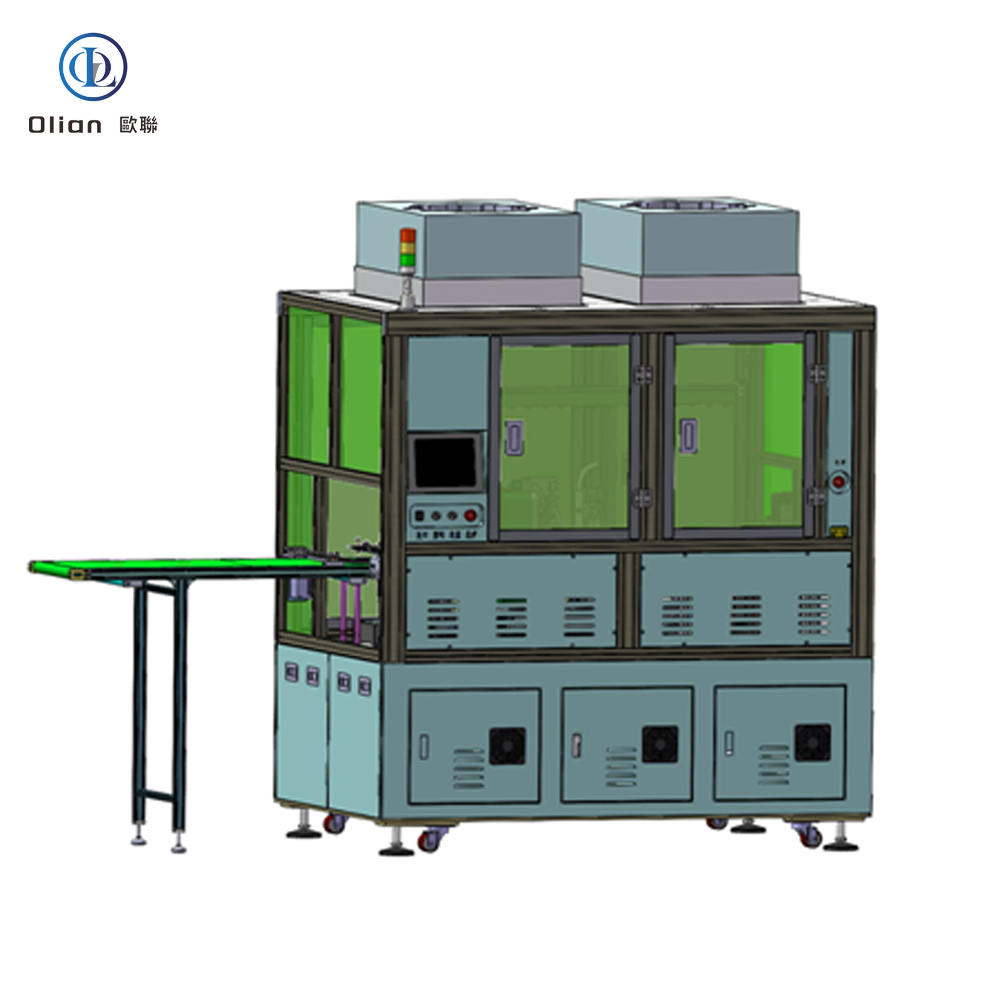

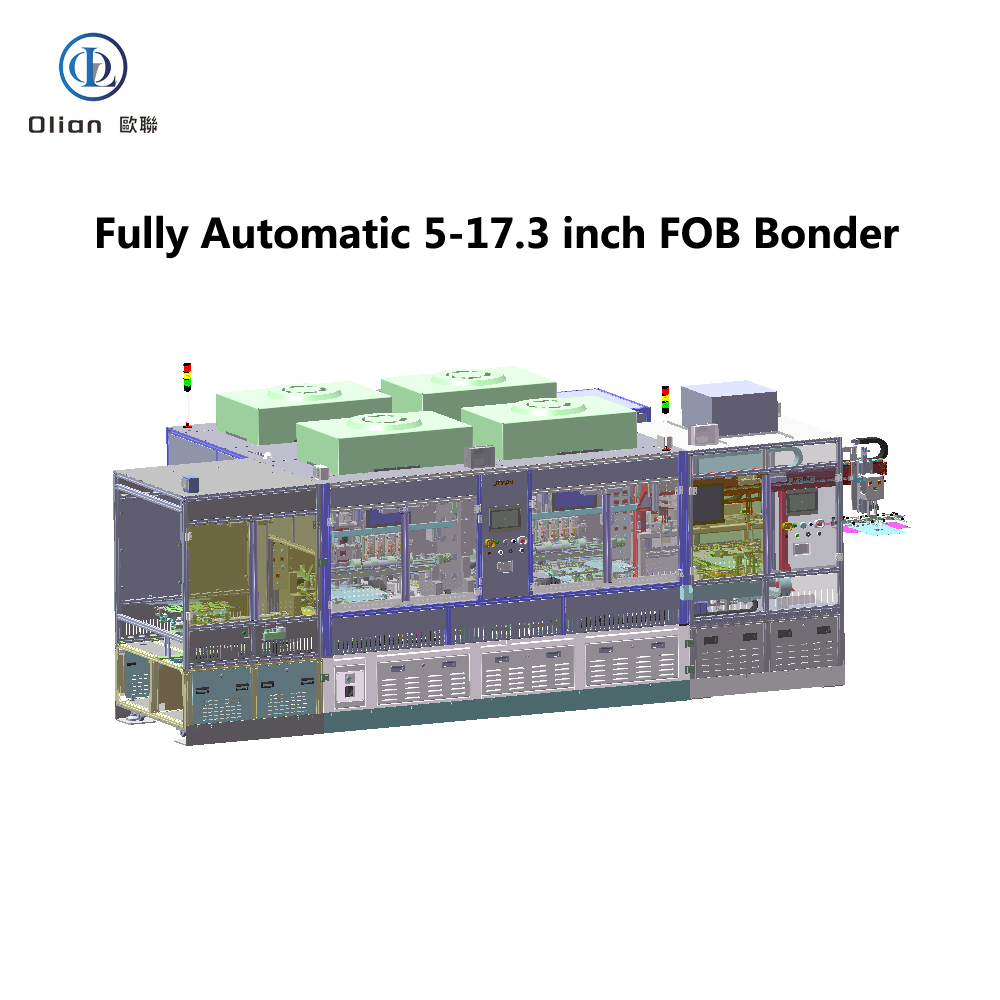

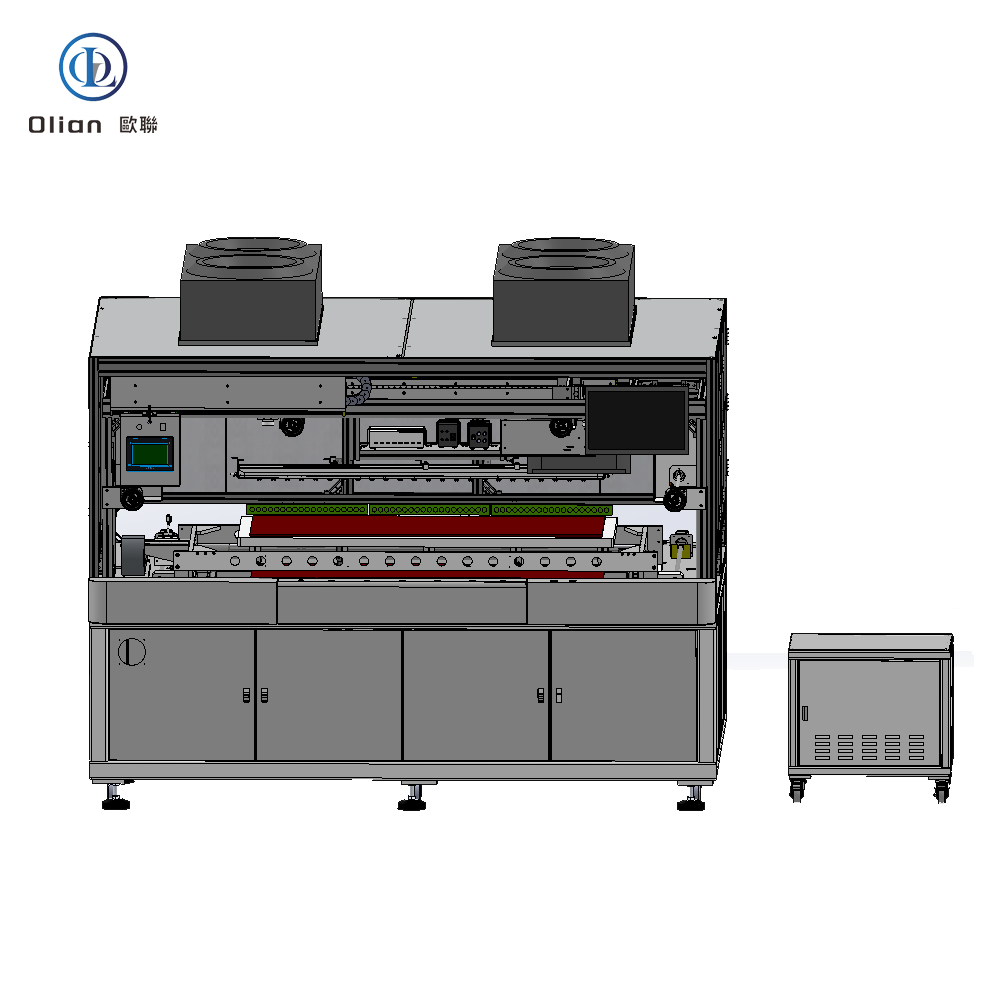

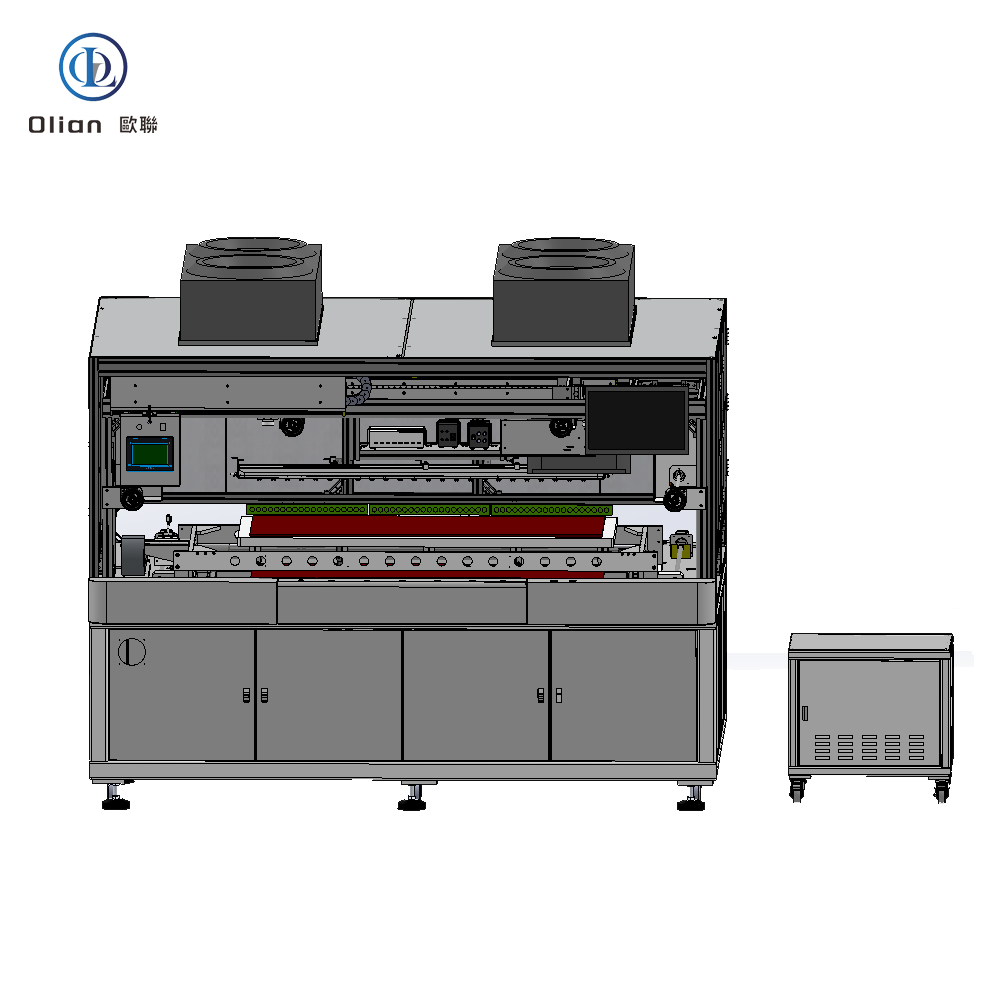

5-17.3 Inch Mid-Size LOAD/EC/COG/FOG/FPC Production Line.

Engineered for High-Mix, High-Precision Display Manufacturing

This document details Olian Automatic’s turnkey solution for mid-size display module assembly (5″–17.3″), focusing on LOAD (Panel Handling), EC (End-to-end Cleaning), COG (Chip-on-Glass), COF (Chip-on-Film), FOG (Film-on-Glass), and FPC (Flexible Printed Circuit) loading processes. Designed for rigid and flexible panel substrates, this production line integrates robotics, vision systems, and precision bonding technologies to achieve sub-micron accuracy and support high-mix production environments.

The production line follows a sequential workflow:

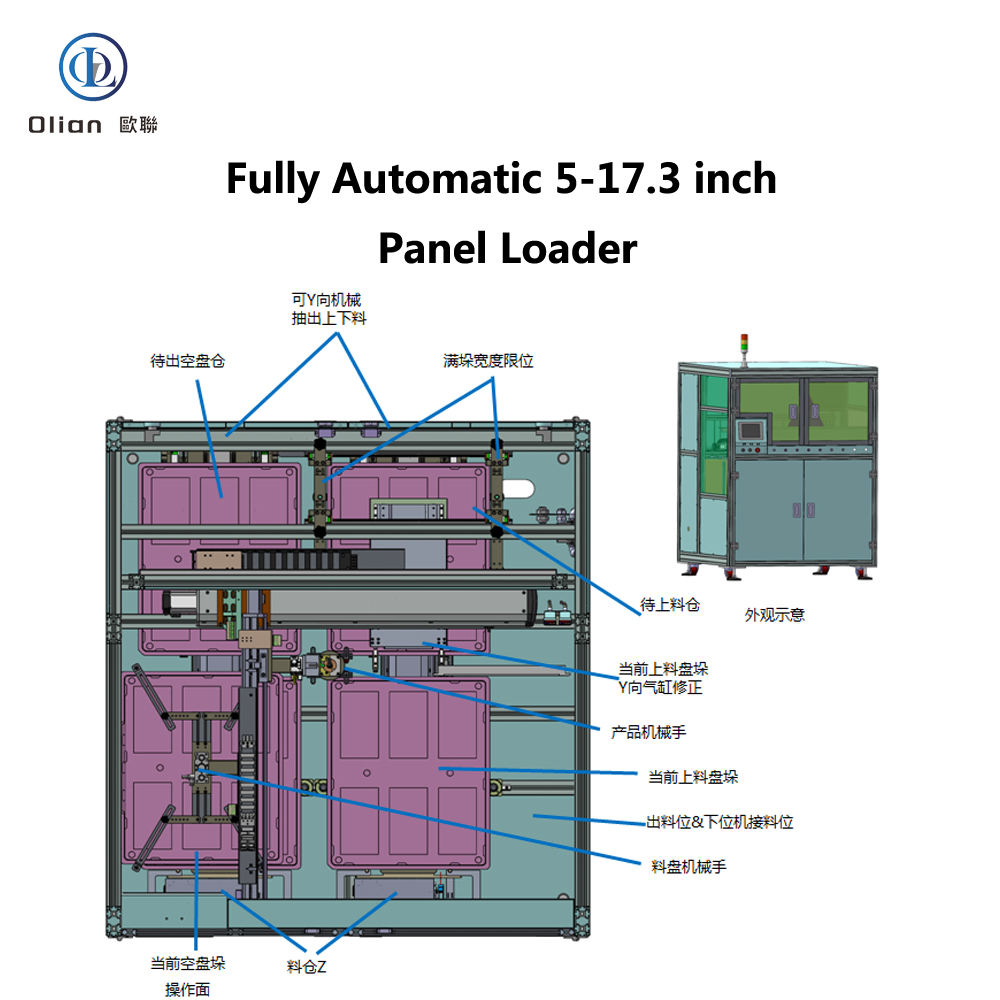

Function: Automated loading of panel trays (400×460mm max) with Y-axis pneumatic correction.

Function: Fully automated multi-edge plasma terminal cleaning.

Function: Full-process IC bonding with ACF application, pre-press, and main press.

Function: Servo-driven COF tape feeding with CCD-guided punching.

Function: FPC-to-glass bonding with Long Bar bonding heads and dual-channel FPC feeding.

Function: Dual-channel FPC feeding with tray-to-bonder transfer.

This solution targets high-mix manufacturing of:

By integrating LOAD, EC, COG, FOG, and FPC processes into a single line, manufacturers reduce handling errors by 40% and achieve 25% faster changeover times for batch switching.

The production line accommodates emerging trends:

SEO Keywords: Mid-size display production line, COG bonding machine, FOG bonding equipment, ACF application system, plasma cleaning for displays, high-precision display assembly, FPC loading system, COF punching machine.COG FOG Bonding production line.

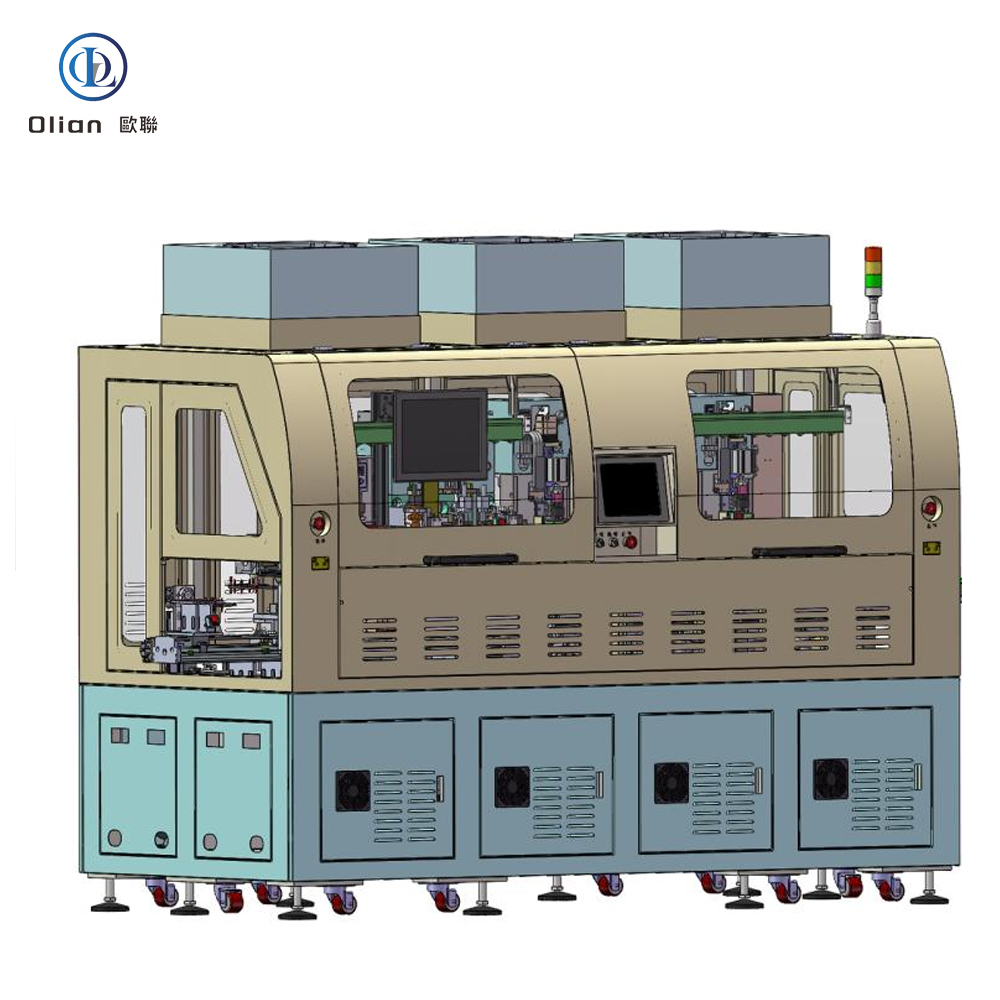

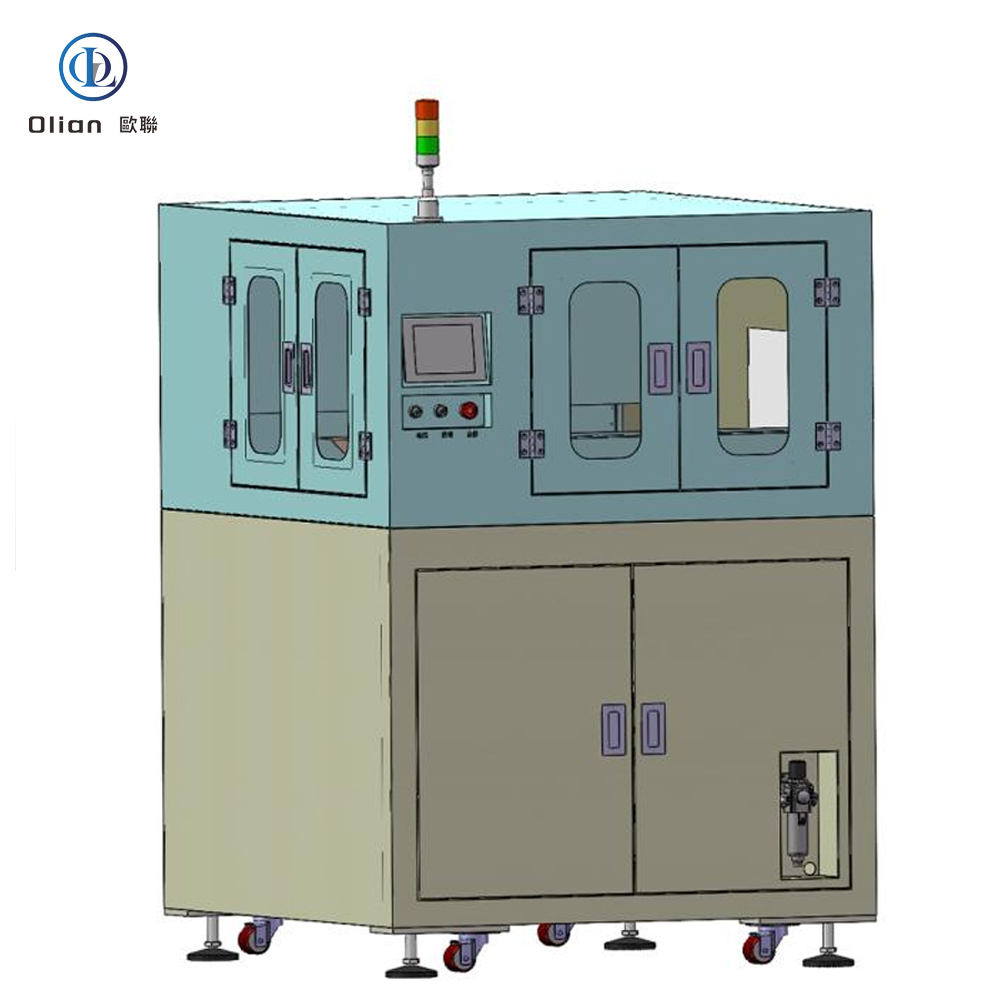

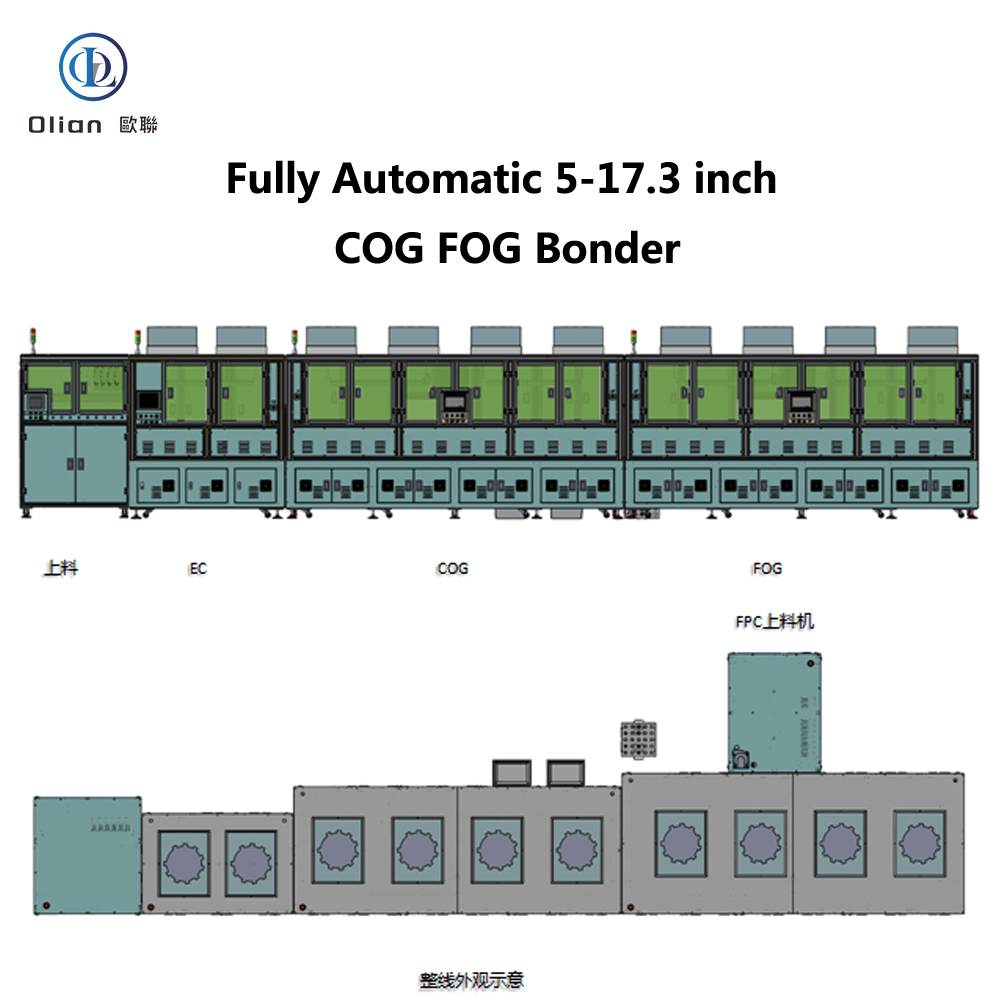

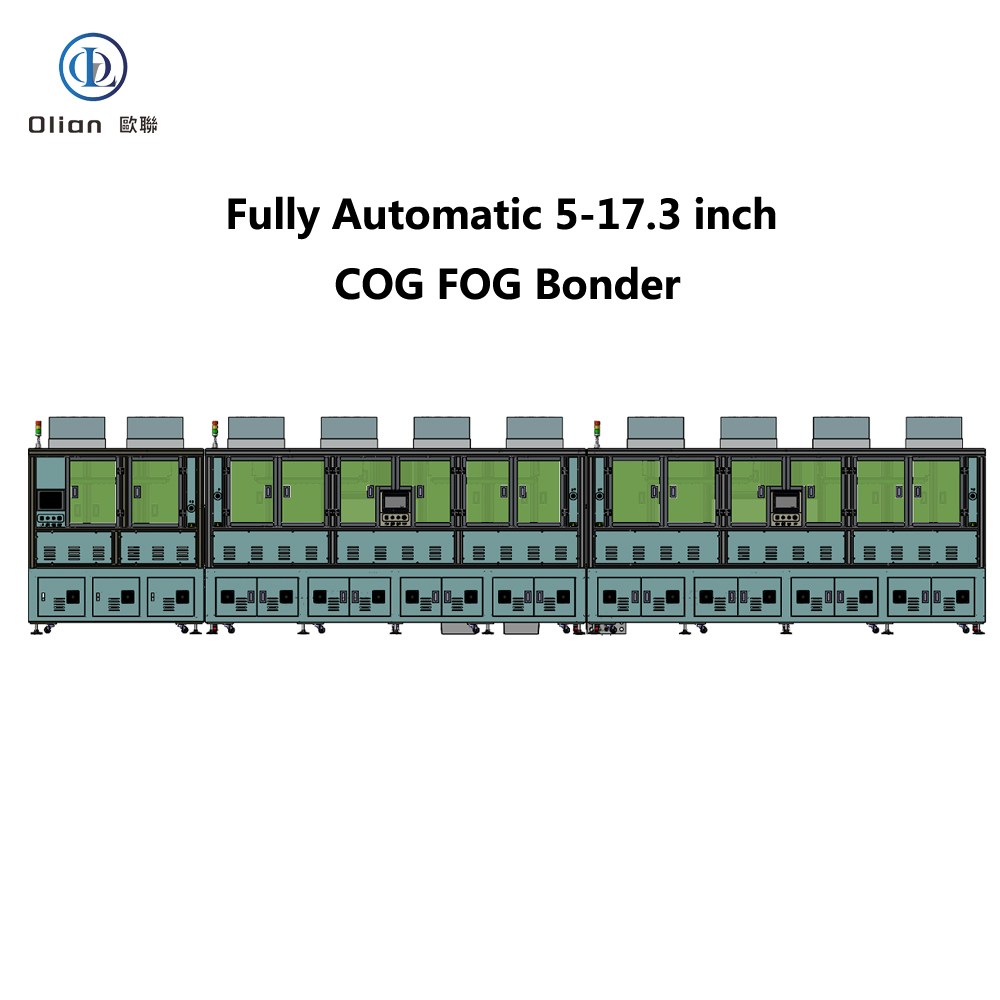

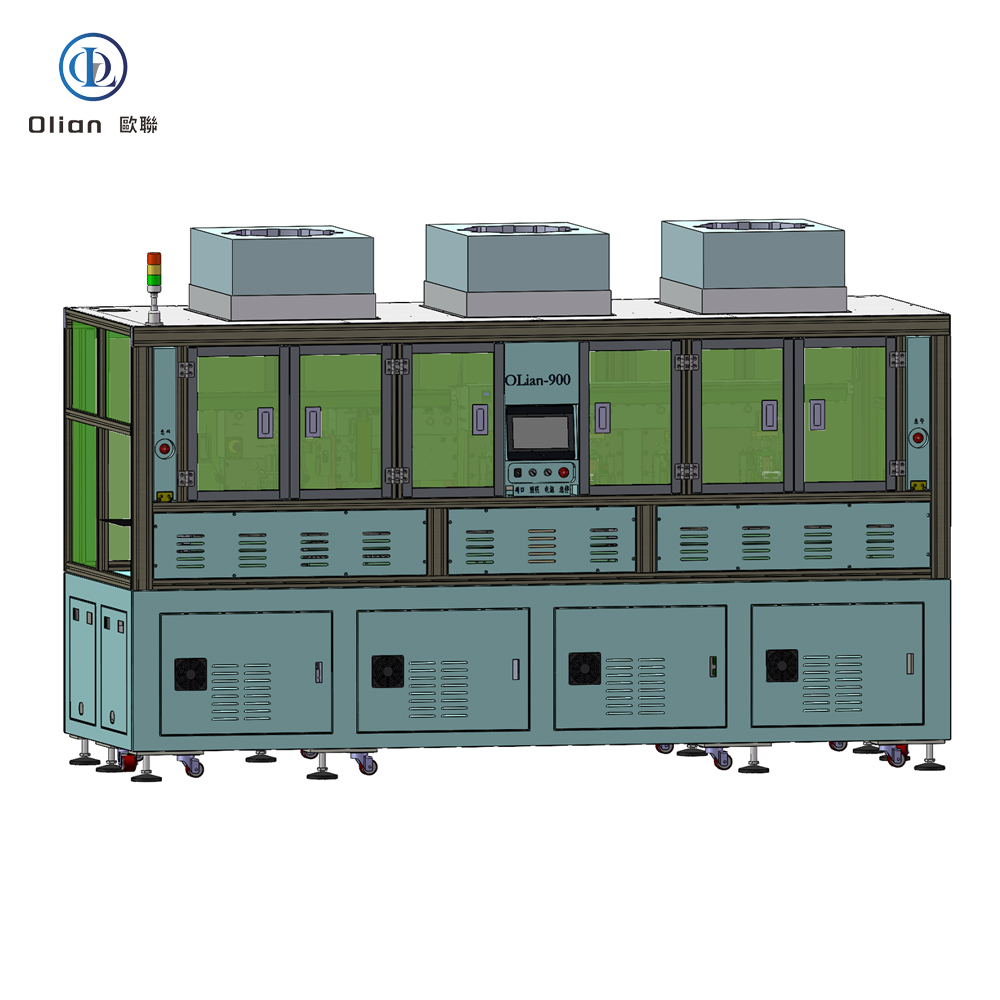

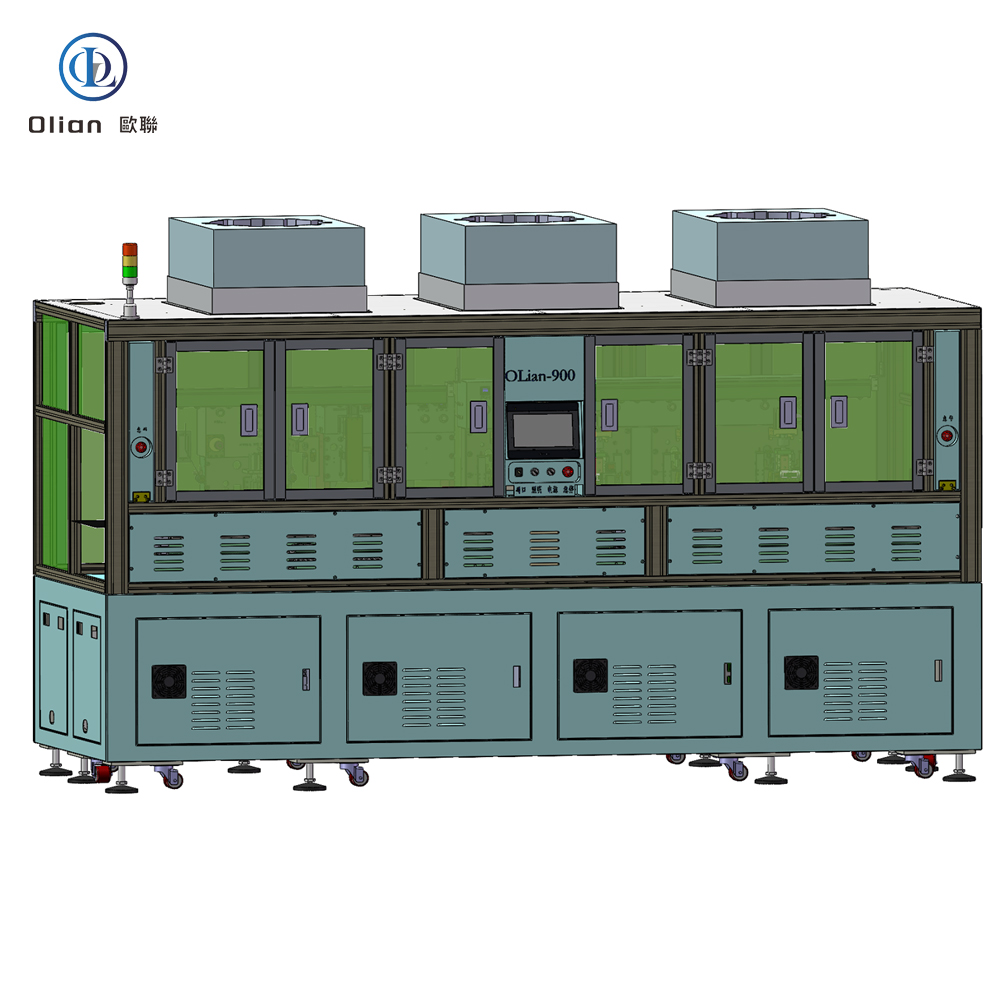

7-17 Inch Mid-Size EC/COG/FOG Production Line

Engineered for Precision, Scalability, and High-Throughput Display Manufacturing

This is automated solution for mid-size display module assembly (7″–17″), focusing on EC (End-to-end Cleaning), COG (Chip-on-Glass), and FOG (Film-on-Glass) processes. Designed for rigid panel substrates, this production line integrates advanced robotics, vision systems, and precision bonding technologies to achieve sub-micron accuracy and high-efficiency throughput.

The production line follows a sequential workflow:

Function: Automated ITO terminal cleaning for both S-side and G-side substrates.

Function: Full-process IC-to-glass bonding with ACF application, pre-press, and main press.

Function: FPC-to-glass bonding with integrated ACF application and thermal compression.

This solution targets high-volume manufacturing of:

By integrating cleaning, COG, and FOG processes into a single line, manufacturers reduce handling errors, minimize footprint, and achieve 20% faster time-to-market.

The production line accommodates emerging trends:

SEO Keywords: Mid-size display production line, COG bonding machine, FOG bonding equipment, ACF application system, plasma cleaning for displays, high-precision display assembly.

OL-3B20 Fully Automatic Particle Dent AOI Inspecting Machine,Automated Optical Inspection (AOI) systems

High-Speed Dual-Side Inspection for 5–17.6″ Displays

Ideal for manufacturers of:

AOI,AOI MACHINE, AOI INSPECTION MACHINE, AOI INSPECTING MACHINE,OL-3B20, particle dent detection machine, conductive particle analyzer, FOG defect detector, COG inspection system, Olian Automaic, display module testing, glass-to-film bonding inspection, high-speed lamination checker, industrial display quality control, China automation equipment, cleanroom-compatible inspector, precision defect detection, display production line, OLB quality tester, FOB inspection solution, reliable particle counter, high-yield display manufacturing.Automated Optical Inspection (AOI) systems

OL-3A20 Fully Automatic Particle Dent Detection Machine

High-Speed Inspection for 0.96–10.1″ Displays

Ideal for manufacturers of:

AOI,AOI machine,AOI inspection machine, AOI inspecting machine,OL-3A20, particle dent detection machine, conductive particle analyzer, FOG defect detector, COG inspection system, Olian Automaic, display module testing, glass-to-film bonding inspection, high-speed lamination checker, industrial display quality control, China automation equipment, cleanroom-compatible inspector, precision defect detection, display production line, OLB quality tester, FOB inspection solution, reliable particle counter, high-yield display manufacturing.

OL-WB650 Automatic Mesh Plate Laminating Machine

High-Precision Lamination for 65-Inch Displays

Ideal for manufacturers of:

OL-WB650, mesh plate laminating machine, 65-inch display laminator, 4CCD alignment laminator, G+F lamination equipment, automatic roller laminator, Olian Automaic, display module assembly, glass-to-film bonding, precision lamination system, touch panel equipment, soft-hard material laminator, industrial display machinery, China automation equipment, cleanroom-compatible laminator, high-yield display manufacturing, display production line, optical film bonder,

OL-FBM037 Flip-Board Mounting Machine

High-Precision Semi-Automatic Mounting for Medium-to-Large Displays

Ideal for manufacturers of:

OL-FBM037, flip-board mounting machine, semi-automatic FPC mounter, 32-inch display equipment, precision mounting system, Olian Automaic, display module assembly, glass-to-film bonding, FPC bonding machine, COF mounting solution, industrial display machinery, China automation equipment, cleanroom-compatible mounter, high-yield display manufacturing, display production line, UVW alignment system, servo-driven mounter, thermocompression bonding, manual loading machine, reliable mounting solution.

OL-WB215A Automatic 4CCD Mesh Plate Laminating Machine

High-Precision Lamination for 21.5-Inch Displays

Ideal for manufacturers of:

OL-WB215A, mesh plate laminating machine, 21.5-inch display laminator, 4CCD alignment laminator, G+F lamination equipment, automatic roller laminator, Olian Automaic, display module assembly, glass-to-film bonding, precision lamination system, touch panel equipment, soft-hard material laminator, industrial display machinery, China automation equipment, cleanroom-compatible laminator, high-yield display manufacturing, display production line, optical film laminator,

OL-FS120 Single-Station Servo-Driven FOG Bonder

High-Precision Manual FOG Bonding for 120-Inch Displays

Ideal for manufacturers of ultra-large LCD/OLED panels, including:

FOG bonding machine,FOG bonder,COF bonder ,COF bonding machine,OL-FS120, single-station FOG bonder, 120-inch display equipment, servo-driven heat press, FPC bonding machine, thermocompression bonding system, large-format display assembler, Olian Automaic, manual FOG bonder, high-precision alignment bonder, flat panel display equipment, constant-temperature bonder, display module assembly, glass-to-film bonding, industrial display machinery, China automation equipment, reliable FOG bonder, cleanroom-compatible bonder, high-yield display manufacturing, display production line, precision display assembler.

OL-OLB120-T Single-Side Multi-Section OLB Bonder

High-Efficiency Semi-Automatic Heat Press for Large-Format Displays

Ideal for manufacturers of ultra-large LCD/OLED panels, including:

OLB bonder,COF bonder,COF bonding machine, OL-OLB120-T, single-side OLB bonder, 120-inch display equipment, semi-automatic heat press, COF bonding machine, thermocompression bonding system, large-format display assembler, Olian Automaic, FOG bonding solution, high-precision alignment bonder, flat panel display equipment, manual thermocompression bonder, display module assembly, glass-to-film bonding, industrial display machinery, China automation equipment, reliable OLB bonder, cleanroom-compatible bonder, high-yield display manufacturing, display production line, OLB bonding machine, precision display assembler.