In the modern electronics repair industry, having the right tools and machines is crucial for efficiently repairing and refurbishing LCD and LED screens, especially for TVs and other large displays. Our company offers a wide range of advanced repair machines and bonding equipment designed to meet the diverse needs of professionals in this field. Whether you are repairing LCD TVs, smartphones, or other display devices, our products are designed to provide high precision, reliability, and efficiency.

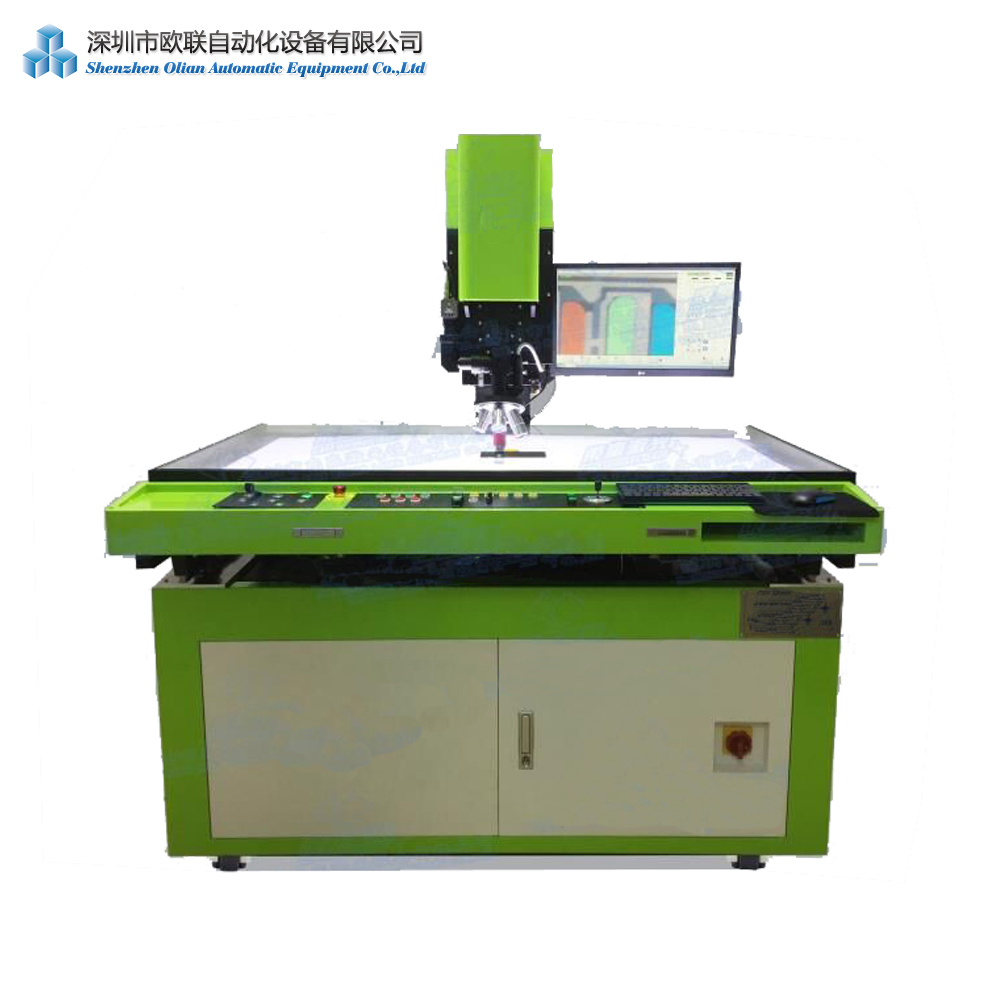

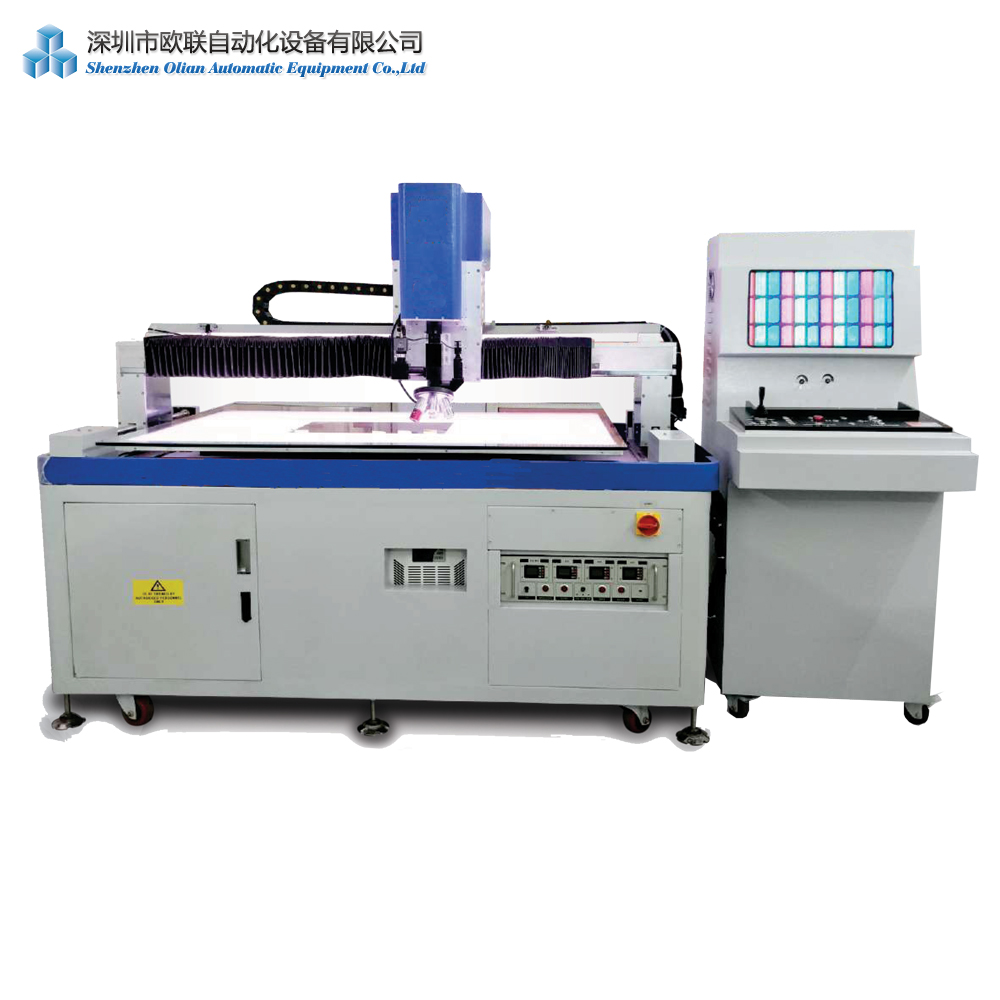

Our LCD screen laser repair machines are designed to efficiently repair a variety of defects in LCD panels, including vertical lines, horizontal lines, black screens, and more. These machines use high-frequency pulse laser beams to cut and trim micron-sized semiconductor circuit components, especially passivation layers (silicon oxide/nitride) and metal interconnects

They are suitable for repairing LCD screens in TVs, PCs, touch teaching machines, splicing screens, notebooks, digital devices, and car displays

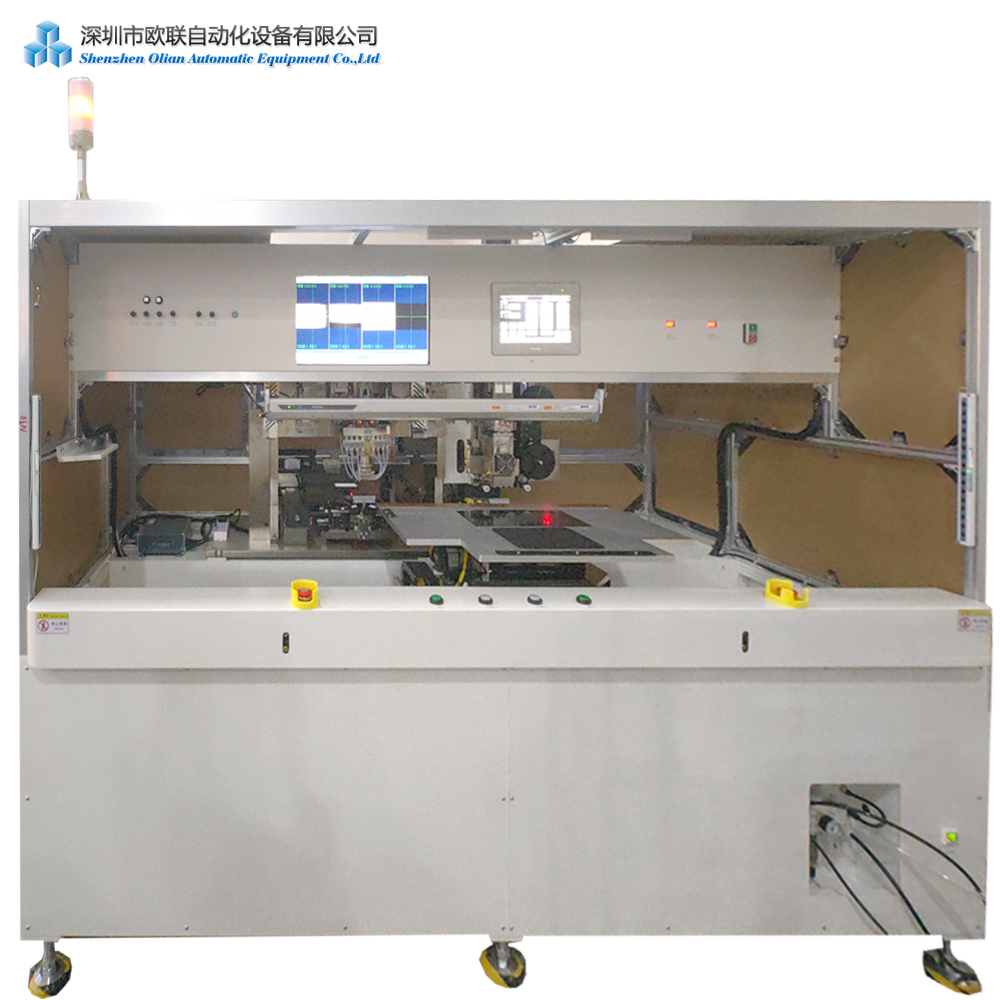

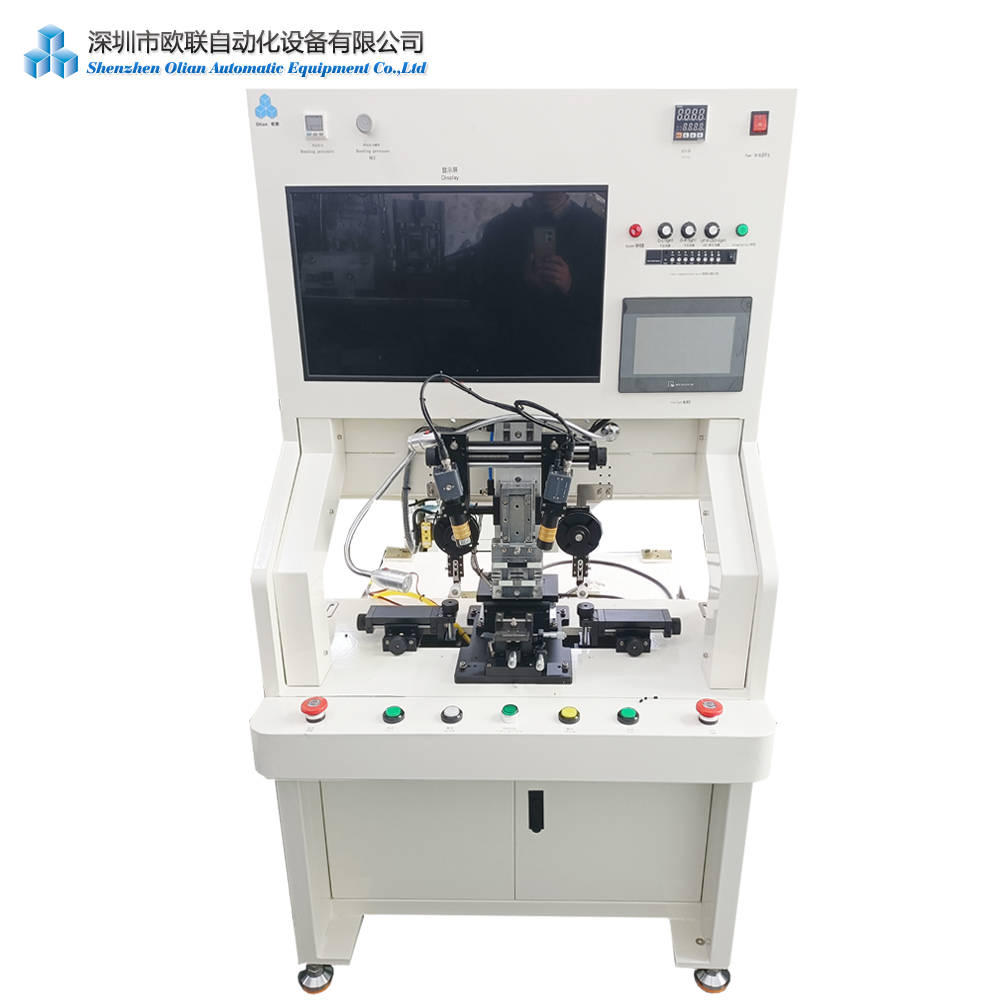

Our COF (Chip-On-Film) bonding machines are essential for repairing and assembling LCD and LED panels. These machines are used to bond integrated circuits (ICs) to flexible film substrates, enabling compact designs and high-resolution displays

They are widely used in the repair and manufacturing of TVs, laptops, mobile phones, and tablets

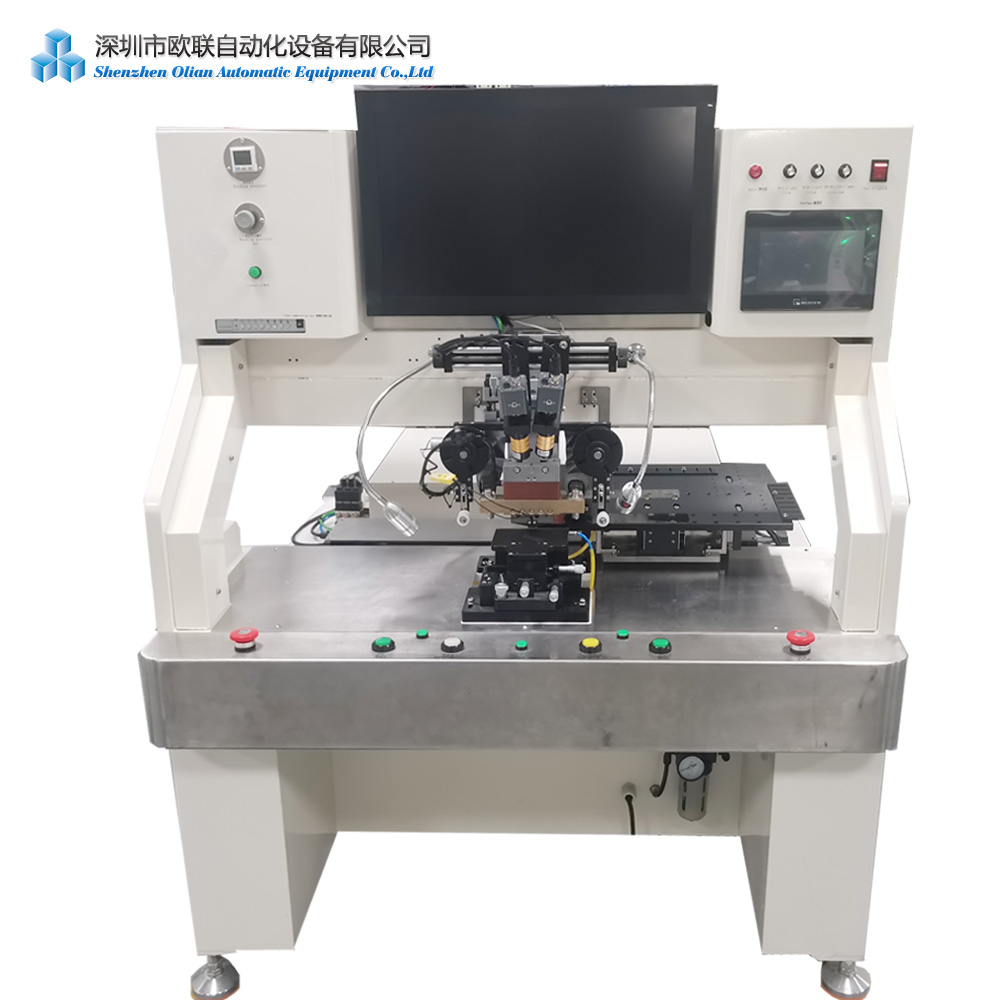

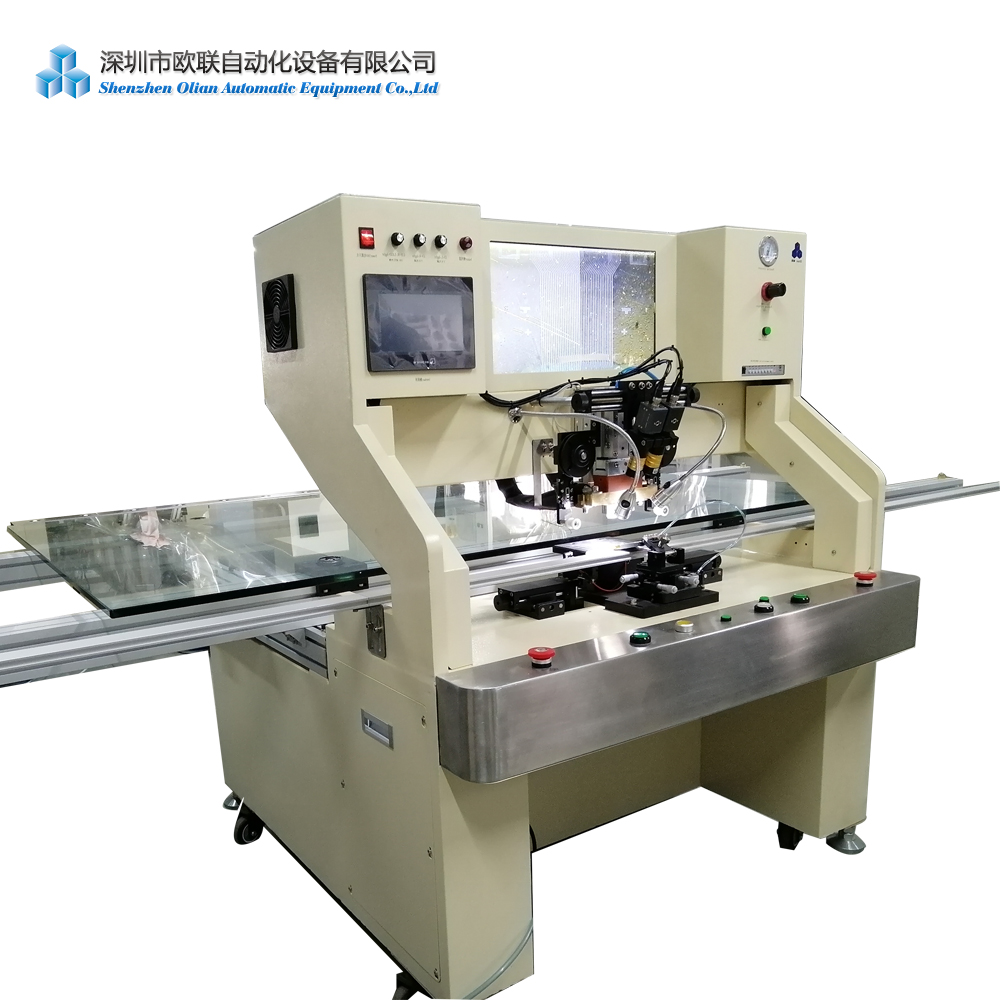

Our FOB (FPC on Board) and FOG (FPC on Glass) bonding machines are designed for bonding flexible printed circuits (FPCs) to PCBs and glass substrates. These machines offer high precision and reliability, making them ideal for applications requiring flexible and compact designs

Our hot bar pressing machines are designed for soldering FPCs, PCBs, LED displays, and other electronic components. These machines use pulse heating technology to achieve accurate temperature control, making them suitable for temperature-critical applications

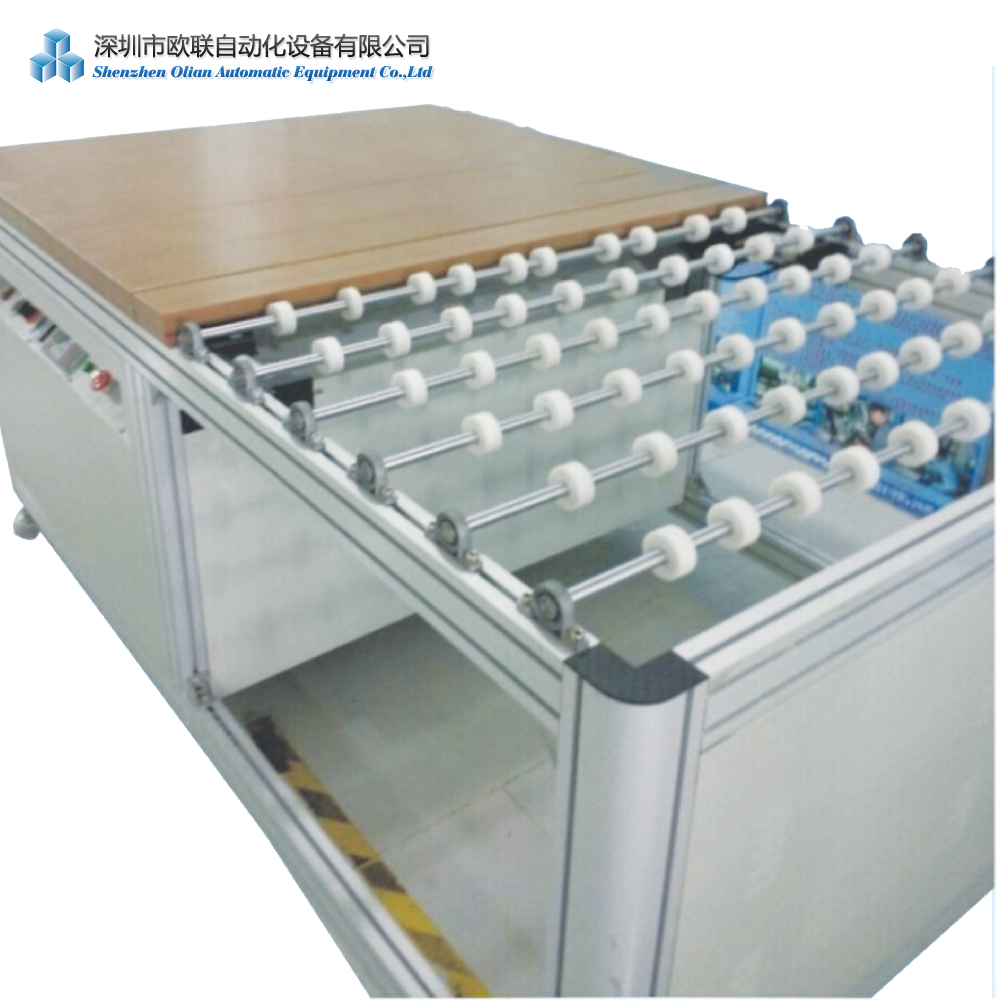

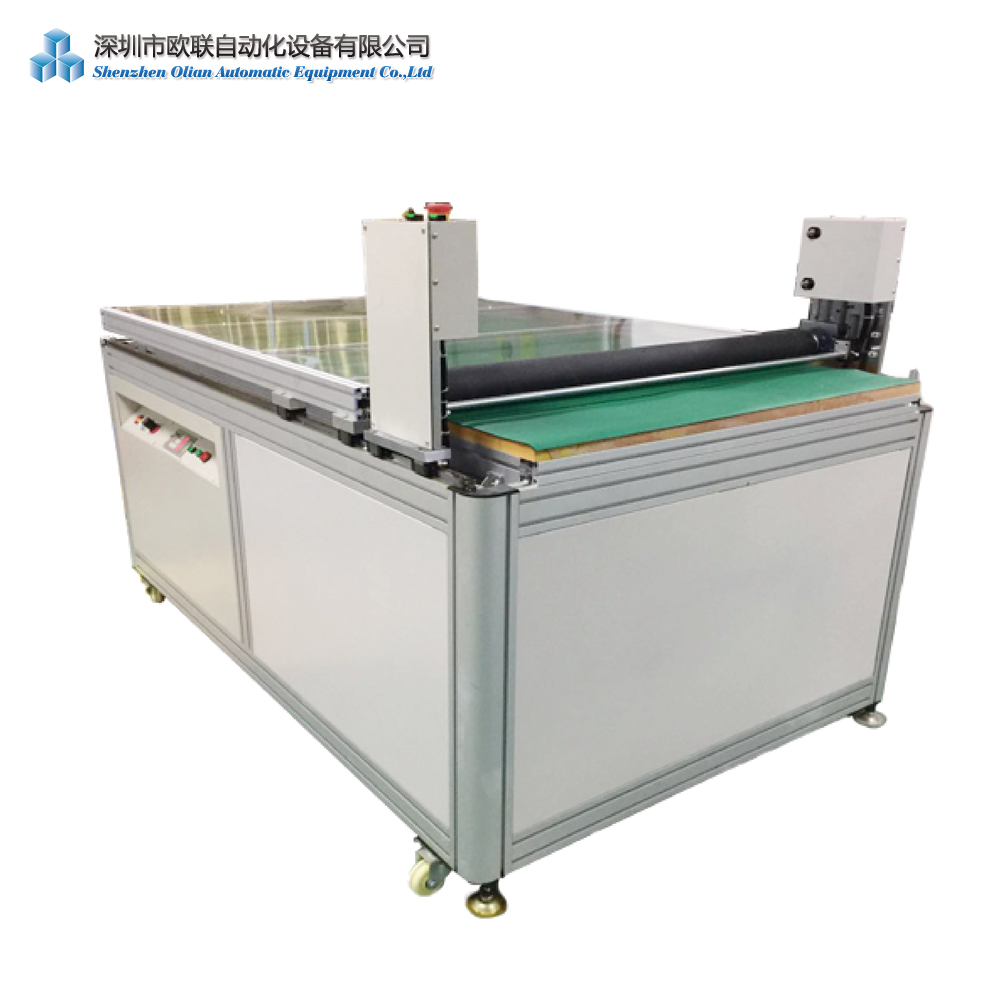

Our LCD panel rework and repair equipment includes a variety of machines designed to refurbish and repair LCD panels. These machines are capable of repairing a wide range of defects, including vertical and horizontal lines, black screens, and more

Our products are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key reasons to choose our products include:

Whether you are repairing LCD TVs, smartphones, or other display devices, our comprehensive range of repair machines and bonding equipment is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality repairs and efficient production processes. Contact us today to find the perfect solution for your application.