COF Bonding Machines Precision Engineering for Modern Display Manufacturing.

In the rapidly evolving world of display technology, the COF bonding machine (Chip-on-Film bonding equipment) stands as a cornerstone for high-precision assembly in OLED, LCD, and emerging flexible display production. This comprehensive guide explores the working principles, industrial applications, maintenance best practices, and future trends of COF bonding machines, empowering manufacturers to optimize yield, reliability, and innovation.

COF bonding machines enable the integration of driver ICs onto flexible film substrates (COF), which are then bonded to display panels (e.g., glass or plastic substrates). The process relies on three core technologies:

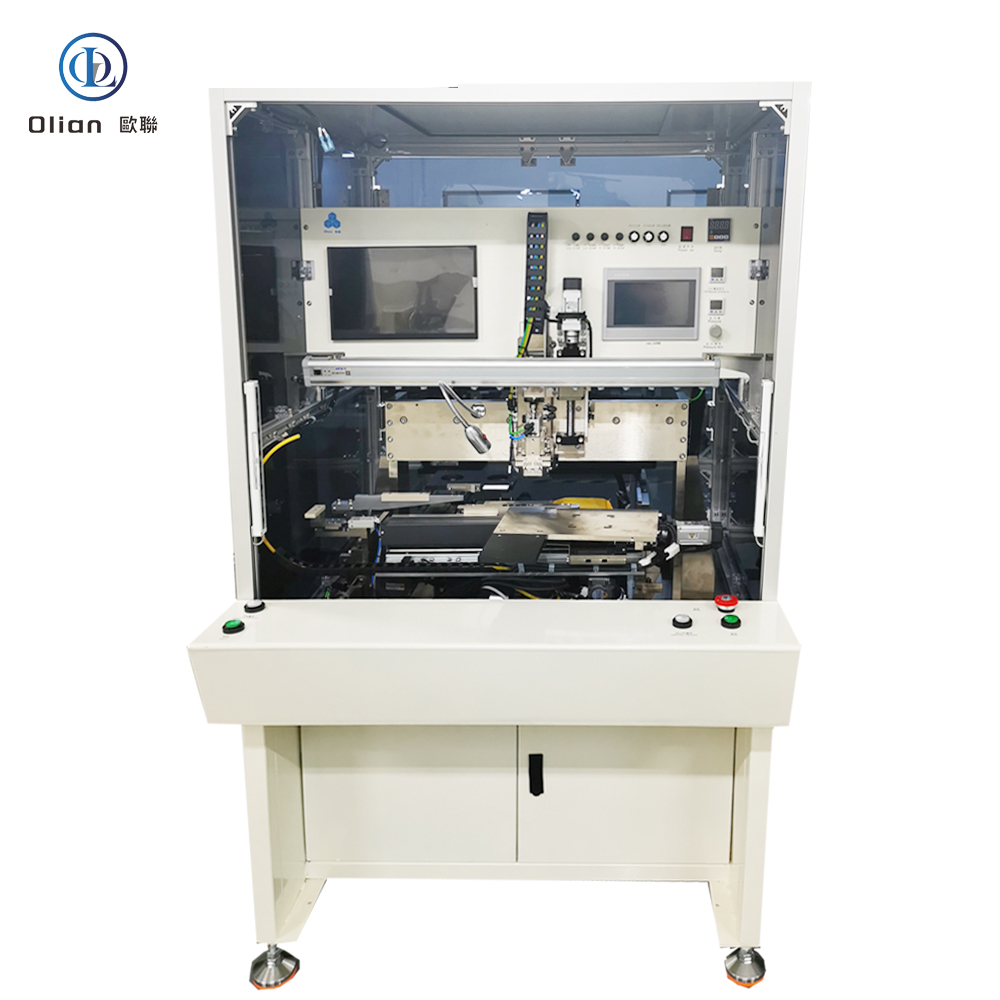

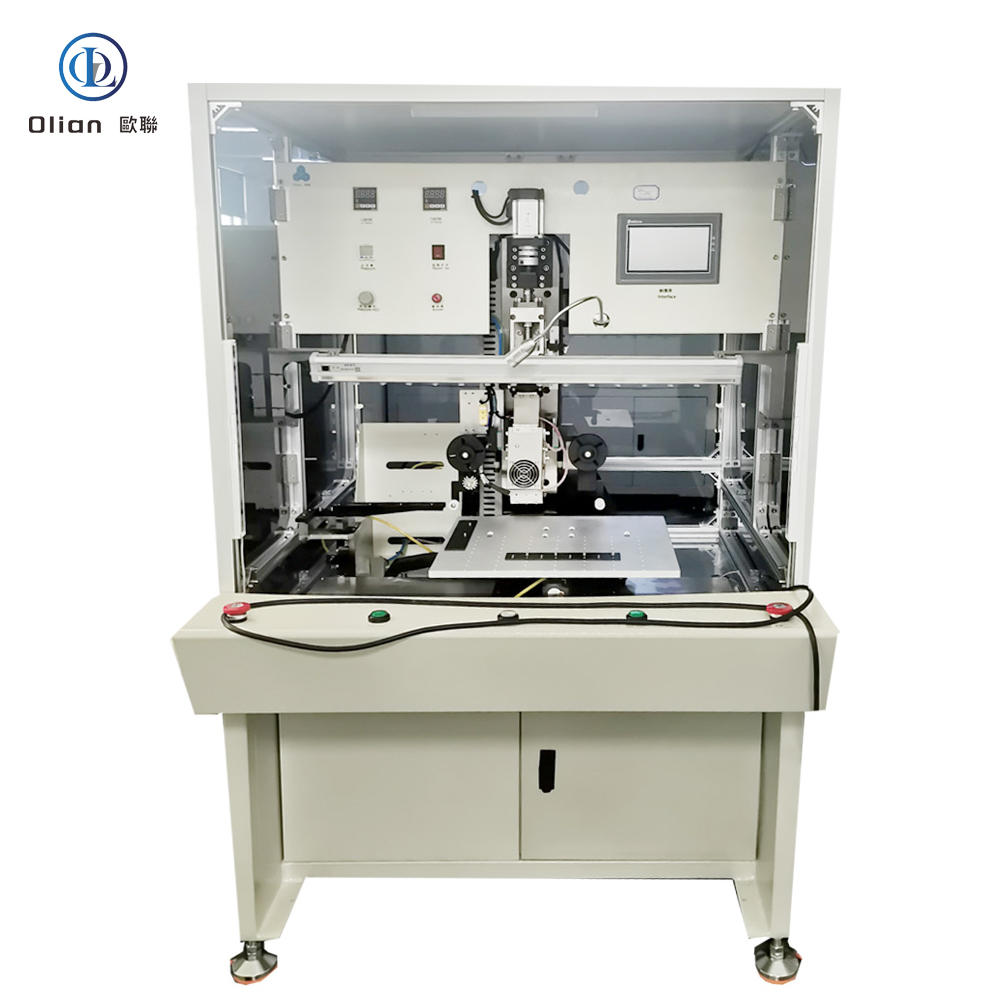

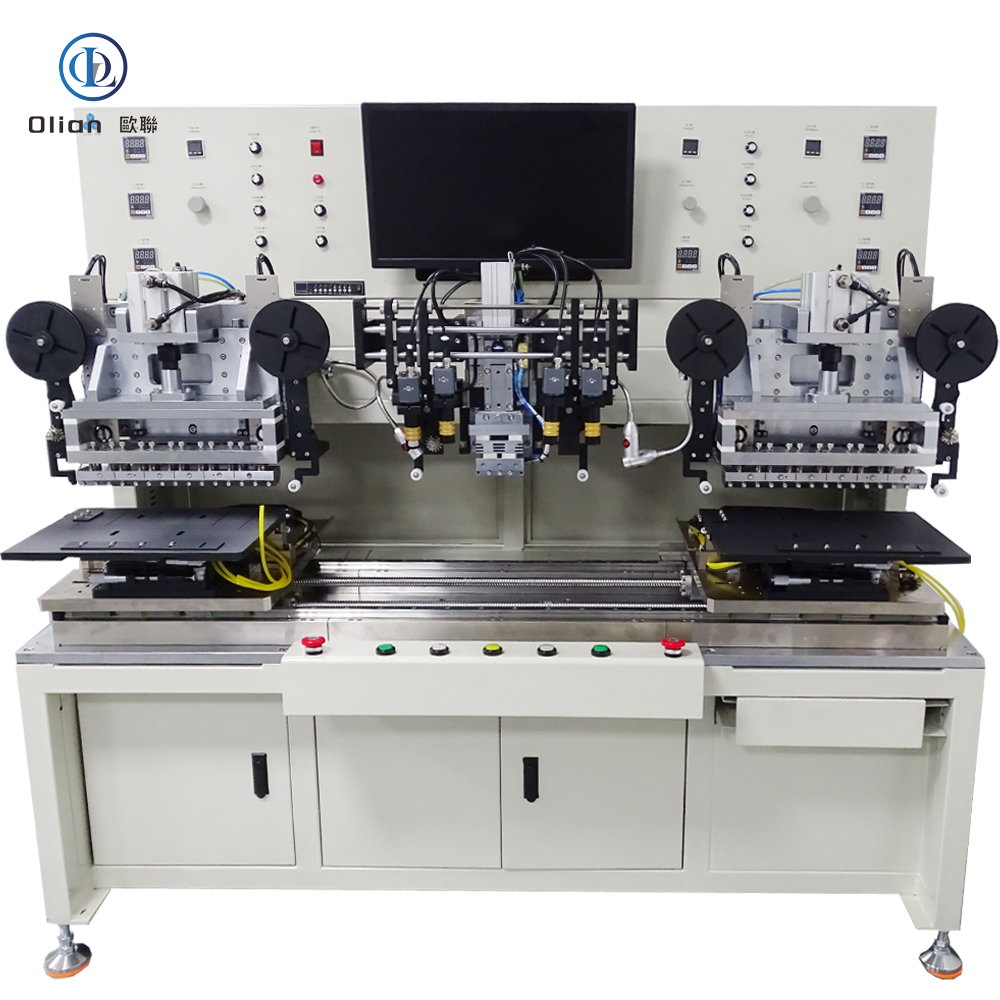

A heated bonding tip applies precise temperature (typically 350–450°C) and pressure (0.2–0.8 MPa) to create electrical and mechanical connections between the IC bumps (e.g., gold or solder) and the panel’s electrodes. Advanced machines use pulse-heating technology with ±0.1°C temperature uniformity to prevent thermal damage to sensitive components.

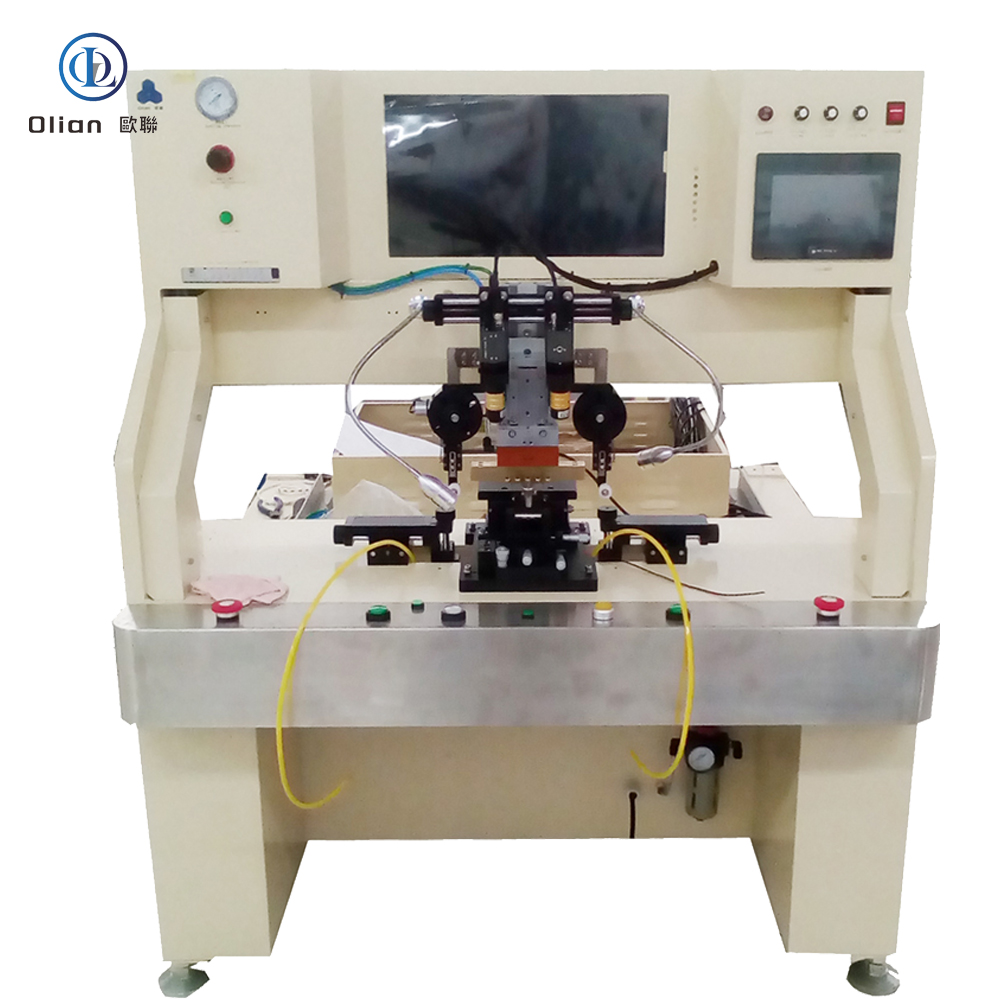

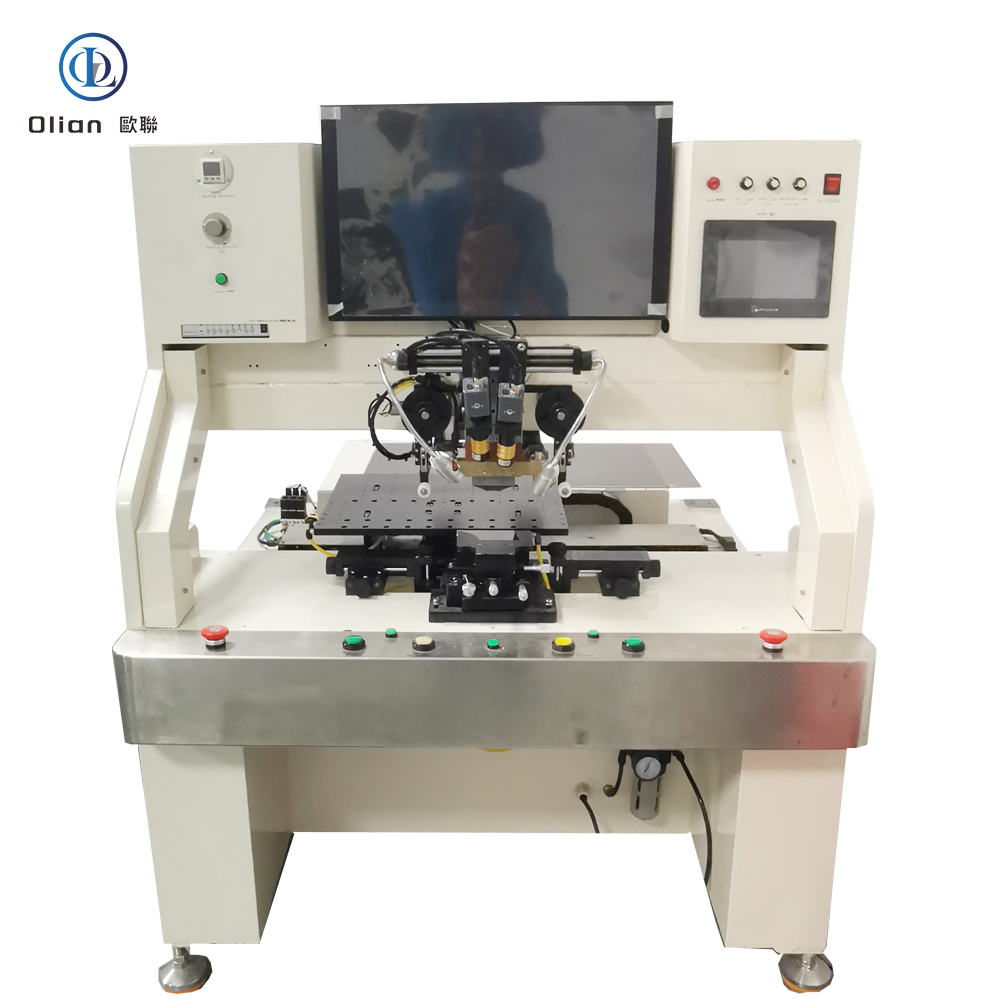

High-resolution CCD cameras and AI-powered image processing enable sub-micron alignment accuracy (±0.05 mm). This ensures perfect registration between the COF’s IC pads and the display’s electrode patterns, critical for high-resolution screens.

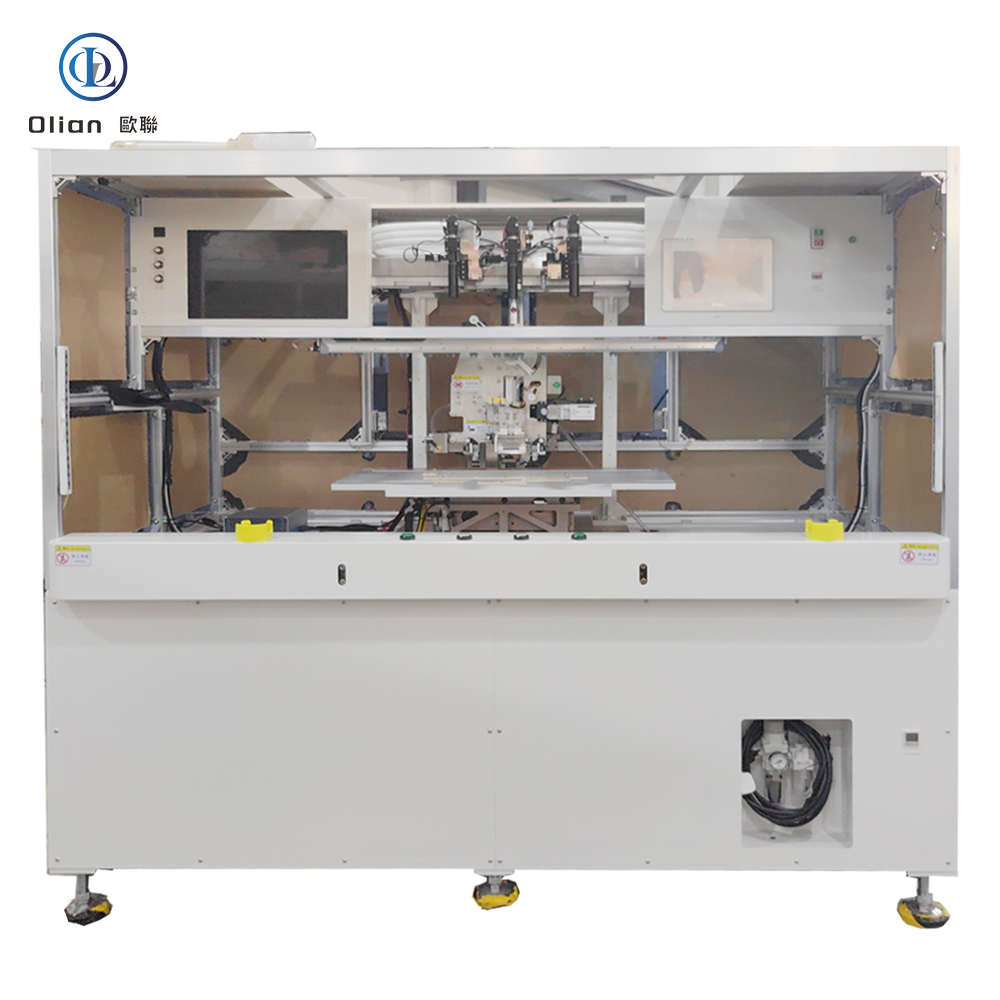

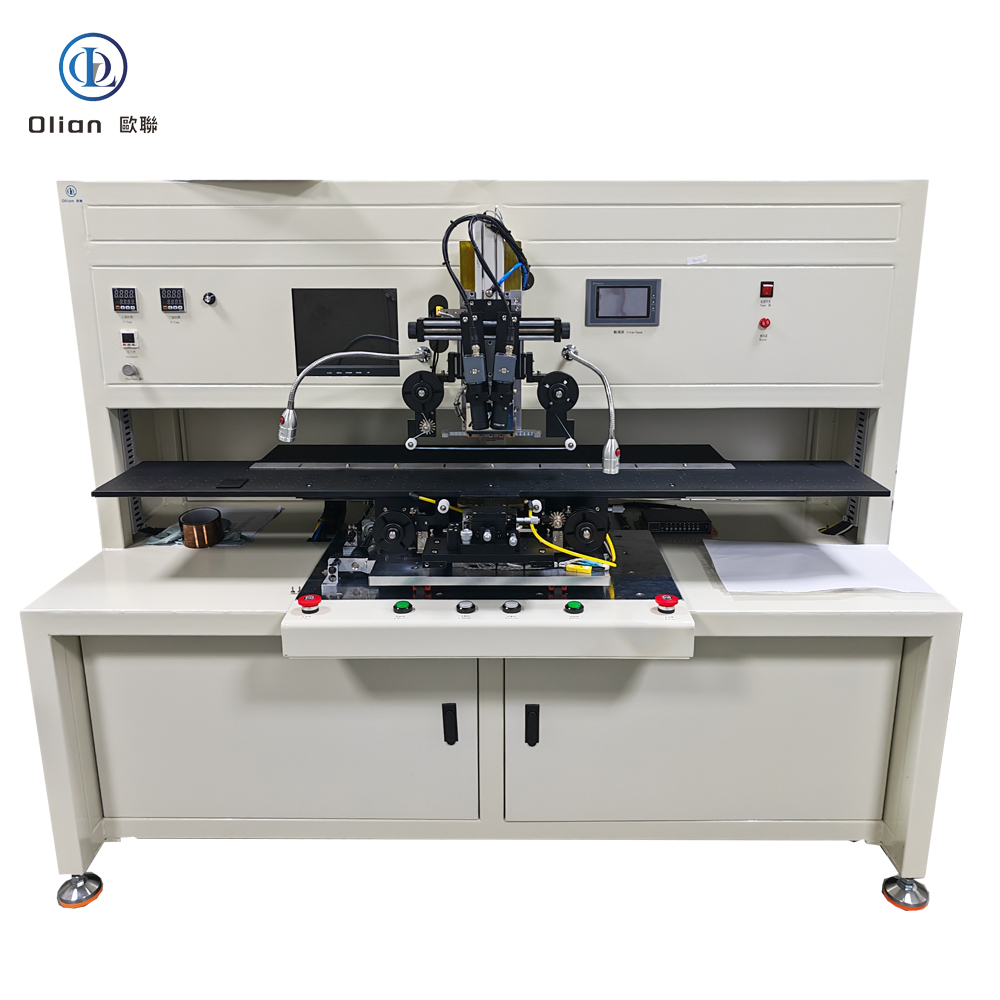

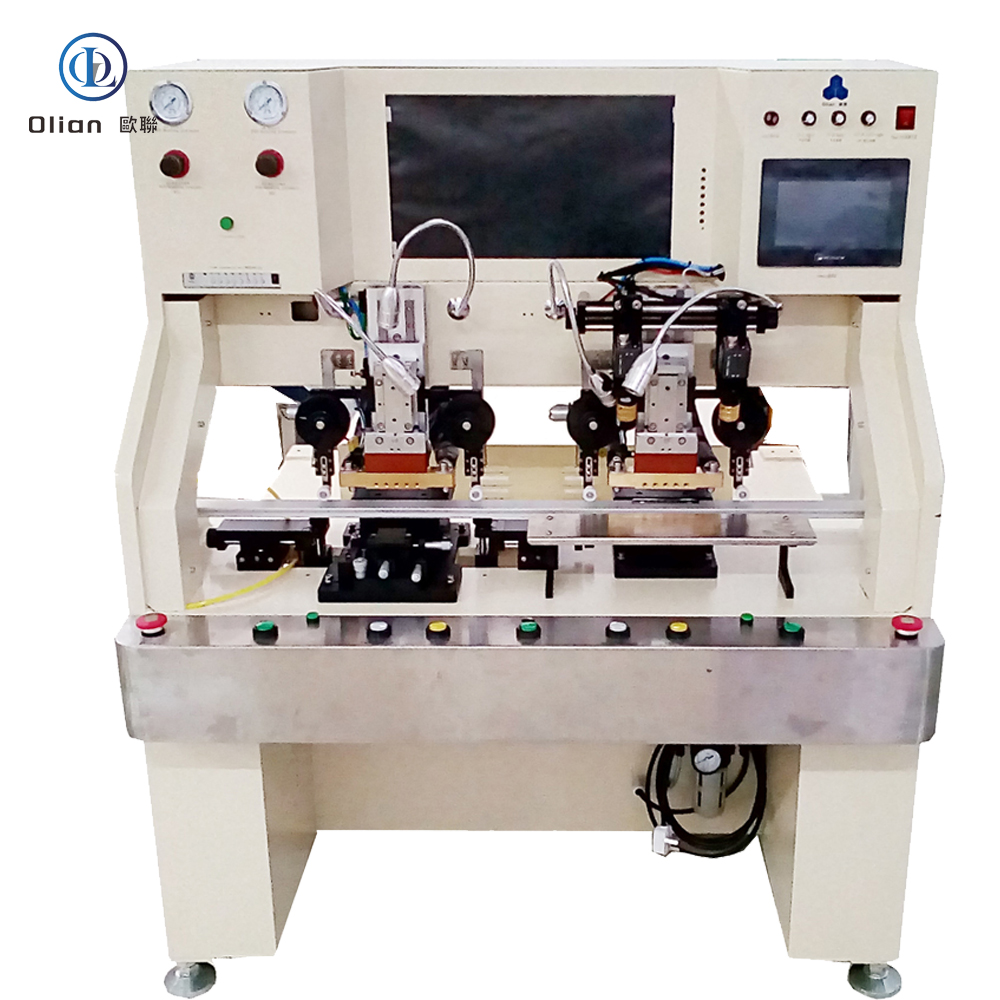

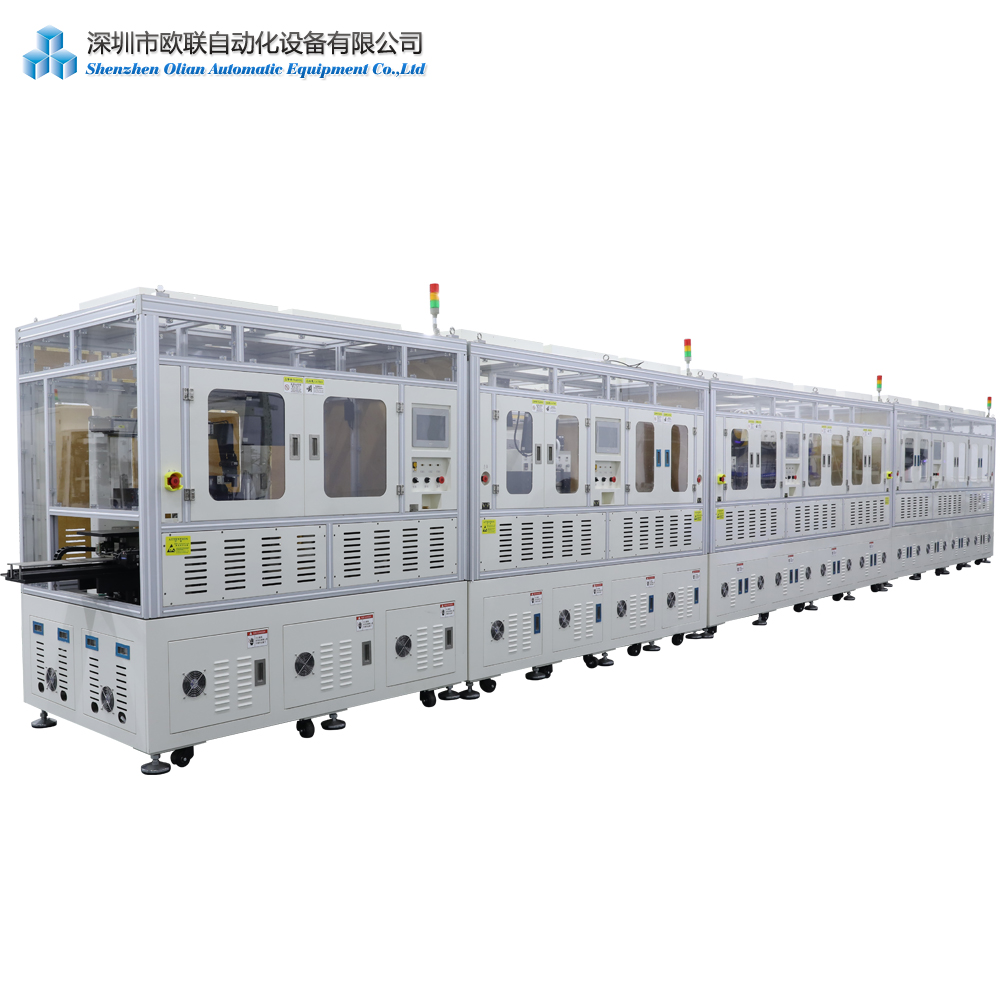

Modern COF bonders feature dual-stage worktables, allowing simultaneous pre-bonding (alignment) and main bonding (compression). This parallel processing boosts throughput to 600–1,200 units per hour, meeting mass-production demands.

For curved or foldable OLED panels, COF bonding machines handle flexible PCBs (FPCs) with minimal warpage. Adaptive pressure control (0.2–0.8 MPa) and anti-static designs prevent damage to delicate organic materials.

In harsh environments (85°C/85% humidity), COF bonding ensures long-term reliability. Features like ACF (Anisotropic Conductive Film) auto-cutting improve moisture resistance, extending module lifespan to over 10,000 hours.

High-density Mini LED arrays require precise bonding of 128+ driver ICs. Modular bonding heads enable multi-zone simultaneous processing, reducing cycle times by 30%.

Ultra-narrow bezel designs demand COF bonding with <0.1 mm pitch accuracy. Machines with nano-positioning stages (e.g., piezoelectric actuators) achieve this, enabling “borderless” displays.

Proactive maintenance prevents costly downtime. Key strategies include:

Misalignment greater than 0.1 mm is often caused by vision system calibration drift and can be corrected by recalibrating using PV310 alignment tools. A high void rate exceeding 5% typically results from non-uniform tip temperature, which can be addressed by replacing the tungsten-carbide heater and optimizing finite element method (FEM) parameters. ACF film jams are usually due to vacuum suction failure and can be prevented by cleaning or replacing vacuum nozzles on a regular basis.

It is recommended to clean CCD lenses and laser sensors daily to prevent dust-induced errors. Pressure sensors should be calibrated monthly within the 0.2–0.8 MPa range to ensure linearity error remains below 1%. Additionally, inspecting bonding tip wear and replacing it if surface roughness exceeds 0.5 µm should be performed quarterly.

The next generation of COF bonding machines will integrate:

Thermal imaging sensors combined with machine learning models, such as BERT, analyze vibration spectra to predict bonding defects up to 24 hours in advance, reducing scrap rates by 40%.

AI algorithms, including reinforcement learning, automatically tune temperature and pressure curves based on real-time yield data, cutting setup time by 30%.

As AR/VR displays demand pixel pitches under 10 µm, COF bonders will adopt laser-assisted alignment and atomic-force microscopy (AFM) feedback for nanometer-scale precision.

Mastering COF bonding machine technology is no longer optional—it’s a competitive necessity. By understanding core principles, implementing rigorous maintenance, and embracing AI-driven innovation, manufacturers can achieve:

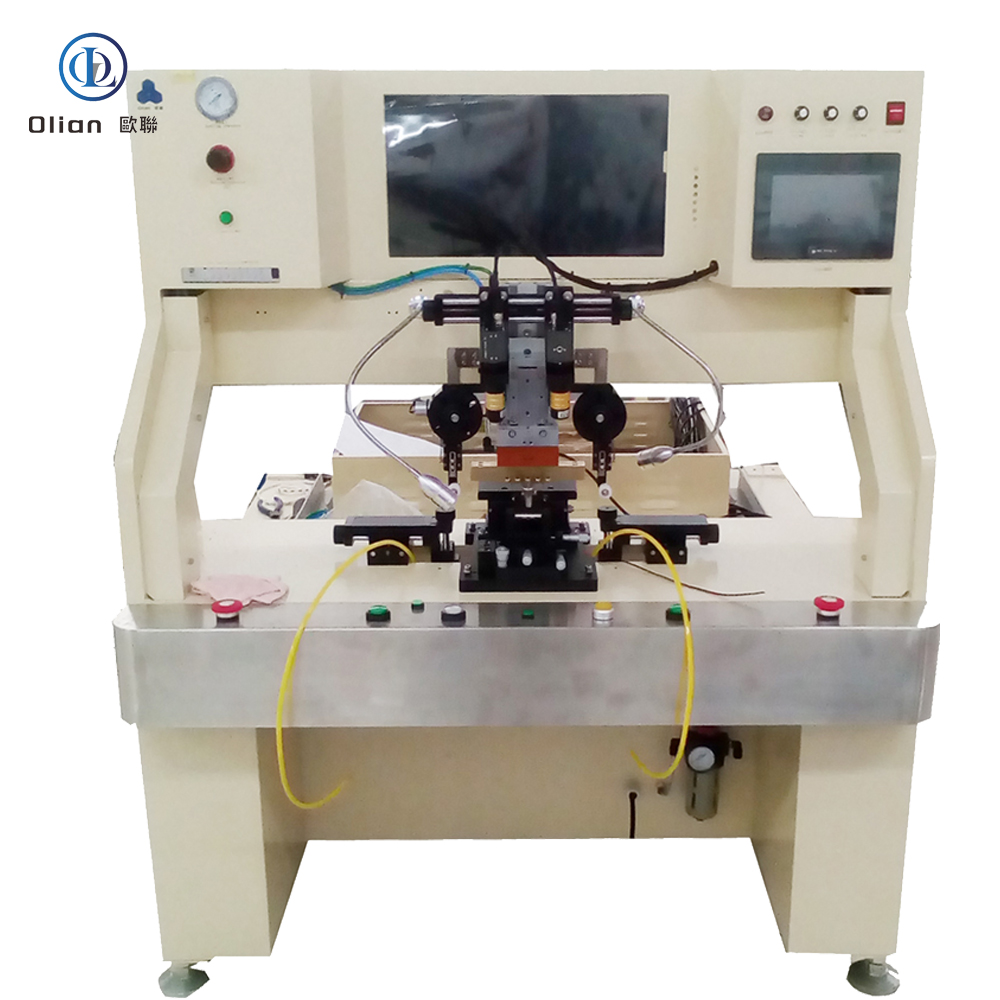

A manual COF bonding machine—often marketed as a manual Chip-On-Film bonder, manual COF ACF press, or hand-operated COF repair unit—is the bench-top heart that repairs or prototypes flexible display drivers by manually aligning and bonding a Chip-On-Film (COF) tail onto glass, PCB, or another flex using anisotropic conductive film (ACF) and operator-controlled heat plus pressure. Every smartphone OLED repair, foldable hinge prototype, and 8-K TV source driver rework you touch has passed through such a bench. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “manual COF bonding machine”, “manual COF bonder”, “hand-operated COF ACF press”, “manual COF repair unit”, and every high-value permutation.

Cycle time: 6–10 s (operator dependent), throughput: 600–3,000 UPH .

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation .

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET .

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Operator Interface: 15-inch touch HMI, joystick jog, one-button lock, recipe encryption.

According to industry analysis, the global manual COF bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

manual cof bonding machine, manual COF bonder, hand-operated COF ACF press, manual COF repair unit, manual COF bonding machine 1 micron accuracy, 200 °C manual temperature, 1 MPa manual force, vertical conduction horizontal insulation, lead-free manual bonding, ROHS compliant manual bonding, foldable phone manual COF bonder, 8-K TV manual COF bonding machine, automotive display manual COF bonder, medical device manual COF bonding machine, roll-to-roll manual COF bonder, 3,000 UPH manual COF bonding machine, 99.9 % yield manual COF bonder, Industry 4.0 manual COF bonding machine, AI predictive maintenance manual COF bonder, remote diagnostics manual COF bonding machine, cloud dashboard manual COF bonder, granite base manual COF bonding machine, servo motor manual COF bonder, voice-coil actuator manual COF bonding machine, telecentric lens manual COF bonder, real-time Linux manual COF bonding machine, OPC-UA manual COF bonder,

A manual COF bonding machine is no longer a manual hot-plate—it is the flexible, AI-driven, cloud-connected gateway that turns operator skill into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these benches deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process and your Google search ranking for the next decade .