- Home

- About us

- Products

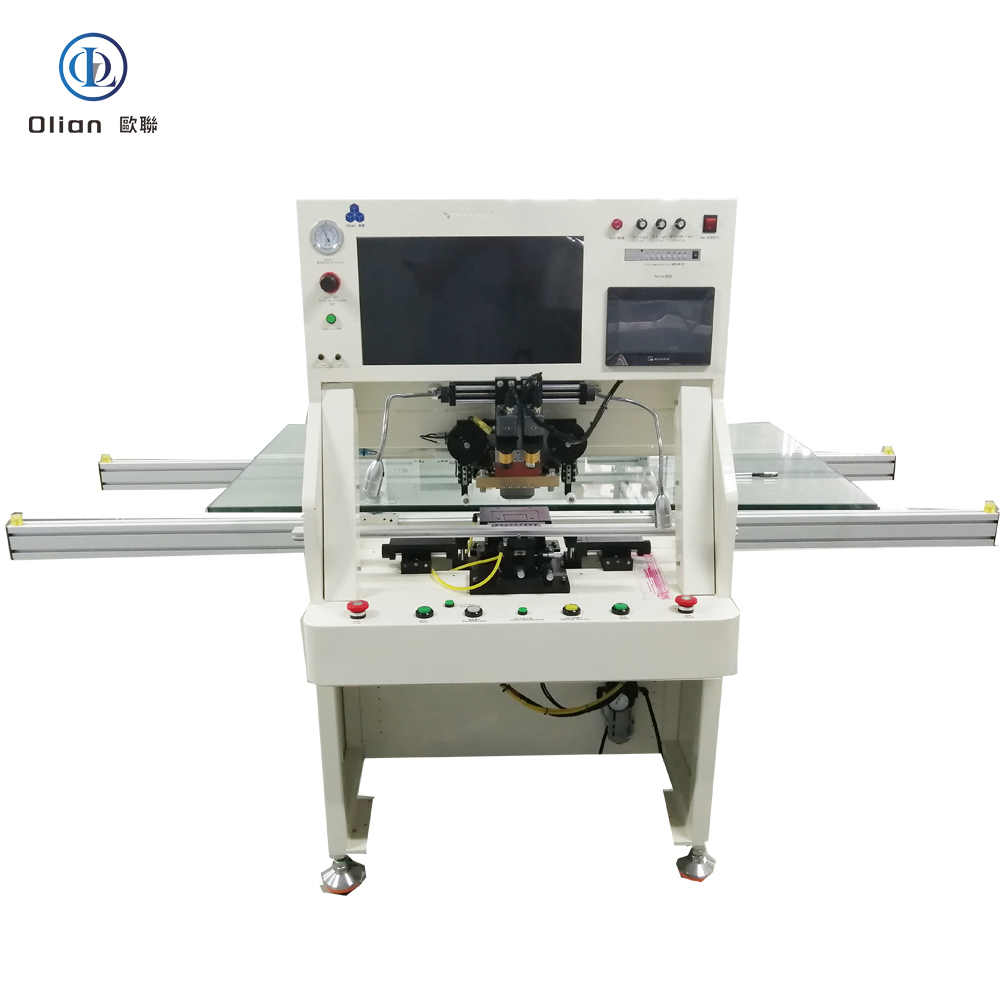

- Bonding Machines

- ACF COF Bonding Machine

- 1-7inch full automatic production lines

- 7-17inch full automatic production lines

- 1-7inch semi automatic machines

- 7-17inch semi automatic machines

- 17-32inch customized machines

- 32-120inch semi automatic customized machines

- Microscopes

- Accessories

- Other machines

- Bonding Machine Working Videos

- News

- Download

- Videos

- Contact us