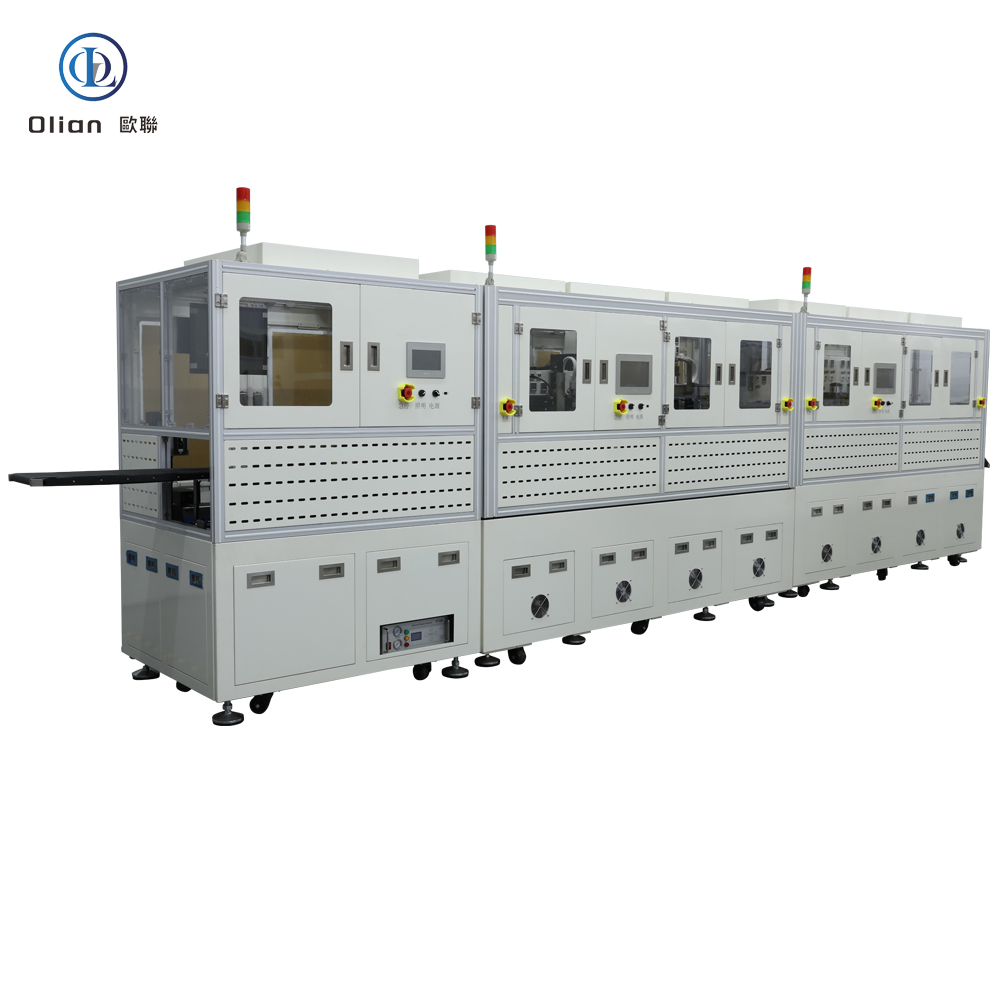

Smart Wear LCD OLED Bonding Production Whole Line Solution

In the rapidly evolving field of smart wear technology, the production of LCD and OLED display modules requires a comprehensive and integrated approach to ensure high efficiency, quality control, and adaptability to market demands. Our Smart Wear LCD OLED Bonding Production Whole Line Solution is designed to meet these challenges by providing a seamless and intelligent manufacturing process.

Glass Loading (玻璃上料)

Automated Glass Loading: The process begins with the automated loading of glass substrates into the production line. This step ensures that the substrates are handled with precision and care, reducing the risk of damage.

Plasma Cleaning (等离子清洗)

High-Purity Cleaning: The glass substrates are cleaned using a plasma cleaning process to remove any contaminants. This step is crucial for ensuring a high-quality bond and reducing defects.

COG (Chip on Glass) and COF (Chip on Film) Bonding

Driver IC Attachment: COG and COF processes are used to attach driver ICs directly to the glass substrate (COG) or to a flexible film (COF) which is then bonded to the glass. These processes ensure a stable and reliable connection, enhancing the performance of the display.

FOG (Film on Glass) and FOF (Film on Film) Bonding

FPC Bonding: FOG and FOF processes involve bonding flexible printed circuits (FPCs) to the glass substrate or to other FPCs. This step is essential for connecting the display module to the mainboard and other components.

Impedance Testing (阻抗测试)

Quality Assurance: Impedance testing is performed to ensure that the electrical connections are stable and reliable. This step is crucial for identifying and correcting any electrical issues before proceeding to the next stage of production.

RT (Room Temperature Curing)

Adhesive Curing: Room temperature curing is used to set the adhesives used in the bonding processes. This ensures that the components are securely attached without the need for high-temperature processes that could damage sensitive materials.

AOI (Automated Optical Inspection)

Quality Control: AOI systems use high-resolution cameras to inspect the display modules for defects. This process ensures that only high-quality products proceed to the next stage of production.

Dispensing (点胶)

Adhesive Application: Precision dispensing machines apply adhesives to the components to ensure a strong bond. This step is crucial for the durability and reliability of the display modules.

Drying (晾干)

Adhesive Drying: After dispensing, the adhesives are allowed to dry under controlled conditions. This ensures that the components are securely bonded and the display modules are ready for further assembly.

TFOG (Thermal Film on Glass)

Thermal Bonding: TFOG processes use heat to bond films to the glass substrate. This step is essential for creating a strong and durable bond, especially in high-stress applications.

Final Dispensing (点胶)

Sealing and Protection: Final dispensing of adhesives is used to seal and protect the display modules. This ensures that the modules are resistant to environmental factors such as dust and moisture.

Our Smart Wear LCD OLED Bonding Production Whole Line Solution is ideal for a wide range of smart wear devices, including:

These devices require high touch sensitivity, durability, and clear displays, making our solution particularly beneficial for these applications.

With our comprehensive Smart Wear LCD OLED Bonding Production Whole Line Solution, manufacturers can achieve high-quality, durable, and responsive displays in their smart wear devices. Our solution combines advanced manufacturing techniques, precision inspection systems, and customizable processes to meet the diverse needs of the smart wear market. By choosing our solution, you can ensure that your smart wear devices stand out in terms of performance and user experience.