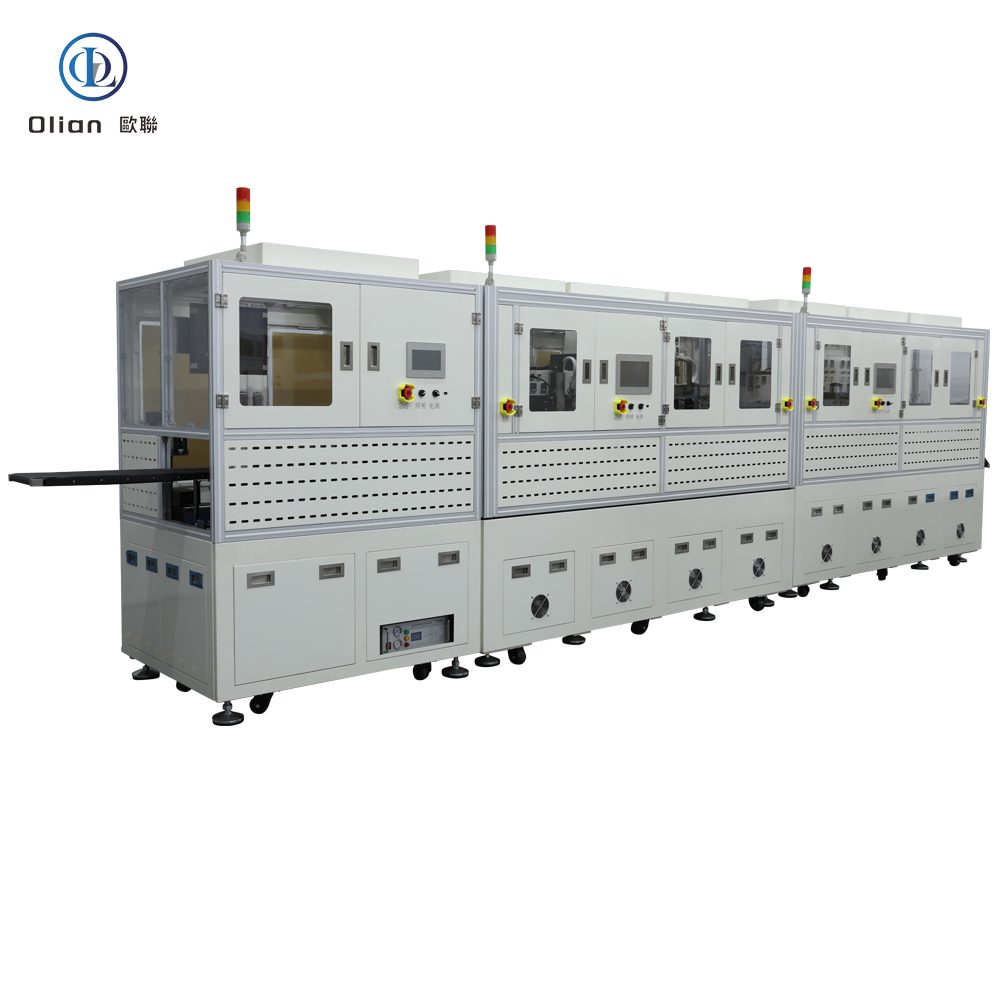

Full Automatic COG/COF/COP Bonding Machines

Full Automatic COG/COF/COP Bonding Machines.

Full-automatic COG (Chip On Glass), COF (Chip On Film), and COP (Chip On Plastic) bonding machines are advanced pieces of equipment used in the electronics industry, particularly for the production of liquid crystal displays (LCDs) and other display technologies. These machines automate the process of bonding integrated circuits (ICs) and flexible printed circuits (FPCs) to glass or plastic substrates, ensuring high precision and reliability. Here is a detailed classification and introduction to these machines:

1. Fully Automatic COG Bonding Machines

COG bonding machines are used to bond ICs directly onto glass substrates. These machines are crucial for the production of compact and lightweight displays, such as those found in smartphones, tablets, and computer monitors.

- Key Features:

- High Precision Alignment: Uses advanced vision systems to ensure accurate alignment of the IC with the glass substrate.

- Pre-Bonding and Main Bonding: Includes both pre-bonding and main bonding steps to ensure a robust connection.

- Automated Loading and Unloading: Reduces manual intervention and increases throughput.

- Applications:

- Consumer Electronics: Smartphones, tablets, and computer monitors.

- Automotive Displays: Vehicle infotainment systems and instrument clusters.

- Industrial and Medical Displays: High-resolution and stable performance for accurate monitoring and control.

- Advantages:

- High Precision: Ensures accurate bonding, reducing misalignment and improving display quality.

- Improved Yield: Increases production efficiency and reduces defects.

- Enhanced Reliability: Ensures long-term performance of electronic devices.

- Example: The SNSQJ+COG+FOG-0717 fully automatic LCD bonding machine includes LCD loading, terminal cleaning, COG bonding, and FPC bonding.

2. Fully Automatic COF Bonding Machines

COF bonding machines are used to bond ICs onto flexible film substrates. These machines are essential for the production of flexible and lightweight displays, such as those used in foldable devices and wearable technology.

- Key Features:

- Flexible Substrate Handling: Designed to handle flexible film substrates with high precision.

- Automated ACF Application: Applies Anisotropic Conductive Film (ACF) with high accuracy.

- Advanced Vision Systems: Ensures precise alignment of the IC with the substrate.

- Applications:

- Smartphones and Tablets: Especially for foldable and flexible displays.

- Wearable Technology: Smartwatches and fitness trackers.

- Automotive Displays: Flexible displays for vehicle interiors.

- Advantages:

- High Precision: Ensures reliable electrical and mechanical connections.

- Increased Productivity: Automation reduces the time required for each bonding process.

- Reduced Labor Costs: Minimizes manual operations, reducing labor costs and the risk of human error.

- Example: The Fully Automatic COF FOF Bonding Machine is designed for high-precision bonding of FPCs to flexible film substrates.

3. Fully Automatic COP Bonding Machines

COP bonding machines are used to bond ICs onto plastic substrates. These machines are ideal for applications where flexibility and durability are required, such as in automotive and industrial displays.

- Key Features:

- Plastic Substrate Compatibility: Designed to handle plastic substrates with high precision.

- Top-Bottom Alignment: Ensures precise alignment of the IC with the substrate.

- Automated Bonding Process: Automates the entire bonding process, from ACF application to final bonding.

- Applications:

- Automotive Displays: Instrument clusters and infotainment systems.

- Industrial Displays: Control panels and monitoring systems.

- Wearable Technology: Smartwatches and fitness trackers.

- Advantages:

- High Precision: Ensures accurate bonding, reducing misalignment and improving display quality.

- Improved Yield: Increases production efficiency and reduces defects.

- Enhanced Reliability: Ensures long-term performance of electronic devices.

- Example: The COP FOP Bonding Machine is designed for bonding FPCs to plastic substrates, ensuring high precision and reliability.

Conclusion

Full Automatic COG/COF/COP Bonding Machines are essential in modern electronics manufacturing, providing reliable and efficient solutions for the production of high-quality displays and electronic devices. These machines offer high precision, increased productivity, and reduced labor costs, making them ideal for various applications in consumer electronics, automotive, and industrial sectors. By choosing the right bonding machine, manufacturers can ensure high-quality and efficient production processes, meeting the demands for smaller, more efficient electronic devices.