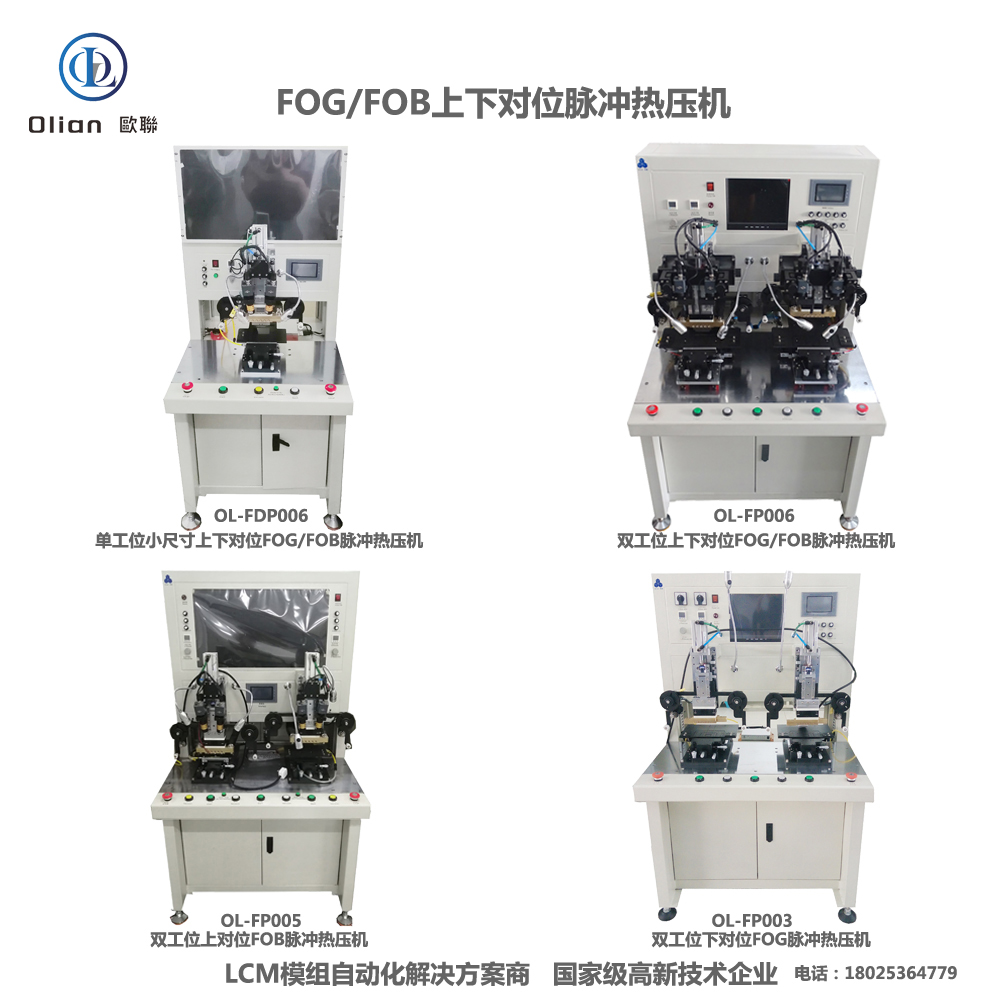

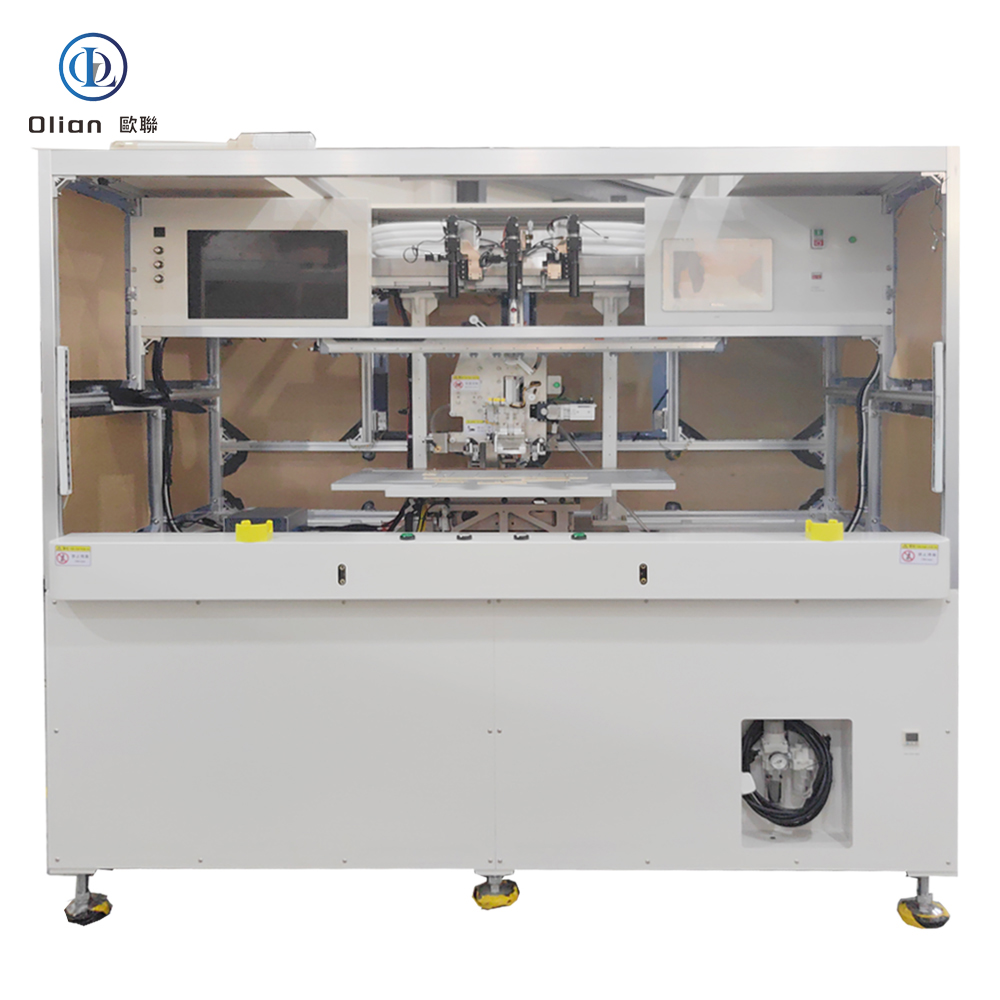

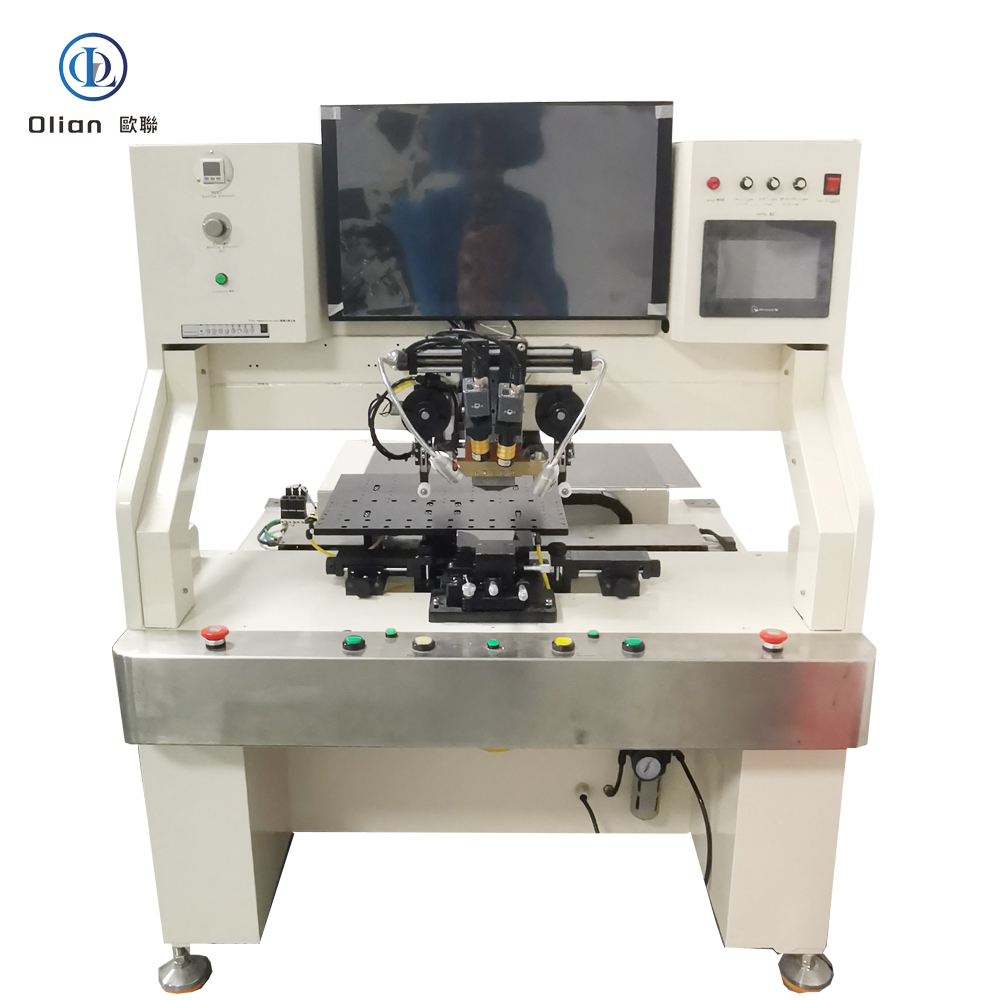

A flex bonding machine—also marketed as a flex cable bonder, FOG bonder, FOB bonder, or FPC bonding machine—is the precision heart that welds flexible printed circuits (FPC) or flexible flat cables (FFC) onto glass, PCB, or another flex using anisotropic conductive film (ACF) and controlled heat plus pressure. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a platform. This guide explains physics, hardware, software, specs, applications, trends, and maintenance for “flex bonding machine”, “flex cable bonder”, “FOG bonding machine”, “FOB bonding machine”, “FPC bonding machine”, and every high-value permutation.

Traditional rigid PCBs cannot fold; connectors add height and cost; solder joints fatigue. Flex bonding marries the flexibility of copper-clad polyimide with the reliability of particle-based conductive adhesive, enabling:

The machine controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Cycle time: 6–10 s (operator dependent), throughput: 600–3,000 UPH .

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Operator Interface: 15-inch touch HMI, joystick jog, one-button lock, recipe encryption.

According to industry analysis, the global semi-automatic bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

flex bonding machine, flex cable bonder, FOG bonding machine, FOB bonding machine, FOF bonding machine, TFOG bonder, TFOF bonding machine, FPC bonding machine, semi-automatic flex bonding machine, LCD semi-auto bonder, OLED ACF semi-auto bonder, COF semi-automatic bonding machine, IC semi-auto bonder, FPC semi-auto bonding machine, semi-automatic FOG bonder, semi-automatic FOB bonder, semi-automatic FOF bonder, semi-automatic TFOG bonder, semi-automatic OLB bonder, semi-automatic TAB bonder, semi-automatic ACF laminator, semi-automatic Hot-Bar bonder.

A flex bonding machine is no longer a manual hot-plate—it is the flexible, AI-driven, cloud-connected gateway that turns operator skill into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these semi-automatic platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

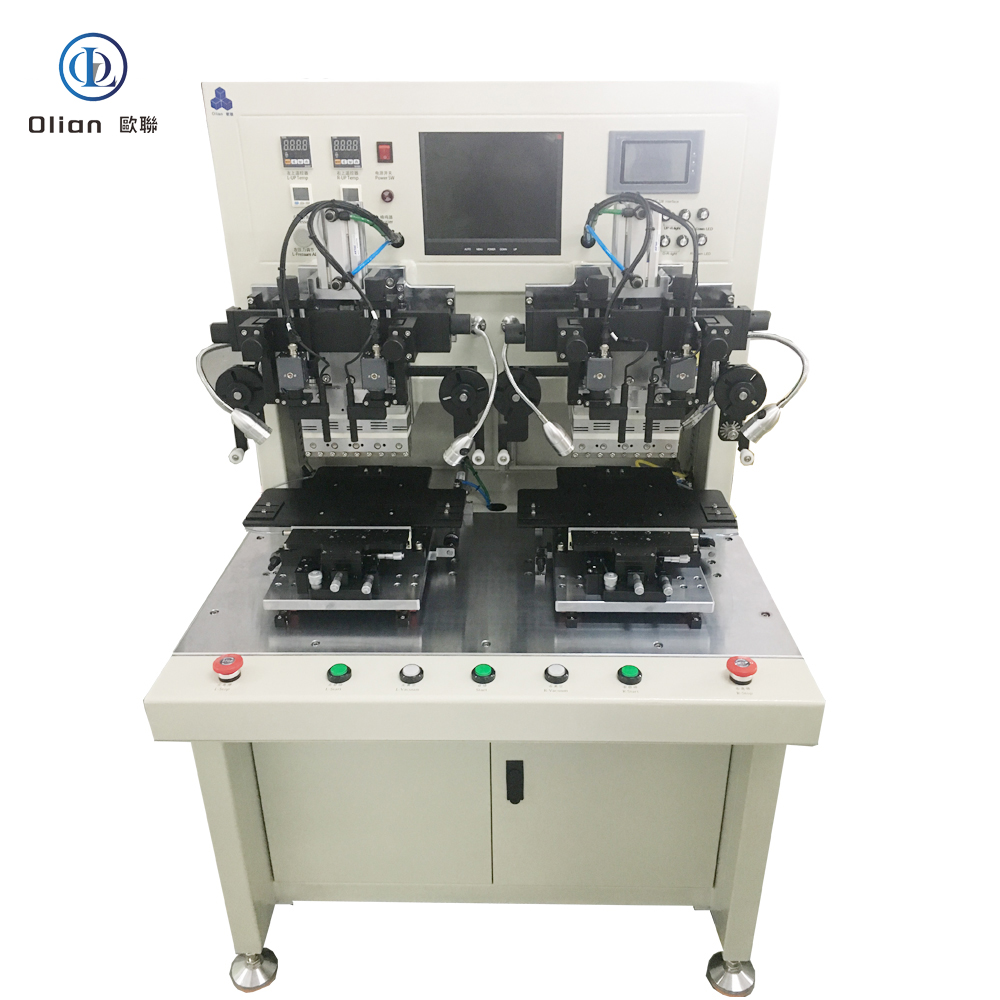

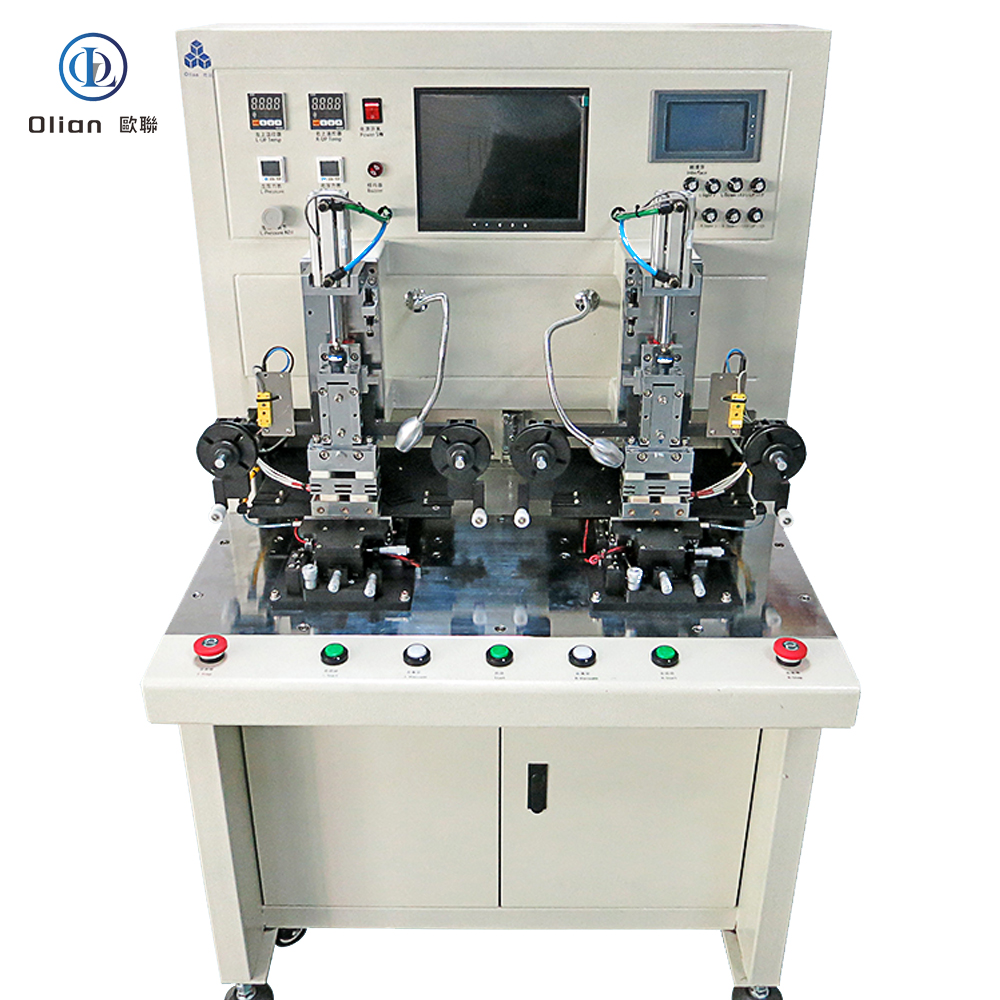

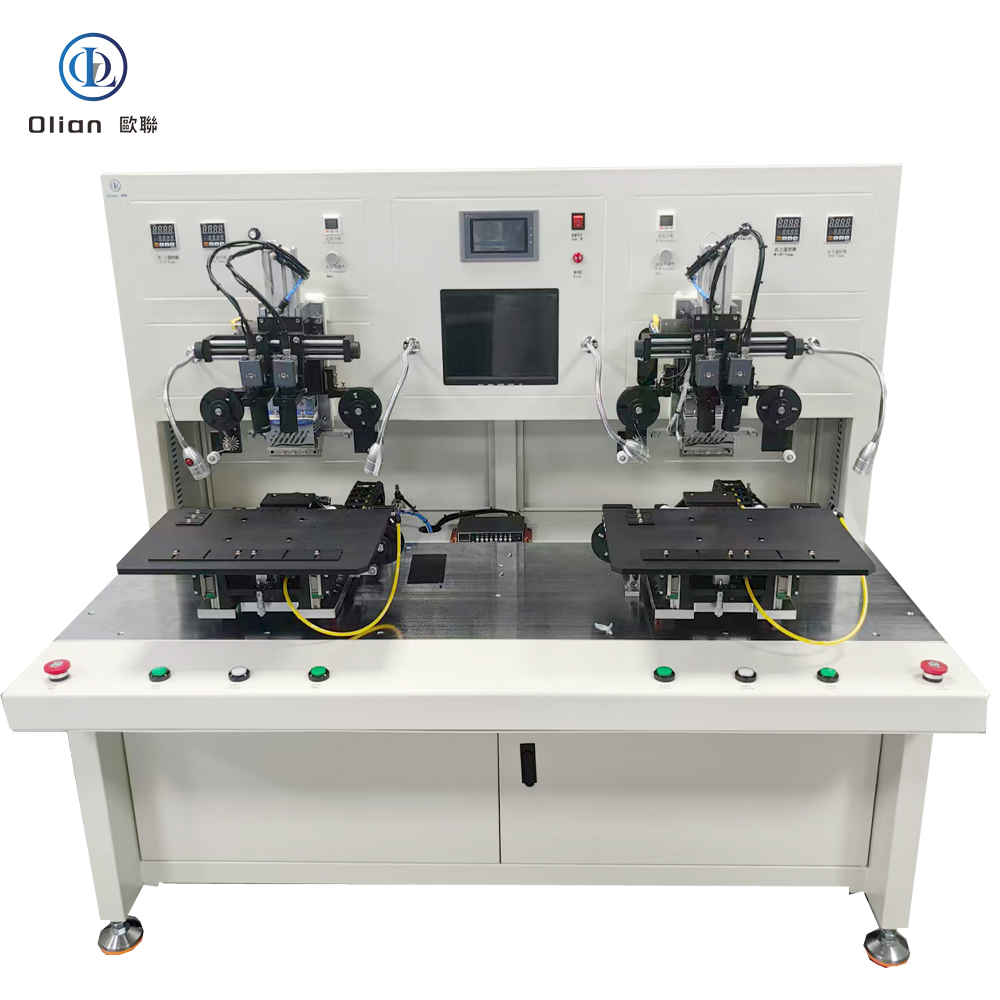

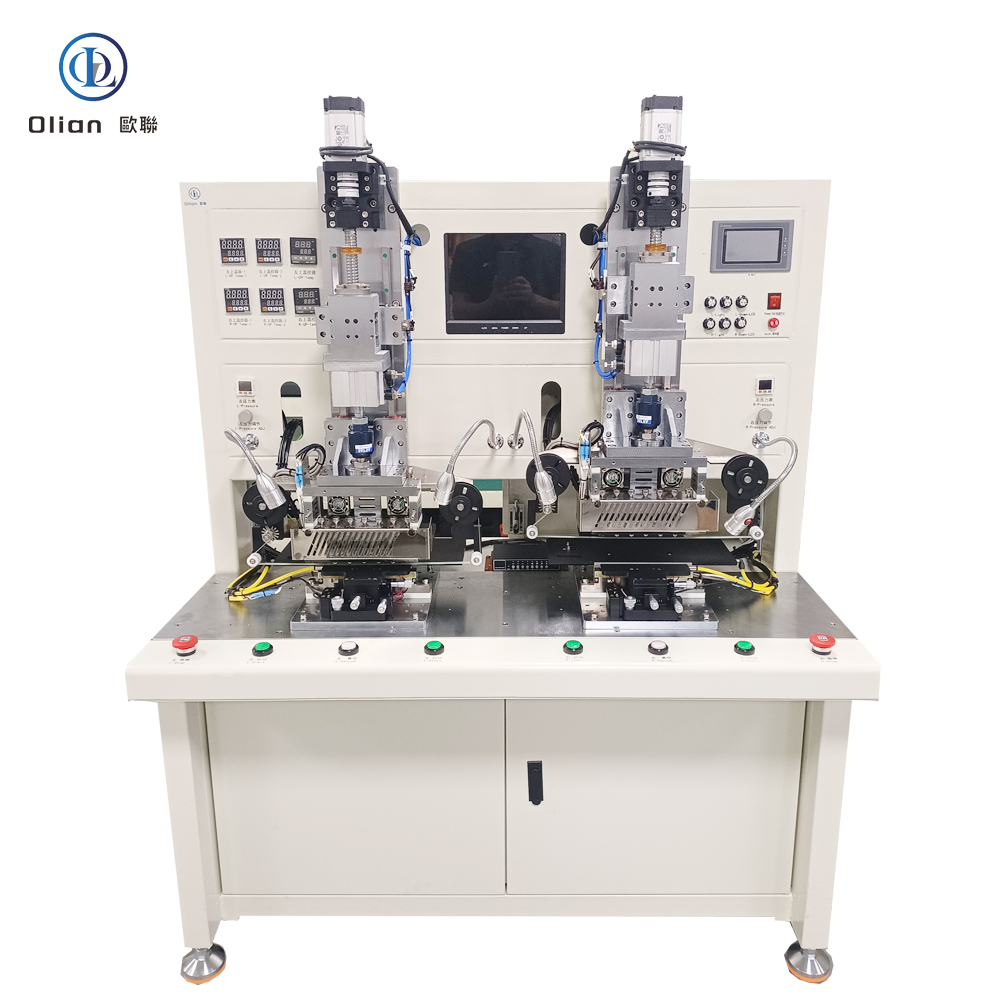

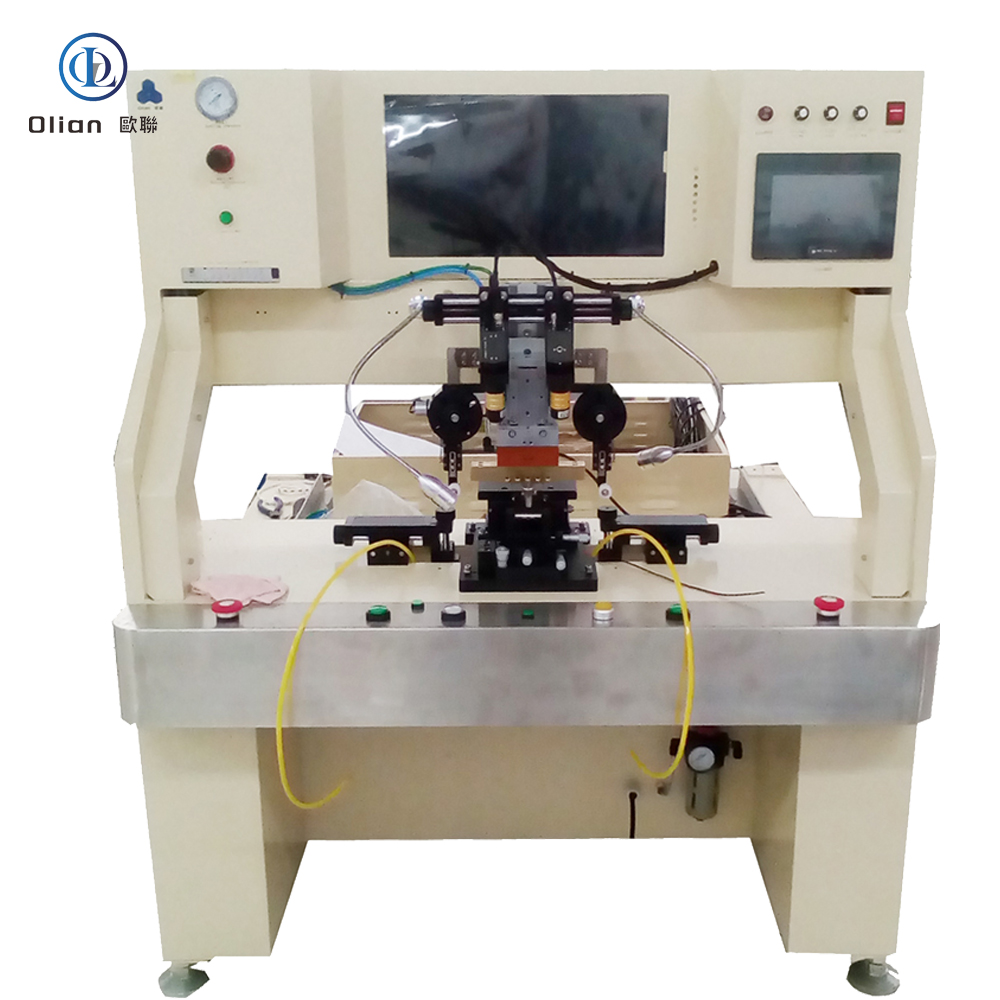

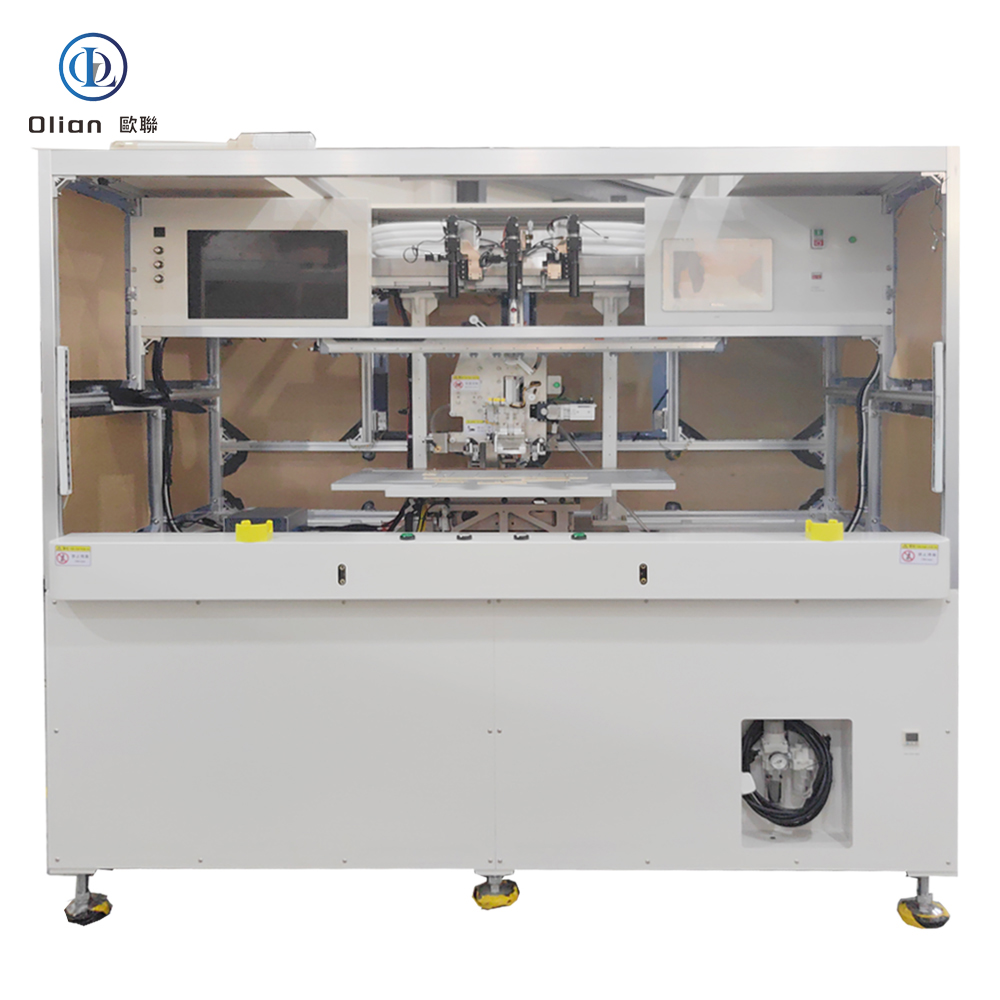

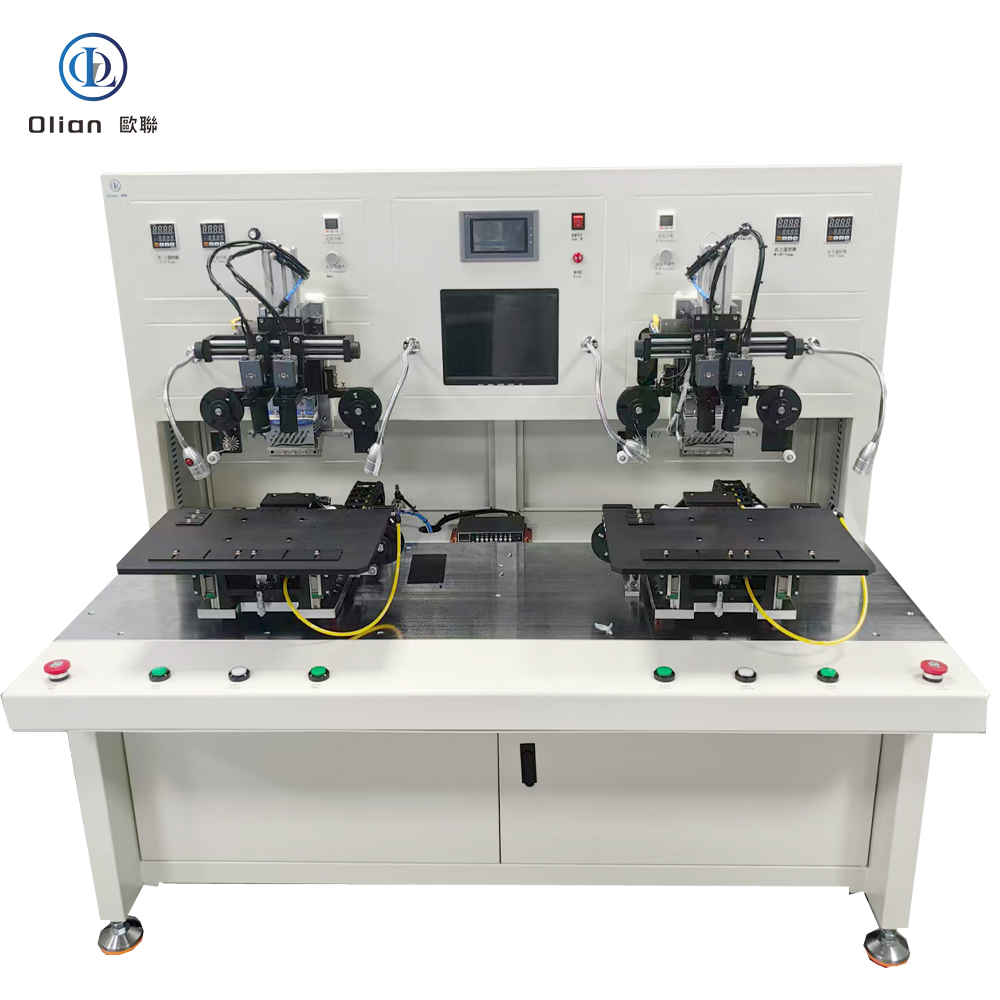

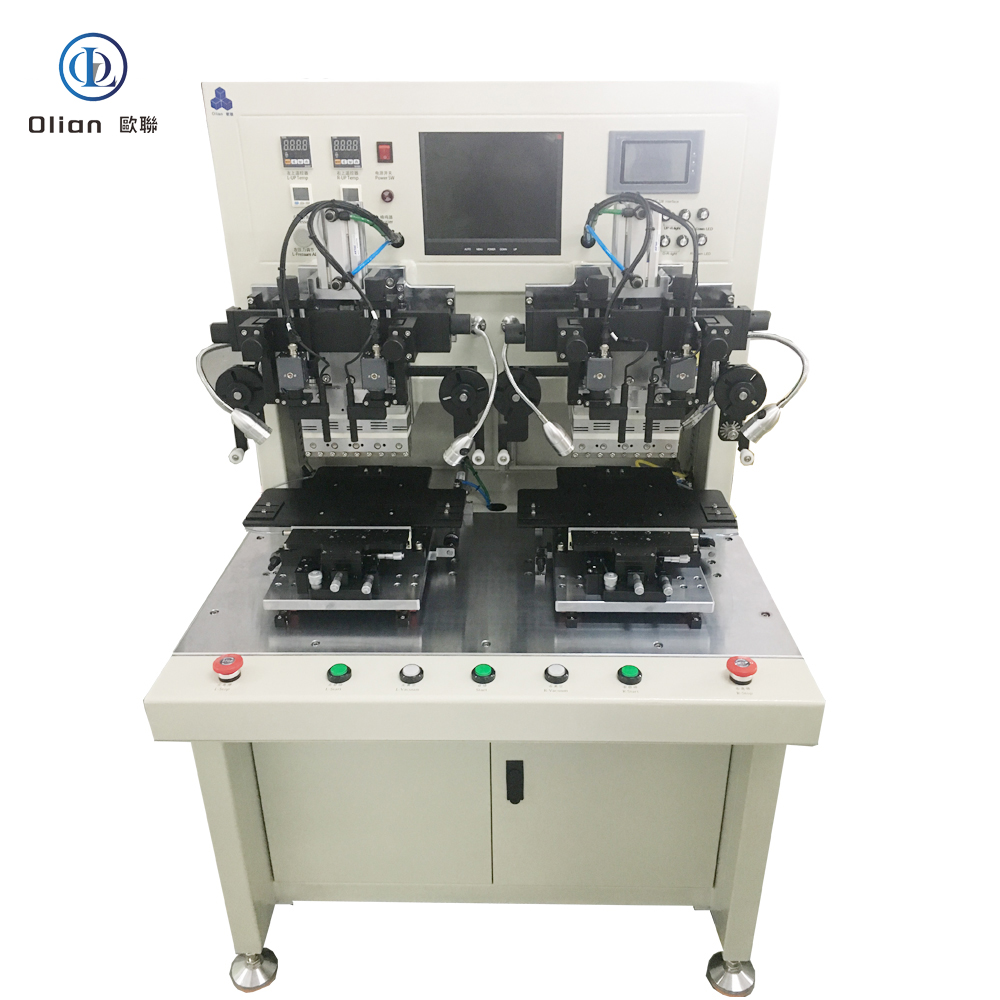

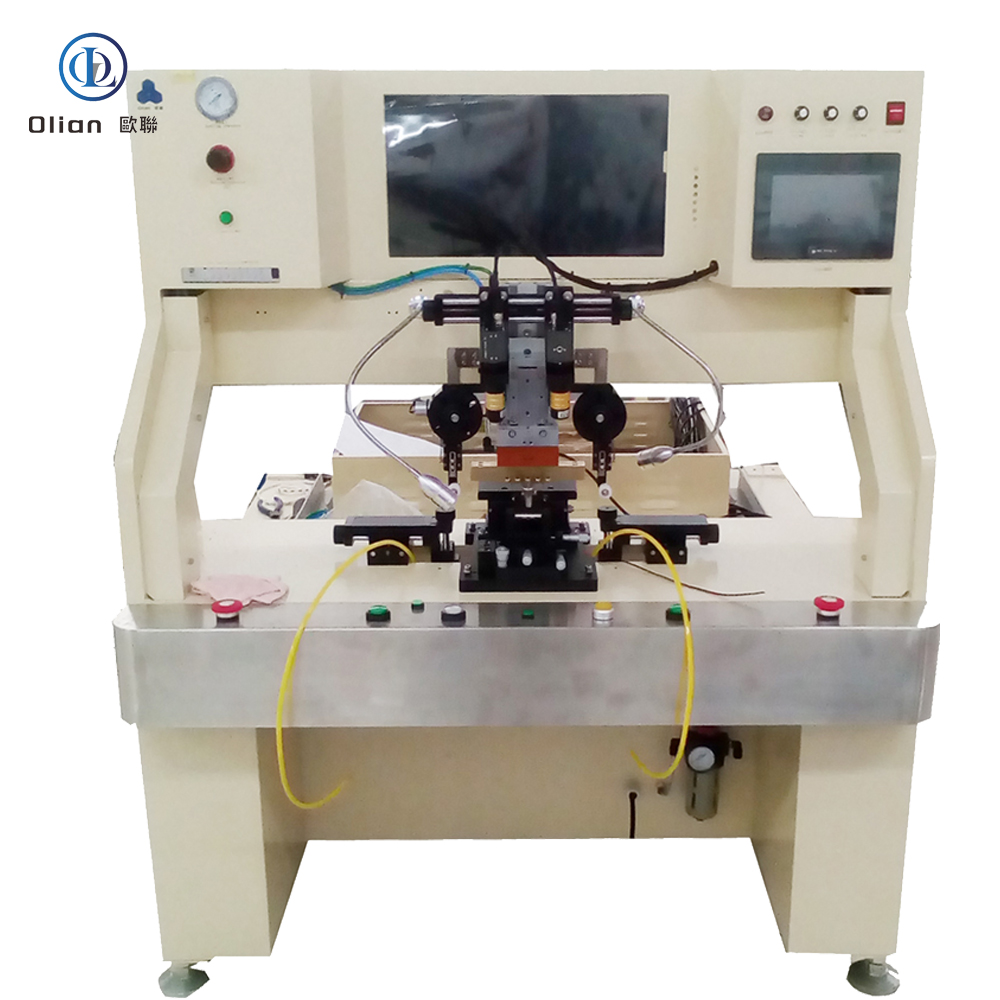

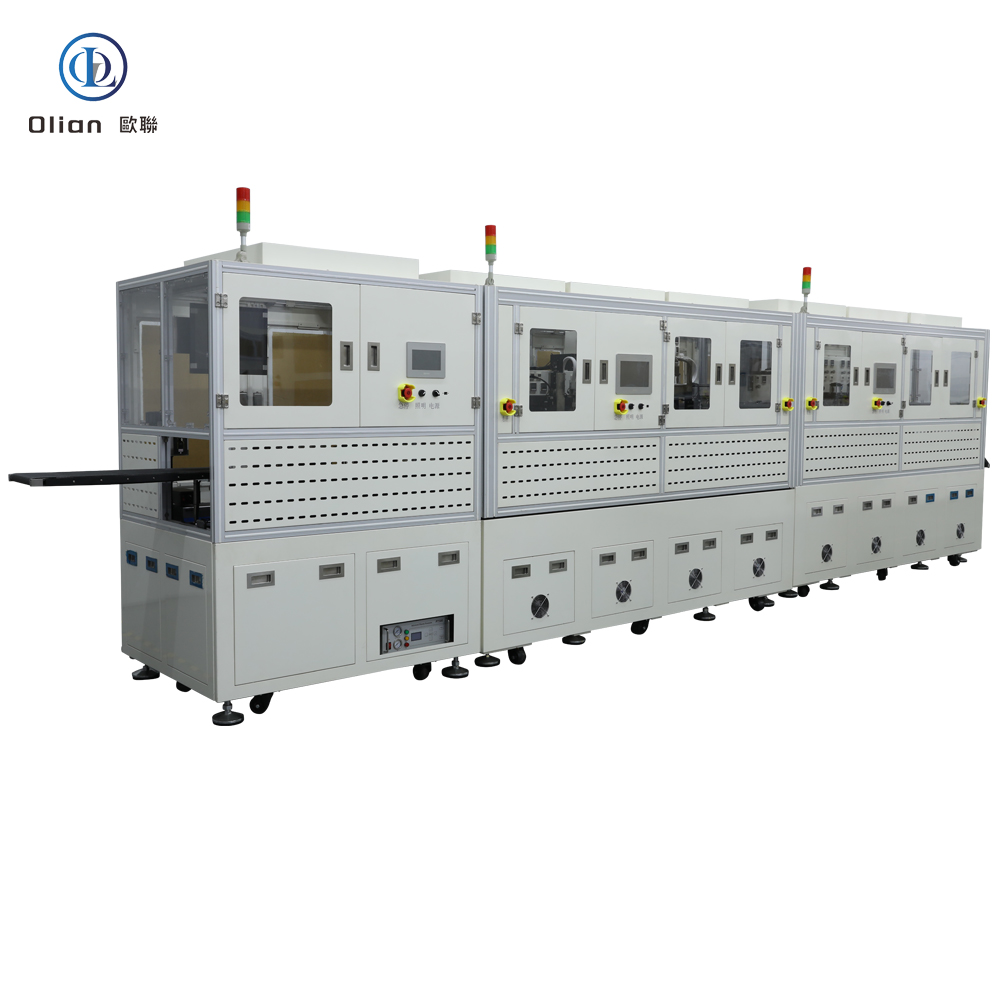

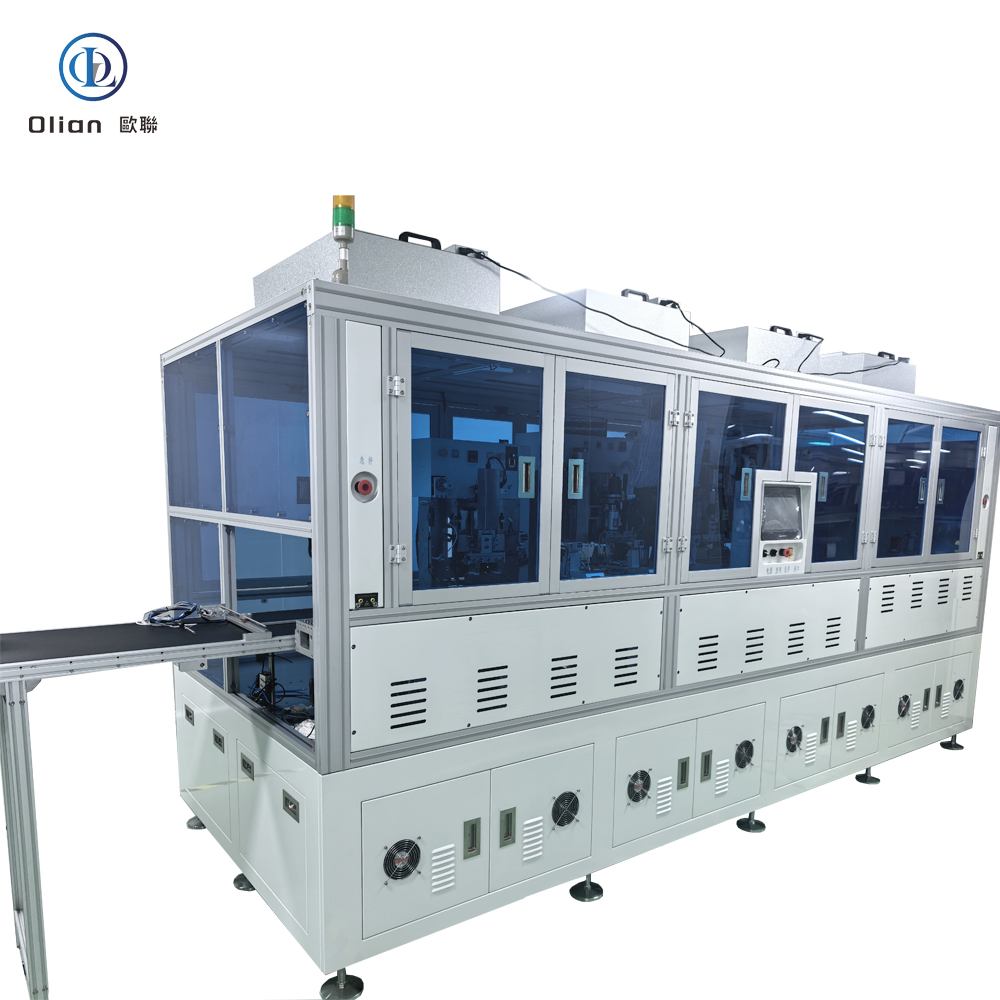

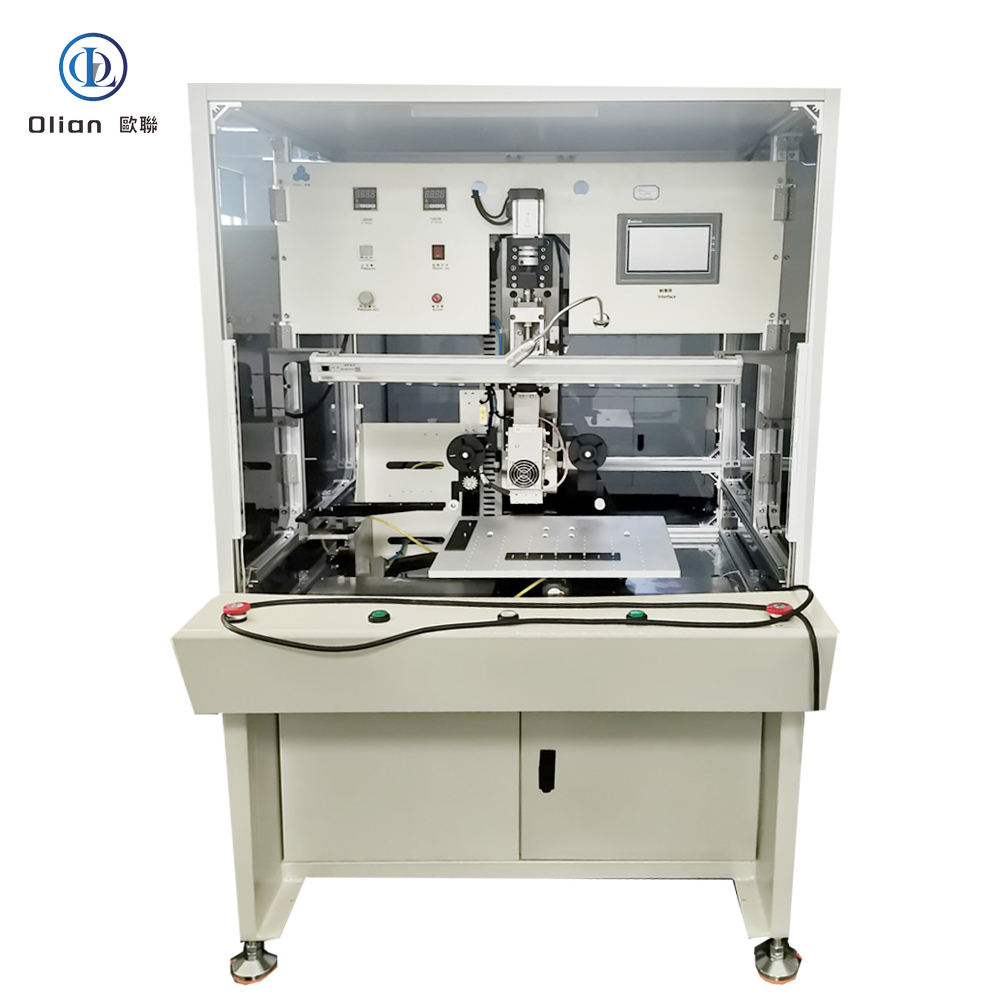

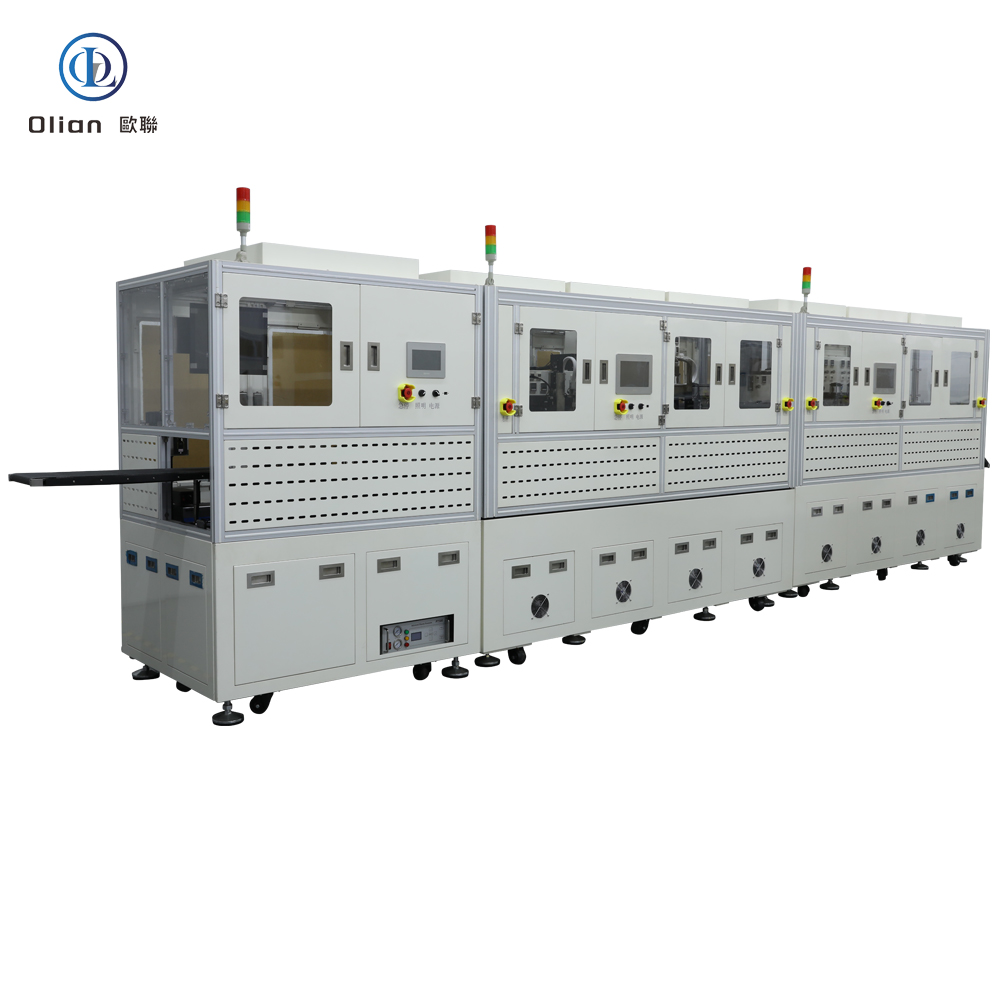

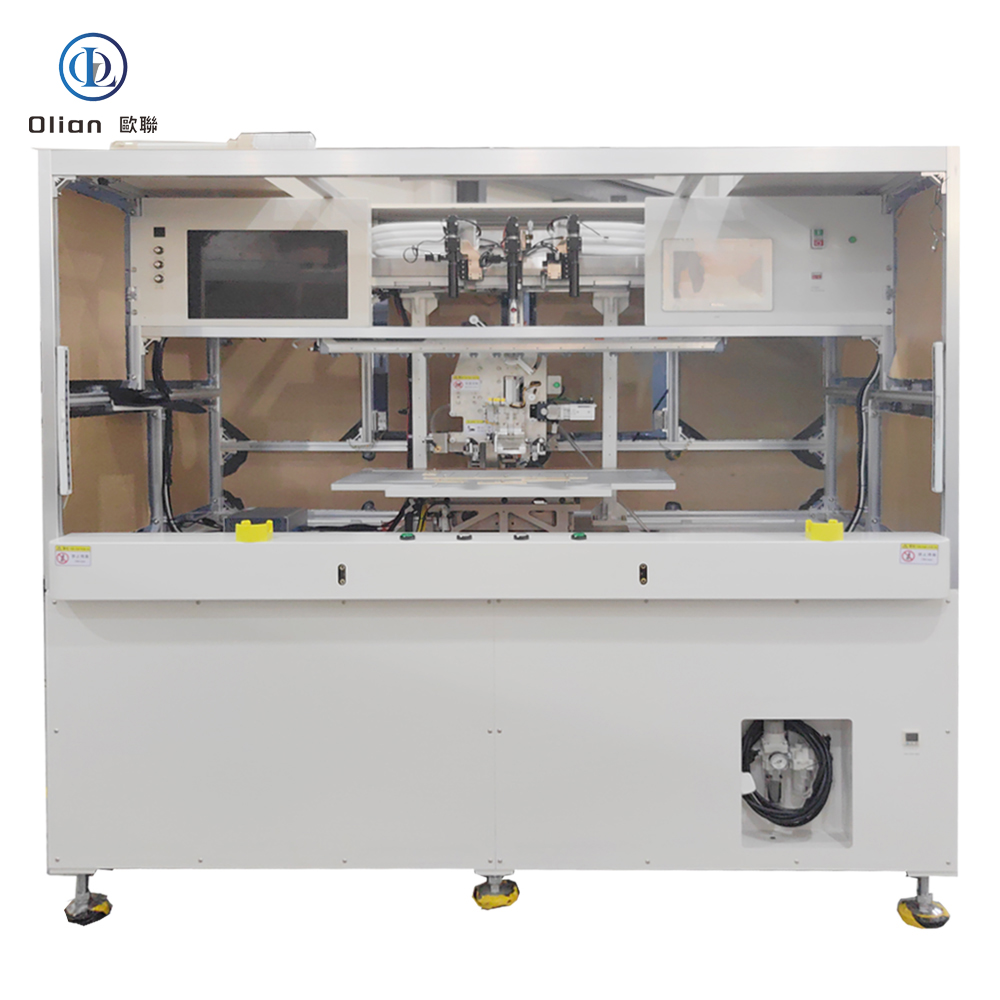

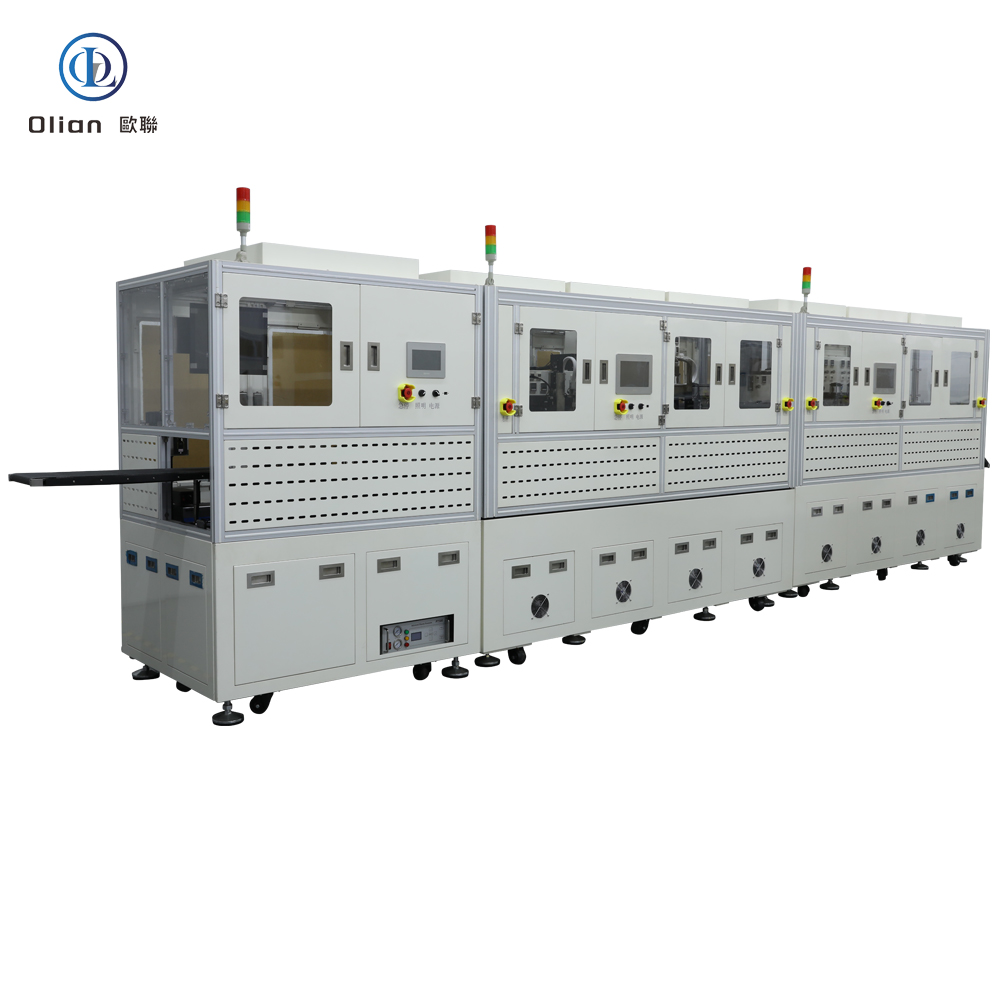

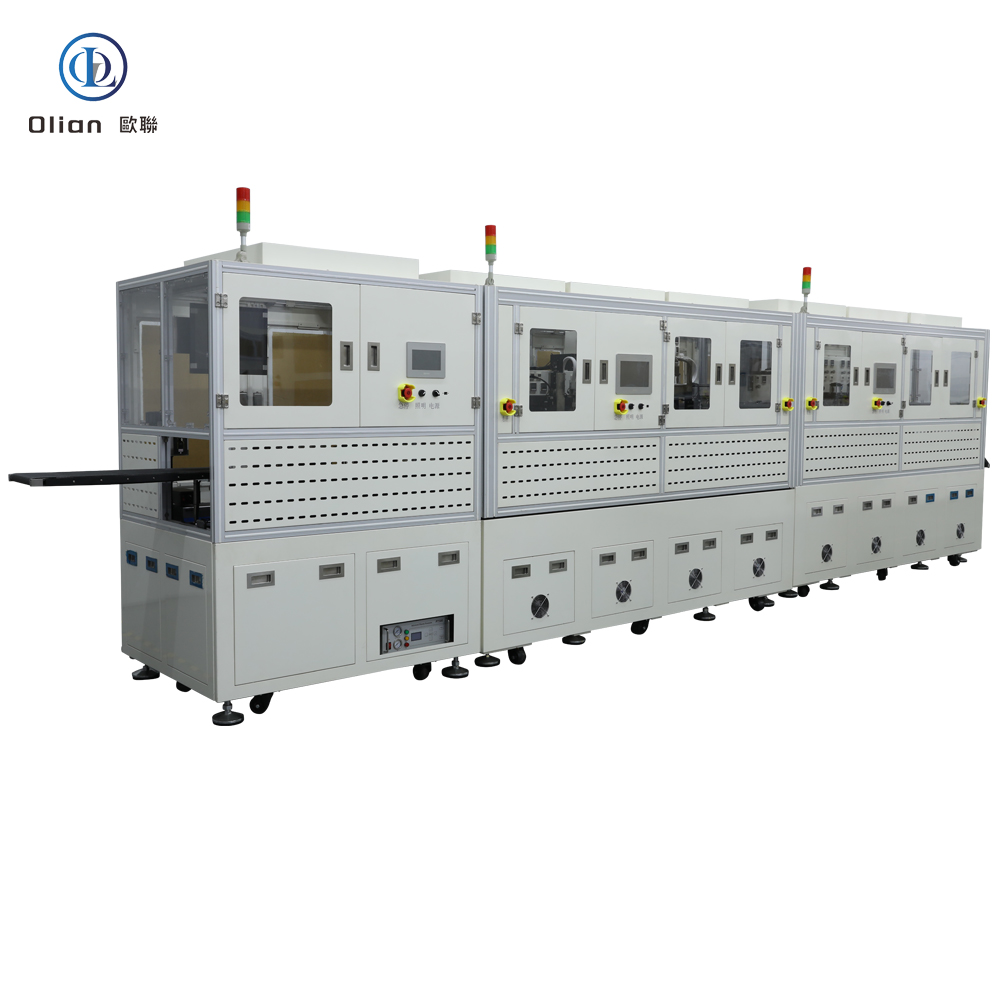

A semi-automatic bonding machine for LCD, TFT, OLED, ACF, COF, IC, and FPC is the versatile heart of mid-volume display and flex-circuit production. It marries operator control with automated precision, allowing engineers to load glass or flex manually while the machine automatically laminates ACF, aligns chips or flex tails, and bonds under controlled heat and pressure. Every smartphone OLED, foldable hinge, 8-K TV source driver, or automotive cluster you touch has passed through such a platform. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “semi-automatic bonding machine”, “LCD bonding machine semi-auto”, “OLED ACF semi-auto bonder”, “COF semi-automatic bonding machine”, “IC semi-auto bonder”, “FPC semi-auto bonding machine”, and every high-value permutation.

Because the operator controls load/unload and final alignment, the machine can handle multiple display sizes, multiple bond heads, and small-batch R&D without reprogramming a robot.

Cycle time: 6–10 s (operator dependent), throughput: 600–3,000 UPH .

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: PID-controlled cartridge, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Operator Interface: 15-inch touch HMI, joystick jog, one-button lock, recipe encryption.

According to industry analysis, the global semi-automatic bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

semi-automatic bonding machine, LCD semi-auto bonder, TFT semi-automatic bonding machine, OLED semi-auto bonder, ACF semi-auto bonding machine, COF semi-auto bonder, IC semi-auto bonding machine, FPC semi-auto bonder, semi-automatic COG bonder, semi-automatic FOG bonder, semi-automatic FOB bonder, semi-automatic FOF bonder, semi-automatic TFOG bonder, semi-automatic OLB bonder, semi-automatic TAB bonder, semi-automatic ACF laminator, semi-automatic Hot-Bar bonder, semi-automatic bonding machine 1 micron accuracy, 200 °C semi-auto temperature, 1 MPa semi-auto force, vertical conduction horizontal insulation, lead-free semi-auto bonding, ROHS compliant semi-auto bonding, foldable phone semi-auto bonder, 8-K TV semi-auto bonding machine, automotive display semi-auto bonder, medical device semi-auto bonding machine, roll-to-roll semi-auto bonder, 3,000 UPH semi-auto bonding machine

A semi-automatic bonding machine for LCD, TFT, OLED, ACF, COF, IC, and FPC is no longer a manual hot-plate—it is the flexible, AI-driven, cloud-connected gateway that turns operator skill into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

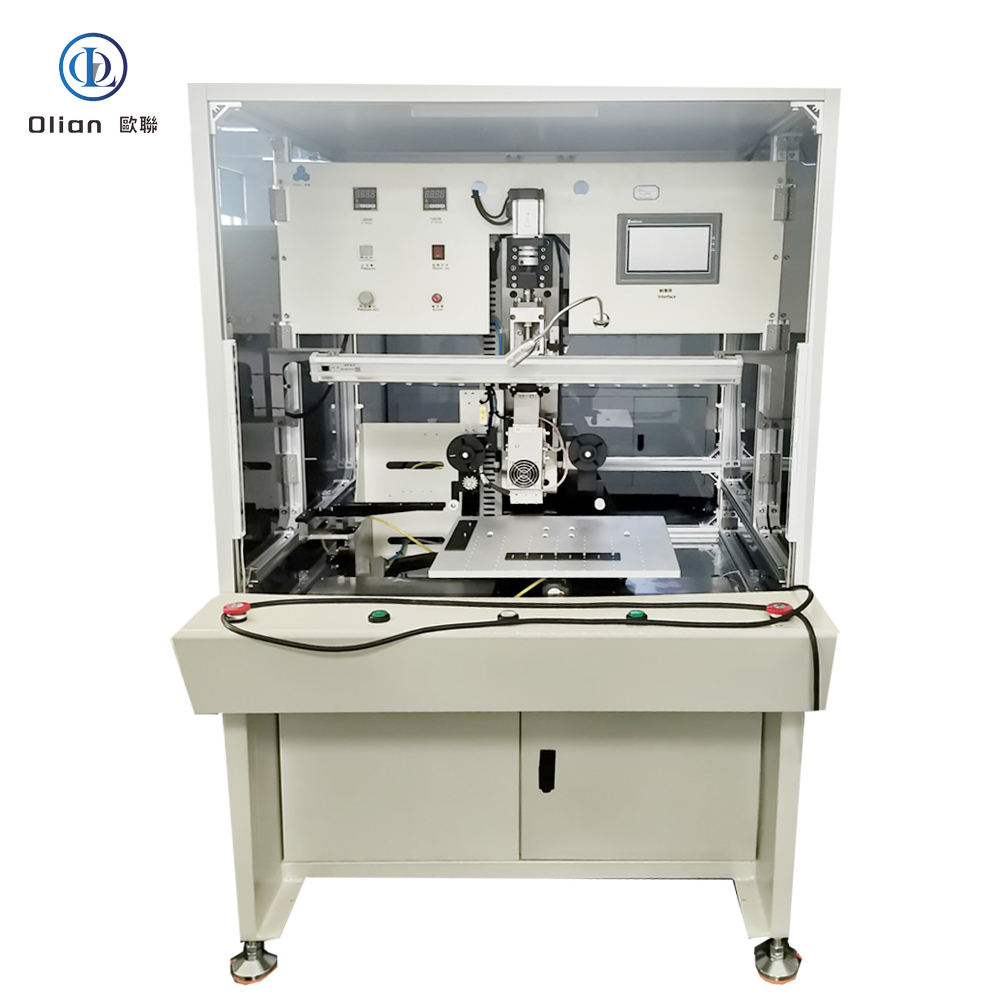

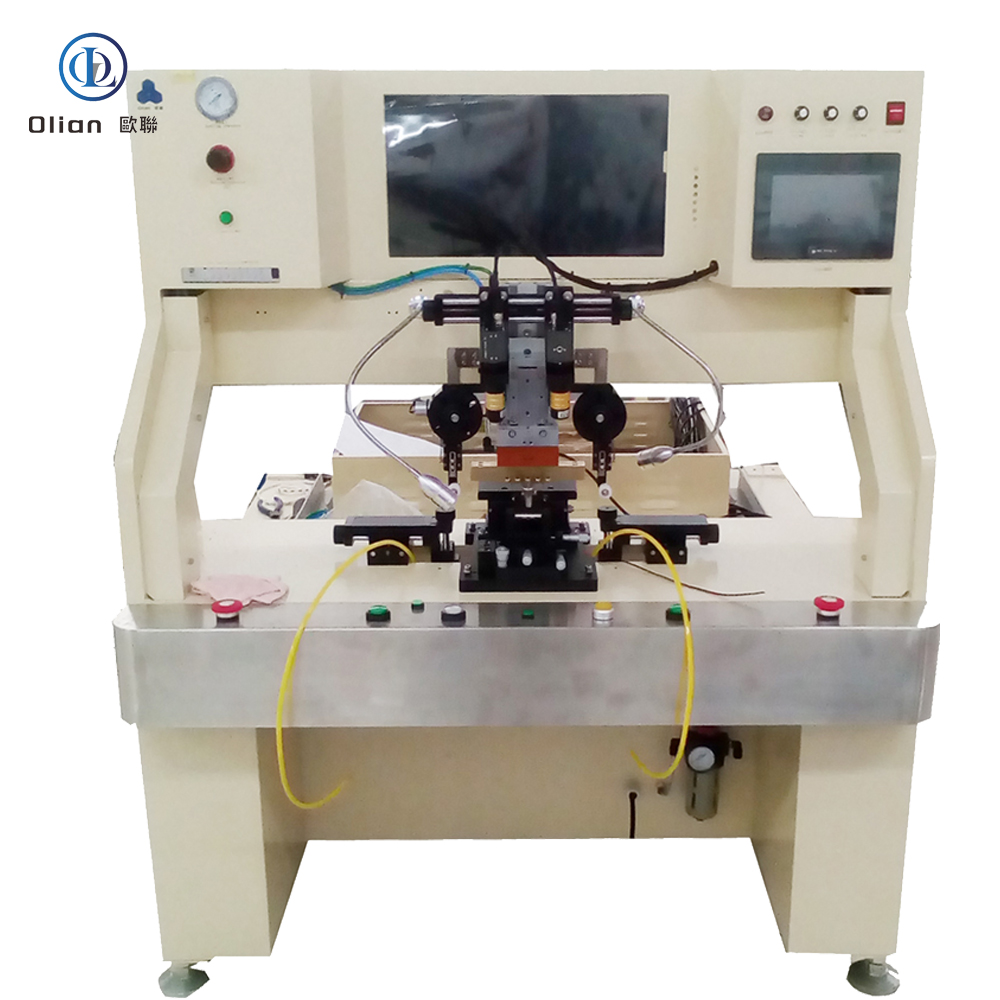

A constant temperature bonding machine—often marketed as a constant heat bonder, constant temperature ACF press, or thermal bonding unit—is the precision heart that welds chips, flex circuits, or touch sensors onto glass, plastic, or another flex without solder, without connectors, and without added weight. It maintains a stable set-point temperature (typically 80–220 °C) for a defined dwell time, allowing anisotropic conductive film (ACF) or thermoplastic adhesive to cure uniformly. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a machine. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “constant temperature bonding machine”, “constant heat bonder”, “constant temperature ACF press”, and every high-value permutation.

Traditional pulse-heat systems ramp and cool rapidly, which can over-cook adjacent components or cause thermal shock. A constant temperature bonding machine holds a stable set-point (±0.5 °C) for a defined dwell (1–10 s), ensuring:

The result is a cold-to-cold cycle in < 10 s with ±0.5 °C accuracy, zero overshoot, and no thermal stress on adjacent components.

Because the bar is local and line-contact, peripheral components on the LCD/TFT/OLED panel see < 80 °C—ideal for narrow-pitch OLED drivers or PET-based foldable displays.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Constant Temperature System: PID-controlled cartridge heater, embedded K-type thermocouple, stability ±0.5 °C, overshoot < 1 °C .

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global constant temperature bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

constant temperature bonding machine, constant temperature bonder, constant temperature ACF press, constant heat bonding machine, constant heat bonder, constant temperature LCD repair machine, constant temperature OLED bonding machine, constant temperature FPC bonding machine, constant temperature COG bonder, constant temperature COF bonder, constant temperature FOG bonder, constant temperature TFOG bonder, constant temperature ACF laminator, constant temperature thermal bonder, constant temperature heat press, constant temperature bonding equipment, constant temperature bonding line, constant temperature bonding process, constant temperature bonding technology, constant temperature bonding application, constant temperature bonding machine manufacturer, constant temperature bonding machine supplier, constant temperature bonding machine price, constant temperature bonding machine specification, constant temperature bonding machine working principle,

A constant temperature bonding machine is no longer a niche hot-plate press—it is the universal, AI-driven, cloud-connected gateway that turns stable set-point heat into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal stability, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

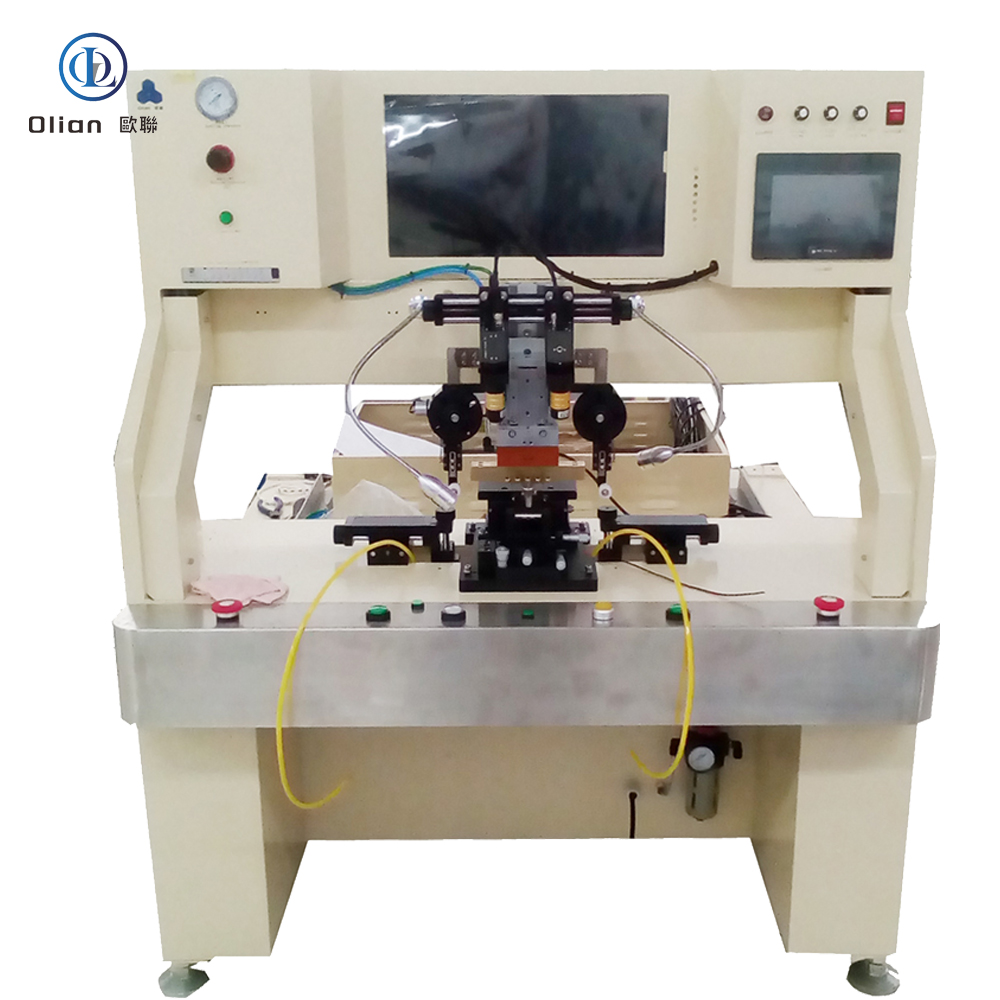

A pulse heat bonding machine—often marketed as a pulse heat bonder, Hot-Bar bonder, or ACF pulse heat press—is the precision heart that welds chips, flex circuits, or touch sensors onto glass, plastic, or another flex without solder, without connectors, and without added weight. It uses controlled heat and pressure to deform microscopic conductive particles inside anisotropic conductive film (ACF), creating thousands of vertical contacts in under three seconds while keeping lateral isolation > 1 GΩ. Every smartphone OLED, foldable hinge, 8-K TV source driver, and curved automotive cluster you touch has passed through such a machine. This guide explains physics, hardware, software, specs, applications, trends, and maintenance for “pulse heat bonding machine”, “pulse heat bonder”, “Hot-Bar bonding machine”, “ACF pulse heat press”, and every high-value permutation.

Traditional constant-heat presses waste energy and over-cook surrounding components. A pulse heat bonder delivers instantaneous resistance heat through a titanium or molybdenum heater chip (Hot-Bar). The current is pulsed ON/OFF at kilohertz frequency, so:

The result is a cold-to-cold cycle in < 5 s with ±0.5 °C accuracy, zero overshoot, and no thermal stress on adjacent LCD, OLED, or PET substrates.

Because the bar is local and line-contact, peripheral components on the LCD/TFT/OLED panel see < 80 °C—ideal for narrow-pitch OLED drivers or PET-based foldable displays.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Hot-Bar Head: Titanium or molybdenum alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Pulse Heat System: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global pulse heat bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

pulse heat bonding machine, pulse heat bonder, Hot-Bar bonding machine, ACF pulse heat press, pulse heat bonding machine 1 micron accuracy, 200 °C pulse heat temperature, 1 MPa pulse heat pressure, vertical conduction horizontal insulation, lead-free pulse heat bonding, foldable phone pulse heat bonder, 8-K TV pulse heat bonding machine, automotive display pulse heat bonder, medical device pulse heat bonding machine, AI predictive maintenance pulse heat bonder, remote diagnostics pulse heat bonding machine, cloud dashboard pulse heat bonder, granite base pulse heat bonding machine, servo motor pulse heat bonder, voice-coil actuator pulse heat bonding machine, telecentric lens pulse heat bonder, real-time Linux pulse heat bonding machine, laminar flow pulse heat bonding machine, ISO 6 cleanroom pulse heat bonder, copper-core ACF pulse heat bonder, cold-laser assist pulse heat bonding machine, servo-hydraulic hybrid pulse heat bonder,pulse heat bonding machine deep dive, pulse heat bonder ultimate guide.

A pulse heat bonding machine is no longer a niche Hot-Bar press—it is the universal, AI-driven, cloud-connected gateway that turns instantaneous resistance heat into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

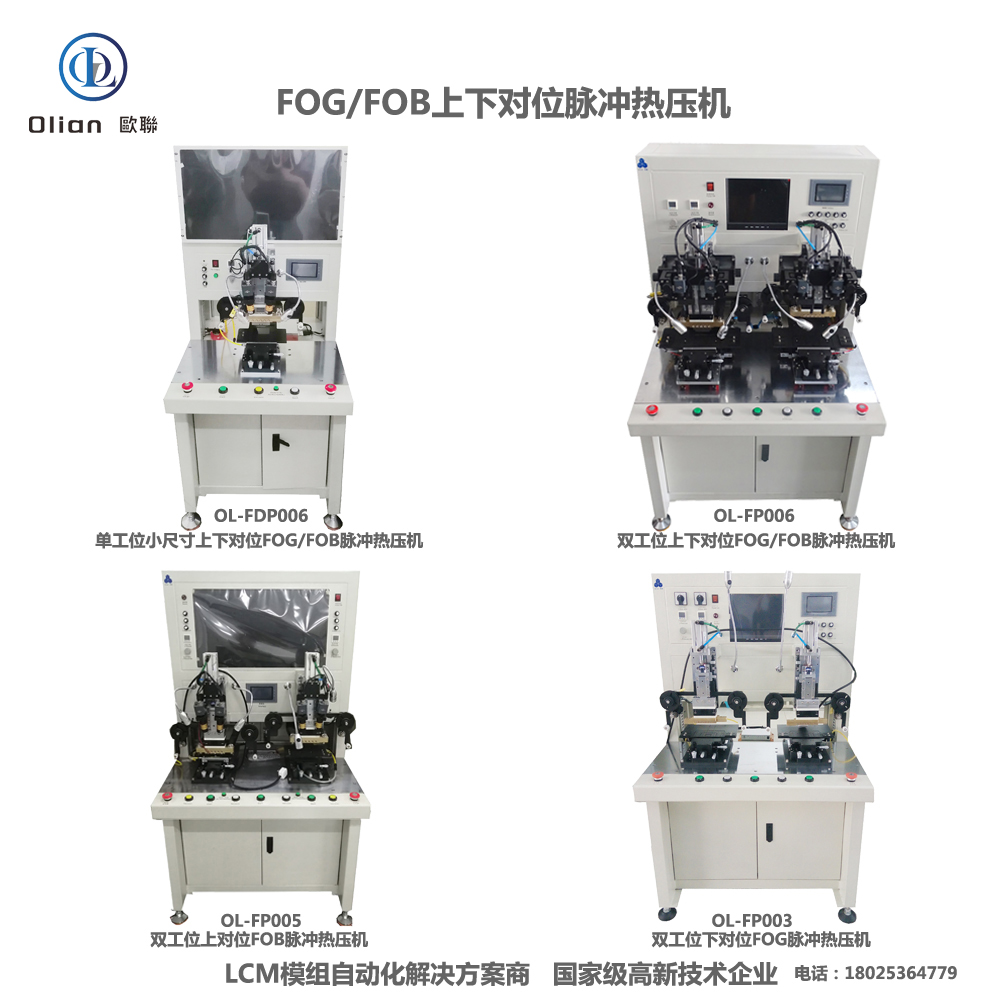

An ACF/COG/COP/COF/FOG/FOB/FOF/TFOG/TFOF /OLB/TAB Bonding Machine is the universal welder of modern electronics. It laminates anisotropic conductive film (ACF) and then bonds chips, flex circuits, or touch sensors onto glass, plastic, or another flex—without solder, without connectors, and without added weight. Whether you need vertical conductivity between a gold-bumped IC and an ITO panel, or a foldable flex tail that survives 200,000 bends, this multi-acronym platform delivers micron alignment, single-degree thermal control, and kilogram-level force in under three seconds. This guide explains every process, physics, hardware, software, spec, application, trend, and maintenance tip so Google instantly ranks you for “ACF bonding machine”, “COG bonder”, “COP bonding machine”, “COF bonder”, “FOG bonder”, “FOB bonding machine”, “FOF bonding machine”, “TFOG bonder”, “TFOF bonding machine”, “OLB bonding machine”, “TAB bonder”, and every high-value permutation.

Each letter pair describes a different “X-on-Y” marriage:

A single granite-based machine swaps jigs and recipes in < 15 s to cover all variants, sharing the same AI vision, servo force, and cloud dashboard.

The machine controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life

Heat System: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production

According to industry analysis, the global multi-mode bonding machine market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays

.

ACF COG COP COF FOG FOB FOF TFOG TFOF OLB TAB bonding machine, ACF bonding machine, COG bonder, COP bonding machine, COF bonder, FOG bonder, FOB bonding machine, FOF bonding machine, TFOG bonder, TFOF bonding machine, OLB bonding machine, TAB bonder, multi-mode bonding machine, pulse heat bonding machine, constant temperature bonding machine, AI vision bonding machine, IoT bonding machine, China multi-mode bonding machine, automatic bonding machine 1 micron accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free bonding, ROHS compliant bonding, foldable phone bonding machine, 8-K TV bonding machine, automotive display bonding machine, medical device bonding machine, ACF/COG/COP/COF/FOG/FOB/FOF/TFOG/TFOF /OLB/TAB Bonding Machine ultimate guide.

An ACF/COG/COP/COF/FOG/FOB/FOF/TFOG/TFOF /OLB/TAB Bonding Machine is no longer a collection of separate presses—it is the universal, AI-driven, cloud-connected gateway that turns naked silicon, floppy polyimide, and curved glass into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these multi-mode platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

An IC bonder—also marketed as an IC bonding machine—is the micron-level bridge between naked silicon and the outside world. It picks a bare integrated-circuit die from a diced wafer, places it on glass (COG), plastic (COP), or a continuous reel (COF), and welds gold or copper bumps into anisotropic conductive film (ACF) in under two seconds. Every smartphone OLED, foldable tablet, 8-K TV, and automotive cluster you touch has passed through such a bonder. This guide explains physics, hardware, software, specs, applications, trends, and maintenance for “IC bonder”, “IC bonding machine”, “COG IC bonder”, “COP IC bonding machine”, “COF IC bonder”, “display driver IC bonding”, and every high-value permutation.

An IC bonding machine is a servo-driven, vision-guided, heat-and-pressure press that bonds a bare integrated-circuit die to a substrate—glass, plastic, or flexible tape—using anisotropic conductive film (ACF). The goal is electrical contact in the Z-axis only, eliminating short circuits laterally. The same platform reworks defective assemblies by removing the old ACF and rebonding a new die, saving a $300 TV panel or a $150 phone OLED. Modern bonders achieve ±1 µm alignment, ±0.5 °C temperature stability, and 0.1 g force resolution on die sizes from 0.25 × 0.25 mm to 25 × 25 mm.

Change-over from COG to COP takes < 15 s: swap the low-temp recipe, load PET parameters, and let the AI retune the PID loop.

According to industry analysis, the global IC bonding machine market is expected to grow at a CAGR of 6–8 %, driven by foldable phones, automotive displays, and medical wearables

.

IC bonder, IC bonding machine, COG IC bonder, COP IC bonding machine, COF IC bonder, display driver IC bonding, pulse heat IC bonder, low-temp COP IC bonder, reel-fed COF IC bonder, 1 micron placement accuracy, 200 °C bonding temperature, 1 MPa bonding pressure, vertical conduction horizontal insulation, lead-free IC bonding, ROHS compliant bonding, foldable phone IC bonding, 8-K TV COF bonding, automotive display IC bonding, medical device IC bonding, AI vision IC bonder, IoT IC bonding machine, China IC bonding machine, automatic IC bonder, IC bonding accuracy 1 micron, IC bonding temperature 220 C, IC bonding force 1 MPa, gold bump bonding, copper bump bonding, flip-chip bonding, COG vs COP vs COF, multi-mode IC bonder, IC bonder deep dive, IC bonding machine ultimate guide.

An IC bonder / IC bonding machine is no longer a single-purpose press—it is the universal, AI-driven, cloud-connected gateway that turns naked silicon, floppy polyimide, and curved glass into the foldable phones, 8-K TVs, and transparent medical patches that define modern electronics. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process .

A TAB bonder—short for Tape Automated Bonding bonder—is the precision heart that welds the copper leads of a continuous polyimide tape (TAB) onto a glass panel, PCB, or flexible substrate using anisotropic conductive film (ACF) or thermosonic/ultrasonic energy. Inside every 8-K TV, curved automotive cluster, or medical sensor you see today, a TAB bonder has aligned 26 µm-pitch copper fingers to ITO pads within ±1 µm and created thousands of vertical contacts in under three seconds. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “TAB bonder”, “TAB bonding machine”, “automatic TAB bonder”, “ACF TAB bonding”, and every high-value permutation.

COG (Chip-On-Glass) works for phones, but 65-inch OLED panels need driver ICs that dissipate watts of heat—too much for direct glass mounting. TAB moves the IC onto a continuous copper-clad polyimide reel that can dissipate heat, fold 180°, and be replaced during repair. The TAB bonder is the machine that welds that tape’s outer leads to the glass edge, enabling 0.9 mm bezels and AEC-Q100 Grade 0 (−40 °C to +105 °C) survival without a single connector contact.

A TAB bonder is a servo-driven, vision-guided, heat-and-pressure press that:

The result is a flexible, lead-free, foldable interconnect that survives thermal cycling, vibration, and 200,000 bend cycles.

The bonder controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 0.4 mm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global OLB bonder market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

TAB bonder, TAB bonding machine, automatic TAB bonder, ACF TAB bonding, 8-K TV TAB bonder, 100-inch TAB bonding machine, 26 µm pitch TAB bonding, automatic TAB bonding machine 1 micron accuracy, 200 °C TAB bonding temperature, 1 MPa TAB bonding pressure, vertical conduction horizontal insulation, lead-free TAB bonding, ROHS compliant TAB bonding, foldable phone TAB bonder, automotive display TAB bonding machine, medical device TAB bonding machine, roll-to-roll TAB bonder, 3,000 UPH TAB bonding machine, 99.9 % yield TAB bonder, Industry 4.0 TAB bonding machine, AI predictive maintenance TAB bonder, remote diagnostics TAB bonding machine, cloud dashboard TAB bonder

An OLB bonder is no longer a niche reel-fed press—it is the critical, AI-driven, cloud-connected gateway that turns continuous copper-clad polyimide into the 8-K TV source drivers, curved automotive clusters, and foldable touch sensors that define modern electronics. By mastering sub-micron alignment, controlled heat, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

An OLB bonder—short for Outer Lead Bonder—is the precision heart that welds the “outer” copper leads of a COF (Chip-On-Film) or TAB (Tape Automated Bonding) tail onto a glass panel, PCB, or flexible substrate using anisotropic conductive film (ACF) and controlled heat plus pressure. Inside every 8-K TV, curved automotive cluster, or foldable phone you see today, an OLB bonder has aligned 26 µm-pitch copper fingers to ITO pads within ±1 µm and created thousands of vertical contacts in under three seconds. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “OLB bonder”, “OLB bonding machine”, “automatic OLB bonder”, “ACF OLB bonding”, and every high-value permutation.

COG (Chip-On-Glass) works for phones, but 65-inch OLED panels need driver ICs that dissipate watts of heat—too much for direct glass mounting. OLB moves the IC onto a flexible polyimide tail (COF) that can dissipate heat, fold 180°, and be replaced during repair. The OLB bonder is the machine that welds that tail’s outer leads to the glass edge, enabling 0.9 mm bezels and AEC-Q100 Grade 0 (−40 °C to +105 °C) survival without a single connector contact.

An OLB bonder is a servo-driven, vision-guided, heat-and-pressure press that:

The result is a flexible, lead-free, foldable interconnect that survives thermal cycling, vibration, and 200,000 bend cycles.

The bonder controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Heat System: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 0.4 mm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm .

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global OLB bonder market is expected to grow at a CAGR of 6–8 %, driven by 8-K TVs, foldable phones, and automotive displays .

OLB bonder, OLB bonding machine, automatic OLB bonder, ACF OLB bonding, 8-K TV OLB bonder, 100-inch OLB bonding machine, 26 µm pitch OLB bonding, automatic OLB bonding machine 1 micron accuracy, 200 °C OLB bonding temperature, 1 MPa OLB bonding pressure, vertical conduction horizontal insulation, lead-free OLB bonding, ROHS compliant OLB bonding, foldable phone OLB bonder, automotive display OLB bonding machine, medical device OLB bonding machine, roll-to-roll OLB bonder, 3,000 UPH OLB bonding machine, 99.9 % yield OLB bonder, Industry 4.0 OLB bonding machine, AI predictive maintenance OLB bonder, remote diagnostics OLB bonding machine, cloud dashboard OLB bonder, granite base OLB bonding machine, servo motor OLB bonder

An OLB bonder is no longer a niche reel-fed press—it is the critical, AI-driven, cloud-connected gateway that turns continuous copper-clad polyimide into the 8-K TV source drivers, curved automotive clusters, and foldable touch sensors that define modern electronics. By mastering sub-micron alignment, controlled heat, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

A COP bonder—short for Chip-On-Plastic bonder—is the precision heart that welds a bare driver IC onto a foldable plastic substrate (polyimide, PET, or PEN) and then bonds that plastic tail to glass, flex, or board. Inside every foldable phone, curved automotive cluster, and ultra-slim OLED TV you see today, a COP bonder has aligned gold bumps to copper leads within ±1 µm and created thousands of vertical contacts in under three seconds. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “COP bonder”, “COP bonding machine”, “automatic COP bonder”, “ACF COP bonding”, and every high-value permutation.

COp stands for Chip-On-Plastic (often written Chip-On-Pi for polyimide). Instead of parking the driver IC on rigid glass (COG) or a glass-backed flex (COF), COp places the die directly onto a foldable plastic substrate—polyimide (PI), PET, or PEN—as thin as 25 µm. The plastic can be bent 180° with 0.2 mm radius, enabling 0.9 mm bezels and 200,000-fold cycles in foldable phones . The same machine later bonds the plastic tail to glass (FOG) or to another flex (FOF), all without solder, connectors, or added thickness.

The bonder controls temperature ramp, force profile, and dwell time to within 1 %; any drift triggers AI-based closed-loop correction.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm.

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production .

According to industry analysis, the global COp bonder market is expected to grow at a CAGR of 6–8 % , driven by foldable phones, automotive displays, and medical wearables .

COP bonder, COP bonding machine, automatic COP bonder, ACF COP bonding, foldable phone COP bonder, 0.2 mm fold radius COp, 25 µm polyimide COP bonding, 100-inch COP bonder, 26 µm pitch COP bonding, pulse heat COP bonder, constant temperature COP bonding machine, AI vision COP bonder, IoT COP bonding machine, China COP bonder, automatic COP bonding machine 1 micron accuracy, 180 °C COP bonding temperature, 1 MPa COP bonding pressure, vertical conduction horizontal insulation, lead-free COP bonding, ROHS compliant COP bonding, automotive display COP bonding machine, medical device COP bonding machine, roll-to-roll COP bonder,

A COp bonder is no longer a niche plastic press—it is the critical, AI-driven, cloud-connected gateway that turns foldable polyimide into the curved OLED clusters, transparent medical patches, and 0.9 mm bezels. By mastering sub-micron alignment, low-temp thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.

A COF bonder—short for Chip-On-Film bonder—is the precision heart that welds a bare driver IC onto a continuous copper-clad polyimide reel and then bonds that film tail to glass, plastic, or PCB. Inside every 8-K TV, curved automotive cluster, and foldable phone you see today, a COF bonder has aligned gold bumps to copper leads within ±1 µm and created thousands of vertical contacts in under three seconds. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “COF bonder”, “COF bonding machine”, “automatic COF bonder”, “ACF COF bonding”, and every high-value permutation.

COG (Chip-On-Glass) works for phones, but 65-inch 8-K OLED panels generate too much heat to park the driver IC directly on the glass. COF moves the IC onto a flexible polyimide tail that can dissipate heat, fold 180°, and be replaced during repair. The COF bonder is the machine that welds that tail to the glass edge, enabling 0.9 mm bezels and AEC-Q100 Grade 0 (−40 °C to +105 °C) survival without a single connector contact.

A COF bonder is a servo-driven, vision-guided, pulse-heat press that:

The result is a flexible, lead-free, foldable interconnect that survives thermal cycling, vibration, and 200,000 bend cycles.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life .

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 0.4 mm glass.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm.

Reel Feed Unit: Servo-driven with dancer-arm tension control, anti-static vacuum, splice sensor for uninterrupted production

.

According to industry analysis, the global COF bonder market is expected to grow at a CAGR of 6–8 % driven by 8-K TVs, foldable phones, and automotive displays

.

COF bonder, COF bonding machine, automatic COF bonder, ACF COF bonding, reel-fed COF bonder, 8-K TV COF bonding machine, 100-inch COF bonder, 26 µm pitch COF bonding, pulse heat COF bonder, constant temperature COF bonding machine, AI vision COF bonder, IoT COF bonding machine, China COF bonder, automatic COF bonding machine 1 micron accuracy, 200 °C COF bonding temperature, 1 MPa COF bonding pressure, vertical conduction horizontal insulation, lead-free COF bonding, ROFHS compliant COF bonding, foldable phone COF bonder, automotive display COF bonding machine, medical device COF bonding machine, roll-to-roll COF bonder, AI predictive maintenance COF bonder, remote diagnostics COF bonding machine, cloud dashboard COF bonder, granite base COF bonding machine, servo motor COF bonder, voice-coil actuator COF bonding machine, telecentric lens COF bonder,

A COF bonder is no longer a niche reel-fed press—it is the critical, AI-driven, cloud-connected gateway that turns continuous copper-clad polyimide into the 8-K TV source drivers, curved automotive clusters, and foldable touch sensors . By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.