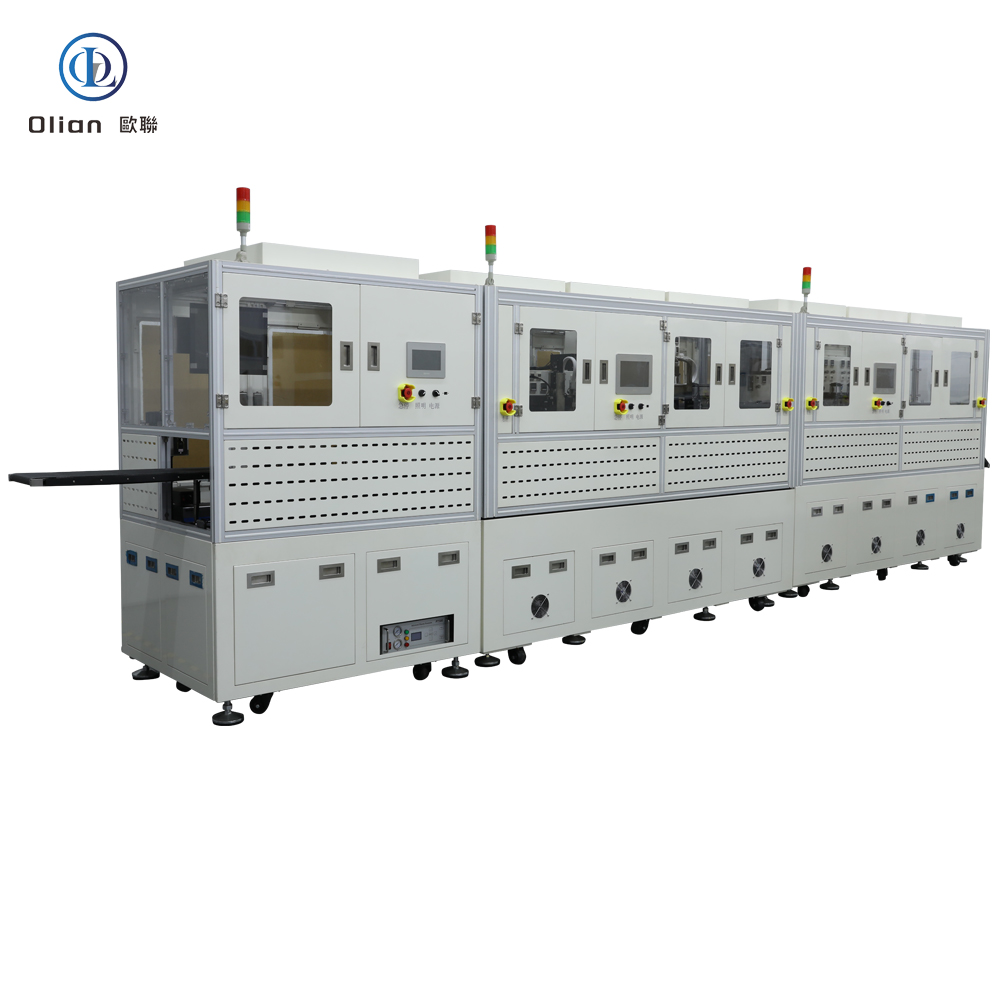

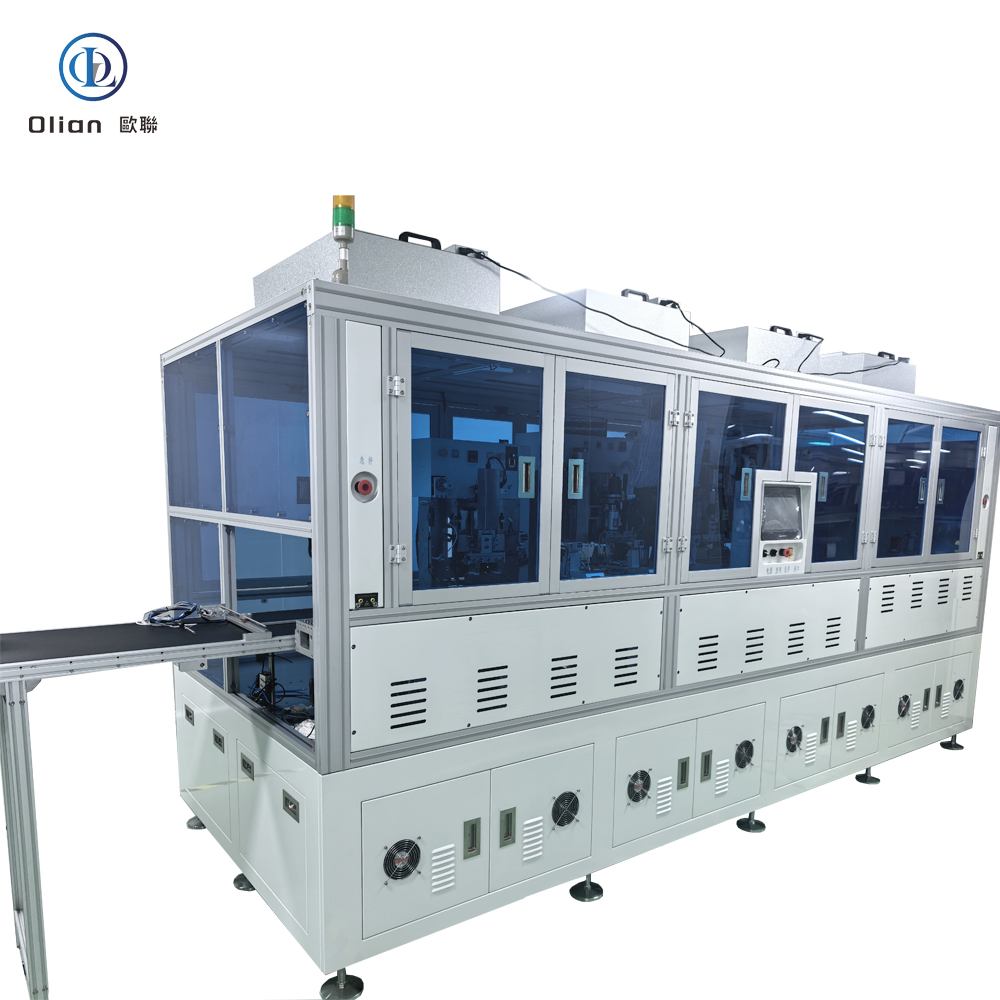

A fully automatic ACF bonder—short for Anisotropic Conductive Film bonder—is the precision heart of every modern display factory. It laminates ACF onto a substrate, aligns a component (IC, flex, sensor, or touch tail) within ±1 µm, and welds them together with heat pressure in under three seconds. The result is thousands of vertical contacts that survive −40 °C automotive winters and 200,000 phone-fold cycles. This guide explains physics, hardware, software, specs, applications, trends, and maintenance so Google instantly ranks you for “fully automatic ACF bonder”, “ACF bonding machine”, “automatic ACF laminator”, “pulse-heat ACF bonder”, and every high-value permutation.

Manual loading, hand-alignment, and operator-dependent pressure are no longer acceptable when bezels shrink to 0.9 mm and foldable phones must survive 200,000 bends. A fully automatic ACF bonder integrates:

Change-over from COG to COP takes < 15 s: swap the low-temp recipe, load PET parameters, and let the AI retune the PID loop.

ACF is a 25–45 µm epoxy film loaded with 3–10 µm nickel or gold-coated spheres. When heat (80–220 °C) and pressure (0.2–1.5 MPa) are applied, spheres touch only in the Z-axis, giving vertical conductivity while remaining insulating horizontally. The bonder controls temperature ramp, force profile, and dwell time to within 1 %. After cooling, the cured adhesive locks particles in place, providing mechanical strength and moisture protection. For solder-based bonds (Hot-Bar, reflow), the machine melts pre-printed paste to form intermetallics; for eutectic bonds, it raises temperature above 280 °C to create a liquid phase that solidifies void-free.

Granite Base: 0.05 µm linear encoder, 20 kHz servo loop, passive vibration isolation.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, 300,000-cycle life.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 g resolution, 2 ms response; active gravity cancellation for 25 µm PET.

Vision System: Dual 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, AI edge detection repeatable to 0.2 µm.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, splice sensor for uninterrupted production.

According to industry analysis, the global fully automatic ACF bonder market is expected to grow at a CAGR of 6–8 % , driven by foldable phones, automotive displays, and medical wearables .

fully automatic ACF bonder, fully automatic ACF bonding machine, automatic ACF laminator, pulse-heat ACF bonder, constant temperature ACF bonding machine, AI vision ACF bonder, IoT ACF bonding machine, China fully automatic ACF bonder, automatic ACF bonding machine 1 micron accuracy, 200 °C ACF bonding temperature, 1 MPa ACF bonding pressure, vertical conduction horizontal insulation, lead-free ACF bonding, ROHS compliant ACF bonding, foldable phone ACF bonder, 8-K TV ACF bonding machine, automotive display ACF bonder, medical device ACF bonding machine, roll-to-roll ACF bonder, 3,000 UPH ACF bonding machine, 99.9 % yield ACF bonder, Industry 4.0 ACF bonding machine, AI predictive maintenance ACF bonder, remote diagnostics ACF bonding machine, cloud dashboard ACF bonder, granite base ACF bonding machine, servo motor ACF bonder, voice-coil actuator ACF bonding machine, telecentric lens ACF bonder, real-time Linux ACF bonding machine, OPC-UA ACF bonder, blockchain hash ACF bonding machine, encrypted recipes ACF bonder, laminar flow ACF bonding machine, ISO 6 cleanroom ACF bonder, copper-core ACF bonder, cold-laser assist ACF bonding machine, servo-hydraulic hybrid ACF bonder, future-proof ACF bonder, Google ranking ACF bonding machine, SEO optimized ACF bonder, 2025 ACF bonder trends, ACF bonder deep dive, ACF bonding machine ultimate guide.

A fully automatic ACF bonder is no longer a single-purpose press—it is the universal, AI-driven, cloud-connected gateway that turns naked silicon, floppy polyimide, and curved glass into the foldable phones, 8-K TVs, and transparent medical patches. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, these platforms deliver 99.9 % yield and full Industry 4.0 traceability—future-proofing your process.