A T-FOG bonding machine (Touch-Flex-On-Glass) is the micron-precision link that welds the capacitive-touch sensor tail directly to the cover glass or sensor glass of a display module. In every smartphone, tablet, curved automotive cluster, or wearable OLED you touch today, a T-FOG bonder has aligned ITO or metal-mesh touch pads to copper leads within ±1 µm and created thousands of vertical contacts in under three seconds. This article explains physics, hardware, software, specs, applications, trends, and maintenance for “T-FOG bonding machine”, “Touch-Flex-On-Glass bonder”, “touch sensor ACF bonding”, “capacitive touch flex bonding”, “OLED T-FOG bonding”

T-FOG stands for Touch-Flex-On-Glass. The capacitive touch layer of a modern display is a separate flex circuit (often with its own controller IC) that must be electrically connected to the cover glass or sensor glass. The flex tail carries fine copper traces that fan out to ITO or metal-mesh touch pads on the glass. A T-FOG bonding machine laminates anisotropic conductive film (ACF) onto the glass, aligns the touch-flex pads to the glass pads within micron accuracy, and executes a pulse-heat bond at 160–200 °C and 0.8–1.5 MPa. Conductive particles trapped between copper and ITO form < 30 mΩ contacts vertically while remaining > 1 GΩ isolated horizontally. After the bond, the tail is folded 180° so the controller IC hides behind the glass, shrinking the bezel to under 1 mm.

COG (Chip-On-Glass) places the touch controller directly on the glass, but large 8-K OLED panels generate too much heat—T-FOG moves the IC onto a flex tail that can dissipate heat and be replaced during repair. Connector solutions add 0.3 mm height and cost $0.50; T-FOG adds 0.03 mm and costs <$0.05. Automotive Tier-1 suppliers prefer T-FOG because it passes AEC-Q100 Grade 0 (−40 °C to +150 °C) without a single connector contact.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, lasts 300,000 cycles.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 0.4 mm glass.

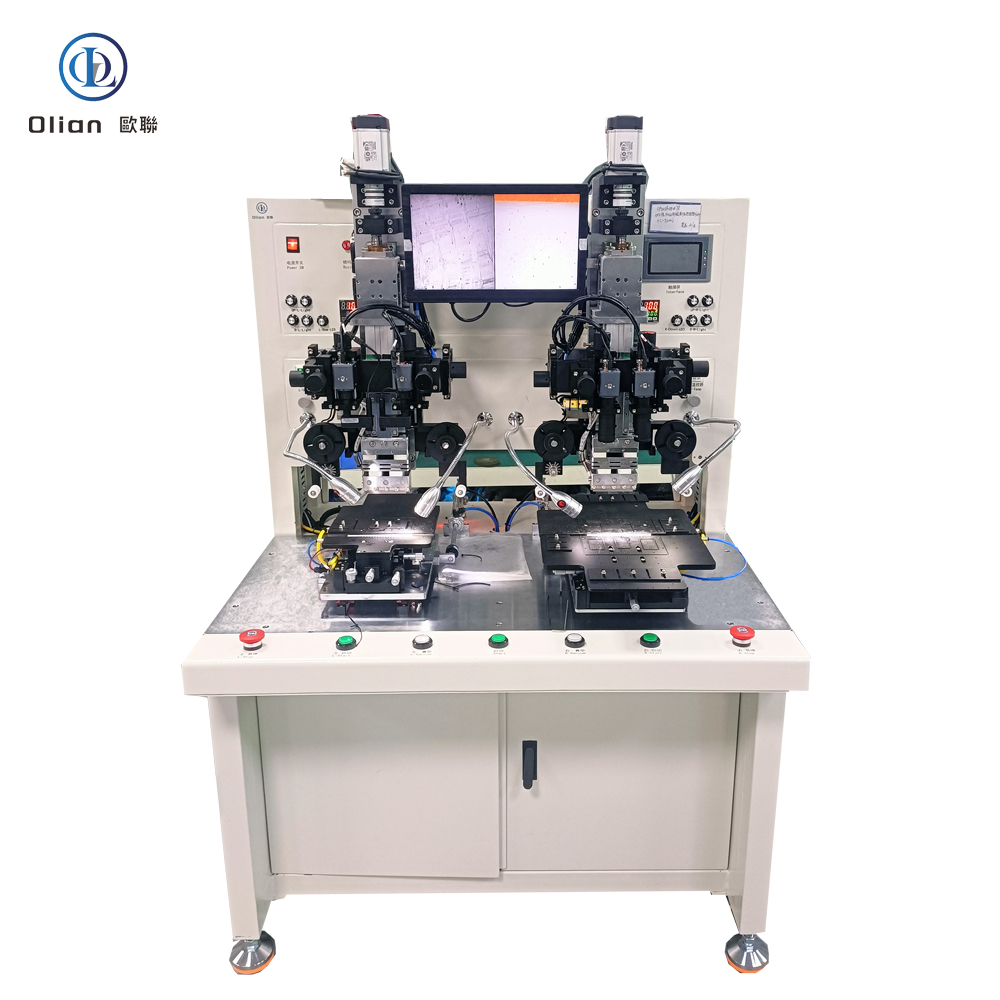

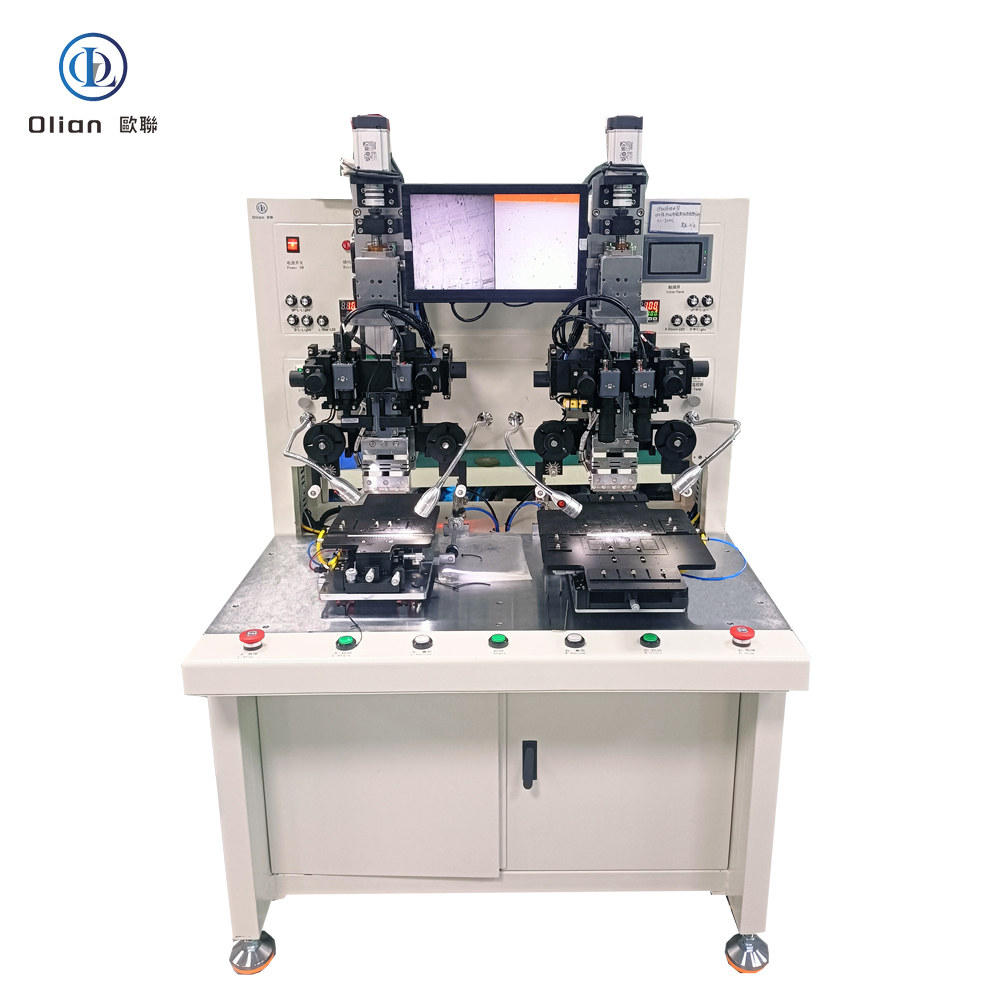

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearings, 0.05 µm linear encoder, servo feedback at 20 kHz, granite base with passive vibration isolation.

Flex Feed Unit: Servo-driven picker, anti-static vacuum, soft-tip collet for 25 µm polyimide.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz.

Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code.

AI vision self-learns new touch-pad patterns from glass vendors, reducing setup time 70 %.

MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability.

Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs.

Consumer Electronics: Smartphone OLED, tablet LCD, laptop mini-LED, smartwatch flexible AMOLED.

TV & Signage: 32″-120″ 4-K/8-K LCD, OLED, mini-LED, curved and foldable screens.

Automotive: Curved instrument clusters, 15-inch OLED infotainment, head-up displays, camera modules—passing 1,000 h 85 °C/85 % RH.

Medical: Surgical monitors, diagnostic tablets, wearable patches—biocompatible polyimide, ISO 13485 traceability.

Industrial & Aerospace: Avionics displays, factory HMI panels, rugged handhelds—shock, altitude, fungus .

T-FOG bonding machine, Touch-Flex-On-Glass bonder, touch sensor ACF bonding, capacitive touch flex bonding, OLED T-FOG bonding, automotive T-FOG bonding, medical T-FOG bonding, 26 µm pitch T-FOG bonding, 8-K touch T-FOG bonding, 100-inch T-FOG bonding, pulse heat T-FOG bonding, constant temperature T-FOG bonding, AI vision T-FOG bonding, IoT T-FOG bonding machine, China T-FOG bonding machine, automatic T-FOG bonder, T-FOG bonding accuracy 1 micron, T-FOG bonding temperature 200 C, T-FOG bonding pressure 1 MPa, vertical conduction horizontal insulation, lead-free T-FOG bonding, ROHS compliant T-FOG bonding.

Copper-Core ACF: Cu-Ag particles cut material cost 50 % while keeping < 20 mΩ contact resistance.

Cold-Laser Fold Assist: Femtosecond laser pre-scores the coverlay, enabling 50 µm bend radius with zero trace damage.

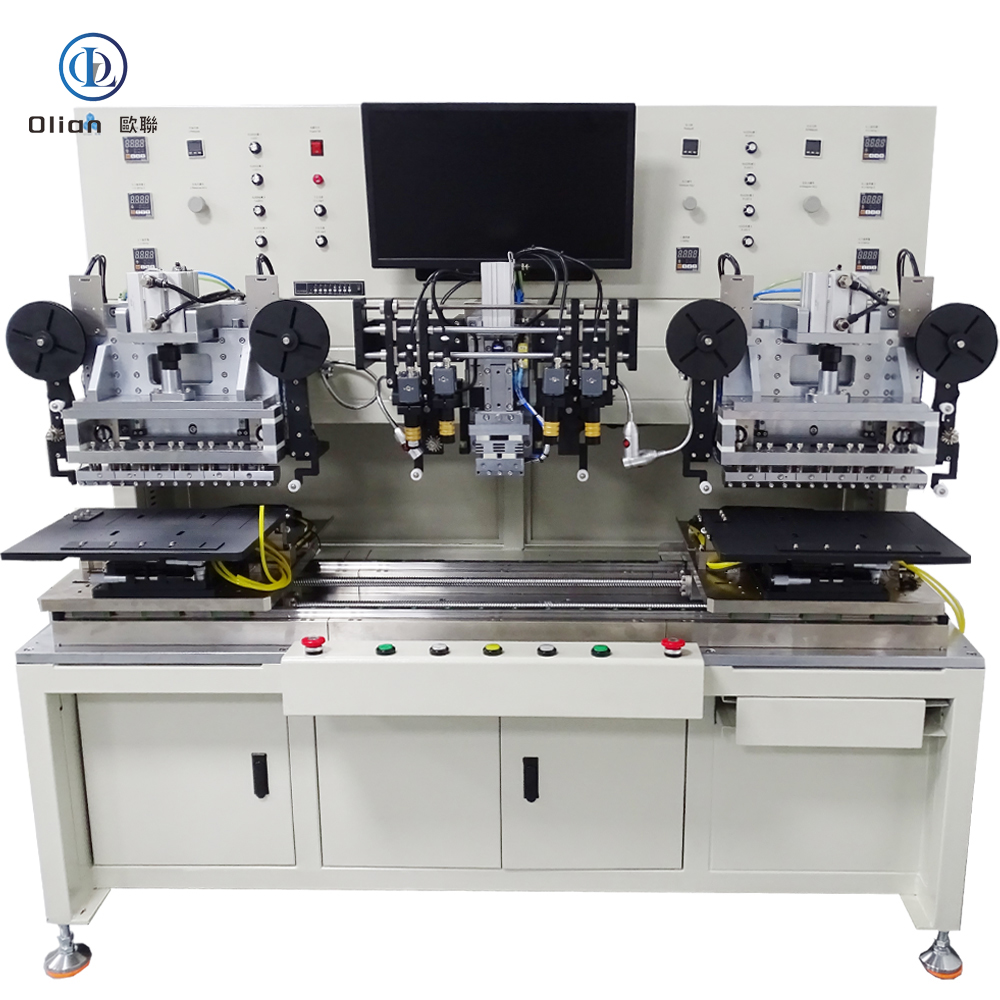

Servo-Hydraulic Hybrid: Delivers 80 kg force on 100″ TV glass while keeping 1 µm position accuracy.

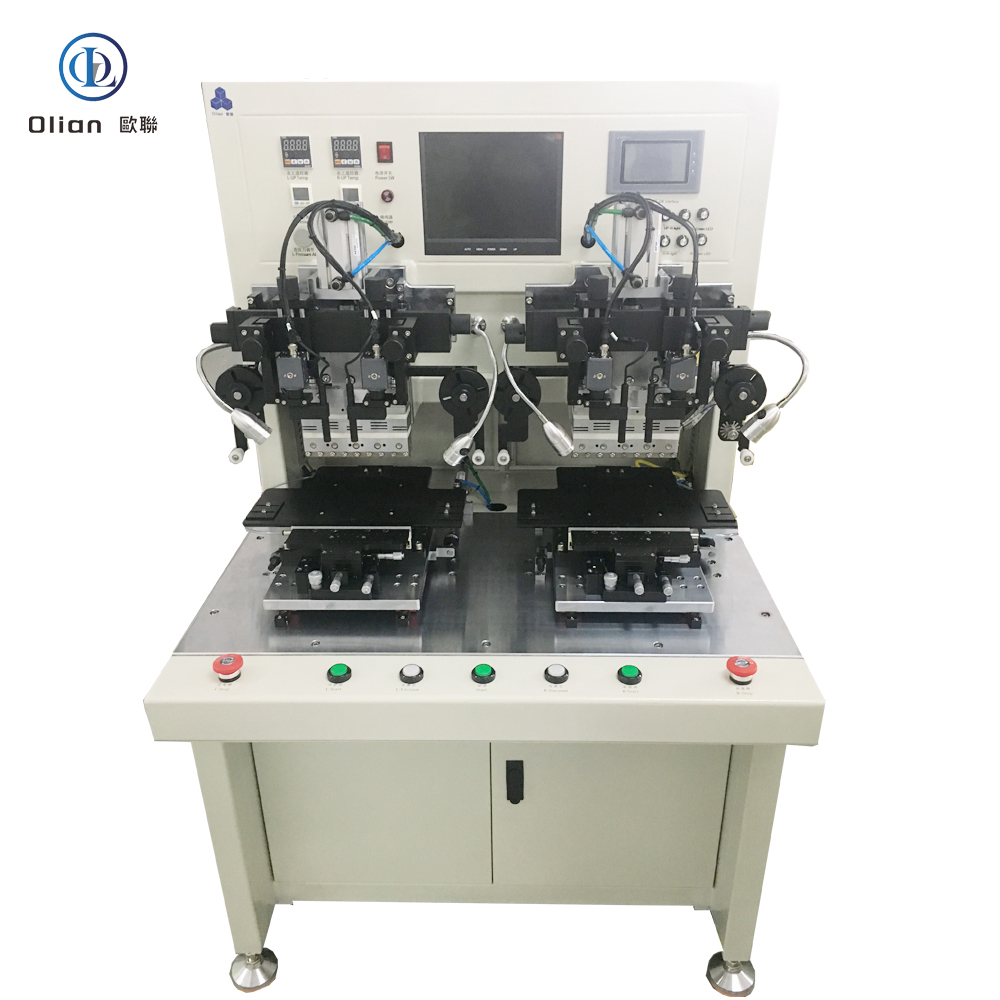

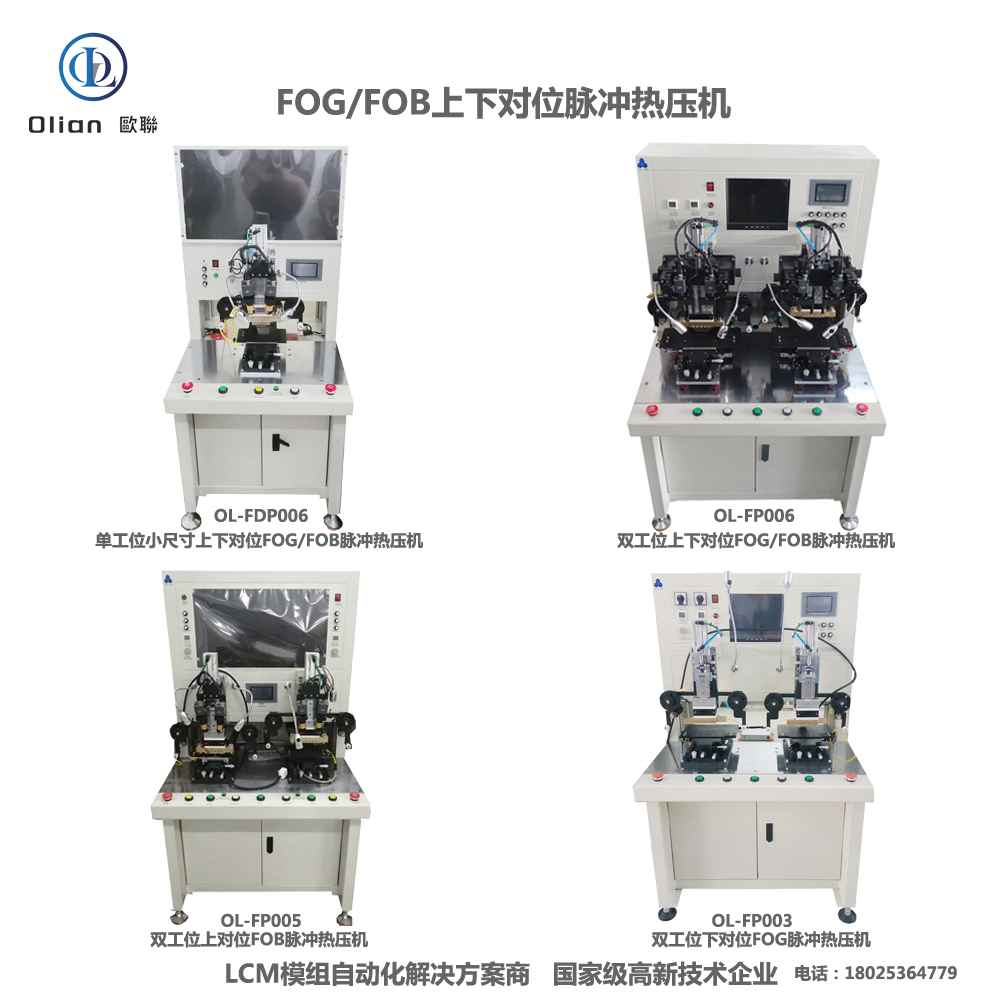

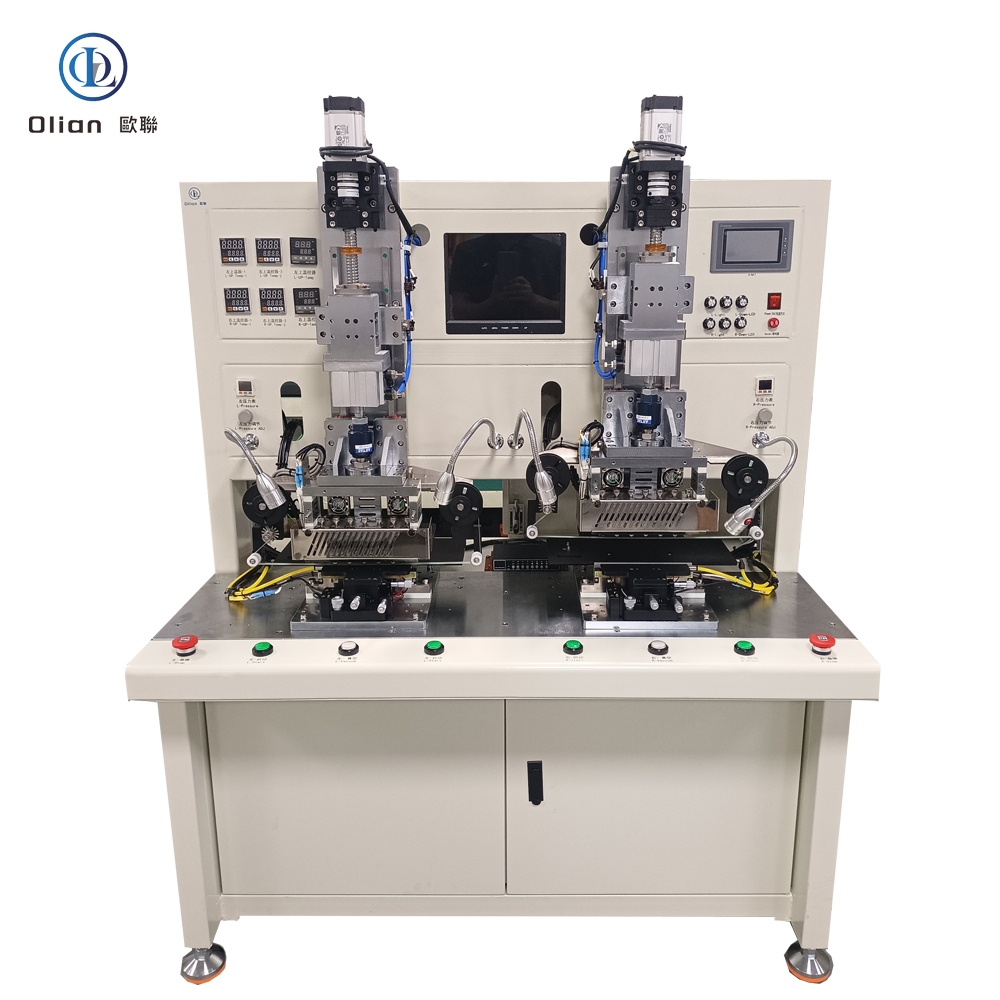

Dual-Head T-FOG: Parallel bonding of touch and source tails doubles throughput without extra floor space.

AI-Driven Calibration: Neural networks auto-optimize temperature profiles for each glass type, pushing yield to 99.9 %.

A T-FOG bonding machine is no longer a niche display tool—it is the critical gateway between microscopic touch-sensor pads and macroscopic glass signals. By mastering sub-micron alignment, single-degree thermal control, and real-time force feedback, the latest T-FOG bonders deliver sub-3-second cycles with 99.9 % yield and full Industry 4.0 traceability. Whether you are a display OEM chasing 0.9 mm bezels, an automotive Tier-1 qualifying 100-inch curved clusters, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected T-FOG bonding platform future-proofs your process.