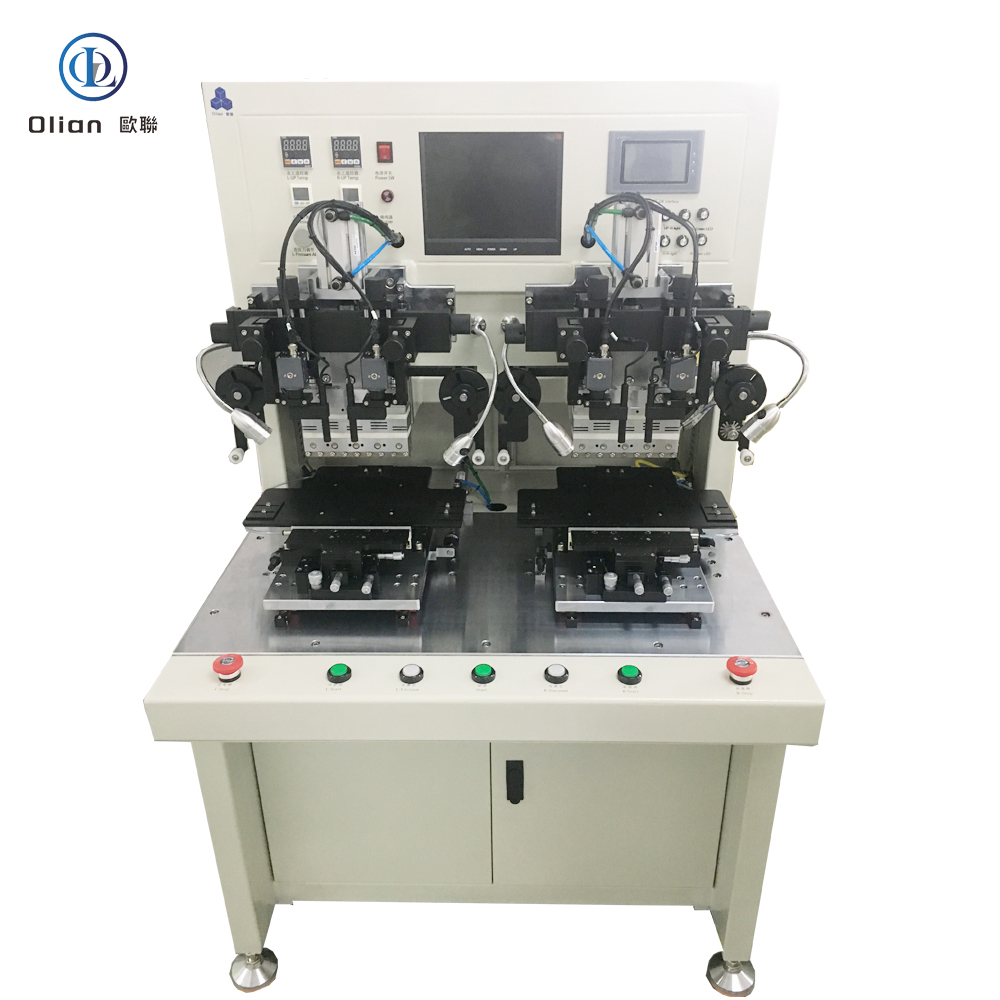

FOP Bonding Machine

A FOP bonding machine—short for Flex-On-Plastic or Film-On-Plastic—is the precision heart that folds a floppy polyimide tail onto a rigid or semi-rigid plastic substrate and welds it there with micron accuracy. The process is driven by anisotropic conductive film (ACF), heat, and force, creating thousands of vertical contacts while keeping lateral insulation. The result is a vibration-proof, chemical-resistant, lead-free joint that survives −40 °C automotive winters, +105 °C engine-bay summers, and 95 % humidity in medical sterilizers. This article explains every angle of the technology for “FOP bonding machine”, “FOP bonder”, “flex-on-plastic bonding”, “ACF FOP machine”, “automotive FOP bonding”, “medical FOP bonding” high-value keywords.

A FOP bonding machine is a servo-driven, vision-guided, pulse-heat press that laminates anisotropic conductive film onto a plastic substrate—typically PET, PEN, PI, or LCP—and then bonds a flexible printed circuit (FPC) or chip-on-film (COF) tail to that plastic with sub-micron accuracy. The film contains nickel or gold-coated spheres that conduct only vertically, giving thousands of simultaneous contacts while remaining insulating laterally. The same platform reworks defective assemblies by removing the old ACF and rebonding a new tail, saving automotive sensor or disposable medical catheter.

Metal chassis are heavy; glass is brittle; FR-4 is thick. Automotive designers want 3D-shaped, lightweight, chemical-resistant plastic dashboards. Medical OEMs need transparent, sterilizable PET circuits that survive autoclave cycles. Consumer brands chase foldable phones with plastic mid-plates that bend 180°. FOP solves these pain points by marrying the flexibility of copper-clad polyimide with the moldability of engineering plastics, all while enabling repair: a defective flex can be removed and rebonded without scrapping the entire plastic assembly.

Bonding Head: Titanium alloy, diamond-lapped to 0.3 µm flatness, DLC-coated for anti-stick, lasts 300,000 cycles.

Pulse Heater: 800 W cartridge, embedded K-type thermocouple, ramp 200 °C/s, overshoot < 0.5 °C.

Force Actuator: Voice-coil or servo motor, 24-bit encoder, 0.1 N resolution, 2 ms response; active gravity cancellation for 0.2 mm PET.

Vision System: 12 MP global-shutter CMOS, telecentric lens, coaxial + side LED, sub-pixel edge detection repeatable to 0.2 µm.

Motion Stage: Cross-roller bearings, 0.05 µm linear encoder, servo feedback at 20 kHz, granite base with passive vibration isolation.

ACF Feed Unit: Stepper-driven, tungsten-steel cutter, anti-static vacuum, waste take-up spool, splice sensor for uninterrupted production.

Real-time Linux kernel guarantees < 1 ms jitter; PID temperature loop updated at 10 kHz.

Recipe manager encrypts parameters—temperature, pressure, time, ramp rate—per product QR code.

AI vision self-learns new pad patterns from plastic vendors, reducing setup time 70 %.

MES interface via OPC-UA uploads cycle data, resistance values, and images for full traceability.

Cloud dashboard predicts heater degradation and schedules maintenance before scrap occurs.

Consumer Electronics: Foldable phone mid-plate, tablet battery flex, smartwatch heart-rate sensor, AR-glass temple arm.

Automotive: 3D-shaped dashboard, curved instrument cluster, 15 inch OLED infotainment, head-up display—passing 1,000 h 85 °C/85 % RH.

Medical: Disposable catheter flex, surgical hand-piece PCB, wearable ECG patch—biocompatible PET, ISO 13485 traceability.

Industrial & Aerospace: Avionics displays, factory HMI panels, rugged handhelds—chemical resistance to Skydrol, shock per MIL-STD-810.

FOP bonding machine, FOP bonder, flex-on-plastic bonding, ACF FOP machine, film-on-plastic bonder, pulse heat FOP bonding, constant temperature FOP bonding, automotive FOP bonding, medical FOP bonding, 0.2 mm fold radius FOP, 25 µm polyimide FOP bonding, 500 mm PET bonding, AI vision FOP bonding, IoT FOP bonding machine, China FOP bonding machine, automatic FOP bonder, FOP bonding accuracy 1 micron, FOP bonding temperature 200 C, FOP bonding pressure 1 MPa, vertical conduction horizontal insulation, lead-free FOP bonding, ROHS compliant FOP bonding.

Copper-Core ACF: Cu-Ag particles cut material cost 50 % while keeping < 20 mΩ contact resistance.

Green Refrigerants: Closed-loop cooling replaces water with R1234ze, reducing carbon footprint 30 %.

AI-Driven Profiles: Neural networks auto-optimize temperature ramps for each plastic type, pushing yield to 99.9 %.

Cold-Laser Fold Assist: Femtosecond laser pre-scores the coverlay, enabling 90° fold with 50 µm radius and zero trace damage.

Servo-Hydraulic Hybrid: Delivers 80 kg force for 500 mm automotive plastic panels while keeping 1 µm position accuracy.

Roll-to-Roll FOP: Reel-fed PET and die-bond-on-the-fly reach 3,000 UPH for smart-membrane switches.

An FOP bonding machine is no longer a niche flex-to-plastic press—it is the critical enabler for foldable OLED, 3D-shaped automotive dashboards, transparent medical circuits, and chemical-resistant industrial membranes that consumer and professional expectations. By mastering sub-micron alignment on 25 µm polyimide, pulse-heat control within half a degree, and real-time force feedback, the latest FOP bonders deliver sub-3-second cycles with 99.9 % yield and full Industry 4.0 traceability. Whether you are a display OEM chasing a 0.9 mm chin, an automotive Tier-1 qualifying 500 mm curved clusters, or a medical start-up prototyping transparent patches, investing in an AI-enhanced, IoT-connected FOP bonding platform future-proofs your process .