Fully automatic COG FOG bonding machine is a sophisticated piece of equipment used in the electronics industry, particularly for the production of liquid crystal displays (LCDs). This machine combines the processes of COG and FOG bonding into a single, integrated system, streamlining the manufacturing process and improving efficiency.

The machine typically includes several modules to handle different stages of the bonding process:

The fully automatic COG FOG bonding machine is widely used in various applications, including:

The industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include the integration of more advanced vision systems and the development of machines capable of handling larger and more complex substrates

Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in the design of these machines.

In summary, the fully automatic COG FOG bonding machine is a critical component in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices.

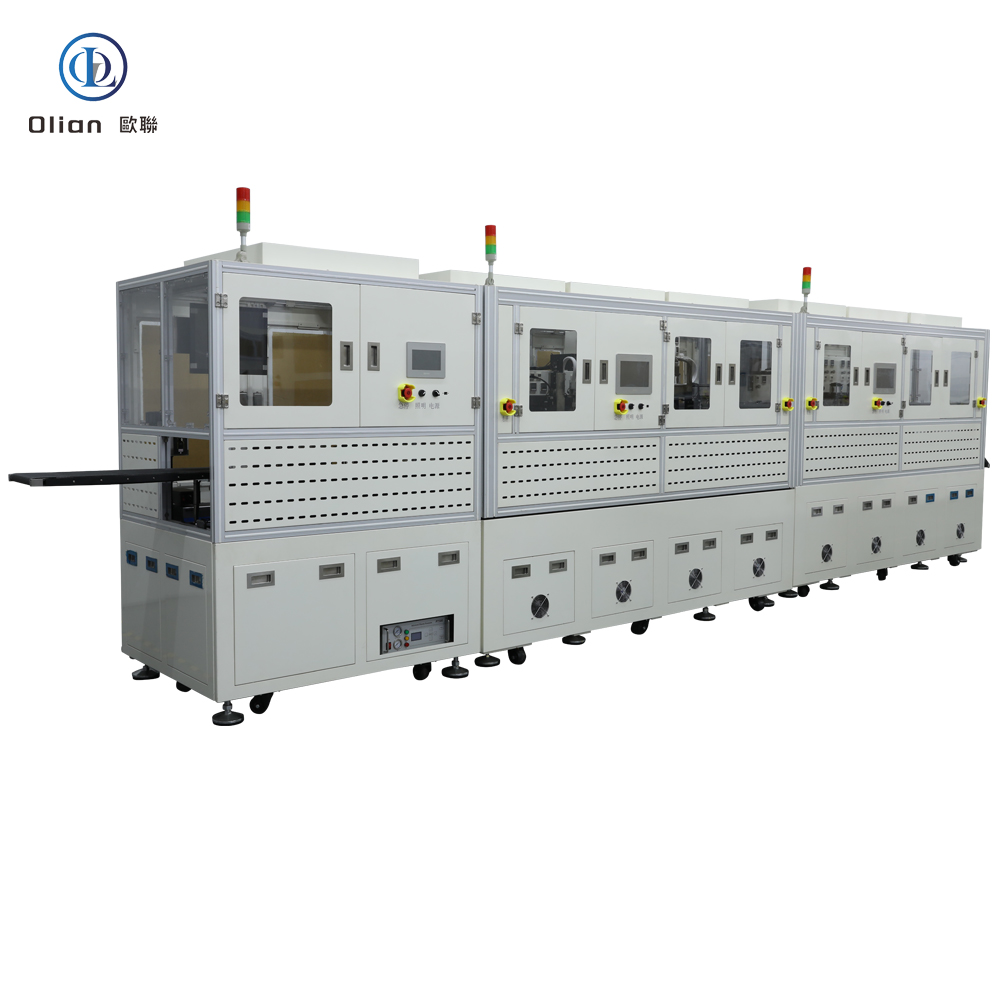

Fully automatic ACF (Anisotropic Conductive Film) bonding machine production line is a sophisticated system designed to streamline the process of bonding electronic components using ACF.

This technology is crucial in the manufacturing of various electronic devices, particularly those involving LCD panels, PCBs, and other high-density electronic assemblies.

The production line typically consists of several integrated modules, each responsible for a specific step in the bonding process:

The fully automatic ACF bonding machine production line is widely used in various industries, including:

The market for ACF bonding machines is driven by the increasing demand for smaller, more efficient electronic devices. As technology continues to advance, the need for more precise and reliable bonding processes is growing

This has led to the development of more sophisticated and automated bonding machines that can handle higher production volumes and more complex assemblies.

Future trends in the industry include the integration of AI and machine learning technologies to further enhance the precision and efficiency of the bonding process.

Additionally, there is a growing focus on developing environmentally friendly materials and processes to reduce the environmental impact of electronic manufacturing

In summary, the fully automatic ACF bonding machine production line is a vital tool in modern electronics manufacturing.

It offers a high degree of precision, reliability, and efficiency, making it an essential component in the production of high-quality electronic devices.

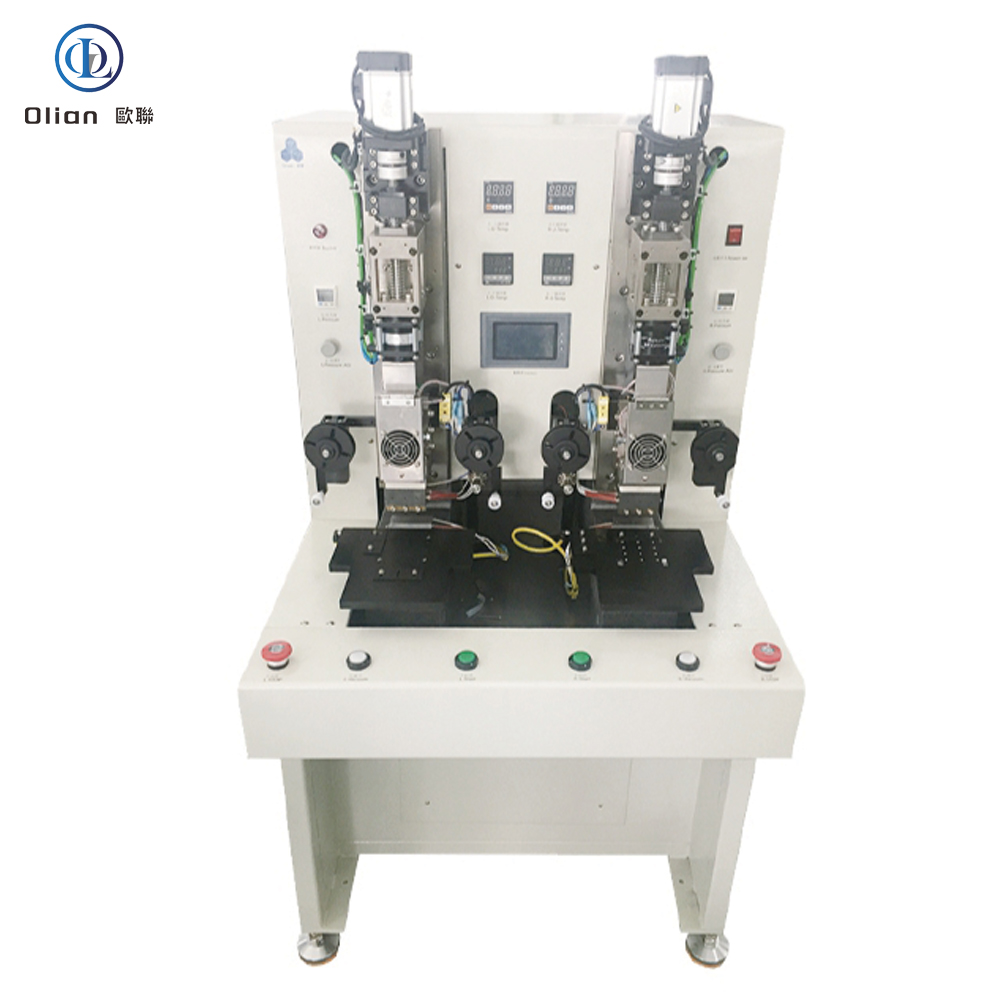

COG (Chip On Glass) Main Bonder is a critical piece of equipment used in the manufacturing of liquid crystal displays (LCDs). It is responsible for the final bonding process where the integrated circuit (IC) is permanently attached to the glass substrate. This step follows the pre-bonding process and ensures a robust and reliable connection between the IC and the display panel.

The COG Main Bonder operates by first aligning the pre-bonded IC with the glass substrate. The machine uses a high-precision alignment system to ensure that the IC is accurately positioned. Once aligned, the bonding process begins. The machine applies heat and pressure to the assembly, causing the Anisotropic Conductive Film (ACF) to bond the IC to the glass substrate. The ACF contains conductive particles that create electrical connections between the IC and the substrate

The COG Main Bonder is primarily used in the production of LCD panels for various electronic devices, including:

The COG Main Bonder offers several benefits in the manufacturing process:

The COG Main Bonder has significantly impacted the electronics industry by enabling the production of high-quality, compact displays. It plays a vital role in meeting the demands for smaller, more efficient electronic devices, contributing to advancements in display technology and overall consumer satisfaction

In summary, the COG Main Bonder is an essential tool in the manufacturing of LCD panels, providing a reliable and precise method for permanently bonding ICs to glass substrates. Its applications are widespread across various industries, driving innovation and enhancing the performance of electronic devices

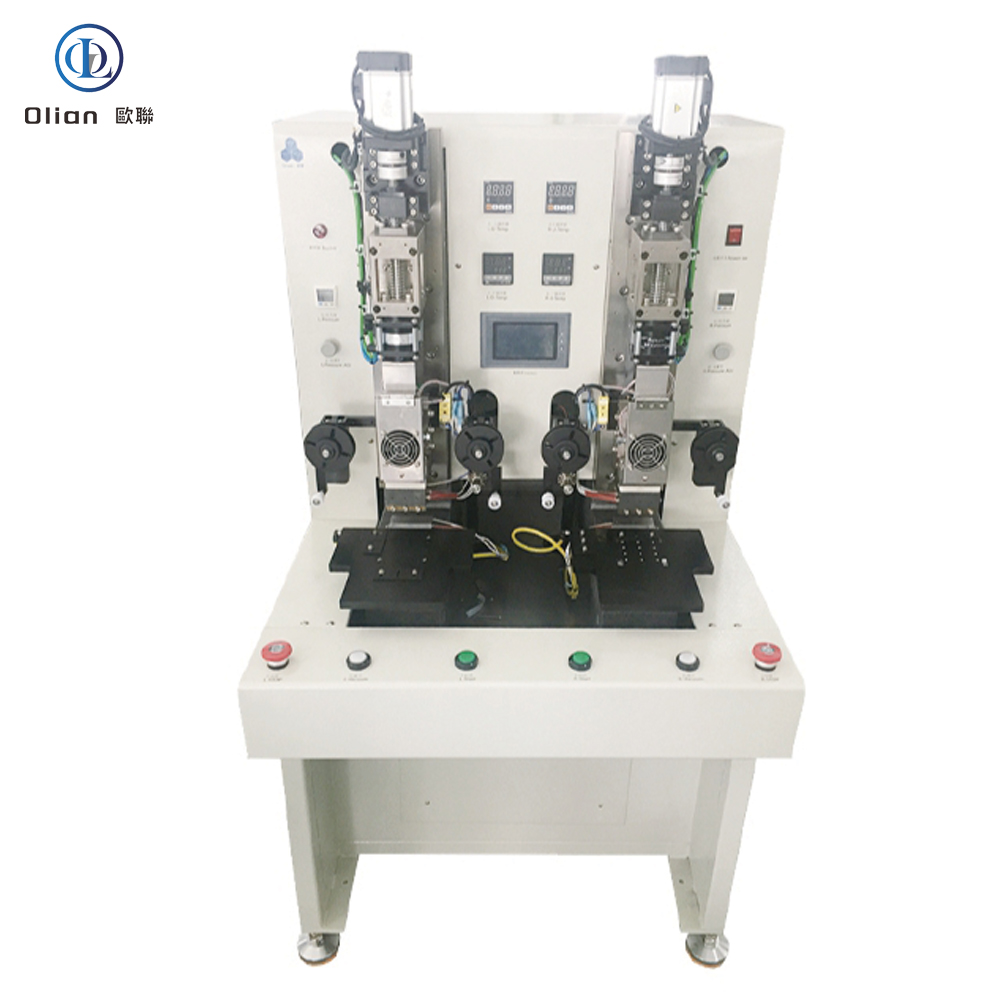

COG (Chip-On-Glass) Pre-Bonder is a specialized piece of equipment used in the electronics industry, particularly in the manufacturing of liquid crystal displays (LCDs). It plays a crucial role in the initial stages of the COG bonding process, ensuring that the integrated circuit (IC) is accurately aligned and pre-attached to the glass substrate before the final bonding step.

The COG Pre-Bonder operates by first aligning the IC with the glass substrate. This alignment is achieved using sophisticated imaging and positioning systems that ensure high precision. The IC is then pre-attached to the glass substrate using a temporary adhesive or a low-temperature bonding process. This pre-attachment step helps to hold the IC in place during the subsequent main bonding process, where higher temperatures and pressures are applied to create a permanent bond

The COG Pre-Bonder is primarily used in the production of LCD panels for various electronic devices, including:

The use of a COG Pre-Bonder offers several benefits in the manufacturing process:

The COG Pre-Bonder has significantly impacted the electronics industry by enabling the production of high-quality, compact displays. It plays a vital role in meeting the demands for smaller, more efficient electronic devices, contributing to advancements in display technology and overall consumer satisfaction

In summary, the COG Pre-Bonder is an essential tool in the manufacturing of LCD panels, providing a reliable and precise method for pre-attaching ICs to glass substrates. Its applications are widespread across various industries, driving innovation and enhancing the performance of electronic devices.

COF (Chip-on-Film) bonding machine is a highly specialized piece of equipment used primarily in the electronics industry for assembling and repairing electronic devices, especially those with LCD (Liquid Crystal Display) screens

This machine is designed to attach semiconductor chips to flexible substrates using a process that involves the use of Anisotropic Conductive Film (ACF) as the adhesive

The COF bonding process begins with the placement of a semiconductor chip onto a flexible printed circuit film. The chip, which typically has gold bumps, is aligned with the inner leads of the flexible substrate. The ACF is then placed between the chip and the substrate. The bonding machine applies heat and pressure to the assembly, causing the ACF to bond the chip to the substrate. This process ensures a reliable electrical connection between the chip and the substrate

COF bonding machines are widely used in various industries, including:

The COF bonding technology offers several advantages over traditional bonding methods:

The COF bonding machine has significantly impacted the electronics industry by enabling the production of more compact, lightweight, and flexible devices. It has also facilitated the development of advanced display technologies, contributing to the growth of the consumer electronics market

In summary, the COF bonding machine is a crucial tool in modern electronics manufacturing, offering a reliable and efficient method for integrating semiconductor chips with flexible substrates. Its applications span across multiple industries, driving innovation and enhancing the performance of electronic devices.

A COF (Chip-On-Film) Bonding Machine is a high-precision device designed to connect integrated circuits (ICs) to flexible film substrates. This technology is widely used in the assembly of LCD, OLED, and other advanced displays. It plays a pivotal role in ensuring the performance and reliability of modern electronic devices. COF bonding is the backbone of many industries, enabling compact designs, high-resolution displays, and durable electronic products. Whether you’re manufacturing smartphones, automotive displays, or industrial control panels, COF Bonding Machines are an essential tool for innovation and efficiency.

COF technology allows semiconductor chips to be directly bonded onto flexible film, enabling:

With the rise of micro-LEDs, foldable displays, and wearable technology, COF technology has become indispensable in keeping up with the latest trends in electronics.

COF Bonding Machines can be classified based on their application and capabilities:

To stay competitive, manufacturers require machines that deliver precision and speed. The key features of a state-of-the-art COF Bonding Machine include:

COF Bonding Machines are indispensable across diverse industries:

COF Bonding Machines are essential in the manufacturing of modern electronic devices, providing high precision and reliability in the bonding process. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, COF technology continues to play a crucial role in the electronics industry.

Shenzhen Olian Automatic Equipment Co., Ltd ,established in 2012, is a national high-tech enterprise specializing in the research and development, sales, production, and service of automation equipment for FPD flat panel displays and new flexible screen displays. The company holds multiple invention patents, utility model patents, and software copyrights. At present, the company has a professional R&D team of more than 70 people, as well as a professional team for production management, quality management, and after-sales service.

Olian has a precision CNC machining center (precision CNC, large water mill, lathe, milling machine, grinder, anime imported from Japan, Olympus differential interference microscope and other production and testing equipment) covers an area of 4000 square meters and has overall manufacturing capabilities from product design to production and processing.

Since its establishment, it has always adhered to the spirit of craftsmanship and continuous innovation, and has been praised for its quality spirit. In the spirit of efficiency and customer satisfaction . Our service spirit and philosophy on the Internet have continuously won the respect of customers and the preferred designated module supporting equipment manufacturers. We are committed to contributing to the progress of the entire industry and striving to become a leading benchmark enterprise in the display industry.

Olian’s products include LCM module factories and full process equipment (bonding, AOI, dispensing, backlighting, soldering), achieving manufacturing of integrated display and touch products. The company’s series of products are widely used in display fields such as mobile phones, electronic tags, tablets, smart wearables, automotive displays, televisions, computers, etc., and provide overall solutions for smart factories.

Olian has established a long-term friendly cooperation relationship with many outstanding and well-known enterprises, such as HUAWEI, CSOT,BOE,BYD, Apple, FOXCONN, Luxshare, TCL ,Skyworth , WINGTECH,TOPBAND,KERSEN,K&D , WGTECH,DBG,CCET,HIMAX,WISTRON, etc. We have also established long-term friendly cooperation relations with Chinese Academy of Sciences, Tsinghua Institute of Soft Electricity, Zhejiang University, China University of Science and Technology, Huazhong University of Science and Technology, South China University of Technology, Shenzhen University, etc,

Through continuous efforts, Olian’s products are sold in more than 20 provinces and cities including Taiwan Province, as well as the United States, Canada, the United Kingdom, Germany, Korea, Singapore, India, Pakistan, Vietnam, Malaysia, Saudi Arabia, Iran, Egypt, Cameroon, Ghana, Pakistan, Colombia, Ecuador, etc., covering five continents in Asia, North America, South America, Europe, and Africa.

Welcome you visit us at any time when you need!