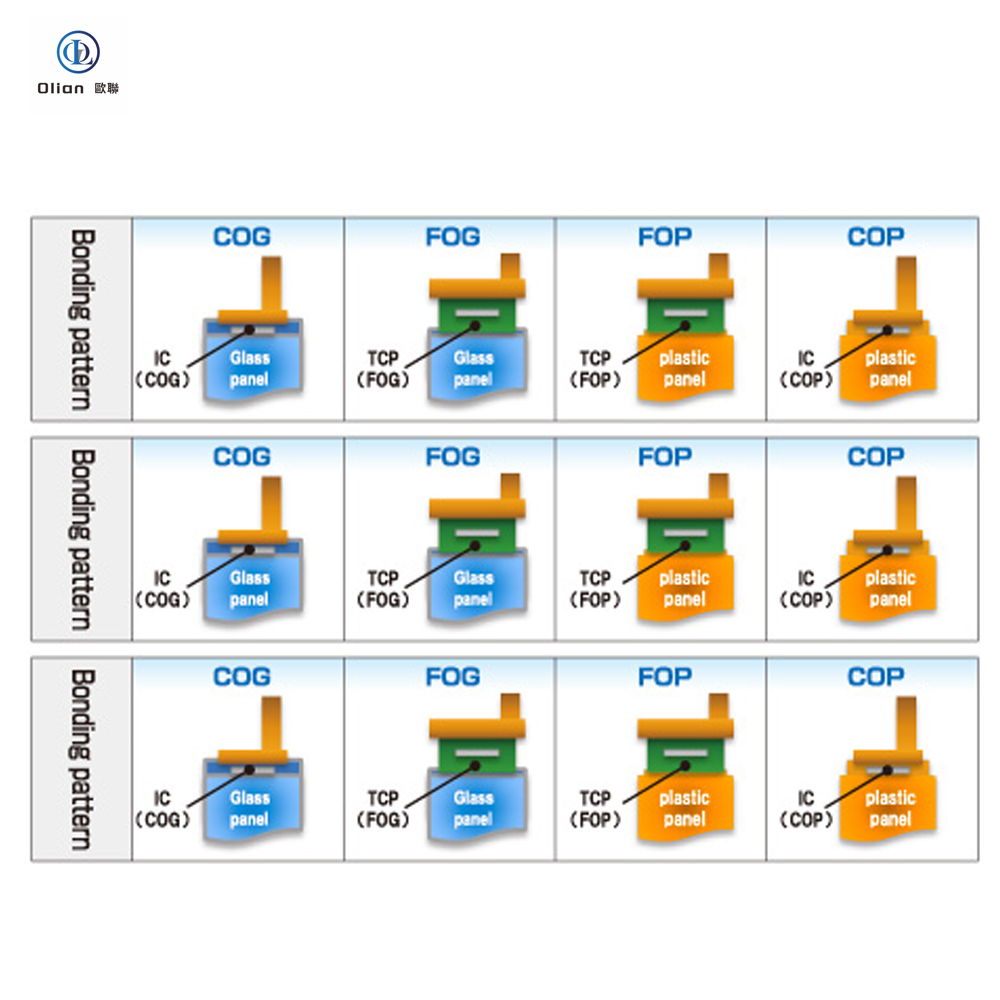

COG (Chip On Glass) Bonding Machine is a critical piece of equipment used in the manufacturing of liquid crystal displays (LCDs). It is responsible for the final bonding process where the integrated circuit (IC) is permanently attached to the glass substrate. This step follows the pre-bonding process and ensures a robust and reliable connection between the IC and the display panel.

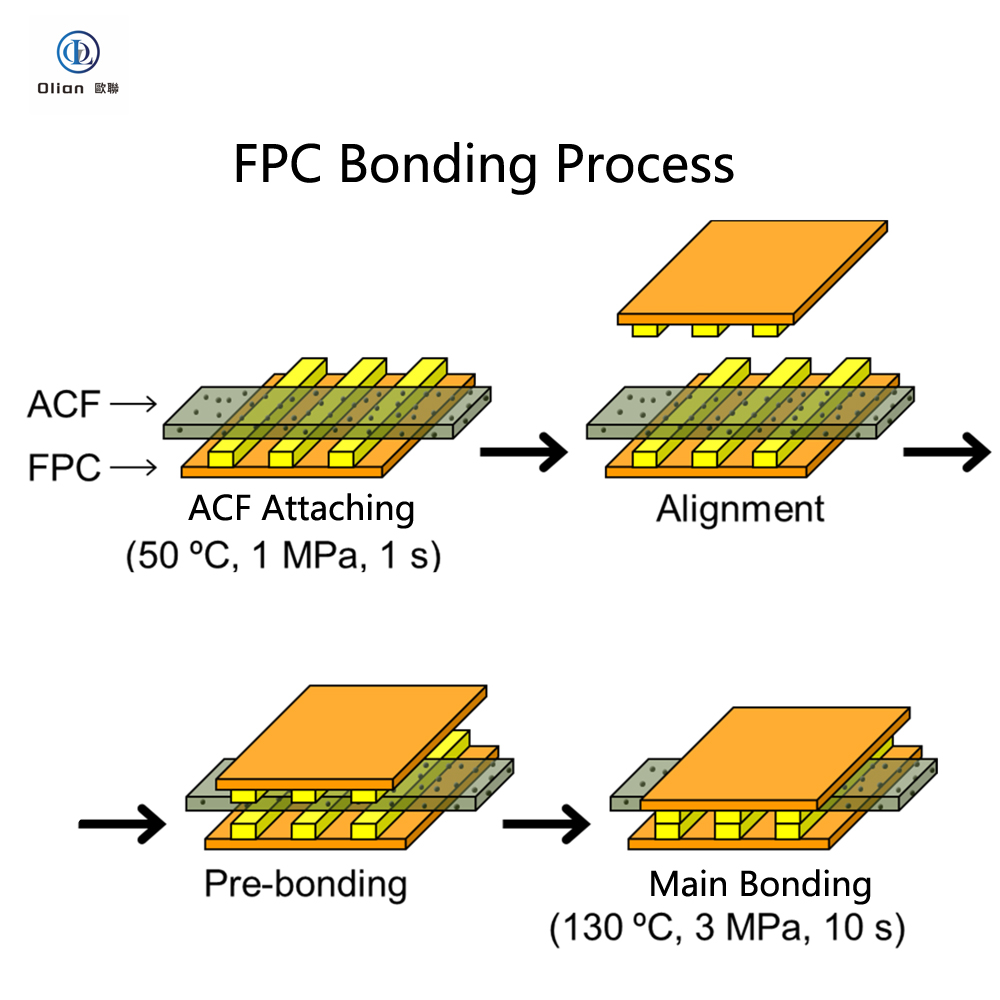

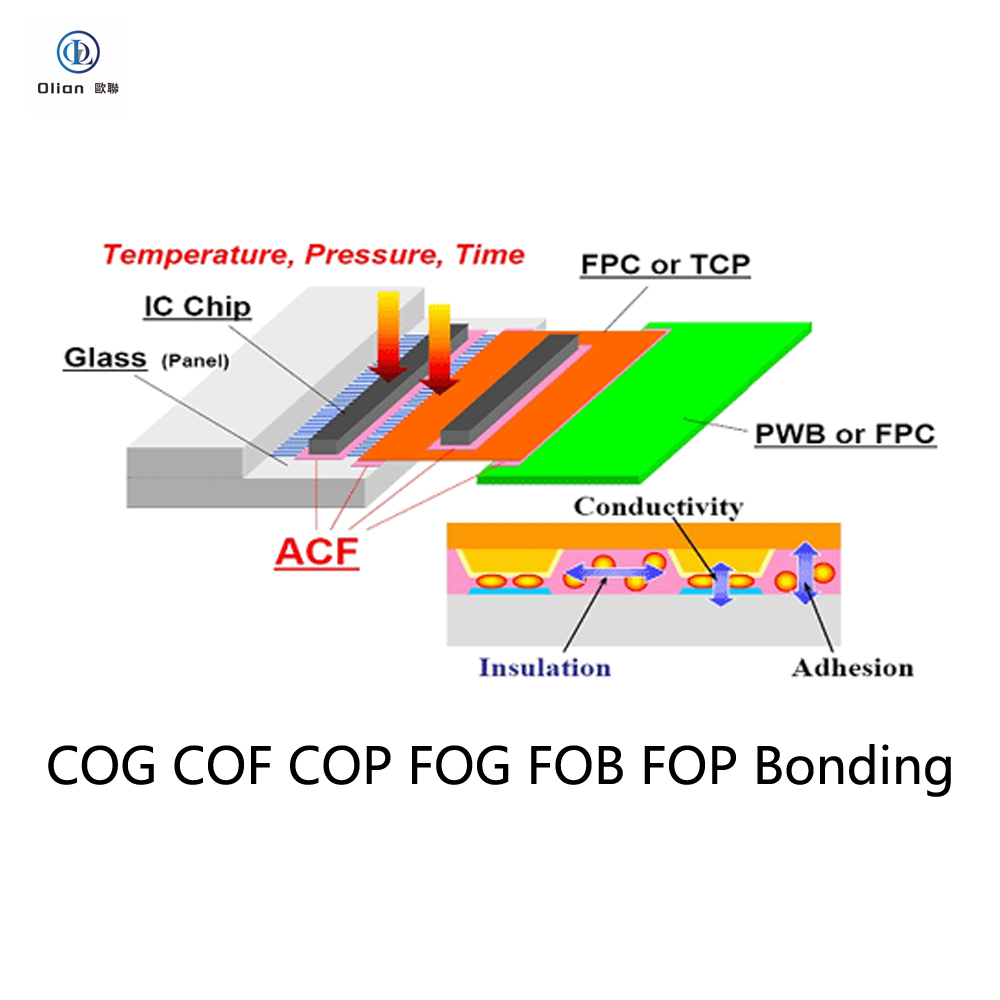

The COG Bonding Machine operates by first aligning the pre-bonded IC with the glass substrate. The machine uses a high-precision alignment system to ensure that the IC is accurately positioned. Once aligned, the bonding process begins. The machine applies heat and pressure to the assembly, causing the Anisotropic Conductive Film (ACF) to bond the IC to the glass substrate. The ACF contains conductive particles that create electrical connections between the IC and the substrate.

The COG Bonding Machine is primarily used in the production of LCD panels for various electronic devices, including:

The COG Bonding Machine offers several benefits in the manufacturing process:

The COG Bonding Machine has significantly impacted the electronics industry by enabling the production of high-quality, compact displays. It plays a vital role in meeting the demands for smaller, more efficient electronic devices, contributing to advancements in display technology and overall consumer satisfaction.

A fully automatic COG bonding line includes multiple machines working together to automate the entire bonding process. This includes:

The COG Bonding Machine is an essential tool in the manufacturing of LCD panels, providing a reliable and precise method for permanently bonding ICs to glass substrates. Its applications are widespread across various industries, driving innovation and enhancing the performance of electronic devices.

COF Bonding Machines are high-precision device designed to connect COF to Glass or PCB substrates. This technology is widely used in the assembly of LCD, OLED, and other advanced displays. It plays a pivotal role in ensuring the performance and reliability of modern electronic devices. COF bonding is the backbone of many industries, enabling compact designs, high-resolution displays, and durable electronic products. Whether you’re manufacturing smartphones, automotive displays, or industrial control panels, COF Bonding Machines are an essential tool for innovation and efficiency.

COF technology allows semiconductor chips to be directly bonded onto flexible film, enabling:

With the rise of micro-LEDs, foldable displays, and wearable technology, COF technology has become indispensable in keeping up with the latest trends in electronics.

COF Bonding Machines can be classified based on their application and capabilities:

To stay competitive, manufacturers require machines that deliver precision and speed. The key features of a state-of-the-art COF Bonding Machine include:

COF Bonding Machines are indispensable across diverse industries:

COF Bonding Machines are essential in the manufacturing of modern electronic devices, providing high precision and reliability in the bonding process. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, COF technology continues to play a crucial role in the electronics industry.

COP (Chip On Plastic) and FOP (Film On Plastic) Bonding Machine is a sophisticated piece of equipment used in the electronics industry, particularly for the production of flexible displays and advanced electronic devices. This machine combines the processes of COP and FOP bonding into a single, integrated system, streamlining the manufacturing process and improving efficiency. COP FOP bonding machines are essential for bonding integrated circuits (ICs) and flexible printed circuits (FPCs) to plastic substrates, ensuring high precision and reliability in display manufacturing.

COP FOP Bonding Machines can be classified based on their level of automation and specific applications:

COP FOP Bonding Machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

COP FOP Bonding Machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, COP FOP technology continues to play a crucial role in the electronics industry.

Introduction to Flex Cable Bonding Machines

Flex cable bonding machines are essential in the manufacturing of electronic devices, particularly for attaching flexible printed circuits (FPCs) or flexible flat cables (FFCs) to various substrates. These machines ensure a seamless and robust connection between the flexible cable and the electronic components, playing a crucial role in the production of devices like smartphones, tablets, and automotive displays.

Flex cable bonding machines can be classified based on their specific applications and the type of bonding process they perform:

Flex cable bonding machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

Flex cable bonding machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, flex cable bonding technology continues to play a crucial role in the electronics industry.

Chip bonding machines are essential in the electronics manufacturing industry, particularly for attaching integrated circuits (ICs) to various substrates. These machines ensure a seamless and robust connection between the ICs and the substrates, playing a crucial role in the production of devices like smartphones, tablets, and automotive displays. The different types of chip bonding machines, including COG (Chip On Glass), COP (Chip On Plastic), COF (Chip On Film), and COB (Chip On Board), are designed to meet specific requirements and applications.

Chip bonding machines are indispensable across diverse industries:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

Chip bonding machines are critical components in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices. They are used in a wide range of applications, from consumer electronics to industrial and medical devices, ensuring that products meet the highest standards of quality and performance. With the increasing demand for thinner, lighter, and more durable devices, chip bonding technology continues to play a crucial role in the electronics industry.

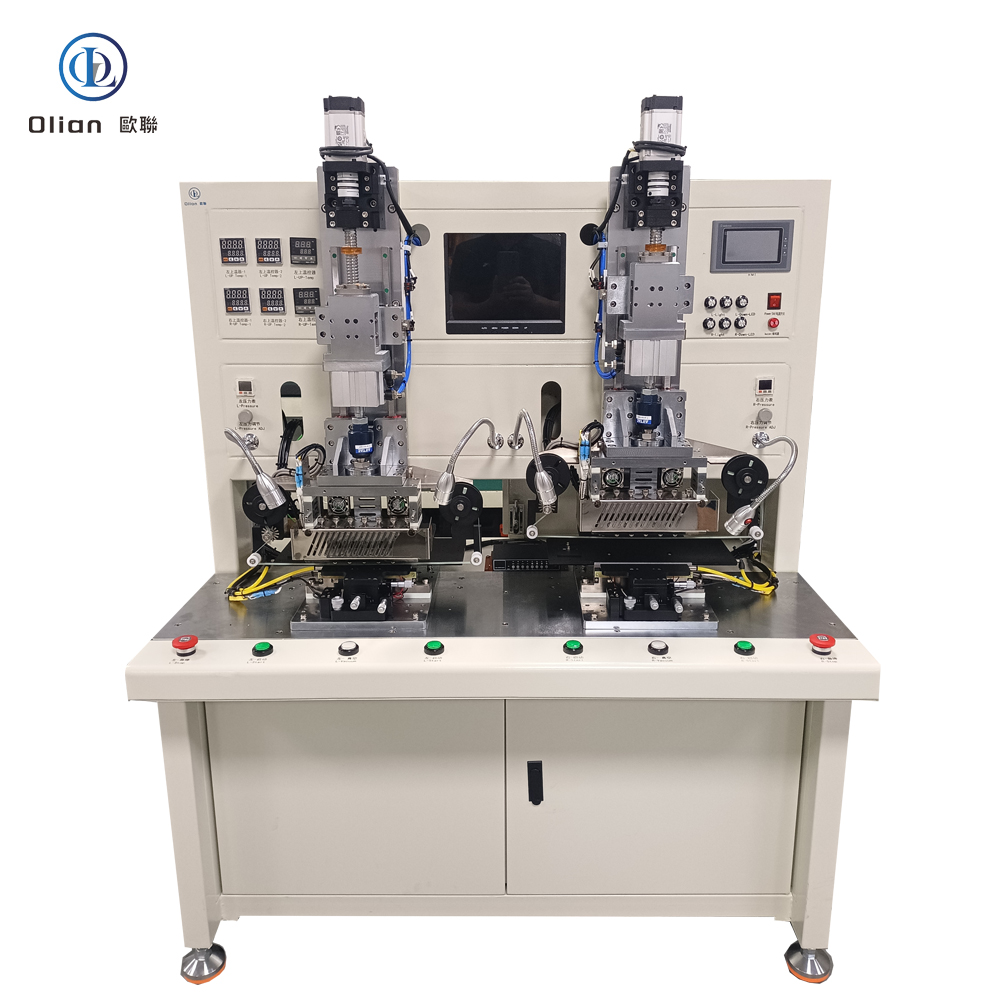

COG/COF Pre-Bonding machine OL-C0156

This device is a semi-automatic Pre Bonding machine, which is a device for aligning and Pre Bonding IC on a panel that has already been attached with a conductive film (ACF). The removal and placement of the panel are manually completed, while the alignment and Pre Bonding are automatically completed by the device.

COG/COF Pre-Bonding machine .This device is suitable for medium sized COG and COF products.

LCD SIZE: 7~17.3inch

Capacity: About400~600pcs IC/hour;

Maximum number of segments ≤10

IC specification range: MIN:60.6mm,MAX385mm;

Pre bonding accuracy: ±0.003mm

Heating method: Constant temperature control;

Temperature range: RT-150℃;

Working air pressure: 0.4~0.6Mpa;

Power Supply: 220V,50HZ,1000W;

Total weight: 488Kg;

Dimensions: L1010W1060H1500;

FOB Bonder is a specialized piece of equipment used in the electronics industry, particularly for bonding flexible printed circuits (FPCs) to rigid printed circuit boards (PCBs) in various electronic devices. This machine plays a crucial role in the assembly process of display technologies such as LCDs and other advanced electronics.

The FOB Bonder is widely used in various applications, including:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include the integration of more advanced vision systems and the development of machines capable of handling larger and more complex substrates

Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in the design of these machines

In summary, the FOB Bonder is a vital component in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices.

FOG bonding machine is a critical piece of equipment used in the electronics industry, particularly for the assembly of liquid crystal displays (LCDs) and other display technologies. It is designed to establish a stable mechanical and electrical connection between a flexible printed circuit (FPC) and a glass substrate, such as an ITO (Indium Tin Oxide) panel

The FOG bonding machine is widely used in various applications, including:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include the integration of more advanced vision systems and the development of machines capable of handling larger and more complex substrates

Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in the design of these machines

In summary, the FOG bonding machine is a vital component in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices.

Fully automatic COF and FOF bonding machine is a high-precision piece of equipment used in the electronics industry, particularly for the assembly of advanced display technologies such as LCD, OLED, and flexible displays. This machine integrates the processes of bonding integrated circuits (ICs) to flexible film substrates and bonding flexible printed circuits (FPCs) to other flexible films, streamlining the manufacturing process and improving efficiency

The machine typically includes several modules to handle different stages of the bonding process:

The fully automatic COF FOF bonding machine is widely used in various applications, including:

The electronics industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include:

In summary, the fully automatic COF FOF bonding machine is a critical component in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices.

Fully automatic COP (Chip On Plastic) and FOP (Film On Plastic) bonding machine is a sophisticated piece of equipment used in the electronics industry, particularly for the production of flexible displays and advanced electronic devices. This machine combines the processes of COP and FOP bonding into a single, integrated system, streamlining the manufacturing process and improving efficiency.

The machine typically includes several modules to handle different stages of the bonding process:

The fully automatic COP FOP bonding machine is widely used in various applications, including:

The industry is continuously evolving, with manufacturers focusing on improving the precision and speed of bonding machines. Future trends include the integration of more advanced vision systems and the development of machines capable of handling larger and more complex substrates

Additionally, there is a growing emphasis on energy efficiency and environmental sustainability in the design of these machines

In summary, the fully automatic COP FOP bonding machine is a critical component in modern electronics manufacturing, providing a reliable and efficient solution for bonding processes in the production of high-quality displays and electronic devices.