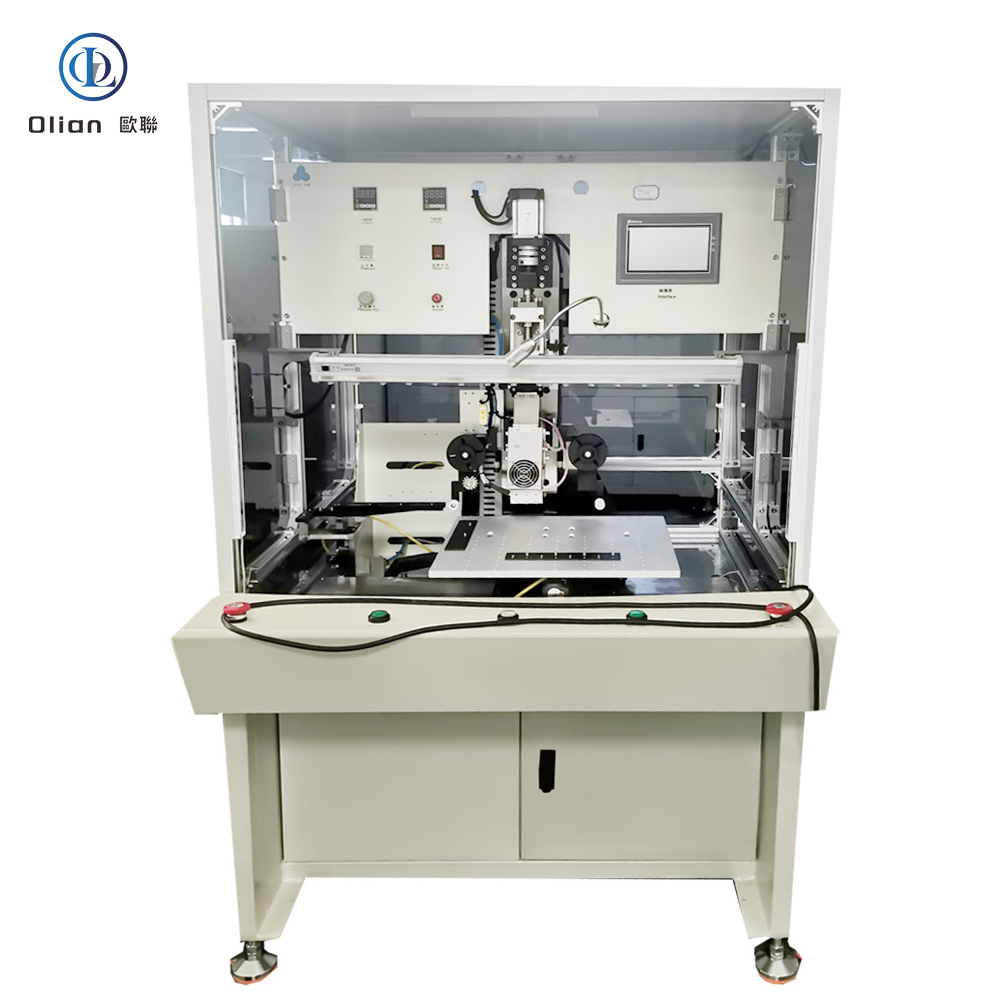

OL-CBY156 – 15.6-Inch Dual-Head IC Servo Main Bonding Machine

High-Efficiency Thermal Compression System for IC Bonding on 7-17.3inch LCD Panels

The OL-CBY156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic dual-head main bonding machine engineered for the final thermal compression of bare driver IC chips onto ACF-pre-laminated edge terminals of large-format rigid LCD panels up to 15.6 inches. Featuring two independent servo-controlled bonding heads, this system enables either simultaneous bonding of two ICs or sequential multi-zone processing along a single panel edge—significantly boosting throughput while maintaining high bond consistency.

As the critical final step in the COG (Chip-on-Glass) process, the OL-CBY156 fully cures the anisotropic conductive film (ACF), creating permanent, low-resistance electrical interconnects essential for display reliability in automotive, industrial, and consumer applications.

⚠️ Note: This machine assumes that ACF has already been applied and ICs have been pre-aligned (e.g., via a pre-bonder). It does not include ACF application, vision alignment, or double-side bonding capability.

This dual-head architecture reduces cycle time by up to 40–50% compared to single-head machines in multi-IC applications (e.g., dual-driver displays).

15.6 inch dual-head IC main bonding machine, OL-CBY156 Olian, double hot bar COG bonder for LCD, servo-controlled dual IC bonding machine, high-throughput IC bonding equipment for display panels, multi-zone dual-head bonding machine, 400°C dual press head main bonder, simultaneous IC bonding machine for automotive displays, dual servo IC main bonding machine with PLC control, OL-CBY156 technical specifications. COG Bonder, COP bonder, COF bonder, Main bonding machine, Final bonding machine, final main bonding machine,main bonder,Final bonder.

OL-CBD156 – 15.6-Inch Single-Station IC Servo Main Bonding Machine,

High-Precision Thermal Compression System for Final IC Bonding on LCD Panels

The OL-CBD156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic main bonding machine designed for the final thermal compression of bare driver IC chips onto ACF-pre-laminated edge terminals of large-format rigid LCD panels up to 15.6 inches. As the critical last step in the COG (Chip-on-Glass) process, this system delivers consistent, high-reliability interconnects through precise servo-controlled pressure, uniform heating, and stable mechanical alignment—ensuring low contact resistance and long-term display performance.

Unlike pre-bonders or ACF applicators, the OL-CBD156 performs full-strength main bonding, fully curing the anisotropic conductive film to create permanent electrical and mechanical connections between the IC and glass substrate.

⚠️ Note: This machine assumes that ACF has already been applied and the IC has been pre-aligned (e.g., via a pre-bonder). It does not include ACF application, vision alignment, or double-side capability.

💡 Smart Feature: The machine includes a “tape not feeding” alarm—if the carrier tape (e.g., from IC feeder) fails to advance, the system halts and alerts the operator to prevent missed bonds.

IC Bonder,ACF IC bonder,IC bonding machine, COF bonding machine, COG bonding machine, IC final main bonding machine, IC main bonder,IC final bonder,COG ,COF,COP bonding machine, COP bonder, 15.6 inch IC main bonding machine, OL-CBD156 Olian, single-head COG bonder for LCD, servo-controlled thermal compression machine, multi-zone IC bonding equipment for display panels, high-precision IC main bonding machine with ±3N repeatability, 400°C hot bar main bonder for driver ICs, single-station COG bonding system, IC main bonding machine for automotive and industrial displays, servo IC final bonder with PLC and touchscreen.

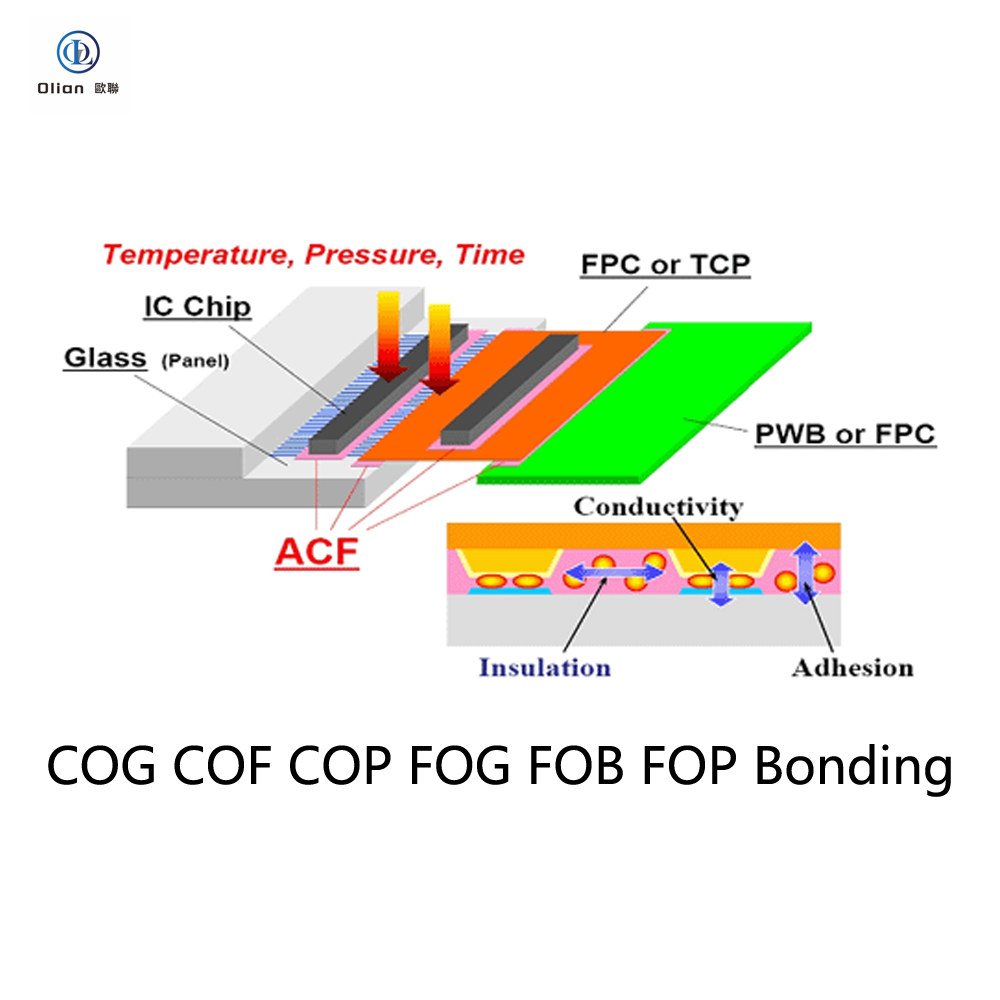

ACF bonding Keywords Categorization and Explanation:

FOB Bonder: A machine used for bonding FOB (Flexible On Board) components.

COG Bonder: Used for bonding COG (Chip On Glass) components.

COF Bonder: Used for bonding COF (Chip On Film) components.

COP Bonder: Used for bonding COP (Chip On Plastic) components.

FOG Bonder: Used for bonding FOG (Flexible On Glass) components.

FOF Bonder: Used for bonding FOF (Flexible On Flexible) components.

FPC Bonder: Used for bonding FPC (Flexible Printed Circuit) components.

TAB Bonder: Used for bonding TAB (Tape Automated Bonding) components.

OLB Bonder: Used for bonding OLB (Outer Lead Bonding) components.

IC Bonder: Used for bonding IC (Integrated Circuit) components.

Glass Bonder: Used for bonding glass components.

LCD Panel Bonder: Used for bonding LCD (Liquid Crystal Display) panels.

LED Panel Bonder: Used for bonding LED (Light Emitting Diode) panels.

Mini LED Bonder: Used for bonding mini LED components.

Micro LED Bonder: Used for bonding micro LED components.

Zebra Paper Bonder: Used for bonding zebra paper components.

Touch Panel FPC Bonder: Used for bonding FPC components in touch panels.

Mobilephone Bonding Machine: Used for bonding components in mobile phones.

Smart Watch LCD Bonder: Used for bonding LCD components in smart watches.

Wearable Equipment Bonder: Used for bonding components in wearable devices.

TV Panel Bonder: Used for bonding components in TV panels.

LCD Module Bonder: Used for bonding LCD modules.

Flat Panel Display Bonder: Used for bonding flat panel displays.

ACF (Anisotropic Conductive Film): A film used in bonding processes to connect different layers.

COG (Chip On Glass): A process where chips are directly mounted on glass substrates.

COF (Chip On Film): A process where chips are mounted on flexible substrates.

COP (Chip On Plastic): A process where chips are mounted on plastic substrates.

FOG (Flexible On Glass): A process where flexible circuits are mounted on glass substrates.

FOB (Flexible On Board): A process where flexible circuits are mounted on boards.

FOF (Flexible On Flexible): A process where flexible circuits are mounted on other flexible circuits.

TAB (Tape Automated Bonding): A process where tape is used to bond components.

OLB (Outer Lead Bonding): A process where the outer leads of components are bonded.

IC (Integrated Circuit): A small chip that contains a complex electronic circuit.

FPC (Flexible Printed Circuit): A flexible circuit board used in various electronic devices.

Zebra Paper: A type of conductive paper used in bonding processes.

LCD Repair Machine: Used for repairing LCD screens.

LED Repair Machine: Used for repairing LED screens.

OLED Repair Machine: Used for repairing OLED screens.

Amoled Repair Machine: Used for repairing Amoled screens.

Mini LED Repair Machine: Used for repairing mini LED screens.

Micro LED Repair Machine: Used for repairing micro LED screens.

TFT Glass Repair Machine: Used for repairing TFT (Thin Film Transistor) glass screens.

LCD Panel Repair Machine: Used for repairing LCD panels.

LED Panel Repair Machine: Used for repairing LED panels.

OLED Panel Repair Machine: Used for repairing OLED panels.

Amoled Panel Repair Machine: Used for repairing Amoled panels.

Flex Cable Repair Machine: Used for repairing flex cables.

IC Remover: A tool used to remove ICs from circuits.

IC Remove Machine: A machine used to remove ICs from circuits.

Differential Interference Microscope: A microscope used to inspect bonding processes.

Metallurgical Microscope: A microscope used to inspect metal surfaces.

Industrial Tool Microscope: A microscope used for industrial inspections.

Large Size Upright Microscope: A large microscope used for detailed inspections.

Second Hand Differential Interference Microscope: A used microscope for inspecting bonding processes.

Whole Line Solution for Intelligent Wearable Products: A comprehensive solution for producing intelligent wearable products.

Whole Line Solution for Intelligent Watches: A comprehensive solution for producing intelligent watches.

Mobile Product Line Solutions: Solutions for producing mobile products.

PAD Display Product Line Solutions: Solutions for producing PAD displays.

Tablet Product Line Solutions: Solutions for producing tablet displays.

Notebook Product Line Solutions: Solutions for producing notebook displays.

Industrial Control Display Product Line Solutions: Solutions for producing industrial control displays.

High-Level Flexible Screen Glue Field Production Solutions: Solutions for producing high-level flexible screens.

Intelligent Locomotive, Notebook Product Line Solutions: Solutions for producing intelligent locomotives and notebooks.

Display Product Line Solution: A comprehensive solution for producing displays.

Commercial Display Screen – Flexible Bonding Production Line Solution: A solution for producing commercial display screens.

Electronic Paper Line Solutions: Solutions for producing electronic paper.

Electronic Paper Laminating, Bonding, Dispensing Field Line Solutions: Solutions for producing electronic paper laminating, bonding, and dispensing.

Backlight Leading, Laminated Film, Shading, Wrapping Line Equipment Solutions: Solutions for producing backlight leading, laminated film, shading, and wrapping.

Fingerprint Module Under the Screen Bond Spot Glue and AOI Intelligent Detection Field Solutions: Solutions for producing fingerprint modules under the screen.

Automatic OCA, OCR Fit Field Production Solutions: Solutions for producing automatic OCA (Optically Clear Adhesive) and OCR (Optical Character Recognition) fits.

FPC Covering Film, EMI Automatic Laminating, FPC Exposure Special Equipment Field Solutions: Solutions for producing FPC covering film, EMI (Electromagnetic Interference) automatic laminating, and FPC exposure.

3C Product Inspection Packaging Production Line Solution: Solutions for producing 3C product inspection and packaging.

Bonding Machine Head: A part of the bonding machine used for bonding.

Bonding Machine Press Head: A part of the bonding machine used for pressing.

Bonding Machine Spare Parts: Various spare parts for bonding machines.

Bonding Machine Parts: Various parts for bonding machines.

ACF Tape: A tape used in bonding processes.

ACF Bonding Tape: A tape used in bonding processes.

ACF Glue: A glue used in bonding processes.

ACF Adhesive: An adhesive used in bonding processes.

ACF Bonding Machine Head: A part of the ACF bonding machine.

ACF Bonding Machine Price: The cost of an ACF bonding machine.

ACF Bonding Machine Manufacturer: A company that manufactures ACF bonding machines.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine PDF: A PDF document related to ACF bonding machines.

ACF Bonding Machine Spare Parts: Spare parts for ACF bonding machines.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for

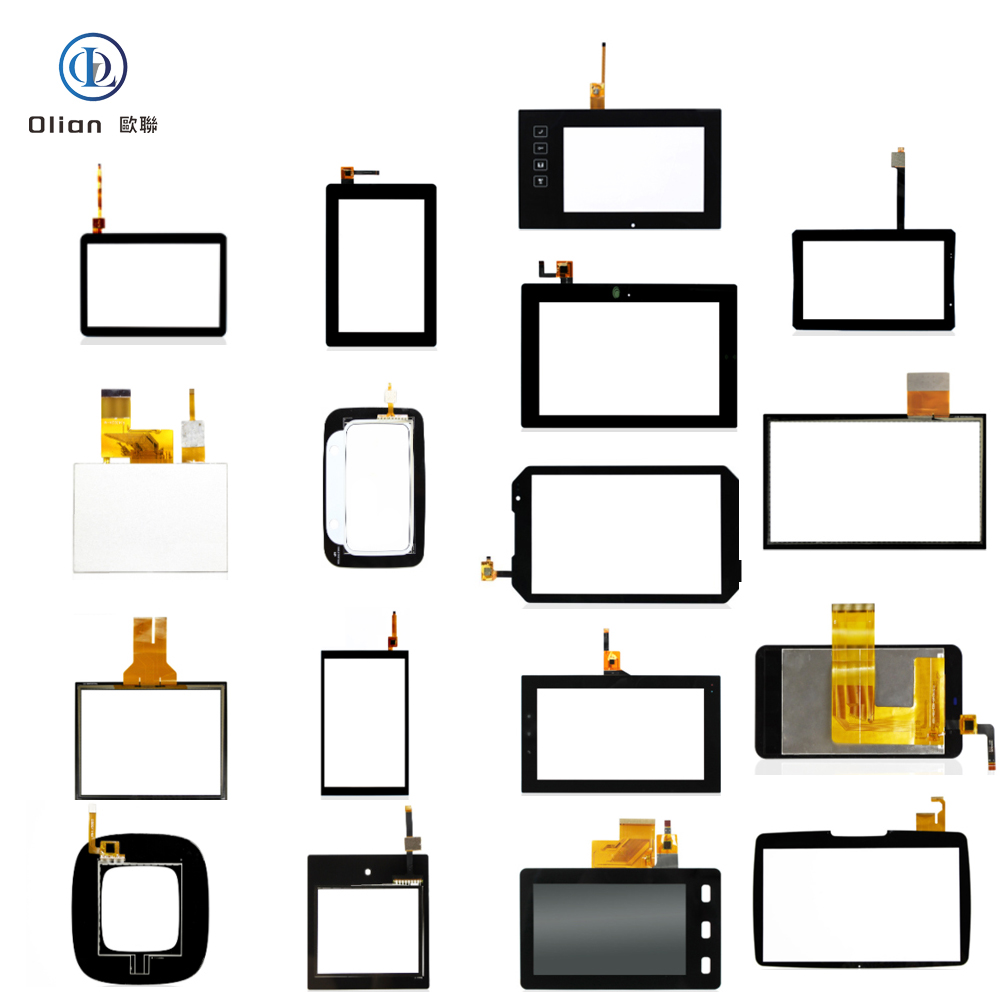

In the rapidly evolving world of electronics and display manufacturing, precision bonding technologies play a crucial role in creating high-quality, reliable, and innovative products. Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our company offers a comprehensive range of bonding machines and solutions to meet your specific needs. Below is an introduction to our product offerings, covering various bonding technologies and applications.

COG (Chip on Glass) technology is a widely used method for mounting LCD driver chips directly onto the glass substrate of a display panel

. This technique is known for its simplicity, cost-effectiveness, and reliability. Our COG bonding machines are designed to provide high precision and efficiency, making them ideal for applications such as smartphone screens, LCD panels, and other display devices

. We offer both pre-bonding and main-bonding machines, ensuring accurate alignment and strong connections.

COF (Chip on Film) technology represents a significant advancement in display manufacturing. It involves mounting integrated circuits (ICs) onto flexible printed circuits (FPCs), which can then be bent and folded to fit compact spaces

. Our COF bonding machines support high-speed production and offer precise temperature and pressure control, ensuring reliable connections for applications such as flexible screens, smartwatches, and other wearable devices

. We provide both COF pre-bonding and main-bonding machines, tailored to meet the demands of modern display manufacturing

.

COP (Chip on Plastic) technology is another innovative approach, where ICs are mounted directly onto plastic substrates. This method is particularly useful for creating lightweight and flexible displays

. Our COP bonding machines are designed to handle the unique challenges of plastic substrates, offering high precision and reliability. These machines are ideal for applications such as flexible OLED displays and wearable devices

.

FOG (FPC on Glass) bonding involves attaching flexible printed circuits to glass substrates. This technique is commonly used in applications requiring flexibility and compact design, such as touch screens and wearable devices

. Our FOG bonding machines feature advanced alignment systems and precise temperature control, ensuring high-quality connections. We offer both hot press and automated bonding solutions for FOG applications

.

FOB (FPC on PCB) bonding machines are designed for attaching flexible printed circuits to printed circuit boards. These machines are essential for creating compact and reliable electronic assemblies, commonly used in smartphones, tablets, and other consumer electronics

. Our FOB bonding machines provide high precision and flexibility, supporting both manual and automated production processes

.

FOF (FPC on FPC) bonding involves connecting flexible printed circuits to each other. This technique is ideal for applications requiring extreme flexibility and compactness, such as wearable devices and flexible displays

. Our FOF bonding machines offer high precision and reliability, ensuring strong and durable connections.

ACF (Anisotropic Conductive Film) bonding is a versatile technique used in various bonding processes, including COG, COF, and FOG

. Our ACF bonding machines are designed to provide precise temperature, pressure, and alignment control, ensuring reliable and high-quality connections. We offer a range of ACF bonding solutions, including pre-bonding and main-bonding machines

.

TAB (Tape Automated Bonding) is a technique used for bonding integrated circuits to substrates using tape carriers. Our TAB bonding machines are designed for high-speed production and offer precise alignment and bonding capabilities

. These machines are ideal for applications requiring high-density interconnections and compact designs

.

FPC (Flexible Printed Circuit) bonding machines are essential for creating flexible and lightweight electronic assemblies. Our FPC bonding machines offer high precision and reliability, supporting various bonding processes and applications

. These machines are ideal for applications such as wearable devices, flexible displays, and other consumer electronics

.

In addition to the above technologies, we also offer specialized bonding machines for various applications, including:

Our bonding machines are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key features of our machines include:

Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our comprehensive range of bonding machines is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality connections and efficient production processes. Contact us today to find the perfect bonding machine for your application.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us