In the rapidly evolving world of electronics and display manufacturing, precision bonding technologies play a crucial role in creating high-quality, reliable, and innovative products. Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our company offers a comprehensive range of bonding machines and solutions to meet your specific needs. Below is an introduction to our product offerings, covering various bonding technologies and applications.

COG (Chip on Glass) technology is a widely used method for mounting LCD driver chips directly onto the glass substrate of a display panel

. This technique is known for its simplicity, cost-effectiveness, and reliability. Our COG bonding machines are designed to provide high precision and efficiency, making them ideal for applications such as smartphone screens, LCD panels, and other display devices

. We offer both pre-bonding and main-bonding machines, ensuring accurate alignment and strong connections.

COF (Chip on Film) technology represents a significant advancement in display manufacturing. It involves mounting integrated circuits (ICs) onto flexible printed circuits (FPCs), which can then be bent and folded to fit compact spaces

. Our COF bonding machines support high-speed production and offer precise temperature and pressure control, ensuring reliable connections for applications such as flexible screens, smartwatches, and other wearable devices

. We provide both COF pre-bonding and main-bonding machines, tailored to meet the demands of modern display manufacturing

.

COP (Chip on Plastic) technology is another innovative approach, where ICs are mounted directly onto plastic substrates. This method is particularly useful for creating lightweight and flexible displays

. Our COP bonding machines are designed to handle the unique challenges of plastic substrates, offering high precision and reliability. These machines are ideal for applications such as flexible OLED displays and wearable devices

.

FOG (FPC on Glass) bonding involves attaching flexible printed circuits to glass substrates. This technique is commonly used in applications requiring flexibility and compact design, such as touch screens and wearable devices

. Our FOG bonding machines feature advanced alignment systems and precise temperature control, ensuring high-quality connections. We offer both hot press and automated bonding solutions for FOG applications

.

FOB (FPC on PCB) bonding machines are designed for attaching flexible printed circuits to printed circuit boards. These machines are essential for creating compact and reliable electronic assemblies, commonly used in smartphones, tablets, and other consumer electronics

. Our FOB bonding machines provide high precision and flexibility, supporting both manual and automated production processes

.

FOF (FPC on FPC) bonding involves connecting flexible printed circuits to each other. This technique is ideal for applications requiring extreme flexibility and compactness, such as wearable devices and flexible displays

. Our FOF bonding machines offer high precision and reliability, ensuring strong and durable connections.

ACF (Anisotropic Conductive Film) bonding is a versatile technique used in various bonding processes, including COG, COF, and FOG

. Our ACF bonding machines are designed to provide precise temperature, pressure, and alignment control, ensuring reliable and high-quality connections. We offer a range of ACF bonding solutions, including pre-bonding and main-bonding machines

.

TAB (Tape Automated Bonding) is a technique used for bonding integrated circuits to substrates using tape carriers. Our TAB bonding machines are designed for high-speed production and offer precise alignment and bonding capabilities

. These machines are ideal for applications requiring high-density interconnections and compact designs

.

FPC (Flexible Printed Circuit) bonding machines are essential for creating flexible and lightweight electronic assemblies. Our FPC bonding machines offer high precision and reliability, supporting various bonding processes and applications

. These machines are ideal for applications such as wearable devices, flexible displays, and other consumer electronics

.

In addition to the above technologies, we also offer specialized bonding machines for various applications, including:

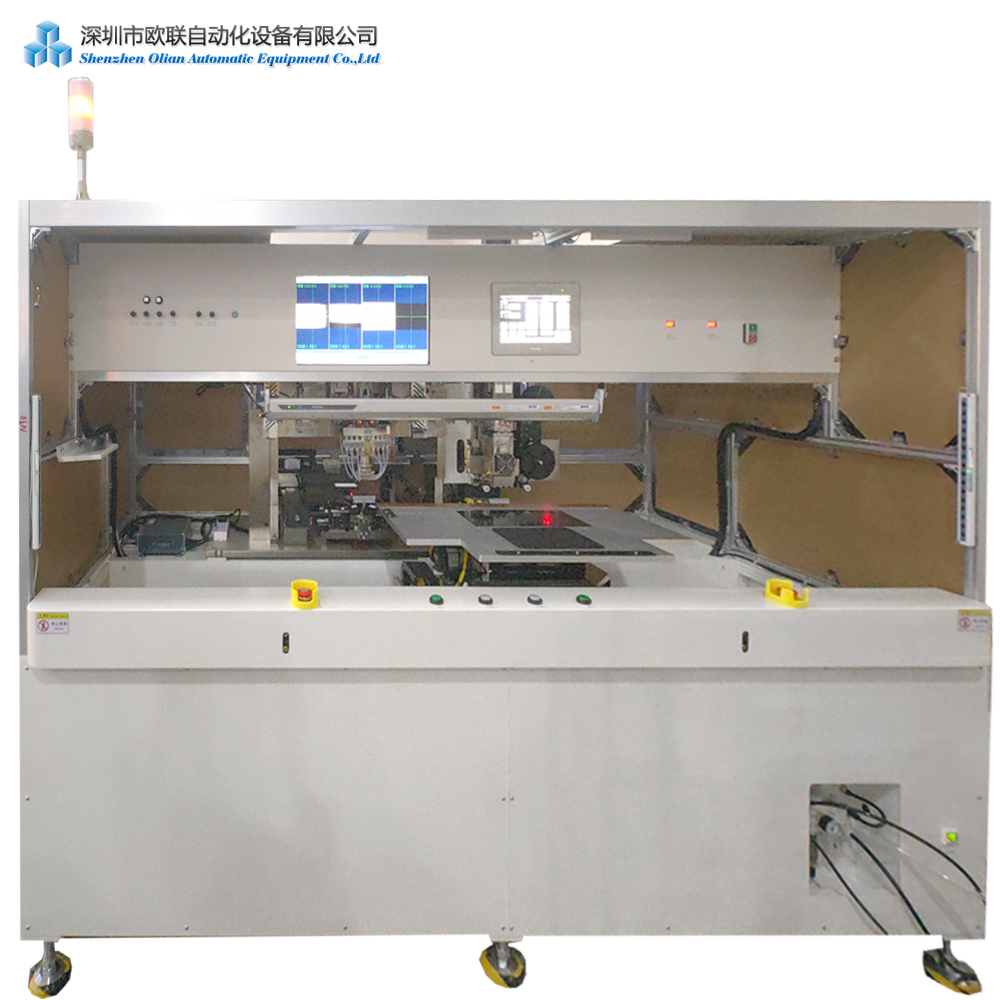

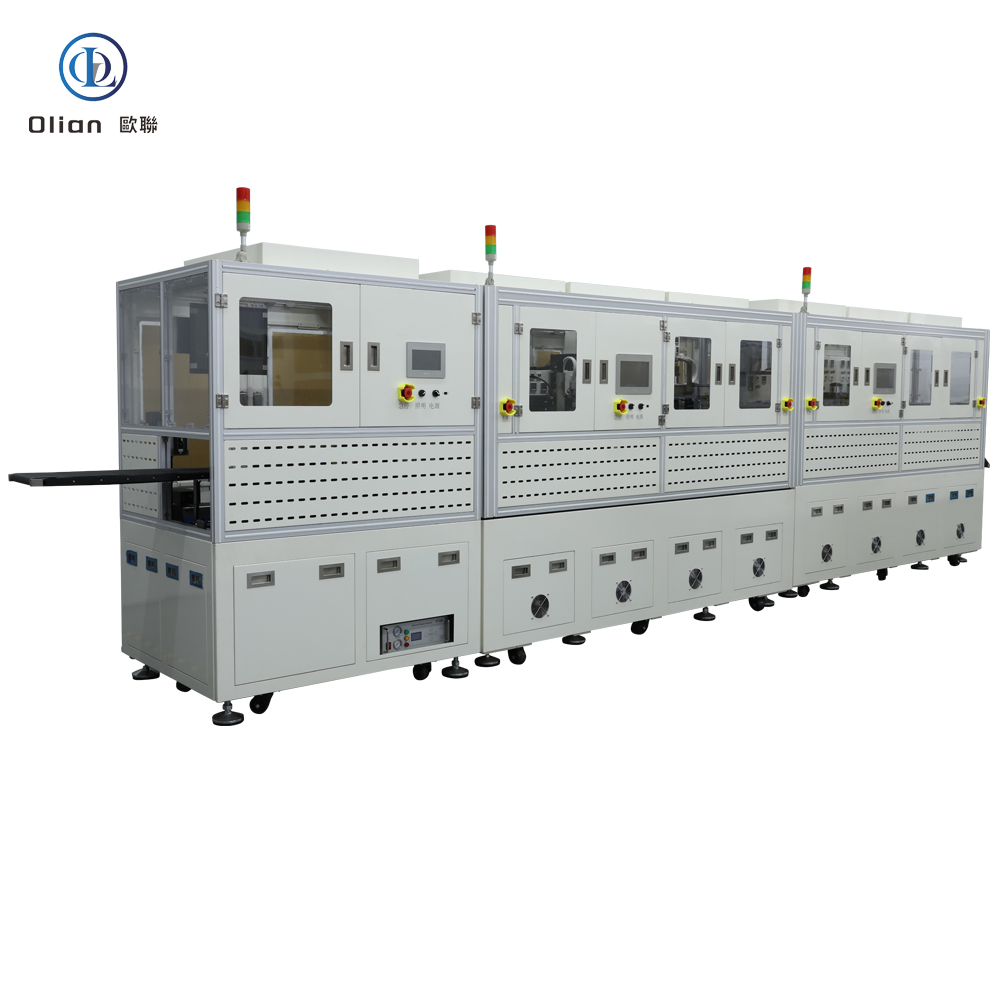

Our bonding machines are designed with the latest innovations in mind, ensuring high precision, reliability, and efficiency. Key features of our machines include:

Whether you are producing smartphone screens, wearable devices, large TV panels, or advanced OLED displays, our comprehensive range of bonding machines is designed to meet your specific needs. With advanced features such as high precision, versatility, and automation, our machines are ideal for ensuring high-quality connections and efficient production processes. Contact us today to find the perfect bonding machine for your application.

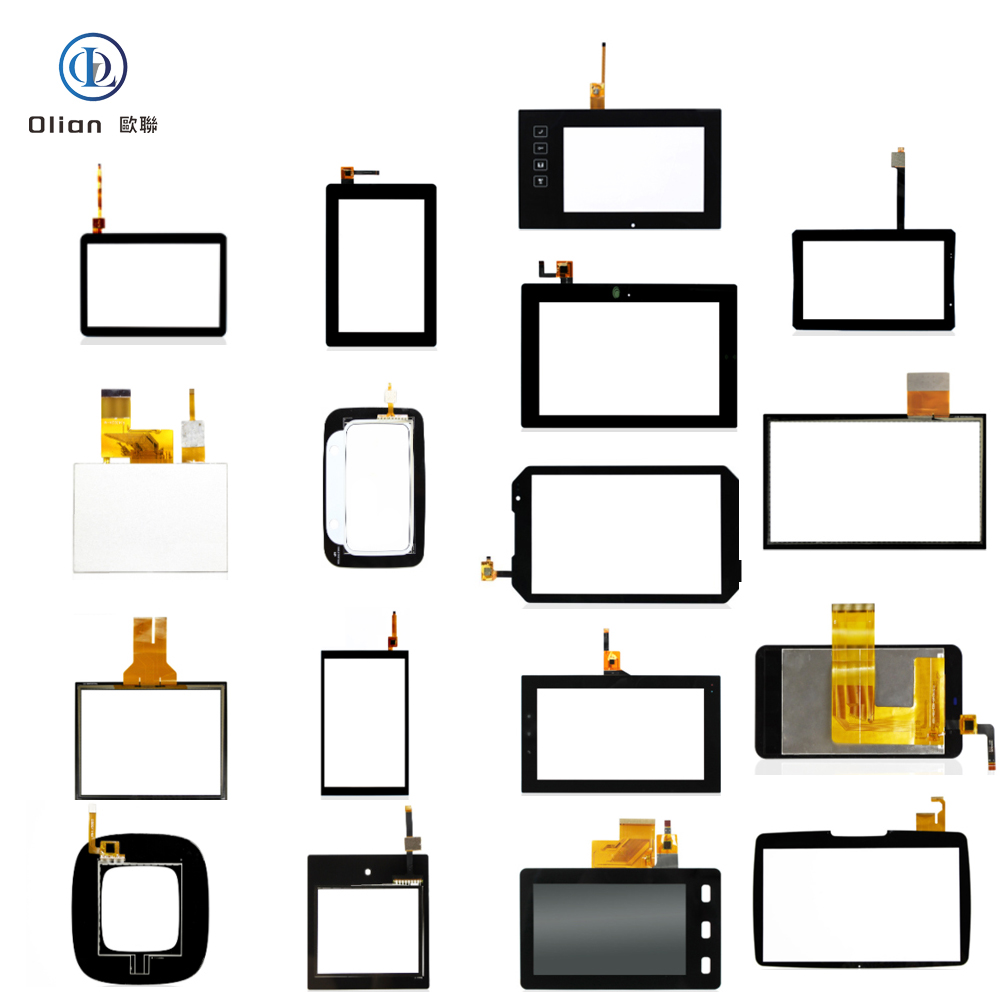

In the modern electronics manufacturing landscape, Anisotropic Conductive Film (ACF) bonding machines have become indispensable tools for creating reliable and high-quality connections between various components. Whether you are involved in the production of LCD panels, flexible circuits, or advanced display technologies, the right ACF bonding machine can significantly enhance your manufacturing efficiency and product quality. This article provides an in-depth introduction to the different types of ACF bonding machines and their applications, helping you find the perfect solution for your needs.

ACF bonding machines are specialized devices designed to bond two substrates using Anisotropic Conductive Film (ACF). These machines apply heat, pressure, and precise alignment to ensure a strong and reliable electrical and mechanical connection between components such as LCD panels, PCBs, FPCs, and IC chips

. ACF bonding is widely used in applications like COG (Chip on Glass), COF (Chip on Film), FOG (Film on Glass), FOB (Film on Board), and more

.

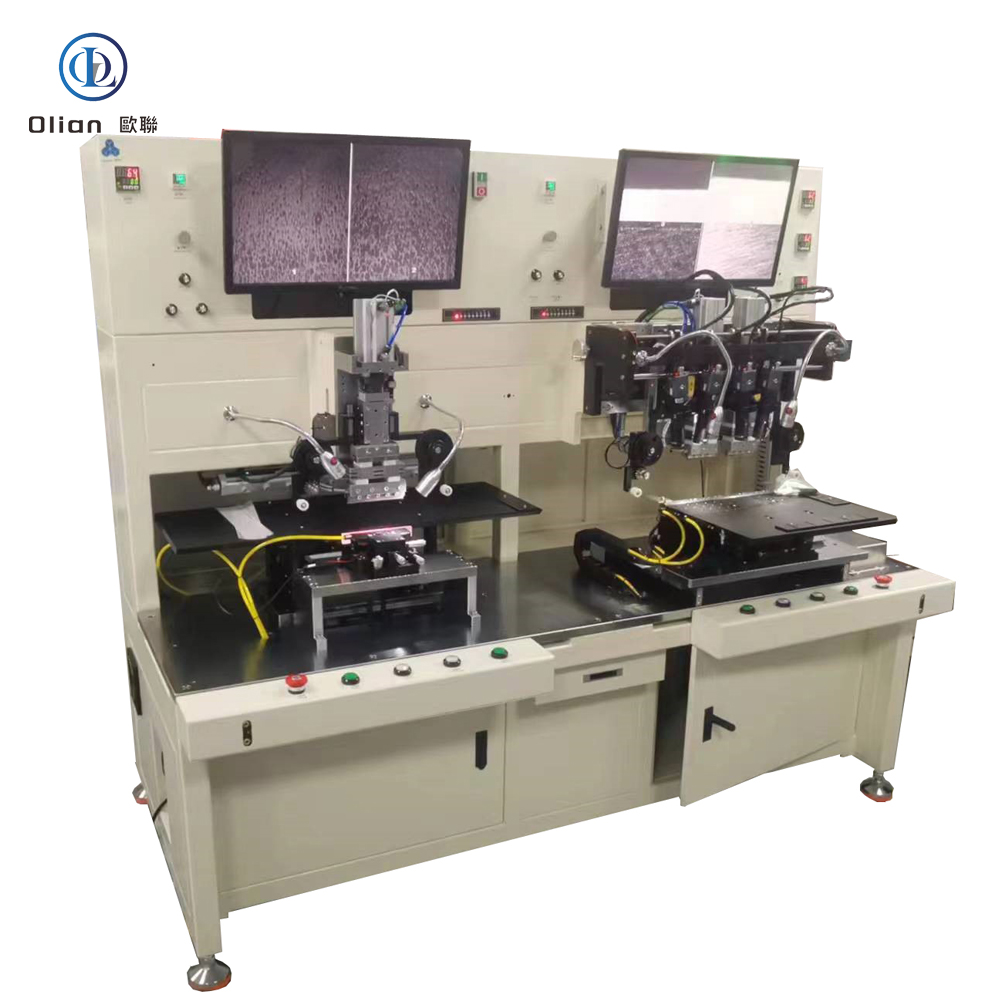

ACF pre-bonding machines are used for the initial alignment and attachment of ACF tape to the substrates. These machines often feature semi-automatic operation, allowing operators to place the components manually while the machine handles precise alignment and pre-bonding

. Pre-bonding ensures that the components are accurately positioned before the final bonding process.

Main-bonding machines are responsible for the final bonding process, where the components are pressed together under precise temperature and pressure conditions. These machines are available in both constant heat and pulse heat systems, offering flexibility based on the specific requirements of the bonding process

. Main-bonding machines can be fully automated, providing high throughput and consistent bonding quality.

ACF heat press machines, also known as hot press machines, are versatile tools used for bonding components using ACF. These machines can operate in both constant temperature and pulse heating modes, making them suitable for a wide range of applications

. They are equipped with features like multi-stage temperature control, real-time temperature curve display, and CCD vision systems for precise alignment

.

Pulse heating bonding machines use a transformer to generate low voltage and high current, which quickly heats the bonding area. This method allows for rapid heating and cooling, ensuring precise temperature control and efficient bonding

. Pulse heating machines are ideal for applications where quick and precise bonding is required, such as in COF and FOG bonding processes

.

Constant temperature bonding machines maintain a steady temperature throughout the bonding process. These machines are widely used in LCD panel assembly and other applications where consistent temperature control is crucial

. They offer features like digital pressure gauges, vacuum generators, and high-definition microscopes for precise bonding

.

ACF bonding machines are used in various industries, including:

Our company offers a comprehensive range of ACF bonding machines designed to meet the diverse needs of the electronics manufacturing industry. Our machines are known for their:

ACF bonding machines are essential tools in modern electronics manufacturing, providing reliable and high-quality connections between various components. Whether you need a pre-bonding machine for initial alignment or a main-bonding machine for the final assembly, our company offers a wide range of solutions to meet your needs. With advanced features like pulse heating, constant temperature control, and precise alignment, our ACF bonding machines are designed to enhance your manufacturing efficiency and product quality. Contact us today to find the perfect ACF bonding machine for your application.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us