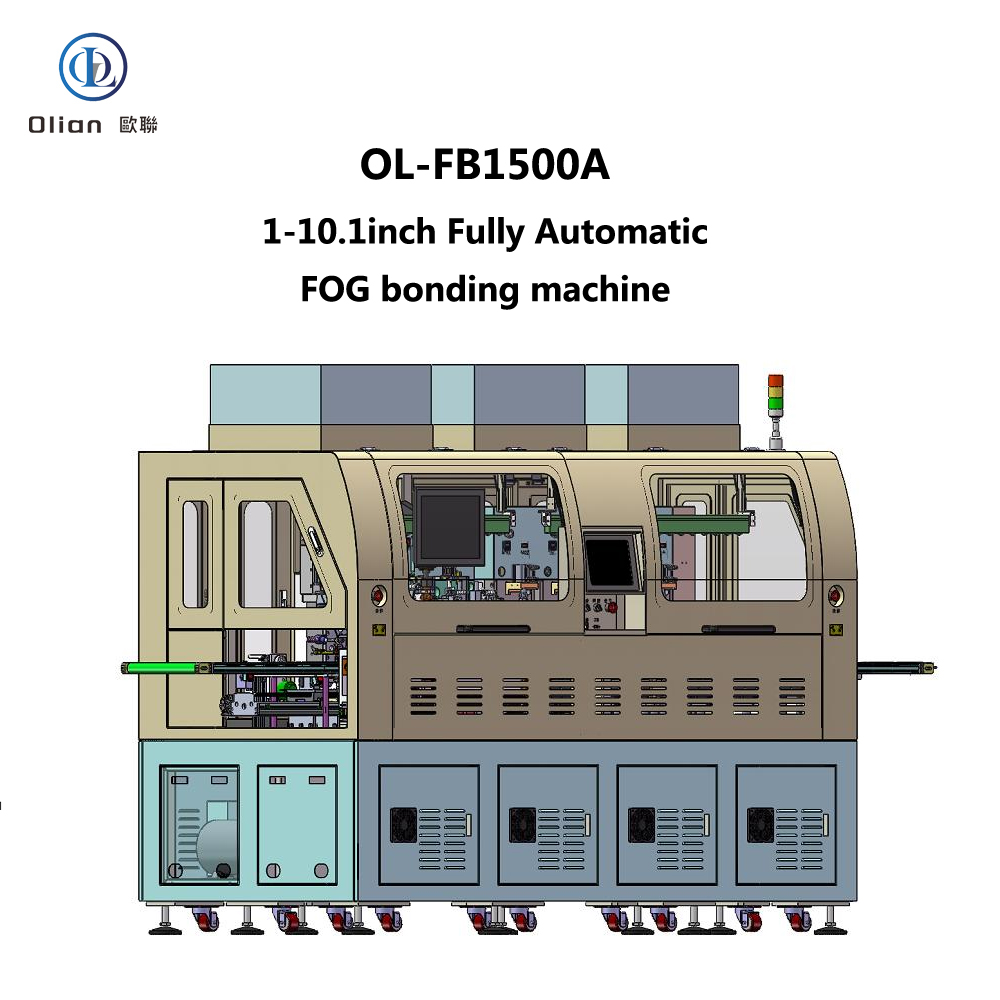

The OL-FB1500A is a state-of-the-art fully automatic FOG (Flexible On Glass)/FOF (Film On Film)/TFOG (Tape Film On Glass) bonding machine designed to meet the precise requirements of the modern electronics manufacturing industry. This advanced equipment is specifically tailored for the automatic ACF (Anisotropic Conductive Film) application, alignment, and thermal bonding of single-sided, single FPC (Flexible Printed Circuit) on LCD (Liquid Crystal Display) products ranging from 1″ to 10.1″ in size. Its innovative design and high-precision features make it an indispensable tool for manufacturers seeking efficiency, accuracy, and reliability in their production processes.

The OL-FB1500A operates through a series of coordinated mechanical and automated processes. The workflow begins with the loading of LCD + COF (Chip on Film) onto the conveyor belt or platform, either manually or via an automated upstream machine. The mechanical arm 0# picks up the LCD + COF and, after position correction by the CCD (Charge-Coupled Device) system, places it on the ACF platform. The ACF platform advances, and the bonding head descends to apply the ACF. After the ACF application, the platform retracts for position detection to ensure proper ACF adhesion.

Next, mechanical arm 1# transfers the LCD + COF to the pre-bonding stage while the FPC is simultaneously loaded and pre-aligned on the carrier stage. The bonding head then picks up the FPC and performs the pre-bonding process. Mechanical arm 2# moves the product to one of the four main bonding platforms for final bonding. Finally, mechanical arm 3# transfers the bonded product to the downstream conveyor or production line.

Mechanical Arm 1# (from Conveyor to ACF Platform):

Vacuum nozzles with adjustable numbers and configurations based on product size.

Digital vacuum gauge for real-time monitoring.

X-axis: Servo motor + ball screw drive.

θ-axis: Stepper motor.

Z-axis: Sliding table cylinder with manually adjustable position.

Mechanical Arm 2# (from ACF Stage to Pre-bonding Stage):

Vacuum nozzles with adjustable numbers and configurations based on product size.

Mechanical Arm 3# (from Pre-bonding Stage to Main Bonding Stage):

Mechanical Arm 4# (from Main Bonding Stage to Discharge Conveyor):

Vacuum nozzles with adjustable numbers and configurations based on product size.

Digital vacuum gauge for real-time monitoring.

X-axis: Linear motor drive.

Z-axis: Cylinder with manually adjustable position.

Sliding table cylinder with manually adjustable position.

ACF Cutter:

Cutting Method: Automatic semi-cutting.

Depth Adjustment: Micrometer fine adjustment.

Blade Movement: Cylinder-driven up and down, with adjustable X-axis position.

ACF Head:

Number of Bonding Heads: 1.

Drive Method: Cylinder + rail.

Pressure Control: Cylinder control with precision pressure regulator.

Material: SUS440C (customizable).

Dimensions: W 6mm × L 60mm (customizable).

Surface Flatness: ≤ 5um.

ACF Stage:

X-axis Movement: Servo motor + ball screw + rail.

Y-axis Movement: Servo motor + ball screw + rail.

Vacuum: 1mm hole diameter, 2mm vacuum slot width.

Material: Aluminum with anodized hard oxidation treatment.

Flatness: ±0.02mm.

ACF Backup:

Material: Quartz.

Dimensions: L100mm × W10mm × H18mm.

Surface Flatness: ≤ 5um.

ACF Inspection: CCD inspection system.

ACF Supply:

Operation Method: Torque motor (or gravity hammer method).

Reel Tensioning: Belt tensioning structure.

Protective Film Recovery: Vacuum吸取 to waste bin.

Separation Rod Movement: Cylinder-driven rod.

Pre-bonding Head:

Number of Bonding Heads: 1.

Z-axis Drive: Servo motor + ball screw + rail.

Y-axis Transmission: Servo motor + ball screw + rail.

θ-axis Movement: DD motor.

Pressure Control: Cylinder control with precision pressure regulator.

Material: SUS 440C HRC58.

Dimensions: W 1.2mm × L 80mm (customizable).

Surface Flatness: ≤ ±5um.

Vacuum: Segmentable vacuum selection with vacuum detection.

Pre-bonding Stage:

X-axis Movement: Servo motor + ball screw + rail.

Y-axis Movement: Servo motor + ball screw + rail.

Vacuum: 1mm hole diameter, 2mm vacuum slot width.

Material: Aluminum with anodized hard oxidation treatment.

Flatness: ±0.02mm.

Pre-bonding Backup:

Material: Quartz.

Dimensions: L136mm × W10mm × H12mm (customizable).

Surface Flatness: ≤ ±5um.

Loading Method: Manual FPC loading or automatic FPC loader (purchased separately).

FPC Main Bonding Unit

Main Bonding Head:

Number of Bonding Heads: 4.

Drive Method: Cylinder + rail.

Pressure Control: Cylinder control with precision pressure regulator.

Material: SUS440C.

Dimensions: W 1.0mm × L 60mm (customizable).

Surface Flatness: ≤ ±4um.

Main Bonding Stage:

Y-axis Movement: Servo motor + ball screw.

Vacuum: 1mm hole diameter, 2mm vacuum slot width.

Material: Aluminum with anodized hard oxidation treatment.

Flatness: ±0.02mm.

Main Bonding Backup:

Material: Quartz strip.

Dimensions: L120mm × W6mm × H18mm.

Surface Flatness: ≤ ±5um.

Note: Vacuum position dimensions are customized based on FPC size.

Buffer Material Supply:

Rotation Method: Stepper motor drive.

Rotation Direction: Automatic front-to-back rotation.

Width Adjustment: Manual width adjustment with limit wheel.

Sensor detection for tape end monitoring.

Image Processing Unit

LCD Correction:

System: Bosch image processing system.

CCD Camera: 1.

Coaxial Light Barrel: 1.

Magnification: 1x.

Field of View: 4.8mm × 3.6mm.

Light Source: Coaxial light LED.

Z-axis Adjustable Travel: 10mm.

ACF Inspection:

System: Bosch image processing system.

CCD Camera: 1.

Coaxial Light Barrel: 1.

Magnification: 0.5x.

Field of View: 9.6mm × 7.2mm.

Light Source: Coaxial light LED.

Pre-bonding Alignment:

System: Bosch image processing system.

CCD Cameras: 2.

Coaxial Light Barrels: 2.

Magnification: 2x.

Field of View: 2.4mm × 1.8mm.

Light Source: Coaxial light LED.

Alignment Method: Coincidence point, with optional TFOG 4-camera configuration.

Main Bonding Alignment:

System: Bosch image processing system.

CCD Camera: 1.

Coaxial Light Barrel: 1.

Magnification: 1x.

Field of View: 4.8mm × 3.6mm.

Light Source: Coaxial light LED.

Z-axis Adjustable Travel: 10mm.

Control Method: PLC control.

Touchscreen:

Interface: Chinese, touch-enabled.

Modes: Manual and automatic.

Functions: Parameter display, data storage for 100 varieties.

Manual Control Buttons:

Emergency Stop Buttons: 3.

Main Power Switch: 1.

Lighting Power Switch: 1.

Access Control: Door opening function, machine pauses during operation.

Operation Indicator Lights: Tri-color lights.

Documentation and After-sales Service

Documentation: Machine operation manual included.

Training: Covers installation, operation, calibration, maintenance, troubleshooting, and safety precautions.

After-sales Service: One year of free service for non-human-induced faults, with lifelong technical support.

Main Component Brands

Servo Motors: Rite (China) / Yaskawa (Japan).

Ball Screws: Hiwin (China) / THK (Japan).

DD Motors: NSK (Japan).

Guideways: Hiwin (China) / THK (Japan).

Pneumatic Components: SMC (Japan) / Airtac (China).

PLC: Keyence (Japan).

Touchscreen: Proface (Japan).

Sensors: Panasonic (Japan) / HUAN (China).

Power Supply: Mean Well (Taiwan).

Circuit Breakers and Contactors: Schneider (France) / Shihlin (Taiwan).

Drag Chains: Igus (Germany).

Equipment 2D Drawing

A 2D drawing of the equipment is included for reference.

Image Processing Unit

The image processing unit of the FB-1500A is equipped with advanced systems to ensure precision in alignment and inspection processes. For LCD correction, it utilizes a Bosch image processing system with a CCD camera, coaxial light barrel, and LED light source. The system offers a field of view of 4.8mm × 3.6mm and allows for Z-axis adjustment over a 10mm travel range. Similarly, the ACF inspection part employs the same high-quality components to achieve a broader field of view of 9.6mm × 7.2mm, ensuring thorough and accurate quality checks.

In the pre-bonding alignment section, two CCD cameras and corresponding coaxial light barrels are used, providing a magnification of 2x and a field of view of 2.4mm × 1.8mm. This setup, combined with the Mark alignment method, guarantees precise positioning of components during the bonding process. The main bonding alignment part mirrors the LCD correction setup, ensuring consistency and accuracy throughout the machine’s operations.

Control Unit

The control unit is the brain of the FB-1500A, featuring PLC control for reliable and efficient operation. The touchscreen interface is user-friendly, offering both manual and automatic modes to cater to different production needs. It displays work parameters and can store data for up to 100 different product varieties, enhancing flexibility and streamlining production workflows.

Manual control buttons, including three emergency stop buttons, a main power switch, and a lighting power switch, provide operators with immediate control over the machine’s functions. The access control system ensures safety by pausing machine operation when doors are opened, and the tri-color operation indicator lights offer visual cues about the machine’s status.

Documentation and After-sales Service

Comprehensive documentation, including a detailed machine operation manual, is provided to guide users through setup, operation, and maintenance procedures. The training program covers a wide range of topics, from installation and parameter settings to equipment repair and common fault排除, ensuring operators are well-equipped to handle various scenarios.

After-sales service is a significant advantage of the FB-1500A, with one year of free service for non-human-induced faults and lifelong technical support. This commitment to customer satisfaction ensures that manufacturers can rely on the machine’s performance and receive assistance whenever needed.

Main Component Brands

The OL-FB1500A incorporates top-tier components from renowned brands worldwide. Servo motors from Rite and Yaskawa, ball screws from Hiwin and THK, and DD motors from NSK highlight the machine’s high-quality build. Pneumatic components from SMC and Airtac, along with PLC and touchscreen systems from Keyence and Proface, further underscore its reliability. Sensors from Panasonic and HUAN, power supplies from Mean Well, and circuit breakers from Schneider and Shihlin complete the list of premium parts that contribute to the machine’s exceptional performance.

Equipment 2D Drawing

A detailed 2D drawing of the OL-FB1500A is available, providing a clear visual representation of the machine’s layout and components. This drawing serves as a valuable reference for installation, maintenance, and integration into production lines.

In summary, the FB-1500A Fully Automatic FOG/FOF/TFOG Bonding Machine represents a significant advancement in the field of LCD manufacturing equipment. Its precise engineering, user-friendly design, and comprehensive support make it an ideal choice for manufacturers seeking to enhance productivity and product quality in the competitive electronics market.

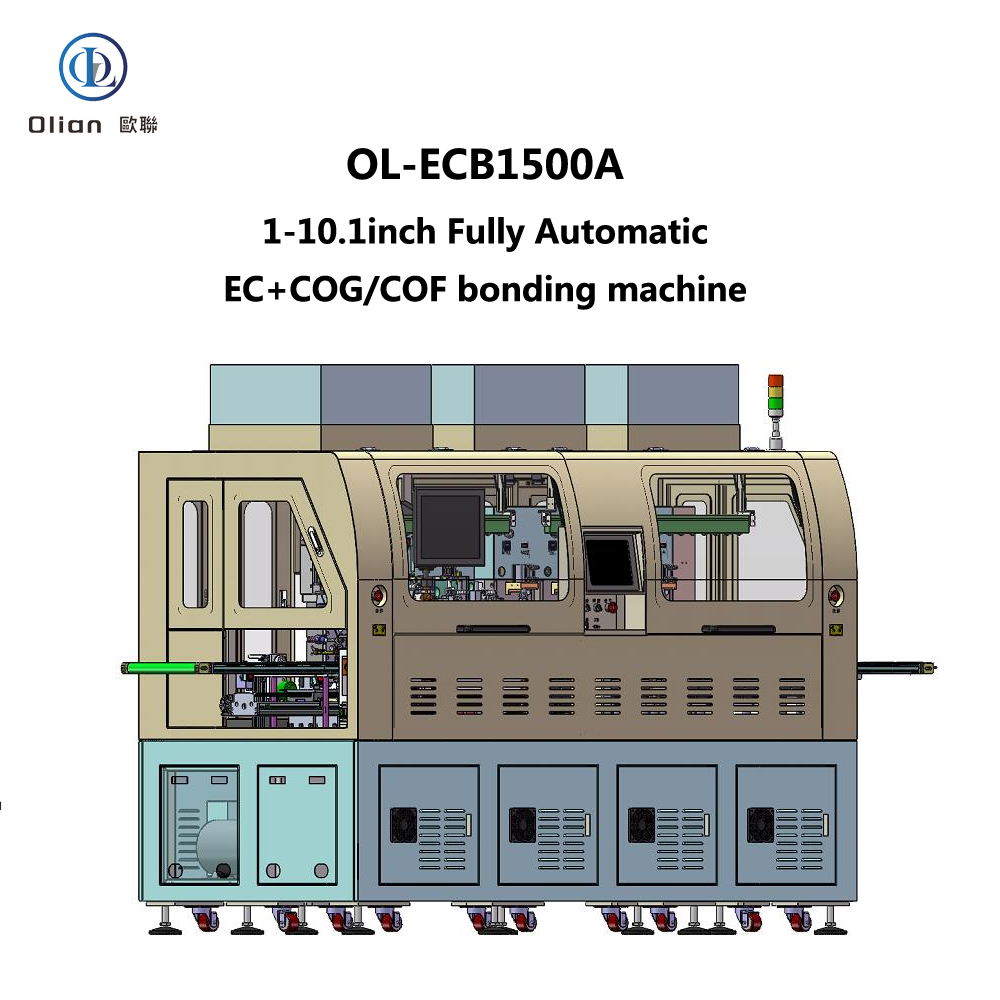

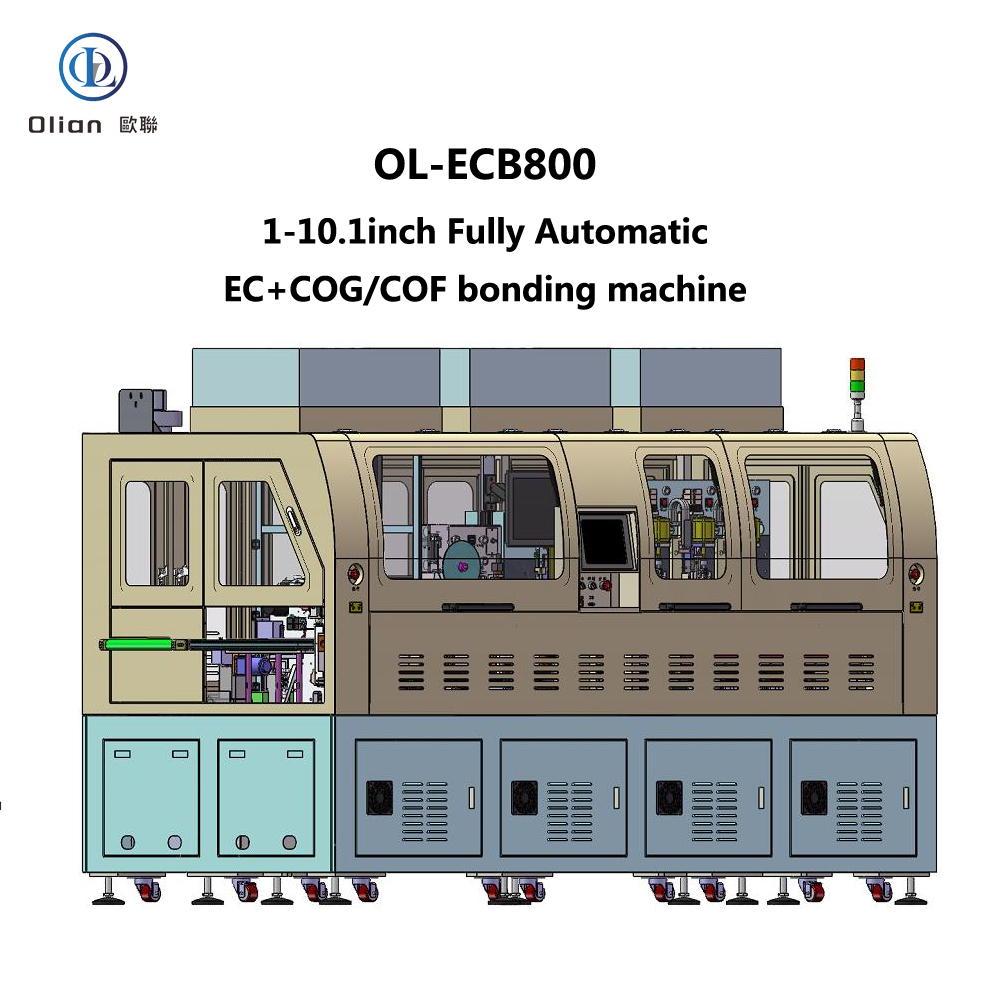

The OL-ECB1500A is a cutting-edge fully automatic EC+COG/COF bonding machine designed to meet the precise manufacturing requirements of modern electronics production. This advanced equipment is specifically tailored for the automatic wiping, ACF (Anisotropic Conductive Film) application, pre-bonding, and main bonding processes of single-sided, single-component LCD products ranging from 1″ to 10.1″ in size. Its innovative design and high-precision features make it an essential tool for manufacturers seeking efficiency, accuracy, and reliability in their production lines.

The OL-ECB1500A operates through a series of coordinated mechanical and automated processes. The workflow begins with the loading of the product onto the conveyor belt or platform, either manually or via an automated upstream machine. Mechanical arm 1# picks up the product, corrects its position using the CCD (Charge-Coupled Device) system, and places it on the wiping platform. The wiping platform advances, and the wiping and plasma cleaning processes are completed across the entire wiping area.

Next, mechanical arm 2# transfers the LCD to the ACF platform. The ACF platform advances, and the bonding head descends to apply the ACF. After the ACF application, the platform retracts to the unloading position. Mechanical arm 3# then picks up the LCD, checks the ACF adhesion, and places it on the pre-bonding stage. Meanwhile, the IC/COF is loaded, and the automatic feeding system visually corrects the IC/COF position. After pre-alignment, the IC/COF is moved to the bonding head position, and the bonding head picks it up for pre-bonding. Mechanical arm 4# moves the product to one of the three main bonding platforms for final bonding. Finally, mechanical arm 5# transfers the bonded LCD to the downstream conveyor or production line.

A detailed 2D drawing of the equipment is available, providing a clear visual representation of the machine’s layout and components. This drawing serves as a valuable reference for installation, maintenance, and integration into production lines.

In summary, the OL-ECB1500A Fully Automatic EC+COG/COF Bonding Machine represents a significant advancement in the field of LCD manufacturing equipment. Its precise engineering, user-friendly design, and comprehensive support make it an ideal choice for manufacturers seeking to enhance productivity and product quality in the competitive electronics market.

The OL-CC1000A Fully Automatic COF Punch & Feed Machine is a highly advanced fully automatic COF (Chip on Film) punching and feeding machine designed to meet the precise requirements of modern electronics manufacturing. This equipment specializes in processing COF products with widths of 35mm, 48mm, and 70mm, ensuring accuracy and efficiency in production environments. Its innovative design and robust performance make it an essential addition to manufacturing lines, particularly when integrated with other bonding equipment for seamless operation.

In summary, the OL-CC-1000A Fully Automatic COF Punch & Feed Machine is a state-of-the-art solution for COF product manufacturing. Its precision, reliability, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.

The OL-LLD1000 is a cutting-edge fully automatic LCD loader designed to efficiently load LCD panels of various sizes using a TRAY disk transmission method. This advanced machine is compatible with other equipment for automated production lines, making it a valuable addition to modern manufacturing environments where precision and speed are paramount.

The OL-LLD1000 operates through a well-coordinated process. It starts with manual placement of loaded TRAY disks (containing LCD panels) onto the loading position. The full TRAY disk is then lifted by the Z-axis to the pick-up position. The product robotic arm picks up the LCD panels and places them onto the downstream discharge position. Simultaneously, the tray robotic arm transfers empty trays to the empty TRAY disk warehouse, ensuring a continuous and efficient workflow.

In summary, the OL-LLD1000 Fully Automatic LCD Loader is a state-of-the-art solution for LCD panel loading in modern manufacturing. Its precision, speed, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.

The OL-FLD1000B is a state-of-the-art fully automatic FPC (Flexible Printed Circuit) loader designed to efficiently load FPCs of various sizes using a TRAY disk transmission method. This advanced machine can be integrated with FOG (Film on Glass) equipment for automated production lines, making it a valuable addition to modern manufacturing environments where precision and speed are critical.

The OL-FLD1000B operates through a well-coordinated process. It starts with manual placement of loaded TRAY disks (containing FPCs) onto the loading position. The Tray loading handling Z-axis lifts a TRAY disk to the intermediate platform. After a full-view photo is taken, the FPC handling XYZθ-axis robotic arm picks up the FPC from the Tray and moves it to the discharge position. The Tray intermediate platform then moves to the unloading position, where the Tray unloading handling Z-axis removes the empty Tray and places it in the empty Tray unloading position, ensuring a continuous and efficient workflow.

In summary, the OL-FLD1000B Fully Automatic FPC Loader is a cutting-edge solution for FPC loading in modern manufacturing. Its precision, speed, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.

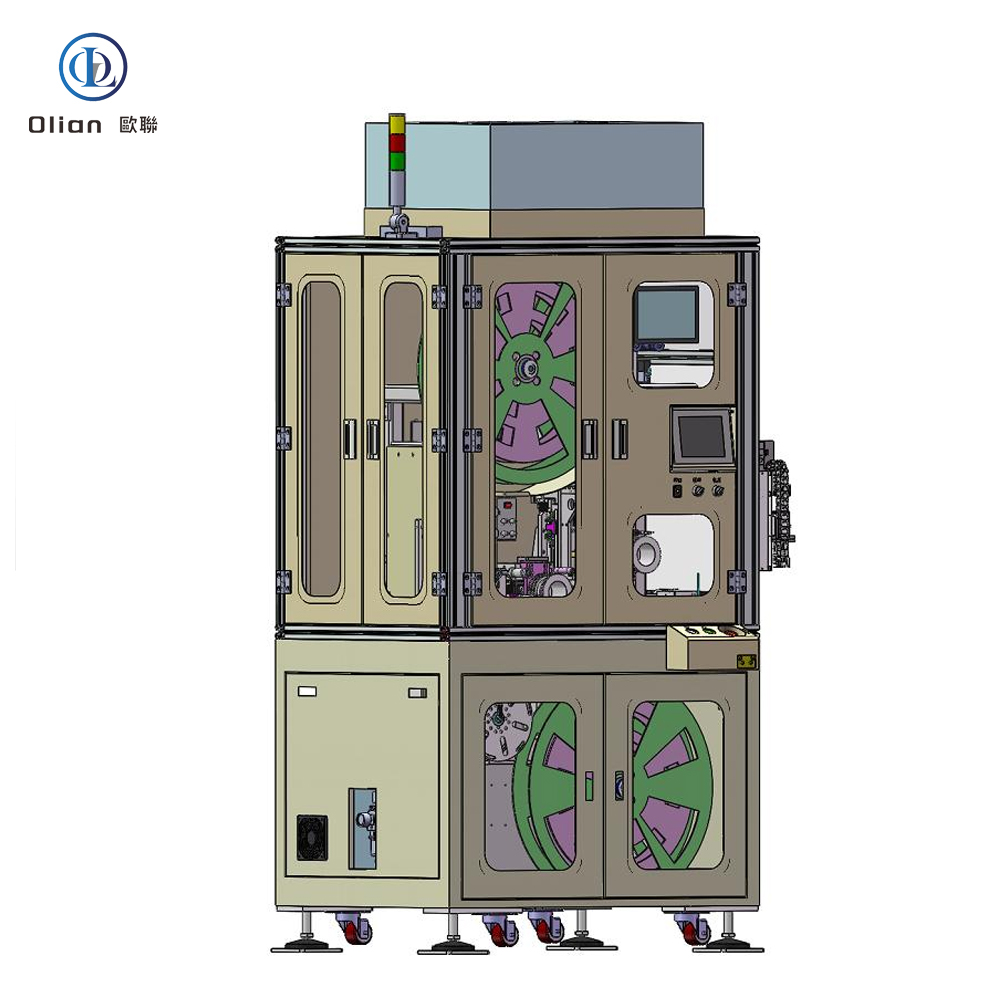

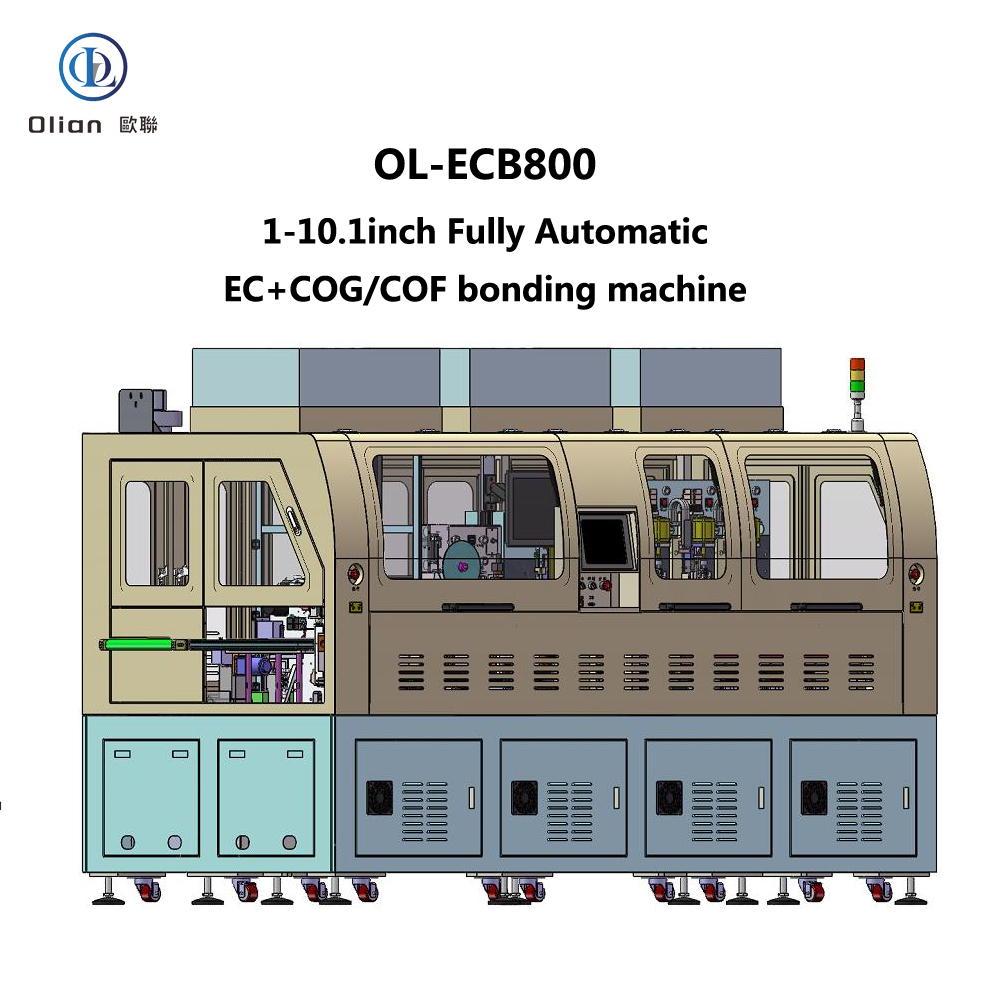

The OL-ECB800 is a highly advanced fully automatic EC+COG (Chip on Glass) bonder designed to meet the precise manufacturing requirements of modern electronics production. This machine specializes in automatic wiping, ACF (Anisotropic Conductive Film) application, pre-bonding, and main bonding processes for LCD products ranging from 1″ to 10.1″ in size. Its innovative design and high-precision features make it an essential tool for manufacturers seeking efficiency, accuracy, and reliability in their production lines.

The OL-ECB800 operates through a series of coordinated mechanical and automated processes. The workflow begins with the loading of the product onto the conveyor belt or platform, either manually or via an automated upstream machine. Mechanical arm 1# picks up the product, corrects its position using the CCD (Charge-Coupled Device) system, and places it on the wiping platform. The wiping platform advances, and the wiping and plasma cleaning processes are completed across the entire wiping area.

Next, mechanical arm 2# transfers the LCD to the ACF platform. The ACF platform advances, and the bonding head descends to apply the ACF. After the ACF application, the platform retracts to the unloading position. Mechanical arm 3# then picks up the LCD, checks the ACF adhesion, and places it on the pre-bonding stage. Meanwhile, the IC is loaded, and the automatic feeding system visually corrects the IC position. After pre-alignment, the IC is moved to the bonding head position, and the bonding head picks it up for pre-bonding. Mechanical arm 4# moves the product to one of the three main bonding platforms for final bonding. Finally, mechanical arm 5# transfers the bonded LCD to the downstream conveyor or production line.

In summary, the OL-ECB800 Fully Automatic EC+COG Bonder represents a significant advancement in the field of LCD manufacturing equipment. Its precise engineering, user-friendly design, and comprehensive support make it an ideal choice for manufacturers seeking to enhance productivity and product quality in the competitive electronics market.

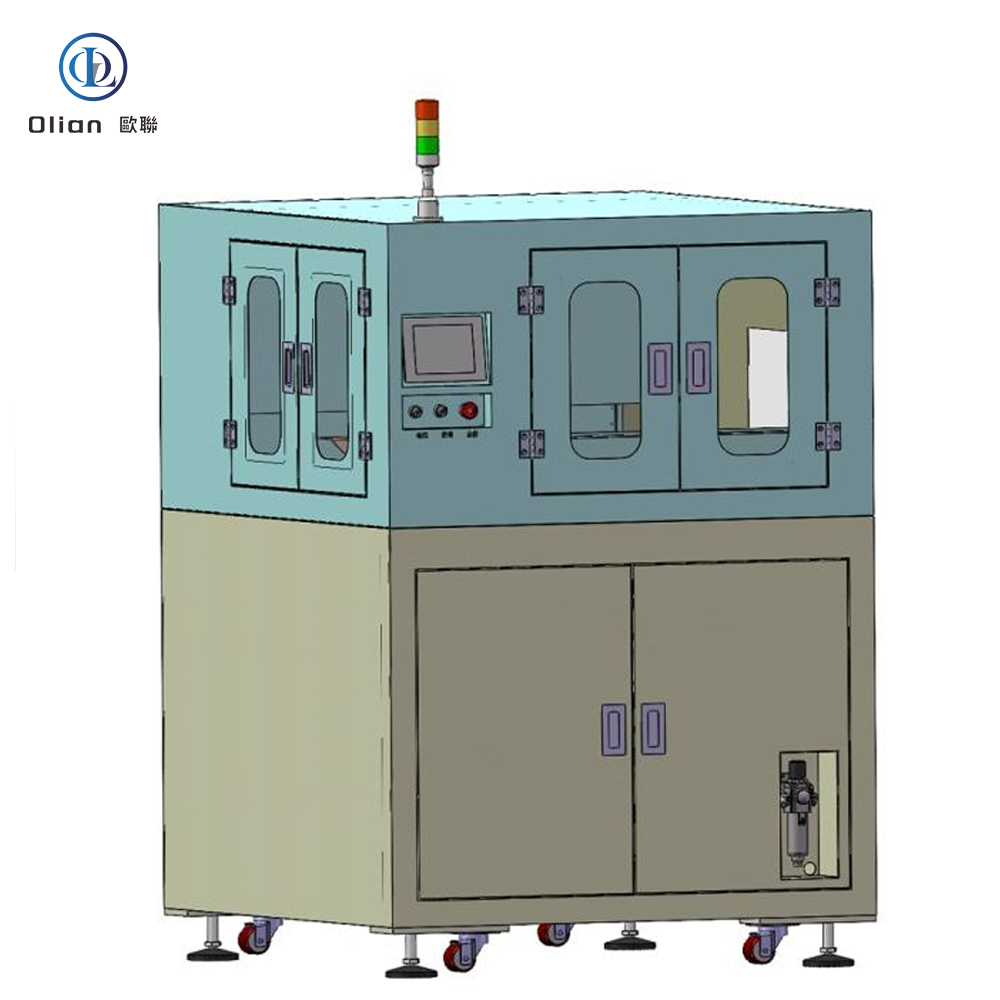

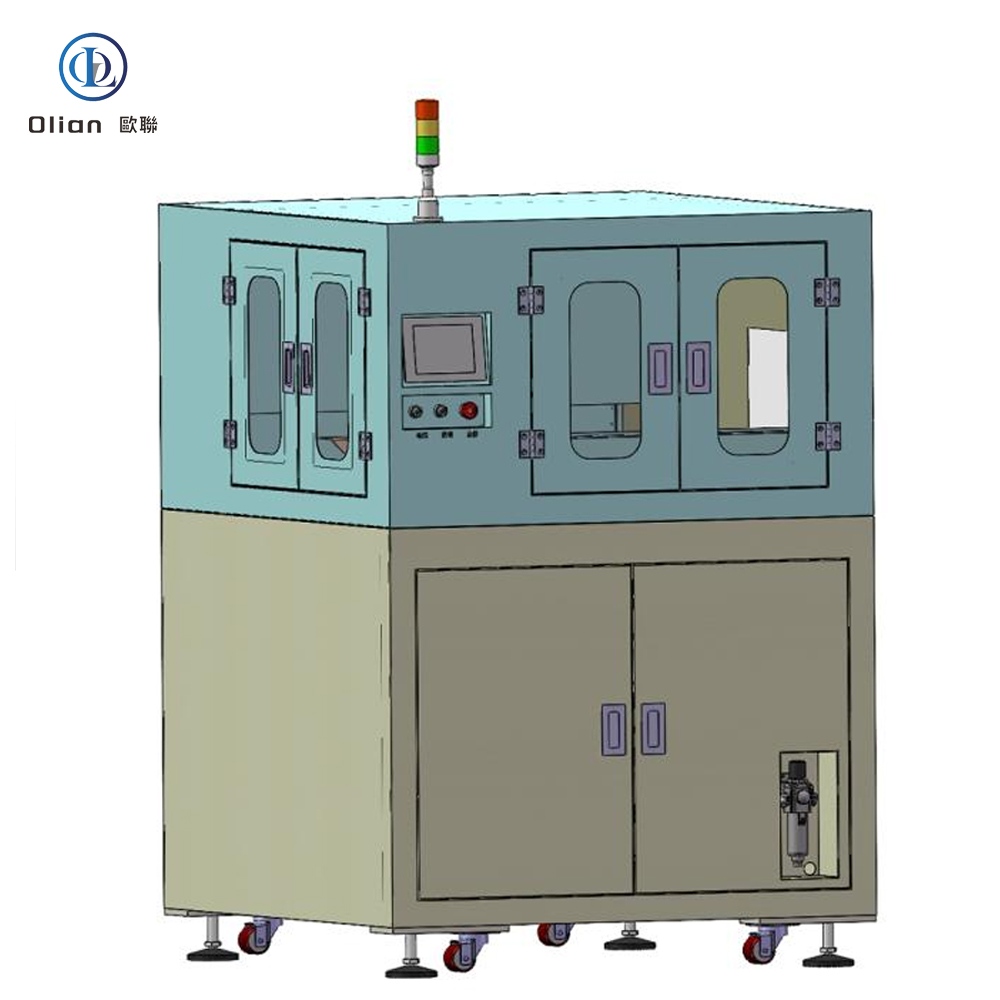

The OL-FB800 is a cutting-edge fully automatic FOG (Film on Glass) bonder designed to meet the precise requirements of modern electronics manufacturing. This advanced machine specializes in automatic ACF (Anisotropic Conductive Film) application, alignment, and thermal bonding for LCD products ranging from 1″ to 10.1″ in size, with single-sided, single FPC (Flexible Printed Circuit) components. Its innovative design and high-precision features make it an essential tool for manufacturers seeking efficiency, accuracy, and reliability in their production lines.

The OL-FB800 operates through a series of coordinated mechanical and automated processes. The workflow begins with the loading of the product onto the conveyor belt or platform, either manually or via an automated upstream machine. Mechanical arm 0# picks up the LCD + COF, corrects its position using the CCD (Charge-Coupled Device) system, and places it on the ACF platform. The ACF platform advances, and the bonding head descends to apply the ACF. After the ACF application, the platform retracts for position detection to ensure proper ACF adhesion.

Next, mechanical arm 1# transfers the LCD + COF to the pre-bonding stage while the FPC is simultaneously loaded and pre-aligned on the carrier stage. The bonding head then picks up the FPC and performs the pre-bonding process. Mechanical arm 2# moves the product to one of the four main bonding platforms for final bonding. Finally, mechanical arm 3# transfers the bonded product to the downstream conveyor or production line.

In summary, the OL-FB800 Fully Automatic FOG Bonder represents a significant advancement in the field of LCD manufacturing equipment. Its precise engineering, user-friendly design, and comprehensive support make it an ideal choice for manufacturers seeking to enhance productivity and product quality in the competitive electronics market.

The OL-LLD2000 is a highly efficient fully automatic LCD loader designed to continuously load LCD panels of various sizes using a TRAY disk transmission method. This advanced machine can operate without stopping, making it a valuable addition to modern manufacturing environments where continuous production and high throughput are critical.

The OL-LLD2000 operates through a well-coordinated process. It starts with manual placement of loaded TRAY disks (containing LCD panels) into the full tray buffer storage. The full tray loading station’s Z-axis descends to the pick-up position, and the full tray buffer storage’s Y-axis moves to the discharge position. The full tray loading station’s Z-axis then ascends to the discharge position. The product robotic arm picks up the LCD panels and hands them over to the downstream process. After the LCD panels are picked up, the material handling robotic arm moves the empty tray to the empty tray warehouse. When the empty tray warehouse is full, it is lowered to the inventory buffer storage for employees to remove the empty trays.

In summary, the OL-LLD2000 Fully Automatic Non-stop LCD Loader is a state-of-the-art solution for LCD panel loading in modern manufacturing. Its continuous operation capability, precision, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.

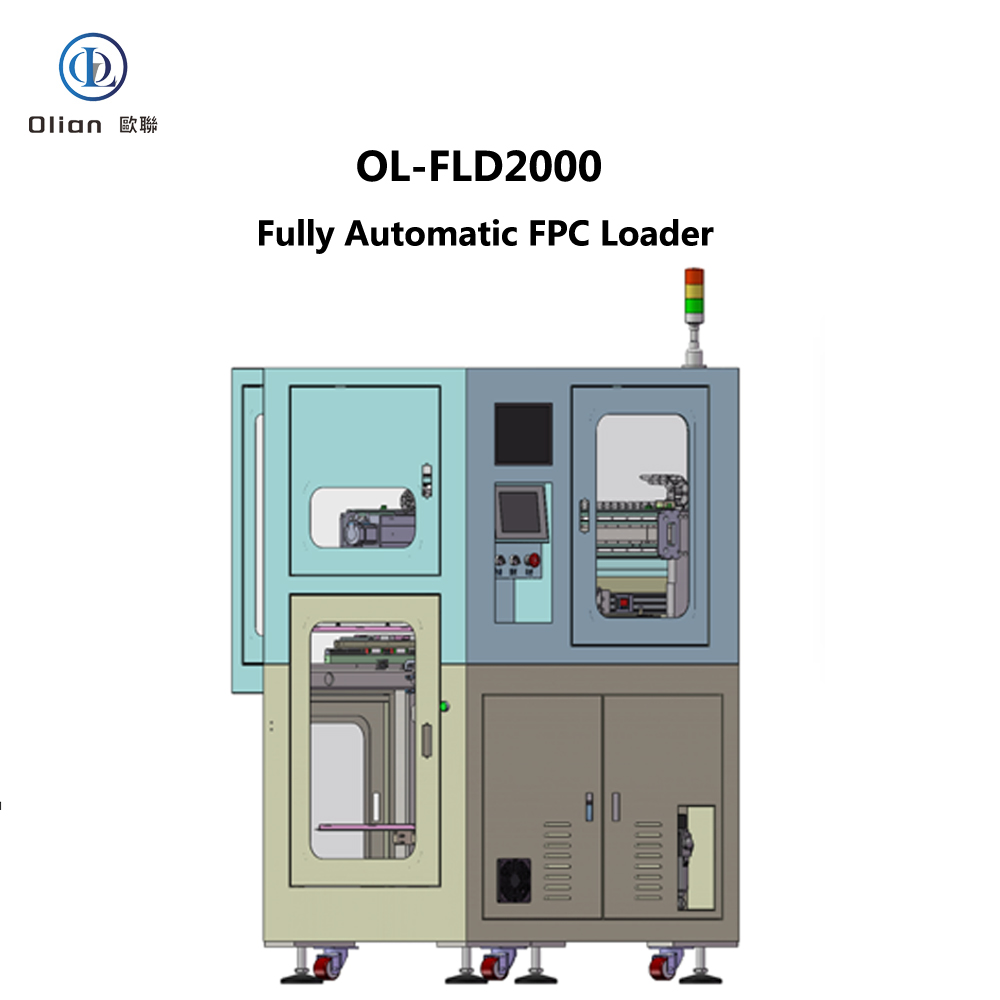

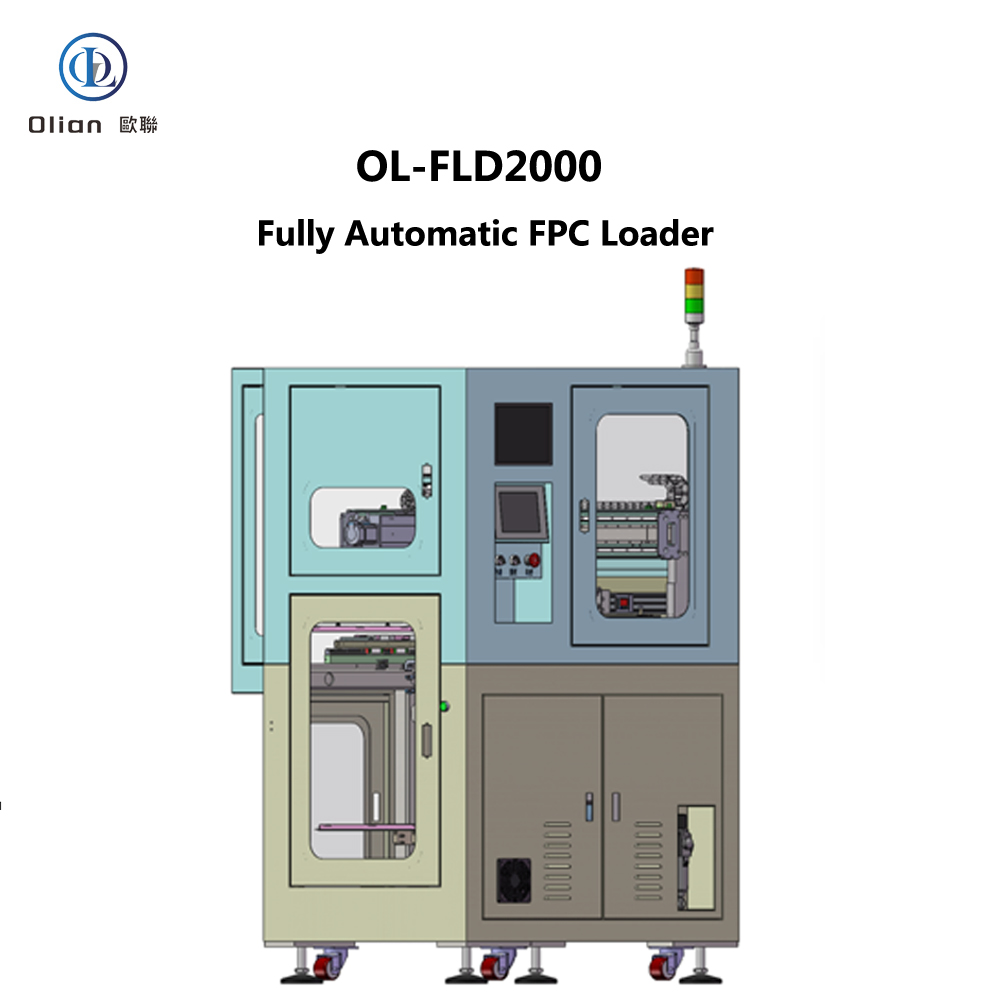

The OL-FLD2000 is a highly efficient fully automatic FPC (Flexible Printed Circuit) loader designed to automatically feed FPCs of various sizes using a TRAY disk transmission method. This advanced machine can be integrated with FOG (Film on Glass) equipment for automated production lines, making it a valuable addition to modern manufacturing environments where precision and speed are critical.

The OL-FLD2000 operates through a well-coordinated process. It starts with manual placement of loaded TRAY disks (containing FPCs) onto the loading position. The Tray loading handling Z-axis lifts a TRAY disk to the intermediate platform. After a full-view photo is taken, the FPC handling robotic arm picks up the FPC from the Tray and moves it to the discharge position. The Tray intermediate platform then moves to the unloading position, where the Tray unloading handling Z-axis removes the empty Tray and places it in the empty Tray unloading position, ensuring a continuous and efficient workflow.

In summary, the OL-FLD2000 Fully Automatic FPC Loader is a state-of-the-art solution for FPC loading in modern manufacturing. Its precision, speed, and user-friendly design make it an invaluable asset for electronics manufacturers looking to optimize their production processes and enhance product quality.

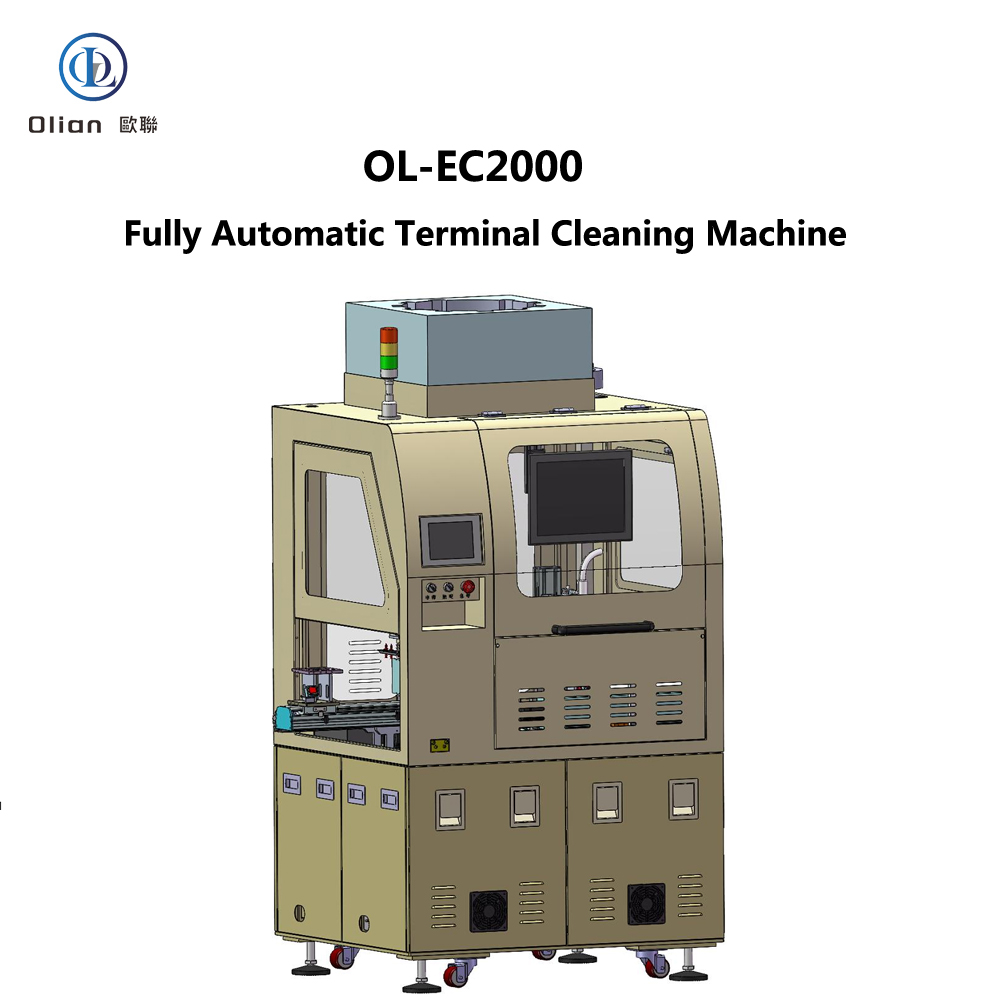

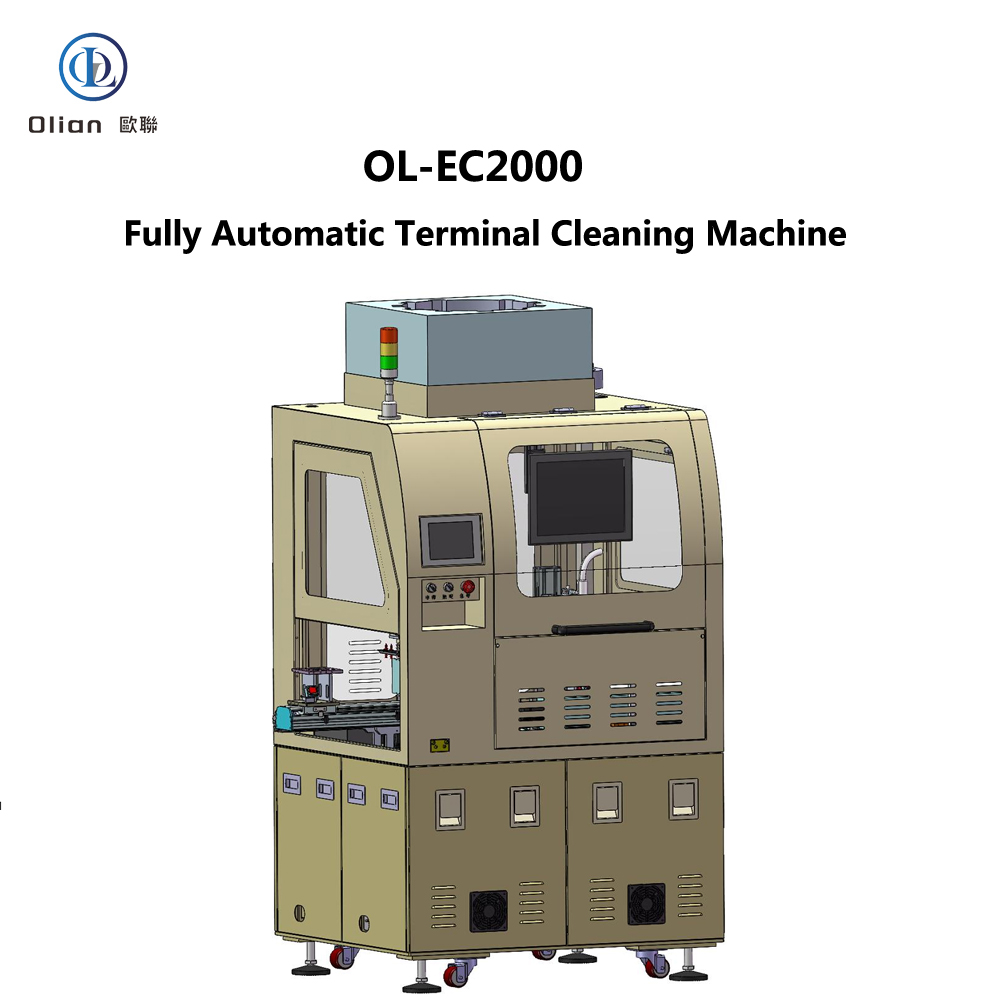

The OL-EC2000 is a cutting-edge fully automatic terminal cleaning machine designed to efficiently clean LCD products of various sizes (1-7 inches) through wiping, cleaning (with optional ultrasonic cleaning), and plasma treatment. This advanced equipment can be integrated with other devices in a production line, making it a valuable addition to modern manufacturing environments where precision and speed are paramount.

The OL-EC2000 operates through a series of automated processes. It starts with manual placement of the LCD onto a platform or conveyor belt. Robotic arm 1# then moves the LCD to a CCD correction station for position adjustment. The LCD is transferred to a wiping platform where it is cleaned by a wiping head. After wiping, robotic arm 2# transports the LCD to a plasma cleaning platform for further cleaning. Finally, the cleaned LCD is moved to a discharge station.

In summary, the OL-EC2000 Fully Automatic Terminal Cleaning Machine represents a significant advancement in LCD manufacturing equipment. Its precise engineering, user-friendly design, and comprehensive support make it an ideal choice for manufacturers seeking to enhance productivity and product quality in the competitive electronics market.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us