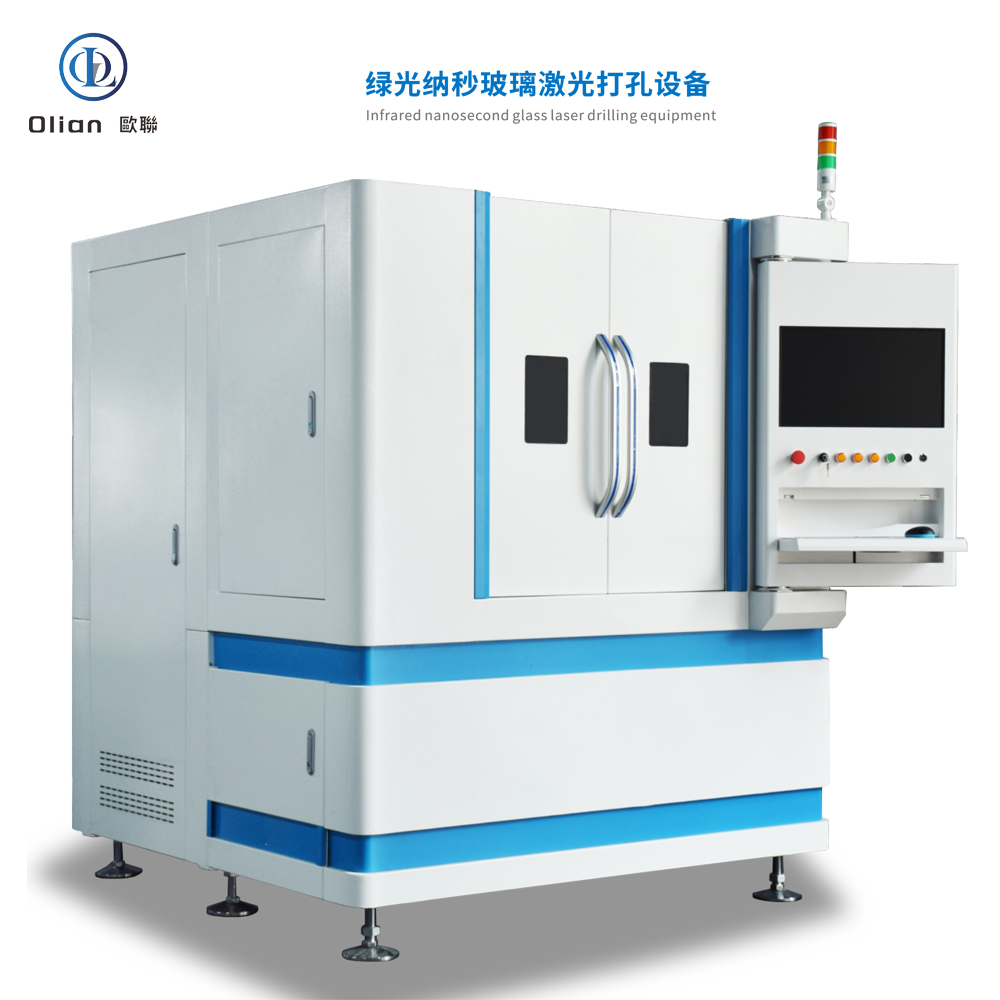

Green-Light Nanosecond Glass Laser Drilling Machine,

Processing Advantages

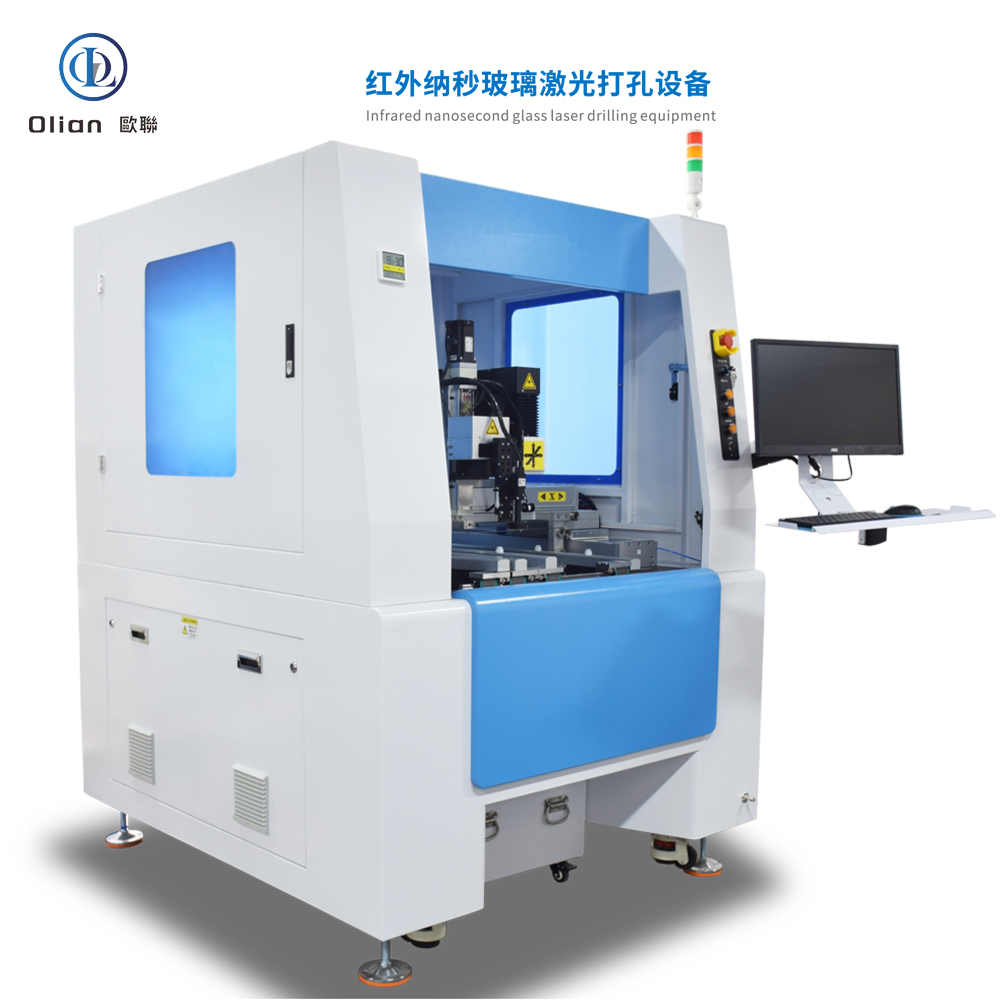

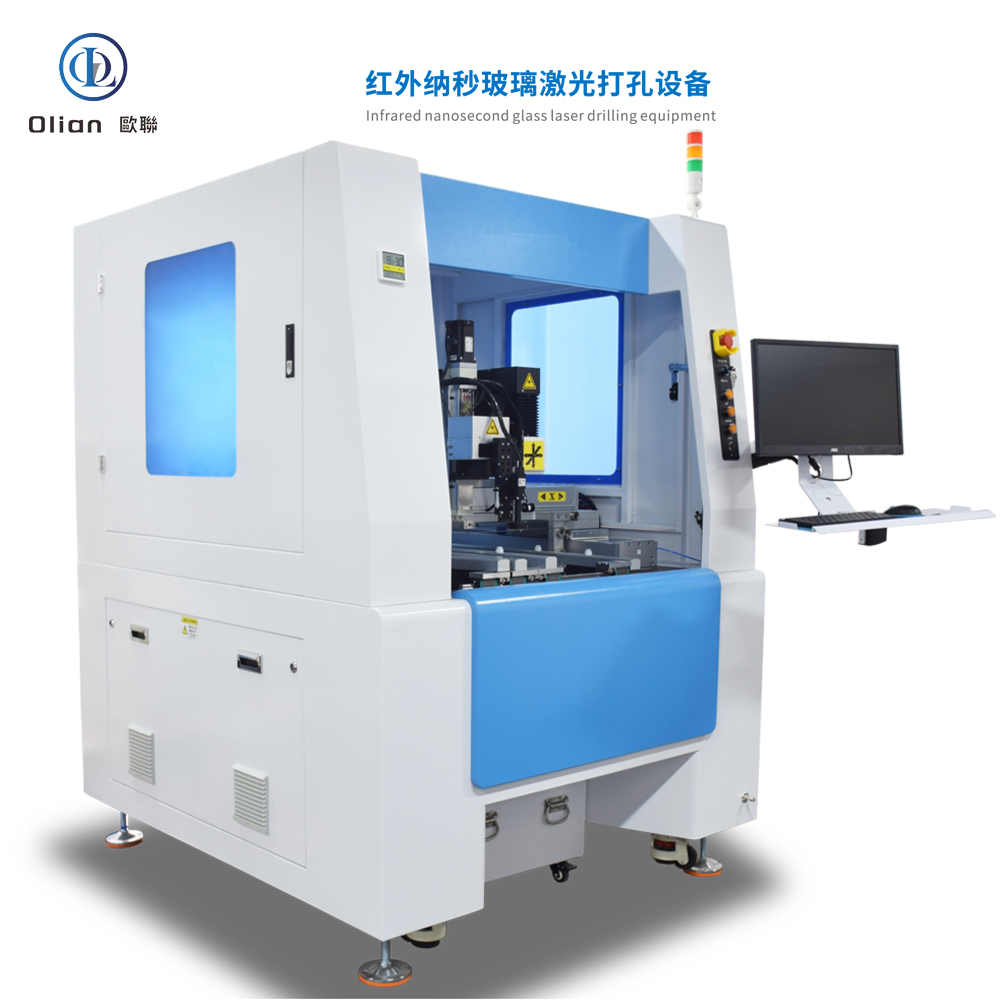

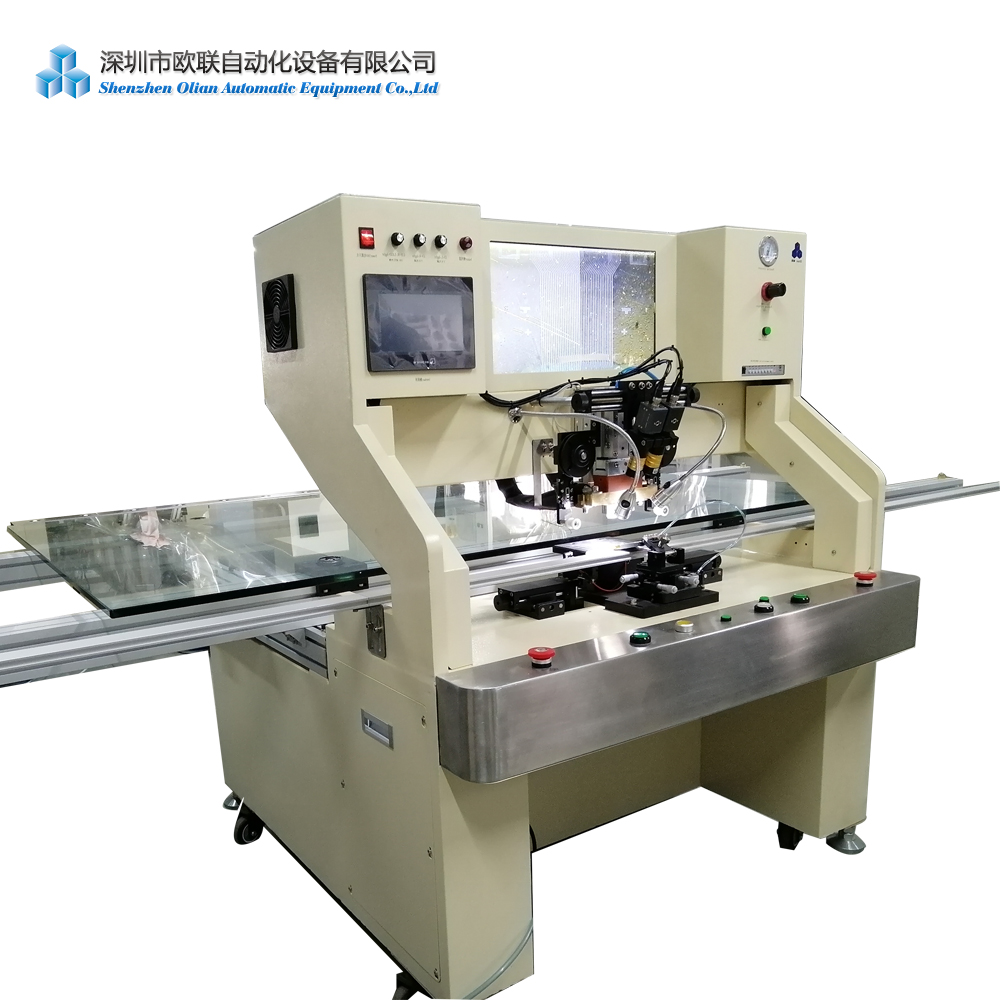

Infrared Nanosecond Glass Laser Drilling Machine

Process Application

Main Parameters

Processing Advantages

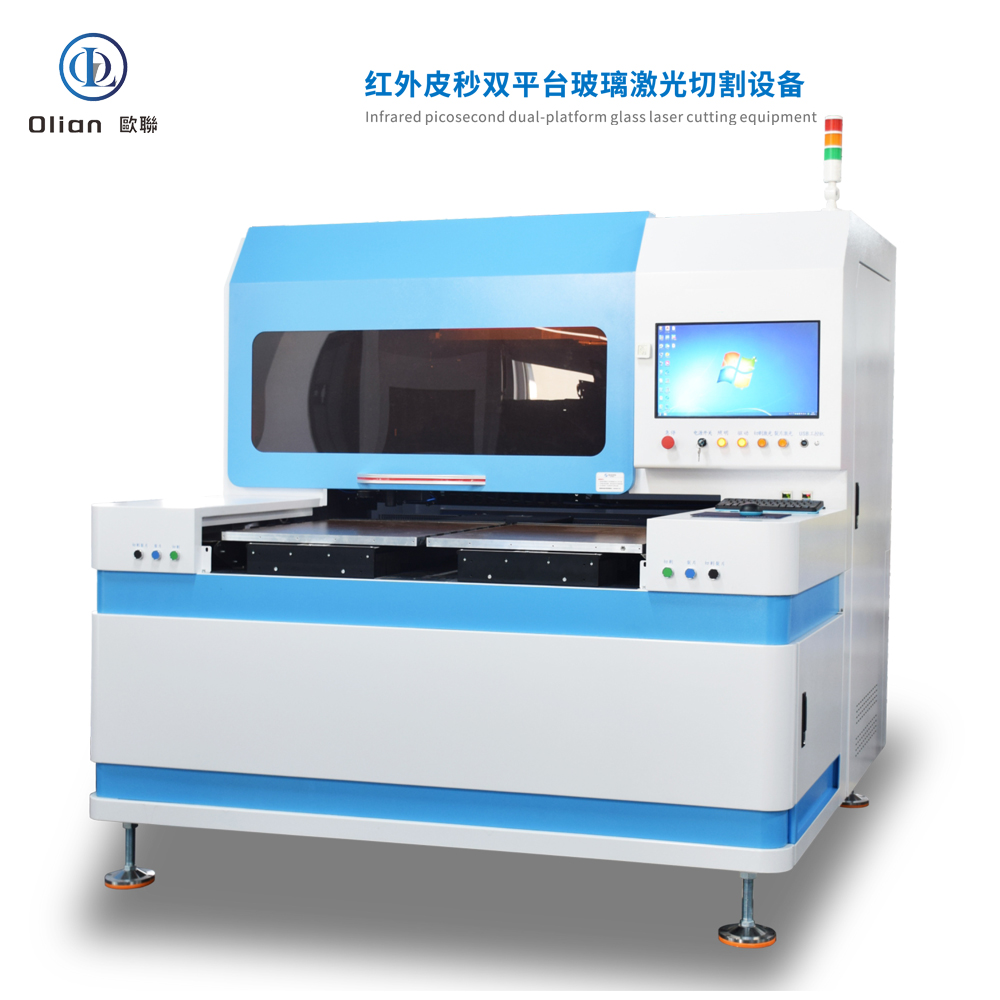

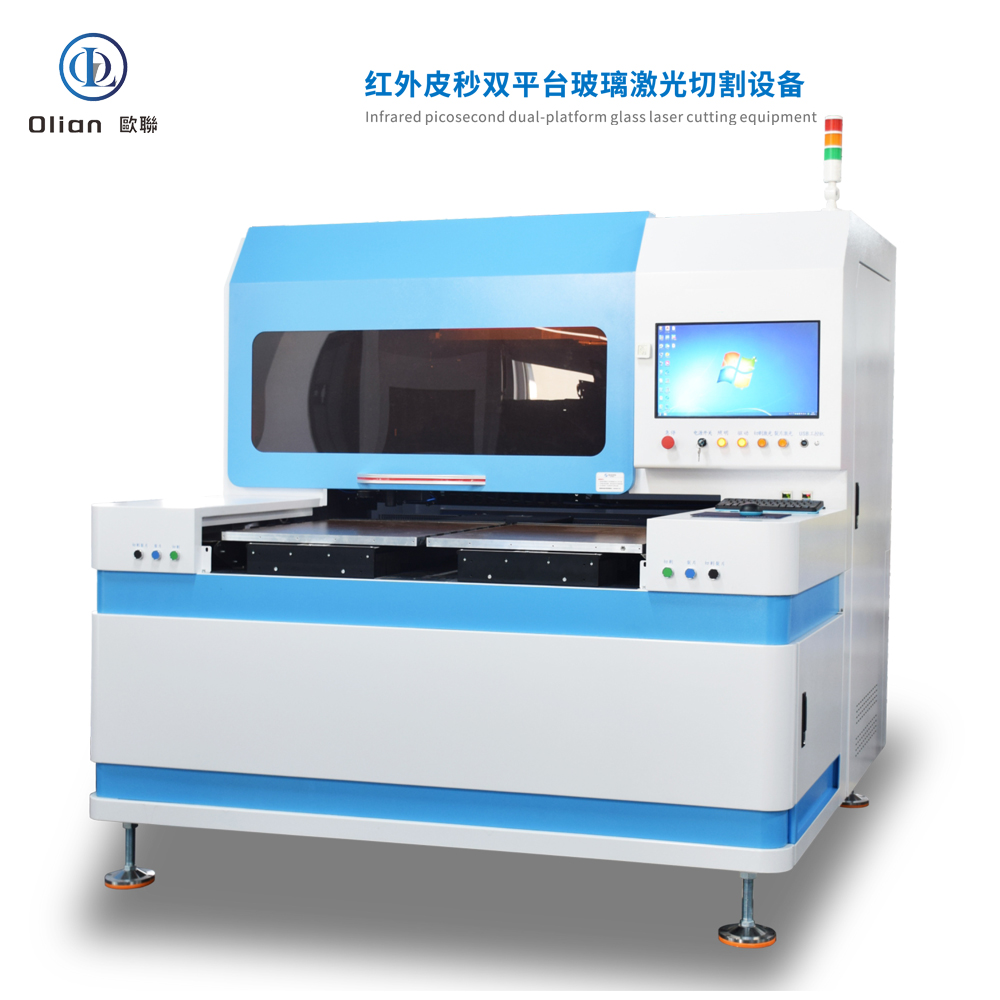

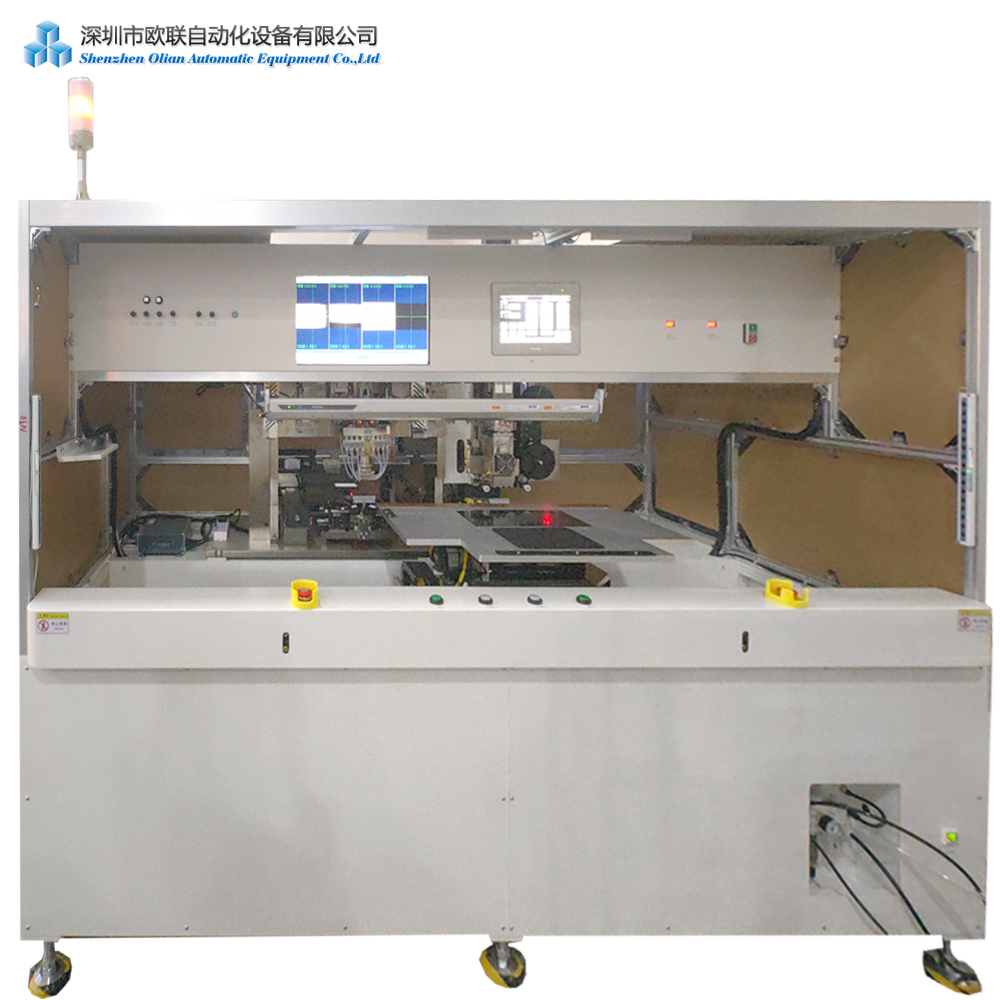

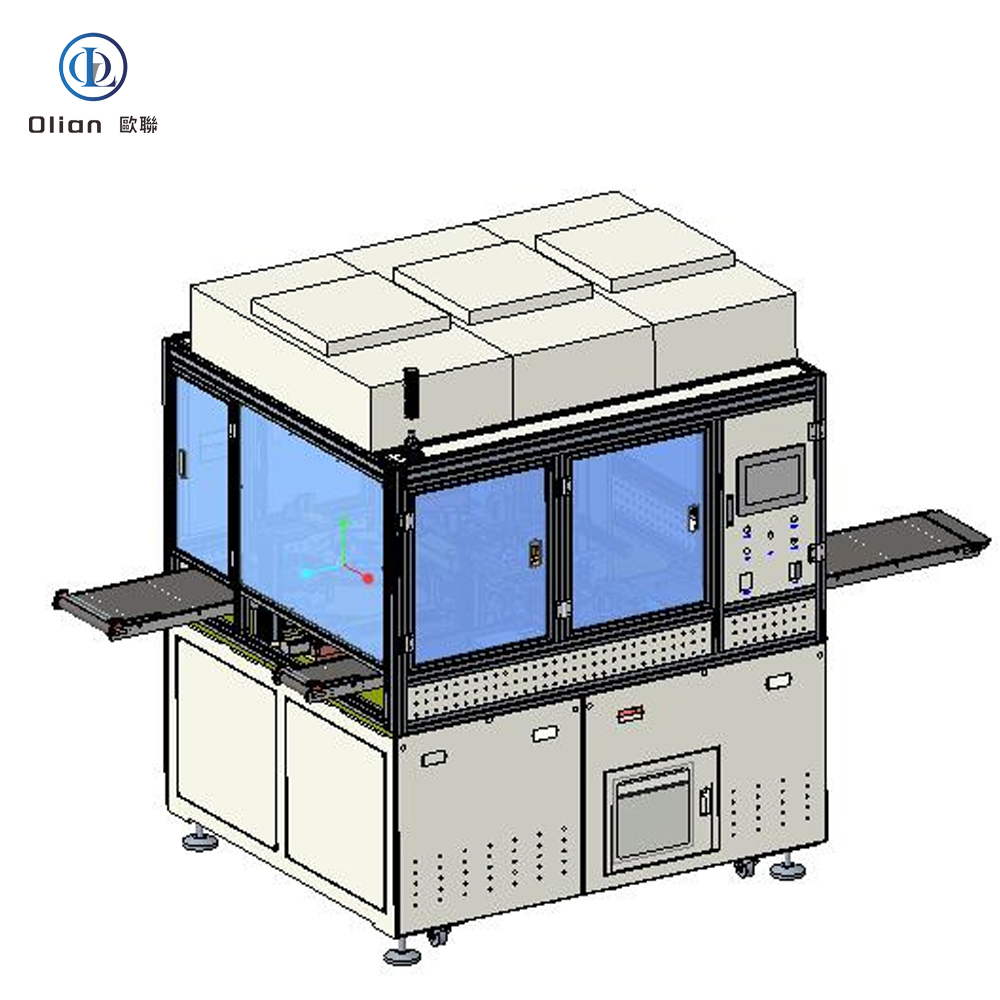

Infrared Picosecond Dual-Platform Glass Laser Cutting Machine

Cuts all hard-brittle sheet materials: ordinary glass, optical glass, quartz, sapphire, reinforced glass, optical filters, mirrors, etc. The same system also produces internal cut-outs and holes to specified dimensions.

Laser type: Infrared picosecond

Model: OL-IPC70120-D/OL-IPC90140-D

Standard platform sizes: 700 mm × 1 200 mm and 900 mm × 1 400 mm (custom sizes on request)

Thickness range: 0.03 – 8 mm

Maximum cutting speed: 1 000 mm/s

Edge chipping: ≤ 10 µm

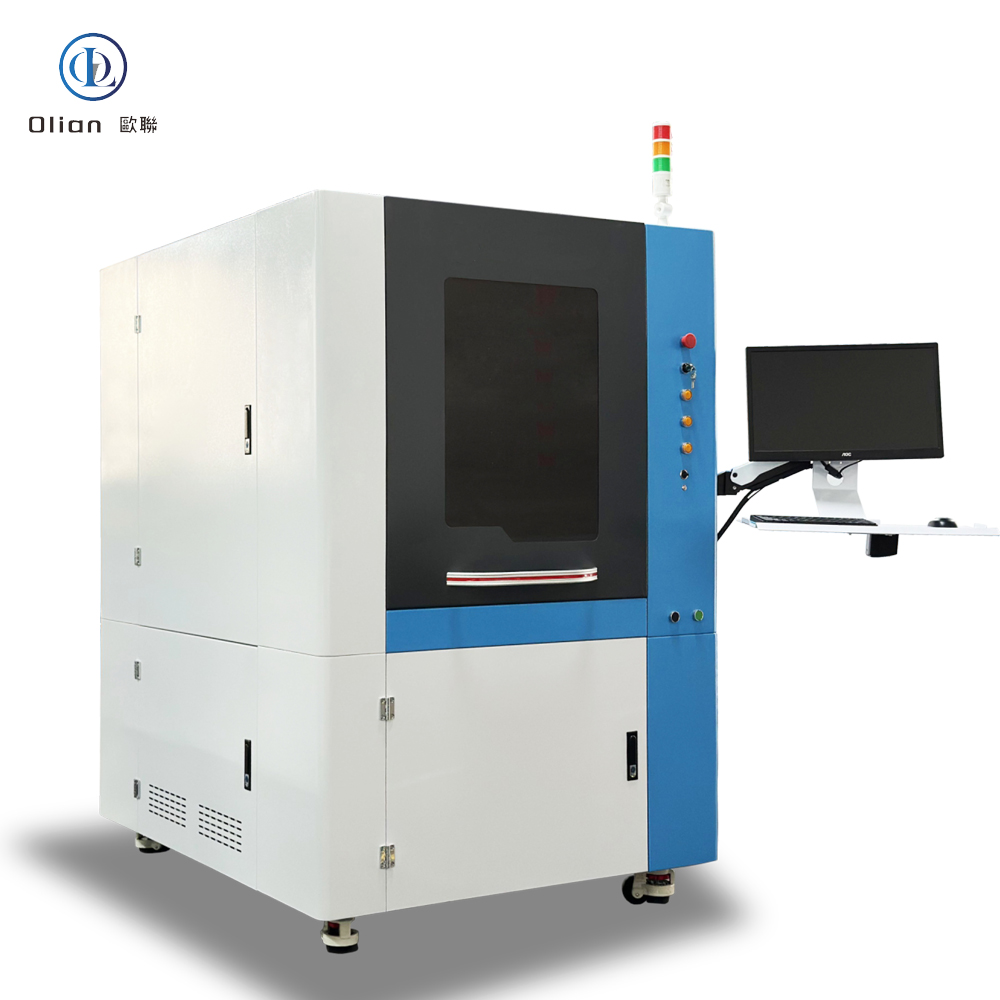

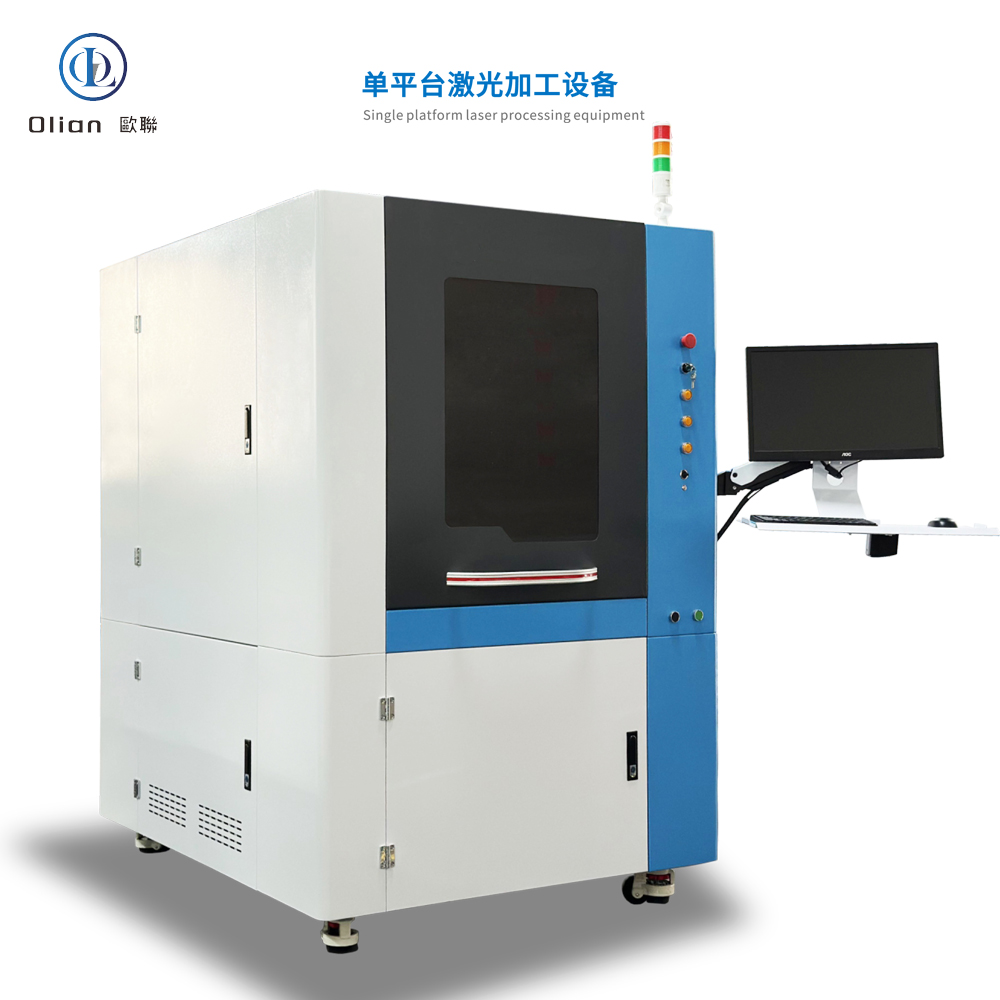

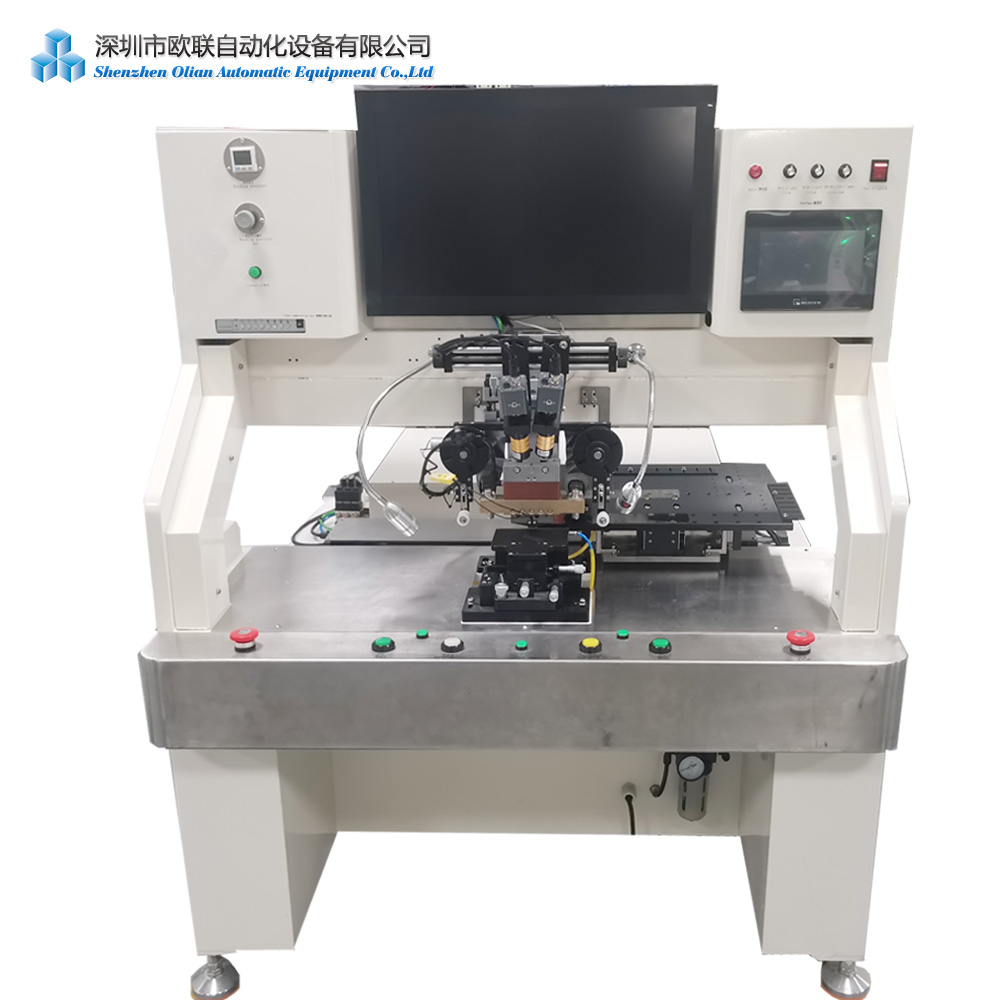

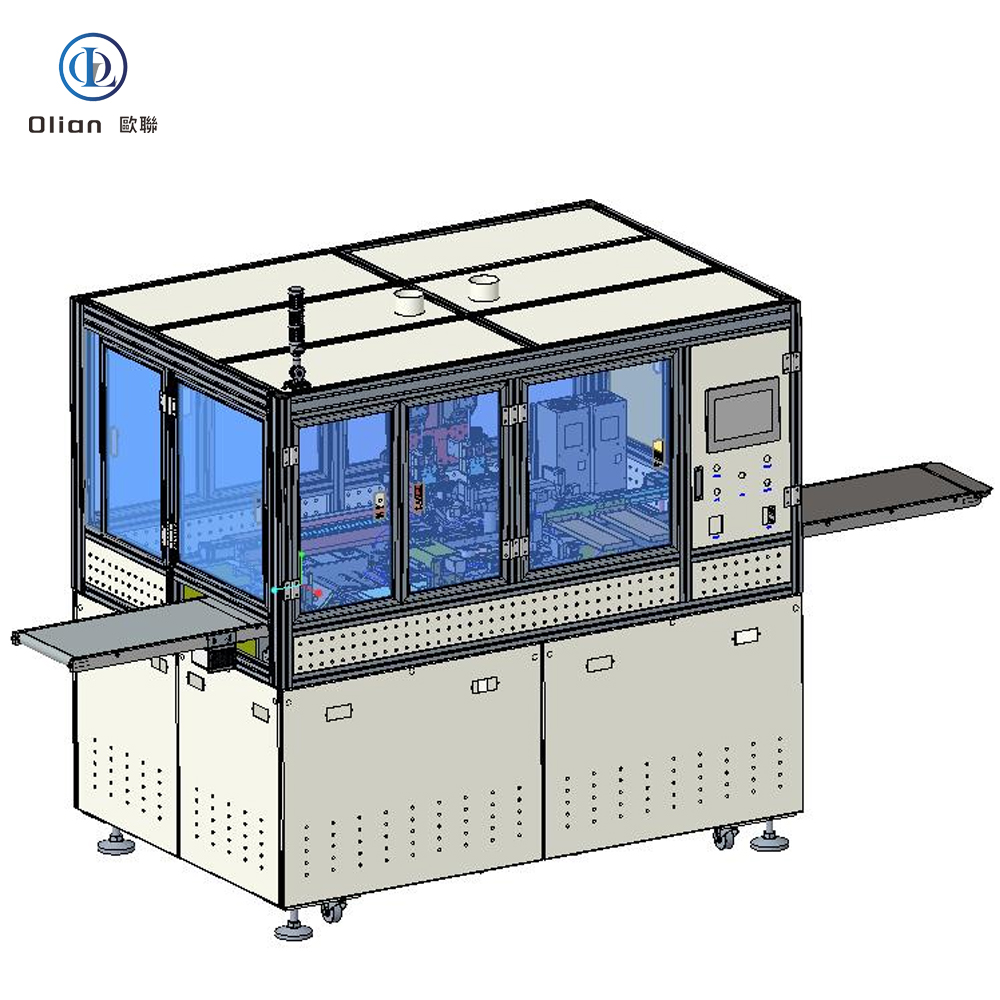

Single-Platform Laser Processing Equipment

Engineered for cutting and drilling every kind of brittle, hard sheet: common glass, optical glass, quartz, sapphire, strengthened glass, optical filters, ceramics, etc.

Cutting Configuration – Infrared Picosecond

Model series: OL-IPC4050-S,

Table size: 400 mm × 500 mm (custom sizes available).

Thickness range: 0.03 – 8 mm.

Cutting speed: 0 – 1 000 mm/s.

Edge chipping: ≤ 10 µm.

Drilling Configuration – Green Nanosecond.

Model series: OL-GND4050-S.

Table size: 400 mm × 500 mm (custom sizes available).

Thickness range: 0.03 – 2 mm.

Drilling speed: 0 – 5 000 mm/s.

Edge chipping: ≤ 100 µm.

Processing Advantages

The machine merges modular architecture with high-density integration, re-engineers the conventional optical path and support structure, and enables on-the-fly switching between cutting and drilling on the same platform. An adaptive process controller guarantees micron-level precision across multiple materials.

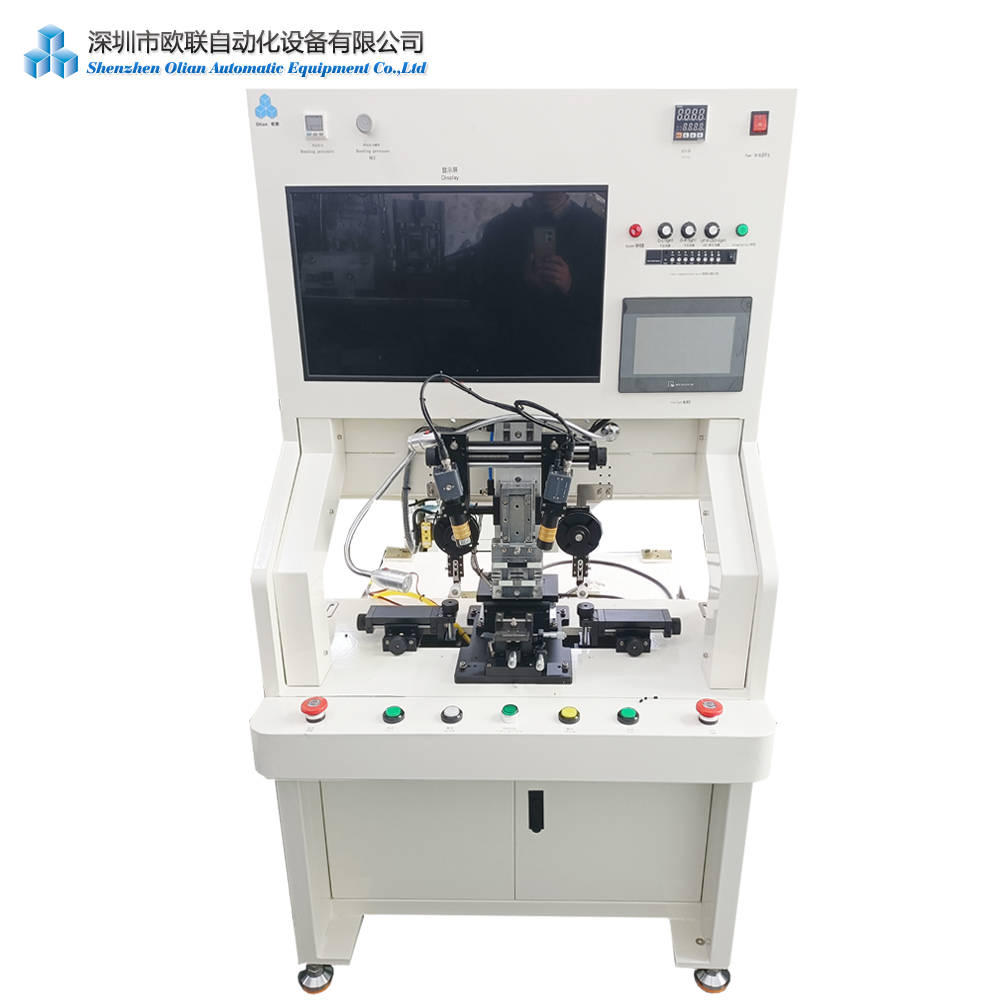

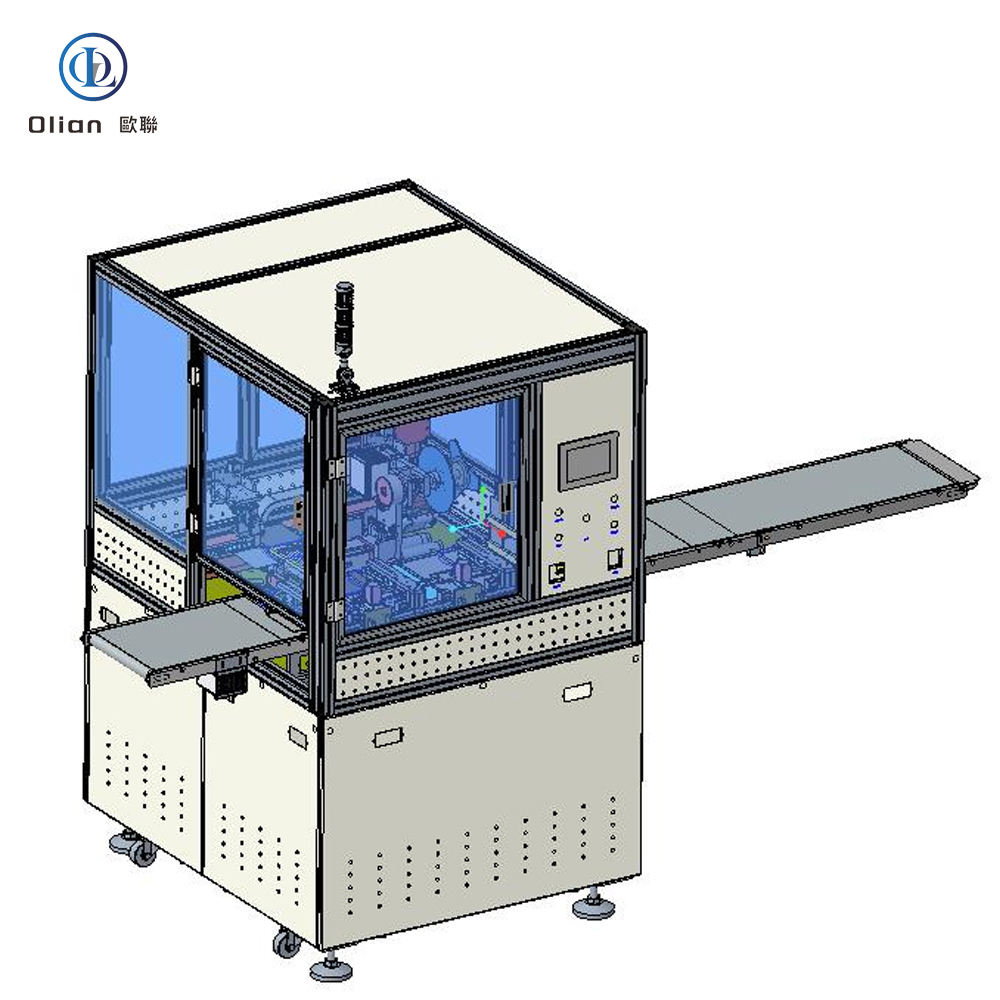

Single-Platform Green Picosecond Laser Glass Cutting Machine

Model: OL-GP4050S

Consumer demand for pristine mobile screens, camera cover glass and other brittle components forces suppliers to achieve higher cutting strength, minimal chipping, excellent edge verticality, high throughput and low cost. Traditional CNC machining consumes cutting fluids, delivers limited accuracy, suffers rapid tool wear and demands large floorspace and labour. The OL-GP4050S was therefore developed to give optical workshops a cleaner, faster and more economical alternative.

Product name: OL-GP4050S single-platform green picosecond laser glass cutting machine.

The system performs dry, dust-free laser ablation of flat glass at several times the speed of conventional methods. A high-precision XY linear motor stage and granite base secure micron-level accuracy and long-term stability.

Effective processing area: 300 mm × 300 mm.

Single-pass cutting depth for K9 glass: up to 3 mm.

Power supply: AC 220 V ± 5 %, single-phase with earth, total load < 4 kW.

Ambient temperature: 24 – 26 °C.

Relative humidity: 10 – 70 %, non-condensing, clean room recommended.

Overall dimensions: length 1 400 mm, width 1 050 mm, height 1 950 mm (without beacon).

Approximate weight: 1 000 kg.

Floor loading: at least 500 kg m⁻².

include optical glass, coated glass, soda-lime glass, sapphire and quartz. High-temperature cleaving is not advised for heat-sensitive coatings.

Processing principle: a 532 nm green picosecond beam creates equally spaced filamentary holes inside the material. A linear motor moves the workpiece so the filaments form a controlled micro-crack line, enabling clean separation. Pulse width < 10 ps confines energy to a tiny volume, so the process is virtually athermal and produces no melt or large HAZ.

Laser source: 50 W green picosecond laser, 50 kHz, 1 mJ pulse energy, water-cooled.

Cutting head: 3 mm depth-of-focus Bessel type for long filament and small spot.

Motion platform: X-Y-Z stages. X and Y driven by linear motors on granite; travel 300 mm × 300 mm; maximum speed 1 000 mm s⁻¹ with 1 g acceleration; positioning accuracy ≤ ±2 µm, repeatability ≤ ±1 µm. Z axis servo-driven, 50 mm travel, focus step resolution 10 µm.

Vision system: 5 MP MindVision CCD, point plus ring illuminator, automatic Mark capture, alignment accuracy ≤ ±3 µm.

Control software: proprietary Windows-based package reads DXF and DWG files; integrates high-precision motion card with PSO (position-synchronized output) for on-the-fly laser triggering. Industrial PC with Taiwan-imported motherboard, LCD monitor, wireless keyboard and mouse.

Hardware: Grade 00 granite base, vacuum chuck for workpiece fixation. Low-voltage elements by Schneider, switch-mode power supplies by Mean Well.

Use the machine only on transparent brittle materials. Do not process metals or temperature-sensitive coated products. Install the unit in a clean, well-ventilated room free of corrosive or acidic vapours.

Daily: remove dust and processing debris.

Weekly: inspect and clean protective lenses.

Monthly: replace chilled-water coolant (distilled or de-ionised water only).

Quarterly: replace coolant filter cartridge.

Photographs in the original file show typical cuts on strengthened glass, sapphire wafers and quartz substrates: edges are smooth, chips < 5 µm, no micro-cracks or discoloration.

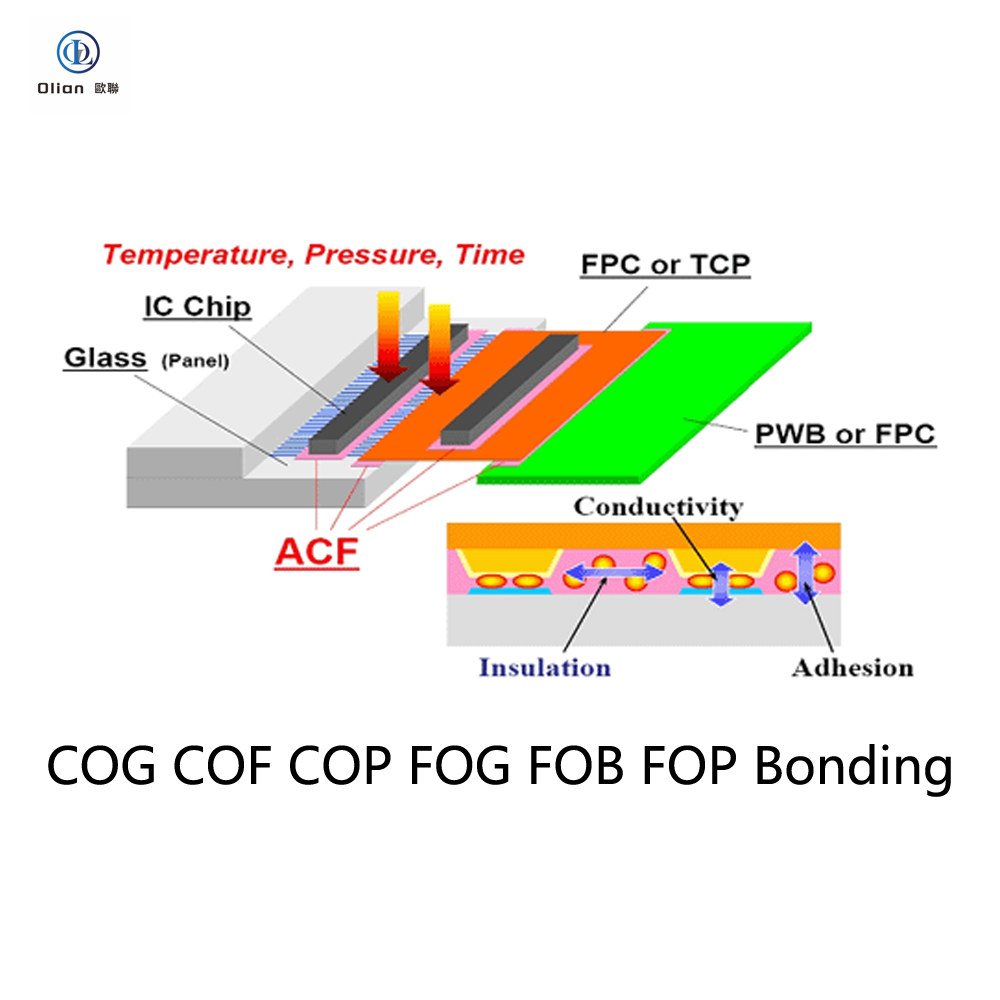

ACF bonding Keywords Categorization and Explanation:

FOB Bonder: A machine used for bonding FOB (Flexible On Board) components.

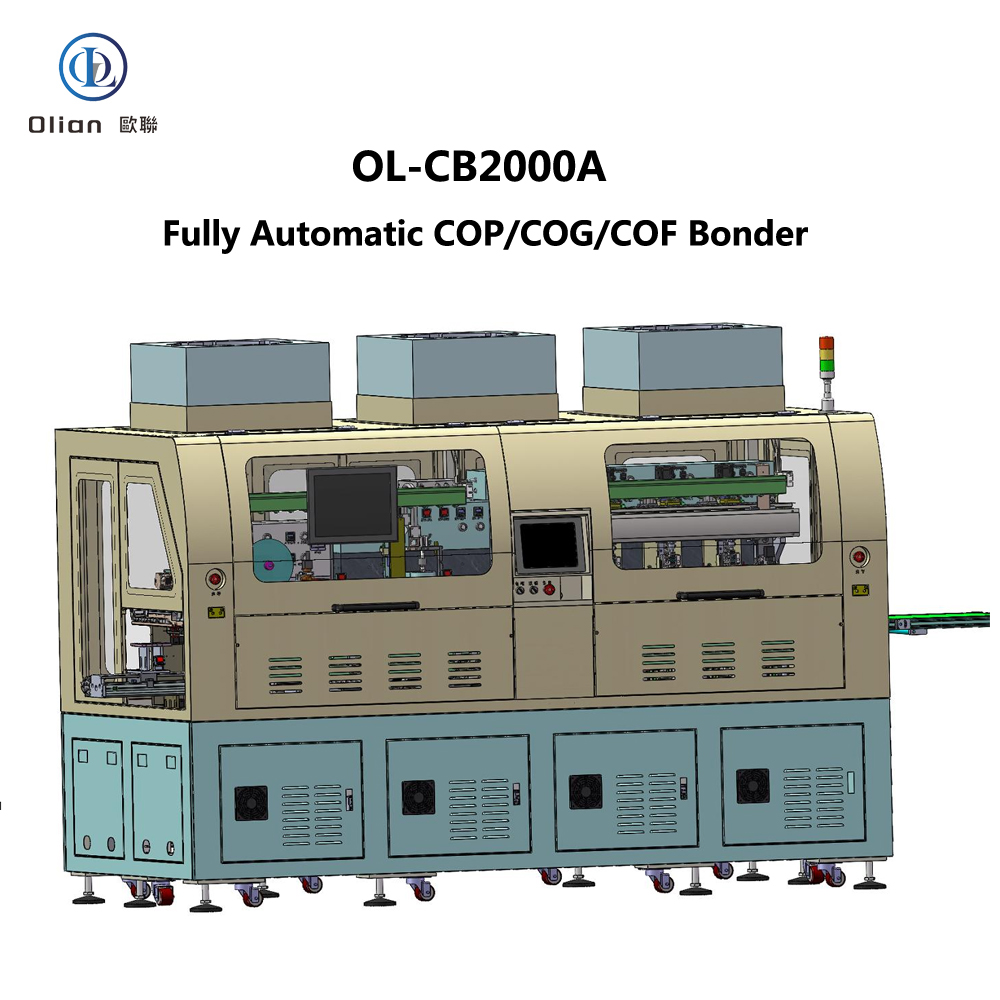

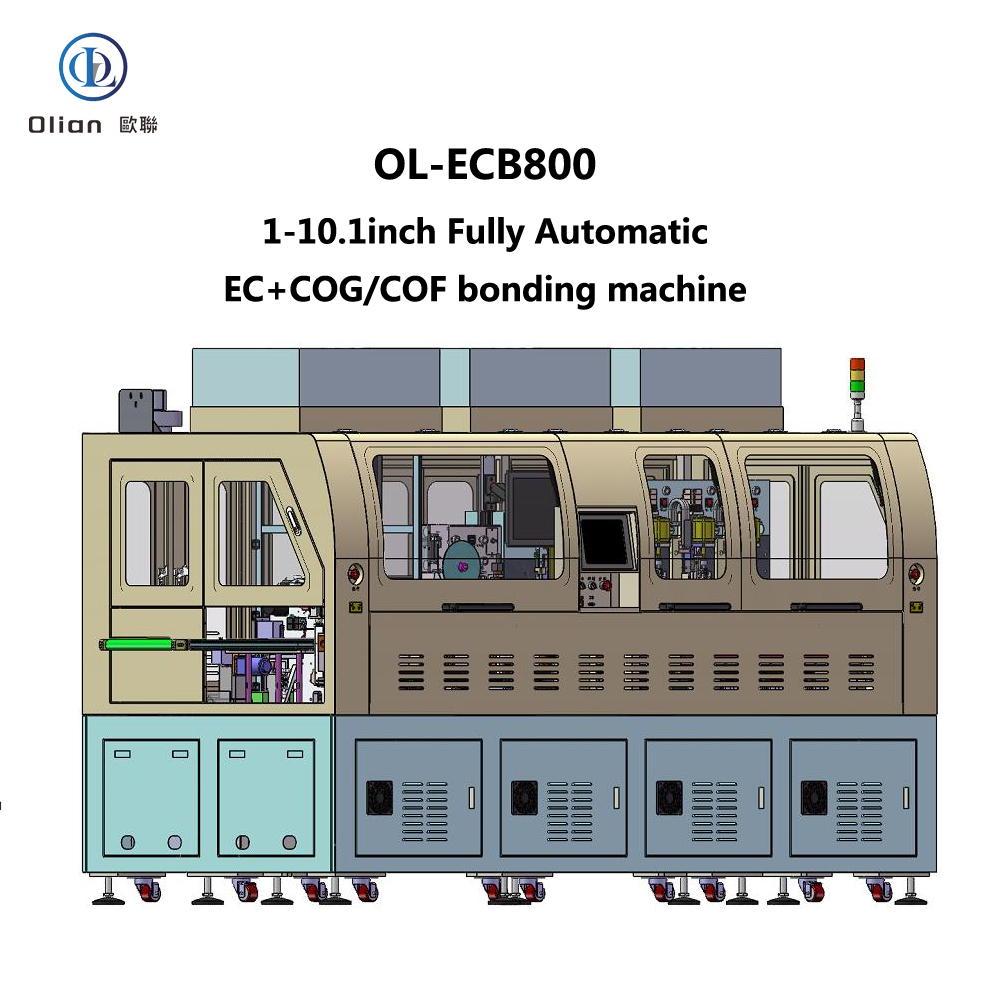

COG Bonder: Used for bonding COG (Chip On Glass) components.

COF Bonder: Used for bonding COF (Chip On Film) components.

COP Bonder: Used for bonding COP (Chip On Plastic) components.

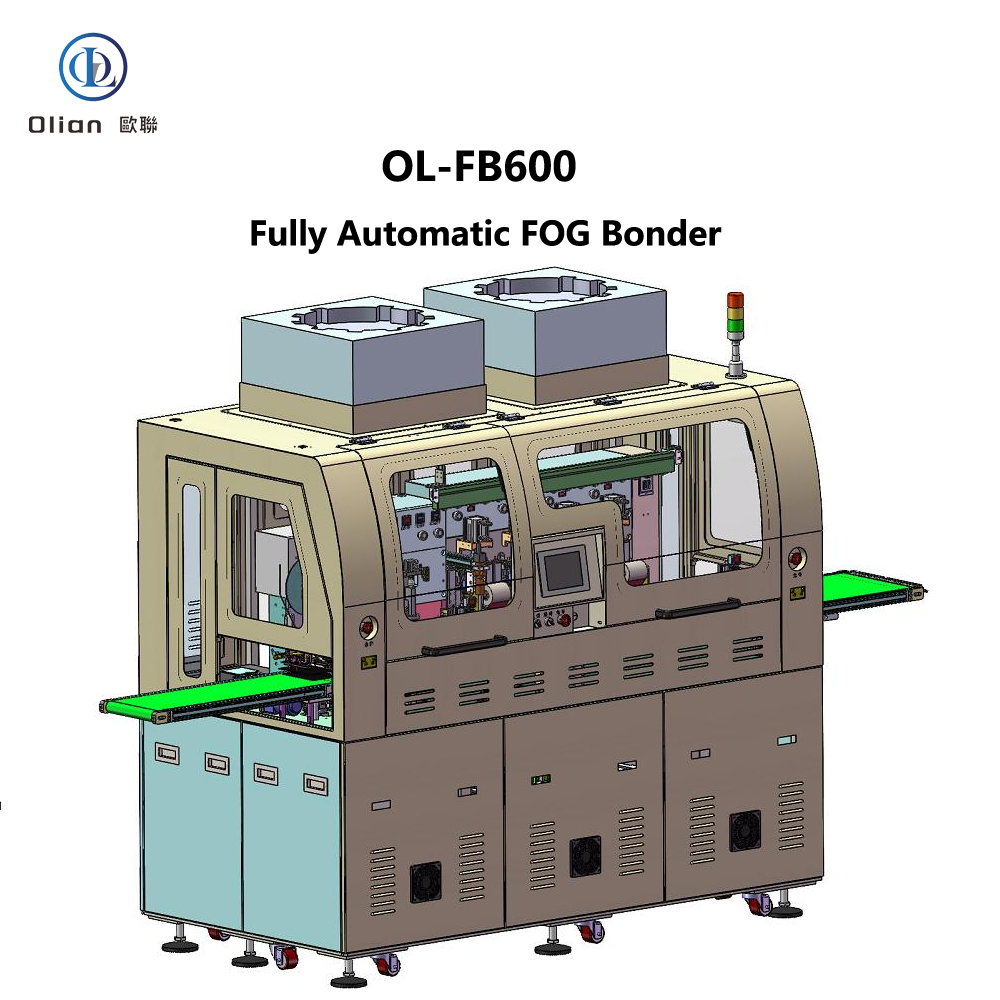

FOG Bonder: Used for bonding FOG (Flexible On Glass) components.

FOF Bonder: Used for bonding FOF (Flexible On Flexible) components.

FPC Bonder: Used for bonding FPC (Flexible Printed Circuit) components.

TAB Bonder: Used for bonding TAB (Tape Automated Bonding) components.

OLB Bonder: Used for bonding OLB (Outer Lead Bonding) components.

IC Bonder: Used for bonding IC (Integrated Circuit) components.

Glass Bonder: Used for bonding glass components.

LCD Panel Bonder: Used for bonding LCD (Liquid Crystal Display) panels.

LED Panel Bonder: Used for bonding LED (Light Emitting Diode) panels.

Mini LED Bonder: Used for bonding mini LED components.

Micro LED Bonder: Used for bonding micro LED components.

Zebra Paper Bonder: Used for bonding zebra paper components.

Touch Panel FPC Bonder: Used for bonding FPC components in touch panels.

Mobilephone Bonding Machine: Used for bonding components in mobile phones.

Smart Watch LCD Bonder: Used for bonding LCD components in smart watches.

Wearable Equipment Bonder: Used for bonding components in wearable devices.

TV Panel Bonder: Used for bonding components in TV panels.

LCD Module Bonder: Used for bonding LCD modules.

Flat Panel Display Bonder: Used for bonding flat panel displays.

ACF (Anisotropic Conductive Film): A film used in bonding processes to connect different layers.

COG (Chip On Glass): A process where chips are directly mounted on glass substrates.

COF (Chip On Film): A process where chips are mounted on flexible substrates.

COP (Chip On Plastic): A process where chips are mounted on plastic substrates.

FOG (Flexible On Glass): A process where flexible circuits are mounted on glass substrates.

FOB (Flexible On Board): A process where flexible circuits are mounted on boards.

FOF (Flexible On Flexible): A process where flexible circuits are mounted on other flexible circuits.

TAB (Tape Automated Bonding): A process where tape is used to bond components.

OLB (Outer Lead Bonding): A process where the outer leads of components are bonded.

IC (Integrated Circuit): A small chip that contains a complex electronic circuit.

FPC (Flexible Printed Circuit): A flexible circuit board used in various electronic devices.

Zebra Paper: A type of conductive paper used in bonding processes.

LCD Repair Machine: Used for repairing LCD screens.

LED Repair Machine: Used for repairing LED screens.

OLED Repair Machine: Used for repairing OLED screens.

Amoled Repair Machine: Used for repairing Amoled screens.

Mini LED Repair Machine: Used for repairing mini LED screens.

Micro LED Repair Machine: Used for repairing micro LED screens.

TFT Glass Repair Machine: Used for repairing TFT (Thin Film Transistor) glass screens.

LCD Panel Repair Machine: Used for repairing LCD panels.

LED Panel Repair Machine: Used for repairing LED panels.

OLED Panel Repair Machine: Used for repairing OLED panels.

Amoled Panel Repair Machine: Used for repairing Amoled panels.

Flex Cable Repair Machine: Used for repairing flex cables.

IC Remover: A tool used to remove ICs from circuits.

IC Remove Machine: A machine used to remove ICs from circuits.

Differential Interference Microscope: A microscope used to inspect bonding processes.

Metallurgical Microscope: A microscope used to inspect metal surfaces.

Industrial Tool Microscope: A microscope used for industrial inspections.

Large Size Upright Microscope: A large microscope used for detailed inspections.

Second Hand Differential Interference Microscope: A used microscope for inspecting bonding processes.

Whole Line Solution for Intelligent Wearable Products: A comprehensive solution for producing intelligent wearable products.

Whole Line Solution for Intelligent Watches: A comprehensive solution for producing intelligent watches.

Mobile Product Line Solutions: Solutions for producing mobile products.

PAD Display Product Line Solutions: Solutions for producing PAD displays.

Tablet Product Line Solutions: Solutions for producing tablet displays.

Notebook Product Line Solutions: Solutions for producing notebook displays.

Industrial Control Display Product Line Solutions: Solutions for producing industrial control displays.

High-Level Flexible Screen Glue Field Production Solutions: Solutions for producing high-level flexible screens.

Intelligent Locomotive, Notebook Product Line Solutions: Solutions for producing intelligent locomotives and notebooks.

Display Product Line Solution: A comprehensive solution for producing displays.

Commercial Display Screen – Flexible Bonding Production Line Solution: A solution for producing commercial display screens.

Electronic Paper Line Solutions: Solutions for producing electronic paper.

Electronic Paper Laminating, Bonding, Dispensing Field Line Solutions: Solutions for producing electronic paper laminating, bonding, and dispensing.

Backlight Leading, Laminated Film, Shading, Wrapping Line Equipment Solutions: Solutions for producing backlight leading, laminated film, shading, and wrapping.

Fingerprint Module Under the Screen Bond Spot Glue and AOI Intelligent Detection Field Solutions: Solutions for producing fingerprint modules under the screen.

Automatic OCA, OCR Fit Field Production Solutions: Solutions for producing automatic OCA (Optically Clear Adhesive) and OCR (Optical Character Recognition) fits.

FPC Covering Film, EMI Automatic Laminating, FPC Exposure Special Equipment Field Solutions: Solutions for producing FPC covering film, EMI (Electromagnetic Interference) automatic laminating, and FPC exposure.

3C Product Inspection Packaging Production Line Solution: Solutions for producing 3C product inspection and packaging.

Bonding Machine Head: A part of the bonding machine used for bonding.

Bonding Machine Press Head: A part of the bonding machine used for pressing.

Bonding Machine Spare Parts: Various spare parts for bonding machines.

Bonding Machine Parts: Various parts for bonding machines.

ACF Tape: A tape used in bonding processes.

ACF Bonding Tape: A tape used in bonding processes.

ACF Glue: A glue used in bonding processes.

ACF Adhesive: An adhesive used in bonding processes.

ACF Bonding Machine Head: A part of the ACF bonding machine.

ACF Bonding Machine Price: The cost of an ACF bonding machine.

ACF Bonding Machine Manufacturer: A company that manufactures ACF bonding machines.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine PDF: A PDF document related to ACF bonding machines.

ACF Bonding Machine Spare Parts: Spare parts for ACF bonding machines.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for replacing ICs.

ACF Pulse Heat Bonding Machine: A machine that uses pulse heat for bonding.

How to Make ACF Bonding Machine: Instructions for making an ACF bonding machine.

Homemade ACF Bonding Machine: A self-made ACF bonding machine.

ACF Bonding Machine eBay: ACF bonding machines available on eBay.

ACF Bonding Machine for Mobile: An ACF bonding machine for mobile devices.

ACF Bonding Machine Head Price: The cost of an ACF bonding machine head.

ACF Bonding Machine Manual: A manual for operating an ACF bonding machine.

ACF Bonding Machine New: A new ACF bonding machine.

ACF Bonding Machine Homemade: A self-made ACF bonding machine.

ACF Bonding Machine Working: The working principle of an ACF bonding machine.

ACF Bonding Machine Cost: The cost of an ACF bonding machine.

Accessoire ACF Bonding Machine: Accessories for ACF bonding machines.

Low Cost ACF Bonding Machine: An affordable ACF bonding machine.

ACF Bonding Machine Demon for Replacing IC: A demonstration of using an ACF bonding machine for

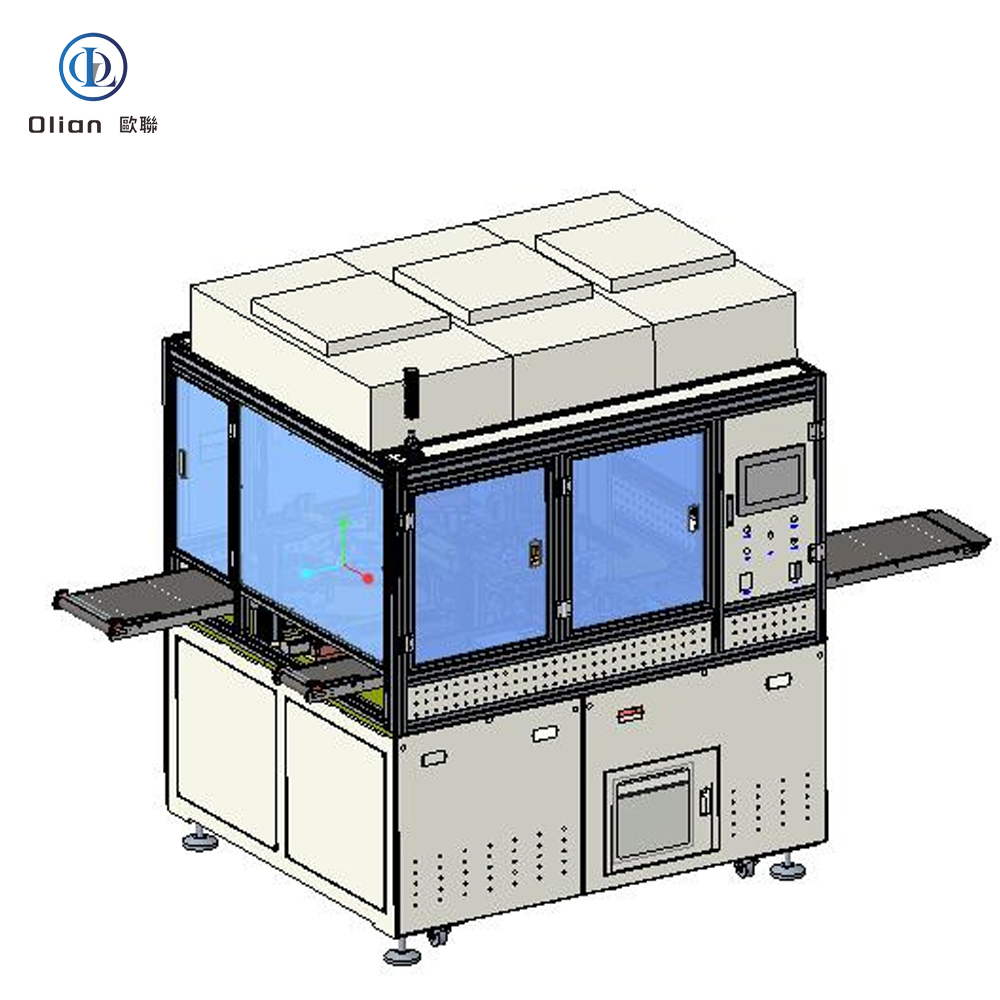

Olian products

These products represent Olian’s commitment to providing high-quality, innovative solutions for the display industry, covering a wide range of applications and meeting the needs of various customers.

The OL-BL800 Full-Automatic Backlight Assembly Machine is a cutting-edge device designed for efficient and precise assembly of backlight units (BLUs) and films on glass (FOGs) for screens ranging from 0.96 to 8 inches, including notch and waterdrop screens. This machine boasts high automation, advanced configuration, strong compatibility, high yield rate, good stability, and various other advantages. It is equipped with high-quality components and offers optional accessories to enhance functionality and convenience.

The machine features a 1+1+2 structure with one FOG placement area, one BLU placement area, and two bonding platforms. Its workflow involves automatic FOG and BLU handling, position correction, film removal, photography, and assembly, with minimal manual intervention required only for material feeding.

The machine consists of a frame, FOG and BLU feeding lines, correction units, handling robots, film removal units, CCD photography units, bonding platforms, and optional accessories like the stacking feeding unit and labeling head. Each component is designed for precision and reliability, with specifications detailed for motors, guides, cameras, and other elements.

Components are sourced from reputable brands such as SMC, CKD, Fuji, Hitachi, Panasonic, and Weilin, ensuring high quality and performance.

Includes an operation manual, comprehensive training on installation, operation, adjustment, maintenance, and troubleshooting, and one year of free after-sales service with lifelong technical support.

In the realm of modern industrial manufacturing, particularly within the electronics and precision instrument sectors, welding processes play a pivotal role in product quality and production efficiency. The OL-TH800 Automatic Drag Welding Machine emerges as a cutting-edge solution, designed to deliver high-precision welding with remarkable automation and reliability.

The OL-TH800 Automatic Drag Welding Machine is engineered for high-precision welding tasks, catering to products ranging from 3 to 7 inches in size. It is extensively used in the production of smartphones, tablets, and wearable devices, where precise welding is crucial. The machine’s advanced features make it an ideal choice for manufacturers seeking to enhance production efficiency and product quality.

The OL-TH800 comprises several sophisticated components that协同工作 to ensure precise and efficient welding operations:

The OL-TH800 follows a highly automated sequence to complete welding tasks:

The OL-TH800 automates the entire welding process, from material handling and flipping to position correction and welding. This minimizes human intervention, reduces labor costs, and enhances production efficiency. The machine can also be integrated with upstream devices for seamless production flow.

Designed to accommodate products ranging from 3 to 7 inches, the OL-TH800 offers versatility across various production tasks. This flexibility allows manufacturers to adapt quickly to different product requirements and market demands.

With an automated exhaust system and contact-free production process, the OL-TH800 significantly improves product yield rates. The reduced human contact minimizes the risk of contamination and damage.

Adopting advanced domestic design concepts and high-quality components from Japan, South Korea, and Taiwan, the OL-TH800 ensures stable operation and a long service life. Strict quality control during component processing further guarantees reliability.

The integrated AOI system detects welding defects such as insufficient solder and solder bridging, ensuring high-quality output. This feature enhances overall product reliability and reduces post-production rework.

The OL-TH800 incorporates high-quality components from reputable brands, including SMC/CKD/AirTAC for pneumatic components, Hui川/Xinjie for servo motors, Hui川 for PLC, TBI for ball screws, HIWIN/12K for guides, Hikvision/Dahua/Dehong for CCD and lenses, Weilong for touch screens, Zhengtai for relays, Mingwei for power supplies, and Panasonic/Tianguang for fiber optic sensors. These components ensure the equipment’s performance and reliability.

The OL-TH800 comes with comprehensive documentation and after-sales support:

In summary, the OL-TH800 Automatic Drag Welding Machine stands out as a top-tier solution for modern industrial welding needs. Its high degree of automation, strong compatibility, stable performance, and comprehensive after-sales service make it an invaluable asset for manufacturers aiming to boost production efficiency and product quality.

In modern industrial production, tape attaching processes are crucial for the manufacturing of electronic devices and precision instruments.

The OL-TF800 Automatic Tape Attaching Machine, as an advanced automated device.

offers efficient and precise tape attaching solutions with its outstanding performance and versatility.

The OL-TF800 Automatic Tape Attaching Machine is designed specifically for high-precision tape attaching tasks.

It can accommodate production requirements for products ranging from 0.96 to 8 inches.

making it widely applicable in the manufacturing of smartphones, tablets, wearable devices, and other electronics. It is especially suitable for production environments with high demands on attaching accuracy and efficiency.

The OL-TF800 consists of several key components that work together to ensure efficient and precise operation:

The OL-TF800 Automatic Tape Attaching Machine has a highly automated working process:

The OL-TF800 achieves full automation in product handling, position correction, tape separation, tape attaching, and outfeed flipping. This not only improves production efficiency and reduces human errors but also lowers labor costs. The equipment can be seamlessly integrated with upstream welding devices in the production line, forming a continuous and stable production process to enhance overall production efficiency and quality control.

The equipment can accommodate products ranging from 0.96 to 8 inches, making it suitable for various production tasks, from small electronic components to larger products like tablets. This versatility allows the equipment to be used in diverse production environments, enabling flexible production and quick response to market changes and customer demands.

Adopting the most advanced domestic design concepts and high-quality components and parts from Japan, South Korea, and Taiwan, the OL-TF800 ensures overall stability and a long service life. The strict testing of key components guarantees reliable operation during extended, high-intensity use, reducing downtime and ensuring continuous production and product quality.

The OL-TF800 has the following key specifications:

The equipment is constructed with:

The equipment uses high-quality components from reputable brands, including SMC/CKD/AirTAC for pneumatic components, Xinjie/Hui川for servo motors, Panasonic/Hui川for PLC, TBI for ball screws, HIWIN/12K for guides, Weilong for touch screens, Zhengtai for relays, Mingwei for power supplies, Zhengtai for circuit breakers, and Panasonic/Tianguang for fiber optic sensors. These components ensure the equipment’s performance and reliability.

The equipment comes with a comprehensive set of documentation and after-sales services:

In summary, the OL-TF800 Automatic Tape Attaching Machine is an ideal choice for modern industrial production with its high degree of automation, strong compatibility, stable performance, and comprehensive after-sales service, helping manufacturers improve production efficiency and product quality.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us