OL-QX17 – 15.6-Inch Single-Side EC Terminal Cleaning Machine

Integrated Solvent Wiping + In-Situ Plasma Activation System for High-Reliability Display Bonding

The OL-QX17 by Olian Automatic Equipment Co., Ltd. is a semi-automatic, single-station cleaning system engineered specifically for the pre-bond surface preparation of edge-conductive (EC) terminals on rigid LCD panels up to 15.6 inches in diagonal size. It addresses one of the most critical failure points in display module manufacturing—poor ACF (Anisotropic Conductive Film) adhesion—by delivering a dual-stage cleaning process: precision solvent-based mechanical wiping followed immediately by low-temperature atmospheric plasma activation.

Unlike simple cloth-wipe stations or standalone plasma cleaners, the OL-QX17 integrates both technologies into a single, synchronized motion cycle, ensuring that the freshly wiped surface is activated before recontamination can occur—a key factor in achieving consistent, high-yield bonding in automotive, medical, and industrial display applications.

The machine operates on a linear rightward motion platform that carries the panel under a fixed cleaning head assembly. The full cycle is as follows:

The entire sequence takes approximately 8–15 seconds, depending on panel length and settings.

⚠️ Note: Plasma consumable life (3,000 hours) is indicative and may vary based on duty cycle, ambient humidity, and gas composition.

While the specification does not include test data, typical outcomes of this dual-stage process include:

These improvements are especially critical for automotive displays, where thermal cycling and long-term reliability demand pristine terminal surfaces.

The OL-QX17 is ideal for:

It is not suitable for:

Olian Automatic provides comprehensive lifecycle support:

Model: OL-QX17

Function: Single-side terminal cleaner with integrated wiping + plasma

Max Panel Size: 15.6-inch diagonal rigid LCD

Throughput: ~200–300 panels/hour (operator-dependent)

Core Innovation: Synchronized wiping-plasma sequence prevents recontamination

Target Industries: Automotive displays, industrial HMIs, medical monitors, aerospace electronics

SEO Keywords:

15.6 inch EC terminal cleaner, OL-QX17 Olian, single-side LCD pad cleaning machine, integrated wiping and plasma cleaner, pre-bond surface activation system, ACF bonding prep machine, contact angle reduction equipment, non-woven fabric solvent wipe station, in-situ plasma cleaner for display terminals, high-reliability FOG pre-treatment workstation.

OL-CC006 – Fully Automatic Offline COF Trimming Machine with Vision-Guided Die Alignment

The OL-CC006 by Olian Automatic is a fully automatic offline trimming machine designed for high-precision die-based cutting of Chip-on-Film (COF) modules. Unlike manual trimmers, it integrates a machine vision system to automatically align the COF to the cutting die before each stroke—ensuring consistent trimming accuracy even with part placement variation.

This machine is used exclusively for post-bonding mechanical finishing. It does not perform bonding, ACF application, or electrical testing, and operates as a standalone workstation.

The core innovation of the OL-CC006 is its integrated vision subsystem for precise registration:

The system captures alignment marks on the COF, calculates positional offset, and either guides the operator or triggers auto-correction (as per configured workflow). This significantly improves trimming yield compared to purely mechanical fixturing.

The entire process—from vision check to cut—is automated after initial loading.

This enables seamless handoff to inspection or packaging stations.

All vision parameters, indexing distance, and cycle settings are configurable through the touchscreen.

(Note: Exact utility specs follow Olian’s standard platform; refer to installation manual for wiring and piping details.)

Ideal for high-volume or high-precision trimming of:

Commonly deployed in Tier-1 display module factories and automotive electronics suppliers.

Olian Automatic provides comprehensive post-sale support:

Model: OL-CC006

Type: Fully Automatic Vision-Guided COF Trimming Machine

Key Features: Die-based cutting + CCD vision alignment + conveyor output

Operation: Manual load → Auto vision check → Auto trim → Auto index

Max Panel Compatibility: Standard COF modules (size defined by die)

SEO Keywords:

COF punching machine,COF punching machine,Automatic COF trimming machine, OL-CC006, Olian Automatic vision-guided COF cutter, offline COF cutting machine with CCD alignment, fully automatic die cutting machine for Chip-on-Flex, COF carrier frame removal with vision system, high-precision COF finishing equipment, vision-aligned flex trimming press, post-bond COF deburring workstation, conveyor-output COF trimmer.

OL-COF-03A – Semi-Automatic Offline COF Trimming Machine (Die-Based)

The OL-COF-03A by Olian Automatic is a semi-automatic offline trimming machine designed for precision die-based cutting of Chip-on-Flex (COF) modules before bonding. It removes excess flex material or trims carrier frames from COF assemblies using custom-made dies, ensuring clean edges and consistent geometry for downstream assembly or packaging.

This machine is intended for post-bonding finishing only—it does not perform bonding, ACF application, or electrical testing.

The OL-COF-03A uses a mechanical press actuated by dual-hand start buttons to drive a custom die set. The operator manually loads the COF module into the die fixture, presses both start buttons simultaneously, and the upper die descends to trim the part in a single stroke.

Each die set is application-specific and must be ordered separately or fabricated per customer drawing.

The dual-hand start ensures hands are clear of the die area during operation, complying with basic machine safety standards.

Ideal for:

Commonly used in LCD, OLED, and automotive display manufacturing.

Olian Automatic provides full lifecycle support:

Model: OL-COF-03A

Function: Semi-Automatic Die-Based COF Trimming

Operation: Manual load → Dual-hand start → Single-stroke trim

Key Advantage: Simple, robust, and cost-effective finishing for COF modules

SEO Keywords:

COF cutting machine, COF punching machine,COF trimming machine, OL-COF-03A, Olian Automatic offline COF cutter, semi-automatic flex trimming press, die-based COF deburring machine, COF carrier frame removal equipment, manual COF finishing workstation, post-bond COF trimmer, custom die cutting machine for Chip-on-Flex, offline FPC trimming press.

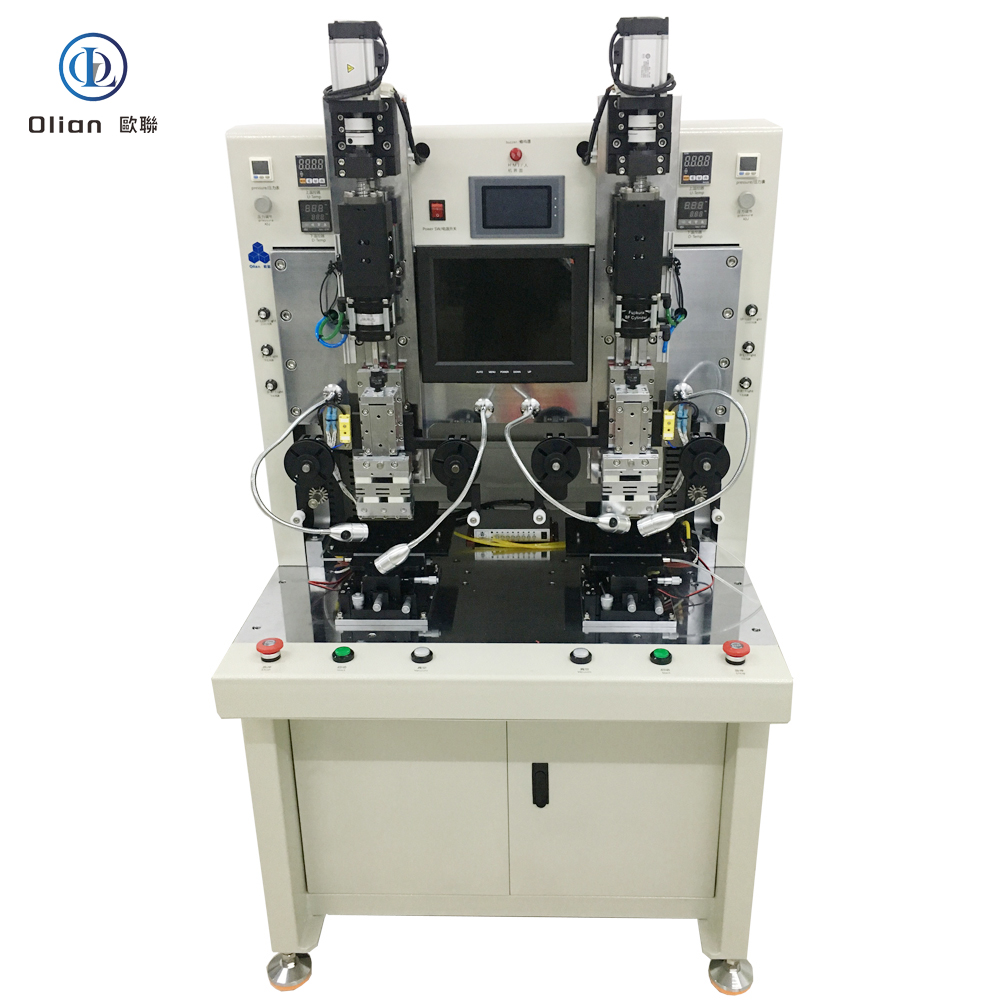

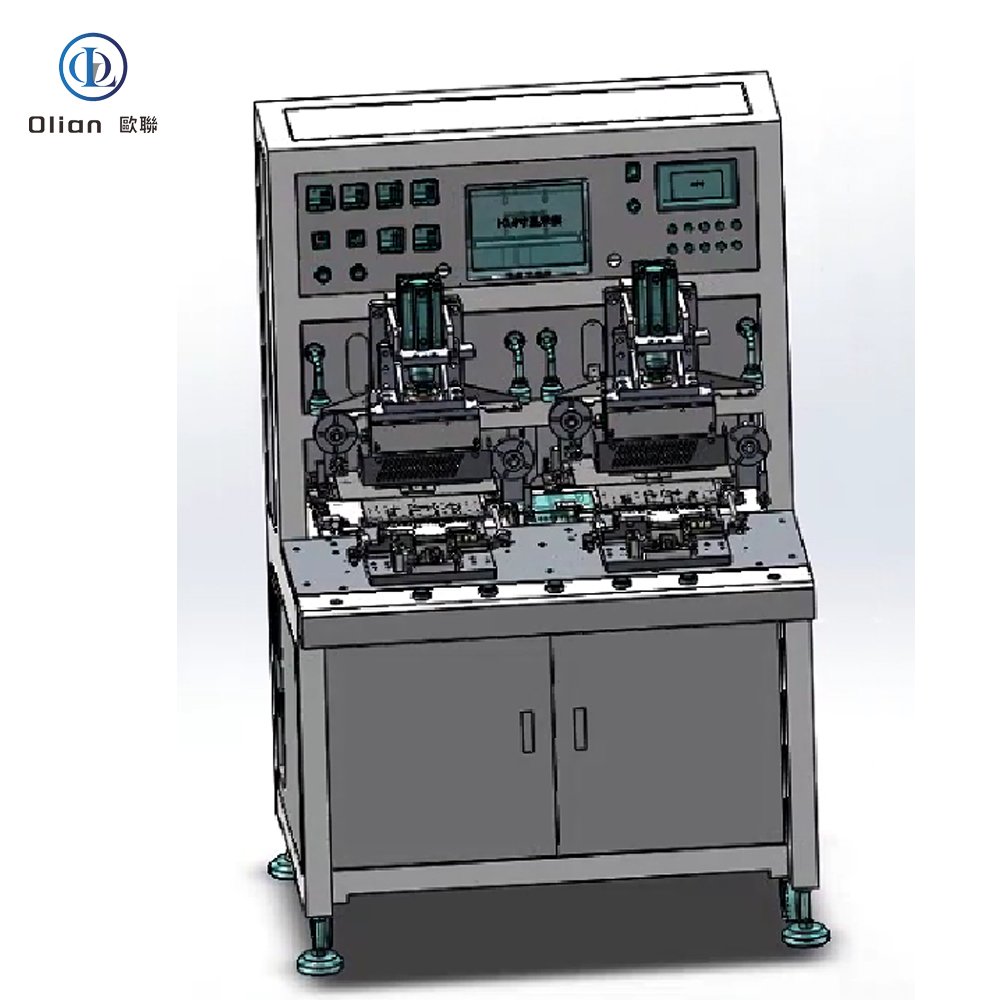

The OL-F0712 by Olian Automatic is a high-precision dual-station FOG (Film-on-Glass) bonding machine designed for thermal compression of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 12 inches. It features dual-side optical alignment—simultaneously viewing both the panel terminals from below and the FPC pads from above—enabling accurate manual registration for demanding display applications.

The system assumes that anisotropic conductive film (ACF) has already been pre-applied to the panel or FPC. It performs main bonding only and does not apply ACF, nor does it support IC or COF chip bonding.

Unlike lower-only systems, the OL-F0712 integrates two coaxial LED-lit microscopes:

Both images are visible simultaneously through a split-view optical path or dual eyepieces (as per design), allowing the operator to manually align FPC and panel with higher precision—critical for narrow-pitch or high-density connectors.

This “top-and-bottom” alignment method significantly improves placement accuracy over single-view systems.

The machine is equipped with a 150 mm long hot press head, ideal for:

Standard head thickness is 1.0 mm, with custom profiles available.

Two fully independent stations enable continuous operation:

The thermal cycle is fully automated once initiated.

Heating is delivered via industrial cartridge heaters with real-time temperature feedback.

Each station includes an automatic buffer tape feed system:

This protects the FPC surface during pressing and ensures consistent bond quality.

All parameters are independently configurable per station via the HMI.

Designed for integration into cleanrooms or controlled manufacturing environments.

Ideal for bonding:

Commonly used where dual-side alignment and wide bonding capability are essential.

Olian Automatic provides comprehensive post-sale support:

Model: OL-F0712

Type: Dual-Station Main Bonding Machine with Dual-Side Vision

Max Panel Size: 12 inches (rigid glass)

Key Features: Upper + lower alignment, 150 mm press head, dual independent stations

SEO Keywords:

12-inch FOG bonding machine, OL-F0712, Olian Automatic dual-vision FPC bonder, upper and lower alignment FOG machine, 150mm hot bar bonding system, manual FOG bonder with top-bottom microscope, large-panel FPC to glass bonding equipment, dual-station main bonding press, thermal compression machine for 12-inch displays, high-precision FOG workstation with coaxial lighting.

OL-FC005 – 7-Inch Dual-Station Pre-Bond Main Bond Integrated COF FOG Machine

The OL-FC005 by Olian Automatic is an integrated dual-station COF(chip on film) FOG (Film-on-Glass) bonding system that combines pre-bonding and main bonding in a single machine. The left station performs pulse pre-bonding to temporarily tack flexible circuits (FPC or COF) onto LCD panels, while the right station executes full main bonding to permanently cure the joint—streamlining workflow and reducing handling errors.

The machine assumes that anisotropic conductive film (ACF) has already been pre-applied to the panel or FPC. It does not apply ACF, nor does it support IC chip bonding.

Operators first align and pre-bond the panel on the left, then transfer it directly to the right station for final bonding—enabling efficient, two-step processing without leaving the workstation.

Both stations use a single lower-view microscope for alignment. The operator places the panel on a transparent glass stage and views terminal marks from below. The COF /FPC is positioned manually from above using visual estimation.

This “lower-only” method provides a practical balance of simplicity and accuracy for mid-precision applications.

Both stations feature independent temperature and time settings to optimize pre-tack and main-cure profiles separately.

Each station includes an automatic buffer tape feed system to protect the FPC during pressing:

Two independent buffer systems ensure reliable protection at both pre-bond and main bond stages.

All parameters—temperature, time, pressure—are set independently for each station via the HMI.

The compact footprint integrates seamlessly into production lines or R&D labs.

Ideal for two-stage bonding of:

Commonly used where process control, reduced contamination, and workflow efficiency are critical.

Olian Automatic provides comprehensive post-sale support:

Model: OL-FC005

Type: Integrated Dual-Station COF /FOG Machine (Pre-Bond + Main Bond)

Layout: Left = Pre-Bond | Right = Main Bond

Max Panel Size: 7 inches (rigid glass)

Key Advantage: Streamlined two-step bonding in one workstation

SEO Keywords:

Integrated pre-bond and main bond machine, OL-FC005, Olian Automatic dual-function COF FOG bonder, 7-inch left pre-right main bonding system, COF FPC tacking and curing workstation, two-station COF FOG machine with buffer feed, manual COF FOG bonder with pre-main integration, lower-view alignment COF FOG equipment, ACF bonding system for display assembly, dual-station pulse and thermal compression bonder.

OL-FS003 – 7-Inch Dual-Station Servo-Controlled FOG Bonding Machine with Lower-Side Alignment。

The OL-FS003 by Olian Automatic is a dual-station manual FOG (Film-on-Glass) bonding machine featuring servo-driven press control for high-precision thermal compression of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches. Unlike pneumatic systems, its servo mechanism delivers superior pressure accuracy, repeatability, and response—ideal for sensitive or high-reliability bonding applications.

The machine assumes that anisotropic conductive film (ACF) has already been pre-applied to the panel or FPC. It performs main bonding only and does not apply ACF, nor does it support IC or COF chip bonding.

The OL-FS003 uses a single lower-view microscope for alignment. The operator places the panel on a transparent glass stage and views terminal marks from below through the microscope. The FPC is then positioned manually from above using visual estimation.

This “lower-only” alignment approach offers simplicity and reliability for applications where FPC pads allow moderate placement tolerance.

A key differentiator of the OL-FS003 is its servo motor-driven press system, replacing traditional pneumatic cylinders. Benefits include:

This makes the OL-FS003 suitable for demanding sectors such as automotive displays, medical devices, and aerospace HMIs.

The machine includes two identical, fully independent stations arranged side by side. Each station features:

Operators can alternate between stations for continuous production, maximizing throughput in pilot lines or small-batch manufacturing.

The entire thermal and mechanical cycle is automated once initiated, ensuring repeatable results.

Heating is delivered via industrial cartridge heaters, monitored by high-accuracy sensors for stable thermal profiles.

An integrated buffer tape feed system protects the FPC during pressing:

All critical parameters—temperature, time, pressure profile—are configured via the HMI for process traceability.

Ideal for bonding:

Commonly deployed in Tier-1 automotive supply chains, certified electronics manufacturers, and R&D centers.

Olian Automatic provides full lifecycle support:

Model: OL-FS003

Type: Dual-Station Servo-Controlled FOG Main Bonding Machine

Key Innovation: Servo-driven press for precision pressure control

Alignment: Lower-side microscope only

Max Panel Size: 7 inches (rigid glass)

SEO Keywords:

Servo FOG bonding machine, OL-FS003, Olian Automatic servo-controlled FPC bonder, 7-inch dual-station FOG press with servo actuator, precision thermal compression bonder, lower-view alignment FOG machine, servo hot bar bonding system, main bonding machine for automotive displays, high-accuracy FPC to glass bonder, electric press FOG workstation.

The OL-FP003 by Olian Automatic is a dual-station manual pulse pre-bonding machine designed for temporary tacking of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches. This system uses short-duration pulse heating to lightly cure anisotropic conductive film (ACF), holding the FPC in place before final main bonding.

The machine assumes that ACF has already been pre-applied to the panel or FPC. It performs pre-bonding only—not full main bonding—and does not support IC, COF, or ACF lamination functions.

The OL-FP003 employs a single lower-view microscope for alignment. The operator places the panel on a transparent glass stage and views terminal marks from below through the microscope. The FPC is then positioned manually from above using visual estimation.

This “lower-only” method provides a simple, cost-effective solution for applications where moderate alignment accuracy is sufficient.

The machine features two identical, fully independent stations arranged side by side. Each includes:

Operators can alternate between stations for continuous workflow, improving efficiency in small-batch or R&D environments.

The cycle is semi-automatic—alignment is manual, but heating and pressing are controlled and repeatable.

Rapid-response cartridge heaters enable precise thermal pulses ideal for ACF tacking without over-curing.

An integrated buffer tape feed system protects the FPC during pressing:

All key parameters—temperature, time, pressure—are set via the HMI for consistent pre-bond quality.

Compact and robust, suitable for cleanrooms, pilot lines, and repair workshops.

Ideal for pre-bonding:

Commonly used in display assembly, prototyping labs, and low-volume production.

Olian Automatic provides comprehensive post-sale support:

Model: OL-FP003

Function: Manual Pulse Pre-Bonding Only

Max Panel Size: 7 inches (rigid glass)

Alignment: Lower-side microscope only

Key Advantage: Dual-station efficiency with simple, reliable pre-tacking

SEO Keywords:

Pulse bonding machine, OL-FP003, Olian Automatic FPC bonder, 7-inch dual-station bond press, lower-view alignment bonder, manual FOG tacking system, thermal pulse machine for ACF, FPC tacking equipment for LCD, economical bond workstation, fixed-platform pulse bonder.

The OL-F0715 by Olian Automatic is a dual-station manual FOG (Film-on-Glass) bonding machine designed for thermal compression of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches. This model features an extended 150 mm press head, enabling bonding of wide FPCs or multiple connectors in a single stroke—ideal for automotive displays, industrial HMIs, and large-flex applications.

The system assumes that anisotropic conductive film (ACF) has already been pre-applied to the panel or FPC. It performs main bonding only, fully curing the ACF joint under controlled heat, pressure, and time. It does not apply ACF, nor does it support IC or COF chip bonding.

The OL-F0715 uses a single lower-view microscope for alignment. The operator places the panel on a transparent glass stage and views terminal marks from below through the microscope. The FPC is then positioned manually from above using visual estimation and experience.

This “lower-only” alignment approach is straightforward, robust, and well-suited for production environments where FPC pads are sufficiently large or where moderate alignment tolerance is acceptable.

A key differentiator of the OL-F0715 is its 150 mm long press head, significantly longer than standard 60 mm heads. This allows:

The head thickness is 1.0 mm, and custom dimensions are available upon request.

The machine includes two identical, fully independent stations arranged side by side. Each station features:

Operators can alternate between stations for continuous workflow, maximizing uptime in small-batch or pilot-line production.

The thermal cycle is fully automated once initiated, ensuring consistent results.

Heating is achieved via high-efficiency cartridge heaters, with temperature monitored by industrial-grade sensors for process stability.

An integrated buffer tape feed system protects the FPC during pressing:

All critical parameters—temperature, time, pressure—are configured via the HMI for repeatability across shifts.

The compact footprint integrates easily into cleanrooms or production lines.

Ideal for bonding:

Commonly used in automotive electronics, medical displays, and heavy-equipment HMI manufacturing.

Olian Automatic provides full lifecycle support:

Model: OL-F0715

Type: Dual-Station Manual FOG Main Bonding Machine

Key Feature: 150 mm extended press head

Alignment: Lower-side microscope only

Max Panel Size: 7 inches (rigid glass)

SEO Keywords:

150mm FOG bonding machine, OL-F0715, Olian Automatic wide-head FPC bonder, 7-inch dual-station FOG press with long hot bar, manual FPC to glass bonding equipment, extended press head FOG machine, thermal compression bonder for wide flex, lower-view alignment FOG workstation, main bonding machine for automotive displays, 150mm hot bar FOG system.

OL-F003 – 7-Inch Dual-Station Manual FOG Bonding Machine with Lower-Side Fixed Alignment

The OL-F003 by Olian Automatic is a dual-station manual FOG (Film-on-Glass) bonding machine designed for thermal compression of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches. This system uses lower-side visual alignment only, where operators view panel terminals from below through a single microscope while manually positioning the FPC from above.

The machine assumes that anisotropic conductive film (ACF) has already been pre-applied to either the panel or the FPC. It performs main bonding only—fully curing the ACF joint under heat and pressure. It does not apply ACF, nor does it support IC or COF bonding.

Unlike dual-lens systems, the OL-F003 employs a single lower-view microscope. The operator places the panel on a transparent glass stage. They look through the microscope from below to see the panel’s terminal marks. Then, they manually place and adjust the FPC from above using visual estimation and experience.

This “lower-only” method is simple, cost-effective, and suitable for applications where ultra-high precision is not required or where FPC pads are large enough for manual placement tolerance.

The machine features two identical, fully independent bonding stations side by side. Each station includes:

Operators can work on one station while the other is idle, enabling continuous production. All loading, unloading, and alignment are performed manually at the front.

The entire bonding cycle is semi-automatic—alignment is manual, but pressing is controlled and repeatable.

Heating is delivered via embedded cartridge heaters, monitored by K-type thermocouples for stable thermal control.

An integrated buffer tape feed system protects the FPC during bonding:

All critical parameters—temperature, time, pressure—are set via the HMI for consistent results.

Compact footprint suits cleanrooms, pilot lines, and repair workshops.

Suitable for bonding:

Commonly used in:

Olian Automatic provides complete post-sale support:

Model: OL-F003

Type: Dual-Station Manual FOG Bonding Machine

Alignment: Lower-side microscope only

Max Panel Size: 7 inches (rigid glass)

Core Advantage: Simple, reliable, cost-effective manual bonding with dual-station throughput

SEO Keywords:

FOG bonding machine, OL-F003, Olian Automatic manual FPC bonder, 7-inch dual-station FOG press, single-microscope FOG machine, manual FPC to glass bonding equipment, thermal compression bonder for IN-CELL flex, fixed-alignment FOG workstation, economical FOG bonding system, main bonding machine with lower-side vision.

The OL-FP005 by Olian Automatic is a dual-station manual pulse pre-bonding machine designed for precise thermal tacking of flexible printed circuits (FPC) or touch sensor flexes onto rigid LCD panels up to 7 inches. This system enables operators to perform high-accuracy pre-bonding—a critical step that temporarily fixes FPCs in place and final main bonding.

The machine assumes that anisotropic conductive film (ACF) has already been applied to the panel or FPC. It does not apply ACF, nor does it perform main bonding, IC attachment, or COF processing.

bonding ensures the FPC remains aligned during transfer to the main bonder. The OL-FP005 uses short-duration pulse heating to lightly cure the ACF without full compression—just enough to hold position. This is distinct from main bonding and requires lower energy and shorter time.

The OL-FP005 features two identical, fully independent stations arranged side by side. Each includes:

Operators can alternate between stations for continuous workflow, or two technicians can work simultaneously—doubling throughput in small-batch production or R&D environments.

Alignment is achieved through a dual-optical-path microscope that provides simultaneous views of the panel terminals (from below) and FPC pads (from above) on a single split-screen monitor.

Key optical specifications:

The operator places the panel on the lower stage and activates vacuum. They then position the FPC on the upper stage. Using manual X-Y adjustment knobs, they shift the panel until fiducial marks align perfectly on screen—ensuring micron-level accuracy before pre-bonding.

After alignment, the operator initiates the cycle. The entire bonding platform automatically moves forward into the press zone. The heated head descends, applies a brief pulse of heat and light pressure, then retracts. The platform then returns backward to the original loading position—keeping the operator’s hands safely away from hot components during actuation.

Heating is delivered via high-response cartridge elements, enabling rapid thermal pulses ideal for pre-tacking ACF without over-curing.

The machine includes an automatic buffer tape feed system to protect the FPC during pressing:

Ideal for pre-bonding:

Commonly used in:

Olian Automatic provides full lifecycle support:

Model: OL-FP005

Function: Manual Pulse Pre-Bonding Only

Max Panel Size: 7 inches (rigid glass)

Key Innovation: Dual-lens upper-lower alignment + front-rear motion + dual stations

Operation: Manual alignment, semi-automatic pulse cycle

SEO Keywords:

Pulse bonding machine, OL-FP005, Olian Automatic FPC bonder, 7-inch dual-station bond press, manual FOG bonding equipment, upper-lower alignment bonder, split-screen vision bond machine, FPC tacking system for LCD, thermal pulse bonder for touch flex, dual-lens pre-alignment workstation.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us