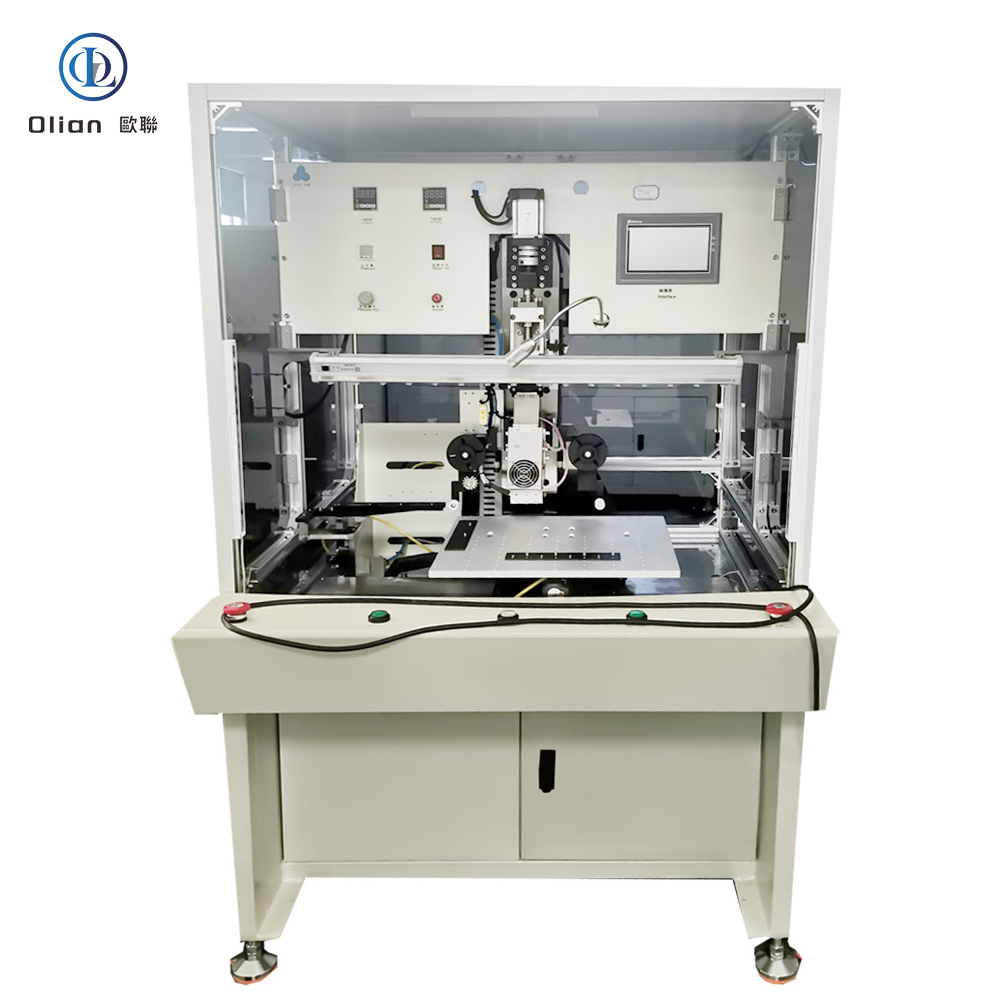

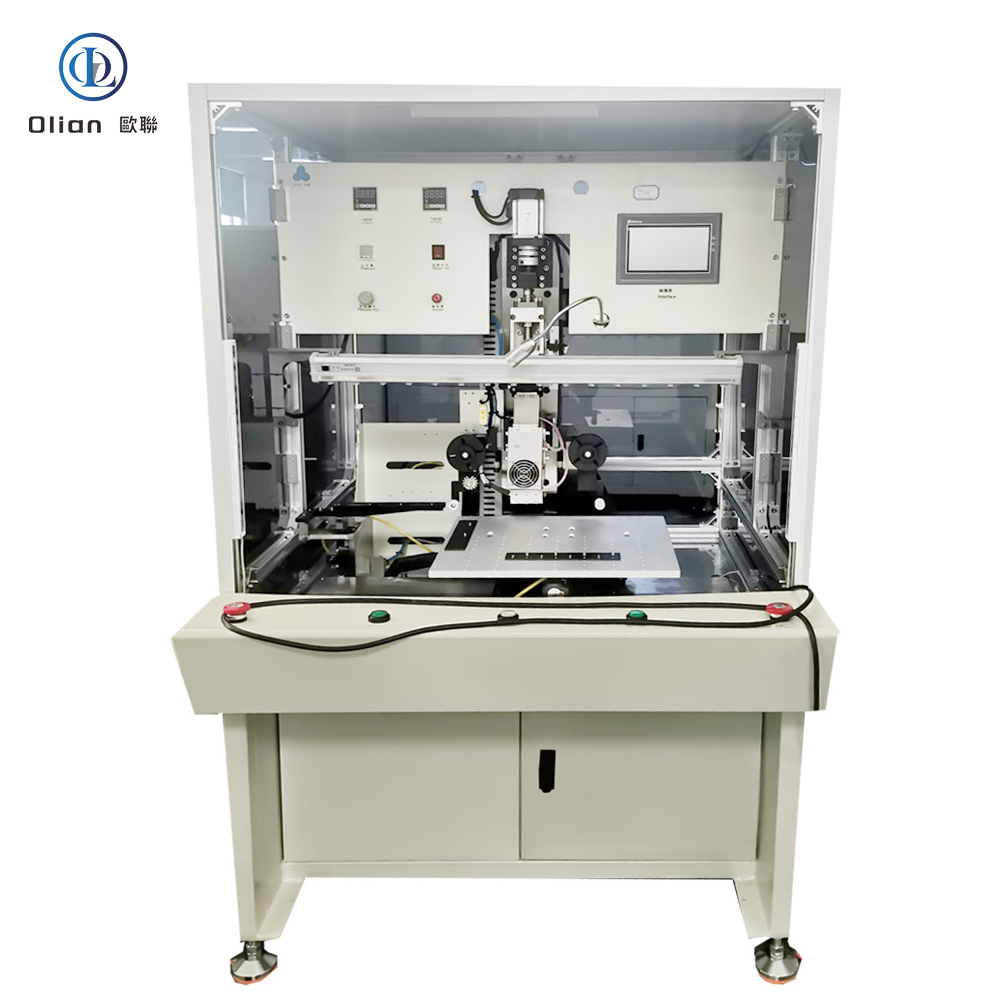

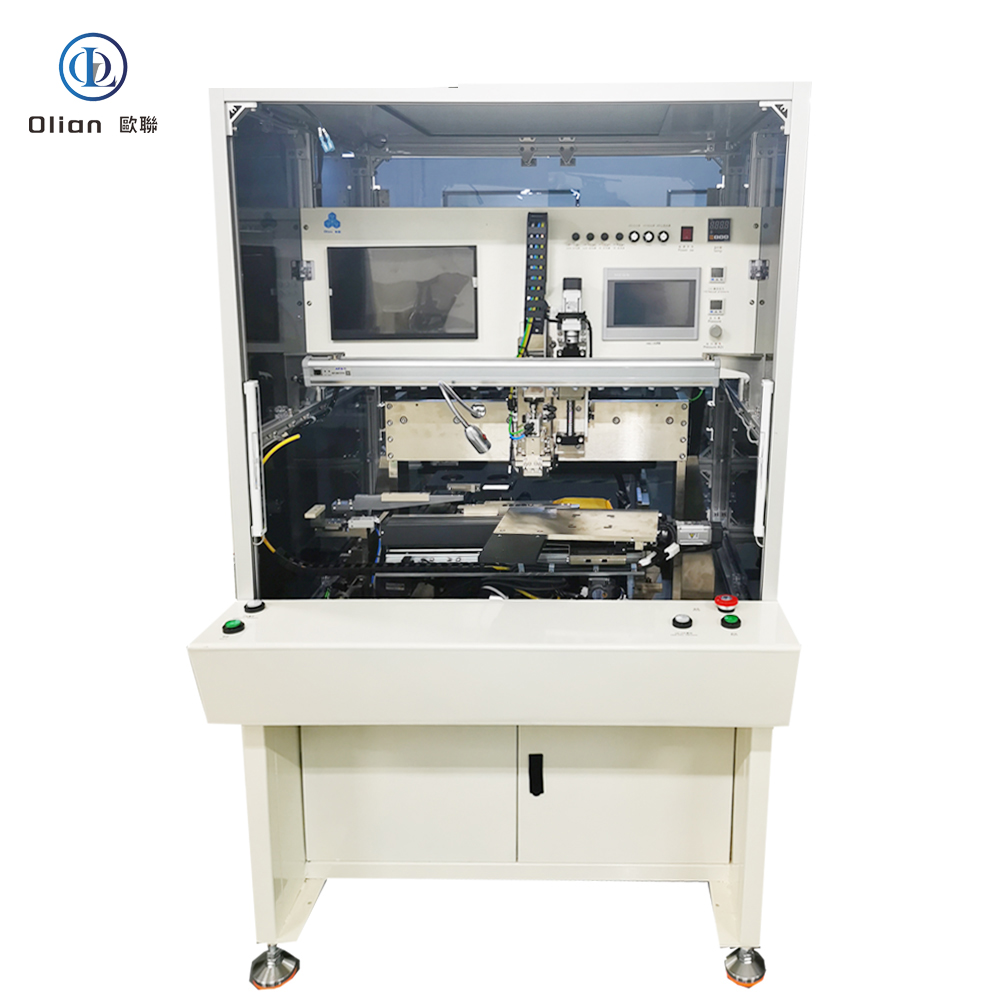

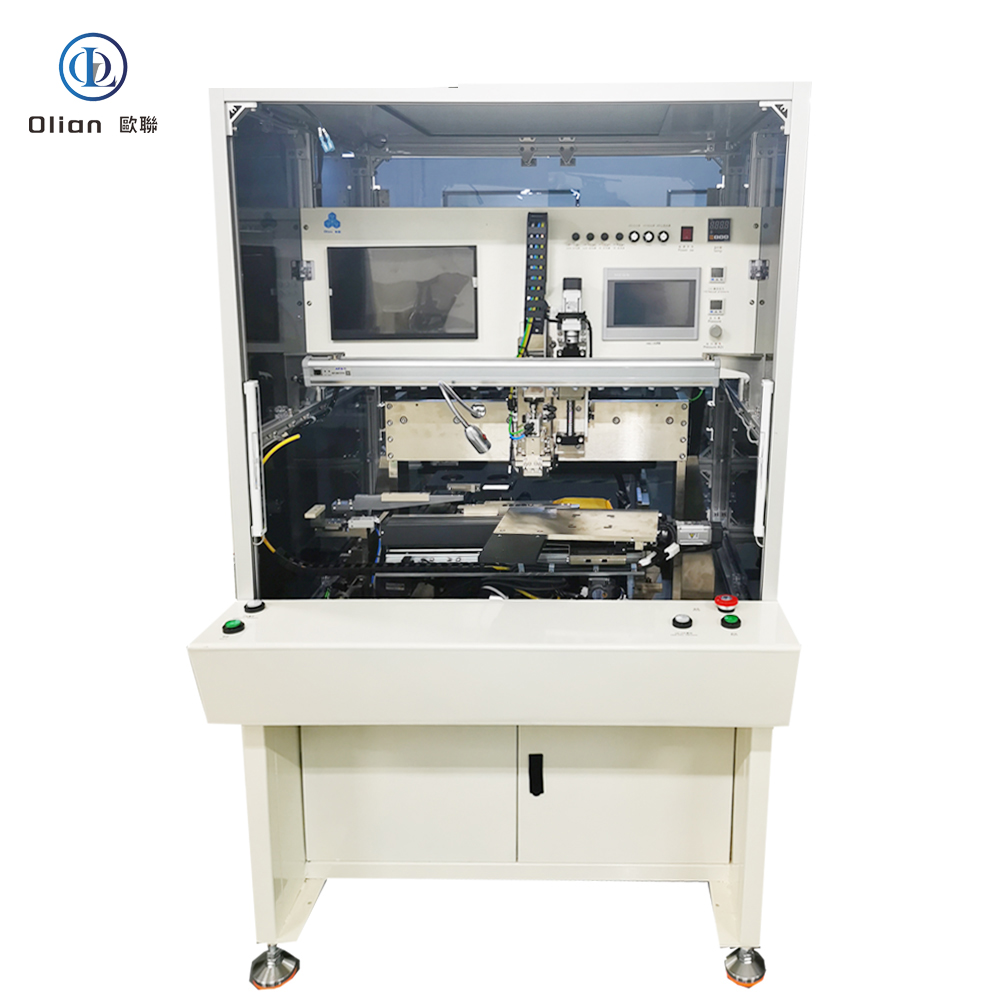

OL-TAB173 – 15.6-Inch Dual-Station Integrated FOG & FOB Bonding Machine,

All-in-One Thermal Compression System for COF (FOG) and COB (FOB) Bonding in a Single Platform

The OL-TAB173 by Olian Automatic Equipment Co., Ltd. is an innovative dual-station integrated bonding machine that combines FOG (Film-on-Glass) and FOB (Film-on-Board) processes in one compact system—left station for FOG, right station for FOB. Designed for panels up to 15.6 inches, it enables seamless production of display modules requiring both COF-to-LCD and COF-to-PCB connections, such as automotive displays, industrial HMIs, and smart appliances.

This integrated approach eliminates the need for separate machines, reduces footprint, minimizes handling, and ensures process consistency between FOG and FOB steps—critical for yield and reliability in high-end applications.

⚠️ Note: This machine assumes that ACF has already been applied to both the LCD panel and PCB. It performs final main bonding only, not ACF lamination or pre-alignment.

💡 Note: Unlike some FOG-only models (e.g., OL-F0712), this unit does not include vision alignment—it is intended for pre-aligned COF from upstream processes.

FOG Bonding machine, FOB bonding machine, FOG bonder, FOB bonder, COF bonder ,COF bonding machine,15.6 inch FOG-FOB integrated bonding machine, OL-TAB173 Olian, dual-station COF bonder for LCD and PCB, left FOG right FOB bonder, all-in-one Film-on-Glass and Film-on-Board machine, servo COF bonding system for automotive displays, OL-TAB173 technical datasheet, dual-function bonding equipment for display module assembly, FOG+FOB 2 in 1, high-repeatability COF bonding machine with PLC control. COF repairing machine for laptop, COF repairing machine for notebook,

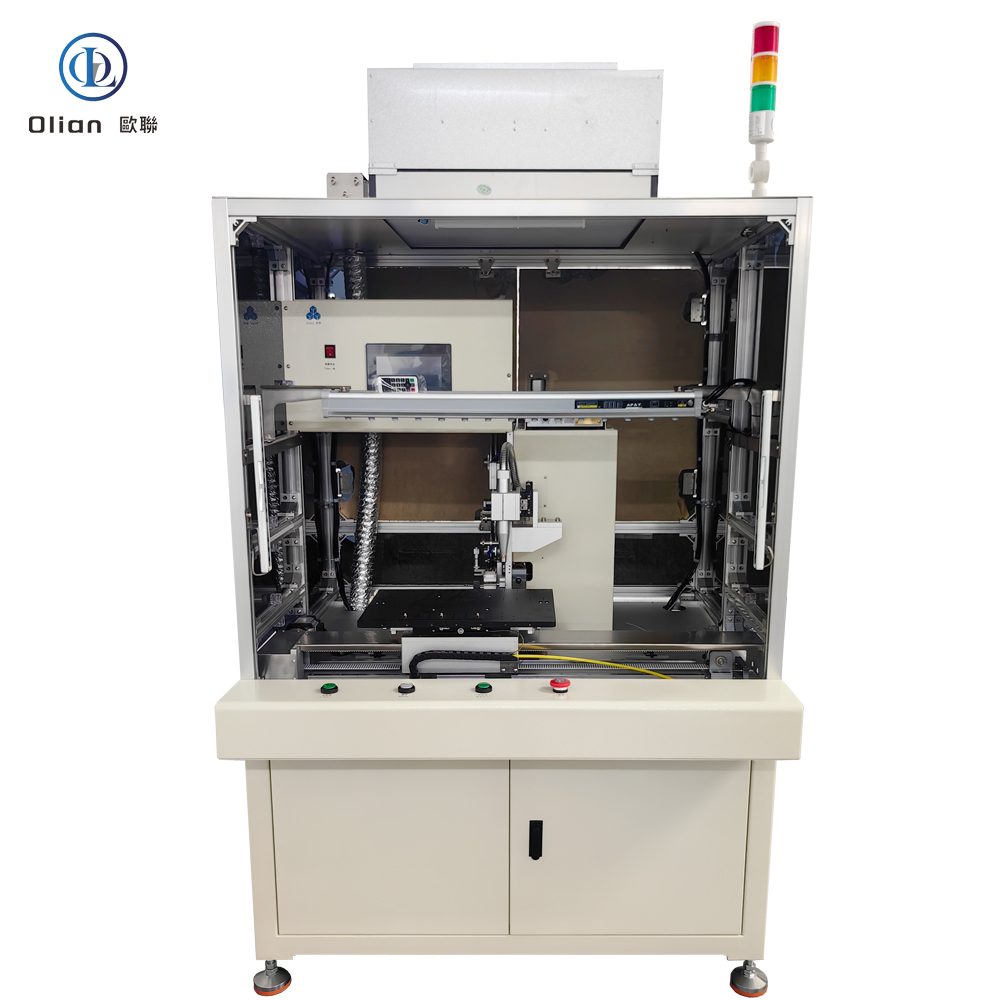

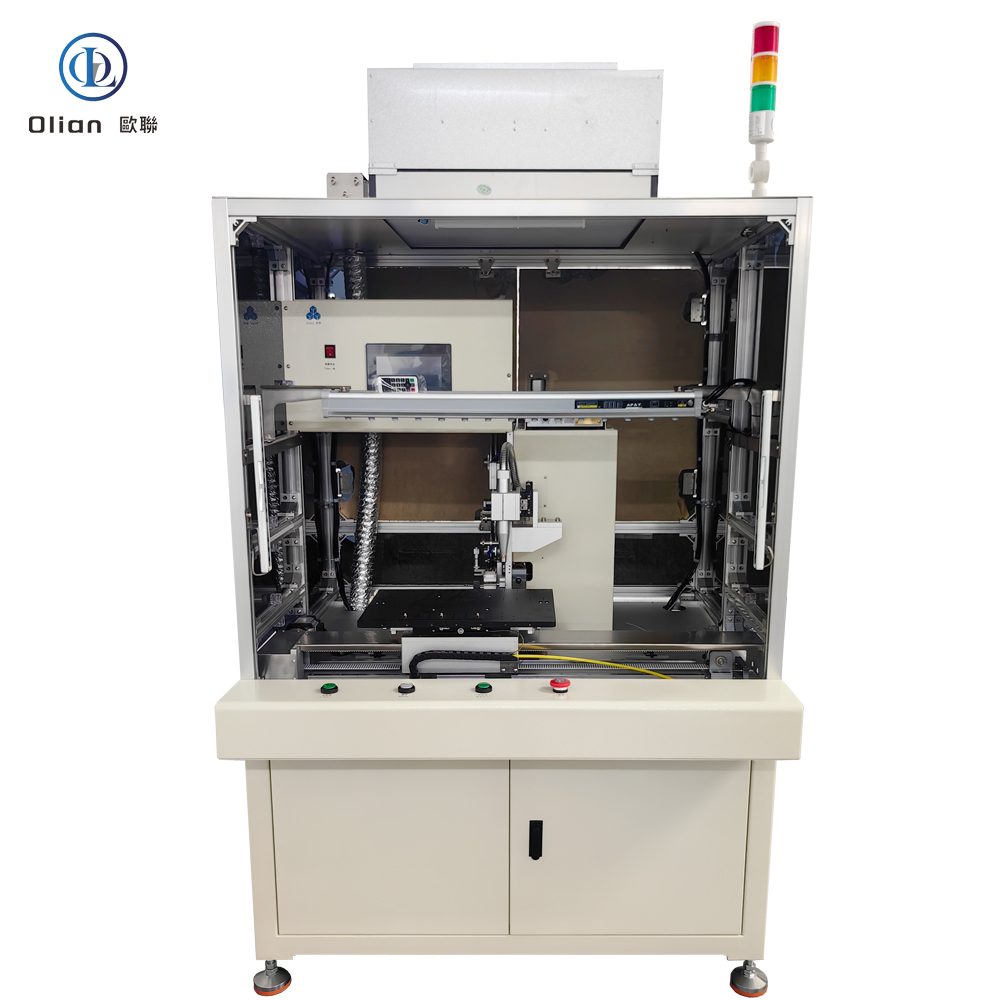

Ultra-High-Precision Thermal Compression System for Front & Rear COF/FOG Bonding on LCD Panels

The OL-F0712 by Olian Automatic Equipment Co., Ltd. is a semi-automatic dual-station FOG (Film-on-Glass) bonding machine engineered for the final thermal compression of COF (Chip-on-Film) flex circuits onto both front and rear edges of large-format rigid LCD panels up to 15.6 inches. What sets it apart is its dual-camera vision system—featuring simultaneous top-view and bottom-view alignment—enabling unparalleled registration accuracy between COF terminals and ITO pads, even on multi-layer, opaque, or high-density interconnect (HDI) panels.

Combined with dual independent workstations, the OL-F0712 delivers both micron-level precision and continuous production throughput, making it ideal for demanding applications in automotive displays, medical imaging, avionics, and premium consumer electronics.

⚠️ Note: This machine assumes that ACF has already been applied to the panel. It performs final main bonding only, not ACF lamination or pre-bonding.

This stereo alignment capability eliminates parallax and layer-shift errors—critical for panels with black matrix, touch sensors, or embedded layers.

FOG bonding machine,FOB bonding machine, 15.6 inch dual-vision FOG bonding machine, OL-F0712 Olian, top and bottom alignment fog bonding machine, dual-camera FOG bonder for LCD, front and rear COF bonding equipment, 2x magnification stereo vision COF aligner, coaxial LED top-bottom FOG machine, high-precision Film-on-Glass system for automotive displays, OL-F0712 technical datasheet, dual-station COF bonding machine with buffer tape alarm.

OL-FP156 – 15.6-Inch Dual-Station FOG Bonding Machine with Bottom Vision Alignment

High-Precision Thermal Compression System for Front & Rear COF/FOG Bonding on LCD Panels

The OL-FP156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic dual-station FOG (Film-on-Glass) bonding machine engineered for the final thermal compression of COF (Chip-on-Film) flex circuits onto both front and rear edges of large-format rigid LCD panels up to 15.6 inches. Featuring bottom-side vision alignment and dual independent workstations, this system delivers exceptional positional accuracy while enabling continuous production—ideal for high-mix, medium-volume manufacturing of automotive displays, industrial HMIs, and premium consumer electronics.

Unlike top-alignment systems, the bottom-view camera design ensures direct imaging of panel bonding pads through the glass substrate, eliminating parallax errors and enabling sub-micron-level registration between COF terminals and ITO traces—even on dark or reflective panels.

⚠️ Note: This machine assumes that ACF has already been applied to the panel. It performs final main bonding only, not ACF lamination or pre-bonding.

FOG bonding machine, FOG bonder, FOG Binding machine, FOG equipment,15.6 inch dual-station FOG bonding machine, OL-FP156 Olian, bottom alignment COF bonding machine, front and rear FOG bonder for LCD, dual-platform Film-on-Glass machine with vision system, 2x magnification bottom camera COF aligner, coaxial LED FOG bonding equipment, high-precision COF main bonder for automotive displays, OL-FP156 technical specifications, servo FOG bonder with buffer tape alarm.

High-Efficiency Thermal Compression System for Continuous COG Production

The OL-C0156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic dual-station main bonding machine designed for the final thermal compression of bare driver IC chips onto ACF-pre-laminated edge terminals of large-format rigid LCD panels up to 15.6 inches. Featuring two independent workstations, this system enables continuous operation: while one station is bonding, the operator can load/unload the other—dramatically improving workflow efficiency and reducing idle time.

As a dedicated COG (Chip-on-Glass) main bonder, the OL-C0156 fully cures the anisotropic conductive film (ACF) under precise heat and servo-controlled pressure, ensuring robust electrical connections and long-term display reliability in demanding applications such as automotive dashboards, industrial HMIs, and medical monitors.

⚠️ Note: This machine assumes that ACF has already been applied and the IC has been pre-aligned (e.g., via a pre-bonder). It performs single-zone, single-side bonding only and does not include vision alignment or double-side capability.

This dual-station layout is ideal for lean manufacturing cells where operator efficiency and throughput are critical.

15.6 inch dual-station IC main bonding machine, OL-C0156 Olian, two-table COG热压机 for LCD, servo IC bonding equipment with dual workstations, single-zone IC本压机 for high-efficiency production, 400°C hot bar main bonder with Panasonic PLC, continuous COG bonding system for automotive displays, dual-platform IC热压设备, OL-C0156 technical datasheet, high-repeatability IC bonding machine with ±3N precision.

OL-CBY156 – 15.6-Inch Dual-Head IC Servo Main Bonding Machine

High-Efficiency Thermal Compression System for IC Bonding on 7-17.3inch LCD Panels

The OL-CBY156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic dual-head main bonding machine engineered for the final thermal compression of bare driver IC chips onto ACF-pre-laminated edge terminals of large-format rigid LCD panels up to 15.6 inches. Featuring two independent servo-controlled bonding heads, this system enables either simultaneous bonding of two ICs or sequential multi-zone processing along a single panel edge—significantly boosting throughput while maintaining high bond consistency.

As the critical final step in the COG (Chip-on-Glass) process, the OL-CBY156 fully cures the anisotropic conductive film (ACF), creating permanent, low-resistance electrical interconnects essential for display reliability in automotive, industrial, and consumer applications.

⚠️ Note: This machine assumes that ACF has already been applied and ICs have been pre-aligned (e.g., via a pre-bonder). It does not include ACF application, vision alignment, or double-side bonding capability.

This dual-head architecture reduces cycle time by up to 40–50% compared to single-head machines in multi-IC applications (e.g., dual-driver displays).

15.6 inch dual-head IC main bonding machine, OL-CBY156 Olian, double hot bar COG bonder for LCD, servo-controlled dual IC bonding machine, high-throughput IC bonding equipment for display panels, multi-zone dual-head bonding machine, 400°C dual press head main bonder, simultaneous IC bonding machine for automotive displays, dual servo IC main bonding machine with PLC control, OL-CBY156 technical specifications. COG Bonder, COP bonder, COF bonder, Main bonding machine, Final bonding machine, final main bonding machine,main bonder,Final bonder.

OL-CBD156 – 15.6-Inch Single-Station IC Servo Main Bonding Machine,

High-Precision Thermal Compression System for Final IC Bonding on LCD Panels

The OL-CBD156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic main bonding machine designed for the final thermal compression of bare driver IC chips onto ACF-pre-laminated edge terminals of large-format rigid LCD panels up to 15.6 inches. As the critical last step in the COG (Chip-on-Glass) process, this system delivers consistent, high-reliability interconnects through precise servo-controlled pressure, uniform heating, and stable mechanical alignment—ensuring low contact resistance and long-term display performance.

Unlike pre-bonders or ACF applicators, the OL-CBD156 performs full-strength main bonding, fully curing the anisotropic conductive film to create permanent electrical and mechanical connections between the IC and glass substrate.

⚠️ Note: This machine assumes that ACF has already been applied and the IC has been pre-aligned (e.g., via a pre-bonder). It does not include ACF application, vision alignment, or double-side capability.

💡 Smart Feature: The machine includes a “tape not feeding” alarm—if the carrier tape (e.g., from IC feeder) fails to advance, the system halts and alerts the operator to prevent missed bonds.

IC Bonder,ACF IC bonder,IC bonding machine, COF bonding machine, COG bonding machine, IC final main bonding machine, IC main bonder,IC final bonder,COG ,COF,COP bonding machine, COP bonder, 15.6 inch IC main bonding machine, OL-CBD156 Olian, single-head COG bonder for LCD, servo-controlled thermal compression machine, multi-zone IC bonding equipment for display panels, high-precision IC main bonding machine with ±3N repeatability, 400°C hot bar main bonder for driver ICs, single-station COG bonding system, IC main bonding machine for automotive and industrial displays, servo IC final bonder with PLC and touchscreen.

Precision Automated System for Anisotropic Conductive Film Lamination on Large LCD Panels

The OL-A156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic ACF (Anisotropic Conductive Film) applicator engineered for high-accuracy lamination of ACF tape onto single-edge bonding zones of large-format rigid LCD panels up to 15.6 inches. Designed as the critical first step in COG/FOG (Chip-on-Glass / Film-on-Glass) display assembly processes, this machine ensures consistent ACF placement, tension control, and pre-compression—laying the foundation for reliable electrical interconnects in subsequent bonding stages.

Unlike manual taping or full-auto systems, the OL-A156 strikes an ideal balance between operator-guided flexibility and automated precision, making it perfect for medium-volume, high-mix production environments such as automotive displays, industrial HMIs, medical monitors, and premium consumer electronics.

⚠️ Note: This machine only applies ACF tape—it does not perform COF/IC bonding, vision alignment, or double-side processing.

The system supports multi-segment ACF application along a single edge—ideal for panels with multiple COF/IC attachment zones.

ACF laminating machine,ACF laminator,ACF attaching machine, ACF attachor, ACF sticking machine, ACF laminating equipment, ACF lamination machine,15.6 inch ACF applicator machine, OL-A156 Olian, single-side ACF taping system for LCD, automated ACF lamination equipment, multi-zone ACF Laminator for COG/FOG process, semi-automatic anisotropic conductive film applicator, ACF tape feeder with tension control, 150°C pre-bond ACF machine for display panels, ACF attaching machine for automotive LCD, high-precision ACF placement system for industrial HMIs.

OL-COF156 – 15.6-Inch Single-Side Multi-Zone Pre-Bonding Machine

Precision Thermal Alignment System for COF/IC to LCD Panel Assembly

The OL-COF156 by Olian Automatic Equipment Co., Ltd. is a semi-automatic pre-bonding machine engineered for the initial alignment and temporary bonding of Chip-on-Film (COF) or bare IC chips onto large-format rigid LCD panels up to 15.6 inches. Designed as the critical first step in the FOG (Film-on-Glass) or COG (Chip-on-Glass) process chain, this system ensures accurate terminal registration and secure tacking before final main bonding—dramatically reducing misalignment defects and rework rates.

Unlike full bonding machines, the OL-COF156 focuses exclusively on pre-compression: applying controlled heat and pressure to activate the ACF just enough to hold components in place during transfer to the main bonder.

⚠️ Note: This machine performs pre-bonding only—it does not apply ACF, conduct final bonding, or support double-side processing.

Cycle time is typically under 20 seconds, depending on operator skill and product complexity.

15.6 inch COF pre-bonding machine, OL-COF156 Olian, single-side COF tacking system, LCD panel pre-bonder for COF and IC, semi-automatic FOG pre-compression machine, thermal alignment system for display driver chips, multi-zone COF pre-bond equipment, 400°C hot bar pre-bonder for LCD, COF temporary bonding machine with vacuum platform, display module pre-bond workstation for automotive and industrial panels.

OL-FFB-156L – 15.6-Inch Single-Side Multi-Zone FOB Bonding Machine with Long Press Head

High-Coverage Thermal Compression System for Rigid PCB + FPC Assembly

The OL-FFB-156L by Olian Automatic Equipment Co., Ltd. is a semi-automatic thermal compression bonding machine designed for single-side Flexible-on-Board (FOB) assembly of large-format rigid printed circuit boards (PCBs) up to 15.6 inches in diagonal size. It bonds flexible printed circuits (FPCs)—typically pre-laminated with anisotropic conductive film (ACF)—to PCB edge terminals using a long, high-uniformity press head capable of covering extended bond zones in a single stroke.

Unlike its short-head counterpart (OL-FFB-156S), this model is optimized for applications requiring simultaneous bonding across multiple terminal rows or long continuous FPC leads, reducing cycle time and improving process consistency for high-pin-count interfaces such as display driver boards, touch controller modules, or industrial I/O panels.

⚠️ Note: This machine performs thermal compression bonding only—it does not apply ACF, nor does it support chip-on-glass (COG) or optical auto-alignment.

The OL-FFB-156L follows a manual-load, semi-automatic press workflow tailored for operator-assisted precision:

This workflow balances operator control with automated pressing—ideal for medium-volume production requiring consistent bond quality.

These measures ensure compatibility with sensitive electronic assembly environments.

Ideal for bonding:

Particularly advantageous when uniform pressure and temperature across a long bond line are critical to reliability.

Olian Automatic provides end-to-end support:

Model: OL-FFB-156L

Type: Semi-Automatic Single-Side FOB Bonder with Long Press Head

Substrate: Rigid PCB (up to 15.6″) + FPC with glass carrier

Key Advantage: Single-stroke bonding of extended or multi-row terminal zones

Operation: Manual load/align → dual-hand start → auto advance & press → manual unload

Target Industries: Display module manufacturing, automotive electronics, industrial automation, medical devices

SEO Keywords:

15.6 inch FOB bonding machine with long head, OL-FFB-156L Olian, single-side flexible-on-board thermal press, 200mm hot bar bonder for PCB, multi-zone FPC to rigid board bonding equipment, high-force thermal compression machine for display drivers, long press head FOB bonder, ESD-safe FPC bonding workstation, semi-automatic FOB press for automotive PCBs, 400°C hot bar with back pressure support.

OL-FFB-156S – 15.6-Inch Single-Side Multi-Zone FOB Bonding Machine with Short Press Head,

Front-to-Back Sequential Thermal Compression System for Rigid PCB + FPC Assembly

The OL-FFB-156S by Olian Automatic Equipment Co., Ltd. is a semi-automatic thermal compression bonding machine engineered for single-side Flexible-on-Board (FOB) assembly of 15.6-inch-class rigid printed circuit boards (PCBs) with flexible printed circuits (FPCs)—typically used in large-format display driver boards, touch control modules, or industrial interface panels.

Unlike standard FOG (Film-on-Glass) machines, this system is designed specifically for PCB-based substrates and supports multi-segment bonding sequences along the FPC length using a short, high-precision press head. The machine assumes that anisotropic conductive film (ACF) has already been pre-laminated onto either the PCB pads or FPC terminals.

⚠️ Note: This machine performs main bonding only—it does not apply ACF, nor does it support IC/COF chip bonding or optical alignment.

The OL-FFB-156S employs a front-to-back sequential pressing method: after initial manual alignment, the bonding platform automatically advances under the fixed press head, enabling multiple bond zones to be compressed in sequence without repositioning the FPC.

The operator-driven workflow is as follows:

This “load–align–press–unload” cycle is optimized for medium-volume production with consistent quality.

These features ensure safe operation in ESD-sensitive electronics environments.

Ideal for bonding:

Commonly used where localized, high-force thermal compression is needed on rigid-flex assemblies.

Olian Automatic provides full lifecycle support:

Model: OL-FFB-156S

Type: Semi-Automatic Single-Side Multi-Zone FOB Bonder

Substrate: Rigid PCB (up to 15.6″) + FPC with glass carrier

Key Feature: Front-back sequential bonding with short press head

Operation: Manual load/align → dual-hand start → auto press cycle → manual unload

Target Industries: Display module assembly, automotive electronics, industrial automation, medical device manufacturing

SEO Keywords:

15.6 inch FOB bonding machine, OL-FFB-156S Olian, single-side flexible-on-board bonder, short press head thermal compression machine, multi-zone FPC to PCB bonding equipment, semi-automatic FOB press for rigid PCB, 400°C hot bar bonder with back pressure, ESD-safe FPC bonding workstation, sequential front-back FOB machine, high-force thermal compression for display driver boards.

Address:Floor 2, Building A1, FuYing Second Industrial Zone, No. 36 Jian'an Road, FuHai Subdistrict, Bao'an District, Shenzhen ,China. E-mail:2307972393@qq.com, olian@szolian.com Whatsapp:+86 18025364779

Copyright @ 2012-2025 -Shenzhen Olian Automatic Equipment Co.,Ltd. Designed by szolian

WhatsApp us